Patents

Literature

36results about How to "Improve vulcanization speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat-resistant corrosion-resistant rubber tube

InactiveCN104595593AImprove heat resistanceAccelerated corrosionFlexible pipesHeat resistanceEngineering

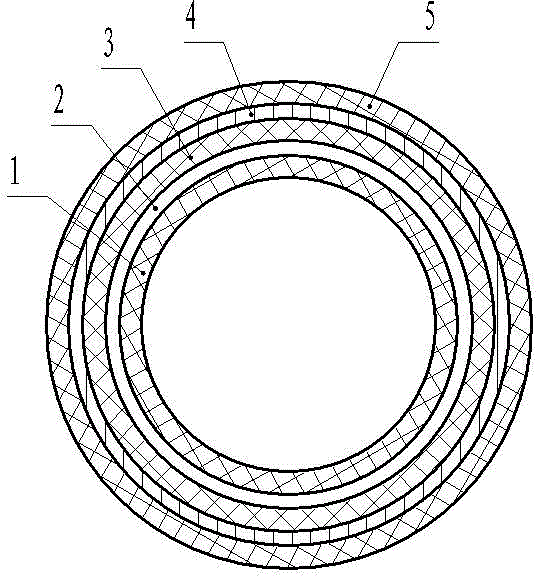

The invention discloses a heat-resistant corrosion-resistant rubber tube, and relates to the technical field of manufacturing of the rubber tube. The heat-resistant corrosion-resistant rubber tube comprises a rubber tube body, wherein the rubber tub body comprises an inner rubber layer, a cord fabric layer, a middle rubber layer, a coppered steel wire woven layer and an outer rubber layer which are arranged from inside to outside in sequence; the inner rubber layer is a fluorine rubber layer; the middle rubber layer and the outer rubber layer are both butadiene styrene rubber layers; the inner rubber layer, the cord fabric layer, the middle rubber layer and the coppered steel wire woven layer and the outer rubber layer are connected in a vulcanized manner. Compared with the prior art, the heat-resistant corrosion-resistant rubber tube has the advantages that the heat resistance and the corrosion resistance are greatly improved and the requirement on delivery of high-temperature gas or liquid with certain corrosiveness is met.

Owner:LIUZHOU ERHE AUTO PART

Rubber tire tread and milling process thereof

The invention discloses a rubber tire tread and a milling process thereof. The rubber tire tread comprises the following components in parts by weight: 70-110 parts of natural rubber, 0-15 parts of styrene-butadiene rubber, 5-20 parts of tread rubber powder, 1.5-2.5 parts of stearic acid, 1-2 parts of sulfur powder, 2-18 parts of white carbon black, 12-15 parts of carbon block, 2-30 parts of aromatic oil, 1-8 parts of zinc oxide, 4-7 parts of an anti-aging agent, 1-4 parts of pine tar, 1-4 parts of an accelerating agent, 0.2-1 part of an anti-reversion agent and 2-5 parts of a binding agent. A three-section milling process is adopted, and the milling process can improve the abrasive resistance, tear resistance and chunking and chipping resistance of the tire tread.

Owner:SHANDONG YONGTAI CHEM GROUP

Rare-earth butadiene rubber composite cable sheath material

InactiveCN104194083ALow costImprove aging resistanceInsulated cablesInsulated conductorsVulcanizationPolymer science

The invention discloses a rare-earth butadiene rubber composite cable sheath material, comprising the following raw materials in parts by weight: 80-100 parts of rare-earth butadiene rubber, 40-50 parts of butadiene styrene rubber, 1.8-2.3 parts of vulcanization system, 5-10 parts of organic montmorillonite, 20-30 parts of a lignin reinforcing agent, 30-40 parts of white carbon black, 20-30 parts of silane modified sepiolite, 2-3 parts of nano-zinc oxide, 1.5-1.8 parts of stearic acid, 1-2 parts of naphthenic oil, 40-50 parts of carbon black N330 and 5-6 parts of N-methylene carboxylic-2-benzothiazole sulfonamide. The rare-earth butadiene rubber composite cable sheath material has the advantages of low cost, good ageing resistance, excellent tensile strength and deflection resistance, good tear resistance, simple preparation process and convenience in practical operation.

Owner:ANHUI LAND GRP

Heat resistant fuel hose

InactiveUS20030188793A1Increase resistanceIncrease costFlexible pipesThin material handlingVulcanizationNitrile rubber

The present invention provides a heat resistant fuel hose comprising a rubber inner pipe with an inner layer and an outer layer in the inner pipe. The inner layer of the inner pipe comprises a hydrogenated acrylonitrile butadiene rubber (H-NBR) that is mixed with zinc oxide (ZnO) and magnesium oxide (MgO) as acid acceptors and is peroxide vulcanized. The outer layer of the inner pipe comprises an epoxy cross-linking type acrylic rubber (ACM) that has been vulcanized bonded to the inner layer of the inner pipe. The inner layer and outer layer of the inner pipe of the heat resistant fuel hose of the present invention are strongly bonded, and the rubber inner pipe has excellent heat resistance.

Owner:SUMITOMO RIKO CO LTD

Special cable material for styrene-butadiene rubber sleeved field detection cable and preparation method of special cable material

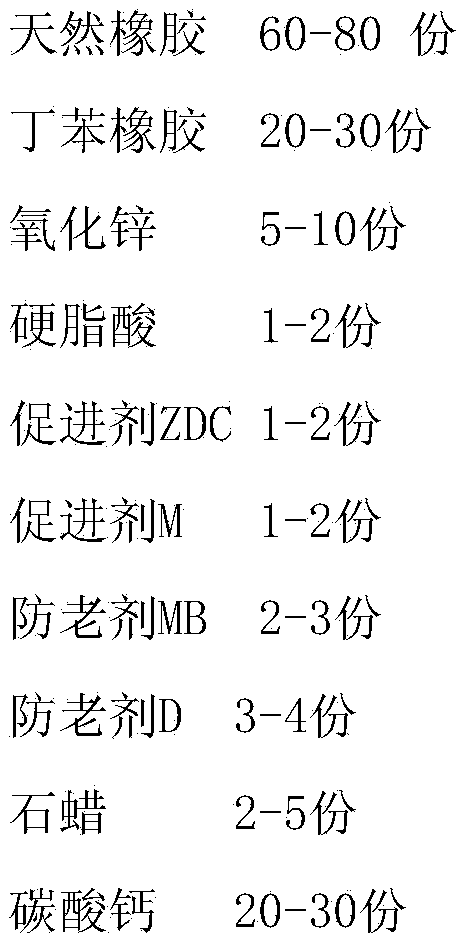

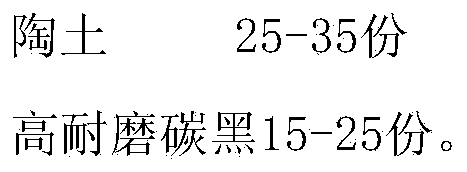

The invention discloses a special cable material for a styrene-butadiene rubber sleeved field detection cable and a preparation method of the special cable material. The special cable material is characterized by comprising the following cable materials in parts by weight: 60-80 parts of natural rubber, 20-30 parts of styrene-butadiene rubber, 5-10 parts of zinc white, 1-2 parts of stearic acid, 1-2 parts of a promoter ZDC, 1-2 parts of a promoter M, 2-3 parts of an antiager MB, 3-4 parts of an antiager D, 2-5 parts of paraffin, 20-30 parts of calcium carbonate, 25-35 parts of pottery clay, and 15-25 parts of high abrasion resistant carbon black. The preparation method provided by the invention is simple; the special cable material is greatly improved in properties, has excellent properties in tensile strength and elongation at break, as well as tensile strength retention rate, breaking extending retention rate, temperature brittleness after ageing, and has more excellent wear resistance, heat resistance, ageing resistance and vulcanization speed compared with a conventional cable material.

