Patents

Literature

67results about How to "Improve flame retardant effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Partially alkylated phosphinic acid nonalkali metal salt and preparing method and application thereof

InactiveCN101747368AImprove flame retardant effectReduce pollutionGroup 5/15 element organic compoundsPhosphinic AcidsDouble bond

The invention provides a partially alkylated phosphinic acid nonalkali metal salt and a preparing method and application thereof. The preparing method comprises the following steps of: ensuring that radical addition occurs between a phosphinic acid nonalkali metal salt and compound containing double bonds in the presence of an initiator, and generating partially alkylated phosphinic acid nonalkali metal salt products. The application is as follows: a flame-retardant polymer comprises a thermoplastic polymer or thermosetting polymer, and more than one of the partially alkylated phosphinic acidnonalkali metal salt. The invention has the advantages of simple technical process, easy operation, less byproducts, low energy consumption and pollution and the like.

Owner:SOUTH CHINA UNIV OF TECH

Polyphenylene oxide composition for LED display

ActiveCN101195704AImprove liquidityImprove flame retardant effectMaleic anhydrideButadiene-styrene rubber

The invention provides a polyphenyl ether compound of LED display unit, which contains 25-60 accounts of polyphenyl ether, 23-35 accounts of polystyrene resin, 3-6 accounts of styrene-butadiene copolymer or relative maleic anhydride grafts, 5-10 accounts of phosphorus-containing organic fire retardant, 10-25 accounts of inorganic oxide, 0.1-0.3 accounts of lubricant and 0.2-0.4 accounts of anti-oxidant. The product is characterized in high light reflectance, high temperature deformation resistance, good ink adhesion, good light resistance, and halogen-free flame retardant, which can be used to produce electric appliance elements as LED display unit.

Owner:广东瑞能新材料有限公司

Fire-resistant paint

ActiveCN105038573AGood dispersion and compatibilityImprove flame retardant effectFireproof paintsPolyurea/polyurethane coatingsPoly(N-isopropylacrylamide)Magnesium

The invention provides a fire-resistant paint which is characterized by comprising 12-20% of polyurethane acrylate, 16-25% of poly(N-isopropylacrylamide) modified magnesium hydroxide, 1.2-3.6% of urea, 0-8.5% of anionic surfactant, 2.8-6% of assistant, 2.2-4.6% of titanium white, 3.5-5% of borax and 30-45% of water. The fire-resistant paint has the advantages of favorable flame-retardant effect, environment friendliness and low toxicity.

Owner:SHANGHAI TOB INTELLIGENT DOORS & WINDOWS SCI&TECH INC

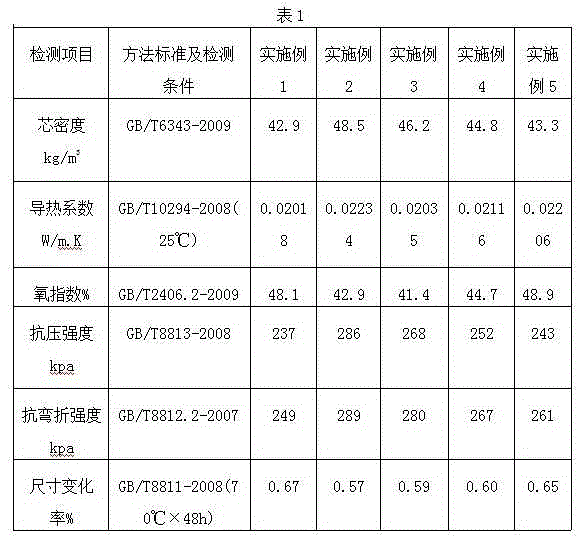

Flame-retardant rigid polyurethane foam heat insulation plate

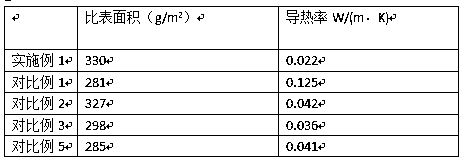

The invention relates to a flame-retardant rigid polyurethane foam heat insulation plate. The flame-retardant rigid polyurethane foam heat insulation plate comprises a component A and a component B, wherein the component A is formed by mixing flame-retardant polyether or flame-retardant polyether polyol, amidogen ether polyol, common polyether polyol, a foam stabilizer, a catalyst, a reactive flame retardant, modified expandable graphite and a foaming agent according to a certain proportion. The component B is isocyanate. The component A and the component B are mixed, and then are subjected to compression molding to obtain the flame-retardant heat insulation plate. According to the prepared flame-retardant rapid polyurethane foam heat insulation plate, flame-retardant testing data exceed a GB8624-2012B1-grade flame-retardant standard, the oxygen index is up to 48.9, and the heat conduction coefficient is about 0.02W / m.k. The flame-retardant rigid polyurethane foam heat insulation plate has excellent compressive strength and bending resistance strength. The flame-retardant rigid polyurethane foam heat insulation plate is suitable for being applied to the fields of flame retardance and heat insulation of building walls, refrigeration houses, refrigerators, solar water heaters and the like.

Owner:WEIHAI YUNSHAN TECH +1

Halogen-free expanded flame-retardant polypropylene film

InactiveCN101831109AImprove flame retardant effectImprove mechanical propertiesMaleic anhydrideAmmonium polyphosphate

The invention discloses a halogen-free expanded flame-retardant polypropylene film, relates to an expanded flame-retardant polypropylene film, and solves the problem that the conventional expanded flame-retardant polypropylene film is not environment-friendly and has low flame-retardant efficiency. The polypropylene film is prepared from the following components in part by weight: 68 to 77 parts of polypropylene, 20 to 32 parts of halogen-free expanded flame retardant, 1 part of processing aid and 0 to 0.08 part of anti-dripping agent, wherein the halogen-free expanded flame retardant consists of a triazine charring foaming agent, ammonium polyphosphate and ethylene-acrylate-maleic anhydride terpolymer intercalated organic montmorillonite master batch. The polypropylene film has the oxygen index between 21.7 and 30.6 percent, the combustion level of UL-94V-TM-0 level, the tensile strength between 13.12 and 18.43 MPa, the tearing strength between 25.67 and 32.98kN / m, and the elongation at break between 200 and 256.4 percent. The halogen-free expanded flame-retardant polypropylene film has excellent flame retardance, maintains excellent mechanical property of the film, and has the advantages of low smoke, low toxin, and environmental protection during combustion.

Owner:NORTHEAST FORESTRY UNIVERSITY

Fire retardation nanometer composite material

The invention discloses a fire retardation nanometer composite material, which is prepared from the following raw materials, by weight: 40-50% of a resin, 15-20% of a fire retardation agent, 0.5-1% of an antioxidant, 2-5% of a toughening agent, 20-25% of nanometer oxide powder, and the balance of deionized water. The fire retardation nanometer composite material has the following advantages that: a fire retardation effects is effectively enhanced with the composition of various raw materials in the fire retardation nanometer composite material, polymer material brittleness can be reduced and impact resistance can be increased with the added toughening agent so as to substantially prolong a service life of the fire retardation nanometer composite material, occurrence of aging phenomenon of the fire retardation nanometer composite material can be effectively prevented with antioxidant addition, and requirements can be met.

Owner:李新琴

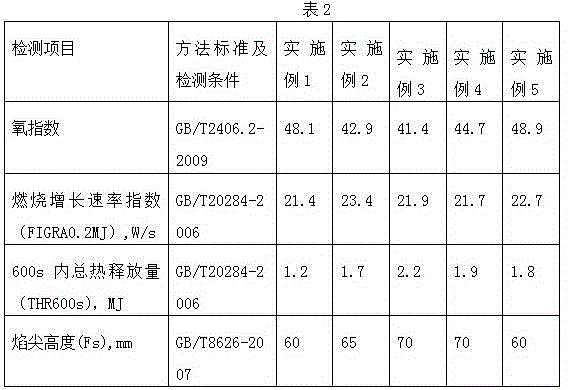

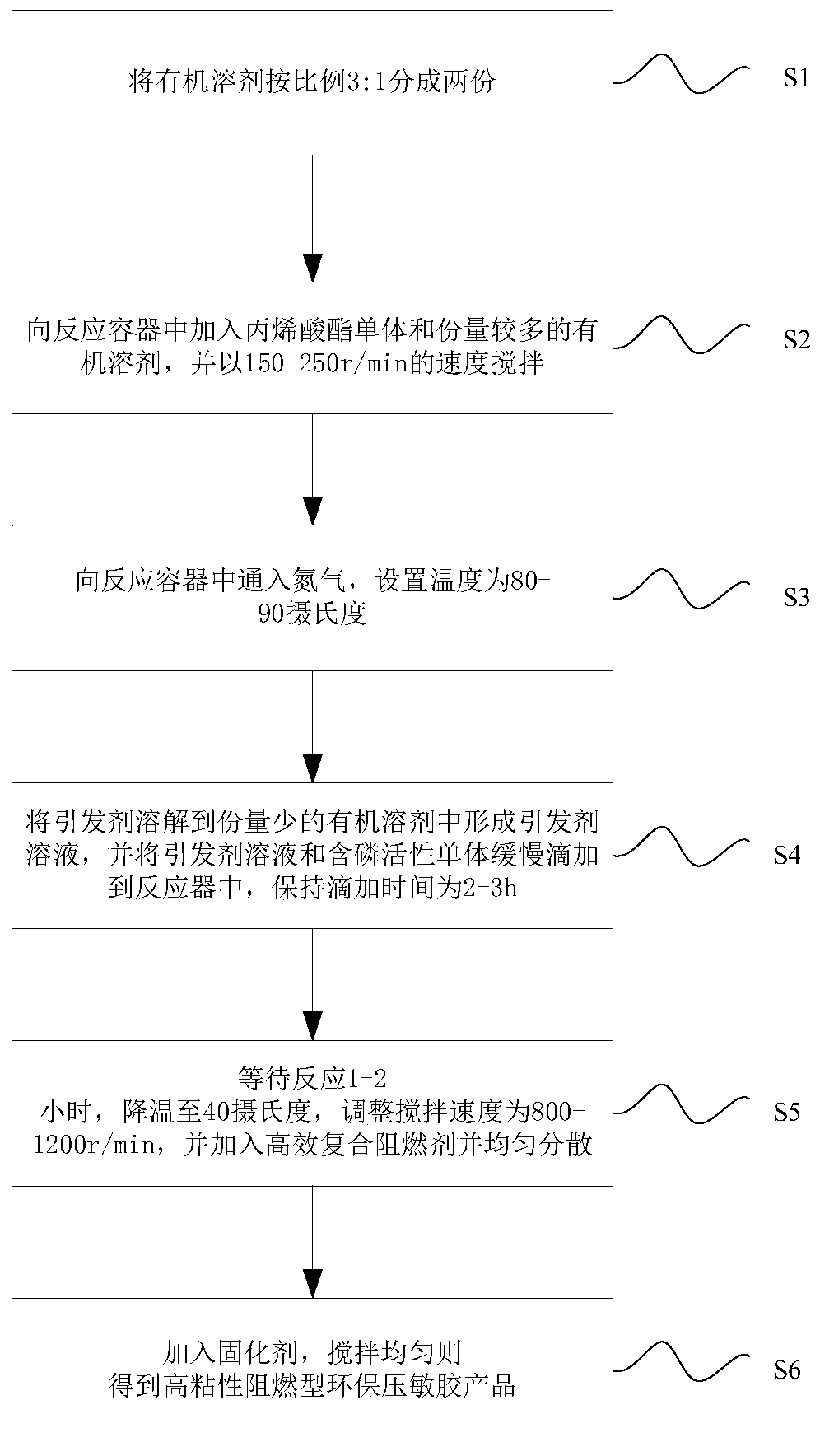

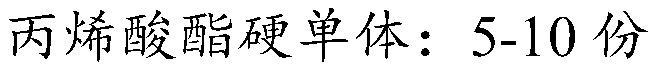

High-viscosity flame-retardant environmentally-friendly pressure-sensitive adhesive and preparation method thereof, and pressure-sensitive adhesive film preparation method

InactiveCN110684491AImprove flame retardant effectExcellent adhesionNon-macromolecular adhesive additivesEster polymer adhesivesFunctional monomerChemical synthesis

The invention discloses a high-viscosity flame-retardant environmentally-friendly pressure-sensitive adhesive and a preparation method thereof, and a pressure-sensitive adhesive film preparation method, wherein the pressure-sensitive adhesive comprises: 5-10 parts of an acrylate hard monomer, 15-25 parts of an acrylate soft monomer, 2-5 parts of an acrylate functional monomer, 5-10 parts of a phosphorus-containing active monomer, 0.5-2 parts of an initiator, 30-40 parts of an organic solvent, 10-20 parts of an efficient composite flame retardant and 0.5-2 parts of a curing agent. According tothe invention, the pressure-sensitive adhesive is prepared by a chemical synthesis and physical compounding method; and the pressure-sensitive adhesive polymer with high adhesion and a certain flame-retardant effect is synthesized by selecting the quantitative acrylate monomers and the phosphorus-containing functional monomer with flame-retardant effect, and various environmentally-friendly efficient flame retardants are added in the later period of synthesis, so that the flame-retardant effect is improved through the synergistic interaction mechanism, the pressure-sensitive adhesive has characteristics of high adhesiveness, high-temperature persistent adhesivity and remarkable flame-retardant effect, the flame-retardant grade reaches the Vo grade, and the processing requirements of electronic industry for fixing, bonding and the like are met.

