Preparation method of composite rubber material for water lubricated bearings

A water-lubricated bearing and composite rubber technology, applied in the field of bearings, can solve the problems of high brittleness, low impact resistance, large starting torque, poor thermal conductivity, etc., and achieve the effects of strong tear resistance, high resilience, and improved water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

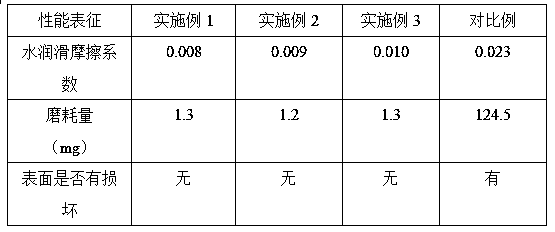

Examples

Embodiment Construction

[0038] In parts by weight, weigh 20-40 parts of butyl acrylate, 20-40 parts of ethyl acrylate, 20-40 parts of methyl methacrylate, 0.6-1.2 parts of sodium lauryl sulfate, 0.1-0.2 1 part of sodium dithionite, 0.1~0.2 part of ammonium persulfate, 10~20 parts of absolute ethanol, 40~80 parts of deionized water, butyl acrylate, ethyl acrylate, methyl methacrylate, sodium lauryl sulfate Add deionized water, stir and mix at a speed of 200~250r / min for 10~12min in a water bath at 50~60°C, keep warm to obtain an acrylate mixture, add sodium dithionite and ammonium persulfate to the acrylate mixture, Introduce nitrogen protection at an airflow rate of 30-40mL / min, stir and react at a speed of 240-280r / min in a water bath at 50-60°C for 1-2 hours to obtain a reaction emulsion, add absolute ethanol to the reaction emulsion, and Stir at a speed of 180~200r / min for 8~10min, let stand for 30~40min, filter, take the solid to obtain the reaction polymer, wash the reaction polymer with absolut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com