Patents

Literature

327results about "Drying safety systems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

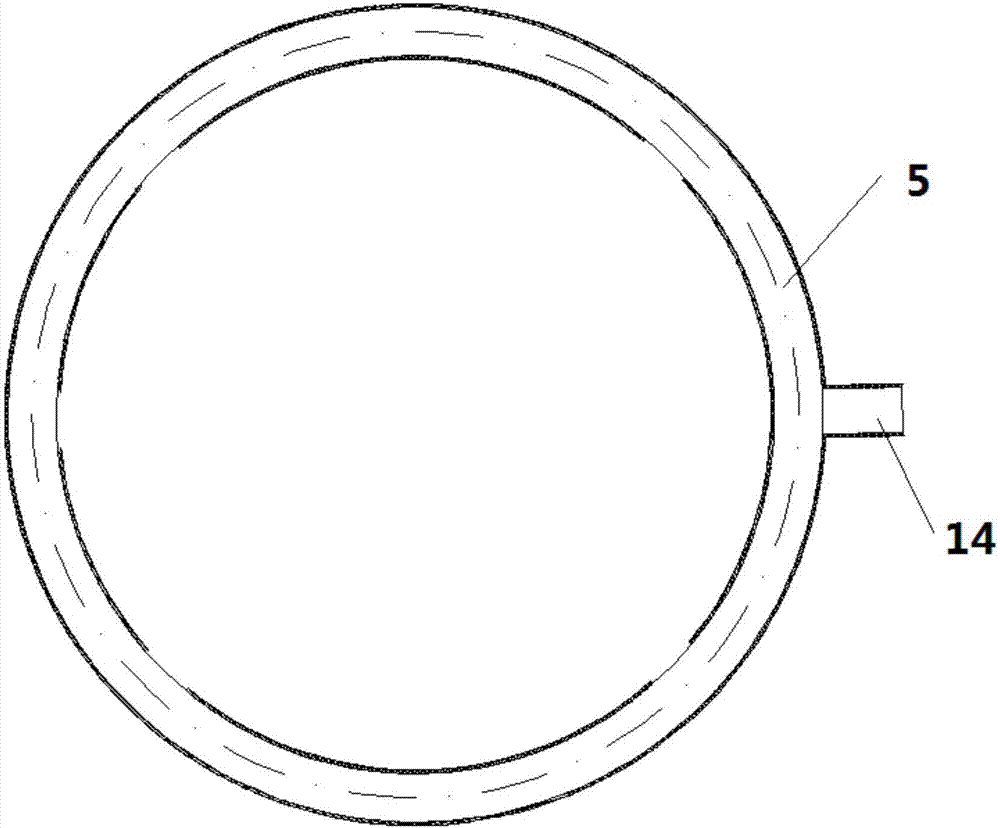

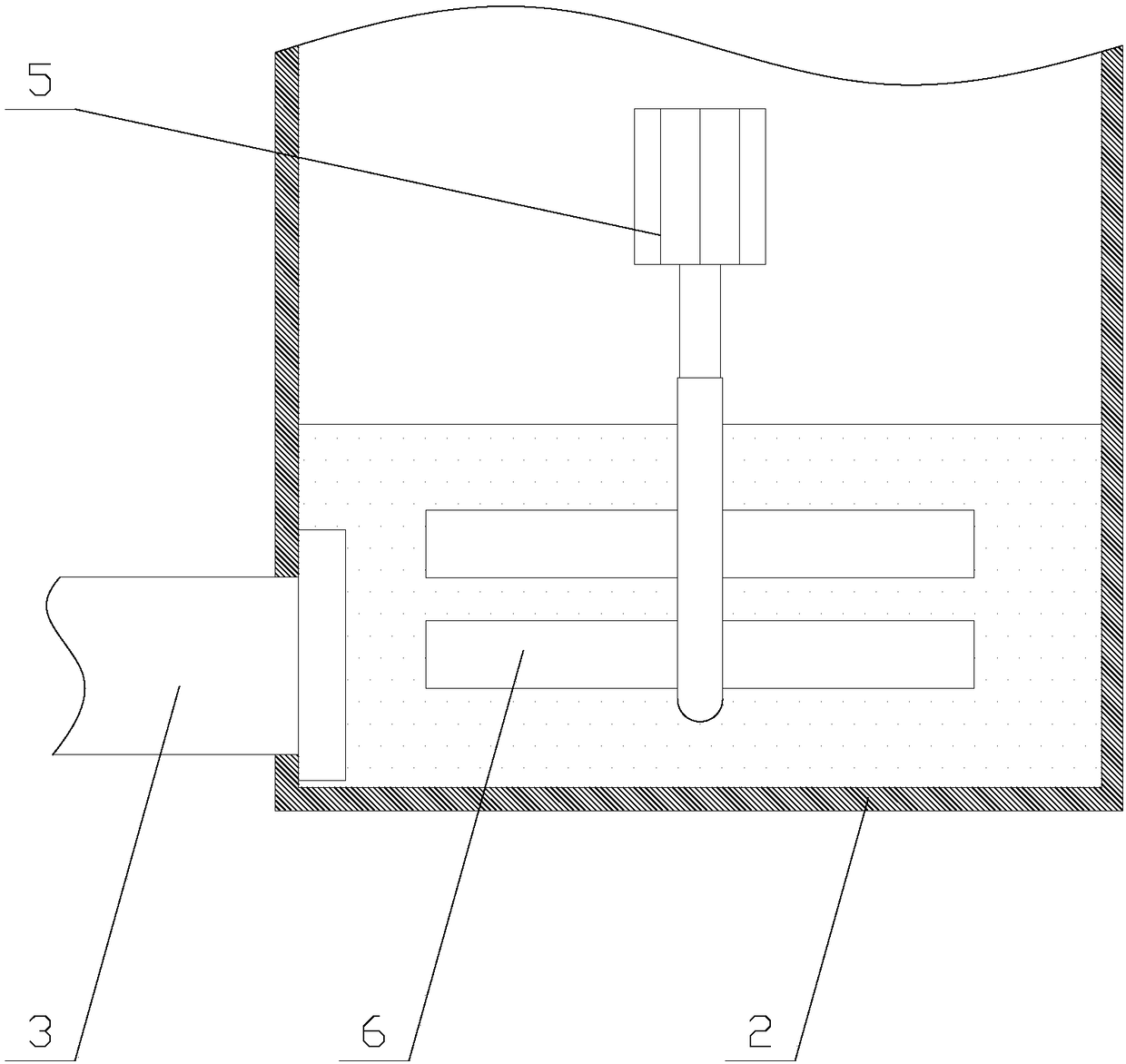

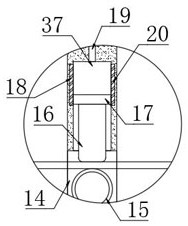

Steam drier capable of intelligently controlling steam flow

ActiveCN107356094AStable outputImprove intelligenceDrying gas arrangementsDrying safety systemsElectricityData connection

The invention provides a steam drier comprising a furnace body, a water tank and a water pump, the water tank is connected with the water pump through a first pipeline, the water pump is connected with the furnace body through a second pipeline, the interior of the furnace body is provided with an electric heater unit, the upper part of the furnace body is provided with a steam outlet pipeline, and the water tank is provided with an inlet pipeline. The steam drier is characterized in that the steam outlet pipeline is provided with a flow sensor used for measuring steam flow produced in unit time, the flow sensor and the electric heater unit are in data connection with a controller, and the controller automatically controls power of the electric heater unit according to the measured steam flow. According to the invention, heating power of the electric heater unit in the steam drier is automatically controlled through the steam flow, and therefore steam output is stable, and intellectualization is improved.

