Low-smoke zero-halogen flame retardant EVA rubber sheath material for mine cable and preparation method of low-smoke zero-halogen flame retardant EVA rubber sheath material

A sheath material and cable technology, applied in plastic/resin/wax insulators, organic insulators, etc., can solve problems such as non-environmental protection, and achieve the effect of improving flame retardant effect, high corrosive pH value, and promoting cross-linking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

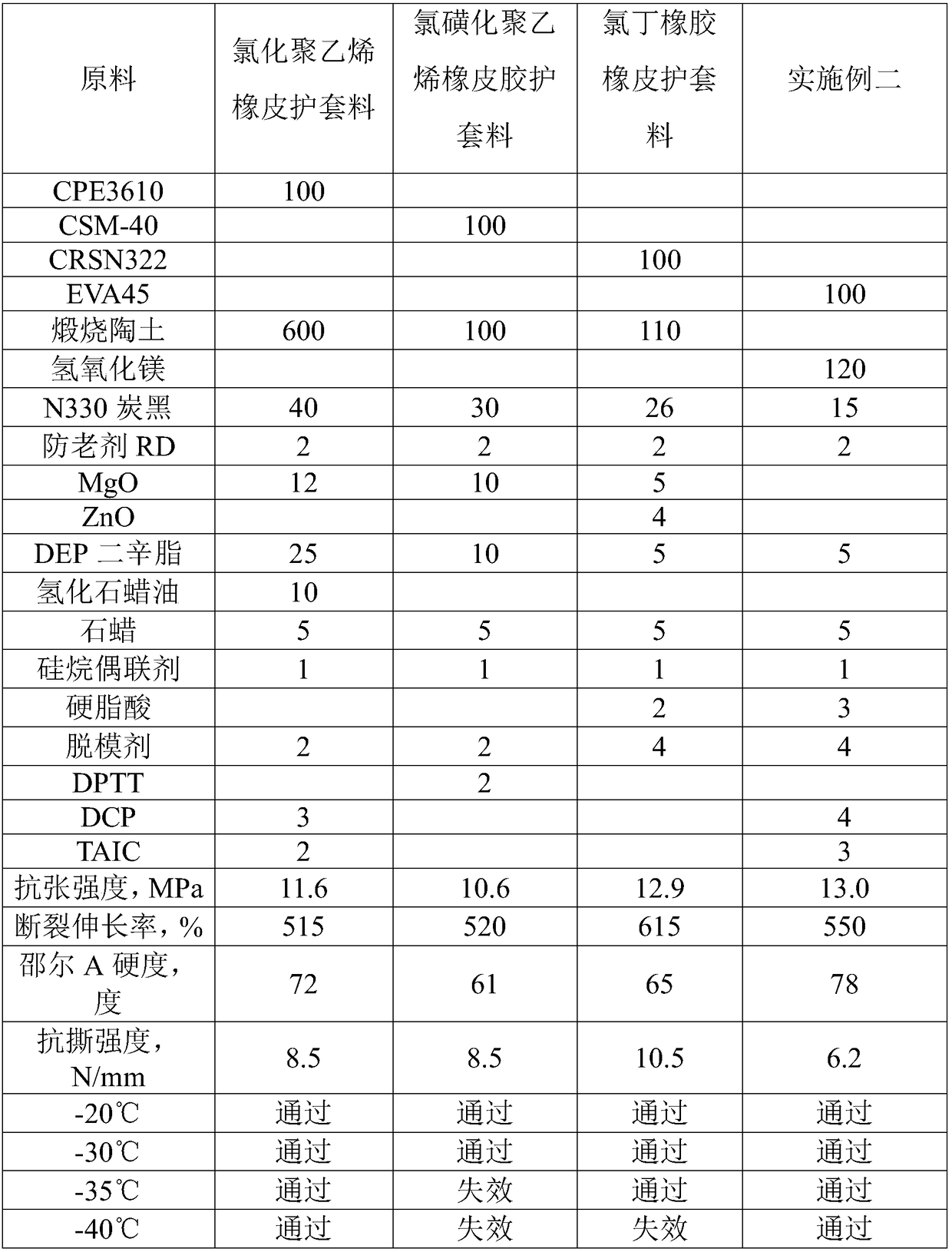

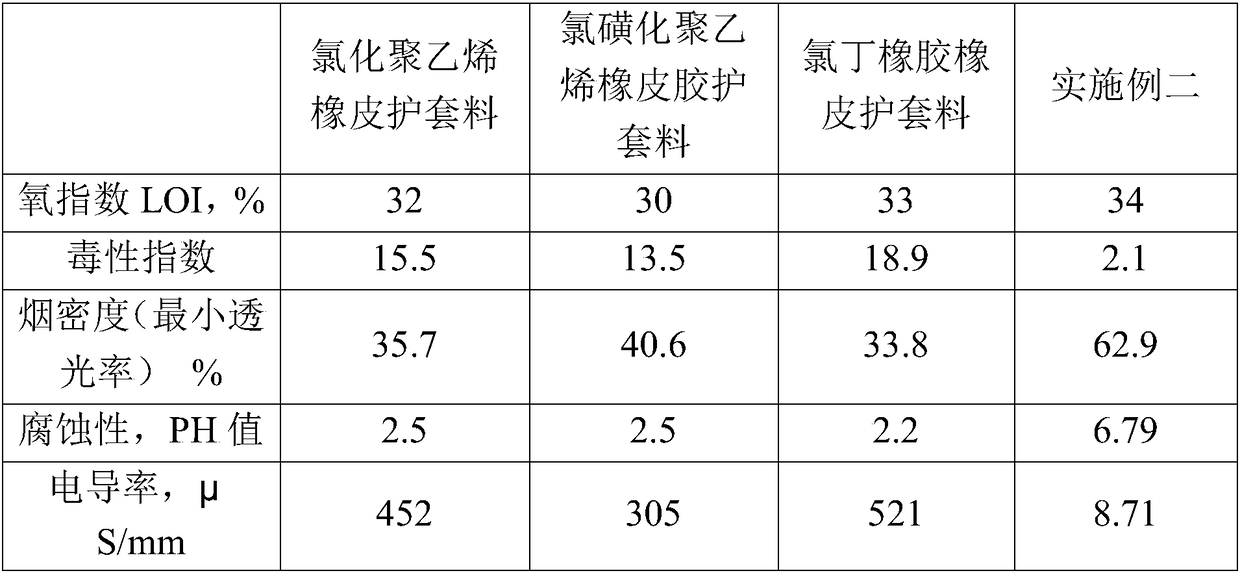

[0020] A low-smoke, halogen-free, flame-retardant EVA rubber sheath material for mine cables:

[0021] The components are calculated in parts by weight: 100 parts of EVA resin, 110 parts of magnesium hydroxide, 18 parts of carbon black, 1 part of antioxidant RD, 8 parts of DEP dioctyl ester, 2 parts of paraffin, 0.5 parts of silane coupling agent, 1 part of stearic acid, 5 parts of release agent, 1 part of vulcanizing agent DCP, 5 parts of crosslinking agent TAIC.

[0022] Its preparation method comprises the following steps:

[0023] (1) Ingredients: Weigh raw materials in parts by weight: 100 parts of EVA resin, 1100 parts of magnesium hydroxide, 18 parts of carbon black, 15 parts of antioxidant RD, 8 parts of DEP dioctyl ester, 2 parts of paraffin, silane 0.5 parts of linking agent, 1 part of stearic acid, 5 parts of release agent, 1 part of vulcanizing agent DCP, 5 parts of crosslinking agent TAIC;

[0024] (2) Mixing: Use an internal mixer to mix the above raw materials...

Embodiment 2

[0029] A low-smoke, halogen-free, flame-retardant EVA rubber sheath material for mine cables:

