High-viscosity flame-retardant environmentally-friendly pressure-sensitive adhesive and preparation method thereof, and pressure-sensitive adhesive film preparation method

A pressure-sensitive adhesive and environmental protection technology, which is applied in the preparation of pressure-sensitive adhesive films, high-viscosity, flame-retardant and environmentally-friendly pressure-sensitive adhesives and preparation fields, can solve the problems of easy safety, poor stickiness, and limited application scope, etc. To achieve the effect of improving the flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

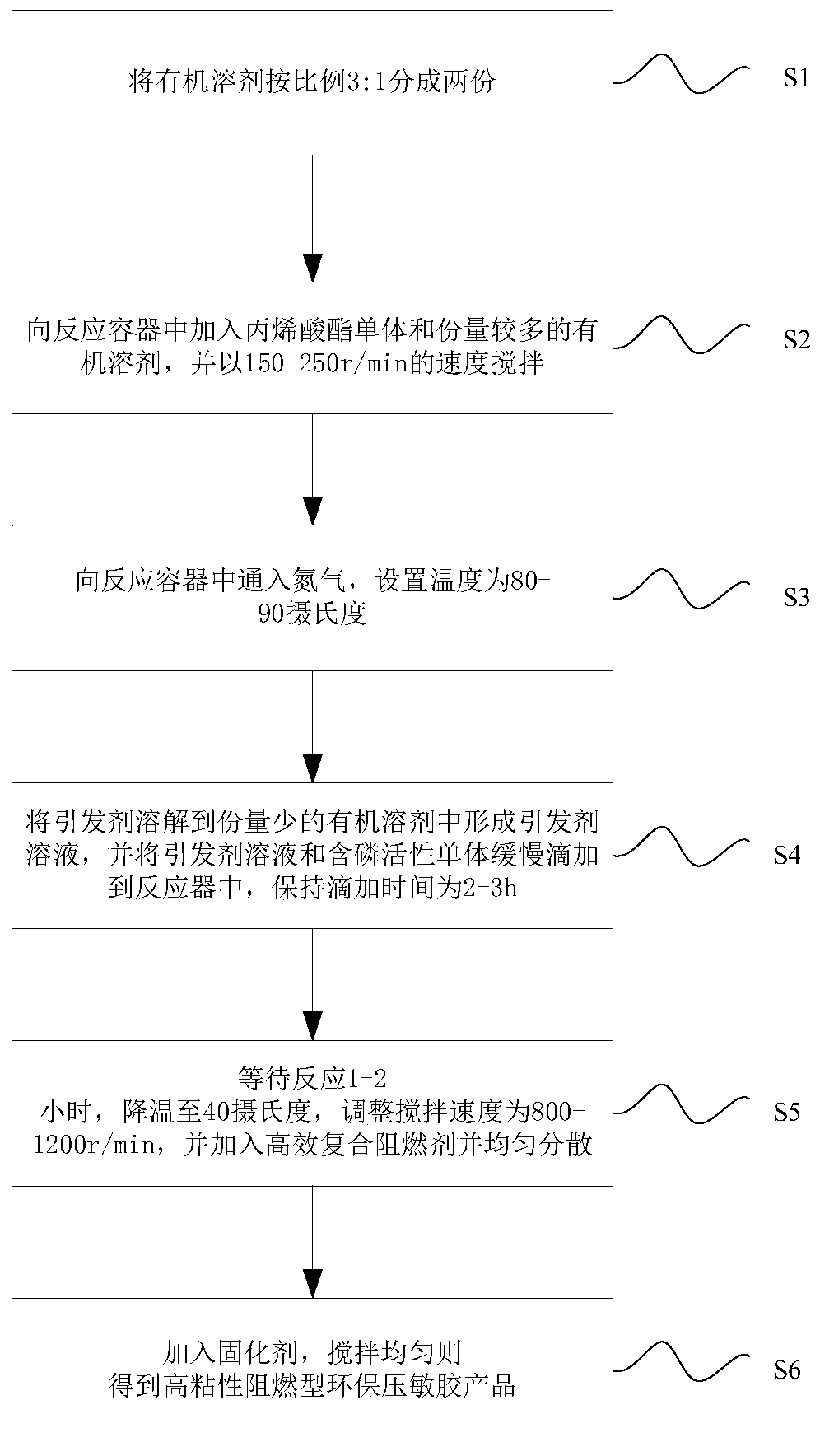

[0048] The preparation method of the high-viscosity flame-retardant environment-friendly pressure-sensitive adhesive of the present embodiment comprises:

[0049] S1: Divide the organic solvent into two parts in a ratio of 3:1;