Owner:来安县永阳知识产权运营有限公司

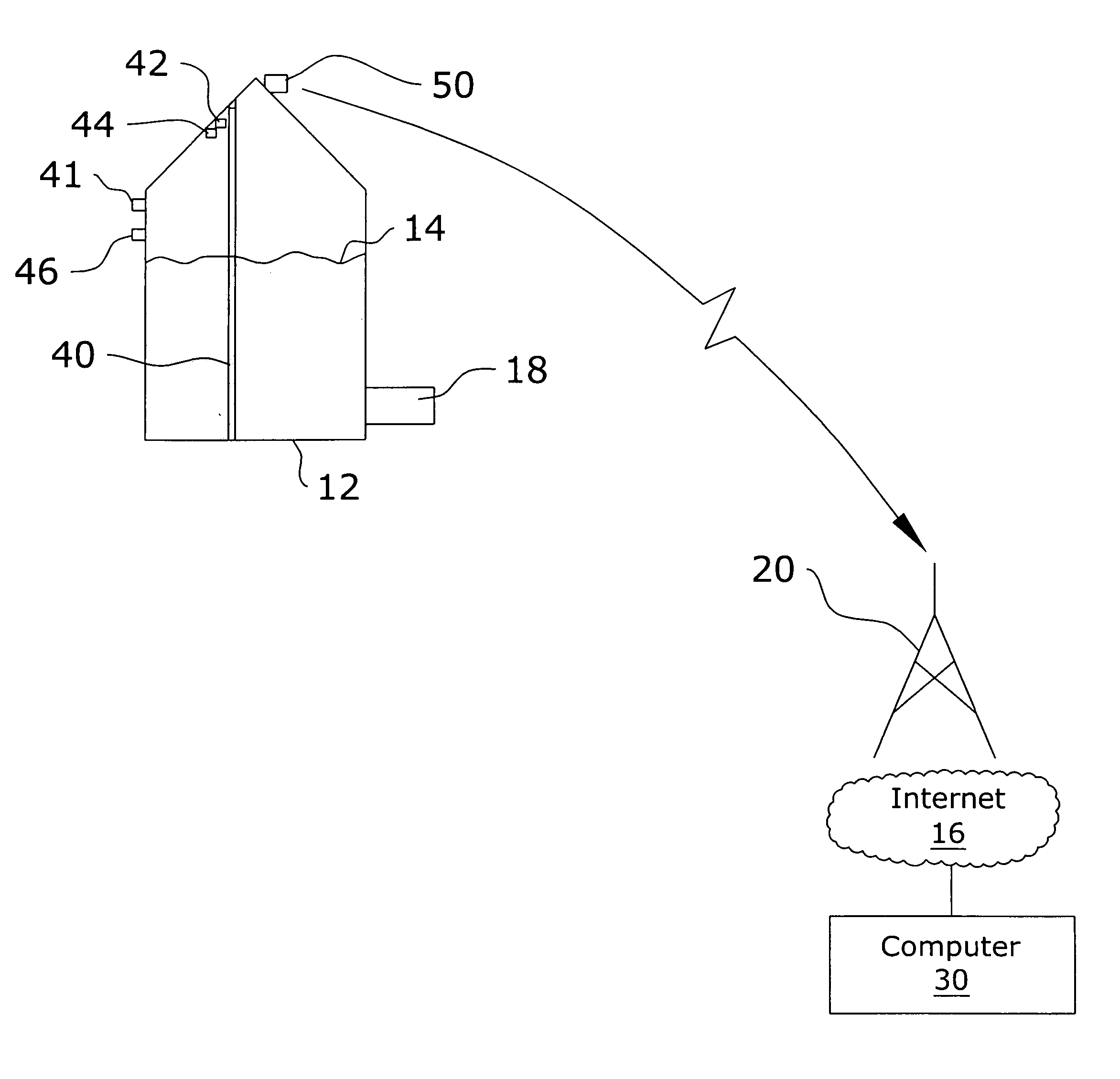

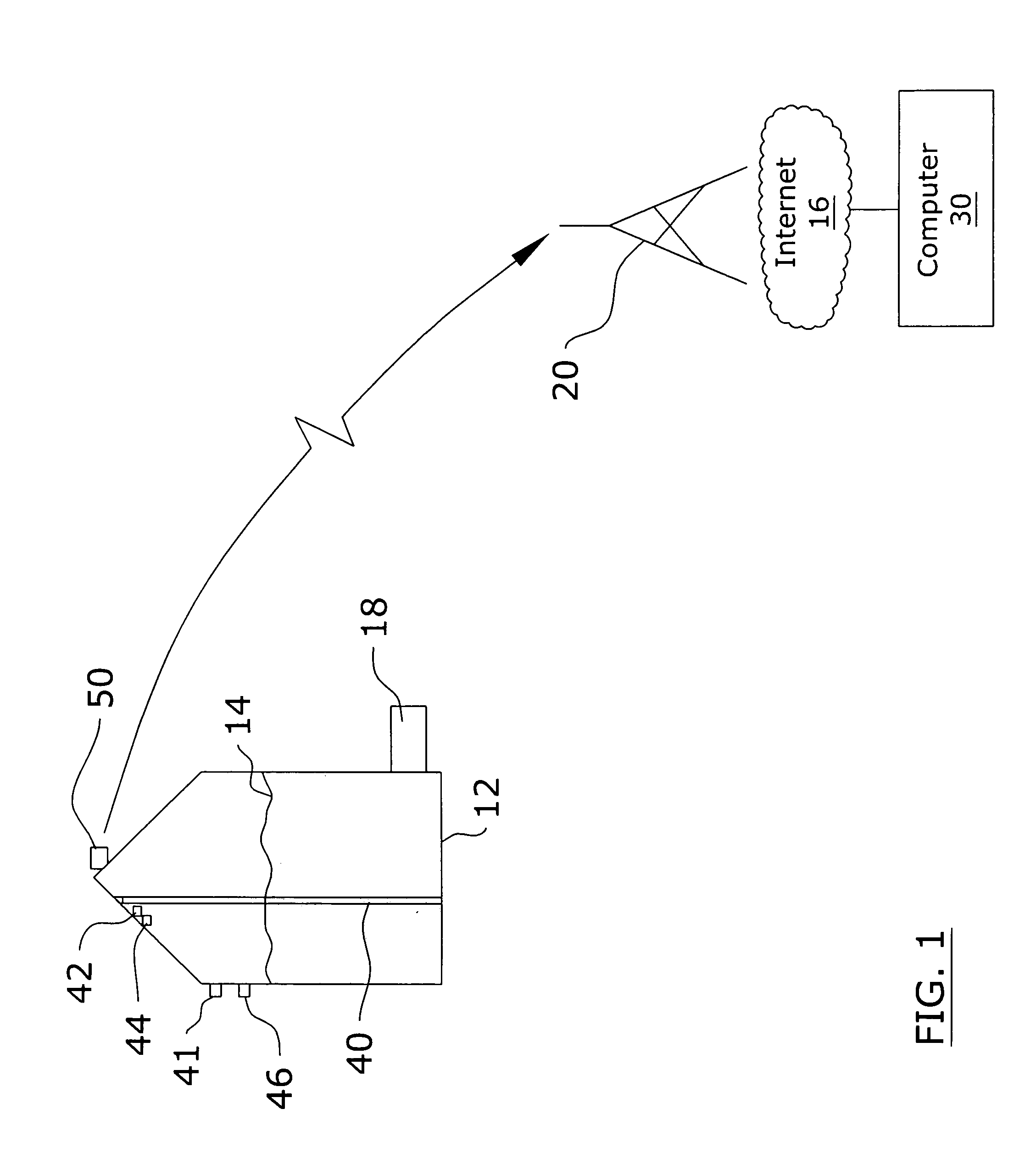

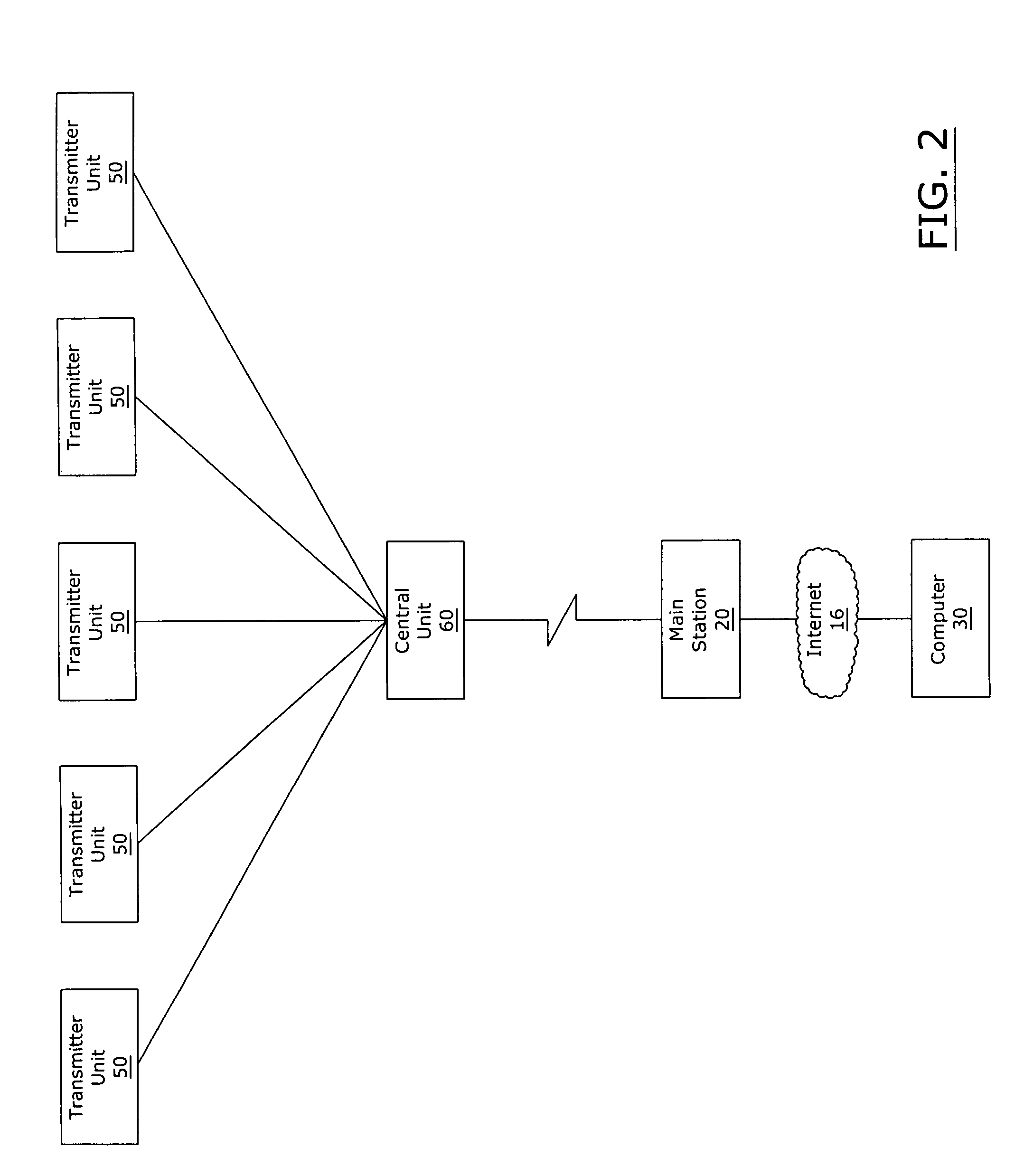

Grain bin monitoring system

InactiveUS20050080567A1Effective monitoringDrying gas arrangementsDrying safety systemsMonitoring systemMaster station

A grain bin monitoring system for efficiently monitoring remote grain bins. The grain bin monitoring system includes a main station, a central unit in communication with the main station, a plurality of transmitter units in communication with the central unit, and at least one sensor positionable within a grain bin for determining condition data with respect to a grain bin. The sensor is in communication with one of the transmitter units for providing the condition data to the transmitter unit, wherein the transmitter unit automatically forwards the condition data to a central unit that automatically forwards the condition data to the main station. In the event of an alarm condition, an individual may be notified.

Owner:WIETING MEL G +1

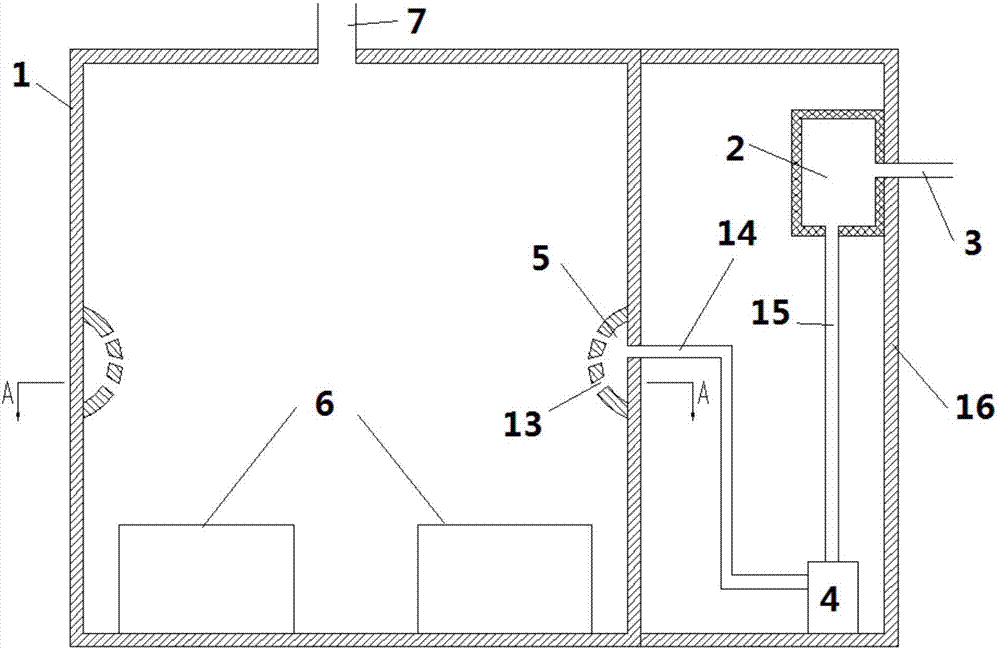

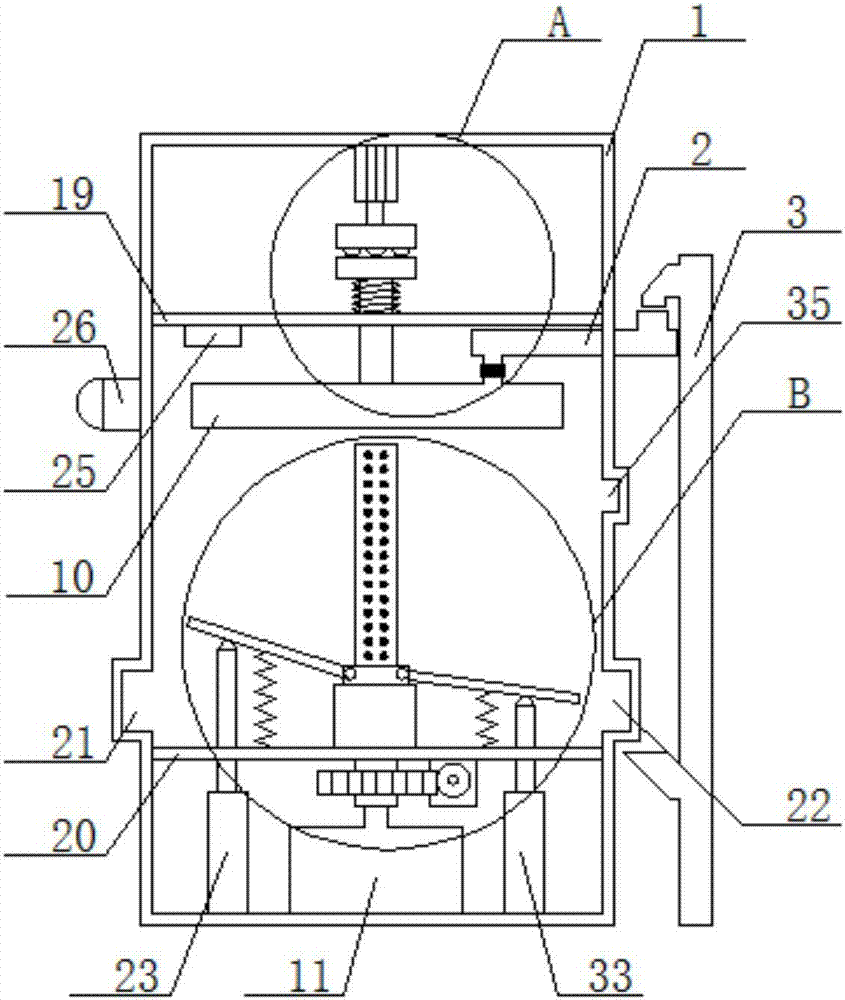

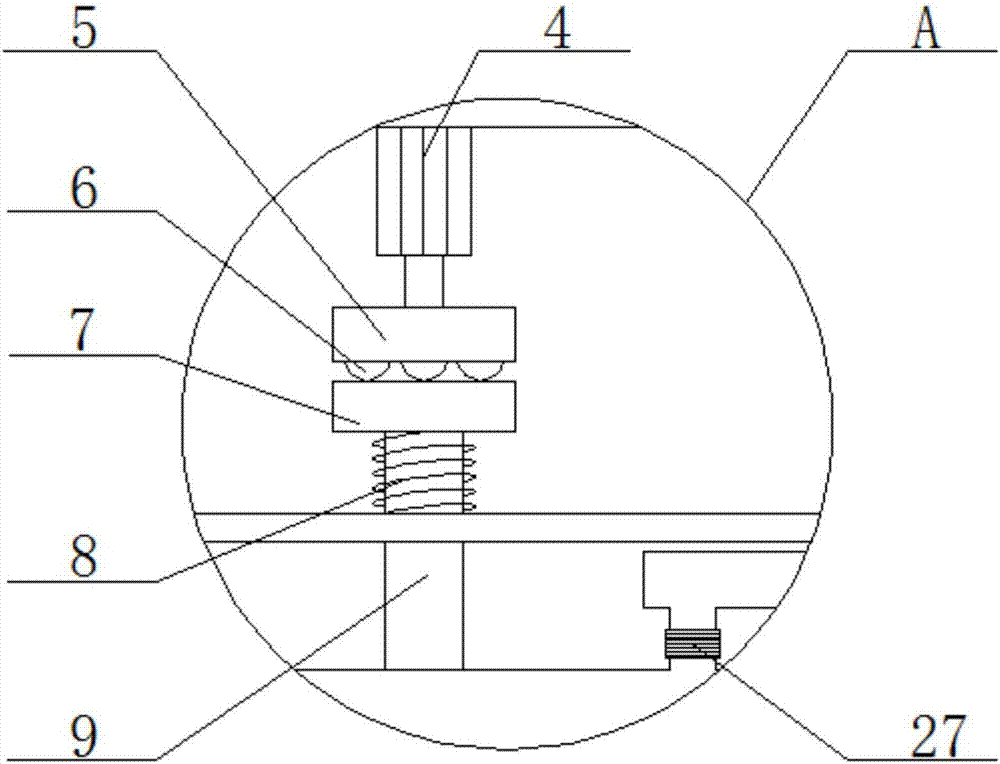

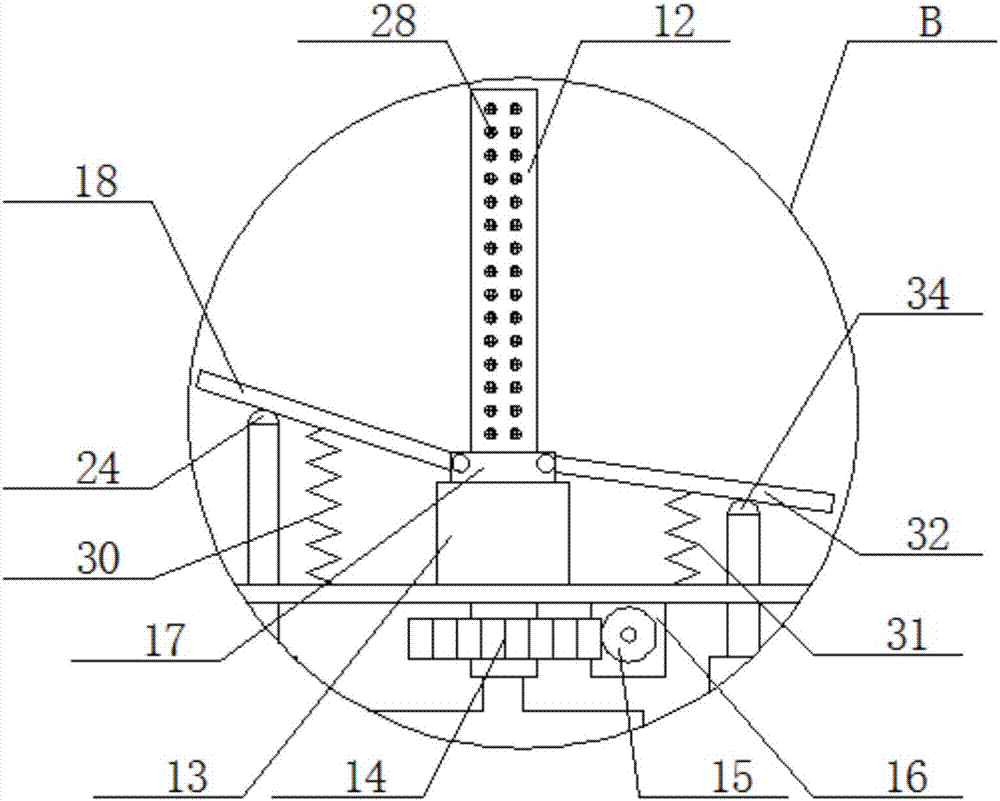

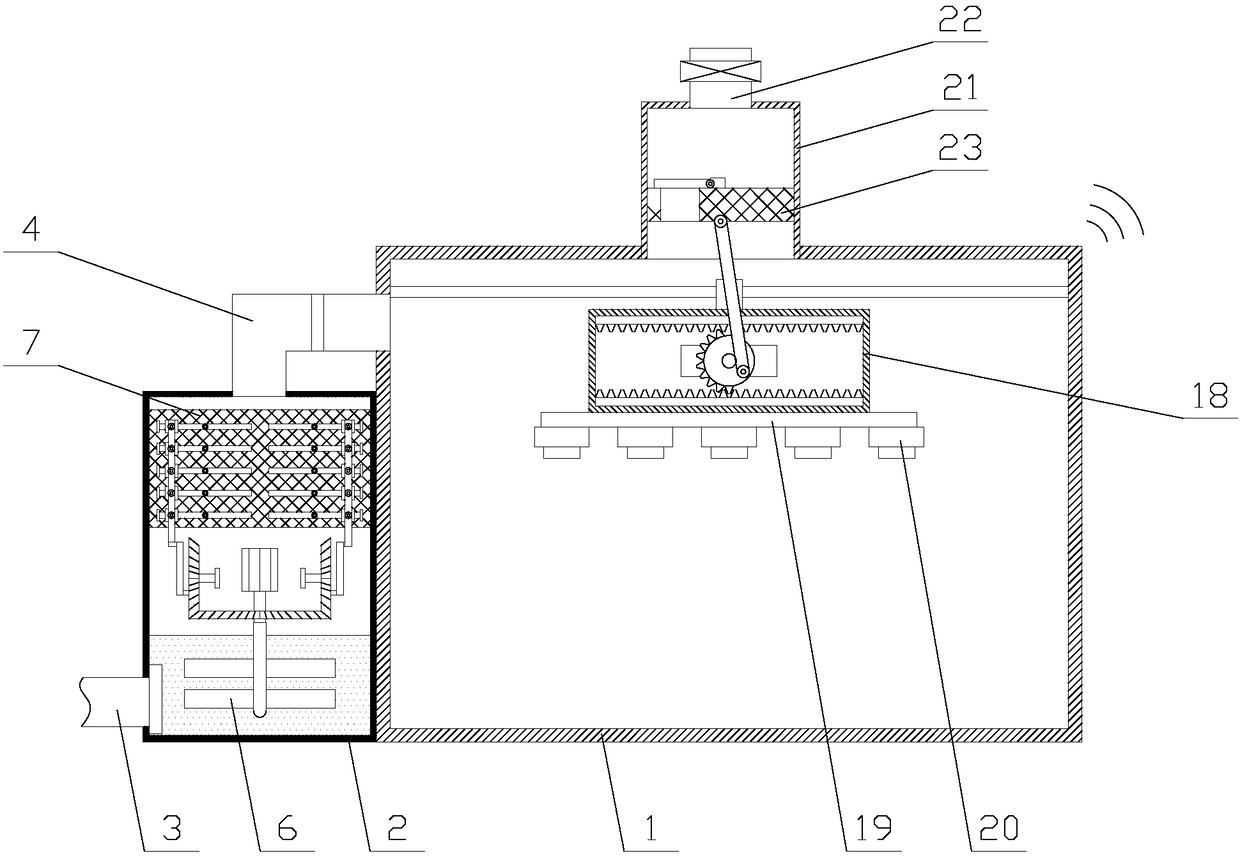

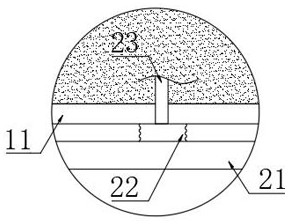

Grain dryer which can improve drying efficiency

InactiveCN107062886AAvoid cakingFalling smoothlyDrying gas arrangementsSeed preservation by dryingEngineeringAir blower

The invention relates to a grain dryer which can improve the drying efficiency. The grain dryer comprises a main body, a winnowing mechanism, a conveying mechanism, a heating mechanism and a material guide mechanism, wherein the winnowing mechanism comprises a first motor, a first support plate, a limiting block, a second support plate, a spring, a support rod and a scattering plate; the conveying mechanism comprises a first conveyor and a second conveyor; the heating mechanism comprises a hot-air blower, a rotation shaft, a bearing, a worm gear, a worm and a second motor; the material guide mechanism comprises a connecting plate, a first baffle plate, a second baffle plate, a second spring and a third spring. Grains are added to the second conveyor, then are sent to the scattering plate through the conveying mechanism, and finally are winnowed down from scattering holes through up and down vibration of the scattering plate, and therefore the uniform dropping out of the winnowed grains is realized. Meanwhile, hot air is blown out from hot air holes and the rotation shaft rotates, therefore the grains are uniformly heated in the falling process. The grains can be guided into the second conveyor again through the material guide mechanism to realize circular drying, and therefore the drying efficiency is improved.

