A low-temperature-resistant and crack-resistant power cable

A power cable and anti-cracking technology, applied in power cables, power cables with shielding/conducting layers, insulated cables, etc., can solve the problem that the cables cannot work well, reduce the service life of power cables, and do not have low temperature resistance effect and other issues, to achieve the effect of improving the protection effect, improving the service life, and improving the strength of mechanical stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

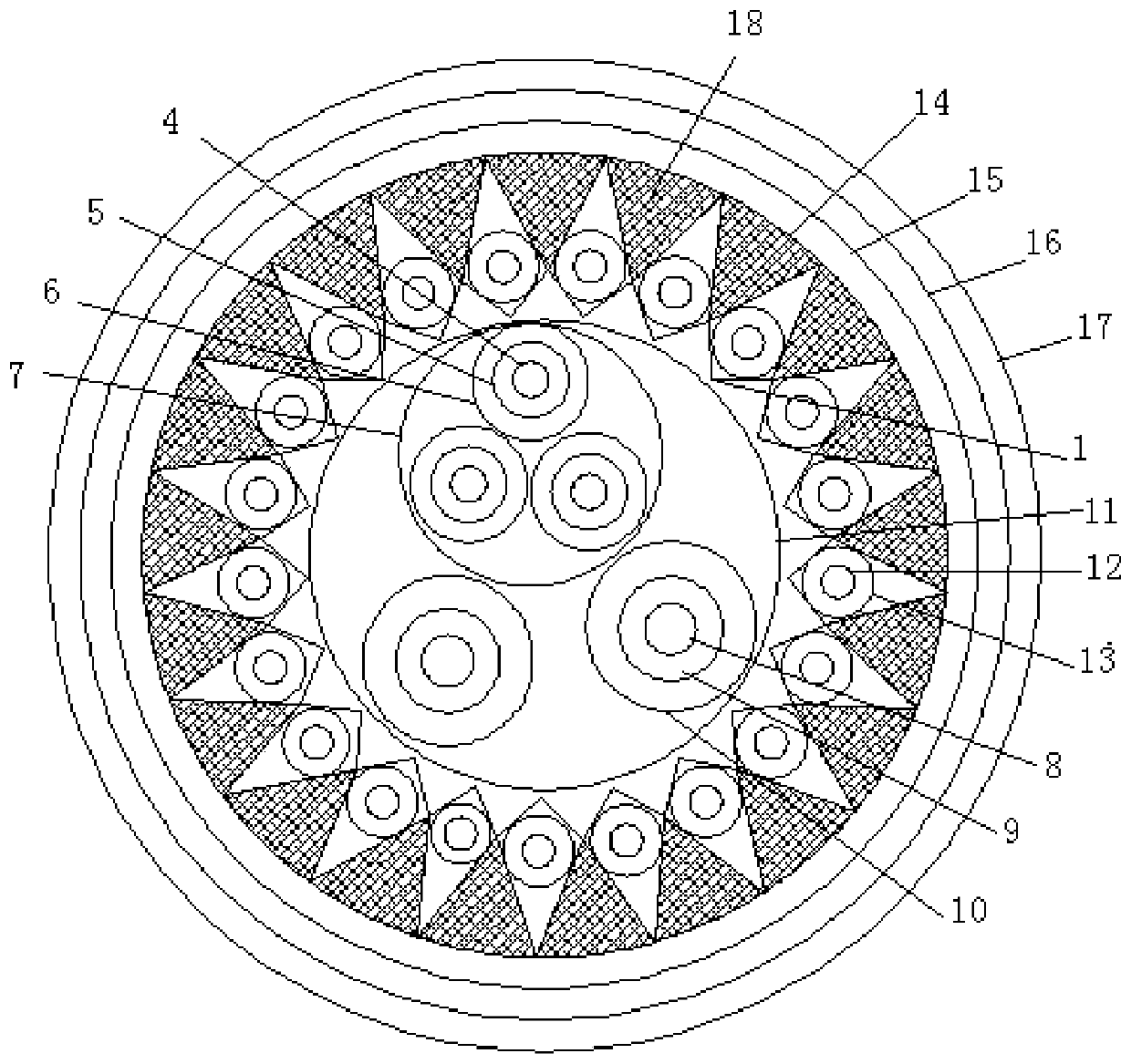

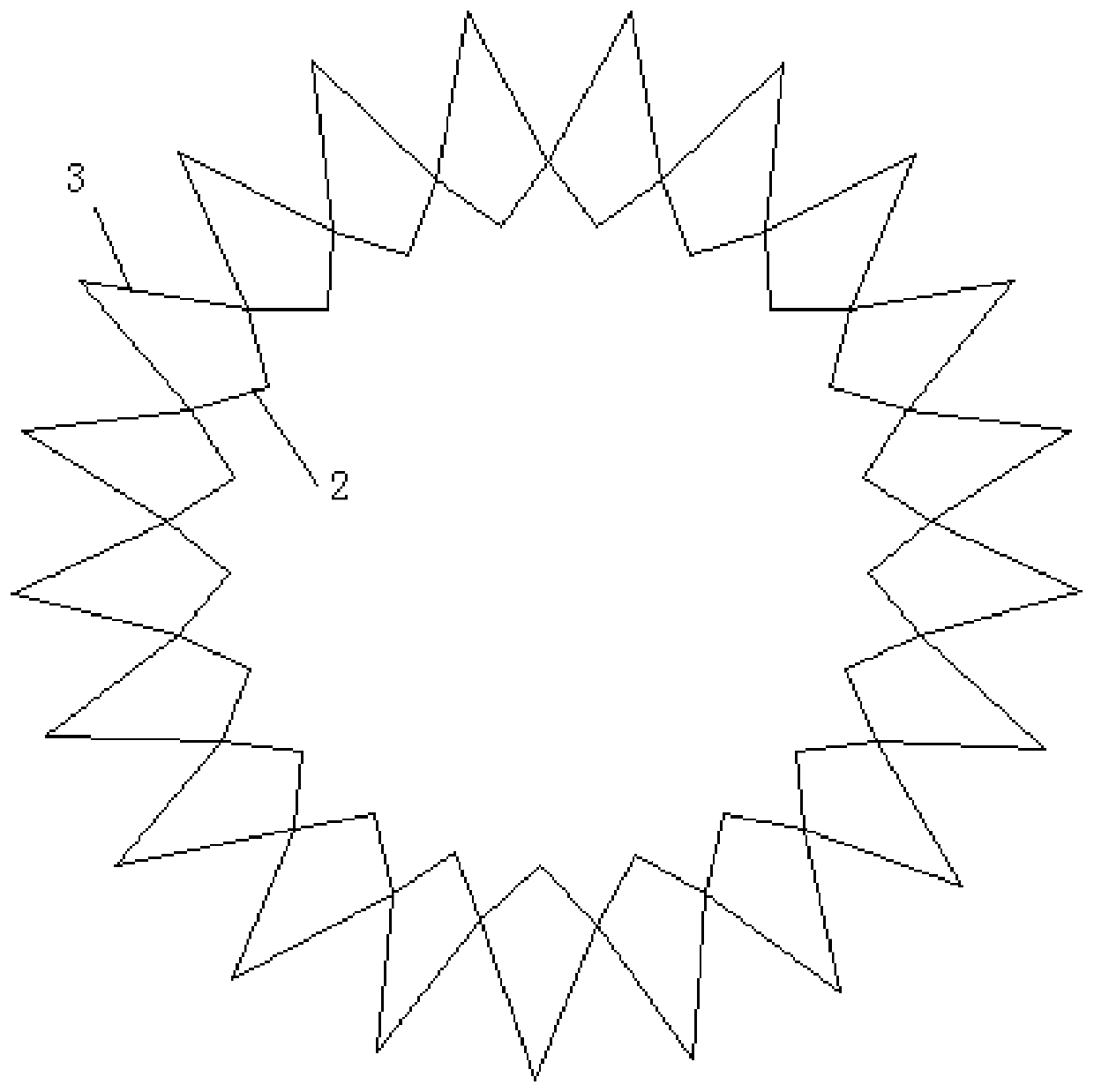

[0022] Such as figure 1 , 2 As shown, a low-temperature-resistant and crack-resistant power cable includes a rubber skeleton 1, and the rubber skeleton 1 includes a sawtooth-shaped annular skeleton 2, and a V-shaped The plate 3 forms a plurality of quadrangular cavities, and a wire core 1 and two wire cores 2 are arranged inside the ring skeleton 2. The wire core 1 includes a conductor 4, and the outside of the conductor 4 is covered with a cross-linked Polyethylene insulation layer 5 and tinned annealed copper wire plus polyester wire braided insulation shielding layer 6, three conductors one 4 bundles are twisted and covered with Kevlar fiber braiding layer 7, and the core two includes conductor two 8 And the polypropylene insulating layer 9 and the aluminum-magnesium alloy wire braided shielding layer 10 that are coated on the outer side of the conductor two 8 in turn, and one wire core one and two wire core two bundles are twisted and covered with a high-density polyethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com