Owner:深圳市益达兴科技股份有限公司

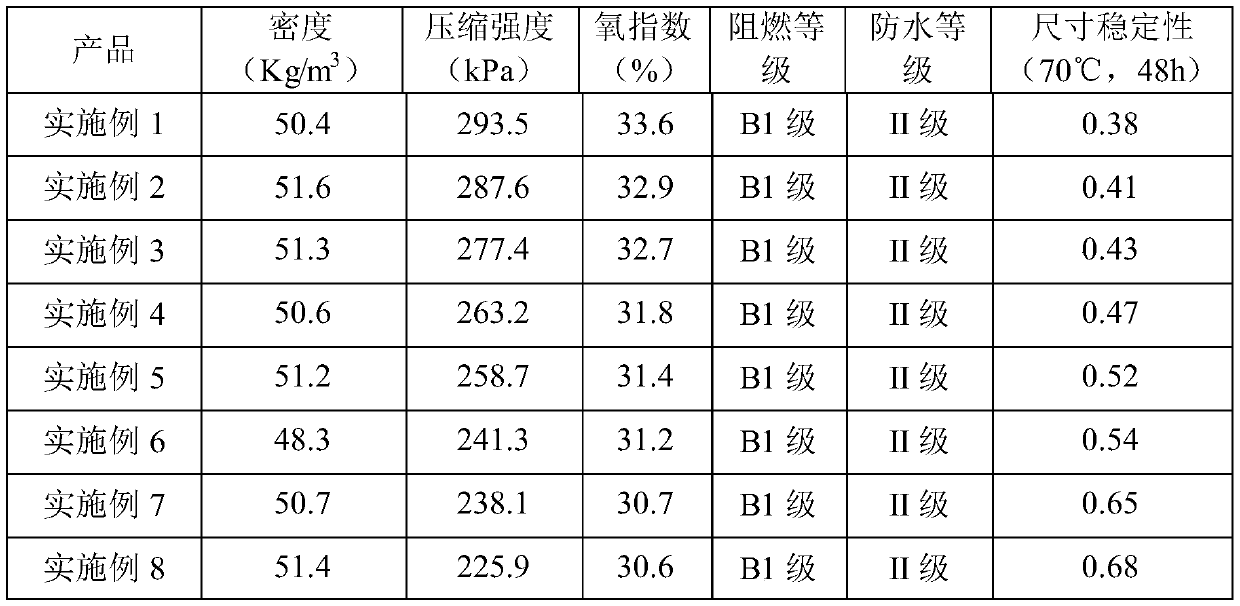

Rigid polyurethane foam with high flame retardance and preparation method of rigid polyurethane foam

ActiveCN109912764AImprove flame retardant effectExcellent compressive strength and dimensional stabilityFireproof paintsPolyurea/polyurethane coatingsIsocyanatePolyester

The invention discloses rigid polyurethane foam with high flame retardance and a preparation method of the rigid polyurethane foam. The rigid polyurethane foam with high flame retardance is prepared from a component A and a component B in a mass ratio being 1:1-1.5, wherein the component A is prepared from 30-60 parts by weight of flame-retardant polyether polyol A, 30-60 parts by weight of flame-retardant polyether polyol B, 20-40 parts by weight of flame-retardant polyester polyol C, 0-10 parts by weight of polyether polyol D, 0.5-5 parts by weight of an antioxidant, 0.5-5 parts by weight ofa hydrolysis stabilizer, 1-5 parts by weight of a foam stabilizer, 1-5 parts by weight of water, 1-5 parts by weight of a catalyst A, 1-5 parts by weight of a catalyst B, 1-5 parts by weight of a catalyst C, 20-60 parts by weight of a flame retardant, 20-60 parts by weight of a foaming agent and 0-7 parts by weight of an assistant; the component B is isocyanate. The rigid polyurethane foam with high flame retardance has the flame retardance level up to B1, the waterproof level up to II and the oxygen index higher than 30, and has excellent compressive strength and dimensional stability.

Owner:广州立泰新材料科技有限公司

Method for processing DE type flame-proof filtering cotton

ActiveCN101219309AImprove flame retardant effectGood thermal stabilityFiltration separationDomestic articlesChemistryPolyester

The invention relates to flame-retardant filtration asbestos of DE type, which employs polyester, durable flame retardant to process DE type filtering material with steps of immersing, drying, thermosetting and cooling setting. With high flame retardant effect, good thermal stability, maintenance performance and resistance to acid and alkali; the invention which can keep the excellent flame retardant performance even after being washed contains no harmful elements such as formaldehyde, etc. and causes no pollution to environment.

Owner:丹东天皓净化材料有限公司

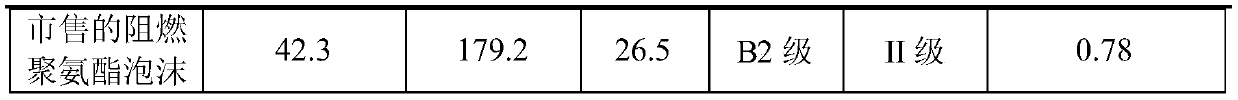

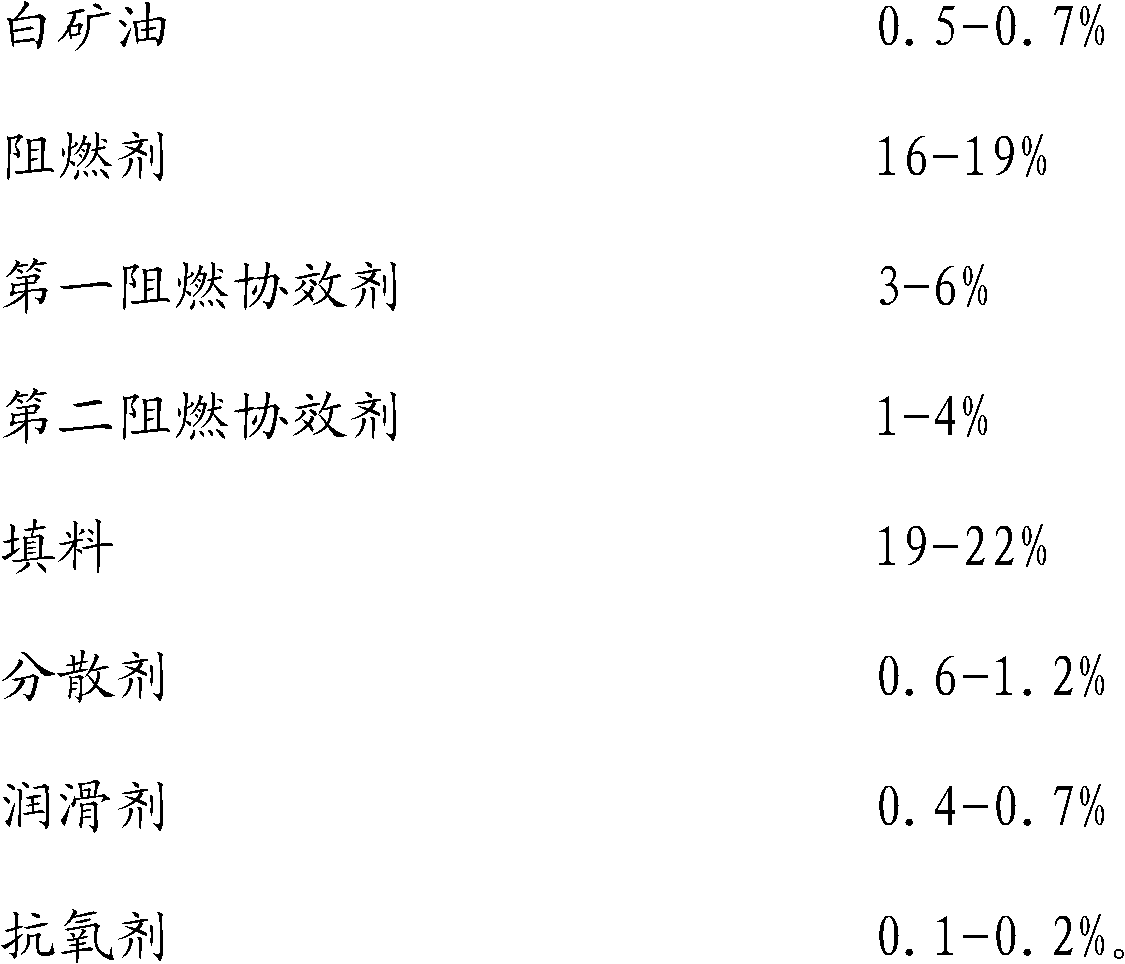

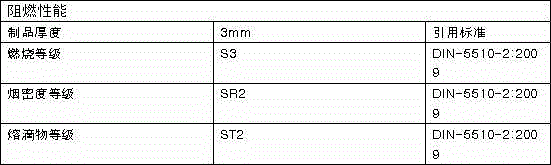

High-glow-wire flame-retardant polypropylene material for fan heater casing and preparation method for same

InactiveCN102604236AImprove flame retardant effectOvercoming low performancePolypropyleneEngineering

The invention discloses a high-glow-wire flame-retardant polypropylene material for a fan heater casing and a preparation method for the same. Components of the polypropylene material comprise, in weight percentage, 49.2-56.4% of polypropylene, 0.5-0.7% of white mineral oil, 16-19% of flame retardant, 3-6% of first flame-retardant synergist, 1-4% of second flame-retardant synergist, 19-22% of filler, 0.6-1.2% of dispersing agent, 0.4-0.7% of lubricant and 0.1-0.2% of antioxidant. The high-glow-wire flame-retardant polypropylene material for the fan heater casing prepared by the method is modified based on a traditional class-V0 flame-retardant formula, so that flame-retardant effects are greatly enhanced, the shortcoming of low-glow-wire performance of the traditional formula is overcome, and the high-glow-wire flame-retardant polypropylene material can pass 850 DEG C GWIT (glow wire ignition temperature) and 960 DEG C GWFI (glow wire flammability index) glow-wire tests.