Owner:吉林省允祥环保设备有限公司 +1

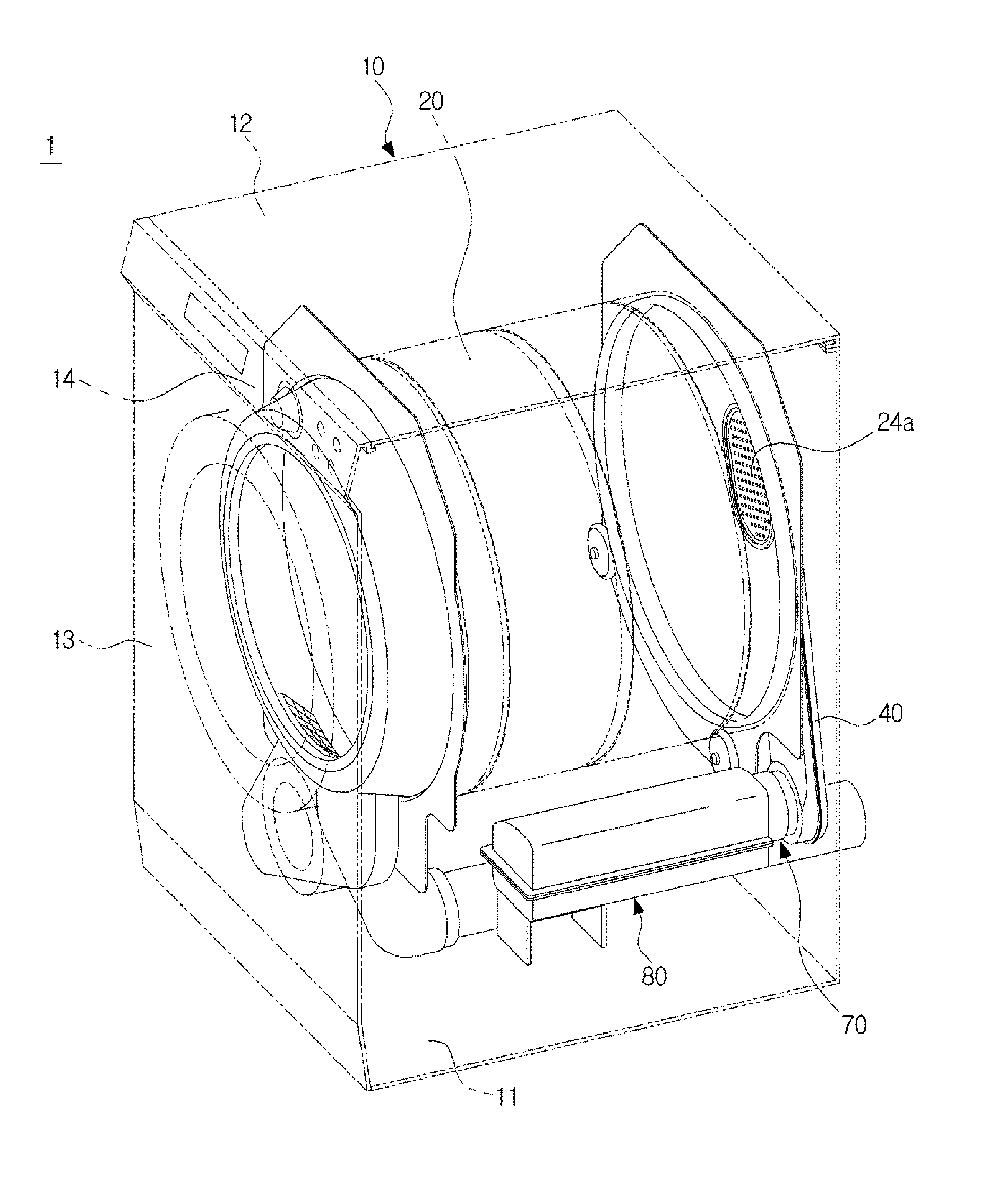

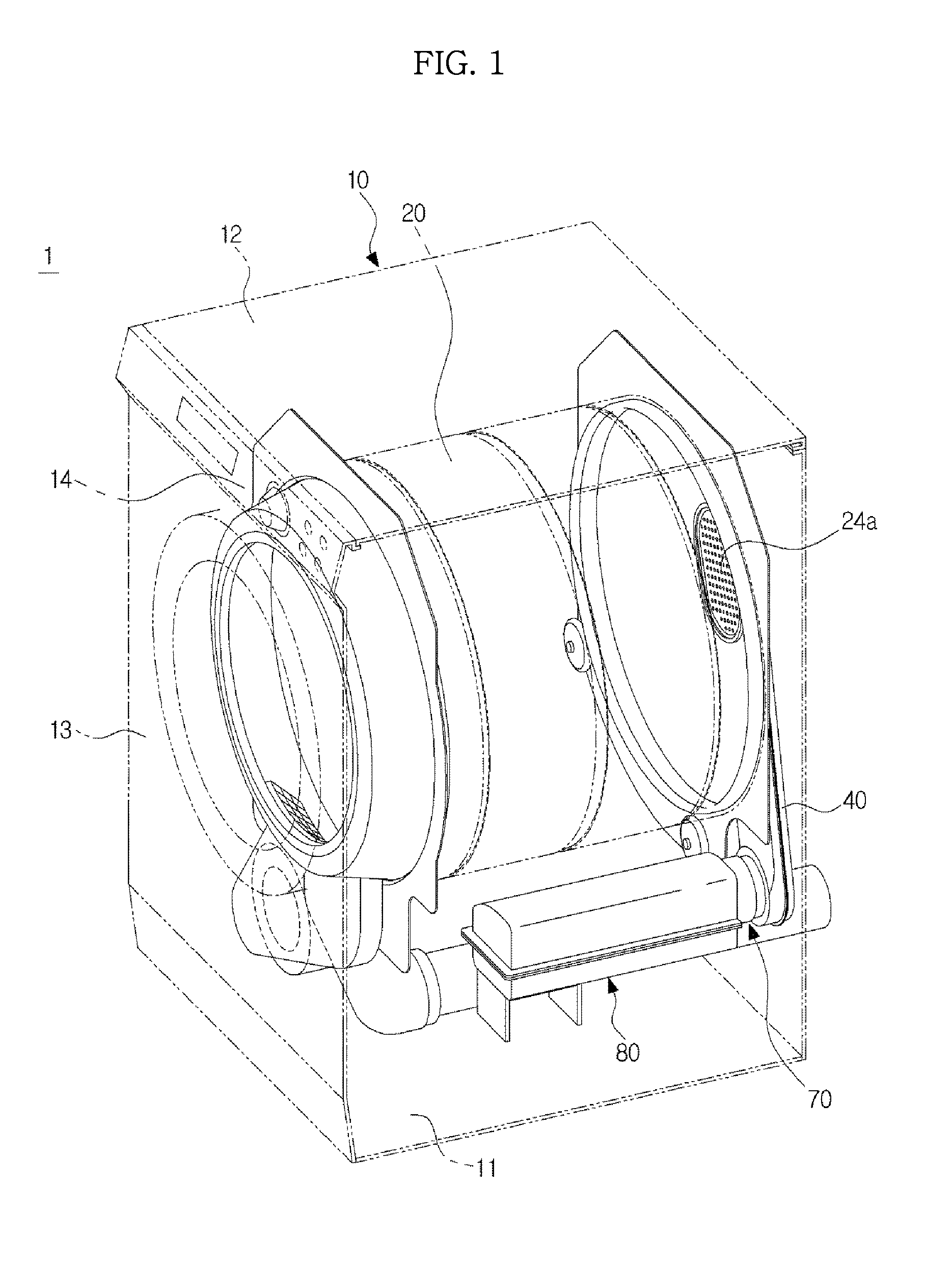

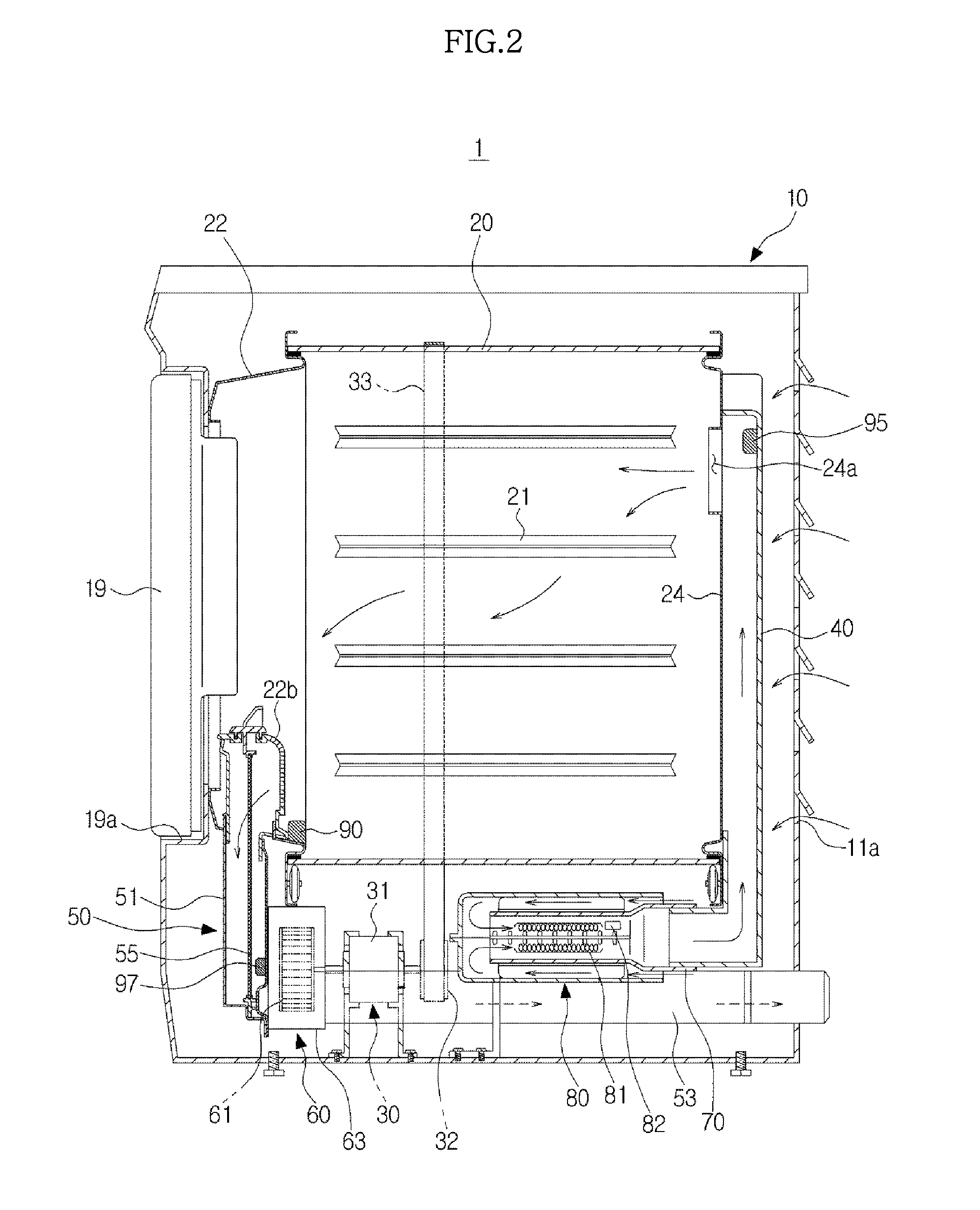

Clothing dryer and blockage detection method thereof

ActiveUS20130255101A1Improve user convenienceEasy to confirmDrying solid materials with heatTemperature measurement in household appliancesEngineering

A method for detecting a degree of blockage of an exhaust duct includes detecting the temperature of air in an intake and exhaust system, calculating a rate of change of the detected temperature, and determining a degree of blockage of the exhaust duct based on the detected temperature and the rate of change of the detected temperature.

