Heat-resistant corrosion-resistant rubber tube

A rubber tube, corrosion-resistant technology, applied in the direction of hoses, pipes, pipes/pipe joints/fittings, etc., can solve the problems of inability to meet production needs, poor heat and corrosion resistance of ordinary rubber pipes, and achieve excellent vulcanization speed. Excellent aging resistance, the effect of enhancing the ability to withstand shock and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

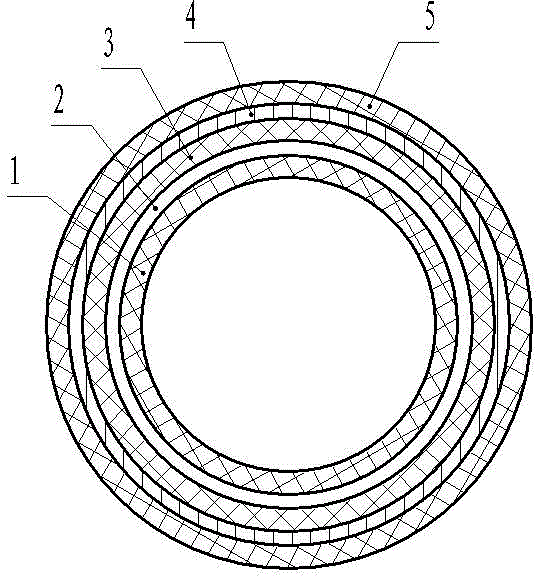

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

[0013] Such as figure 1 The shown heat-resistant and corrosion-resistant rubber tube includes a rubber tube body, and the rubber tube body includes an inner rubber layer 1, a ply layer 2, a middle rubber layer 3, a copper-plated steel wire braid layer 4 and an outer layer arranged sequentially from the inside to the outside. Rubber layer 5, inner rubber layer 1, carcass layer 2, middle rubber layer 3, copper-plated steel wire braid layer 4 and outer rubber layer 5 are connected by vulcanization; middle rubber layer 3 and outer rubber layer 5 have the same thickness; inner rubber layer 1 is The fluorine rubber layer, the middle rubber layer 3 and the outer rubber layer 5 are all styrene-butadiene rubber layers.

[0014] The heat resistance and corrosion resistance of the heat-resistant and corrosion-resistant rubber tube of the invention are greatly imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com