Owner:SHENZHEN KEJU NEW MATERIAL

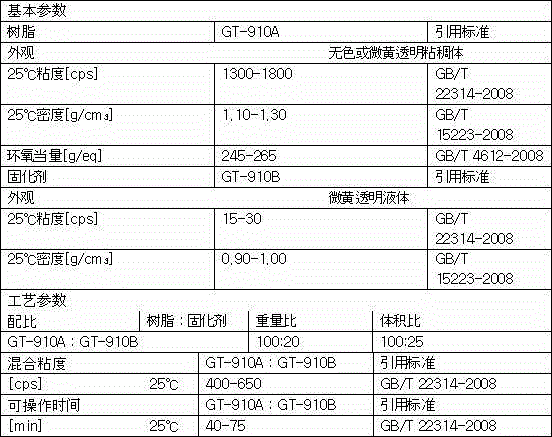

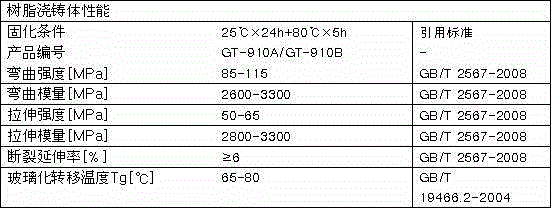

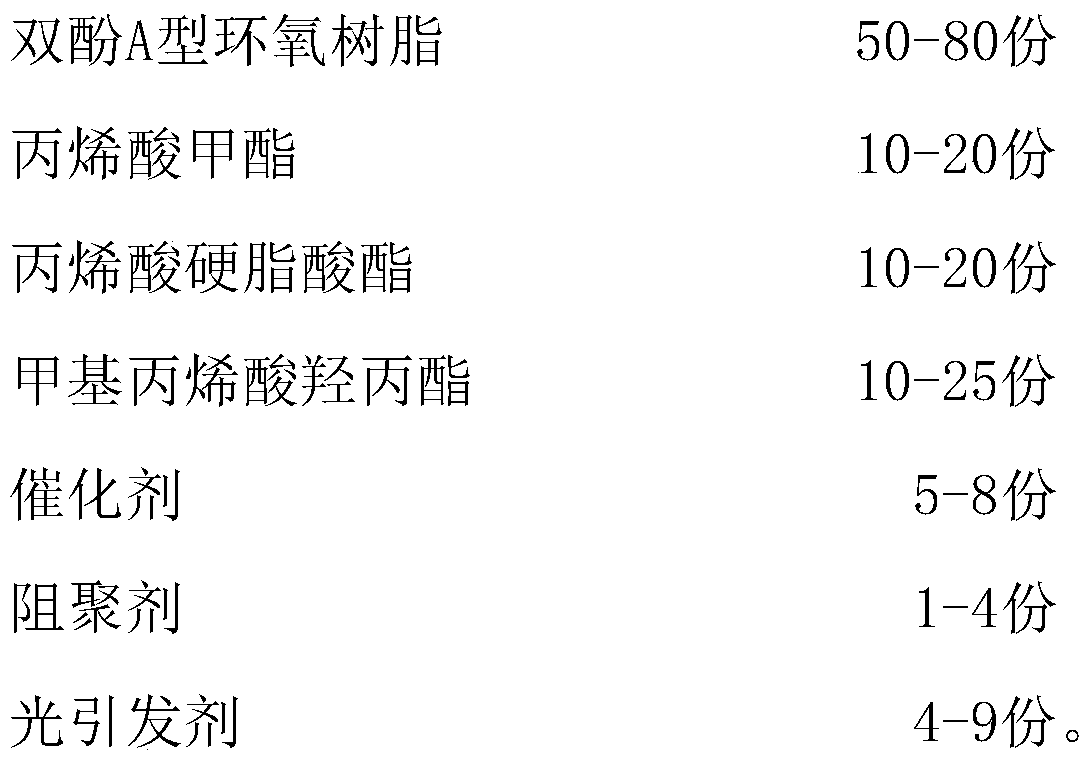

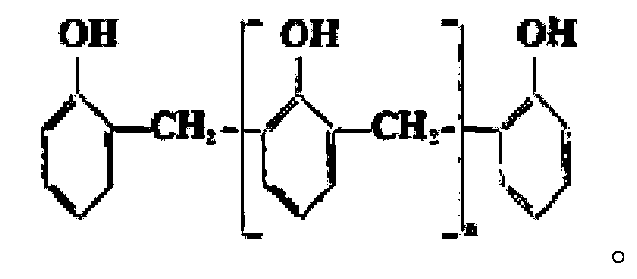

Filler-free halogen-free flame-retardant epoxy resin composition

The invention relates to a flame-retardant composite material formed by multiple techniques, particularly a filler-free halogen-free flame-retardant epoxy resin composition. The filler-free halogen-free flame-retardant epoxy resin composition comprises a component A and a component B. The component A comprises the following components in percentage by weight: 55-75% of low-halogen bisphenol A epoxy resin 128, 5-15% of bisphenol F epoxy resin 170, 10-30% of phosphorus-nitrogen flame retardant and 10-20% of phosphate flame retardant. The component B comprises the following components in percentage by weight: 10-20% of polyetheramine curing agent D230, 50-70% of isophorone diamine (IPDA) and 20-30% of N-aminoethyl piperazidine. The component A and component B are mixed according to the weight ratio of 100:(19-21) to obtain the composition. On the premise of ensuring various physiochemical properties of the cured resin and especially the mechanical properties and halogen-free flame retardancy, the composition does not use any filler-type flame retardant, and satisfies the operating requirements for multiple techniques.

Owner:WELLS ADVANCED MATERIALS SHANGHAI

Inorganic flame retardant surface modification method

InactiveCN103265826AReasonable useImprove flame retardant effectPigment treatment with non-polymer organic compoundsSurface modificationFire retardant

The invention discloses an inorganic flame retardant surface modification method which comprises the following steps: filling an inorganic flame retardant in a surface pretreatment device for heating and preheating, adding a coupling agent into an organic solvent, dissolving the coupling agent in a container, spraying the dissolved coupling agent into a reaction container in the respective container in a high-pressure spraying mode, mounting a stirring rod for fully stirring in the reaction container, and fusing to obtain the surface modified inorganic flame retardant. According to the mode, the aluminum hydroxide and other inorganic flame retardants can be modified through surface treatment and are used for enhancing the adhesion force to polymers and improving the affinity to an interface, so that the dehydration reaction is finished in a certain temperature range.

Owner:SUZHOU NEW DISTRICT HUASHIDA ENG PLASTICS

Preparation method of organic silicon-phosphorus synergistic flame retardant

The invention relates to the field of flame retardants, in particular to a preparation method of an organic silicon-phosphorus synergistic flame retardant. The preparation method comprises the following steps: (1) preparing polyhydroxy silsesquioxane: performing hydrolytic reaction on trichlorosilane in an aqueous solution in the presence of a catalyst to obtain the polyhydroxy silsesquioxane; (2)performing phosphate esterification: enabling the polyhydroxy silsesquioxane and phosphate to have condensation reaction under the catalysis of pentafluorophenyl borane to obtain phosphate esterifiedpolyhydroxy silsesquioxane; (3) performing grafting reaction: mixing the phosphate esterified polyhydroxy silsesquioxane and a silane coupling agent, and performing hydrolysis to obtain the organic silicon-phosphorus synergistic flame retardant. The preparation method has the following advantages: (1) the silicon and phosphorus are synergistic to resist the flame, so that the flame-retardant effect of the flame retardant can be effectively improved; (2) the flame retardant contains no halogen element, so that no harm is caused to the environment; and (3) while the high flame-retardant efficiency is ensured, the synthetic cost of the flame retardant can be effectively reduced.

Owner:德清顾舒家华高分子材料有限公司

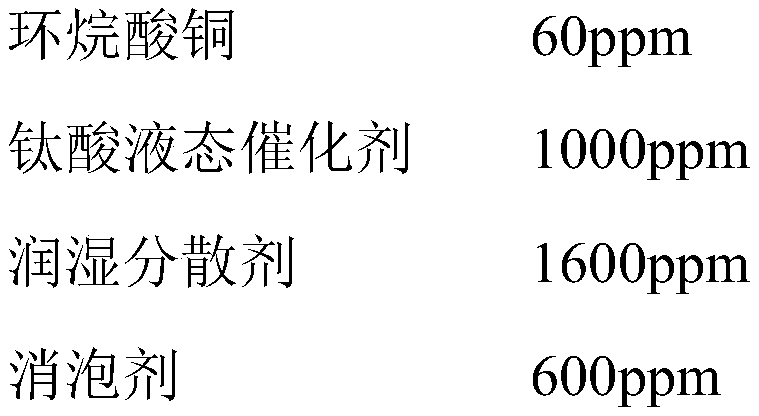

Water-based acrylic amino baking varnish as well as preparation method and application process thereof

ActiveCN109096916AImprove flame retardant effectReduce surface resistanceFireproof paintsAntifouling/underwater paintsAntistatic agentFire retardant

The invention discloses water-based acrylic amino baking varnish in the field of coatings as well as a preparation method and an application process of the water-based acrylic amino baking varnish. The water-based acrylic amino baking varnish is prepared from the following components in parts by weight: 30-40 parts of epoxy modified acrylic resin, 5-10 parts of amino resin, 2-6 parts of flame retardant microcapsules, 2-3 parts of an antistatic agent, 2-5 parts of a nano silver antibacterial agent, 3-5 parts of diethylene glycol monobutyl ether, 3-6 parts of propylene glycol monoethyl ether, 1.2-1.5 parts of a dispersant, 2-3 parts of an adhesion promoter, 0.2 part of a leveling agent, 20-40 parts of titanium dioxide, 0.4 part of a defoaming agent, 2-3 parts of a neutralizing agent and 15-25 parts of distilled water; a core material of the flame retardant microcapsules is prepared from the following components in parts by weight: 2-6 parts of an organic phosphorus-nitrogen coordinated flame retardant, 0.2-0.5 parts of expanded graphite and 0.1-0.5 parts of a light stabilizer. Long-term flame retardance is realized through slow release performance of the flame retardant microcapsules, and flame retardant effect is improved by the synergistic effect of the organic phosphorus-nitrogen coordinated flame retardant and expanded graphite.

Owner:扬州郎康汽车水性涂料有限公司

Anti-static flame retarding fabric

InactiveCN103264539AImprove flame retardant effectImprove flame retardant performanceMetal layered productsPolyesterFiber

The invention discloses an anti-static flame retarding fabric which is formed by weaving wraps and wefts, wherein the wefts are formed by blending conductive fibers and gold and silver wires of which the diameters are 3-8 mu m; the distances among the gold and silver wires are 0.8-1.2cm; the wraps are formed by blending flame retarding polyester fibers and carbon fibers; the carbon fibers are long-wire fibers; and the weight of the flame retarding polyester fibers in the wraps is greater than 80%. In such a mode, the anti-static flame retarding fabric can enhance the flame retarding effect on the basis of static resistance.