Owner:SAMSUNG ELECTRONICS CO LTD

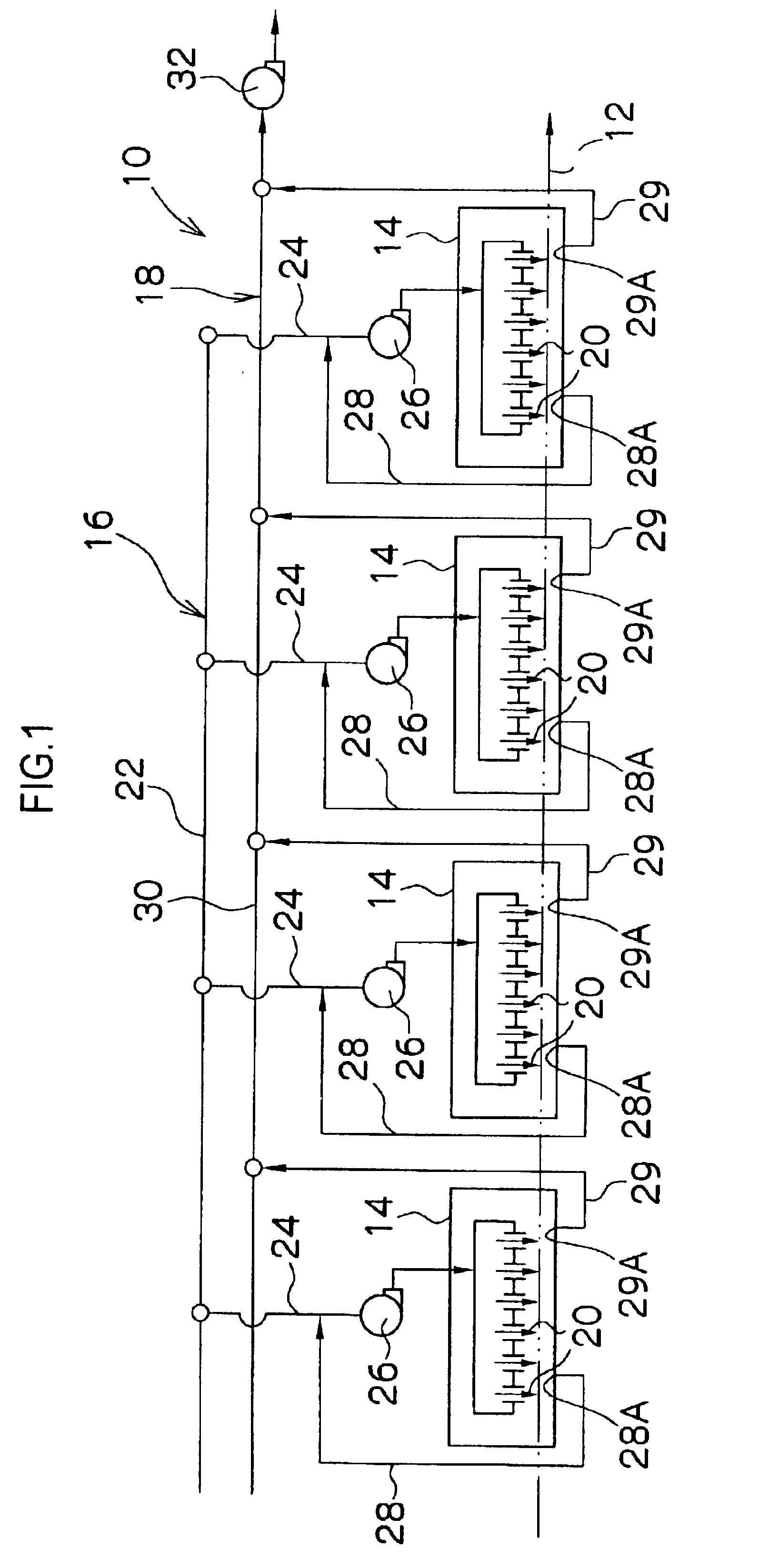

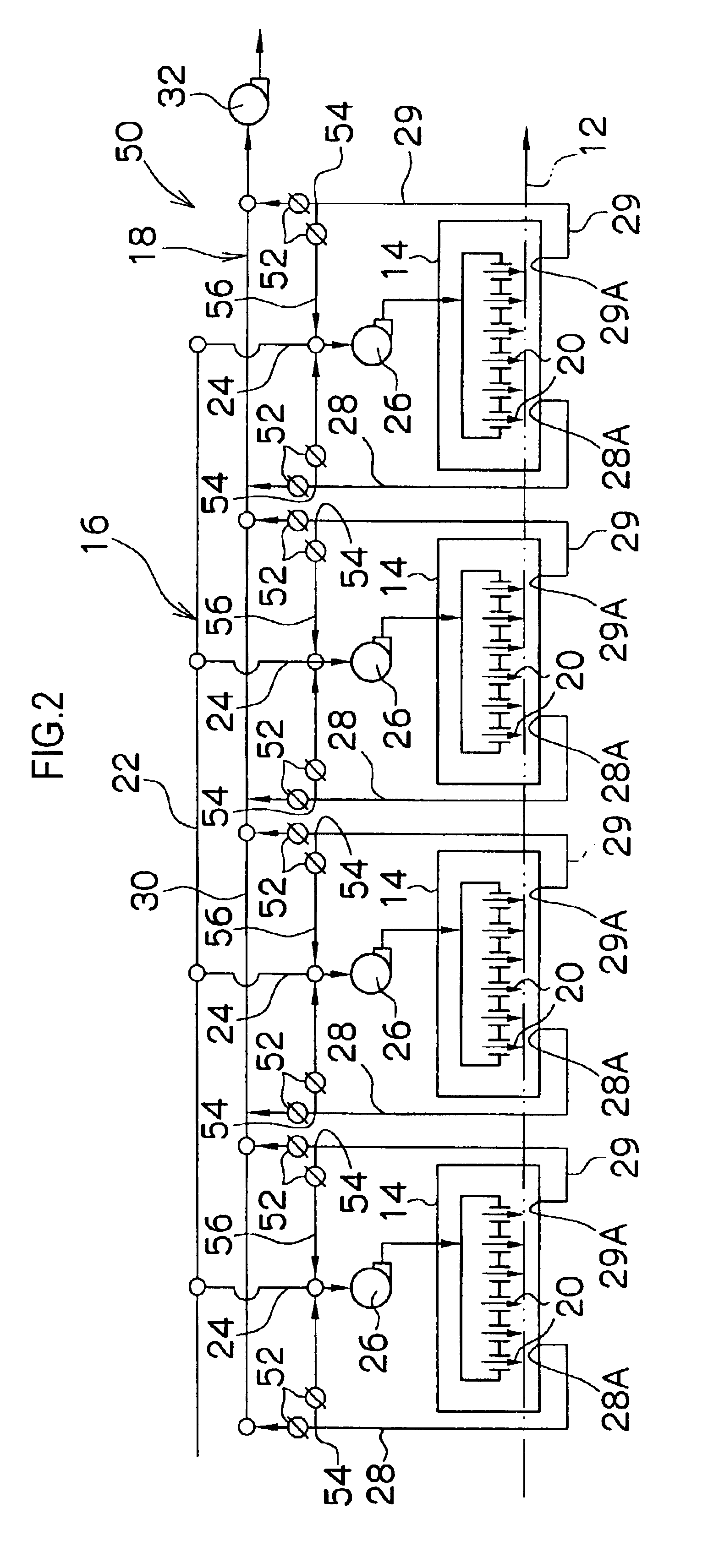

Drying apparatus

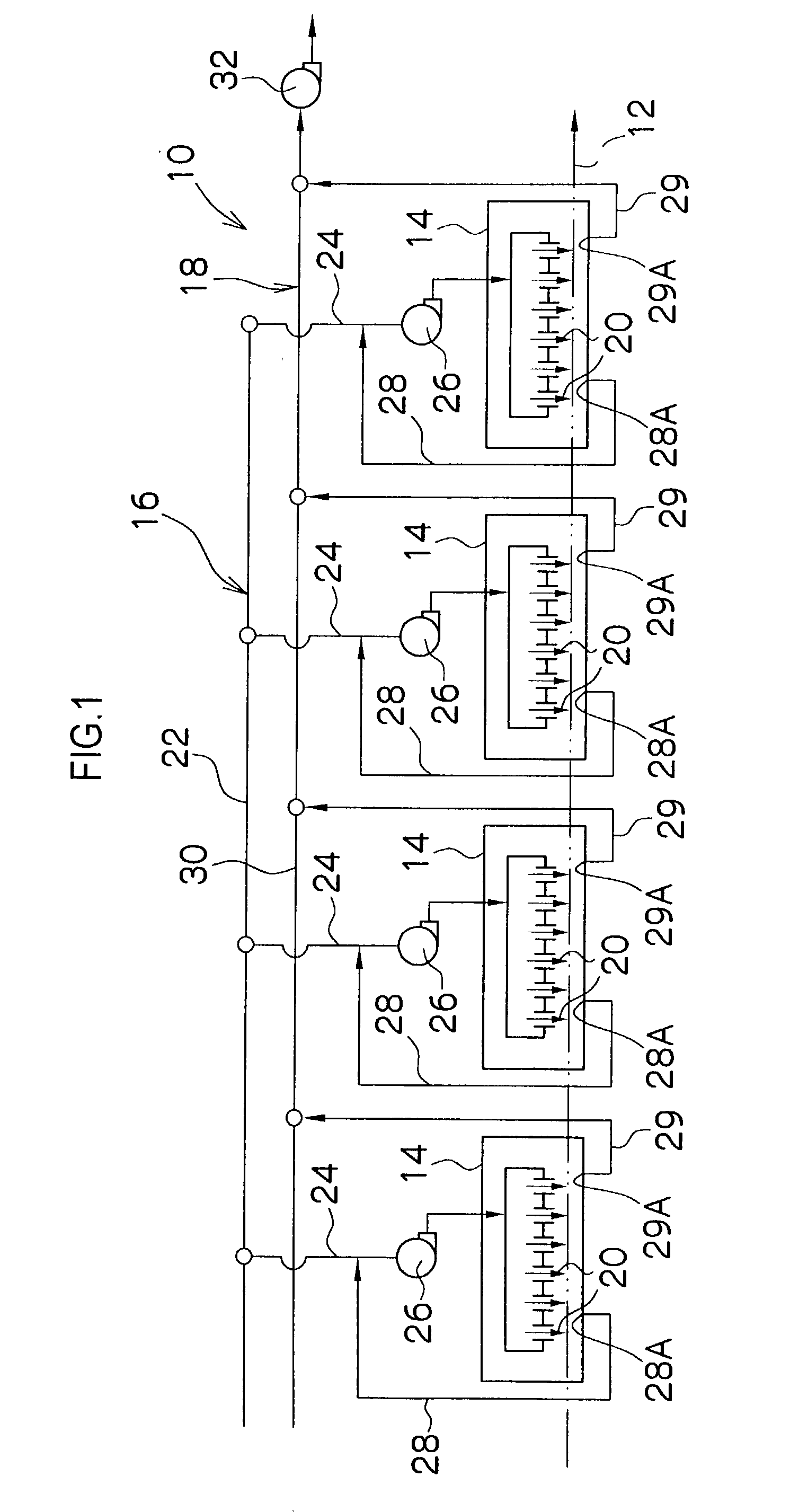

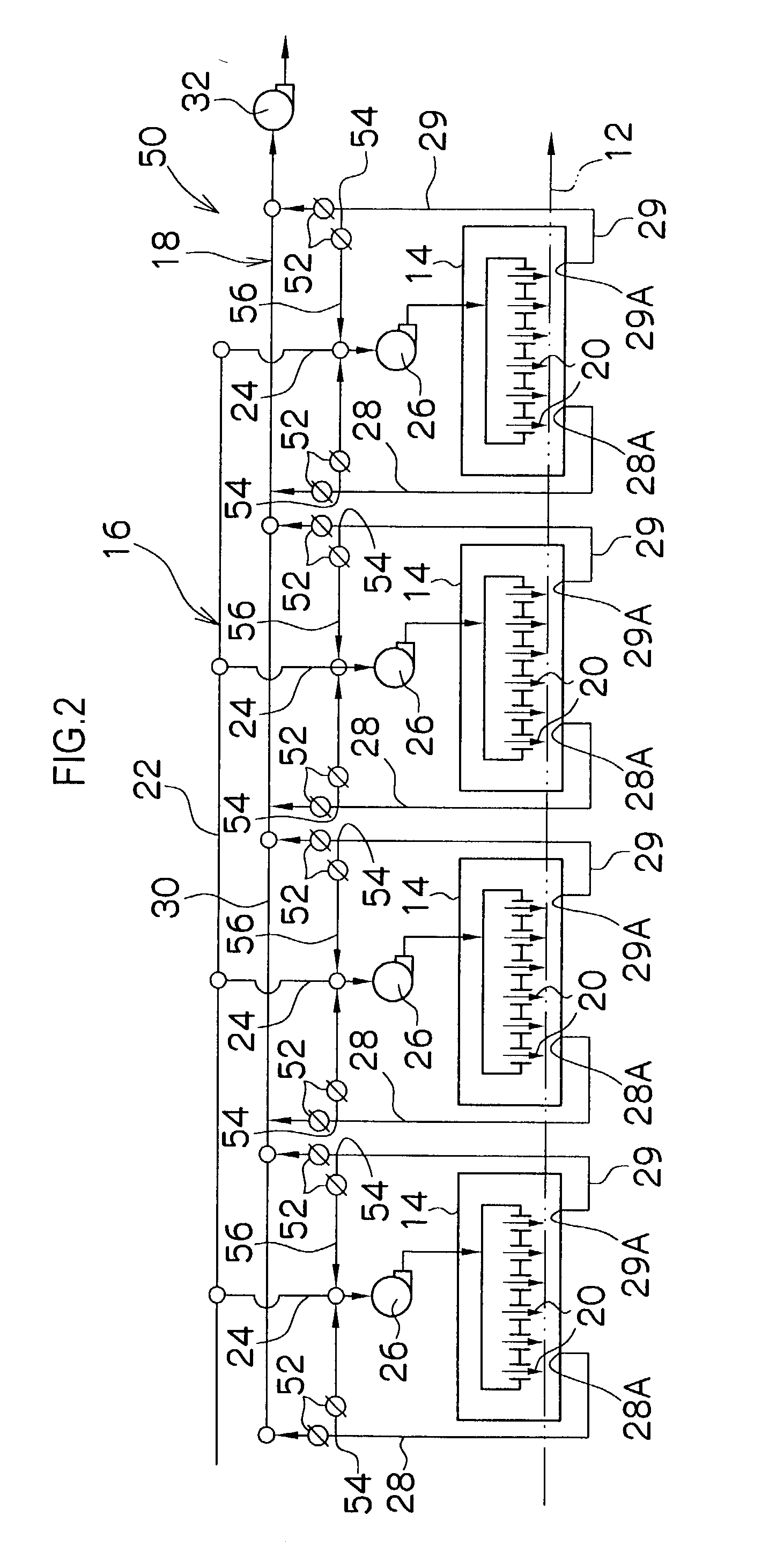

InactiveUS6735882B2Explosion proofing safetySimple configurationDrying gas arrangementsDrying chambers/containersExhaust fumesProduct gas

A concentration of a gas introduced into a circulation blower and an exhaust blower is reduced with a simple apparatus configuration. In an exhaust system, exhaust gases from a plurality of drying chambers are joined to a joining duct to be then exhausted by an exhaust blower. A plurality of exhaust ducts having inlets at different positions in each drying chamber are provided, and the exhaust duct having the inlet in the lowest gas concentration area is used as a duct for an exhaust gas circulated to a circulation blower.

Owner:FUJIFILM CORP +1

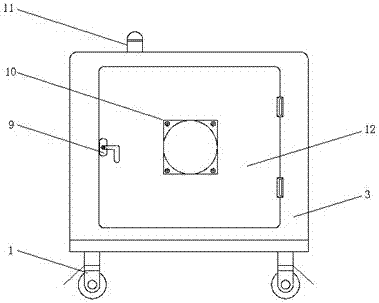

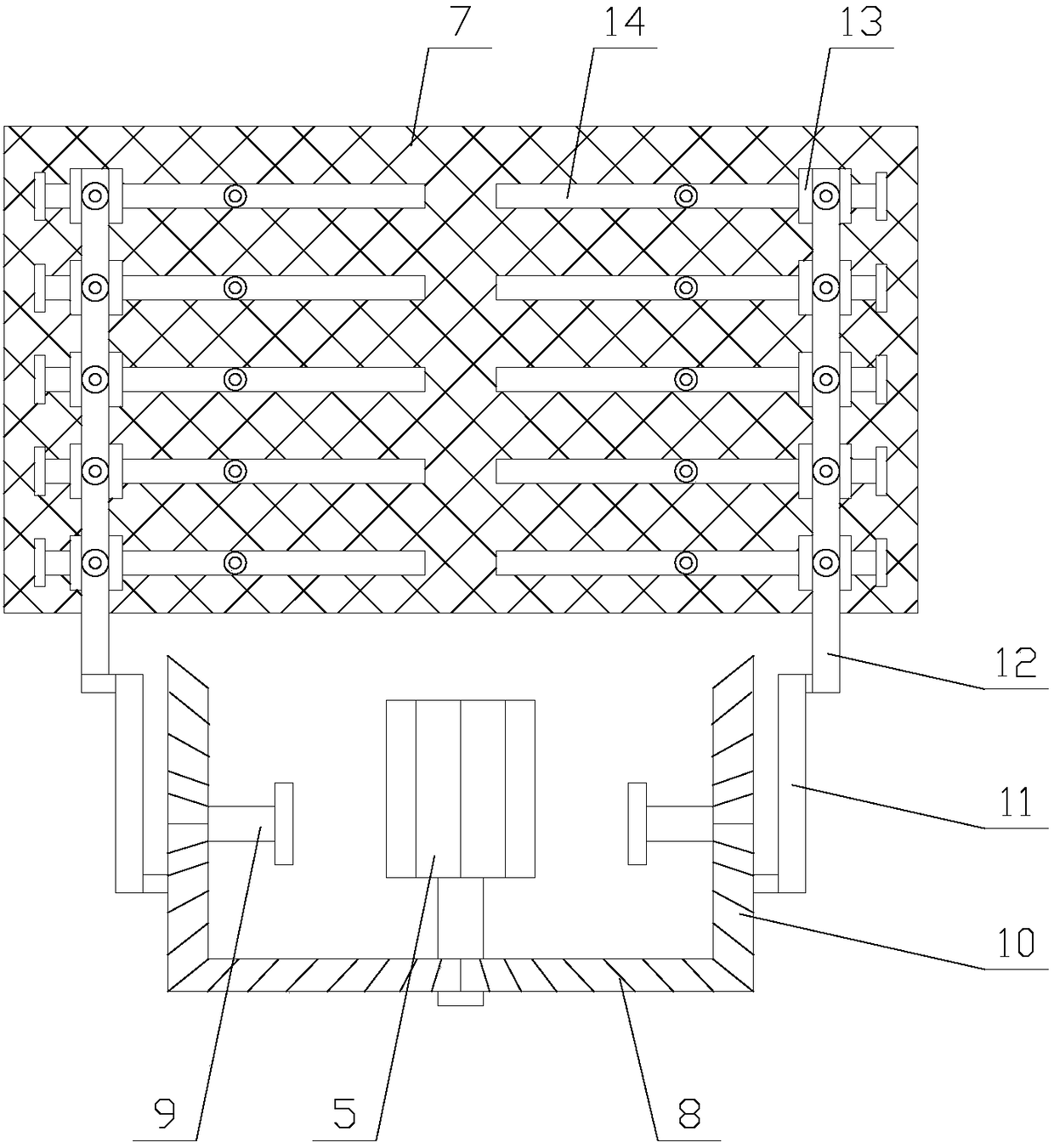

Wood drying equipment

InactiveCN107490270AKeep dryDry evenlyWood treatment detailsDrying gas arrangementsPulp and paper industryWood drying

The invention discloses wood drying equipment. The wood drying equipment comprises a base, a main box body and a supporting frame, the main box body is installed on the top of the base; a moving observing window is installed on the surface of the main box body through hinges, and a door body is installed on the surface of the other end of the main box body through hinges; a blower is installed at the bottom end in the main box body, and an air cavity is formed in the main box body on one side of the blower; a ventilating net is installed on the top part of the air cavity, and supporting frames are installed above the ventilating net; electric heating layers are installed on the bottom parts of the supporting frames, and motors are installed in the supporting frames; and electric telescopic rods are installed in the supporting frames on the two sides of each motor, and lifting platforms are installed on the top ends of the electric telescopic rods through bolts. According to the wood drying equipment, a series of structures are arranged, so that during the wood drying process, wood heating and drying by gear shifting is facilitated specific to characteristics of all woods, a compound type drying method is adopted, and the drying quality of the woods is guaranteed.