Owner:ANHUI GUODIAN CABLE GRP

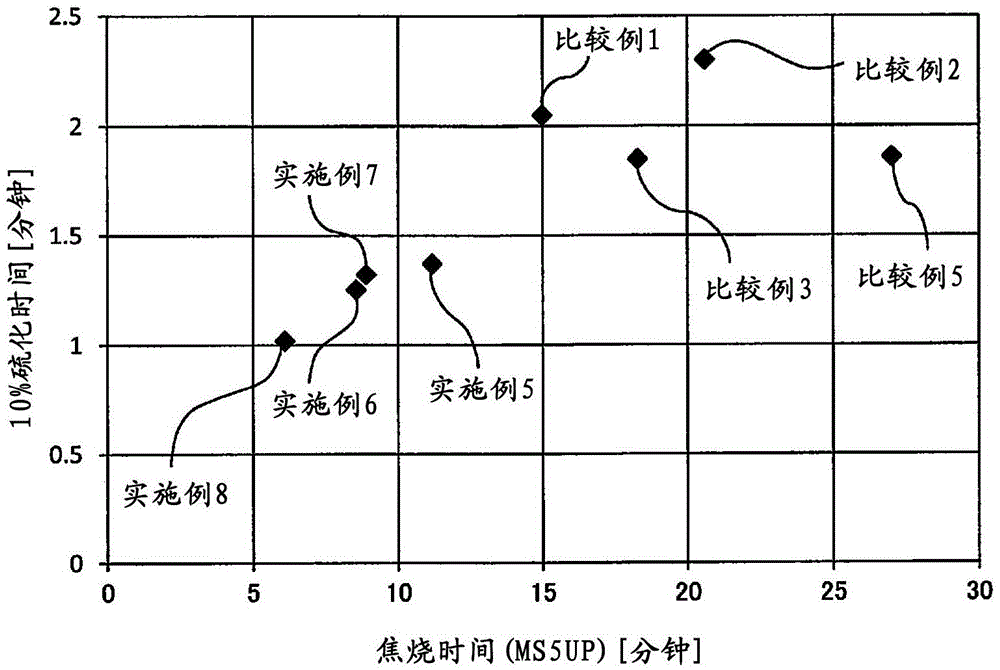

Rubber composition for tread

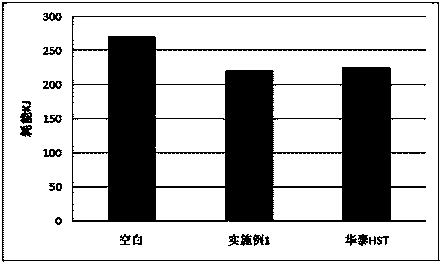

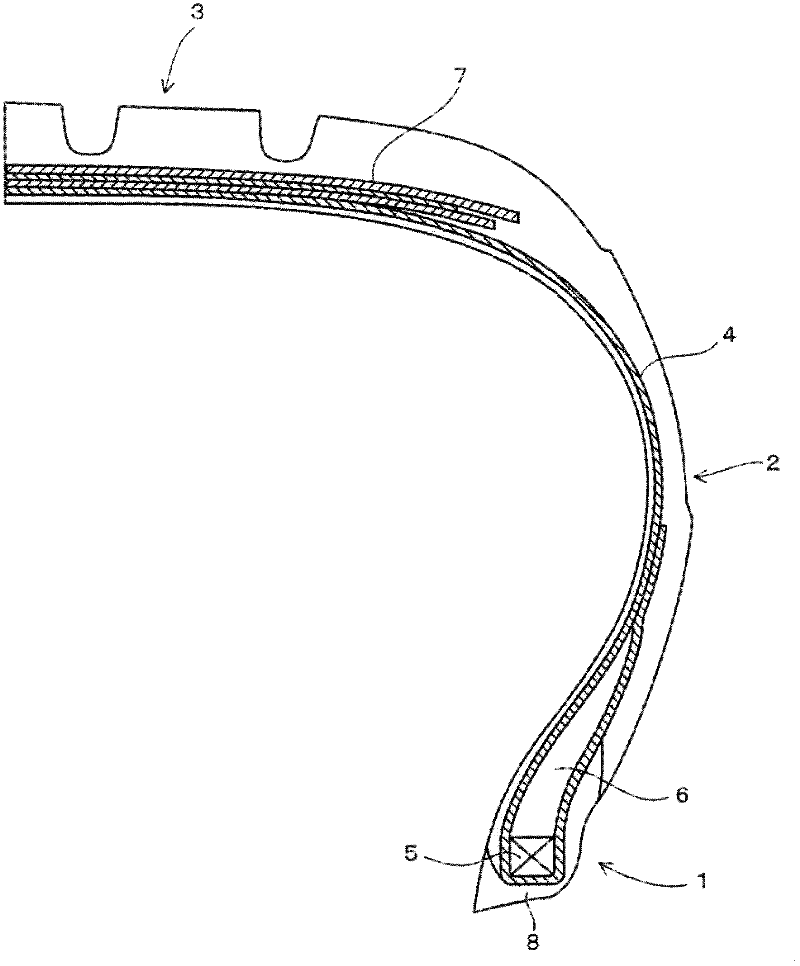

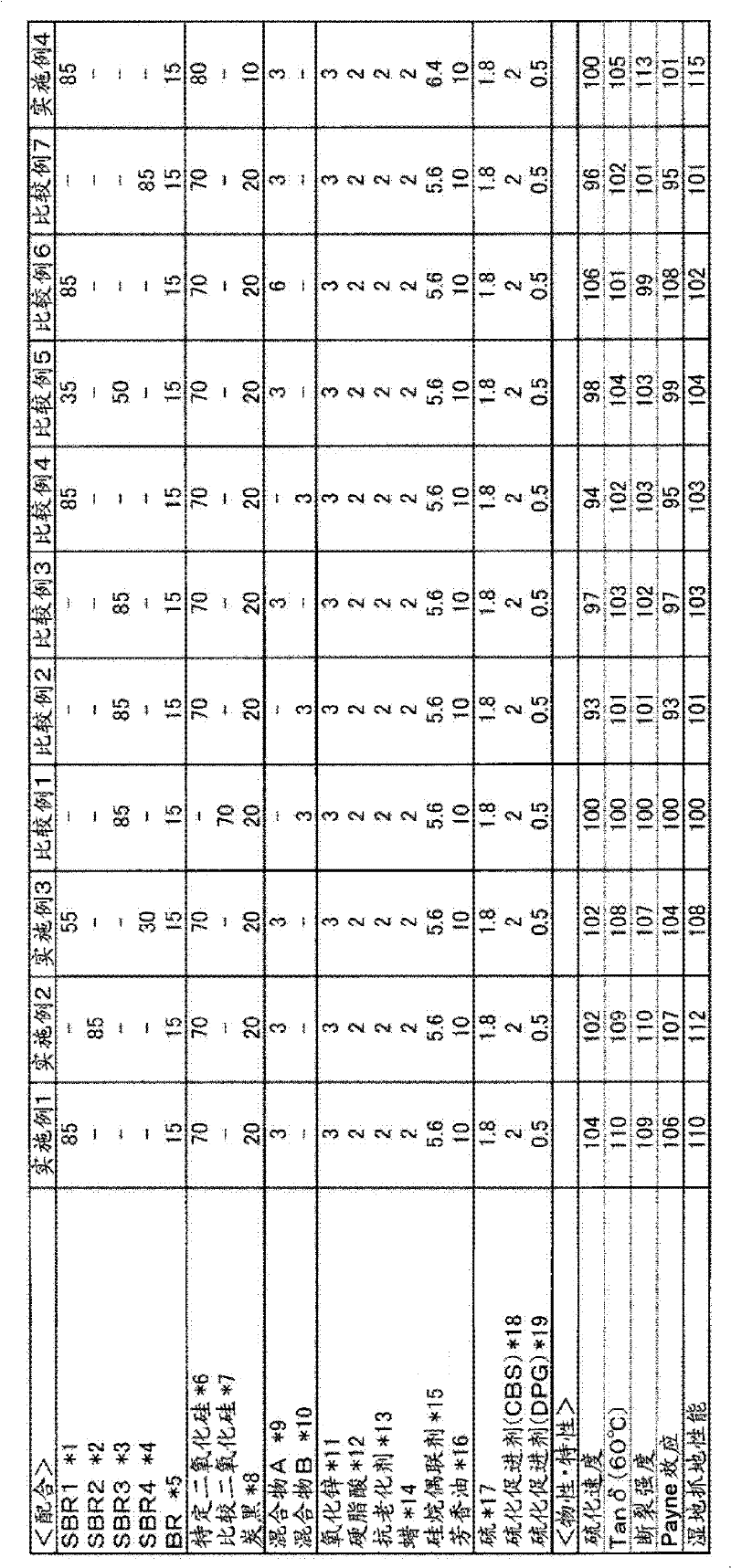

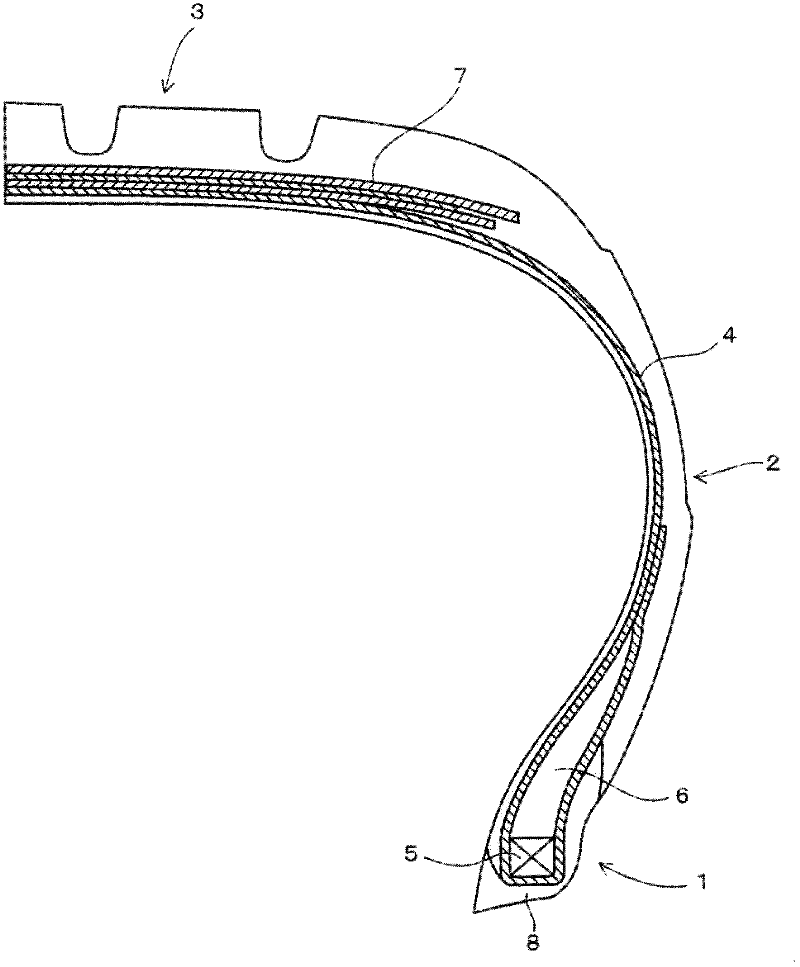

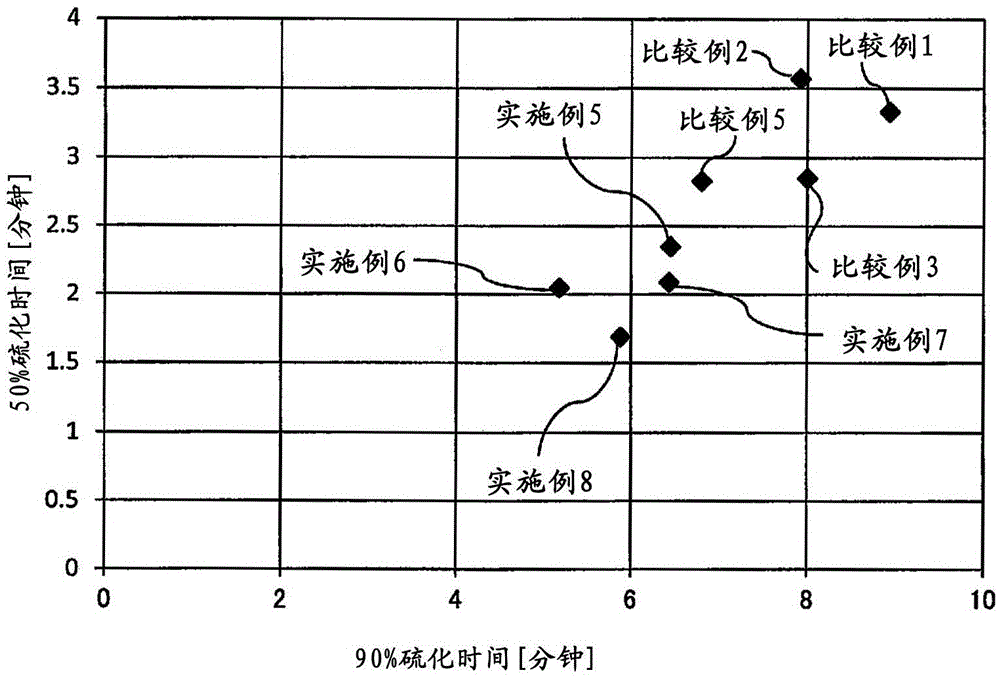

ActiveUS20060276583A1Improve vulcanization speedImprove heat aging resistanceSpecial tyresPolymer scienceSulfenamide

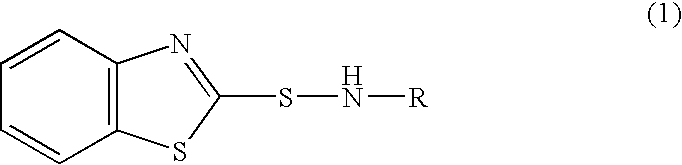

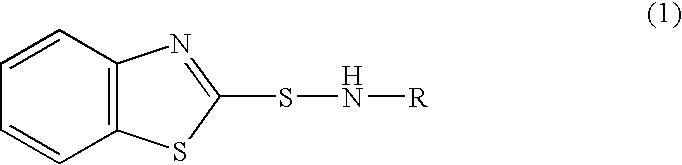

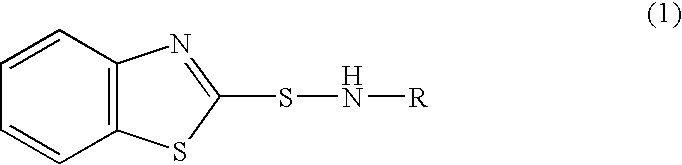

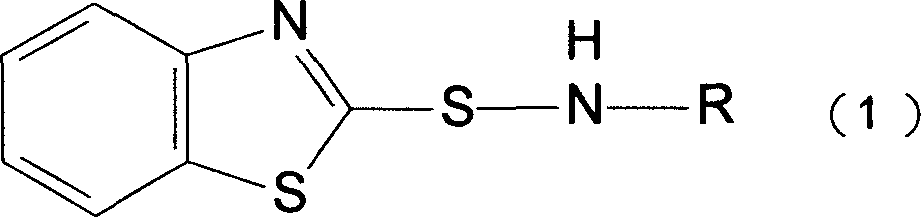

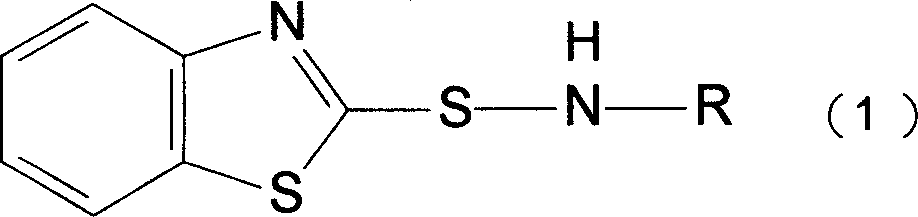

A rubber composition for a tread optimizing a vulcanization speed in a vulcanization step and, further, improving heat aging resistance is provided. A rubber composition for a tread comprising 20 to 90 parts by weight of silica, 0.5 to 2 parts by weight of (A) a guanidine vulcanization accelerator, 0.1 to 0.5 part by weight of (B) a thiuram vulcanization accelerator, and 0.5 to 2 parts by weight of (C) a sulfenamide vulcanization accelerator represented by the general formula (1): (wherein R is a linear alkyl group or a branched alkyl group having 1 to 18 carbons), based on 100 parts by weight of a rubber component.

