Modified PVC pellet and preparation method thereof

A PVC resin and modification technology, applied in building thermal insulation materials, building components, buildings, etc., can solve other problems such as damage to performance and not very obvious effects, and achieve the improvement of performance, compatibility, and high temperature resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

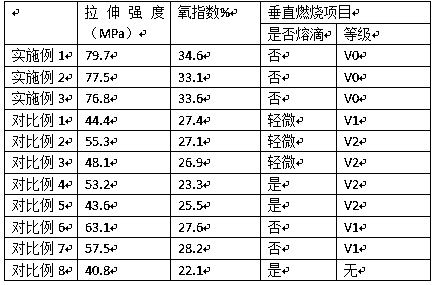

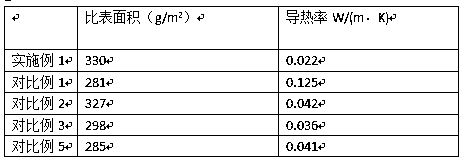

Examples

Embodiment 1

[0033] A modified PVC pellet prepared by using the following raw materials by weight:

[0034] 55 parts of PVC resin, 3.8 parts of plasticizer, 0.8 parts of anti-aging agent, 13 parts of modified silica airgel;

[0035] The preparation method of the modified silica airgel comprises the following steps:

[0036] (1) Add attapulgite to 3-5 times its weight in a nitric acid solution with a mass fraction of 5% and soak for 10-15 minutes, then wash it with deionized water for 3-4 times, and then treat it at 425°C for 2.5 hours. Add the treated attapulgite to 4 times its weight in deionized water, and stir for 18-20 minutes to disperse the attapulgite to form a suspension;

[0037] (2) To prepare modified asphalt, crush the asphalt, pass through a 200-mesh sieve, mix the asphalt with 1% oxalic acid solution in a weight ratio of 1:2, and then add 2.5% by weight of asphalt Methyl ammonium bromide, stirred at 480-500r / min for 22min, then heated up to 124°C, stirred at 1350r / min for 1...

Embodiment 2

[0049] A modified PVC pellet prepared by using the following raw materials by weight:

[0050] 55 parts of PVC resin, 4.2 parts of plasticizer, 0.9 parts of anti-aging agent, and 12 parts of modified silica airgel.

Embodiment 3

[0052] A modified PVC pellet prepared by using the following raw materials by weight:

[0053] 58 parts of PVC resin, 4.5 parts of plasticizer, 0.9 parts of anti-aging agent, 14 parts of modified silica airgel;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com