Owner:湖州南浔研艺斋工艺品有限公司

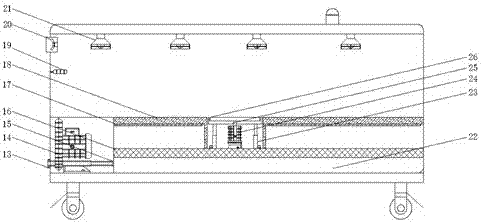

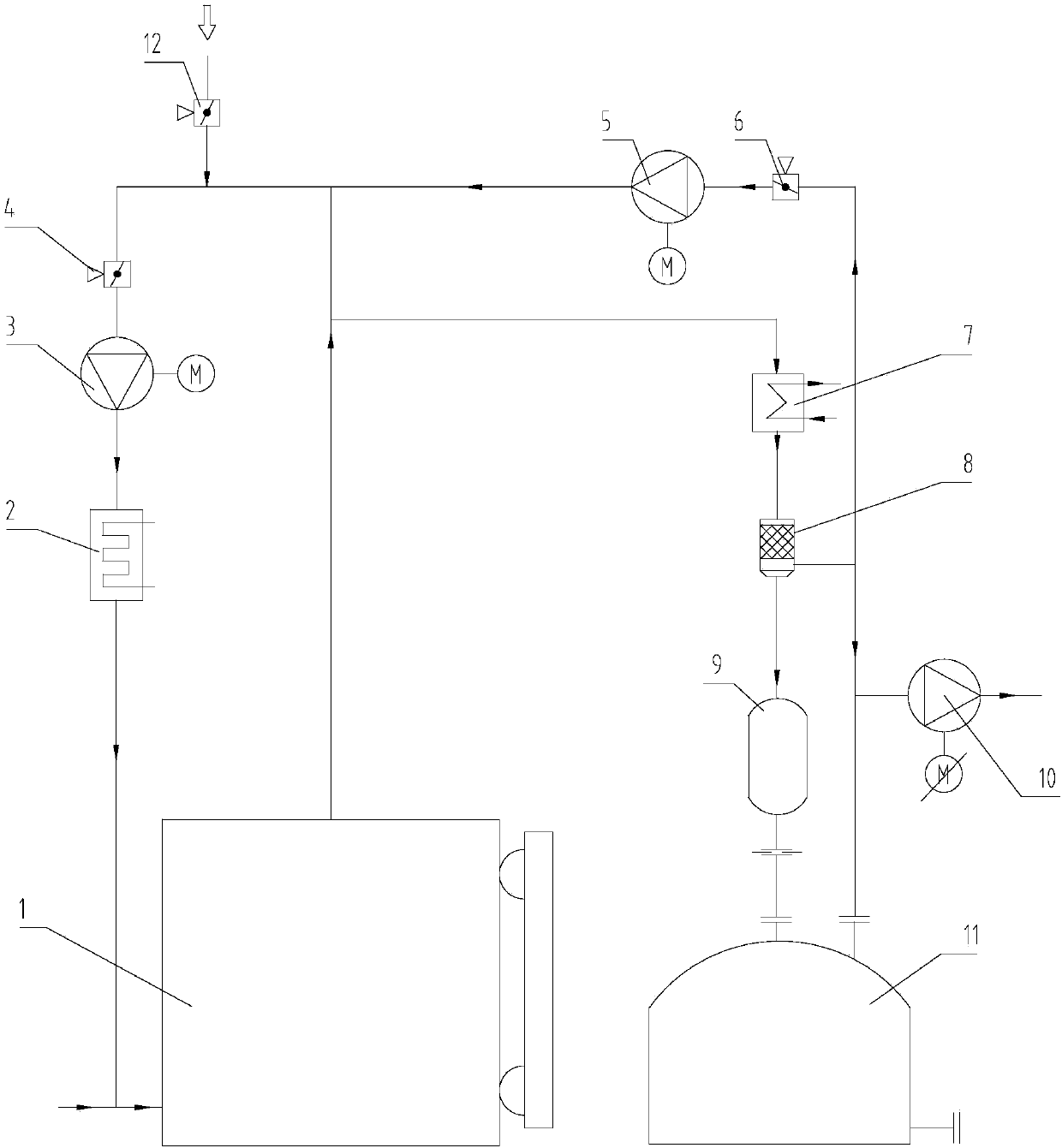

Drying system in radioactive solid waste furnace and drying method

InactiveCN107830698APrevent leakageAvoid effluxDrying solid materials without heatDrying gas arrangementsRadioactive gasVacuum pumping

The invention relates to a drying system in a radioactive solid waste furnace, meanwhile relates to a corresponding drying method, and belongs to the technical field of radioactive waste treatment. The system comprises a drying furnace and a condensate box; the drying furnace is provided with a main circulation loop and a flow dividing pipeline, wherein the top of the main circulation loop is connected to one side of the drying furnace through a heating draught fan and a heater which are in series connection, and the flow dividing pipeline is connected to the condensate box through a cooler, asteam and water separator and a metering device, a gas outlet of the steam and water separator is connected to the main circulation loop through a cooling draught fan to form an air returning pipeline, the cooling draught and the heating draught fan are each provided with a corresponding adjusting valve, and the condensate box and a gas outlet of the gas and water separator are connected with a vacuum pumping device to form a vacuum generation passage. Discharging of radioactive gas in the drying process can be effectively avoided, air utilization rate is improved, energy consumption is saved, and secondary pollutions can be obviously reduced.

Owner:AEROSUN CORP +1

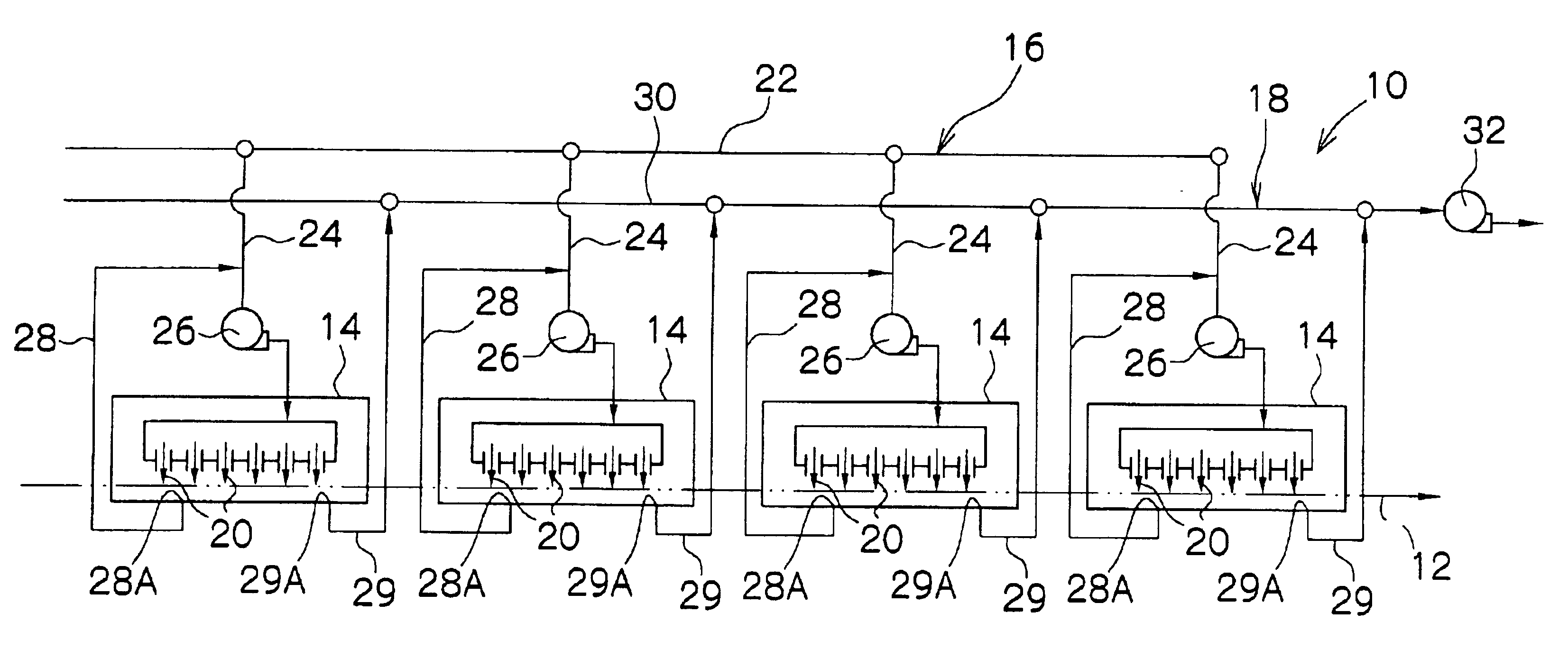

Drying apparatus

InactiveUS20030079372A1Explosion proofing safetySimple configurationDrying gas arrangementsDrying chambers/containersExhaust fumesGas concentration

A concentration of a gas introduced into a circulation blower and an exhaust blower is reduced with a simple apparatus configuration. In an exhaust system, exhaust gases from a plurality of drying chambers are joined to a joining duct to be then exhausted by an exhaust blower. A plurality of exhaust ducts having inlets at different positions in each drying chamber are provided, and the exhaust duct having the inlet in the lowest gas concentration area is used as a duct for an exhaust gas circulated to a circulation blower.