Owner:SUMITOMO RUBBER IND LTD

Rubber composition for tread

InactiveCN1876704AImprove vulcanization speedImprove heat aging resistanceSpecial tyresTyre tread bands/patternsVulcanizationSilicon dioxide

A rubber composition for a tread optimizing a vulcanization speed in a vulcanization step and, further, improving heat aging resistance is provided. A rubber composition for a tread comprising 20 to 90 parts by weight of silica, 0.5 to 2 parts by weight of (A) a guanidine vulcanization accelerator, 0.1 to 0.5 part by weight of (B) a thiuram vulcanization accelerator, and 0.5 to 2 parts by weight of (C) a sulfenamide vulcanization accelerator represented by the general formula (1): (wherein R is a linear alkyl group or a branched alkyl group having 1 to 18 carbons), based on 100 parts by weight of a rubber component.

Owner:SUMITOMO RUBBER IND LTD

Application of zinc isoocatanoate in reduction on agglomeration of white carbon black, white carbon black dispersing agent containing zinc isoocatanoate and preparation method thereof

The invention provides application of zinc isoocatanoate in reduction on agglomeration of white carbon black. According to research, the inventor discovers that the polarity of a silanol group on the surface of white carbon black can be reduced by zinc isoocatanoate so as to play a role in dispersing white carbon black. Under the support of the function, zinc isoocatanoate can be used in the application field of multiple white carbon blacks. The invention also provides a white carbon black dispersing agent containing zinc isoocatanoate and a preparation method thereof. The method is simple, free of pollution, energy-saving and environment-friendly; the obtained dispersing agent has functions of physical dispersion and chemical dispersion, and is suitable for dispersing sizing materials with high filling amount of white carbon black, so that the dispersibility of the white carbon black can be improved, the processing performance of the sizing material also can be improved, the mixing time is shortened, the smoothness and dispersion uniformity of the sizing material is increased, the flowability of the sizing material in the processing and mixing stage is increased, and the Mooney viscosity is reduced; moreover, the white carbon black dispersing agent has a strengthening effect, and the mechanical property of vulcanized rubber is improved.

Owner:SHANDONG YANGGU HUATAI CHEM

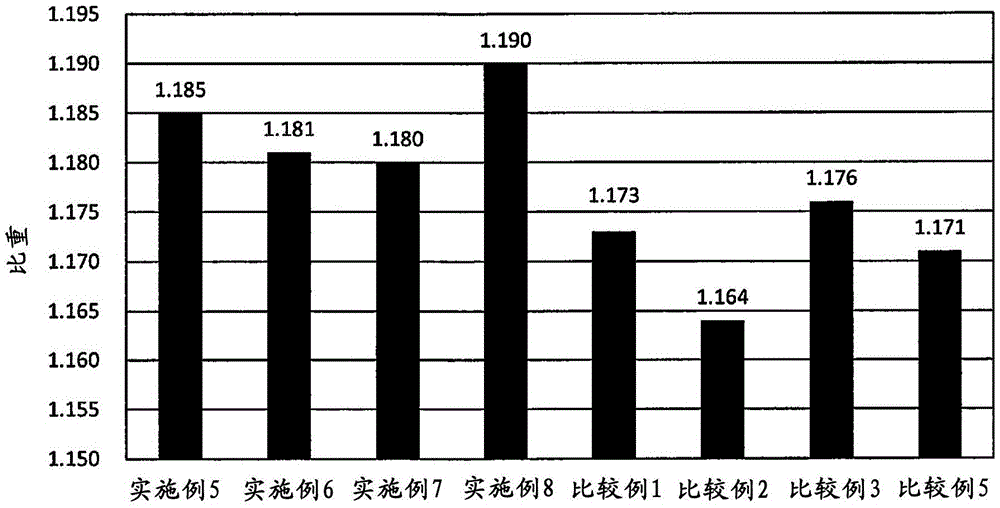

Rubber composition for tire tread and pneumatic tire using the rubber composition

InactiveCN102268149AGood dispersionImprove vulcanization speedSpecial tyresRolling resistance optimizationTire beadPolymer science

The object of the present invention is to provide a rubber composition for tire treads which has a good vulcanization rate and excellent wet grip and fuel efficiency. As a means of solving the problems of the present invention, there is provided a rubber composition for tire treads containing 40 parts by mass or more of a solution-polymerized SBR diene having a Mw of 900,000 to 1.5 million and a styrene content of 35 to 45%. 100 parts by mass of rubber, compounded with 60 to 110 parts by mass of silicon dioxide satisfying all the conditions of (1) to (4) below, and relative to the silicon dioxide, compounded with fatty acid metal salts (except zinc salts) 2-8 mass % of the mixture formed with fatty acid ester. The conditions for the above silica are: (1) N2SA is 194-225m2 / g. (2) The specific surface area of CTAB is 170-210m2 / g. (3) The relationship between the above-mentioned N2SA and the above-mentioned CTAB specific surface area is that the N2SA / CTAB specific surface area is 0.9 to 1.4. (4) DBP absorption is 190ml / 100g or more.

Owner:THE YOKOHAMA RUBBER CO LTD

High-strength cable material and preparation method thereof

InactiveCN107083046AIncrease elasticityGood physical propertiesPlastic/resin/waxes insulatorsButadiene-styrene rubberCircuit breaker

The invention discloses a high-strength cable material, belonging to the technical field of breaker materials. The high-strength cable material is prepared from the following raw materials in parts by weight: 70-90 parts of thermoplastic polyurethane, 8-11 parts of butadiene styrene rubber, 4-6 parts of carbon black, 40-50 parts of calcium carbonate, 15-25 parts of vinyl acetate ethylene, 3-5 parts of cyanoacrylate, 12-14 parts of glass fibers, 2-4 parts of epoxidized soybean oil, 20-30 parts of a plasticizer, 0.5-2 parts of a crosslinking agent and 0.2-0.8 part of a light stabilizer. The invention further discloses a preparation method of the high-strength cable material. The cable material has high strength and relatively good physical properties.

Owner:山东励仙电力工程有限公司

Insulating layer material for high-voltage electrical cabinet and preparation method thereof

InactiveCN107254178AImprove physical performancePrevent flammable safety hazardsRubber insulatorsEpoxyStearic acid

The invention discloses an insulating layer material for a high-voltage electrical cabinet. The material is prepared from the following raw materials in parts by weight: 8-24 parts of vinyl silicone rubber, 3-12 parts of chlorinated polyethylene rubber, 4-6 parts of ABS resin, 2-14 parts of decabromodiphenyl ethane, 5-15 parts of epoxy resin, 5-13 parts of stearic acid, 3-5 parts of cyanoacrylate, 2-4 parts of polyacrylate glue powder, 5-20 parts of a filler, 2-5 parts of a plasticizer, 1-6 parts of flame retardants and 0.5-1.5 parts of a stabilizer. A preparation method disclosed by the invention is simple and feasible, and the prepared insulating layer material can prevent the potential safety hazard that the insulating layer materials such as cables and electric wires are flammable in a high voltage environment. As flame retardants such as magnesium oxide, aluminum oxide and antimonous oxide are added into the raw materials, the insulating layer material has relatively high flame retardance and has the advantages of no toxicity, low smoke and the like.

Owner:HEFEI ZEJUN ELECTRICAL EQUIP CO LTD

Wear-resistant flame-retardant heat-conducting insulating material and preparation method thereof

The invention discloses a wear-resistant flame-retardant heat-conducting insulating material and a preparation method thereof. The wear-resistant flame-retardant heat-conducting insulating material comprises the following raw materials in parts by weight: 80-120 parts of compound rubber, 10-20 parts of wear-resistant additives, 8-14 parts of modified reinforcing fibers, 10-14 parts of a flame-retardant additive, 3-5 parts of a coupling agent, 7-9 parts of a processing auxiliary agent, 6-8 parts of a toughening auxiliary agent and 7-9 parts of a modified nano additive. The wear-resistant flame-retardant heat-conducting insulating material provided by the invention has good performances of being insulating, stretch-resistant and wear-resistant, excellent in heat-conducting flame-retardant effect, cold and hot impact resistant and high in toughness, free from toxicity and free of peculiar smells, high in strength, good in elasticity, relatively long in service life and safe and environment-friendly; meanwhile, the preparation method is relatively low in cost, easily available in raw material and concise in process, and has relatively high practical value and good application prospect.

Owner:合肥市闵葵电力工程有限公司

Heat-resistant and aging-resistant chloroprene rubber tube

The invention discloses a heat-resistant and aging-resistant chloroprene rubber tube. The chloroprene rubber tube comprises chloroprene rubber, chlorinated butyl rubber, poly-octene rubber, polyisoprene rubber, polyether urethane, zinc oxide, bis(2,4-dichlorobenzoyl) peroxide, 2,5-dimethyl-2,5-di(tert-butylperoxy) hexane, stearic acid, nano calcium carbonate, hollow glass microspheres, nano montmorillonite, basic sodium and aluminum carbonate, a silane coupling agent, an anti-aging agent DFC-34, an anti-aging agent A, dipentaerythritol diphosphite, hexaphenoxy cyclotriphosphazene, vinyl silicone oil, an accelerant, zinc diricinoleate, aluminum dihydrogen phosphate and 1,3-bis(citraconimidomethyl)benzene. The heat-resistant and aging-resistant chloroprene rubber tube has high strength, good heat resistance and aging resistance and excellent storage stability, and products of the chloroprene rubber tube can meet use requirements in various fields and have long service life.

Owner:安徽都邦电器有限公司

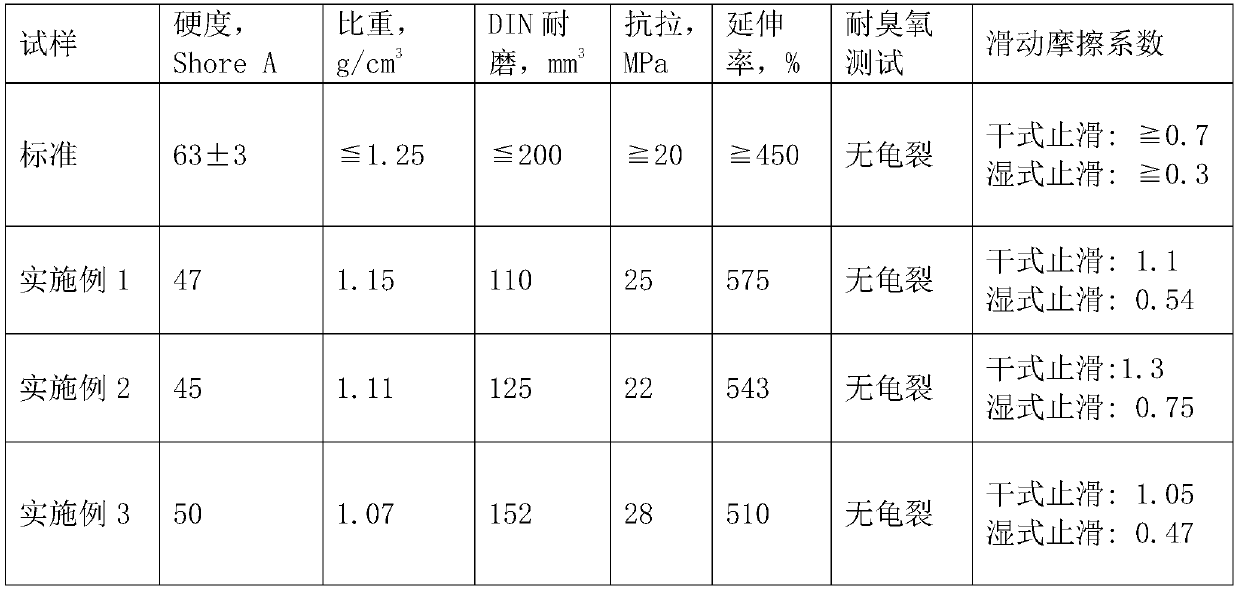

Slippery resistant safe shoe rubber sole and preparation method thereof

ActiveCN106589499AExcellent anti-oil performanceImprove gripSolesPersonal protective equipmentVulcanization

The invention relates to a rubber sole and provides a slippery resistant safe shoe rubber sole and a preparation method thereof. The provided rubber sole has a strong performance on resisting slipping. The friction coefficient is not less than 0.45 and is obvious higher than the slippery resistant requirements (heelpiece 0.13, smoothness 0.18) of international standard BS EN ISO 20345:2011 personal protective equipment safe shoes. The rubber sole is composed of the following raw materials: high vinyl solution polymerized styrene-butadiene rubber, high acrylonitrile nitrile rubber, NBR / PVC emulsion co-precipitated alloy, white carbon black, an anti-aging agent, polyethylene glycol, a silane coupling agent, polyethylene wax, yellow resin, diglycol, zinc oxide, insoluble sulfur, and a vulcanization promoter.