Owner:张容宣

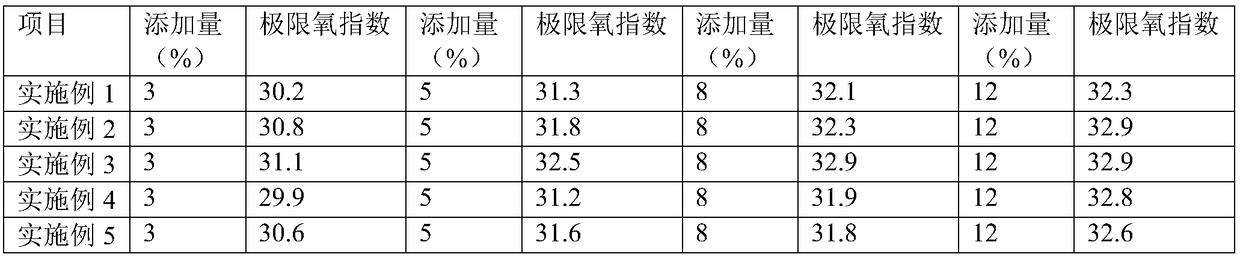

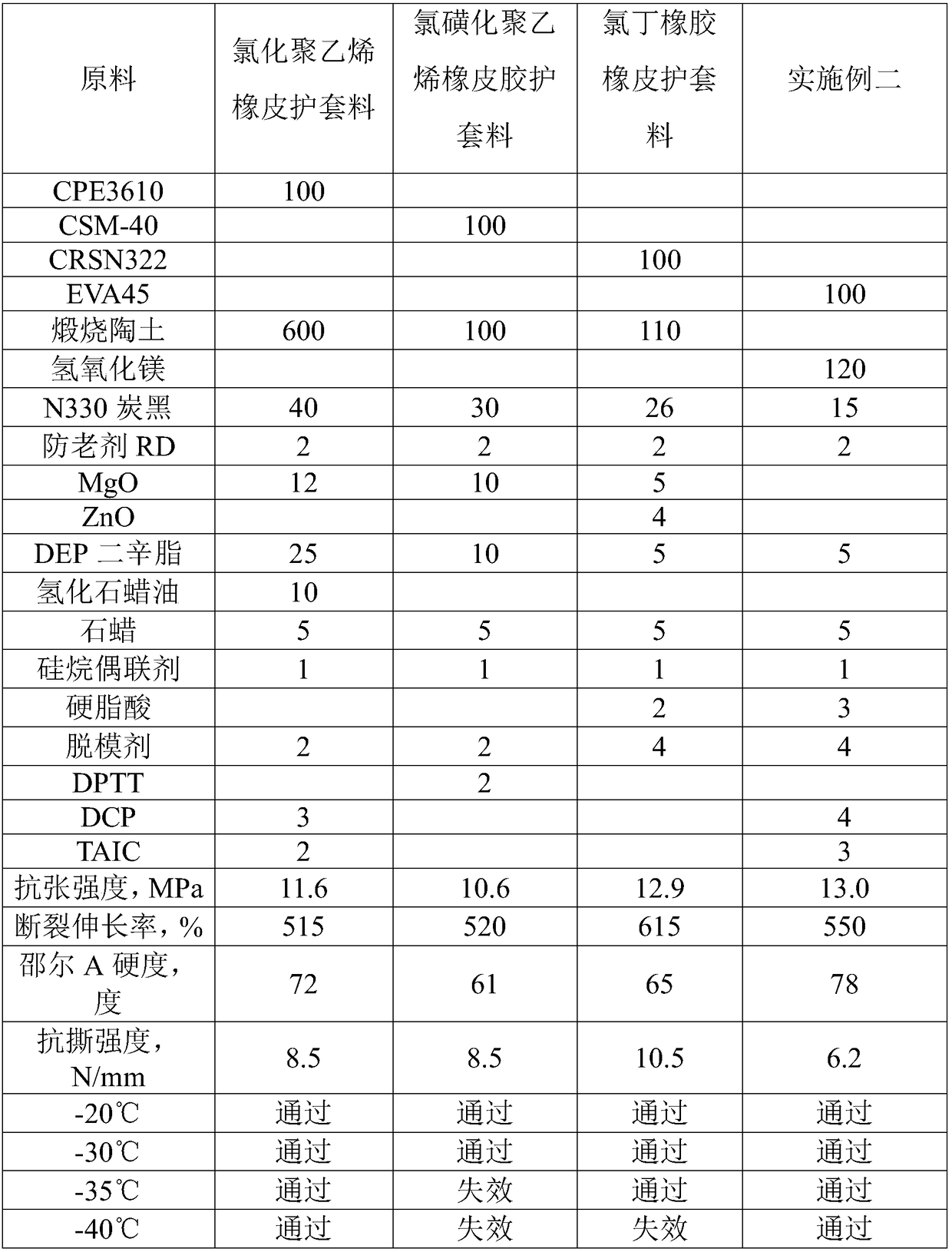

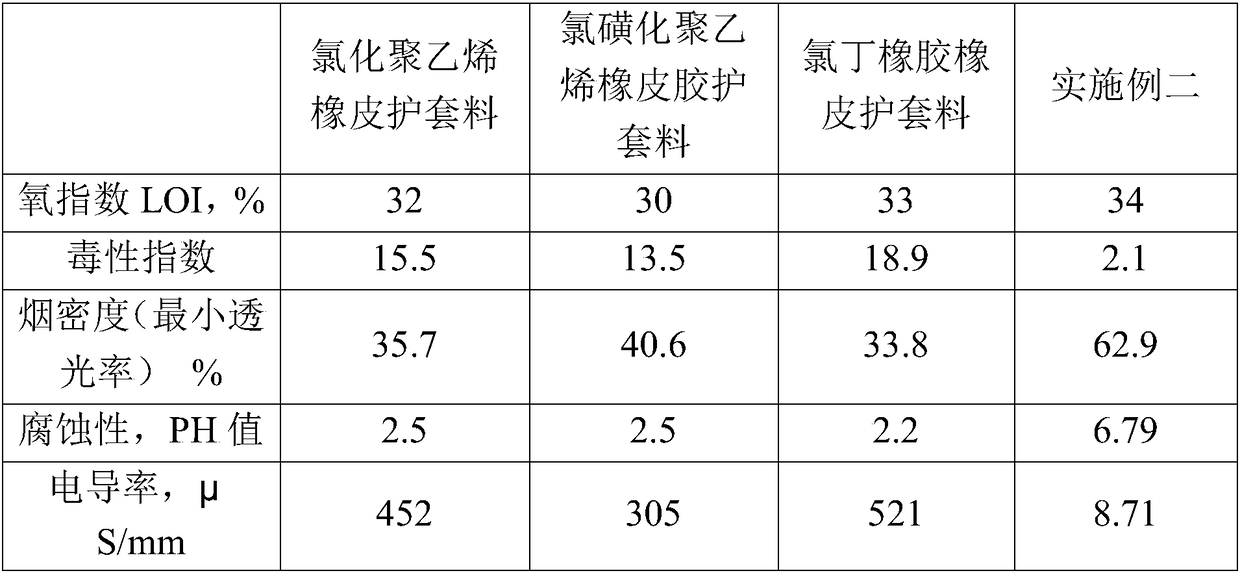

Low-smoke zero-halogen flame retardant EVA rubber sheath material for mine cable and preparation method of low-smoke zero-halogen flame retardant EVA rubber sheath material

InactiveCN108102206AImprove flame retardant effectImprove cross-linkingPlastic/resin/waxes insulatorsTransmittanceCarbon black

The invention relates to a low-smoke zero-halogen flame retardant EVA rubber sheath material for a mine cable. The low-smoke zero-halogen flame retardant EVA rubber sheath material comprises the following components by weight: 100 parts of EVA resin, 110-130 parts of magnesium hydrate, 10-18 parts of carbon black, 1-5 parts of an antiager RD, 2-8 parts of DEP dioctyl ester, 2-8 parts of paraffin,0.5-2 parts of a silane coupling agent, 1-5 parts of stearic acid, 1-5 parts of a release agent, 1-5 parts of a vulcanizing agent DCP and 1-5 parts of a crosslinking agent TAIC, the preparation sequentially comprises the steps of preparing the materials, mixing, sulphurating, discharging a sheet, extruding and forming. A preparation method is simple, the steps are easy to operate, the EVA resin istaken as a main body and the magnesium hydrate is taken as a flame retardant to prepare and obtain the rubber sleeve material, the tensile strength of the rubber sleeve material is large, the rubbersleeve material is better in light transmittance in the combustion, the toxicity index is low, the corrosive PH value is higher than the national standard requirement, and the low-smoke zero-halogen flame retardant EVA rubber sheath material meets the requirements of low smoke, zero halogen, flame retarding and low toxicity of the mine cable.

Owner:JIANGSU ZHONGMEI CABLE

Modified polycaprolactam and preparation method thereof

The invention relates to modified polycaprolactam and a preparation method thereof. The modified polycaprolactam is composed of the components of, by weight: 68-77% of polycaprolactam, 4-6% of red phosphorus, 13-15% of decabromodiphenylethane, 3-5% of melamine phosphate, 1-2% of an enhancer, 1-2% of a flow modifier, 0.5-1% of an antioxidant, and 0.5-1% of a lubricant. According to the invention, a phosphorus-series flame-retardant, a nitrogen-series flame retardant and a halogen-series flame-retardant are composed, such that a maximal synergetic effect of the flame-retardants is developed. A flame-retarding effect of nylon products is greatly improved, and dose of flame-retardant can be reduced, such that cost is reduced. Also, compatibility between the flame-retardant and resin is improved, such that a synergetic effect of flame-retardant is optimized.

Owner:SUZHOU NAITESU ENG PLASTICS TECH

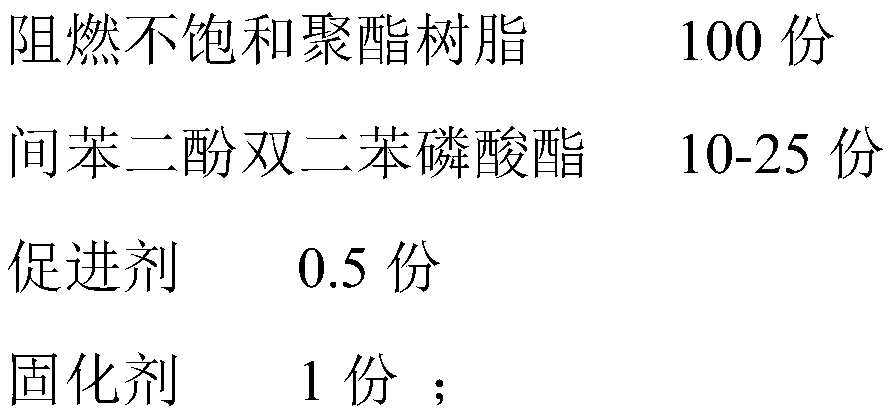

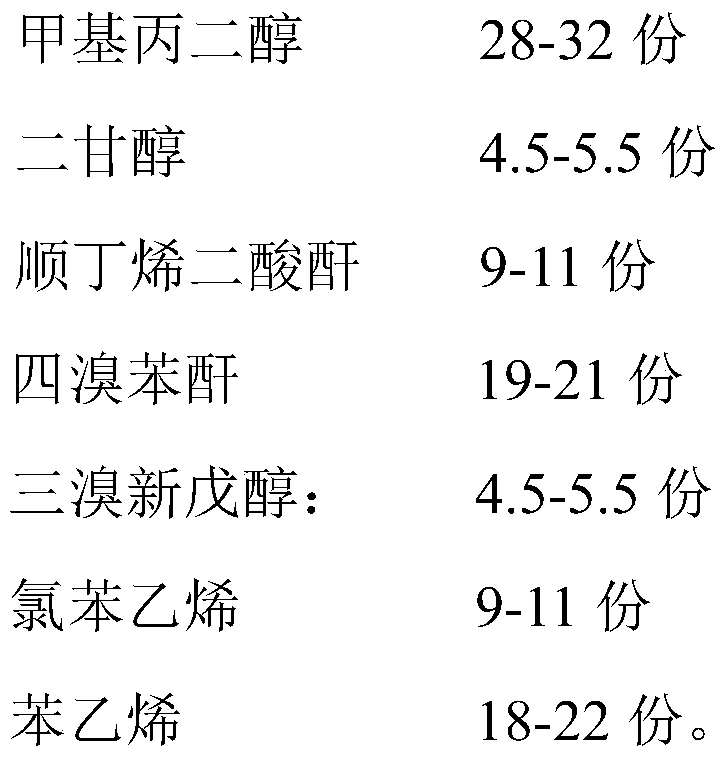

Novel environment-friendly flame-retardant modified unsaturated polyester resin and preparation method thereof

The invention discloses novel environment-friendly flame-retardant modified unsaturated polyester resin and a preparation method thereof. By synthesizing flame-retardant unsaturated polyester matrix resin and adopting a high-temperature pressurized catalysis and vacuumizing double-process control optimization production process, and a novel environment-friendly flame retardant resorcinol bis-diphenyl phosphate is added based on the flame-retardant matrix resin with certain flame-retardant efficiency, so that the flame-retardant effect is improved by more than 15%.

Owner:惠州市固德尔合成材料有限公司

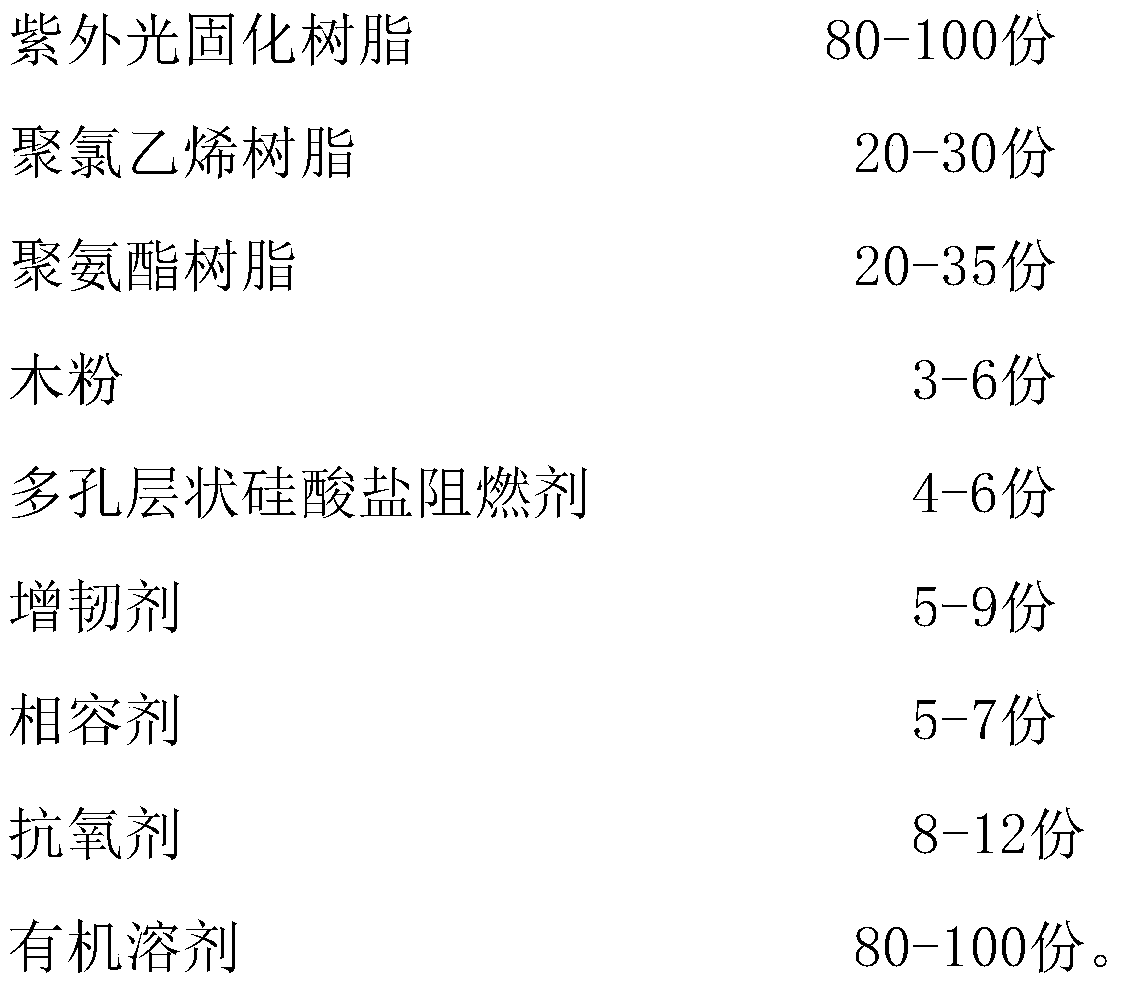

PET flame-retarding monofilament

ActiveCN109797541AIncrease the interlayer spacing and specific surface areaImprove flame retardant effectFibre typesChemistryFlame resistance