Owner:FUJIFILM CORP +1

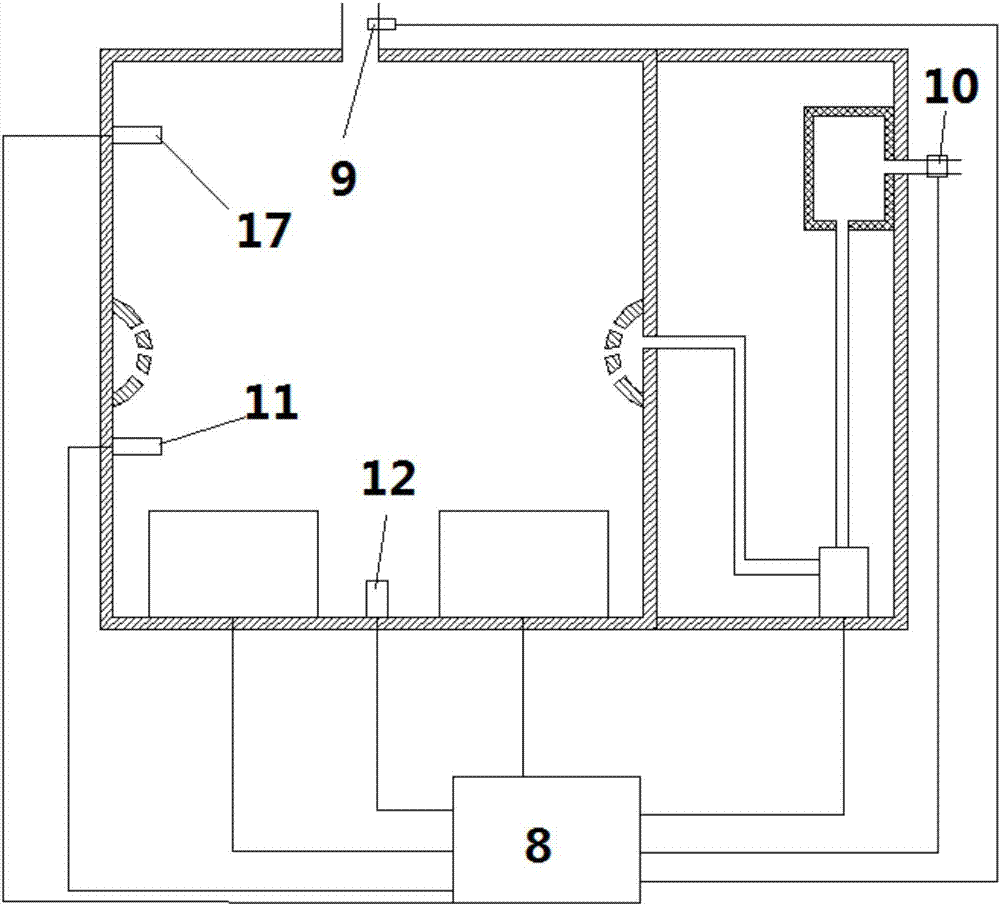

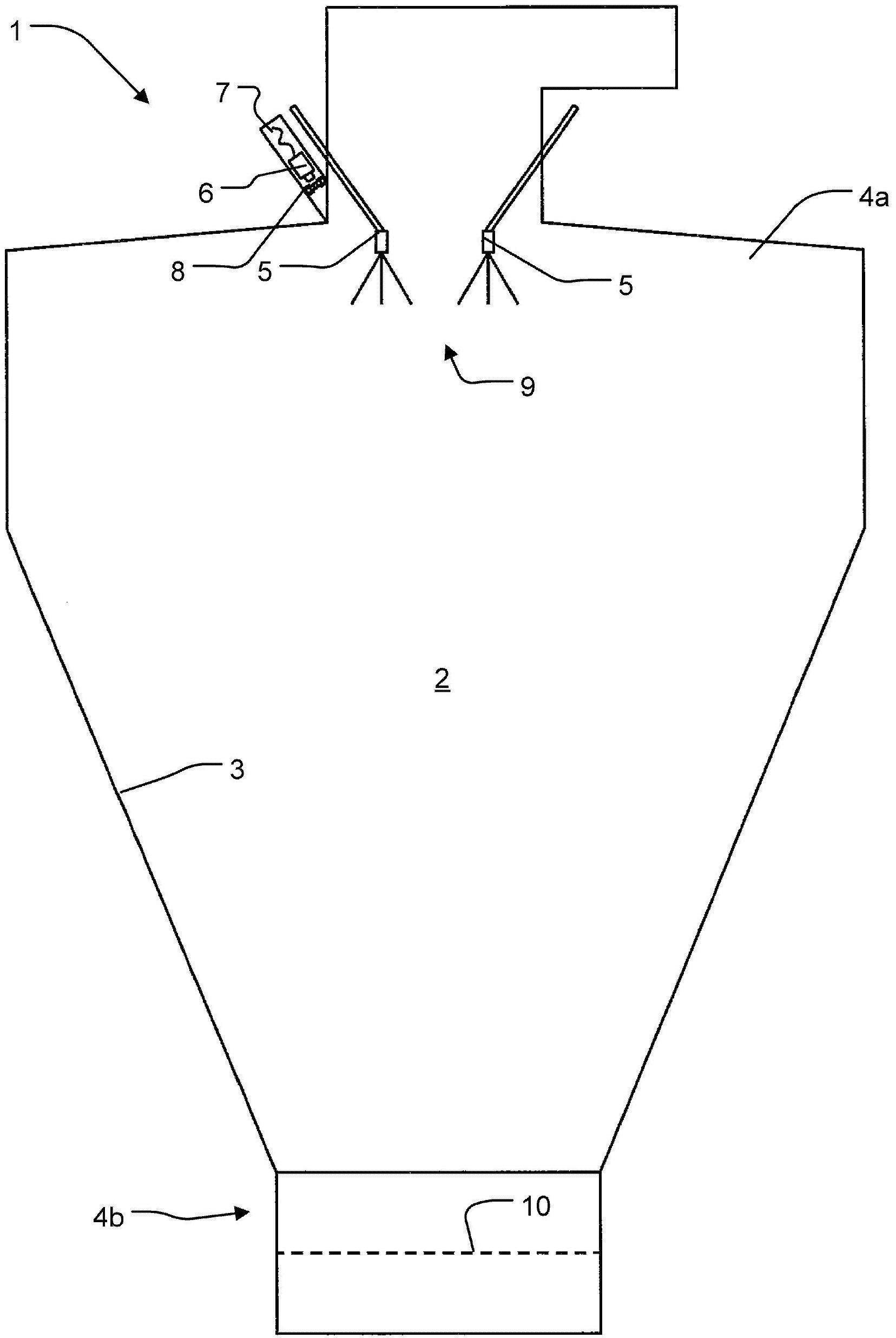

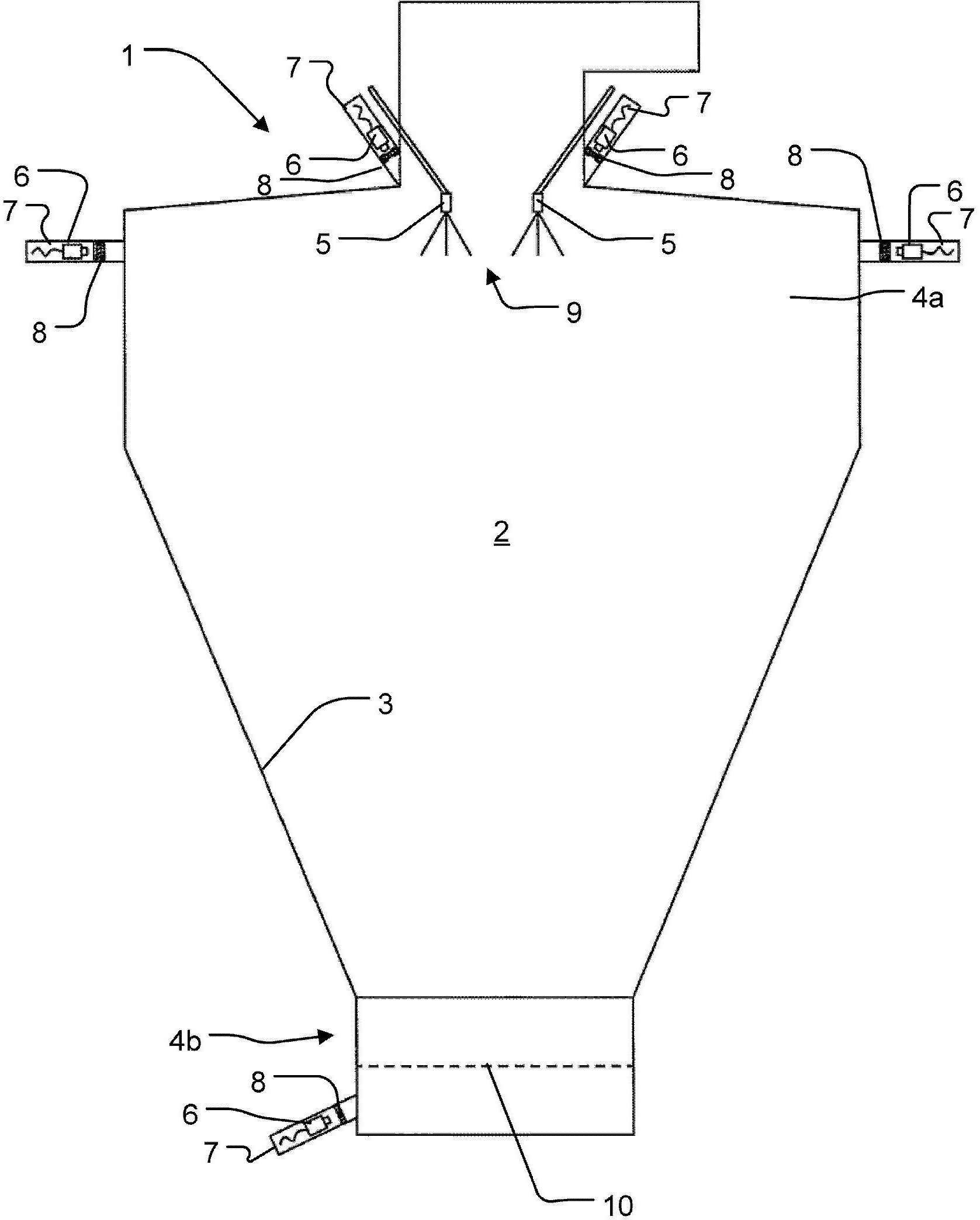

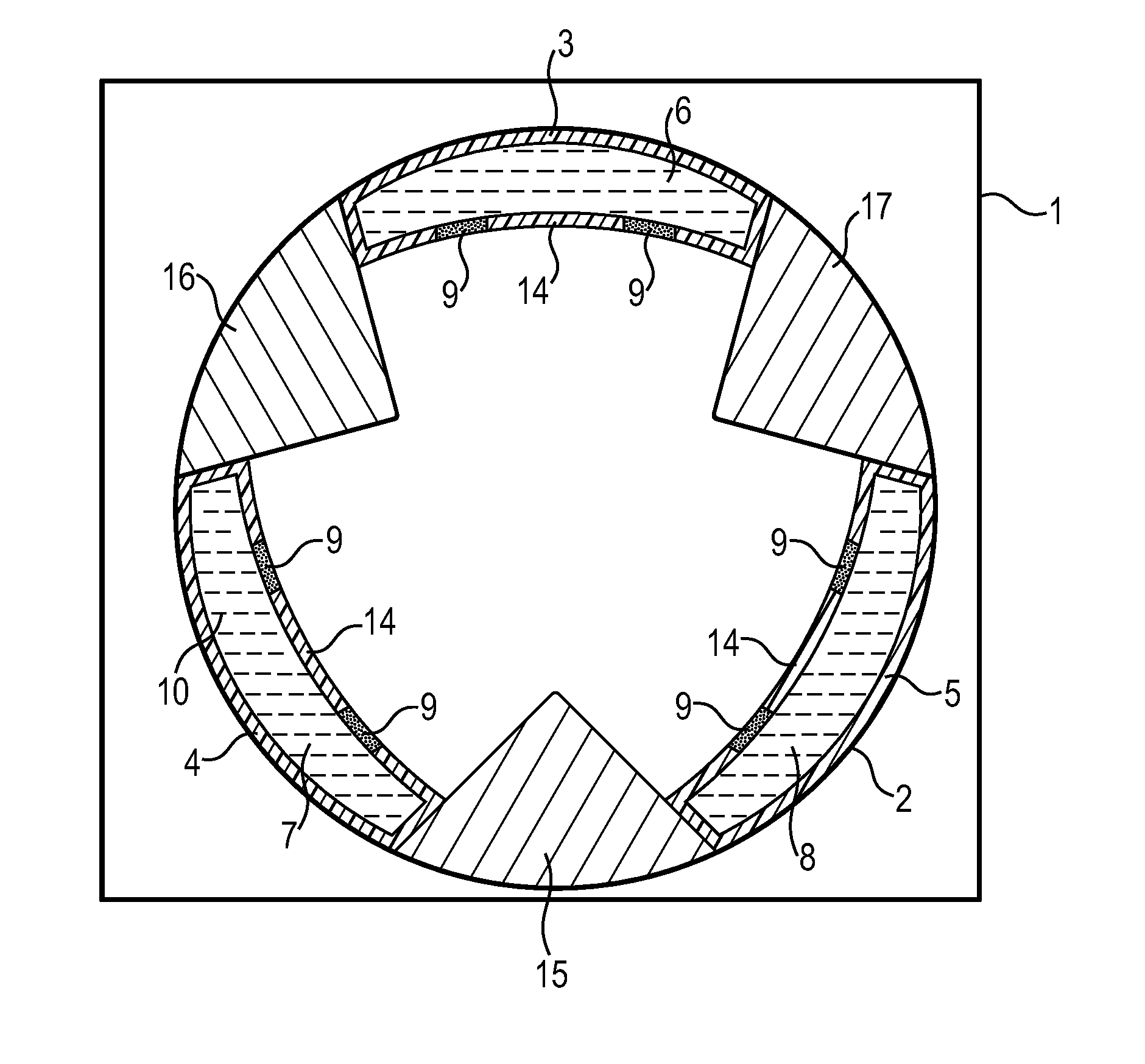

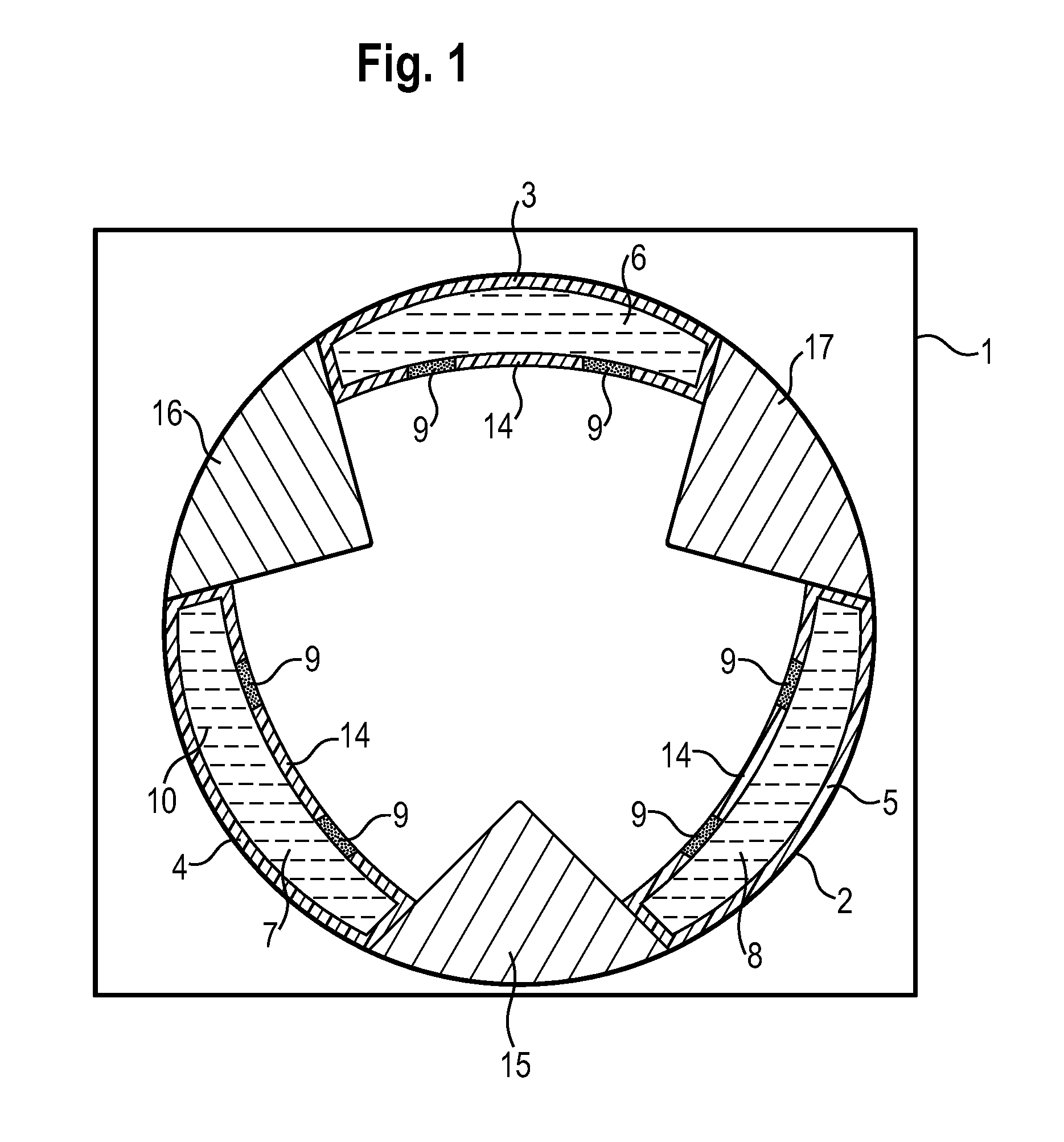

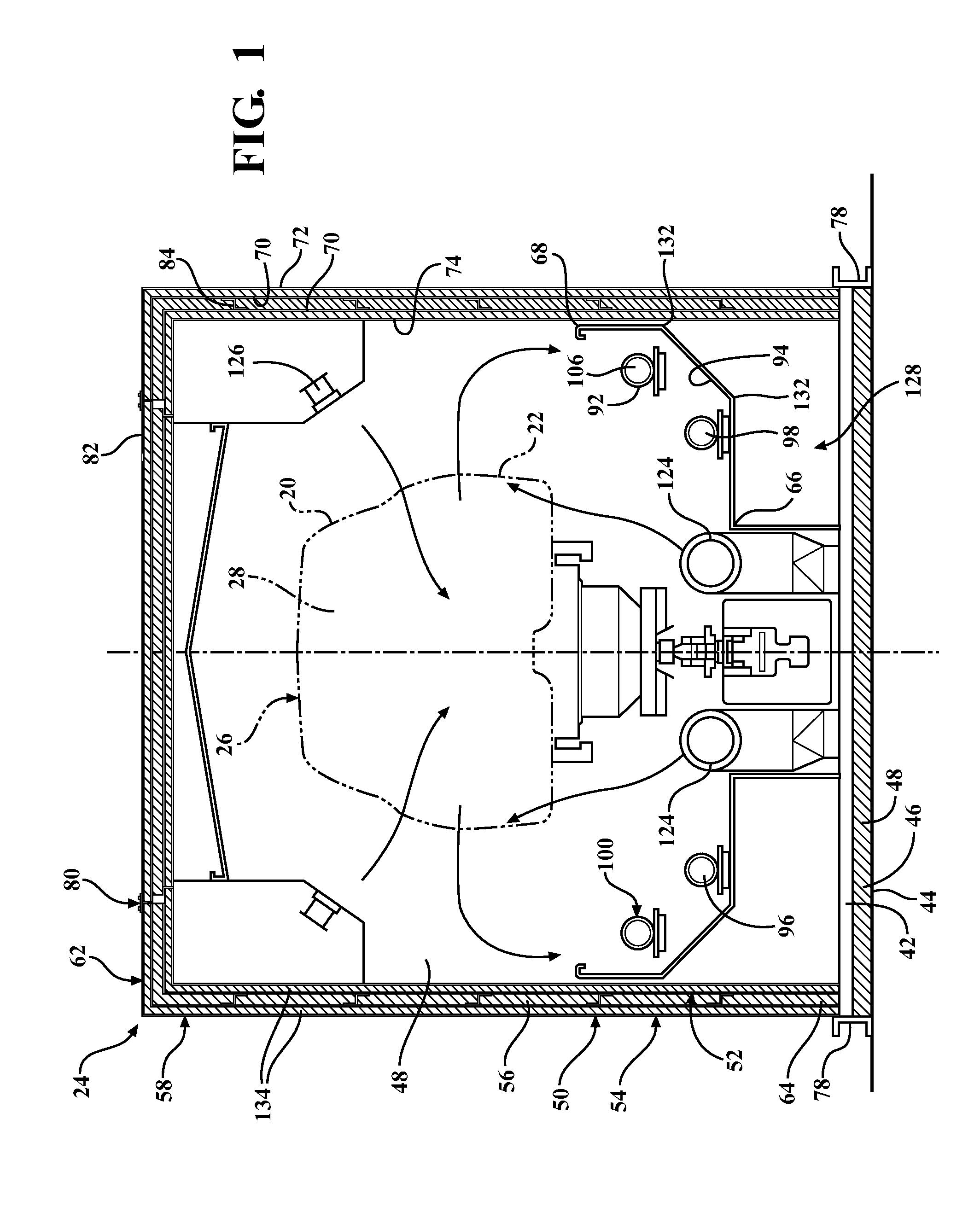

A method of monitoring a spray dryer and a spray dryer comprising one or more infrared cameras

ActiveCN102648041ADrying solid materials with heatSpraying apparatusMechanical engineeringSpray dryer

The spray dryer (1) comprises a spray drying chamber(2)having a substantially cylindrical top section (4a), a conical wall (3)and a narrowed lower section (4b). In the top section (4a), atomizing means (9)is provided. One or more cameras (6) are associated with the drying chamber (2) in order to monitor the process. At least one of the cameras is an infrared camera adapted for measuring the temperature within a predefined area.