Owner:MAOTAI FUJIAN SOLES CO LTD

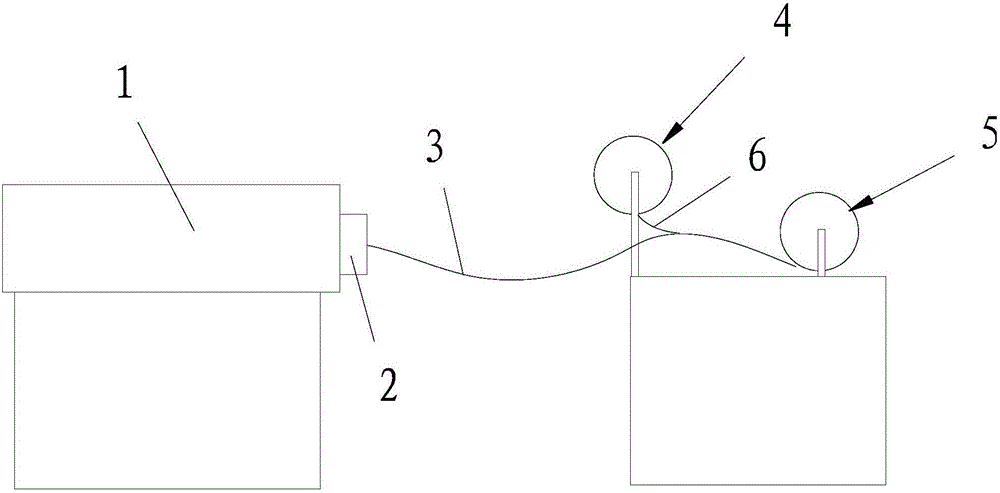

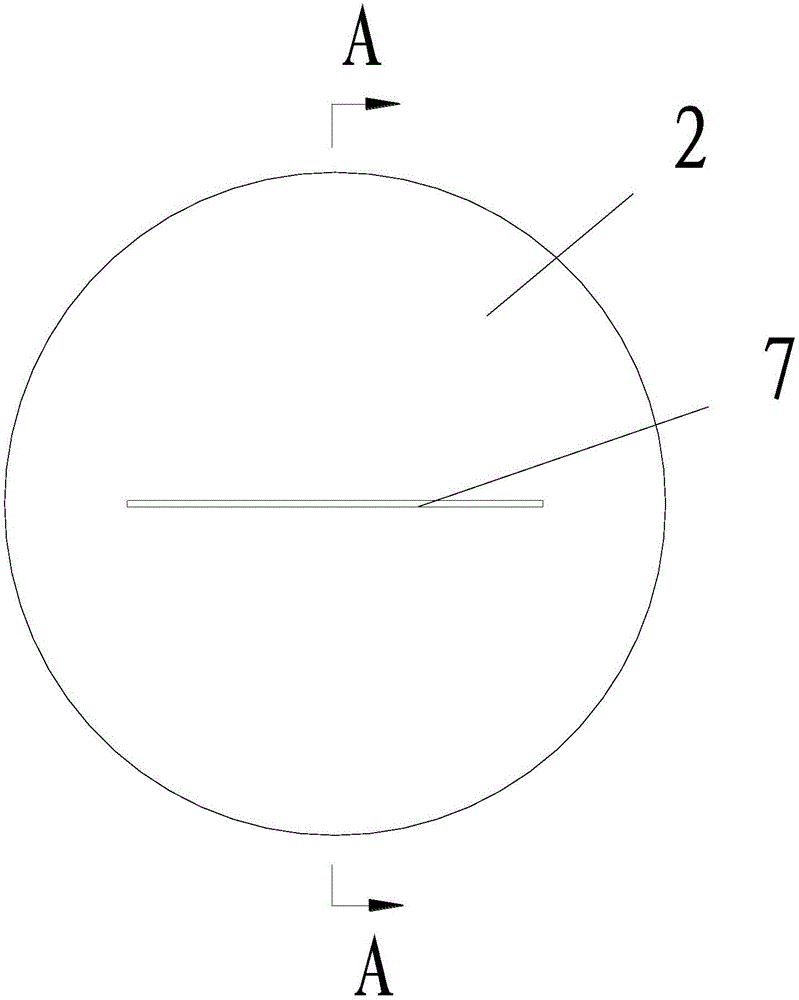

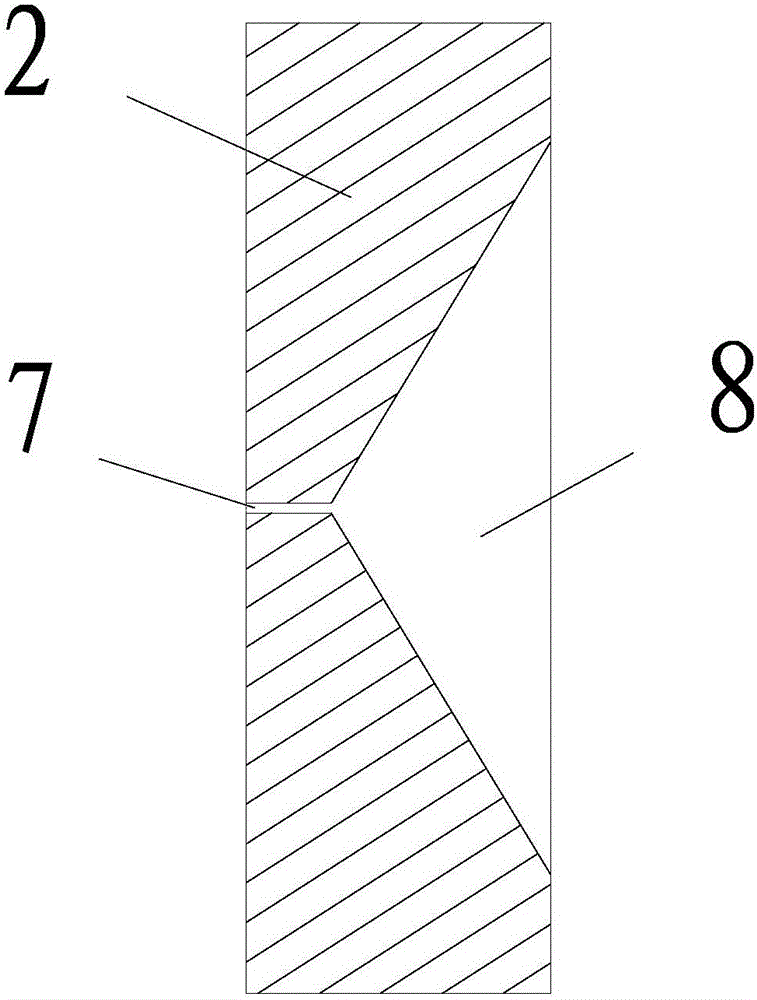

Sealing strip butt-joint thin slice rubber material and preparation method thereof, and sealing strip butt-joint thin slice rubber sheet processing method and processing device

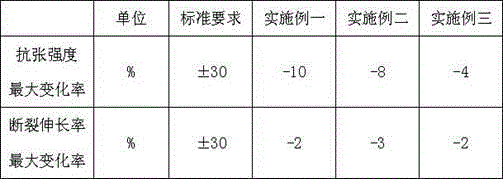

The invention provides a sealing strip butt-joint thin slice rubber material and a preparation method thereof, and a sealing strip butt-joint thin slice rubber sheet processing method and processing device. According to the sealing strip butt-joint thin slice rubber material and the preparation method thereof, various raw material components are screened and compounded, a rubber one-section mixing process is adopted, and the sealing strip butt-joint thin slice rubber material for preparing a sealing strip butt-joint thin slice rubber sheet having excellent properties by an extruding process can be obtained. Compared with a conventional sealing strip butt-joint thin slice rubber sheet processing method, the sealing strip butt-joint thin slice rubber sheet processing method can significantly improve the processing efficiency and the product quality, solves the storage problems of a product in a conventional process, and is beneficial to wide application.