[0050]S2: Add acrylate monomer and a larger amount of organic solvent into the reaction vessel, and stir at a speed of 150-250r / min;

[0051] S3: feed nitrogen into the reaction vessel, and set the temperature to 80-90 degrees Celsius;

[0052] S4: Dissolving the initiator into an organic solvent with a small amount to form an initiator solution, and slowly adding the initiator solution and phosphorus-containing active monomers into the reactor dropwise, keeping the dropping time for 2-3 hours;

[0053] S5: Wait for the reaction for 1-2 hours, lower the temperature to 40 degrees Celsius, adjust the stirring speed to 800-1200r / min, and add a high-efficiency composite flame retardant and disperse it evenly;

[0054] S6: Add a curing agent and stir eve...

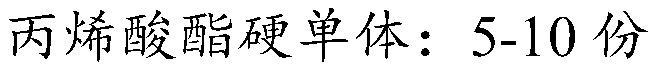

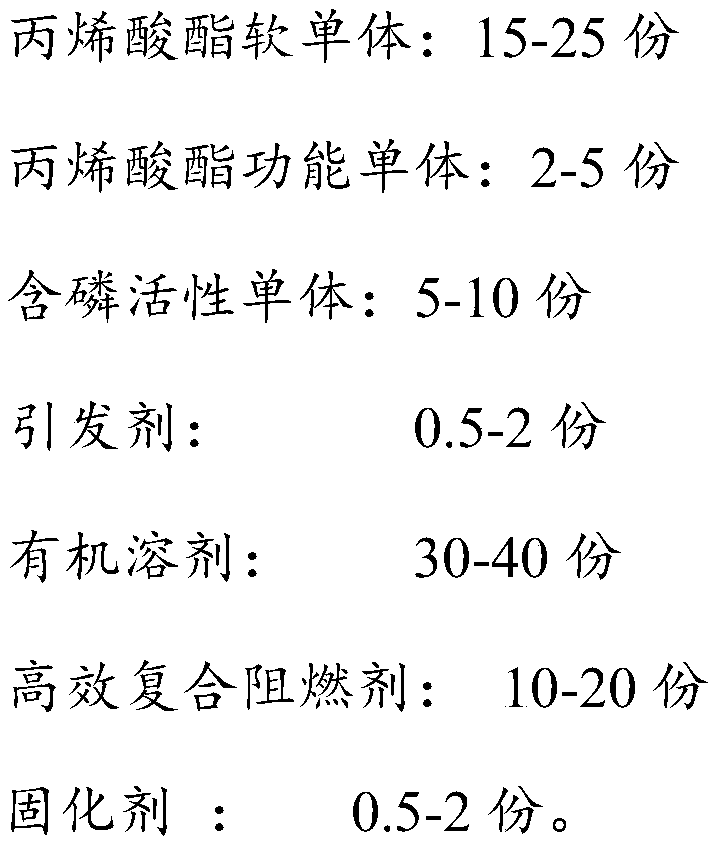

Embodiment 1

[0059] Example 1: Add 5g methyl acrylate, 25g butyl methacrylate, 2g acrylic acid, 12.5g ethyl acetate, 10g methyl butyl ketone to the reactor, turn on nitrogen, start stirring, and the stirring speed is 150 rpm , heat up to 80°C, slowly add 5g of hydroxyethyl acrylate phosphate, 0.5g of benzoyl peroxide and 7.5g of ethyl acetate solvent, dropwise for 2 hours, continue to react for 2 hours after dropping, cool down to 40°C, increase the stirring speed to 800 rpm, add 15g ammonium polyphosphate, 5g trimethyl phosphite, stir and disperse for 20 minutes, add 0.5g triethylenetetramine curing agent, that is, a high-viscosity flame-retardant environmental protection Pressure sensitive adhesive products.

Embodiment 2

[0060] Example 2: Add 10g of ethyl methacrylate, 15g of butyl acrylate, 5g of methylol acrylamide, 20g of ethyl acetate, 10g of N,N-dimethylformamide into the reactor, turn on the nitrogen, turn on the stirring, and stir The speed is 250 rpm, the temperature is raised to 90°C, and 10g of 2-ethyl (methacrylic acid acyloxymethyl) phosphate, 2g of dicumyl peroxide and 10g of ethyl acetate solvent are slowly added dropwise, and the addition time is 3 hours, continue to react for 1 hour after dropping, lower the temperature to 40°C, increase the stirring speed to 1200 rpm, add 5g triethyl phosphate, 5g aluminum hydroxide, stir and disperse for 30 minutes, add 2g methylene bisphenyl Amine curing agent, that is, to prepare high-viscosity flame-retardant environmental protection pressure-sensitive adhesive products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com