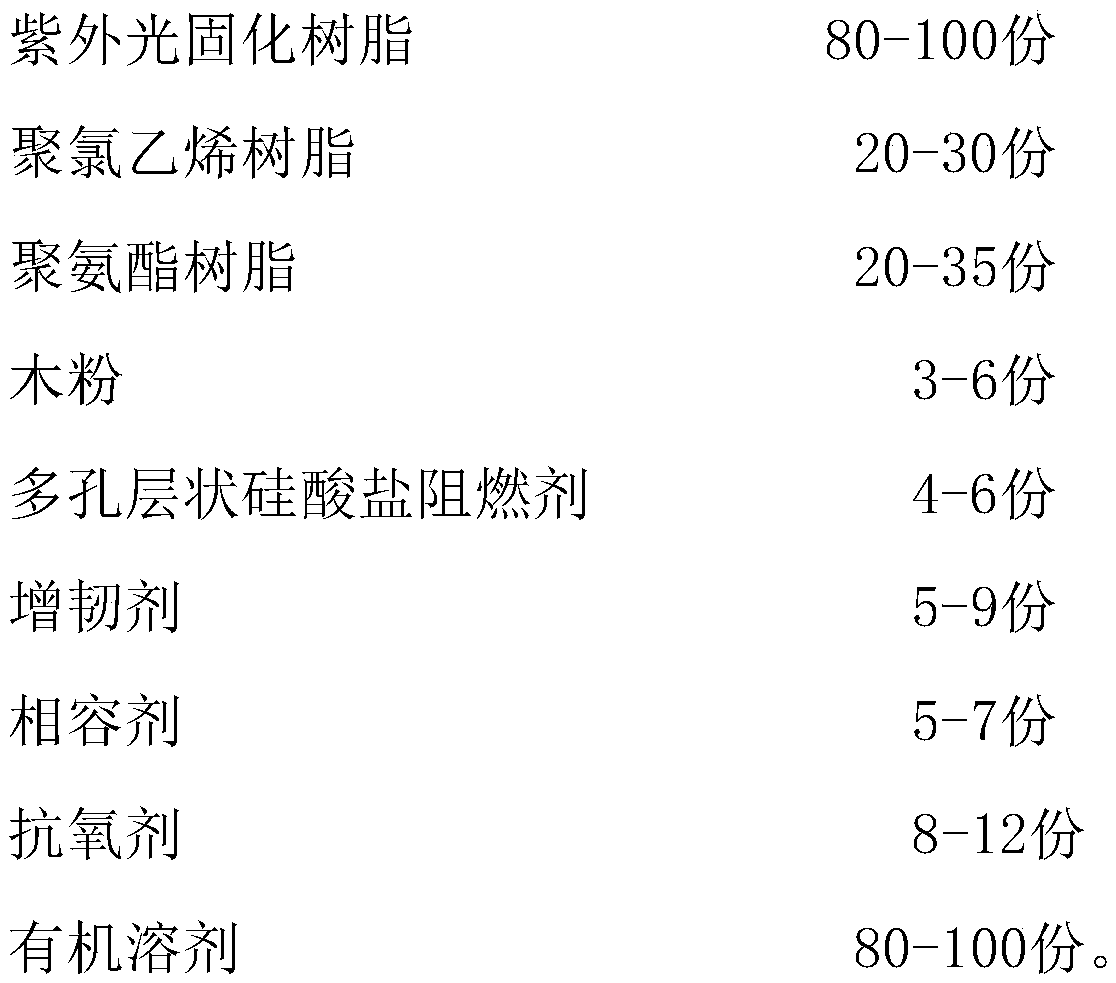

The invention relates to the technical field of PET monofilaments and in particular to a PET flame-retarding monofilament. The PET flame-retarding monofilament comprises a PET core beam and a flame-retarding layer covering the outside of the PET core beam. The flame-retarding layer comprises the following raw materials in parts by weight: 80-100 parts of ultraviolet curable resin, 20-30 parts of polyvinyl chloride resin, 20-35 parts of polyurethane resin, 3-6 parts of wood meal, 4-6 parts of a porous phyllosilicate flame retardant, 5-9 parts of a flexibilizer, 5-7 parts of a compatilizer, 8-12parts of an antioxidant, and 80-100 parts of an organic solvent. The PET flame-retarding monofilament has excellent flame resistance and drop resistance, and is good in smoke suppression effect.

Owner:DONGGUAN YICHANG PLASTICS TEXTILE CO LTD

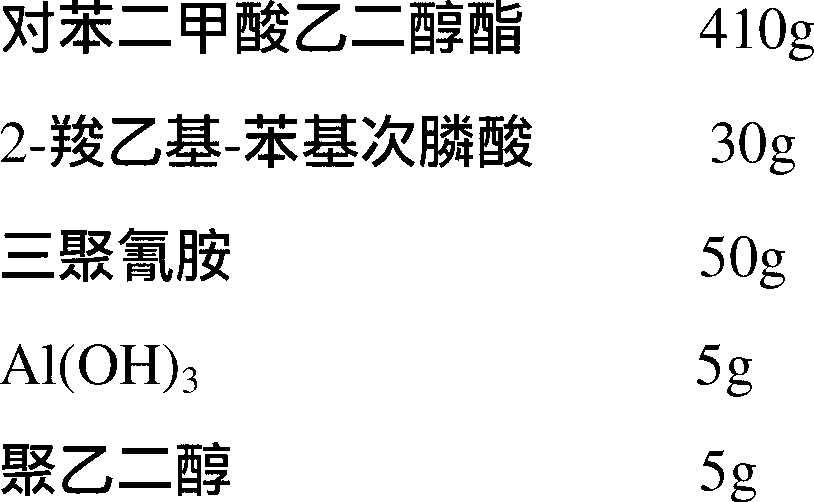

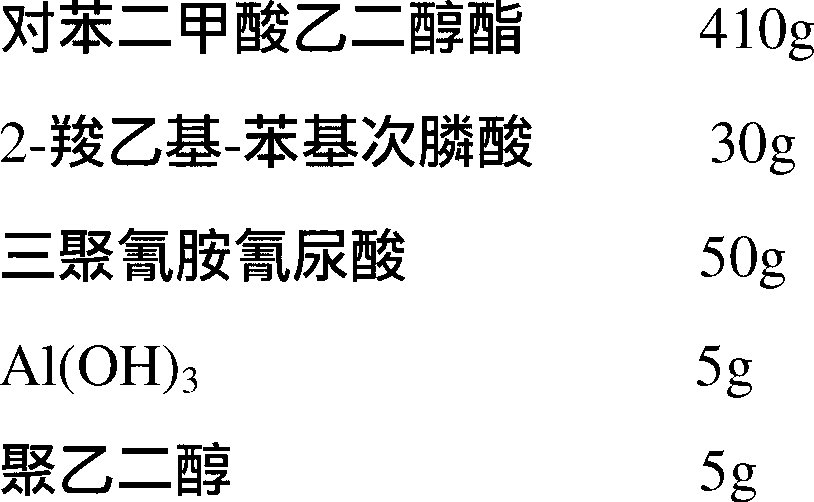

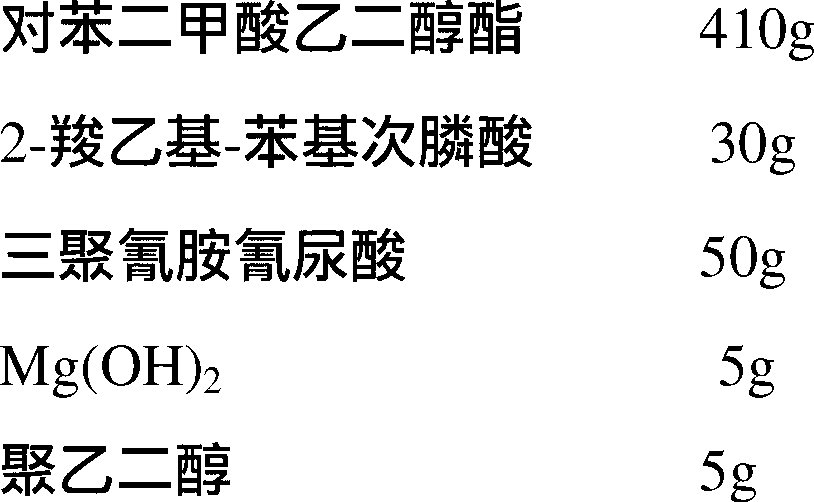

Flame-retardant polyester and preparation method thereof

The invention relates to flame-retardant polyester and a preparation method thereof. The flame-retardant polyester is characterized by comprising the following components in percentage by weight: 6-8% of phosphorus flame retardant, 5-15% of nitrogen flame retardant, 1-3% of metallic compound powder, 0-1% of antioxidant and the balance of polyester. The flame-retardant polyester is prepared from common polyester, phosphorus flame retardant and nitrogen flame retardant. The composite flame-retardant polyester is prepared by a process of in-situ copolymerization and melt blending; the flame retardant efficiency of the polyester can be improved; forming of polyester metal is retarded; meanwhile, no toxic product is generated, and the flame-retardant polyester is suitable for the fields such as textile articles, film products and auto parts.

Owner:IRICO

Processing method for flame retardant bamboo curtain plywood

ActiveCN107263629AImprove flame retardant effectStable structureWood treatment detailsReed/straw treatmentEngineeringBoard type

The invention belongs to the technical field of bamboo curtain plywood processing and particularly relates to a processing method for flame retardant bamboo curtain plywood. The method comprises the steps of sliced veneer bamboo treatment through treating liquid, smudging drying furnace treatment, composite bamboo curtain board preparation and finished product obtaining. Compared with the prior art, the processing method for the flame retardant bamboo curtain plywood has the following advantages that the prepared bamboo curtain plywood is stable in structure and not prone to being damaged, a board type with a corresponding area can be obtained through splicing according to actual requirements, the flame retardant effect is good, and the good insect prevention and mold prevention effects are achieved.