Owner:BAODING WEIYI AUTOMOBILE CO LTD

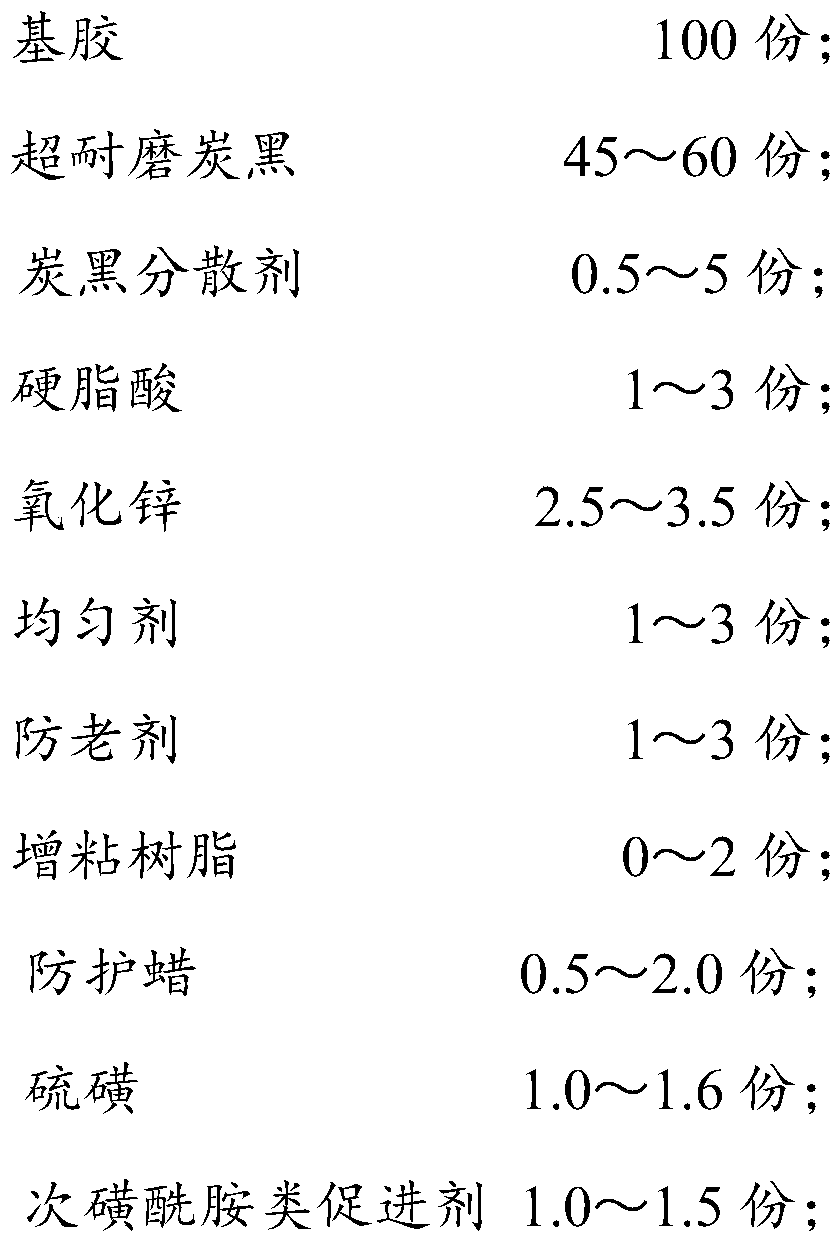

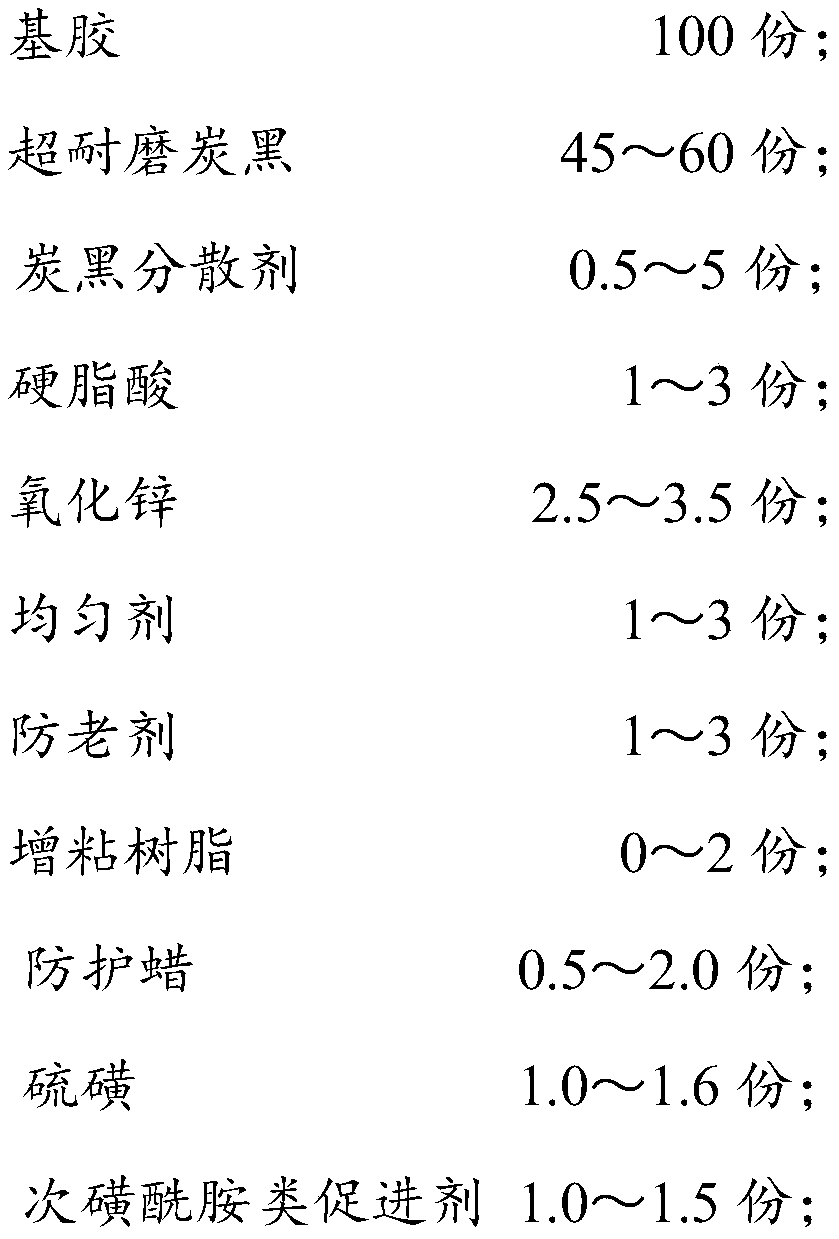

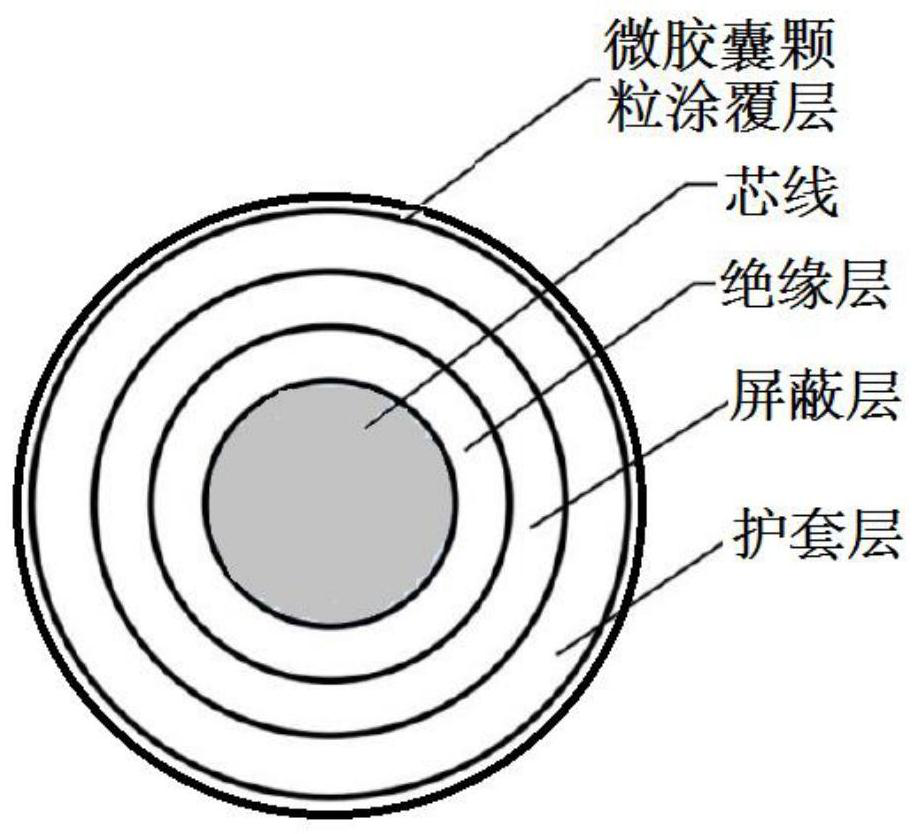

All-steel tread formula with high wear resistance and long mileage and preparation process of all-steel tread formula

The invention relates to an all-steel tread formula with high wear resistance and long mileage and a preparation process of the all-steel tread formula. The all-steel tread formula comprises the following components: 100 parts of base rubber; 45 to 60 parts of super wear-resistant carbon black; 0.5-5 parts of a carbon black dispersant; 1-3 parts of stearic acid; 2.5 to 3.5 parts of zinc oxide; 1-3parts of a homogenizing agent; 1-3 parts of an anti-aging agent; 0-2 parts of tackifying resin; 0.5 to 2.0 parts of protective wax; 1.0 to 1.6 parts of sulfur; 0.6 to 1.5 parts of a sulfenamide accelerator. According to the invention, the carbon black with low heat generation and high wear resistance is adopted; meanwhile, an NR / BR / SBR (natural rubber / polyisoprene rubber / styrene butadiene rubber)three-gel combined system is adopted; the carbon black dispersant capable of participating in the reaction of rubber and carbon black is used, the interaction between rubber and carbon black is enhanced, the aggregation of the filler and the heat generation of the rubber material are reduced, the adverse effect of hysteresis on aging is reduced, and the friction coefficient of the rubber materialis reduced, so that the wear resistance and durability of a tread can be effectively improved.

Owner:SAILUN GRP CO LTD

Low-temperature-resistant protective sleeve for underground cable

PendingCN113201188AImprove heat resistanceAccelerated corrosionEthylene-propylene-diene-monomerPlasticizer

The invention discloses a low-temperature-resistant protective sleeve for underground cables, and belongs to the technical field of cable protection. The protective sleeve is prepared from the following raw materials by weight: 20-30 parts of silicone rubber, 35-45 parts of ethylene propylene diene monomer, 2.5-3.5 parts of white carbon black, 5-8 parts of a vulcanizing agent, 2-5 parts of an accelerator, 3-8 parts of a plasticizer, and 2-4.5 parts of a flame retardant. Compared with a traditional cable protective sleeve and a preparation process thereof, the elongation at break of the protective sleeve at normal temperature reaches 678% or above, the tensile strength reaches 28.6 Mpa or above, and the mechanical performance is excellent; the low-temperature retraction temperature TR10 is -24.5 DEG C or below, and the low-temperature-resistant protective sleeve can keep good elasticity under the low-temperature condition and is suitable for being used in the low-temperature environment; and the oxygen index reaches 48 or above, the flame retardant property is good, the use requirement of the underground cable can be met, the cable can be used in a low-temperature environment, and the service life of the underground cable is prolonged.

