Flame-retardant wear-resistant polyurethane wheel and preparation method thereof

A polyurethane and polyurethane prepolymer technology, which is applied in the field of polyurethane tires, can solve the problems of poor antistatic performance of polyurethane tires, gaps formed by pouring materials, deviations in hub groove grinding, etc., and achieve durable and reliable antistatic ability and heat resistance The effect of improving and improving the wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

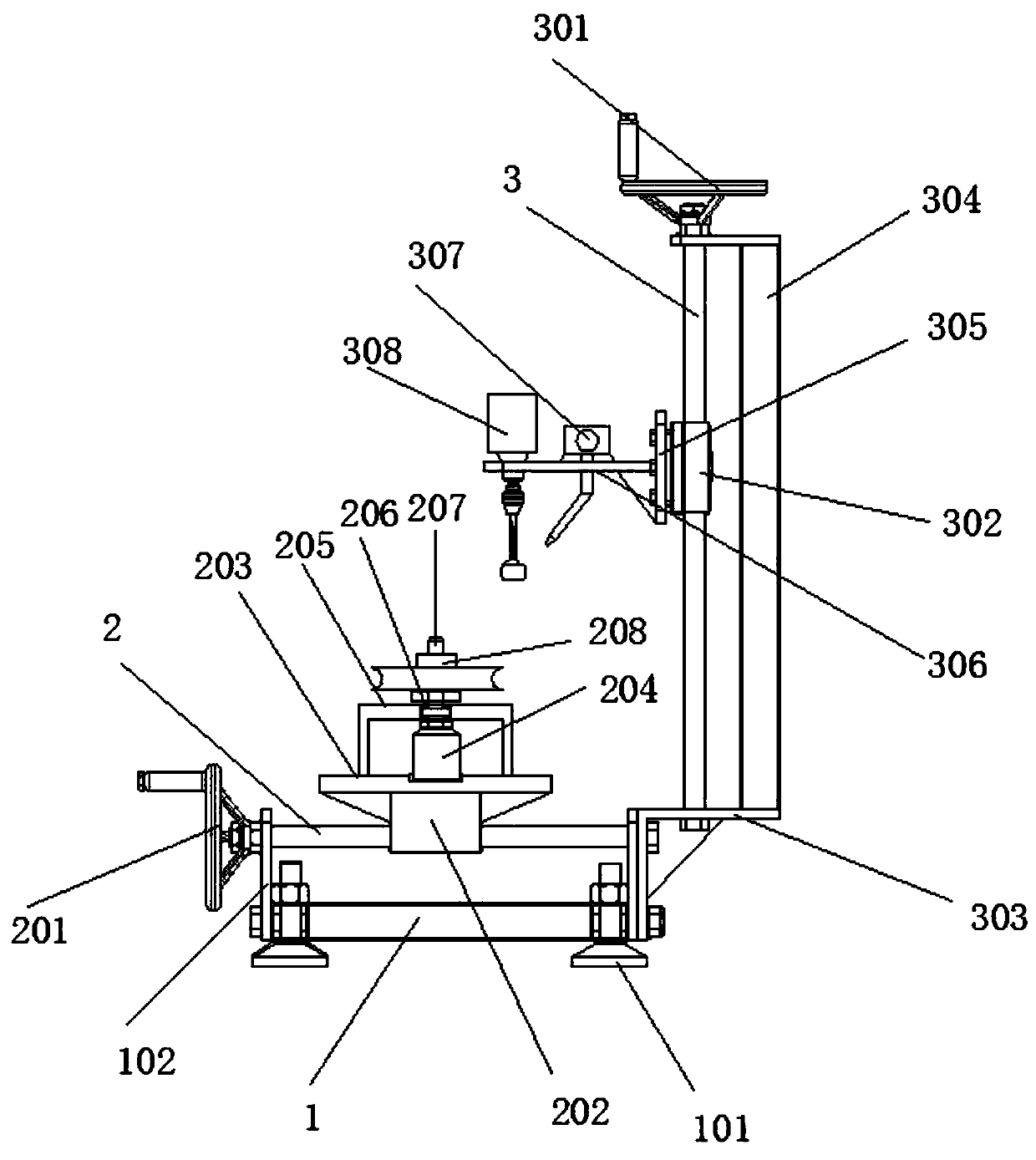

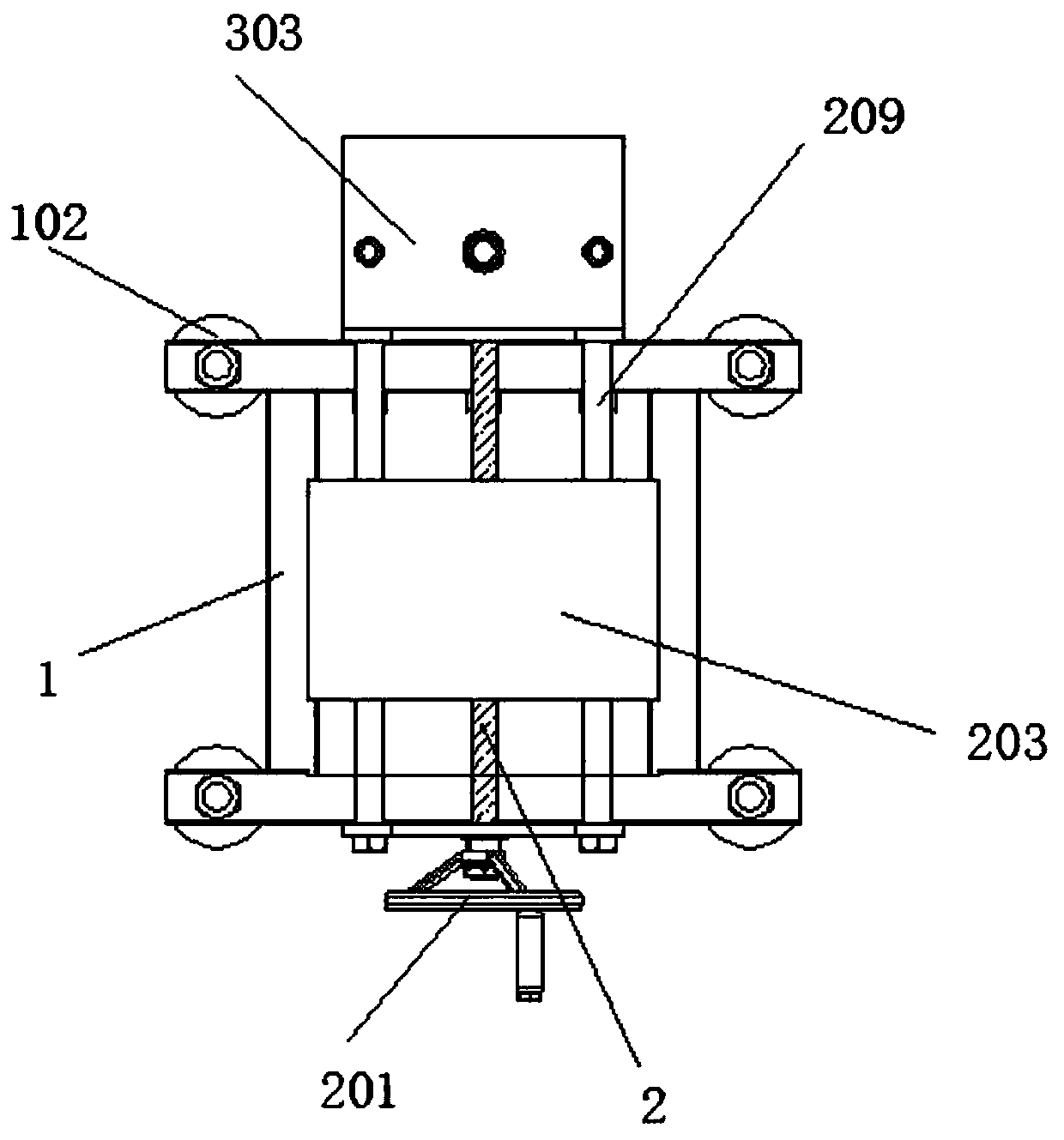

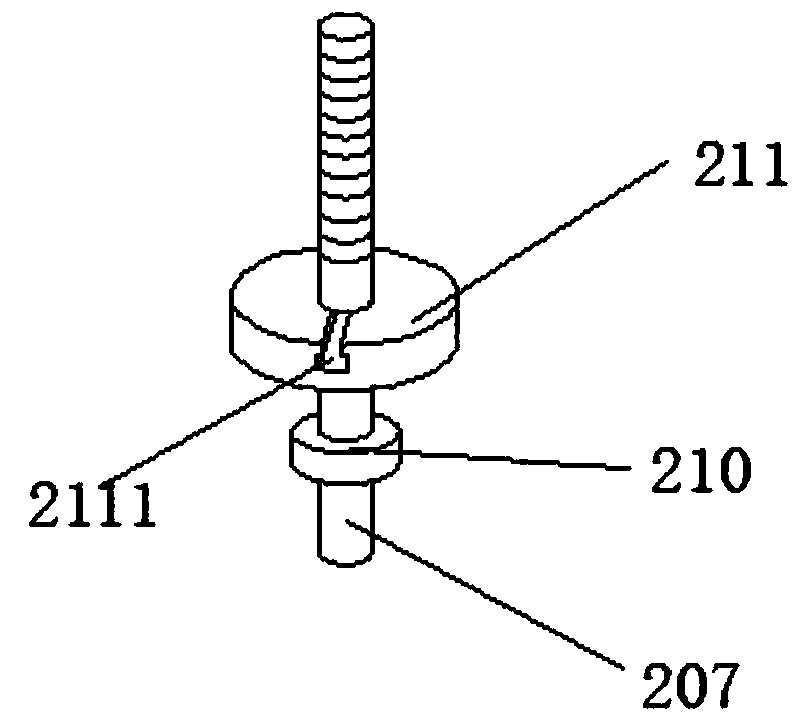

[0037] see Figure 1~5 , a flame retardant and wear-resistant polyurethane wheel, comprising the following raw materials in parts by weight: 50 parts of polyether polyol, 20 parts of diphenylmethane diisocyanate, 1 part of foam stabilizer, 1 part of chain extender, 1 part of defoamer, 1 part of fuel, 1 part of glass fiber, 0.5 part of crosslinking agent, 3 parts of polyaniline modified bentonite, 10 parts of expandable graphite;

[0038] The preparation of the fire-resistant wear-resistant polyurethane wheel comprises the following steps:

