Rubber composition for tire tread and pneumatic tire using the rubber composition

A rubber composition, tire tread technology, applied in special tires, tire parts, transportation and packaging, etc., can solve the problems of lack of effect, increased interaction, slow vulcanization speed, etc., to achieve wet grip And the effect of excellent fuel consumption, good vulcanization rate, good dispersion state

Inactive Publication Date: 2011-12-07

THE YOKOHAMA RUBBER CO LTD

View PDF4 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, according to the studies of the present inventors, the following problem was found: if the specific surface area of silica is increased, the interaction between silicas increases, the dispersibility deteriorates, and the desired effect cannot be obtained.

In addition, there is a problem that if a large amount of silica with a high specific surface area is blended, the vulcanization accelerator will be adsorbed and the vulcanization rate will be slowed down.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

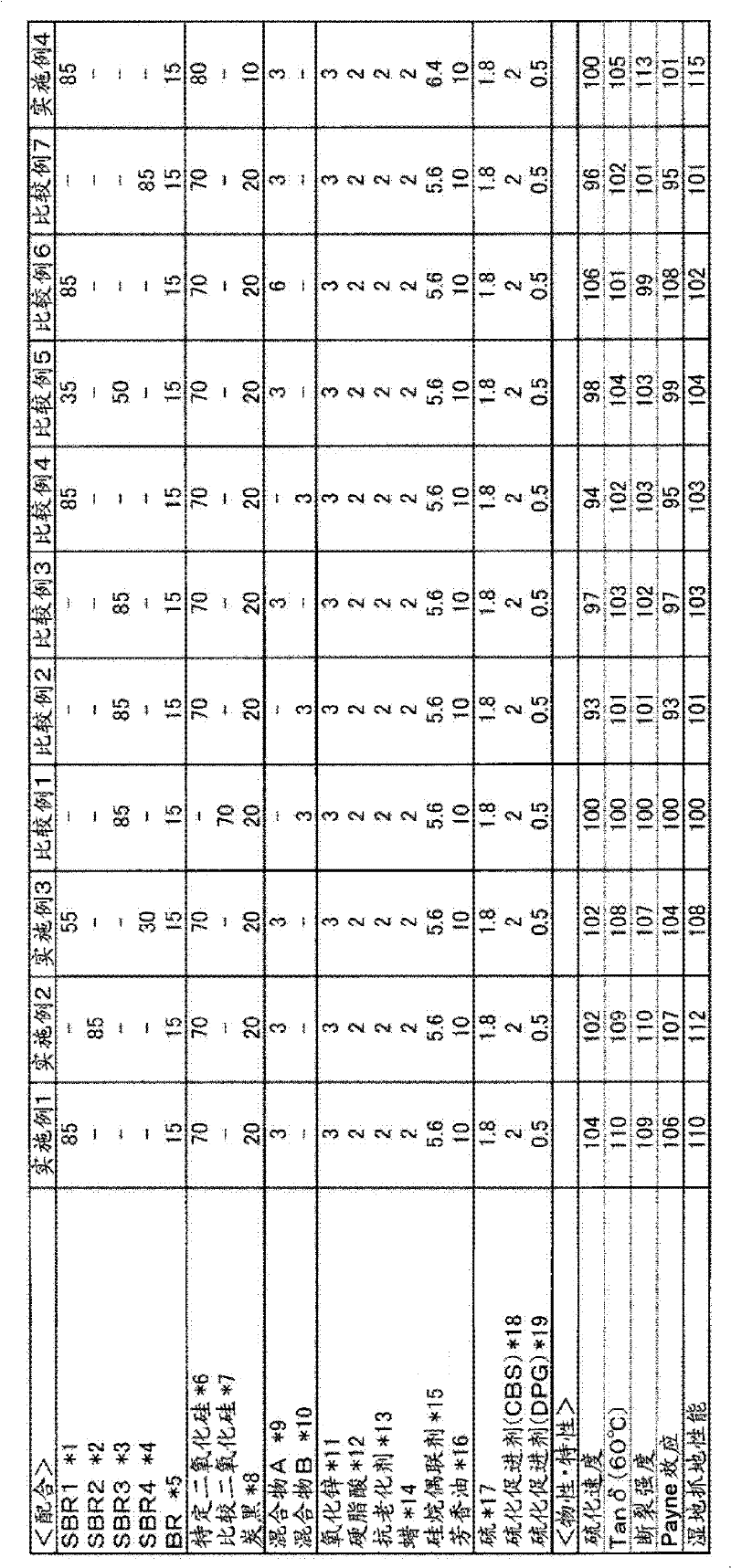

Embodiment 1 and comparative example 1~5

[0072] sample preparation

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Login to View More

Abstract

The object of the present invention is to provide a rubber composition for tire treads which has a good vulcanization rate and excellent wet grip and fuel efficiency. As a means of solving the problems of the present invention, there is provided a rubber composition for tire treads containing 40 parts by mass or more of a solution-polymerized SBR diene having a Mw of 900,000 to 1.5 million and a styrene content of 35 to 45%. 