Owner:国网河南省电力公司镇平县供电公司

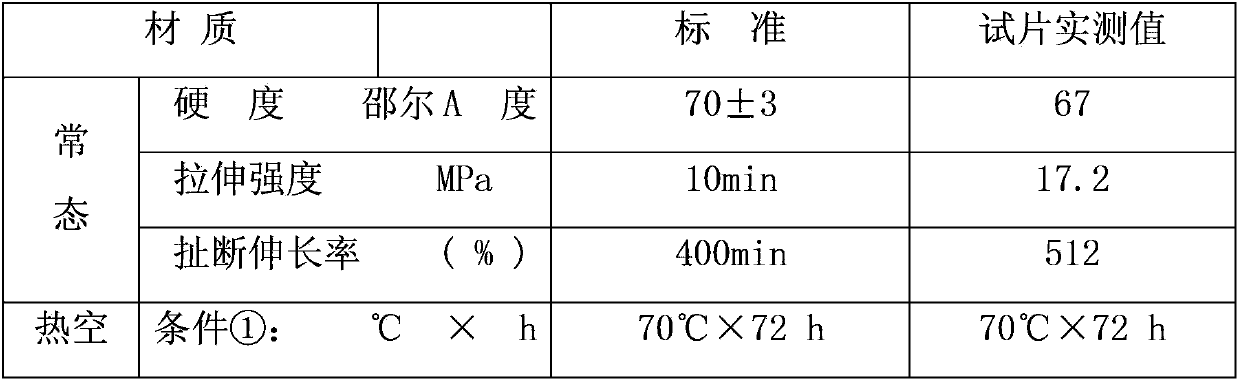

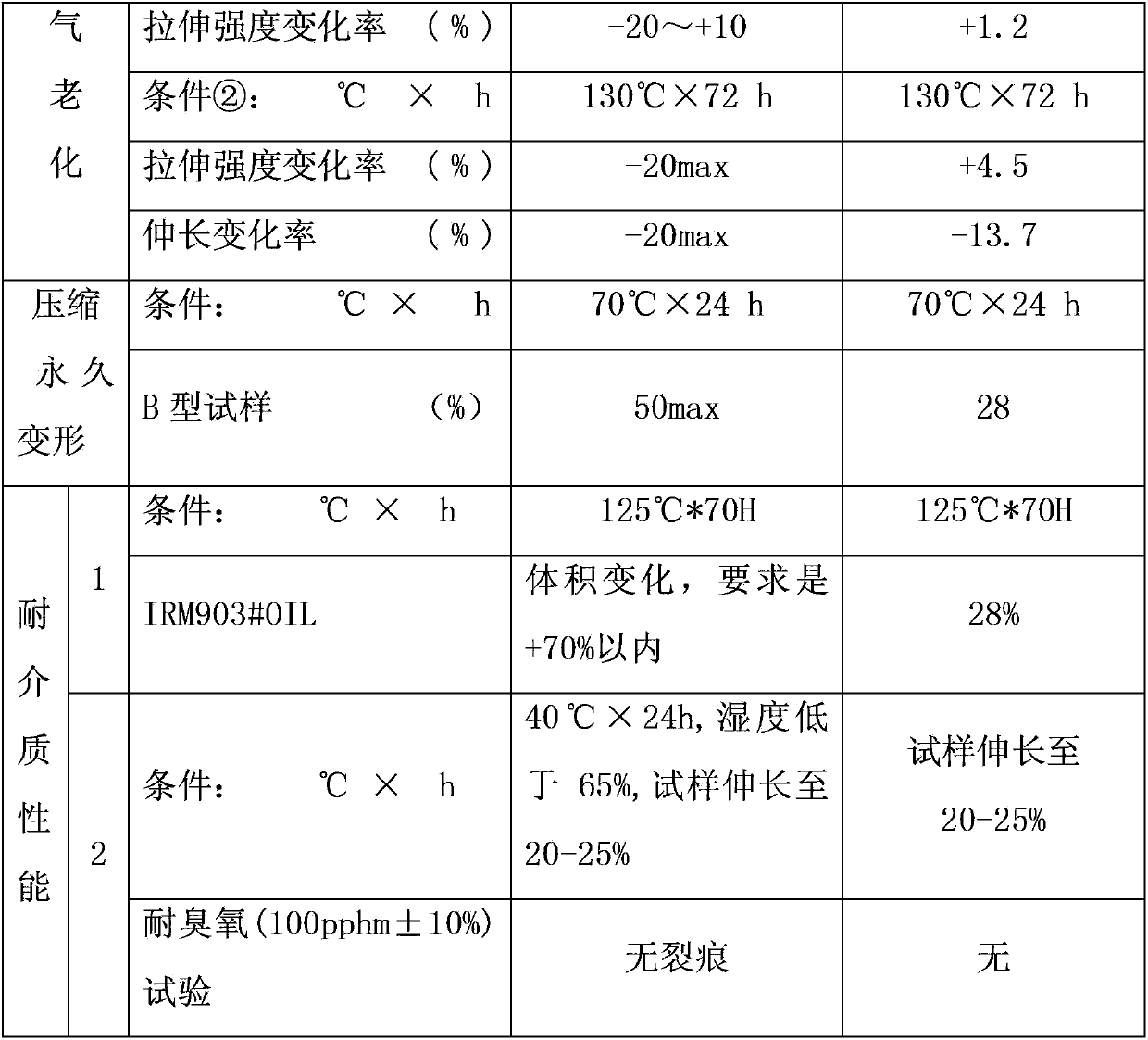

Preparation method of composite rubber material for water lubricated bearings

Belonging to the technical field of bearings, the invention relates to a preparation method of a composite rubber material for water lubricated bearings. The method provided by the invention adopts acrylate rubber as the matrix material for mixing with nitrile butadiene rubber to prepare the composite rubber material for water lubricated bearings. The acrylate rubber is an elastomer formed by copolymerization of an acrylate main monomer, a vulcanization point monomer and a functional monomer, and has good mechanical properties, wear resistance and strong tear resistance. Acrylate rubber has stable chemical properties and good cold resistance, and at the same time has low gas permeability and good oil resistance. Nitrile butadiene rubber has good chemical resistant stability, good processability, fast vulcanization speed and high tensile strength. Therefore, mixing of acrylate rubber with nitrile butadiene rubber to prepare the composite rubber material for water lubricated bearings caneffectively improve the mechanical properties, high temperature resistance and oil resistance of the composite rubber.

Owner:秦家千

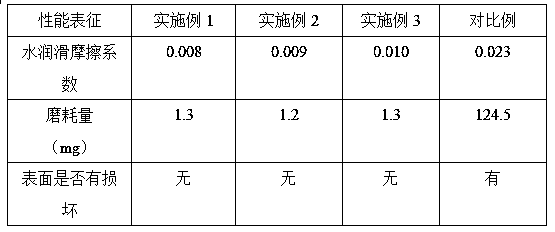

Preparation method of anti-corrosion combustion-supporting wire or cable

InactiveCN111968798AGood heat resistance and weather resistanceExcellent elasticity and weather resistanceBiocideAntifouling/underwater paintsWeather resistanceCorrosive substance

The invention discloses a preparation method of an anti-corrosion combustion-supporting wire or cable. Firstly, a plurality of wires are intertwisted into a bundle and are sequentially wrapped with aninsulating layer and a shielding layer to obtain wire cores, groups of wire cores are arranged in bundles to form a cable core; a sheath layer wraps the outer side of the cable core; finally, a protective sleeve is coated with a microcapsule particle coating layer to obtain the cable, the sheath layer uses polyvinyl chloride, a stabilizing agent and a plasticizer as main raw materials. Polyvinylchloride has high high-temperature resistance, low-temperature resistance and corrosion resistance; a stabilizer has high heat resistance and weather resistance, the plasticizer has excellent elasticity, weather resistance and mechanical properties, the three components are blended and vulcanized, respective advantages are reserved, in addition, capsaicin released from the microcapsules can repelants and mice without causing other damage, and the microcapsule is environmentally friendly and convenient to use.

Owner:WUXI HUAMEI CABLE

Low-hardness high-wear-resistance non-slip sole material for shoes and preparation method of low-hardness high-wear-resistance non-slip sole material

InactiveCN111349277AImprove wear resistanceGood wear resistance and non-slipSolesAcrylonitrileWear resistance

The invention provides a low-hardness high-wear-resistance non-slip sole material for shoes and a preparation method of the low-hardness high-wear-resistance non-slip sole material, wherein the sole material mainly comprises the raw materials in parts by weight: 25 parts of rare earth cis-butadiene, 5 parts of NBR butadiene-acrylonitrile rubber, 15 parts of carbon black and 20 parts of ointment oil. The wear resistance of the product is improved by matching rare earth cis-butadiene and butadiene-acrylonitrile rubber, the hardness of the product is reduced by matching German imported ointment oil with carbon black, the product is low in hardness, good in wear resistance and resistant to skid, the sole made of the product has good wear resistance and toughening effect, and the wear resistance and the skid resistance are improved while the characteristic of comfort in wearing due to low hardness is kept.

Owner:黄成余

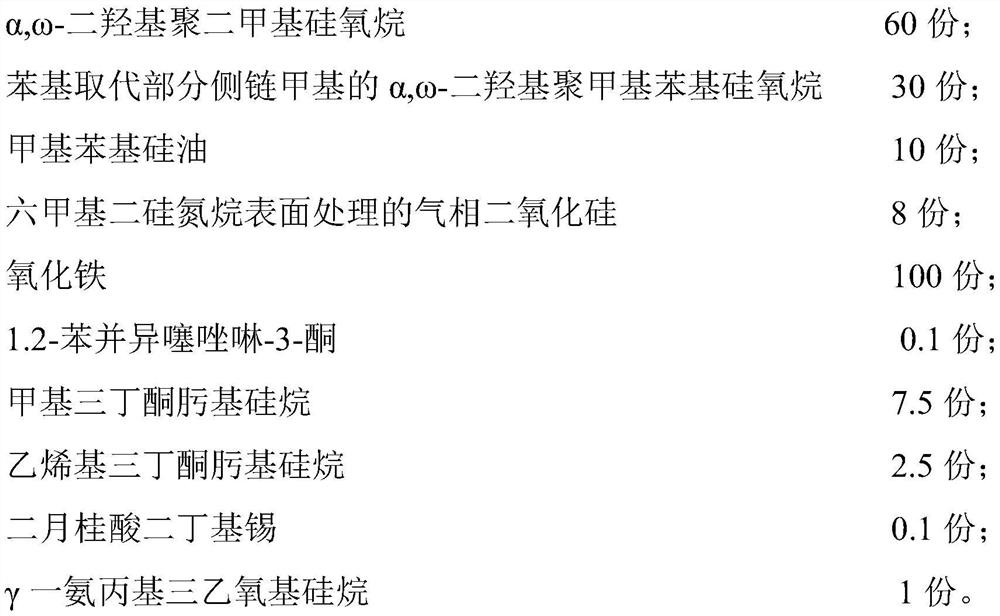

A kind of high-temperature-resistant mildew-proof silicone sealant and preparation method thereof

ActiveCN108676544BImprove resistance to degradation and oxidation temperatureImprove heat resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer sciencePtru catalyst

The invention discloses a high-temperature-resistant mildew-proof silicone sealant and a preparation method thereof. The high-temperature-resistant mildew-proof silicone sealant comprises the following components calculated in parts by weight: α,ω-dihydroxy polysiloxane 50 ~100 parts; 5~20 parts of reinforcing filler; 5~20 parts of methyl phenyl silicone oil; 40~100 parts of high temperature resistant filler; 0.05~0.2 parts of antifungal agent; 0.2-1 part of coupling agent; the α,ω-dihydroxypolysiloxane is α,ω-dihydroxypolydimethylsiloxane, α,ω-dihydroxypolydimethylsiloxane, phenyl substituted partial side chain methyl Mixture of dihydroxypolymethylphenylsiloxanes. The high-temperature resistant and mildew-resistant silicone sealant prepared by the invention has good elasticity, high tensile strength and elongation at break, and excellent high-temperature resistance and heat-and-humidity resistance.

Owner:KESHUN WATERPROOF TECH CO LTD

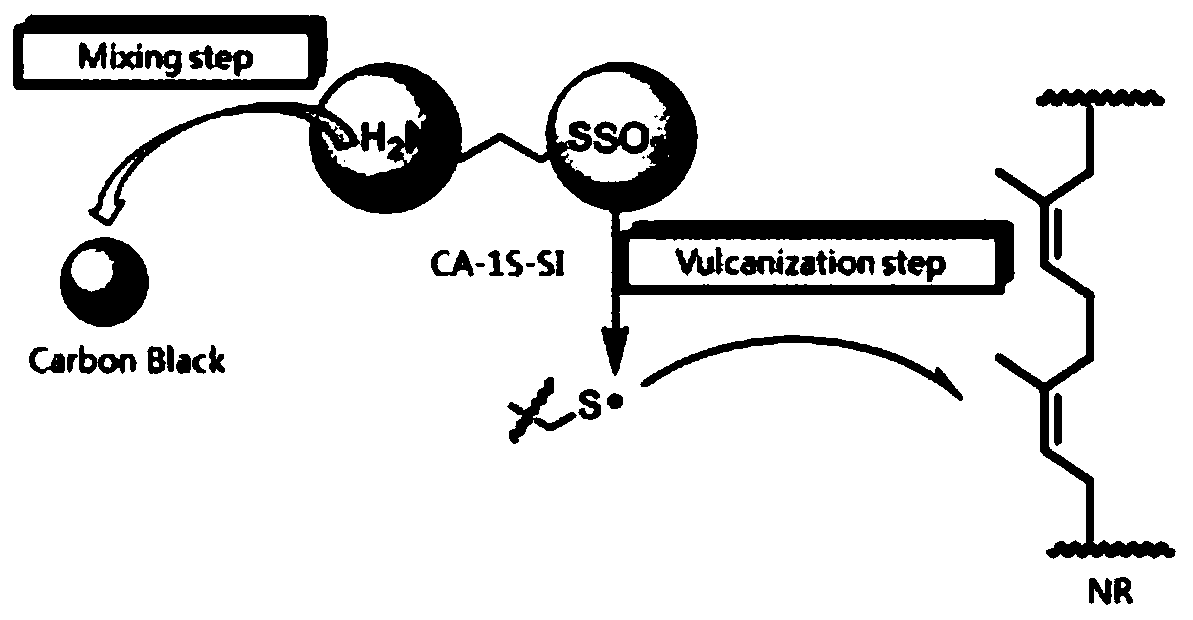

Silica granules, rubber composition, tire, production method for silica granules, and production method for rubber composition.

InactiveCN105473644AFast vulcanizationImprove vulcanization speedPigmenting treatmentSpecial tyresPolymer scienceRosin

In the present invention, silica granules are obtained by mixing silica and a rosin resin and subjecting the product to granulation.

Owner:HARIMA CHEM INC

Composite functional reinforcing agent for rubber production and preparation method thereof

Belonging to the field of rubber plastic products, the invention in particular relates to a composite functional reinforcing agent for rubber production and a preparation method thereof. The raw materials include: red mud, a conditioning agent and a dispersing agent. The conditioning agent is stearic acid and gypsum, the dispersing agent is calcium phosphate, and the weight ratio of the red mud, the conditioning agent and the dispersing agent is 8-12:0.8-1.2:0.8-1.2. The composite functional reinforcing agent provided by the invention realizes utilization of waste red mud, has a good reinforcing effect on rubber products, can partially replace carbon black and white carbon black, can completely replace other traditional inorganic filler (like potter's clay, ordinary silicon powder and calcium carbonate, etc) in the rubber formula of rubber products, also can serve as a rubber reinforcing agent and filler. At the same time, the composite functional reinforcing agent also has vulcanization promoting and flame retardant effects, thereby reducing the dosage of carbon black, a vulcanization accelerator, a flame retardant and other expensive raw materials involved in the rubber formula, lowering the production cost of rubber products, and improving the performance of the prepared product.