[0039] Step 1: Add polyether polyol and diphenylmethane diisocyanate into the reactor, heat the reactor to 50-70°C through an electric heating mantle, replace the air in the reactor with nitrogen, and then add polyaniline into the reactor Modified bentonite, foam stabilizer, and chain extender, heat up to 80-90°C, stir at 200-300r / min for 25-35 minutes, after stirring, stand still, control the temperature in the reactor at 30-40°C, keep wa...

Embodiment 2

[0047] A flame-retardant and wear-resistant polyurethane wheel, comprising the following raw materials in parts by weight: 70 parts of polyether polyol, 30 parts of diphenylmethane diisocyanate, 2 parts of foam stabilizer, 2 parts of chain extender, 1.5 parts of defoamer, flame retardant 3 parts of agent, 5 parts of glass fiber, 0.5 part of crosslinking agent, 5 parts of polyaniline modified bentonite, 15 parts of expandable graphite;

[0048] The preparation of the fire-resistant wear-resistant polyurethane wheel comprises the following steps:

[0049] Step 1: Add polyether polyol and diphenylmethane diisocyanate into the reactor, heat the reactor to 50-70°C through an electric heating mantle, replace the air in the reactor with nitrogen, and then add polyaniline into the reactor Modified bentonite, foam stabilizer, and chain extender, heat up to 80-90°C, stir at 200-300r / min for 25-35 minutes, after stirring, stand still, control the temperature in the reactor at 30-40°C, ke...

Embodiment 3

[0057] A flame-retardant and wear-resistant polyurethane wheel, comprising the following raw materials in parts by weight: 60 parts of polyether polyol, 25 parts of diphenylmethane diisocyanate, 1.5 parts of foam stabilizer, 1.5 parts of chain extender, 1.25 parts of defoamer, flame retardant 2 parts of agent, 4 parts of glass fiber, 0.75 parts of crosslinking agent, 4 parts of polyaniline modified bentonite, 12.5 parts of expandable graphite;

[0058] The preparation of the fire-resistant wear-resistant polyurethane wheel comprises the following steps:

[0059] Step 1: Add polyether polyol and diphenylmethane diisocyanate into the reactor, heat the reactor to 50-70°C through an electric heating mantle, replace the air in the reactor with nitrogen, and then add polyaniline into the reactor Modified bentonite, foam stabilizer, and chain extender, heat up to 80-90°C, stir at 200-300r / min for 25-35 minutes, after stirring, stand still, control the temperature in the reactor at 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com