100 parts by mass of rubber, compounded with 60 to 110 parts by mass of silicon dioxide satisfying all the conditions of (1) to (4) below, and relative to the silicon dioxide, compounded with fatty acid metal salts (except zinc salts) 2-8 mass % of the mixture formed with fatty acid ester. The conditions for the above silica are: (1) N2SA is 194-225m2 / g. (2) The specific surface area of CTAB is 170-210m2 / g. (3) The relationship between the above-mentioned N2SA and the above-mentioned CTAB specific surface area is that the N2SA / CTAB specific surface area is 0.9 to 1.4. (4) DBP absorption is 190ml / 100g or more.

Description

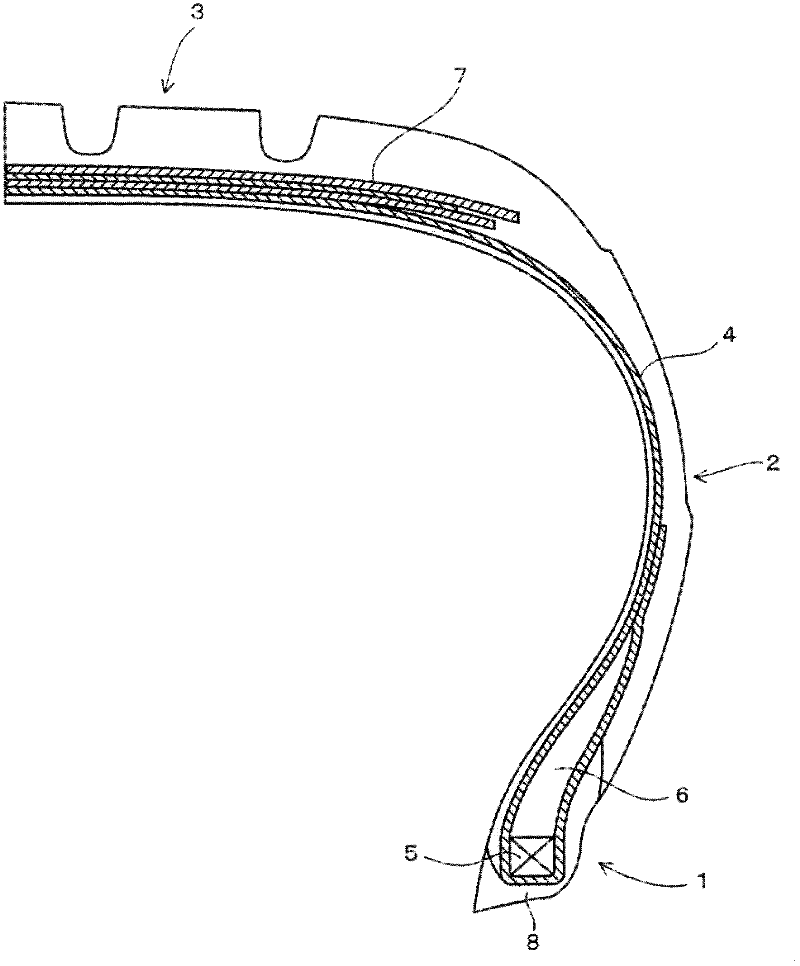

technical field [0001] The present invention relates to a rubber composition for tire treads and a pneumatic tire using the rubber composition, and more particularly, to a rubber for tire treads having a good vulcanization rate, wet grip and excellent fuel consumption performance Composition and a pneumatic tire using the rubber composition. Background technique [0002] Pneumatic tires are required to have various performances, but a high balance between wet grip and fuel consumption performance is particularly desired. It is known to compound silica into rubber compositions for tires in order to improve these performances. [0003] In addition, if silica with a high specific surface area is used, the number of bonds between silica and rubber increases, and reinforcement improves, which is presumed to improve wet grip performance. However, according to the studies of the present inventors, it has been found that if the specific surface area of silica is increased, the i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L9/06C08L9/00C08K13/02C08K3/36C08K5/098C08K5/10B60C1/00

CPCC08L9/00C08K5/548Y02T10/862C08K5/101B60C1/0016C08K5/098C08K3/36C08L21/00C08L9/06C08L2666/08C08L2666/02

Inventor 佐藤正树

Owner THE YOKOHAMA RUBBER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com