Manufacturing method of whole-piece bamboo-bunch veneer and overlong bamboo-bunch laminated veneer lumber

A technology for laminated veneer lumber and a manufacturing method, which is applied to the joining of wooden veneers, manufacturing tools, and wood processing utensils, etc., can solve the problems of low efficiency, occupying a large production site and labor force, etc., and achieve high production efficiency. , saving raw materials, the same effect of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

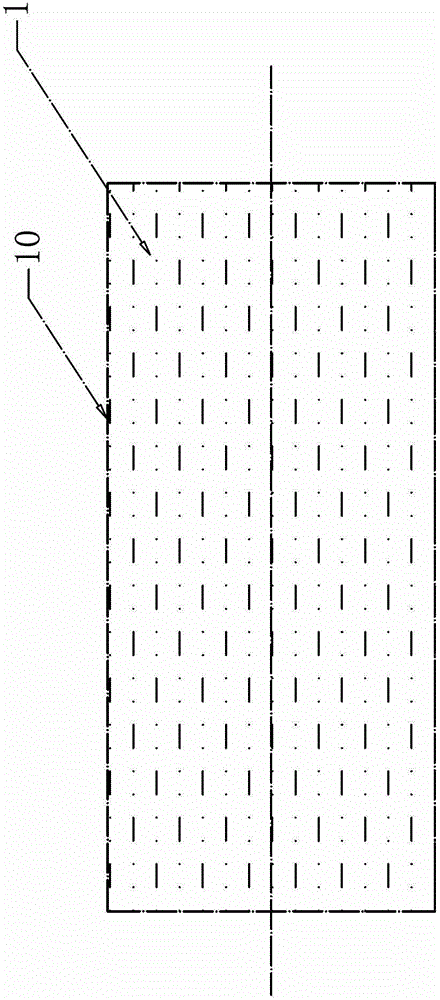

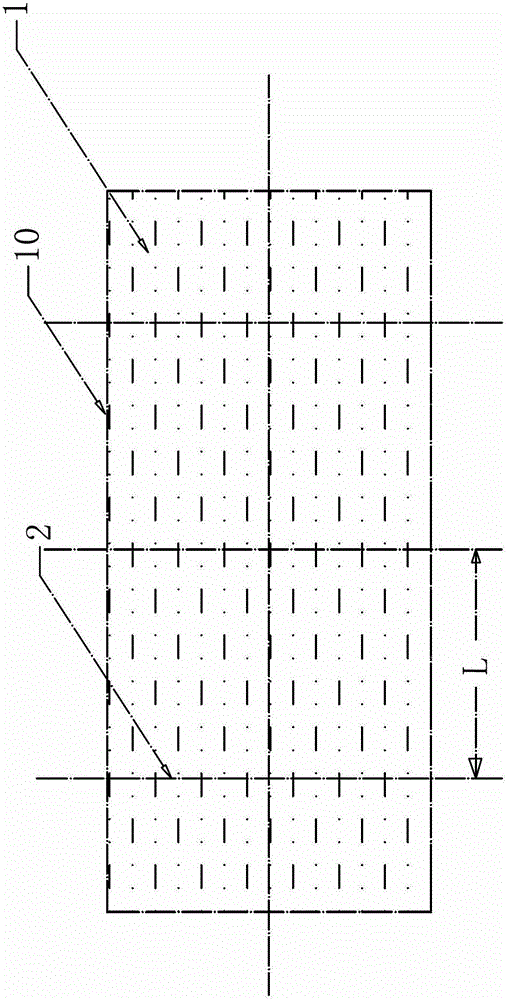

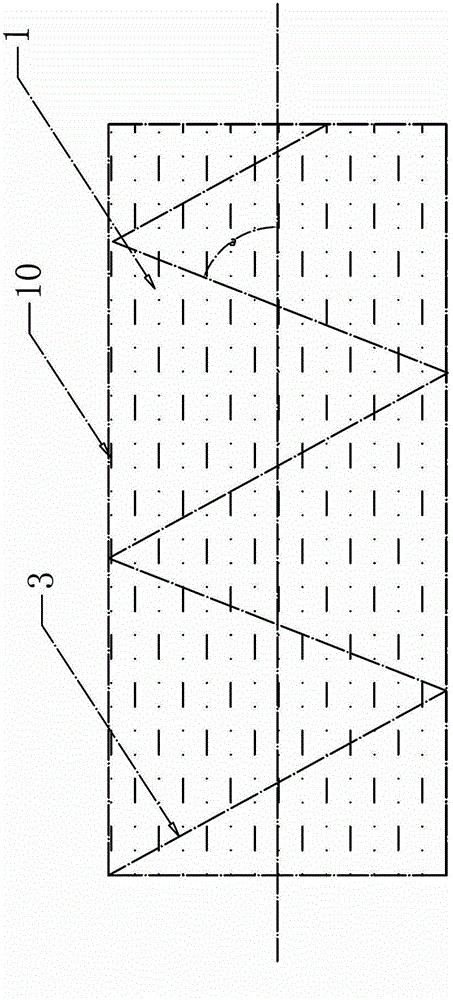

[0041] The specific steps for making the whole veneer of chemical bamboo bundles in the present invention are: 1) selection and pretreatment of raw materials; 2) preparation of bundle fiber units; 3) production of the veneer of bamboo bundles; 4) completion of the production of the whole veneer of chemical bamboo bundles.

[0042] The specific steps of the method for manufacturing the super-long bamboo bundle veneer lumber of the present invention are: 1) stacking a group of whole bamboo bundle veneers to form blanks; 2) cold pressing; 3) hot pressing. Or: 1) A number of whole bamboo bundle veneers are superimposed and continuously superimposed to form a unit billet, and then a group of unit billets are continuously assembled; 2) cold pressing; 3) hot pressing. The ultra-long bamboo bundle laminated veneer lumber obtained after hot pressing can be further cut to the preset required length

[0043] The selection and pretreatment of the raw material: select bamboo with a length ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com