Low-hardness high-wear-resistance non-slip sole material for shoes and preparation method of low-hardness high-wear-resistance non-slip sole material

A low-hardness, high-wear-resistant technology, used in the rubber field, can solve problems such as poor wear resistance, achieve good wear resistance and toughening effect, improve wear resistance and anti-skid performance, and low hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

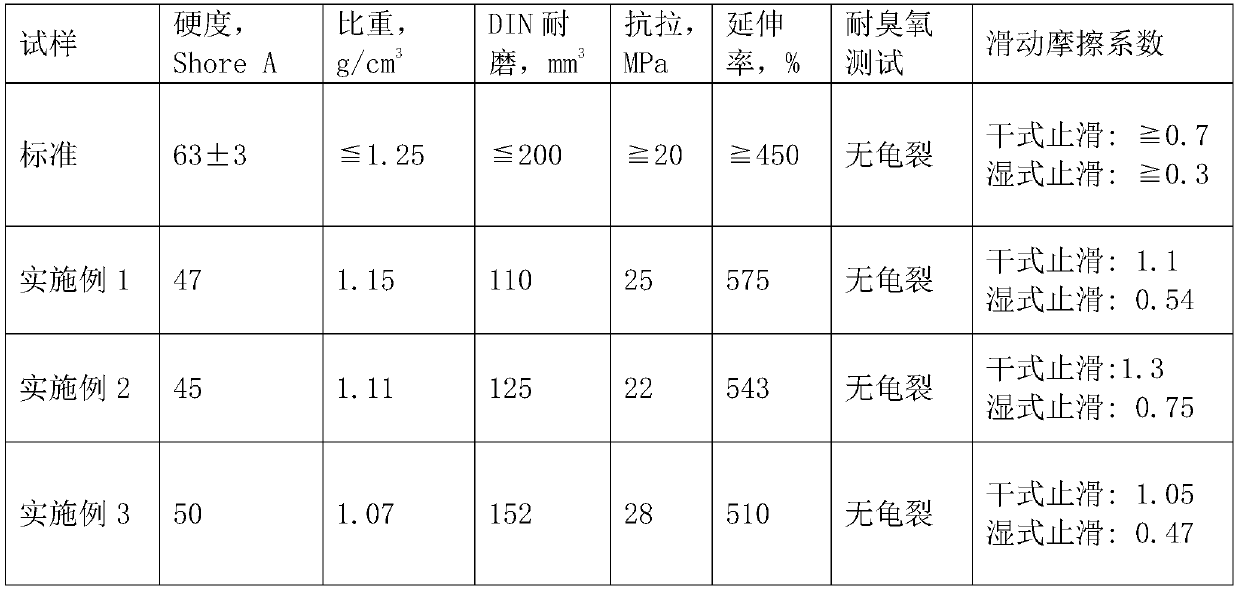

Examples

Embodiment 1

[0024] A low-hardness and high wear-resistant anti-skid sole material for shoes, which includes the following raw materials in parts by weight:

[0025] The core raw materials mainly include the following four types, rare earth butadiene: 25 parts, NBR nitrile rubber: 5 parts, carbon black: 15 parts, ointment oil: 20 parts; also include: 3L: 50 parts, styrene-butadiene: 20 parts, black Masterbatch: 6 parts, white carbon black: 15 parts, diethylene glycol: 3 parts, 99 zinc oxide: 5 parts, stearic acid: 1 part, PEG4000: 3 parts, SI69: 1.5 parts, antioxidant: 3 parts, Wax: 1 part, DM: 2 parts, TMTM: 0.4 parts, S: 2.2 parts. Wherein, the ointment oil adopts the ointment oil imported from Germany.

[0026] The preparation method of this sole material is as follows:

[0027] (1) Put the main rubber into the internal mixer and mix evenly, the mixing temperature is 60 degrees, and the mixing time is 2 minutes;

[0028] (2) Add 2 / 3 of white carbon black and powder oil, the mixing te...

Embodiment 2

[0034] The difference from Example 1 is that the preparation method of the sole material is as follows:

[0035] (1) Put the main rubber into the internal mixer and mix evenly, the mixing temperature is 80 degrees, and the time is 5 minutes;

[0036] (2) Add 2 / 3 of white carbon black and powder oil, the mixing temperature is 100 degrees, and the time is 2 minutes;

[0037] (3) Add the remaining amount of white carbon black and accelerators, the mixing temperature is 120 degrees, and knead for 2 minutes;

[0038] (4) When the material is discharged above 120 degrees, the rubber material is cooled and left for more than 24 hours as a mixing base rubber for use;

[0039] (5) Add the vulcanization accelerator to the base rubber in step (4) according to the amount, knead evenly on the open mill, and then punch out the semi-finished blanks with the size of finished products after being cooled.

[0040] (6) The semi-finished blank in step (5) is pressurized and vulcanized, the vulc...

Embodiment 3

[0042] The difference from Example 1 is that the preparation method of the sole material is as follows:

[0043] (1) Put the main rubber into the internal mixer and mix evenly, the mixing temperature is 70 degrees, and the mixing time is 3 minutes;

[0044] (2) Add 2 / 3 of white carbon black and powder oil, the mixing temperature is 95 degrees, and the time is 4 minutes;

[0045] (3) Add the remaining amount of white carbon black and accelerators, the mixing temperature is 110 degrees, and knead for 2 minutes;

[0046] (4) When the material is discharged above 120 degrees, the rubber material is cooled and left for more than 24 hours as a mixing base rubber for use;

[0047] (5) Add the vulcanization accelerator to the base rubber in step (4) according to the amount, knead evenly on the open mill, and then punch out the semi-finished blanks with the size of finished products after being cooled.

[0048] (6) The semi-finished blank in step (5) is pressurized and vulcanized, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com