Rubber composition for tread

一种橡胶组合物、胎面的技术,应用在轮胎胎面/胎面花纹、特殊轮胎、轮胎零部件等方向,能够解决没有积极地混合二氧化硅、硫化延迟等问题

Inactive Publication Date: 2006-12-13

SUMITOMO RUBBER IND LTD

View PDF1 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] JP-A-2002-226629 discloses a rubber composition for treads containing tetrabenzylthiuram disulfide and N-cyclohexyl-2-benzothiazole sulfenamide As a vulcanization accelerator, but silica is not actively mixed, and when silica is used, there is a problem that silica adsorbs the vulcanization accelerator and vulcanization is delayed

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1 to 6 and comparative example 1 to 6

[0052]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

Login to View More

Abstract

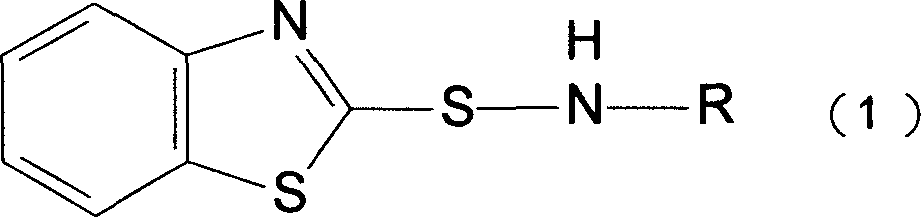

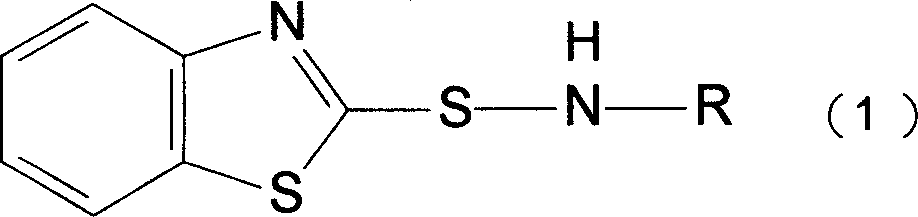

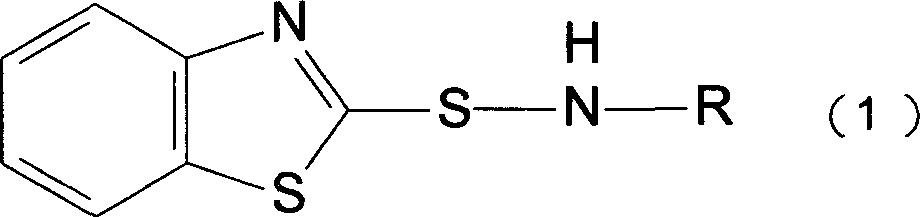

A rubber composition for a tread optimizing a vulcanization speed in a vulcanization step and, further, improving heat aging resistance is provided. A rubber composition for a tread comprising 20 to 90 parts by weight of silica, 0.5 to 2 parts by weight of (A) a guanidine vulcanization accelerator, 0.1 to 0.5 part by weight of (B) a thiuram vulcanization accelerator, and 0.5 to 2 parts by weight of (C) a sulfenamide vulcanization accelerator represented by the general formula (1): (wherein R is a linear alkyl group or a branched alkyl group having 1 to 18 carbons), based on 100 parts by weight of a rubber component.

Description

technical field [0001] The present invention relates to a rubber composition for treads. Background technique [0002] Among the various parts of the tire, the tread is the part that especially affects the rolling resistance of the tire. In order to reduce the rolling resistance, mixed silica is usually used as a reinforcing filler. [0003] Since the rubber composition for treads is prone to aging due to heat generated during running, it is required to have excellent heat aging resistance. [0004] In the step of vulcanizing the rubber composition for treads containing silica, when the vulcanization rate becomes high, problems such as premature vulcanization occur due to the influence of the silane coupling agent used in combination with silica, Therefore it is necessary to vulcanize at an appropriate vulcanization rate. [0005] Therefore, rubber compositions for treads containing silica are required to have excellent heat aging resistance ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L21/00C08K5/44B60C1/00B60C11/00C08K5/31C08K3/36C08K5/40

CPCC08K3/36C08K5/0025C08K5/31C08K5/40C08K5/47C08L21/00

Inventor 宫崎达也

Owner SUMITOMO RUBBER IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com