Owner:五河县鸿鑫木业有限公司

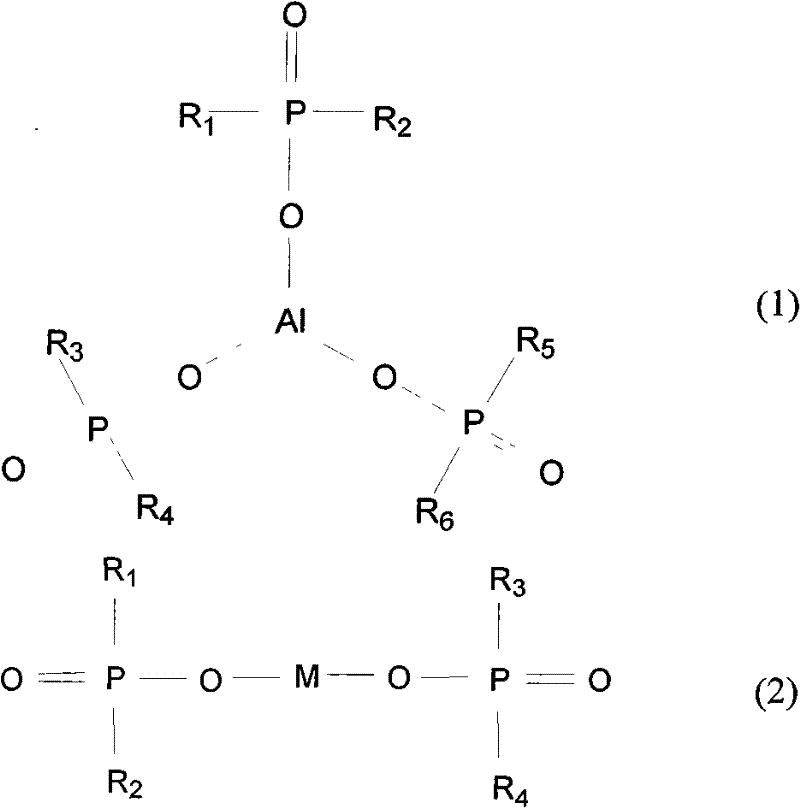

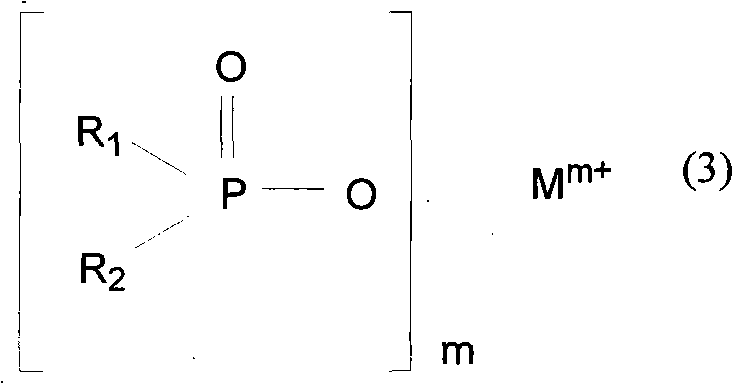

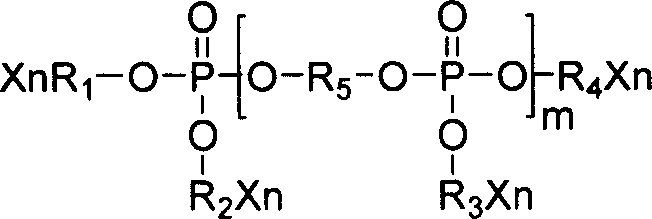

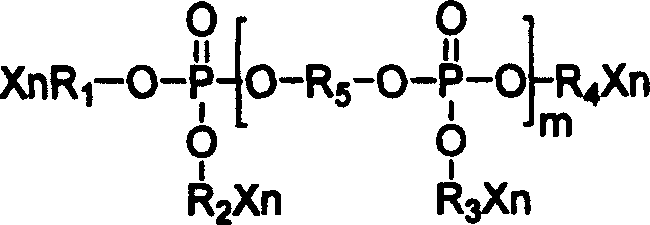

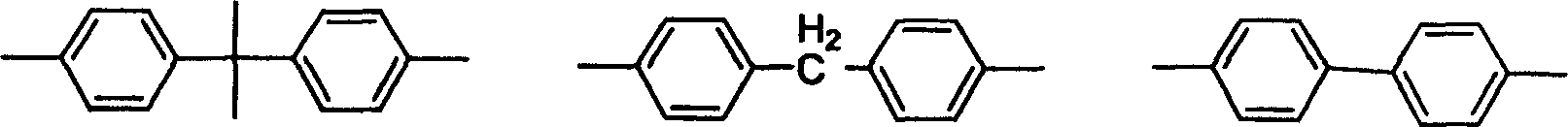

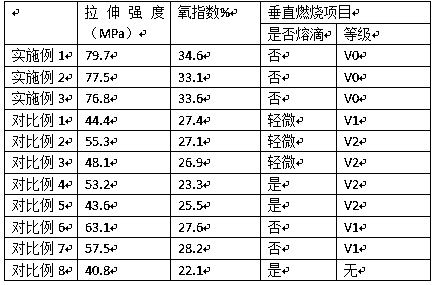

Polycondenseng phosphate and its preparation process and application thereof

InactiveCN100362001CImprove flame retardant effectLess flame retardantPhosphorus organic compoundsPhosphoric acidPhosphate

The invention relates to a polycondensation type phosphate ester. R1, R2, R3 and R4 each contains alkyl of 2-4 carbon atom, and R5 is bivalent aromatic radical. The invention supplies a stable method to make phosphate ester that could be used as fire retardant or used combining fire retardant.

Owner:HEBEI UNIV OF TECH

Modified PVC pellet and preparation method thereof

InactiveCN109096658AGood heat insulation effectImprove flame retardant effectBuilding insulationsTemperature resistanceChemistry

The invention relates to a modified PVC pellet and a preparation method of the modified PVC pellet. The modified PVC pellet is prepared from the following raw materials by weight: 50-60 parts of PVC resin, 3-5 parts of plasticizer, 0.8-1 part of antiager, and 12-15 parts of modified silicon dioxide aerogel. The plasticizer and the antiager are added in the preparation process of the PVC pellet inthe application so as to further improve the flame retardant efficiency and the high temperature resistance effect of the PVC; the modified silicon dioxide aerogel is added in the raw materials in theapplication, and the silicon dioxide aerogel is modified after being added, so that the compatibility of the silicon dioxide aerogel and the PVC resin material is obviously improved, and the flame retardance and the high temperature resistance property of the material are improved.

Owner:界首永恩机电科技有限公司

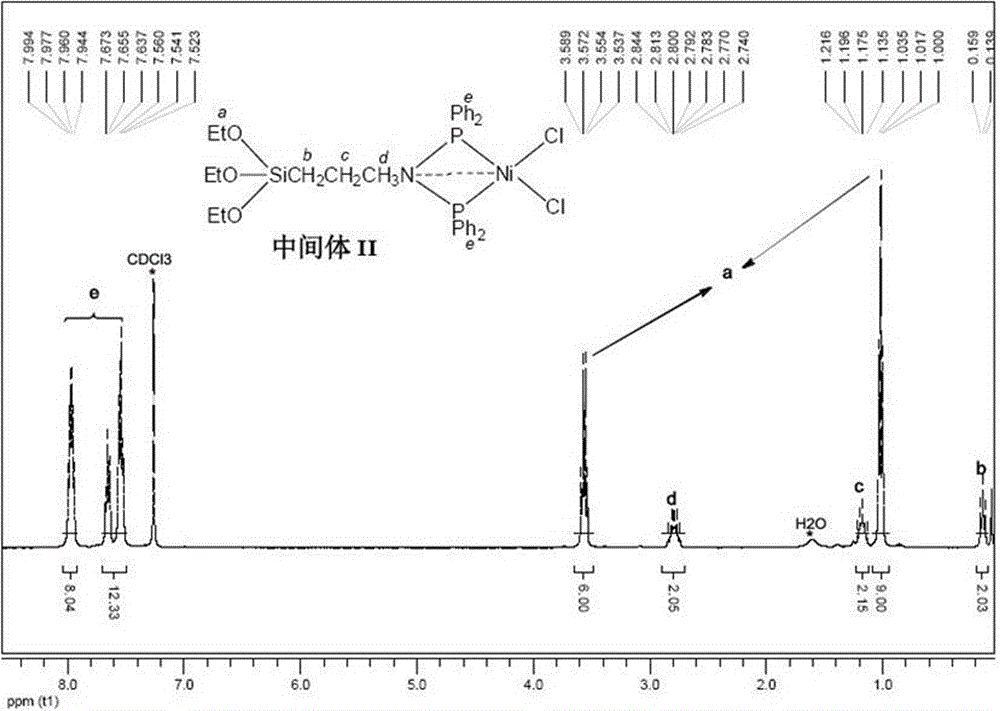

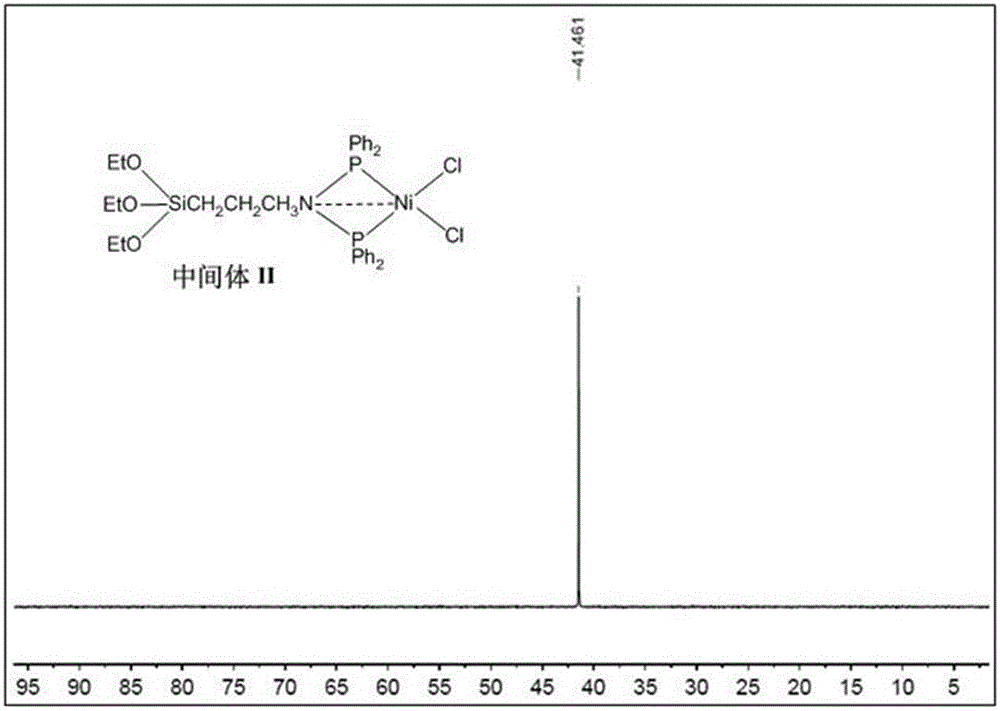

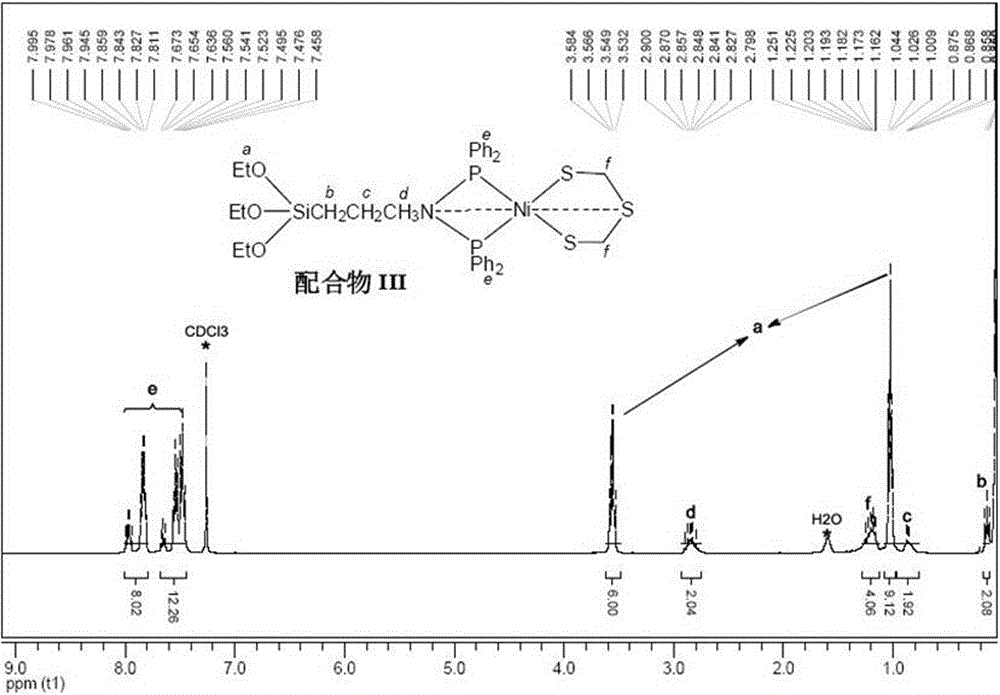

Concerted catalysis flame-retardant metal complex containing P/N/Si/S/Ni and preparation method of complex

ActiveCN106543235AImprove flame retardant effectThe synthesis process conditions are mild and stableNickel organic compoundsHeat resistant fibresHalogenFlame resistance

The invention relates to an intumescent metal flame-retardant agent, in particular to a concerted catalysis flame-retardant metal complex containing P / N / Si / S / Ni and a preparation method of the complex. An intermediate II can be used for preparing various concerted catalysis flame-retardant metal complexes containing P / N / Si / S / Ni. According to the metal complex, the four flame-retardant elements including P, N, Si and S are integrated into one molecule and coordinated on a metal atom, synergetic intumescent flame resistance of various flame-retardant elements and catalyzing carbonization flame resistance of metal elements are fully achieved, and the flame-retardant effect of the metal complex serving as a flame-retardant agent is greatly improved. Molecules of the flame-retardant agent do not contain halogen atoms and contain siloxane groups easy to react and decompose, so no harmless gas or formaldehyde is released in the combustion process, and the requirement for environmental friendliness in the flame-retardant combustion process of modern flame-retardant agents is met. Meanwhile, under the condition that consumption is small, the metal complex can be used for durability flame-retardant treatment of various cotton fabric substrates, and a good expected flame-retardant effect can be achieved.