Owner:山东沣泉环保橡塑有限公司

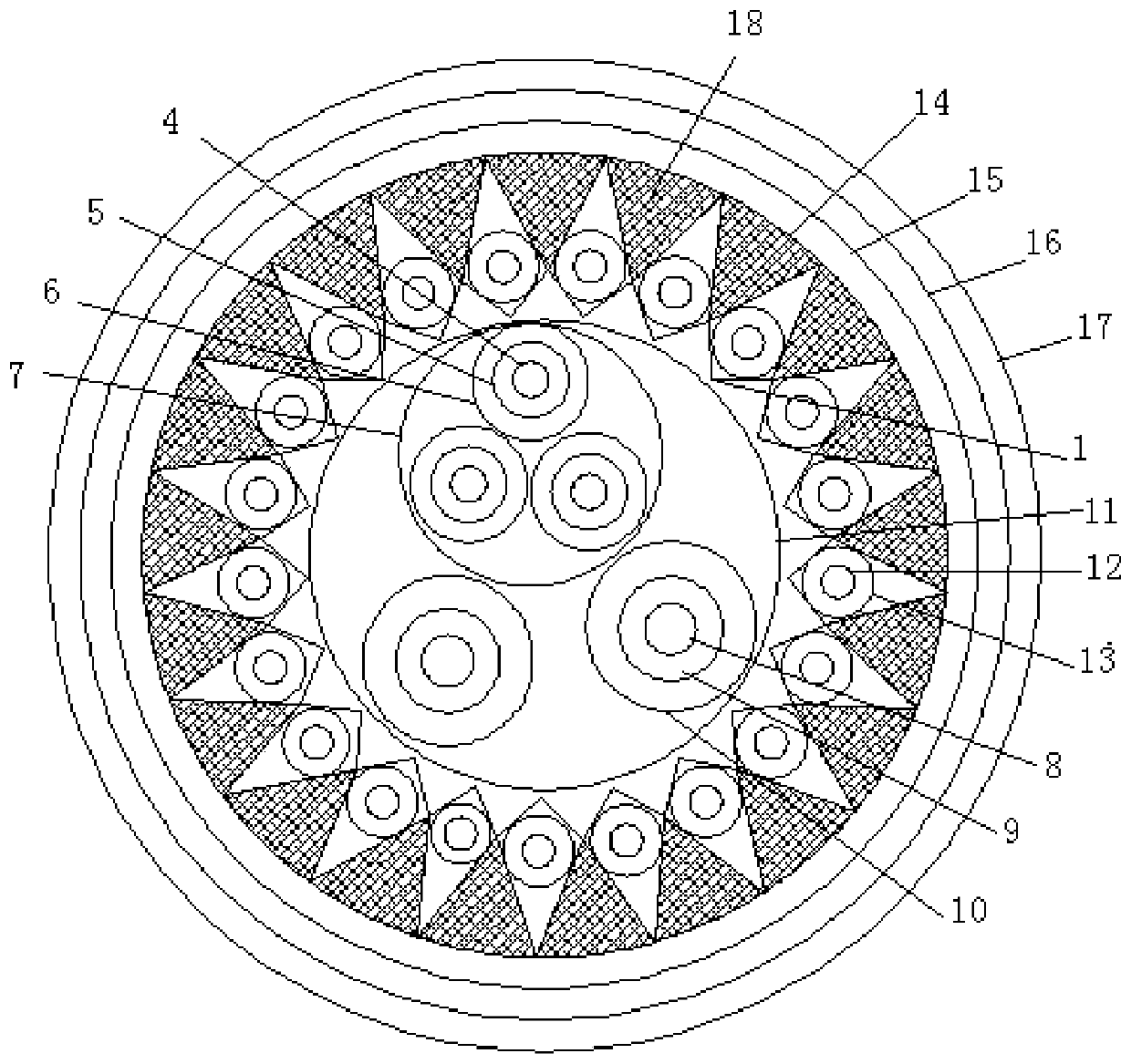

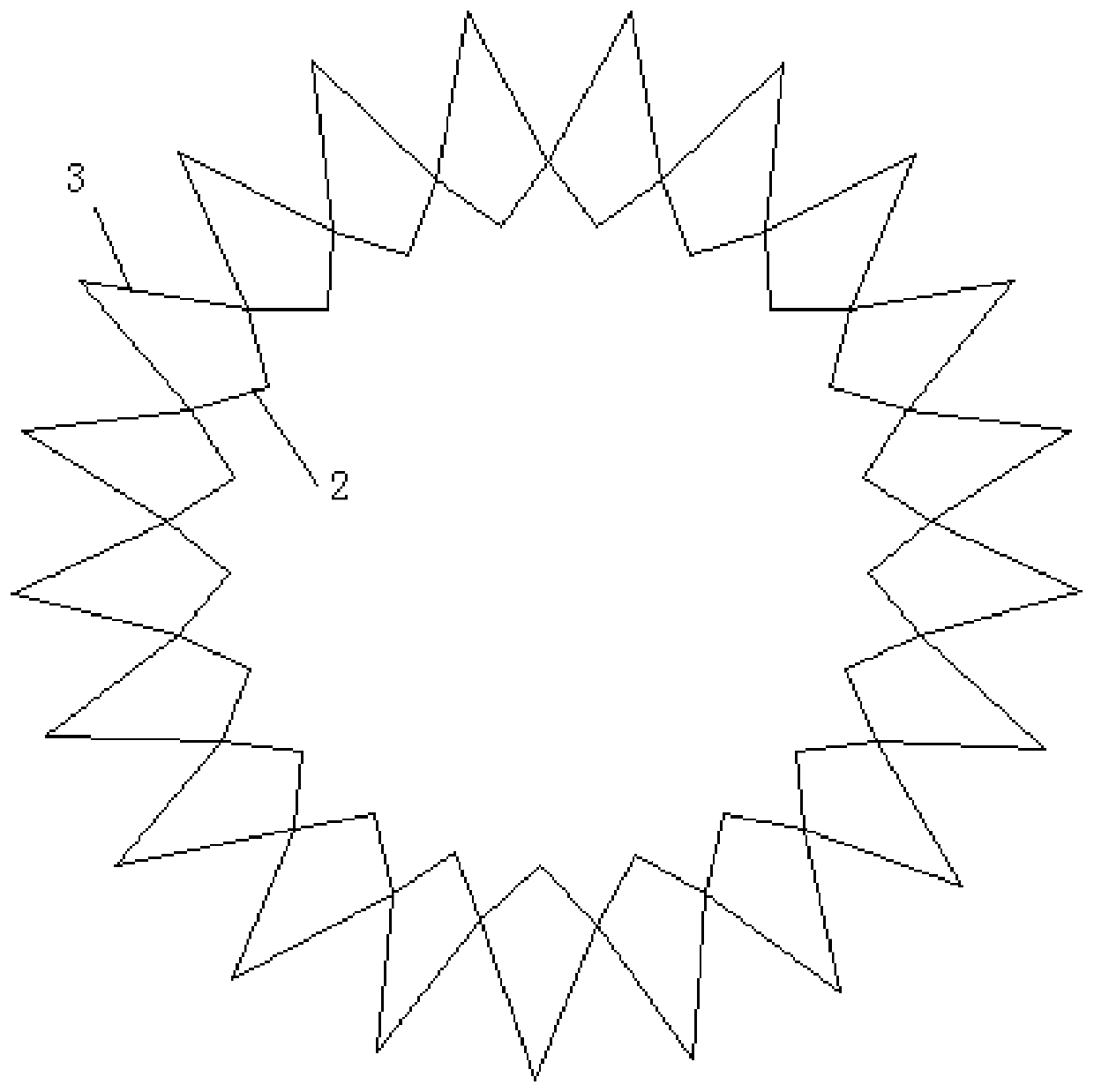

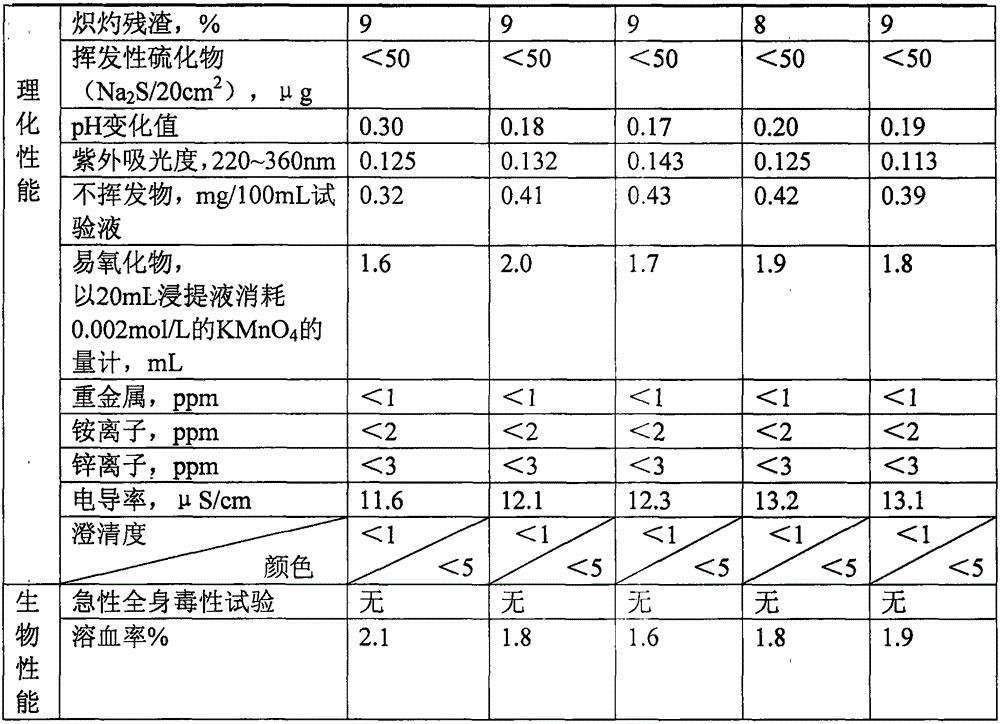

A low-temperature-resistant and crack-resistant power cable

ActiveCN110111925BImprove protectionImprove wear resistanceRubber insulatorsClimate change adaptationGlass fiberPower cable

The invention discloses a low-temperature-resistant anti-cracking power cable. The cable comprises a rubber skeleton, and the rubber skeleton comprises a serrated-edge-shaped annular skeleton. Each serrated concave corner of the outer side of the annular skeleton is fixedly connected with a V-shaped plate to to form a plurality of quadrilateral cavities; a first wire core and two second wire coresare arranged in the annular skeleton; the first wire core and the two second wire cores are twisted and then coated with a high-density polyethylene protective layer; third wire cores are respectively arranged in the quadrilateral cavities, and the outer side of the rubber skeleton is sequentially coated with a glass fiber woven layer, a heat preservation cotton layer, an aluminum belt interlocking armor layer and a butadiene styrene rubber outer sheath. The serrated-edge-shaped annular skeleton has a very good pressure-resistant buffer effect, and can well protect the wire cores in the skeleton; the V-shaped plate from forms a plurality of quadrilateral cavities to protect the third wire cores in the skeleton, and has very good pressure-resistant, tensile and torsional effects; the internal structure of the cable is more compact and tidy, and the cable is not liable to deform after being used for a long time.

