Special cable material for styrene-butadiene rubber sleeved field detection cable and preparation method of special cable material

A technology for detecting cables and special cables, applied in the direction of rubber insulators, organic insulators, etc., can solve the problems of hindering safe evacuation and fire extinguishing work, easy wear and tear of wires and cables, loss of life and property, etc. The effect of improved performance, excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

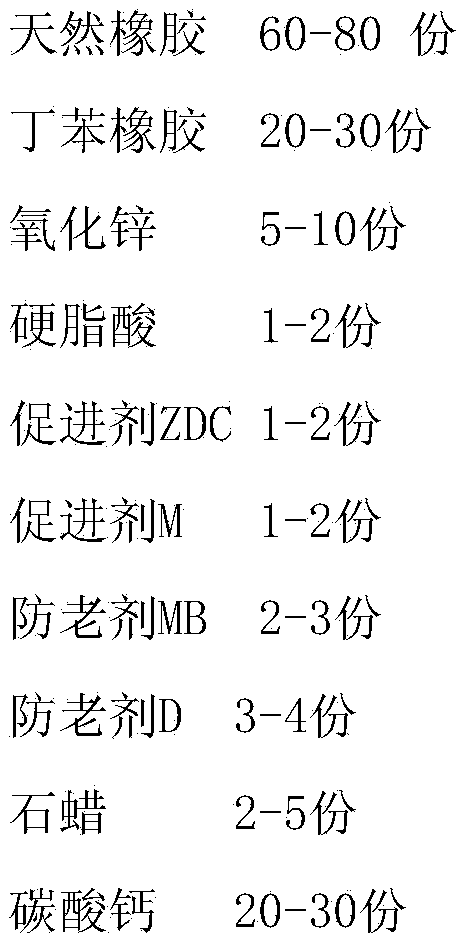

[0016] The composition of the cable material is as follows in parts by weight:

[0017]

[0018]

[0019] The preparation method of cable material is as follows:

[0020] Each raw material was weighed according to the weight portion of the raw materials, and then after banburying at a temperature of 120°C for 15 minutes, the finished product was obtained by wrapping the rolls at a temperature of 55°C. The performance of the resulting finished product assay is shown in Table 1.

Embodiment 2

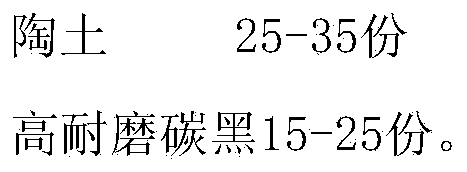

[0022] The composition of the cable material is as follows in parts by weight:

[0023]

[0024] The preparation method of cable material is as follows:

[0025] Weigh each raw material according to the weight of the raw materials, and then banbury at a temperature of 100° C. for 15 minutes, wrapping a roll to obtain a finished product, and the wrapping temperature is 60° C. The performance of the resulting finished product assay is shown in Table 1.

Embodiment 3

[0027] The composition of the cable material is as follows in parts by weight:

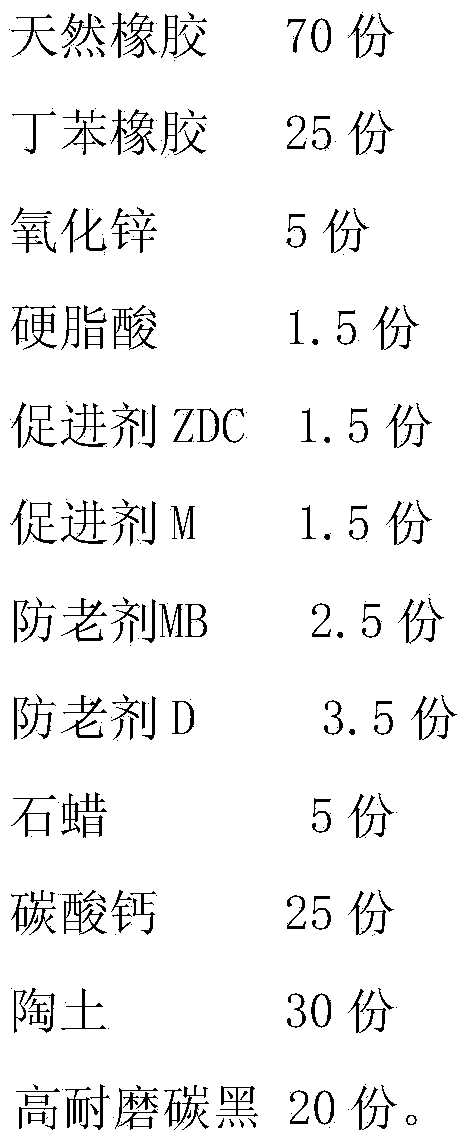

[0028]

[0029] The preparation method of cable material is as follows:

[0030] Each raw material is weighed according to the weight portion of the raw materials, and then banburying at a temperature of 120° C. for 10 minutes, wrapping a roll to obtain a finished product, and the wrapping temperature is 50° C. The performance of the resulting finished product assay is shown in Table 1.

[0031]

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com