[0030] The components are calculated in parts by weight: 100 parts of EVA resin, 120 parts of magnesium hydroxide, 15 parts of carbon black, 2 parts of antioxidant RD, 5 parts of DEP dioctyl ester, 5 parts of paraffin, 1 part of silane coupling agent, 3 parts of stearic acid, 4 parts of release agent, 4 parts of vulcanizing agent DCP, 3 parts of crosslinking agent TAIC.

[0031] The preparation method comprises the following steps:

[0032] (1) Ingredients: Weigh raw materials in parts by weight: 100 parts of EVA resin, 110-130 parts of magnesium hydroxide, 10-18 parts of carbon black, 1-5 parts of antioxidant RD, 2-8 parts of DEP dioctyl ester 2-8 parts of paraffin, 0.5-2 parts of silane coupling agent, 1-5 parts of stearic acid, 1-5 parts of release agent, 1-5 parts of vulcanizing agent DCP, 1-5 parts of cross-linking agent TAIC;

[0033] (2) Mixing: Use an internal mixer to mix...

Embodiment 3

[0038] A low-smoke, halogen-free, flame-retardant EVA rubber sheath material for mine cables:

[0039] The components are calculated in parts by weight: 100 parts of EVA resin, 130 parts of magnesium hydroxide, 10 parts of carbon black, 5 parts of anti-aging agent RD, 2 parts of DEP dioctyl ester, 8 parts of paraffin wax, 2 parts of silane coupling agent, 5 parts of stearic acid, 1 part of release agent, 5 parts of vulcanizing agent DCP, and 1 part of crosslinking agent TAIC.

[0040] Its preparation method comprises the following steps:

[0041] (1) Ingredients: Weigh raw materials in parts by weight: 100 parts of EVA resin, 110-130 parts of magnesium hydroxide, 10-18 parts of carbon black, 1-5 parts of antioxidant RD, 2-8 parts of DEP dioctyl ester 2-8 parts of paraffin, 0.5-2 parts of silane coupling agent, 1-5 parts of stearic acid, 1-5 parts of release agent, 1-5 parts of vulcanizing agent DCP, 1-5 parts of cross-linking agent TAIC;

[0042] (2) Mixing: Use an internal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com