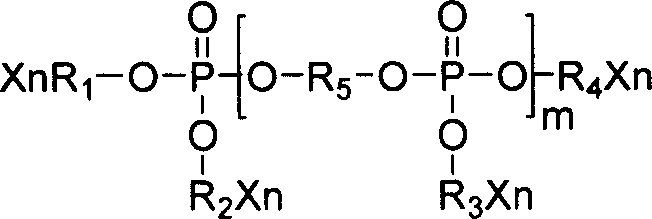

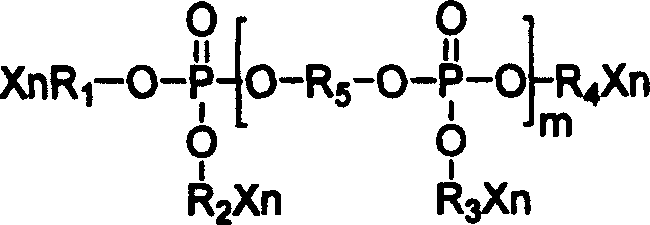

Polycondenseng phosphate and its preparation process and application thereof

A phosphate ester and polycondensation technology, applied in the direction of phosphorus organic compounds, etc., to reduce the amount of flame retardants and improve the flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

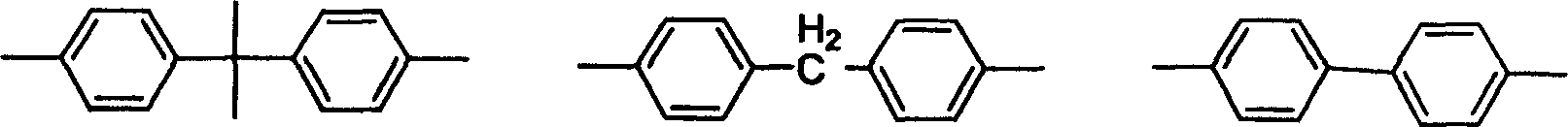

Method used

Image

Examples

example 1

[0020] Preparation of resorcinol tetrakis(1-chloro-2-isopropyl) diphosphate

[0021] 22.0g (0.2mol) of resorcinol, 184.0g (1.2mol) of phosphorus oxychloride and 0.5g of AlCl were charged in a 250ml reactor equipped with a stirrer, a thermometer, a hydrogen chloride absorption device and a condenser 3 , these materials were heated to 115°C within 0.5h, stirred and reacted for 3h, no HCl was released as detected by a pH meter, and the hydrogen chloride gas produced was absorbed by a hydrogen chloride absorption device. Distill under reduced pressure in nitrogen atmosphere (130 ℃ 5h under 50mmHg column), remove unreacted phosphorus oxychloride, obtain 67.7g phosphorus oxychloride (y 1 = 98.43%).

[0022] The intermediate produced by the above reaction was heated to 65°C, and 54.8g (20wt% excess, measured by the amount of intermediate phosphorus oxychloride) propylene oxide was added dropwise within 1h, and after continuing the reaction for 3.5h, the unreacted ring was distilled ...

example 2

[0026] In the first step reaction, the phosphorus oxychloride consumption is changed into 153.3g (1.0mol), and the temperature of reaction is changed into 90 DEG C, and other reaction processes are with example 1. The yield of the target product obtained was 78.2%.

example 3

[0028] In the second step reaction, the propylene oxide consumption is changed to 69.7g (50wt% in excess, in resorcinol), and other reaction processes are the same as in Example 1. The yield of the obtained target product was 89.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com