Owner:ANHUI HUININGELECTRIC INSTR & APPLIANCE GRP

Composite functional reinforcing agent for rubber production and preparation method thereof

InactiveCN106009138BImprove vulcanization speedImprove flame retardant performanceCalcium biphosphateVulcanization

Belonging to the field of rubber plastic products, the invention in particular relates to a composite functional reinforcing agent for rubber production and a preparation method thereof. The raw materials include: red mud, a conditioning agent and a dispersing agent. The conditioning agent is stearic acid and gypsum, the dispersing agent is calcium phosphate, and the weight ratio of the red mud, the conditioning agent and the dispersing agent is 8-12:0.8-1.2:0.8-1.2. The composite functional reinforcing agent provided by the invention realizes utilization of waste red mud, has a good reinforcing effect on rubber products, can partially replace carbon black and white carbon black, can completely replace other traditional inorganic filler (like potter's clay, ordinary silicon powder and calcium carbonate, etc) in the rubber formula of rubber products, also can serve as a rubber reinforcing agent and filler. At the same time, the composite functional reinforcing agent also has vulcanization promoting and flame retardant effects, thereby reducing the dosage of carbon black, a vulcanization accelerator, a flame retardant and other expensive raw materials involved in the rubber formula, lowering the production cost of rubber products, and improving the performance of the prepared product.

Owner:山东沣泉环保橡塑有限公司

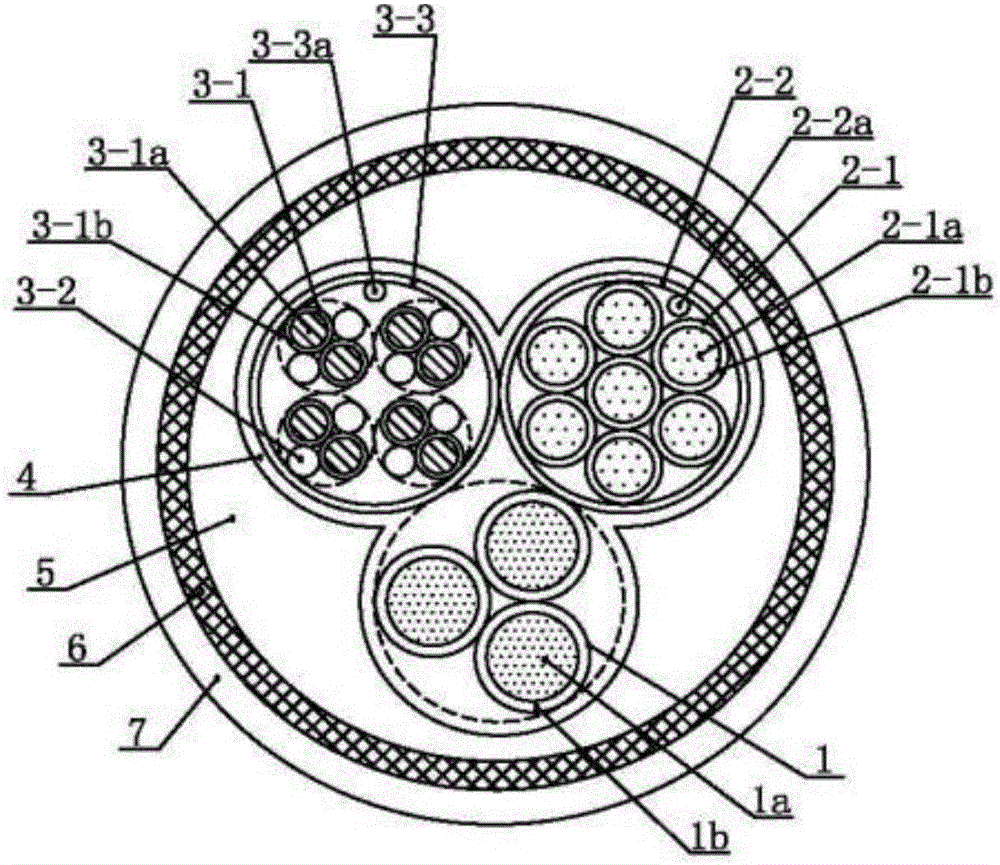

Manufacturing method of composite cable

InactiveCN106548823AIncrease working temperatureEliminate voidsInsulated cablesCable/conductor manufacturePower cableEngineering

The invention relates to a manufacturing method of a composite cable. A power cable core, a control cable core and an instrument cable core are mutually twisted to form the composite cable; the periphery of the composite cable is coated with a low-intensity non-woven fabric longitudinal covering; an inner sheath is extruded on the periphery of the low-intensity non-woven fabric longitudinal covering; the periphery of the inner sheath is coated with an armored braid; and an outer sheath is extruded on the periphery of the armored braid. The low-intensity non-woven fabric longitudinal covering is completely coincided with the shape of an insulated conductor so as to eliminate a gap between the low-intensity non-woven fabric longitudinal covering and the insulated conductor and facilitate preventing inward spread of flame; and meanwhile, the inner sheath and the insulated conductor are guaranteed not to be adhered so as to facilitate not damaging the insulated conductor when the sheaths are stripped off in the construction process.

Owner:重庆三峡电线电缆科技股份有限公司

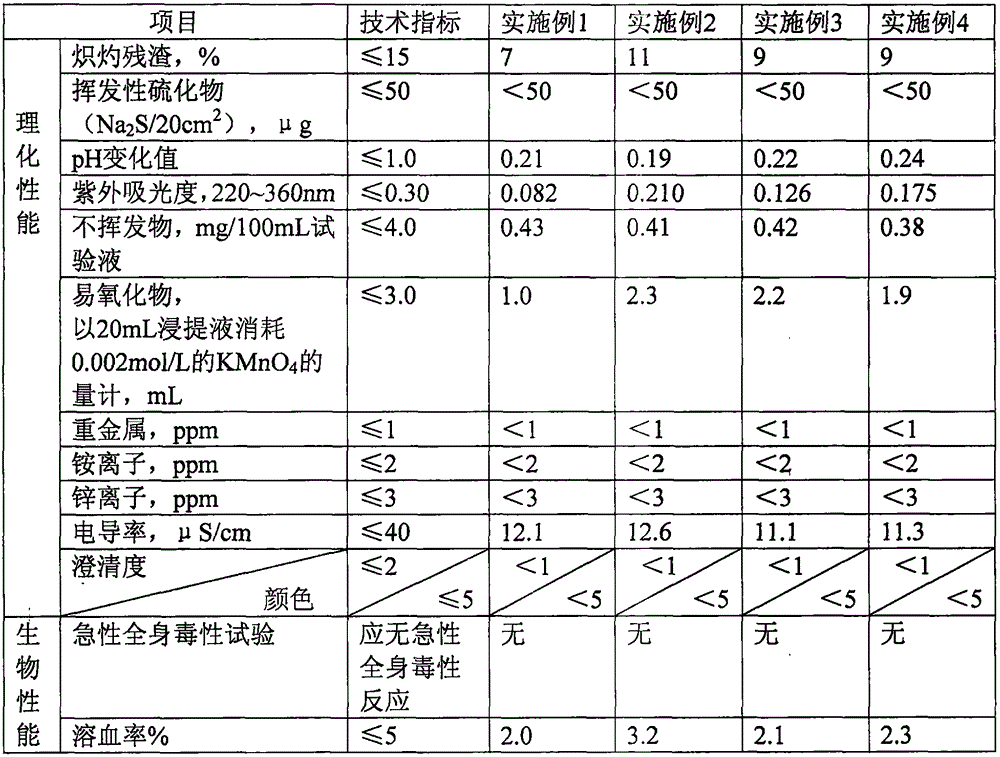

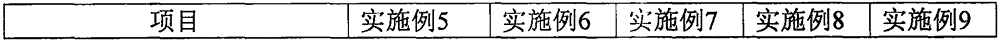

Rubber plug for puncture-type infusion connecting member heparin cap

The invention discloses a rubber plug for a puncture-type infusion connecting member heparin cap and belongs to the technical field of medical instruments. The rubber plug comprises, by weight, 100 parts of isoprene rubber, 3-5 parts of transparent zinc oxide, 1-3 parts of stearic acid, 1-1.3 parts of sulfur, 0.1-0.4 part of promoter TRA, 0.1-0.3 part of promoter TMTM and 5-8 parts of lightweight magnesium carbonate. The rubber plug has the advantages of stable physiochemical and biological performance, excellent compatibility with medicine, resistance to perforation, good closing performance after puncture and capability of meeting clinical using needs.

Owner:林洁

Anti-aging bicycle inner tube rubber composition

The invention belongs to the technical field of bicycle inner tube production, and discloses an anti-aging bicycle inner tube rubber composition, which is prepared from the following raw materials in parts by weight: 30 to 40 parts of combined rubber, 10 to 20 parts of reinforcing filler, 3 to 5 parts of vulcanization accelerator, 1 to 3 parts of cross-linking agent and 2 to 5 parts of rubber anti-aging agent, the combined rubber comprises natural rubber, butyl rubber and butadiene styrene rubber. According to the anti-aging bicycle inner tube rubber composition disclosed by the scheme, the combined rubber formed by combining the natural rubber, the butyl rubber and the butadiene styrene rubber is matched with the reinforcing filler, the vulcanization accelerator, the cross-linking agent and the rubber anti-aging agent for assistance, so that the anti-aging bicycle inner tube rubber composition has good properties such as aging resistance, tear resistance and air tightness; wherein the butyl rubber has excellent air tightness and water tightness, so that the air tightness of the inner tube is ensured, and the butadiene styrene rubber has the advantages of wear resistance, heat resistance, aging resistance, better vulcanization speed than natural rubber and the like, so that the comprehensive performance of the bicycle inner tube is improved when the butadiene styrene rubber is combined with the natural rubber and the butyl rubber.

Owner:海门市协和车辆配件有限公司

Salt-corrosion-resistant torsion-resistant double-shielded communication cable for marine wind power and manufacturing method thereof

ActiveCN103227012BEasy not to hurtEliminate voidsInsulating conductors/cablesCables with twisted pairs/quadsCopper conductorElectricity

The invention relates to a salt corrosion resistant and twisting resistant double-shielded communication cable for ocean wind power and a manufacturing method of the communication cable. Each stranded copper conductor is wrapped in a salt corrosion resistant and twisting resistant extruded rubber insulation layer to form an insulated core; each two insulated cores are stranded to form a twisted pair of which the gaps are filled with fillers; each twisted pair is wrapped in a twisted pair copper foil shielding layer to form a twisted-pair group; the twisted-pair groups are mutually stranded to form a cable core; and the cable core is wrapped in a low-strength non-woven fabric longitudinal wrap, an inner sheath, a cable core copper foil shielding layer and an outer sheath in sequence from inside to outside. The communication cable provided by the invention adopts the low-strength non-woven fabric longitudinal wrap which completely fits the insulated cores in shape, so that gaps between the low-strength non-woven fabric longitudinal wrap and the insulated cores are eliminated, convenience is provided for stopping flame from spreading inwards under a combustion condition and the resistance to moisture impregnation is enhanced; and meanwhile, the low-strength non-woven fabric longitudinal wrap can ensure that the sheaths are not stuck to the insulated cores, and provides convenience for stripping the sheathes in a construction process without damaging the insulated cores.

Owner:浙江华威设备制造有限公司

Blending type rubber compound and preparation method thereof

ActiveCN102816390BRetain corrosion resistanceImprove mechanical propertiesRubber materialPolymer science

The invention belongs to the technical field of rubber materials and preparation of the rubber materials, and particularly relates to a blending type rubber compound and a preparation method thereof. The rubber compound comprises, by weight, 75-85 parts of ethylene-propylene-diene monomer (EPDM), 15-25 parts of rubber type chlorinated polyethylene (CPE), 2-3 parts of dicumyl peroxide (DCP), 0.8-1.5 parts of triallyl isocyanurate (TAIC), 25-35 parts of talcum powder, 25-35 parts of N660, 4-6 parts of TP759, 1-1.5 parts of SA and 3-6 parts of ZnO. The rubber type CPE and the EPDM are mixed in a certain proportion and other assistants are added simultaneously to obtain the blending type rubber compound through corresponding preparation processes, so that chlorine elements are added on the molecular weight of the EPDM, and the modified ethylene propylene rubber (EPR) not only reserves corrosion resistance of the EPR, but also is provided with good physical and mechanical properties and processability. The problems of the poor oil resistance and high cost of the existing EPR can be solved.

Owner:山东钧策科技服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com