A kind of high-temperature-resistant mildew-proof silicone sealant and preparation method thereof

A silicone sealant, high temperature resistant technology, applied in adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problem of low tensile strength and elongation at break, slow deep curing, sticky In order to improve the tensile strength and high temperature resistance, improve the resistance to humidity and heat, and improve the heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

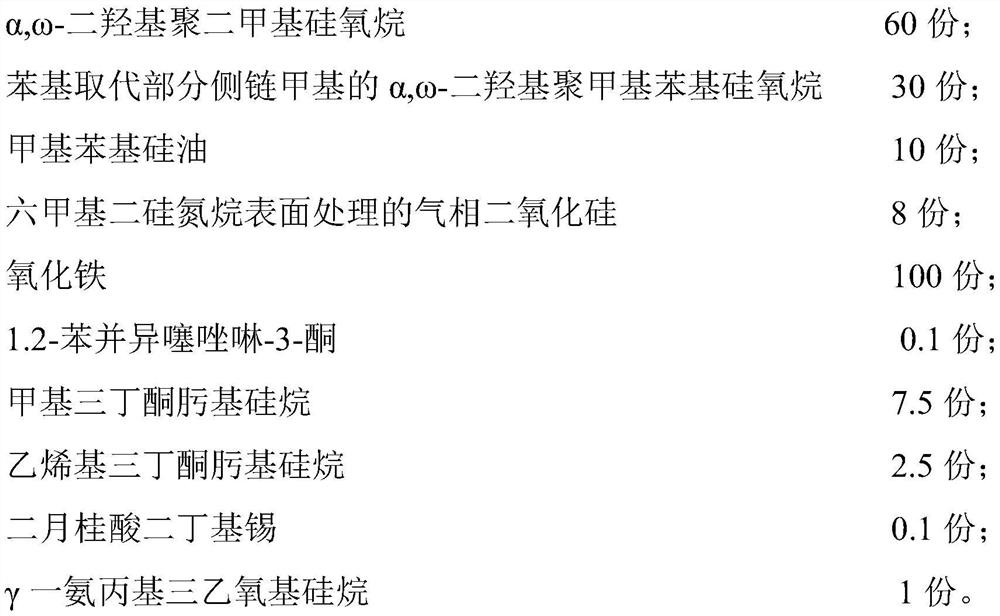

[0034] A high-temperature-resistant and mildew-proof silicone sealant, which consists of the following components calculated in parts by weight:

[0035]

[0036] The preparation method of the high temperature-resistant mildew-proof silicone sealant is as follows:

[0037] (1) Add α,ω-dihydroxypolysiloxane, methylphenyl silicone oil, anti-fungal agent, and crosslinking agent to the planetary mixer, start stirring, rotate at 200-400r / min, vacuumize, and control the vacuum degree at -0.09MPa or more, stir for 5 minutes;

[0038] (2) Stop stirring, fill with nitrogen to relieve the vacuum, add reinforcing filler, start stirring at a speed of 100-200r / min, and stir for 10 minutes; stop, add high-temperature-resistant fillers, start stirring, and turn at a speed of 200-300r / min, and stir for 15 minutes ;

[0039] (3) Stop stirring, use a spatula to scrape the planetary paddle, then start stirring, adjust the speed to 600-800r / min, vacuumize, connect the cooling water, control ...

Embodiment 2

[0043] A high-temperature-resistant and mildew-proof silicone sealant, which consists of the following components calculated in parts by weight:

[0044]

[0045] The preparation method of the high-temperature-resistant and mildew-proof silicone sealant is the same as that in Example 1.

Embodiment 3

[0047] A high-temperature-resistant and mildew-proof silicone sealant, which consists of the following components calculated in parts by weight:

[0048]

[0049]

[0050] The preparation method of the high-temperature-resistant and mildew-proof silicone sealant is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com