Owner:ZHONGBEI UNIV

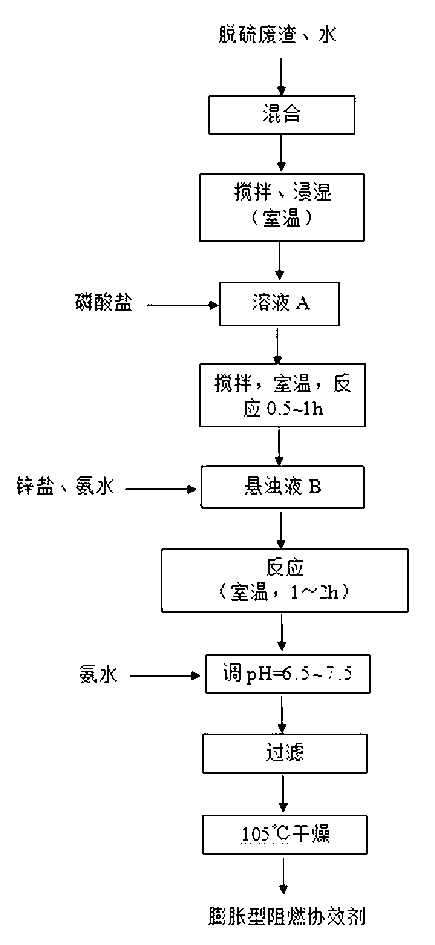

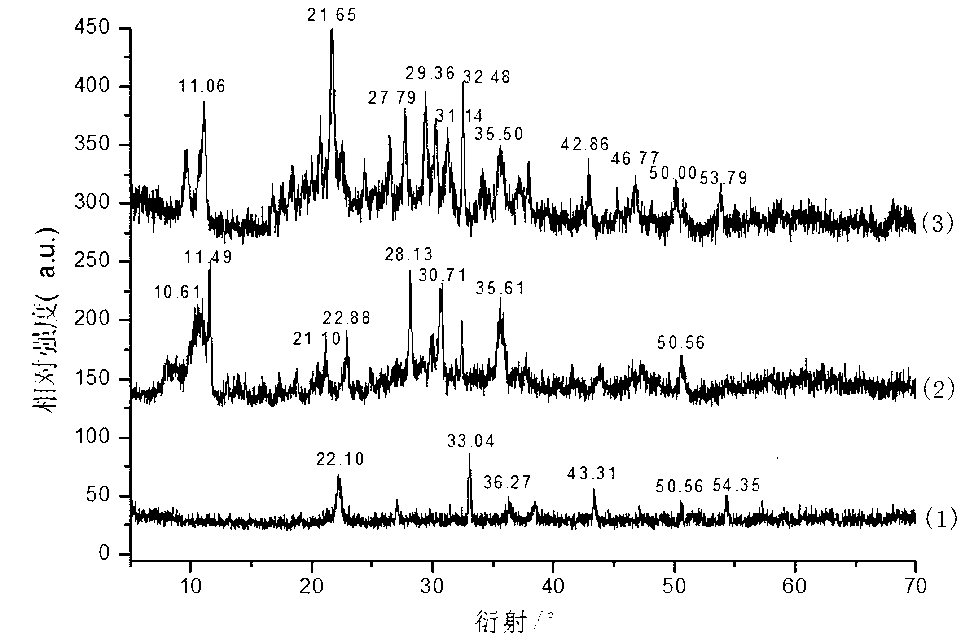

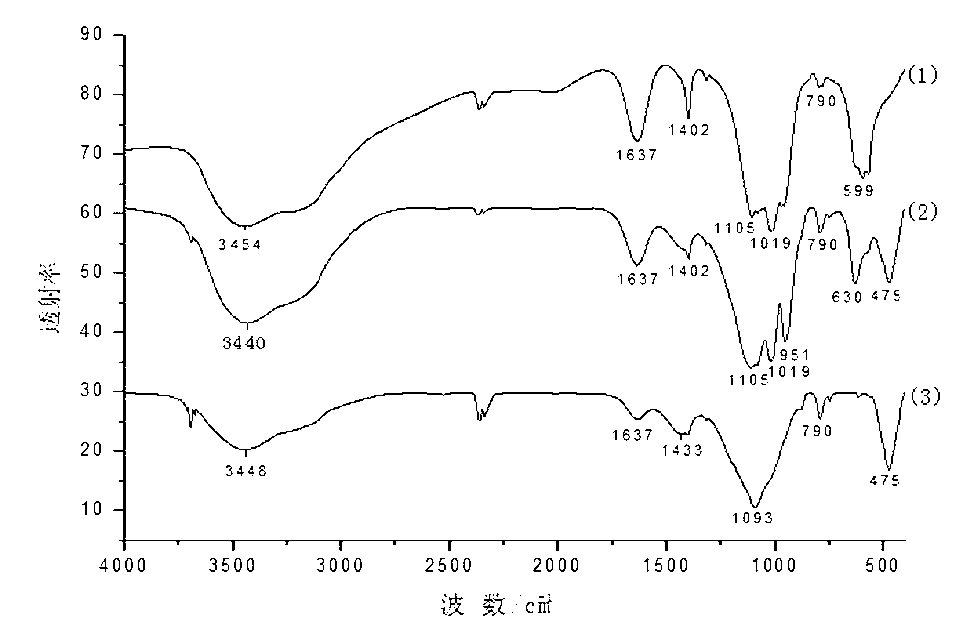

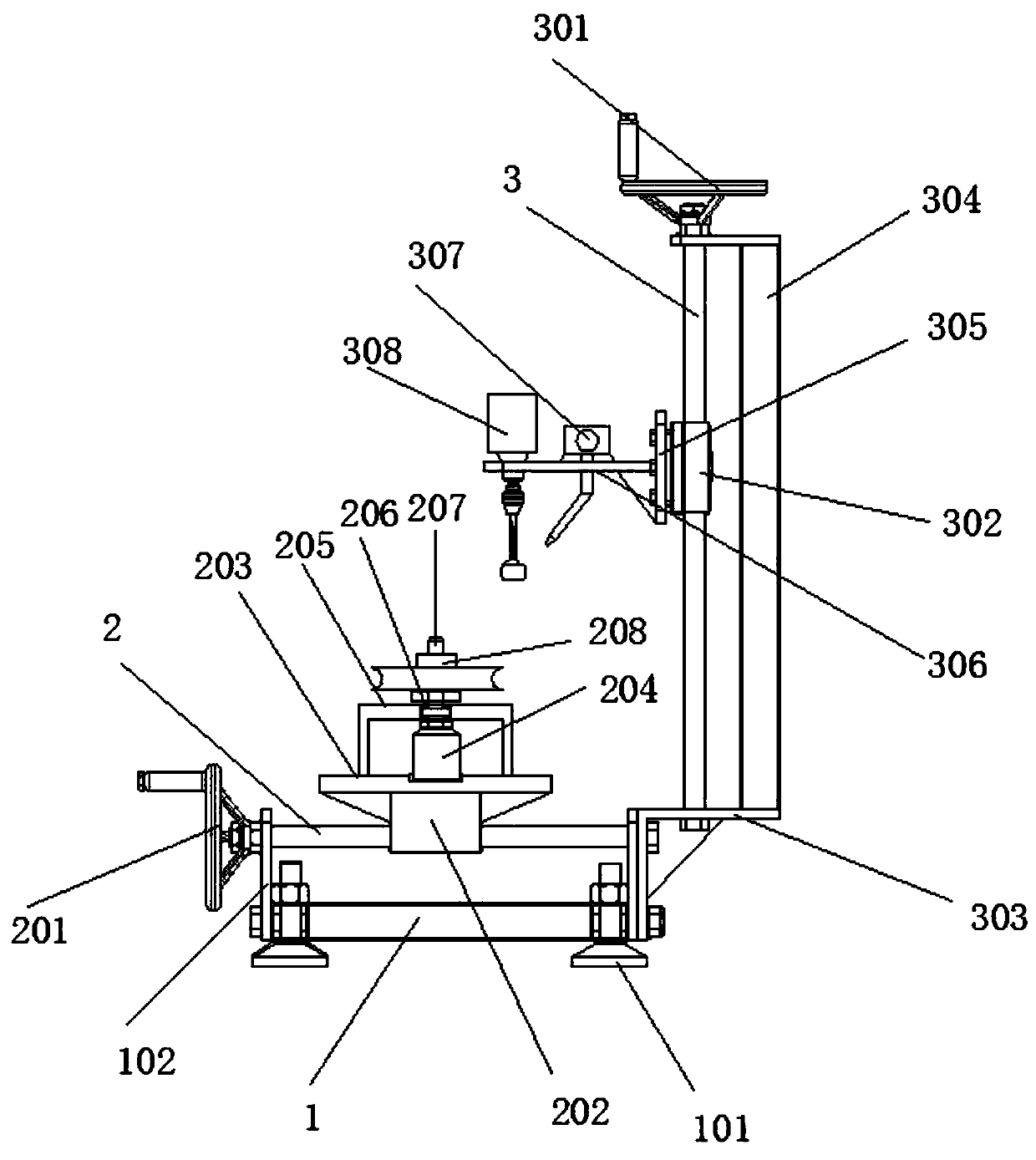

Preparation of intumescent type flame retardant synergist on basis of magnesium oxide flue gas desulfurization residue

ActiveCN103012849AImprove collaboration efficiencyImprove flame retardant effectFire retardantPhosphate

Owner:SUZHOU GUOYU CARBON FIBER TECH

Flame-retardant wear-resistant polyurethane wheel and preparation method thereof

InactiveCN111253550AImprove flame retardant effectImprove heat resistanceGrinding carriagesRevolution surface grinding machinesChemistryFire retardant

The invention discloses a flame-retardant wear-resistant polyurethane wheel and a preparation method thereof. The flame-retardant wear-resistant polyurethane wheel comprises the following raw materials in parts by weight: 50 to 70 parts of polyether polyol, 20 to 30 parts of diphenylmethane diisocyanate, 1 to 2 parts of a foam stabilizer, 1 to 2 parts of a chain extender, 1 to 1.5 parts of a defoaming agent, 1 to 3 parts of a flame retardant, 3 to 5 parts of glass fibers, 0.5 to 1 part of a cross-linking agent, 3 to 5 parts of polyaniline modified bentonite and 10 to 15 parts of expandable graphite. Polyether polyol and diphenylmethane diisocyanate are used as polyurethane tire base materials; the glass fibers and the flame retardant are added into a raw material reaction kettle; by addingthe flame-retardant material, the flame-retardant effect of a tire is greatly improved, so that the heat resistance of the tire during friction can be improved, and the flame-retardant wear-resistantpolyurethane tire has the tensile strength of more than or equal to 37 MPa, the elongation at break of more than or equal to 720%, the shore hardness of more than or equal to 1 A and the peel strength of more than or equal to 5 KN*m<-1>.

Owner:CHUZHOU YULIN POLYURETHANE

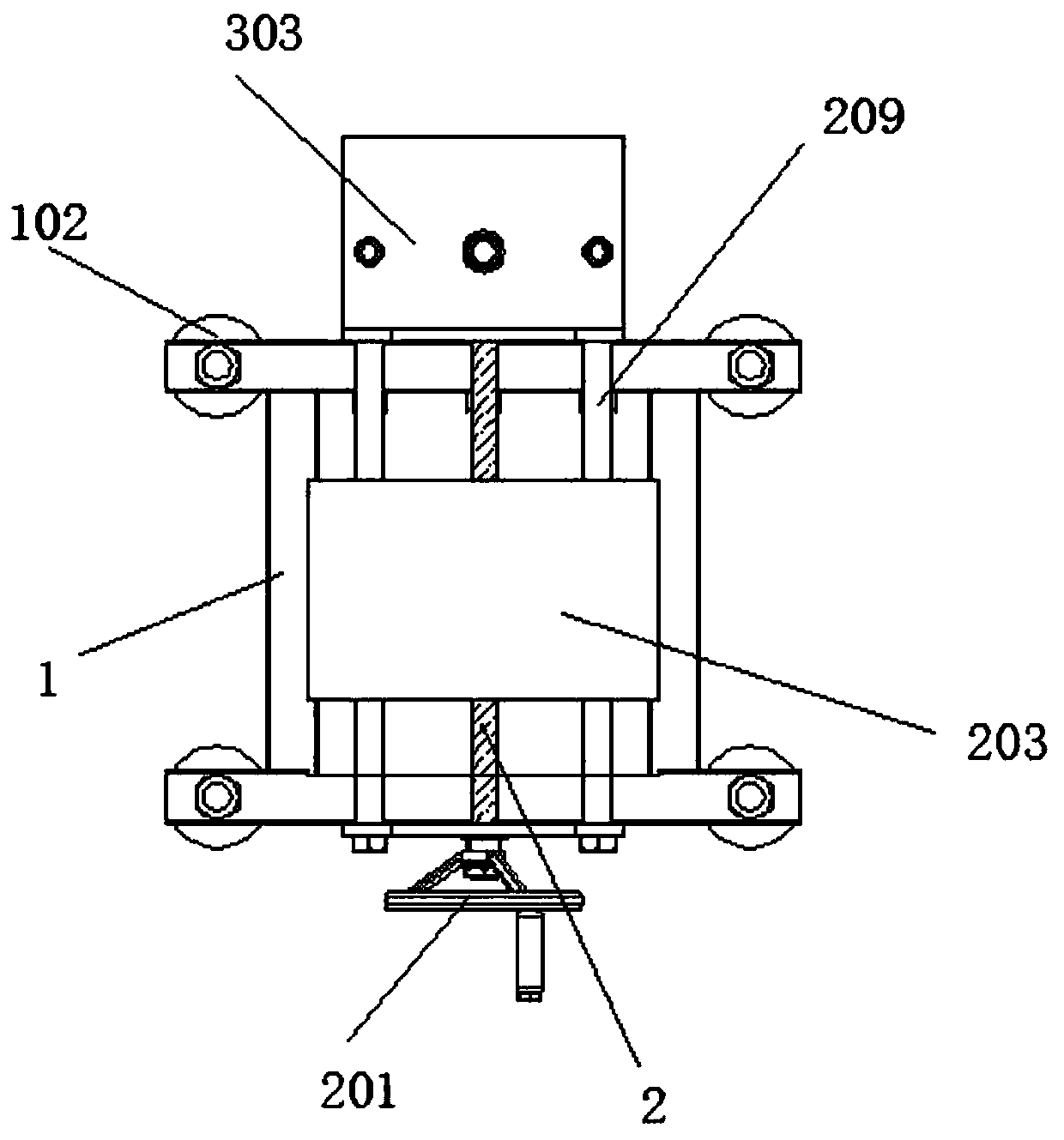

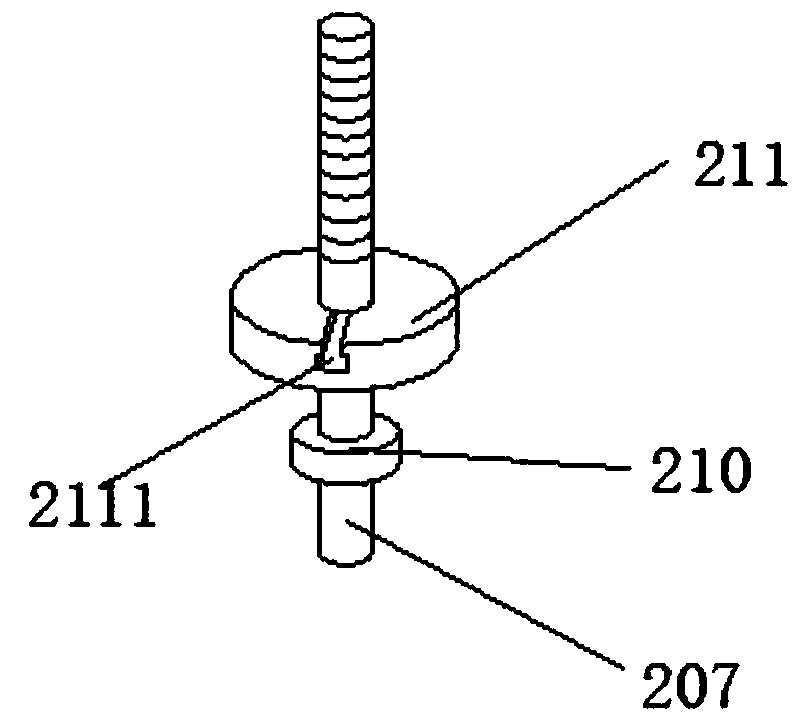

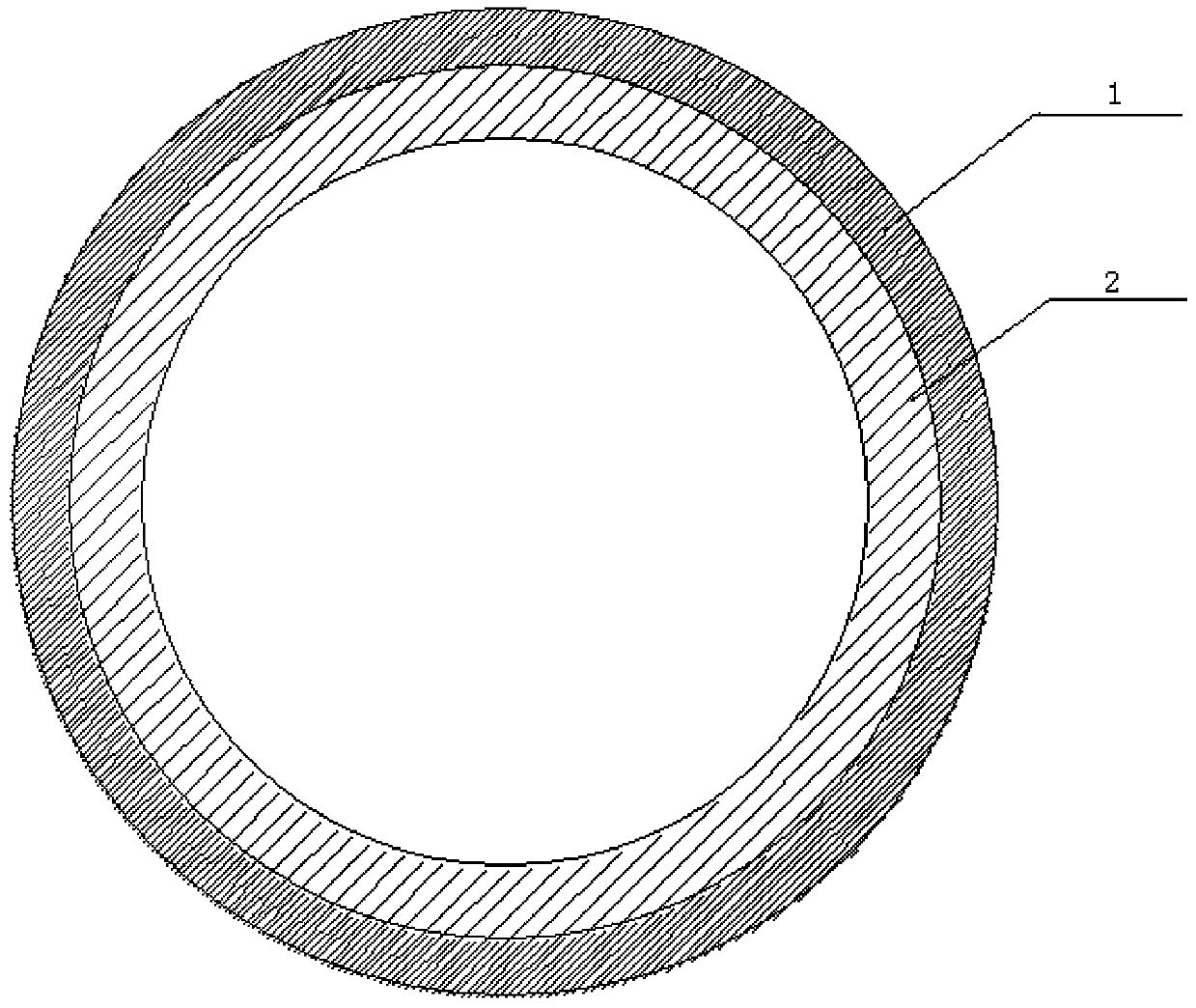

Fireproof pipeline made from new composite material

InactiveCN104653885AImprove performance parametersImprove flame retardant effectThermal insulationPipe protection by thermal insulationPipe layerResin matrix

The invention discloses a fireproof pipeline made from a new composite material. The fireproof pipeline is characterized by comprising an FRP (Fiber Reinforced Plastic) pipe layer and a fireproof insulating layer arranged at the outer part of the FRP pipe layer, wherein the fireproof insulating layer is made from GP-486G34 phenolic resin as a substrate material, 8-15% of hexamethylenetetramine CGH12N4 is added into the resin matrix material; soaked fibers are twisted on the surface of the a formed FRP pipe to solidify and form after the uniformly mixing. According to the fireproof pipeline provided by the invention, the flame retardant efficiency and the performance parameters of the product can be greatly improved, and the brittleness of the FRP pipe cannot be affected completely when the flame retardant efficiency is improved, therefore the code requirements of the IMO (International Maritime Organization) ISO753. (18) can be completely met, and the excellent fireproof products can be provided to a ship industry.

Owner:JIUMEI FIBER GLASS

High-flame retardant high temperature-retardant cable insulation material and preparation method thereof

InactiveCN107383638AImprove temperature stabilityImprove flame retardant effectRubber insulatorsDicumyl peroxidePhosphate

The invention discloses a high-flame retardant high-temperature retardant cable insulation material. The cable insulation material comprises, by weight, 100 parts of an ethylene propylene diene monomer, 10 to 20 parts of vinyl polysiloxane, 5 to 15 parts of vinyl phenyl polysiloxane, 20 to 40 parts of bis(2, 3-dichloropropyl)hexamethylenetetramine phosphate (single-component intumescent flame retardant), 10 to 20 parts of cyclodextrin, 5 to 10 parts of nano-mica, 5 to 10 parts of nano-kaolin, 0.5 to 1 part of glyceryl monostearate and 1 to 3 parts of dicumyl peroxide. The bis(2, 3-dichloropropyl)hexamethylenetetramine phosphate and cyclodextrin can form an inclusion compound in the cable insulation material. Through use of excellent transportation and dispersion ability of the cyclodextrin, the flame retardant can be uniformly dispersed at the molecular level in the resin matrix so that the flame retardant effects are greatly improved.

Owner:JIANGSU PUCAO TECH CO LTD

Composite functional reinforcing agent for rubber production and preparation method thereof

Belonging to the field of rubber plastic products, the invention in particular relates to a composite functional reinforcing agent for rubber production and a preparation method thereof. The raw materials include: red mud, a conditioning agent and a dispersing agent. The conditioning agent is stearic acid and gypsum, the dispersing agent is calcium phosphate, and the weight ratio of the red mud, the conditioning agent and the dispersing agent is 8-12:0.8-1.2:0.8-1.2. The composite functional reinforcing agent provided by the invention realizes utilization of waste red mud, has a good reinforcing effect on rubber products, can partially replace carbon black and white carbon black, can completely replace other traditional inorganic filler (like potter's clay, ordinary silicon powder and calcium carbonate, etc) in the rubber formula of rubber products, also can serve as a rubber reinforcing agent and filler. At the same time, the composite functional reinforcing agent also has vulcanization promoting and flame retardant effects, thereby reducing the dosage of carbon black, a vulcanization accelerator, a flame retardant and other expensive raw materials involved in the rubber formula, lowering the production cost of rubber products, and improving the performance of the prepared product.

Owner:山东沣泉环保橡塑有限公司

Preparation method of polypropylene composite flame-retardant material

InactiveCN103087406AImprove flame retardant performanceImprove flame retardant effectHydroxidePolypropylene composites

The invention relates to a preparation method of a polypropylene composite flame-retardant material. The preparation method comprises the following steps of 1, taking 45 parts by weight of polypropylene, and crushing the polypropylene into polypropylene particles having the diameter less than 5mm by a crusher, 2, uniformly mixing the polypropylene particles and 50 parts by weight of organic clay MMT, and adding 5 parts by weight of aluminum hydroxide into the mixture, and 3, heating the mixture until partial fusion, and cooling to obtain the polypropylene composite flame-retardant material. Through utilization of the organic clay MMT in polypropylene, polypropylene flame-retardant performances are improved effectively. Through utilization of aluminum hydroxide, composite material flame retardation is not influenced and can be improved. The preparation method has simple processes. The polypropylene composite flame-retardant material obtained by the preparation method has good flame retardation.

Owner:SICHUAN DUJIANGYAN HAIWANG FLAME RETARDANT MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com