Owner:GEA PROCESS ENG

Drying device for production of automobile spare parts

InactiveCN108413758AImprove practicalityImprove reliabilityDrying gas arrangementsFire rescueAir Pump AssemblySpare part

The invention relates to a drying device for production of automobile spare parts. The drying device comprises a main body, and further comprises a purifying mechanism and a fire extinguishing mechanism, wherein the purifying mechanism comprises a purifying chamber, a dust removing assembly and a drying assembly, and the fire extinguishing mechanism comprises a spray assembly and an air pumping assembly. According to the drying device for the production of the automobile spare parts, air can be dedusted and heated by the purifying mechanism, compared with an existing drying device, the situation that dust in the air being sucked on the surfaces of the spare parts affects subsequent surface treatment of some precision spare parts can be avoided, the role of preheating the air is achieved, and the drying device is more energy saving and environmentally friendlier; self-igniting spare parts can be extinguished through the fire extinguishing mechanism, and harmful gases in the main body can be removed; and compared with the existing device, the fire extinguishing effect is better, harm caused by the harmful gases to a human body is reduced, the drying device is safer and more reliable,and the practicability and reliability of the drying device are greatly improved.

Owner:泉州德化宇胜技术咨询有限公司

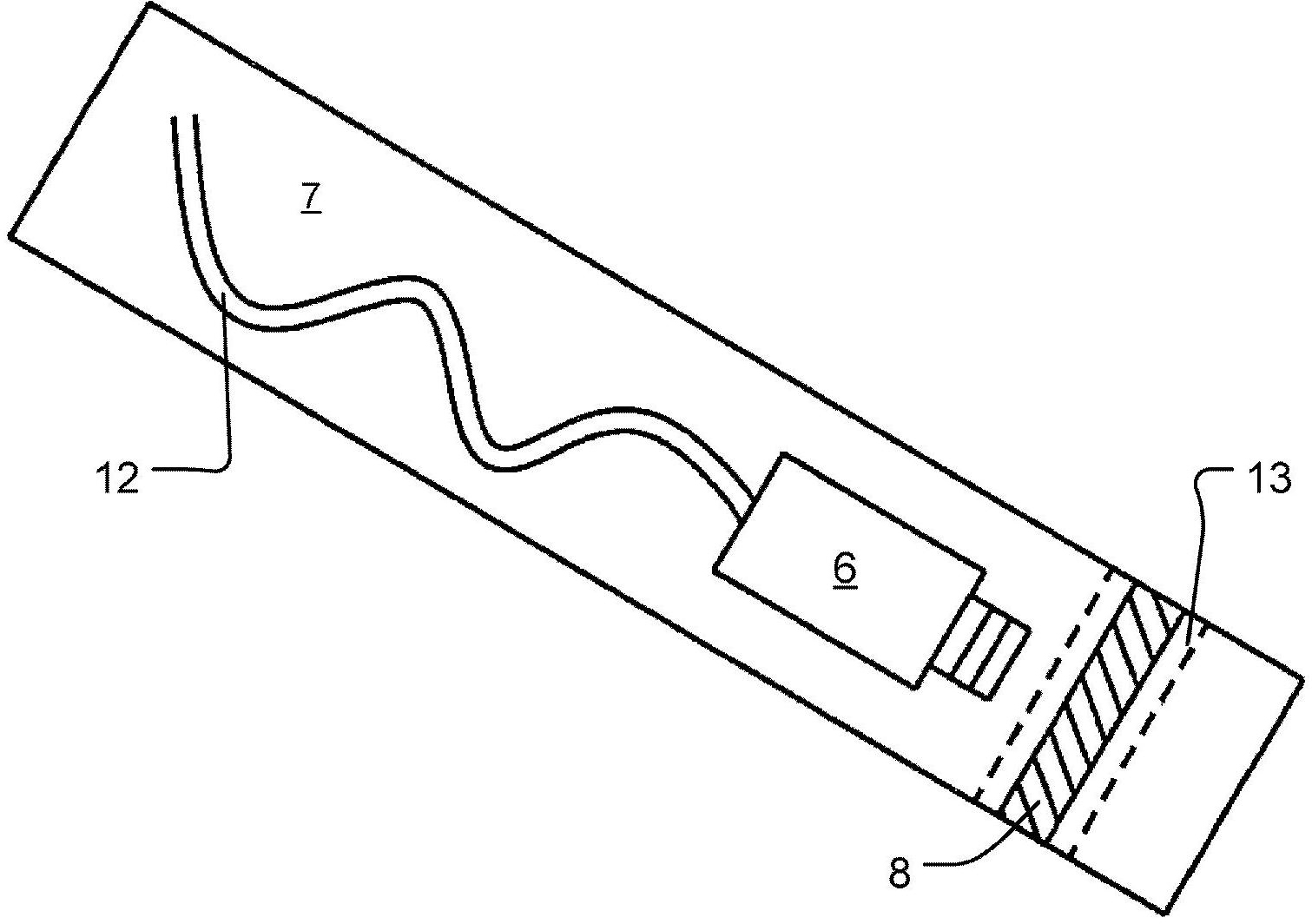

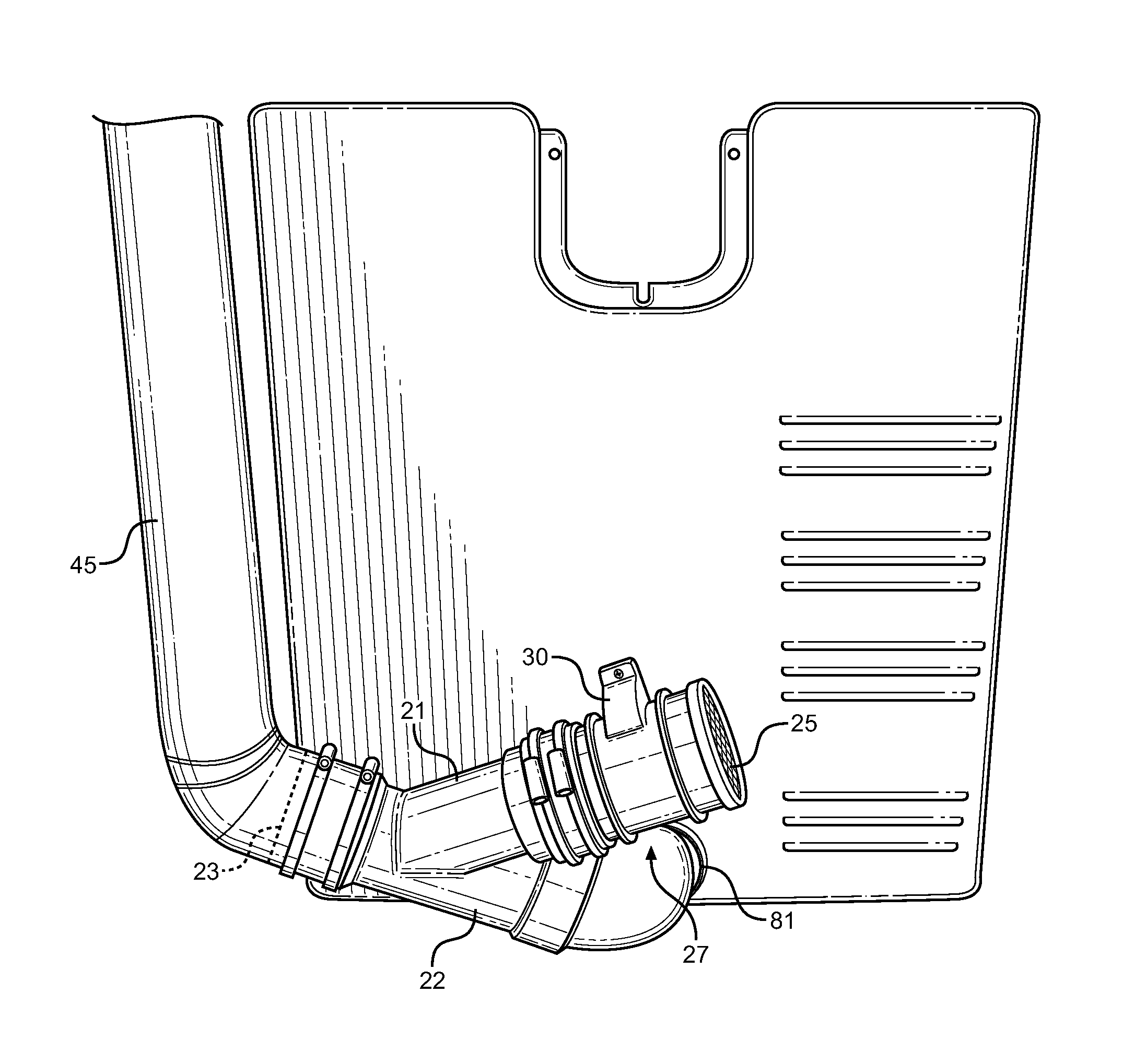

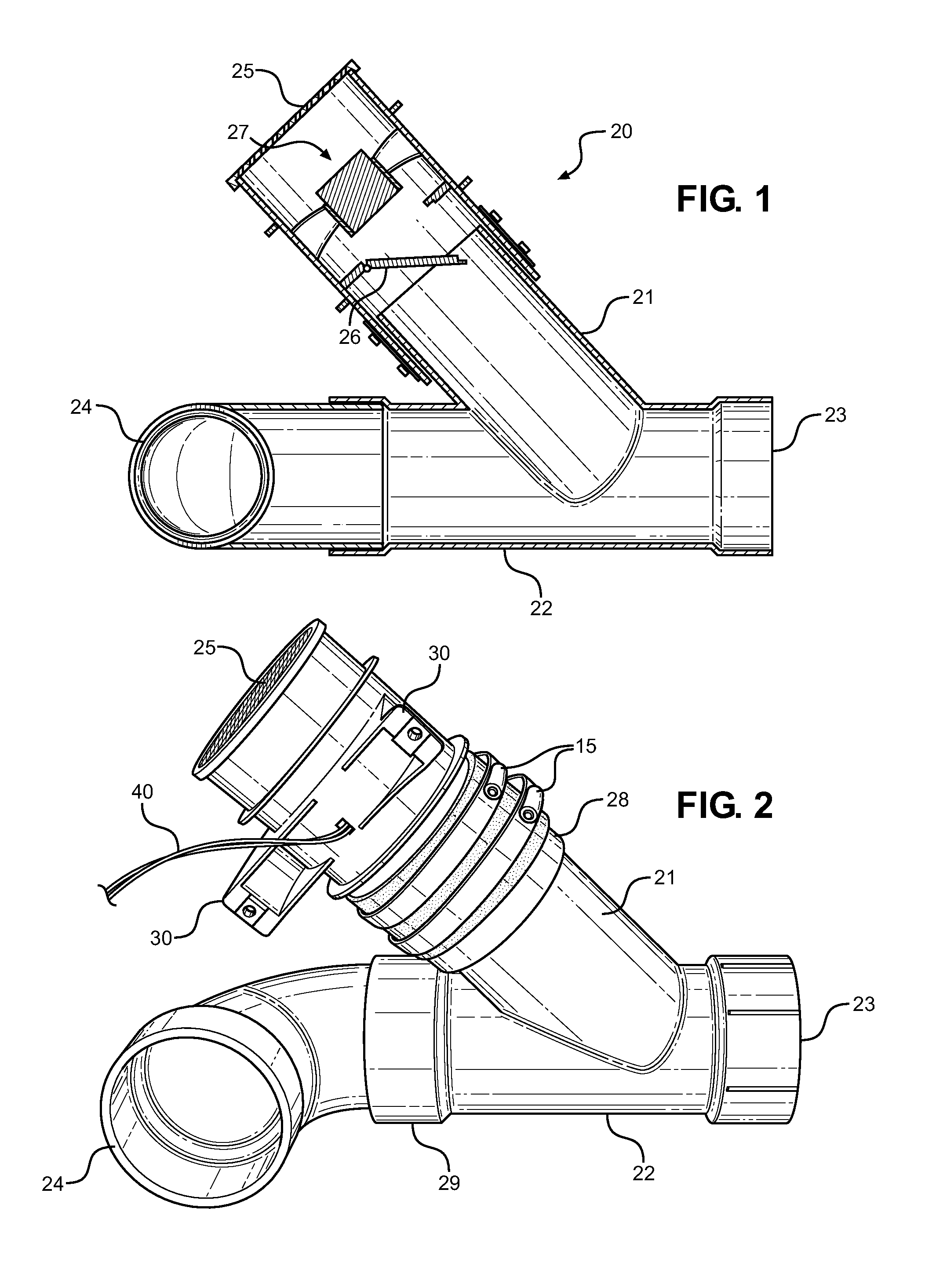

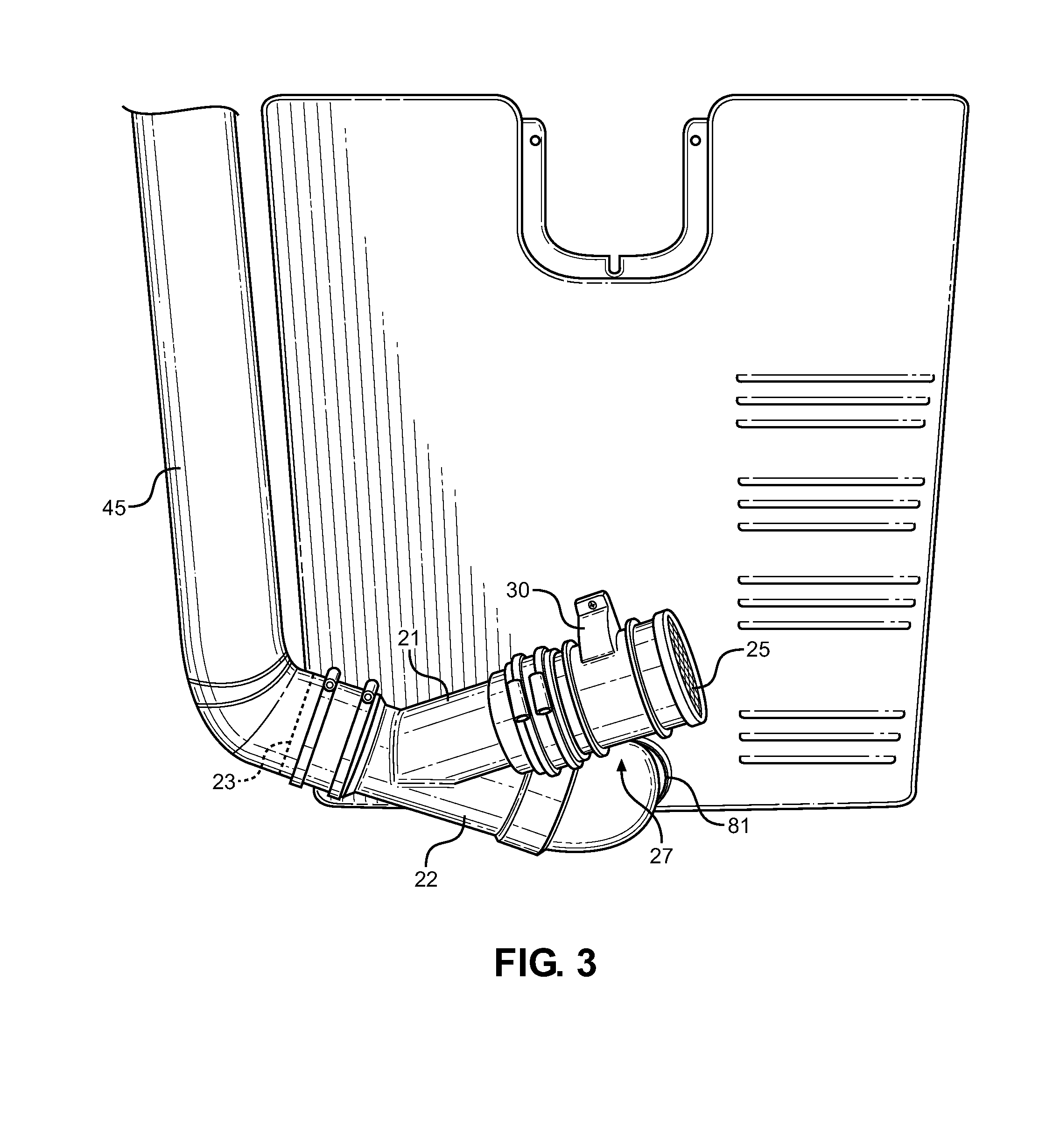

Clothes Dryer Exhaust Device

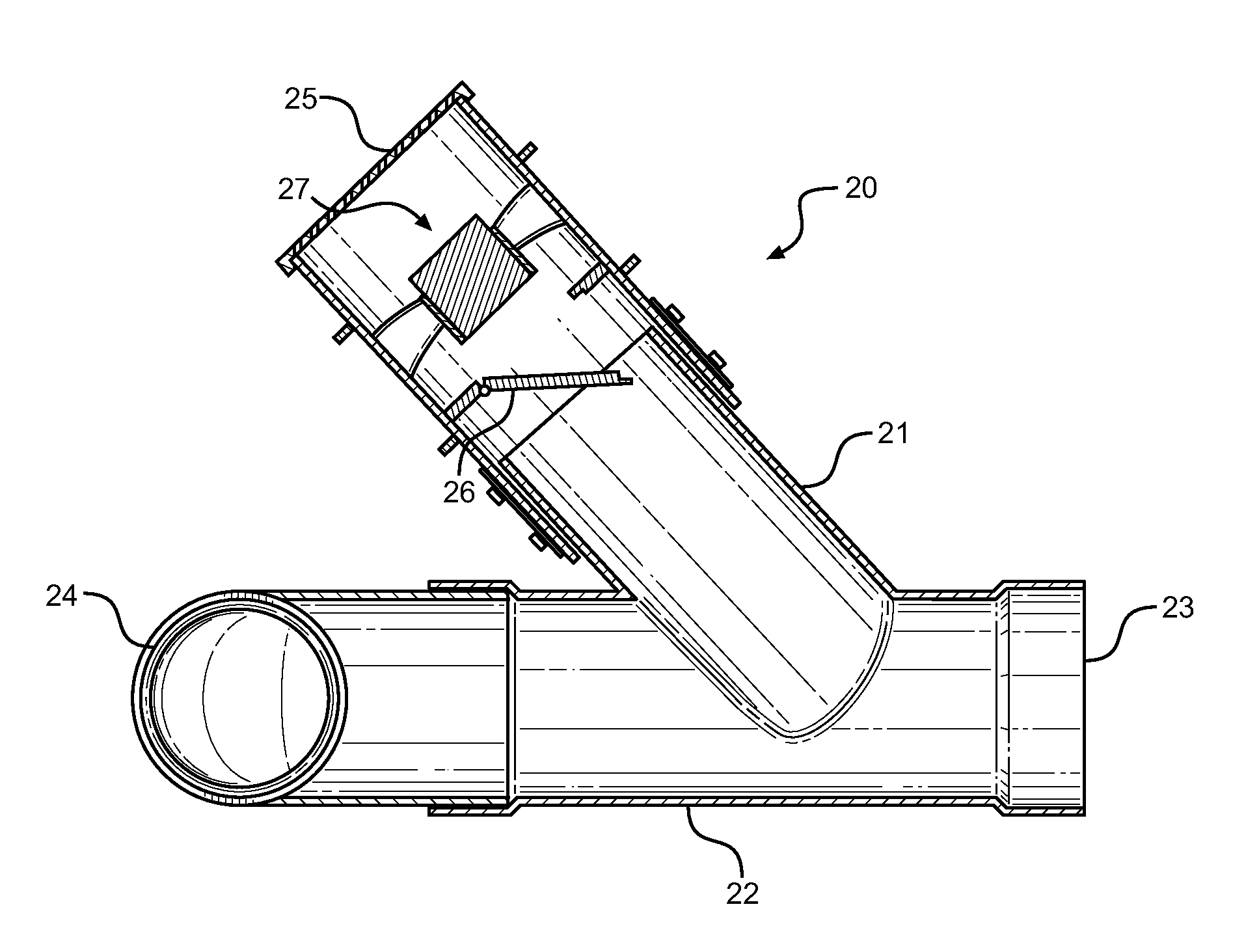

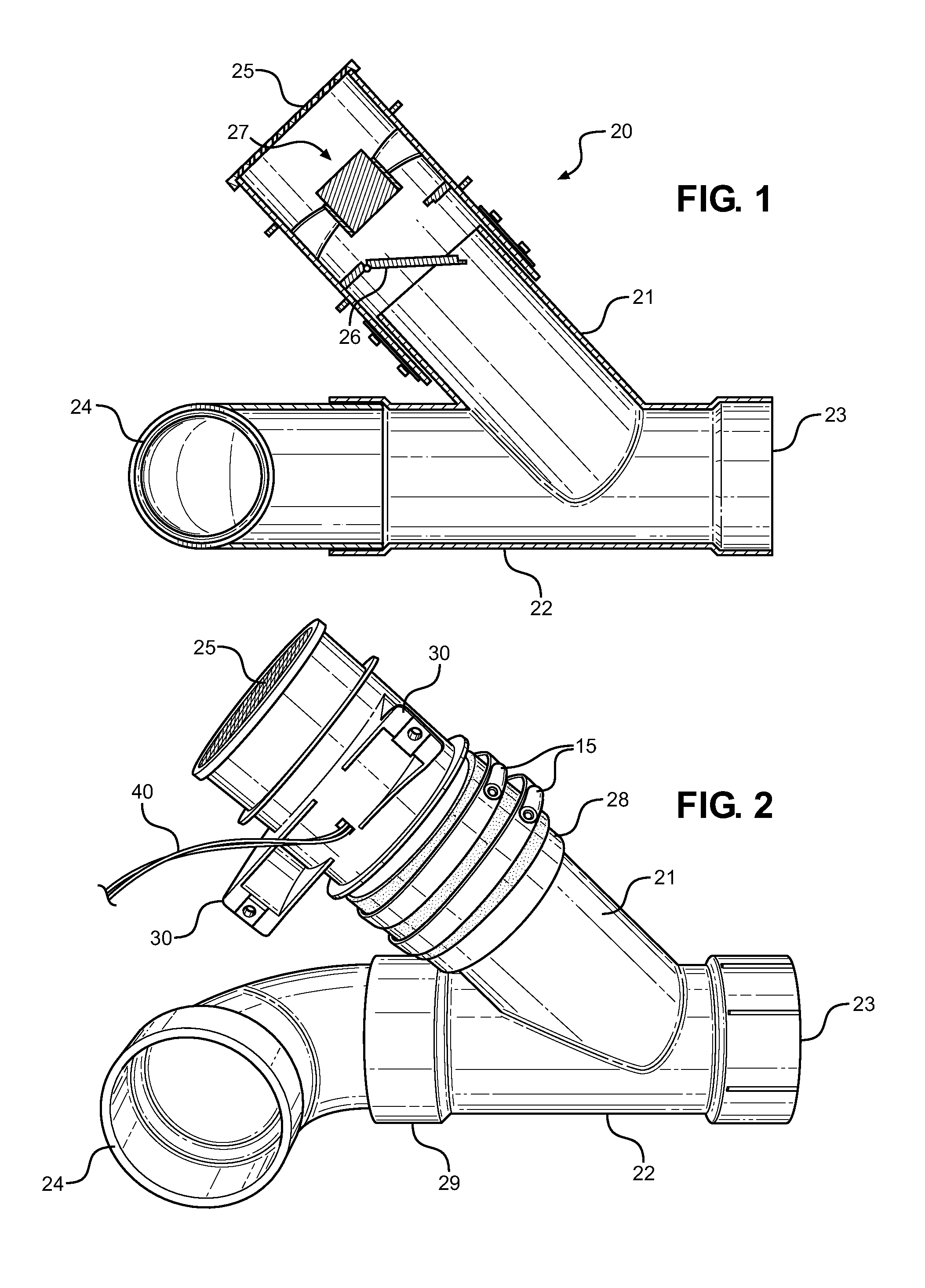

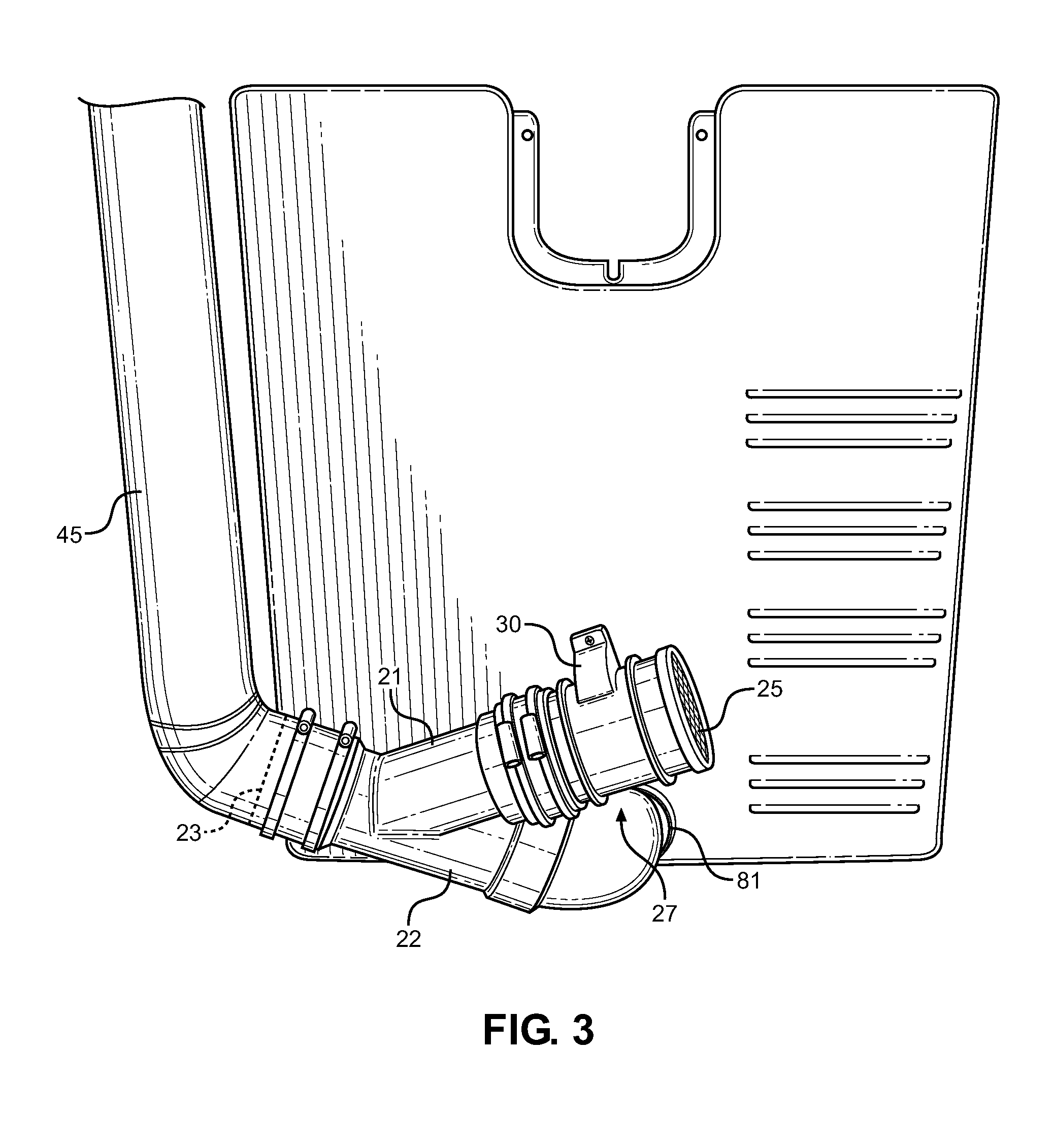

ActiveUS20140082956A1Provide convenienceImprove efficiencyDrying gas arrangementsDrying safety systemsPulp and paper industry

A clothes dryer exhaust line blower system is provided that assists a clothes dryer venting hot air and lint from the dryer interior and through the length of the dryer ducting to maintain a clear pathway and maintain the dryer's efficiency over time. A Y-pipe having a main exhaust line and an intermediate line is installed on the dryer exhaust port and connects the dryer exhaust outlet to an existing dryer duct that is adapted to communicate dryer exhaust from the dryer to the exterior of a dwelling. An intermediate section of the Y-pipe connection includes an electric blower assembly that functions as an auxiliary venting means, which generates air pressure to assist the dryer assembly vent the heated air through the exhaust conduit during the drying process. The blower is electrically driven and is controlled via a manual switch or timer switch that functions in conjunction with the drying cycles of the dryer.

Owner:SULLIVAN LOWELL R

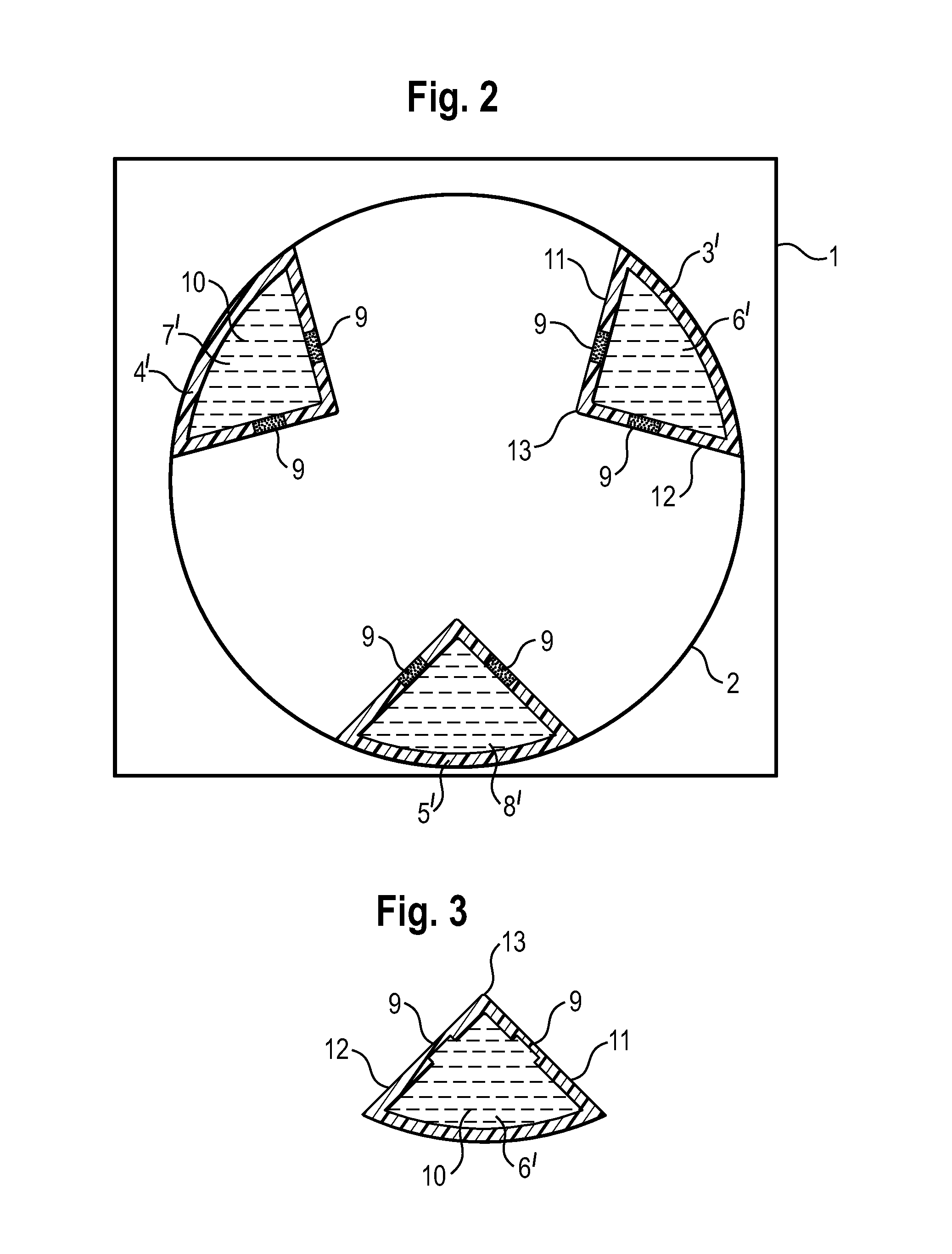

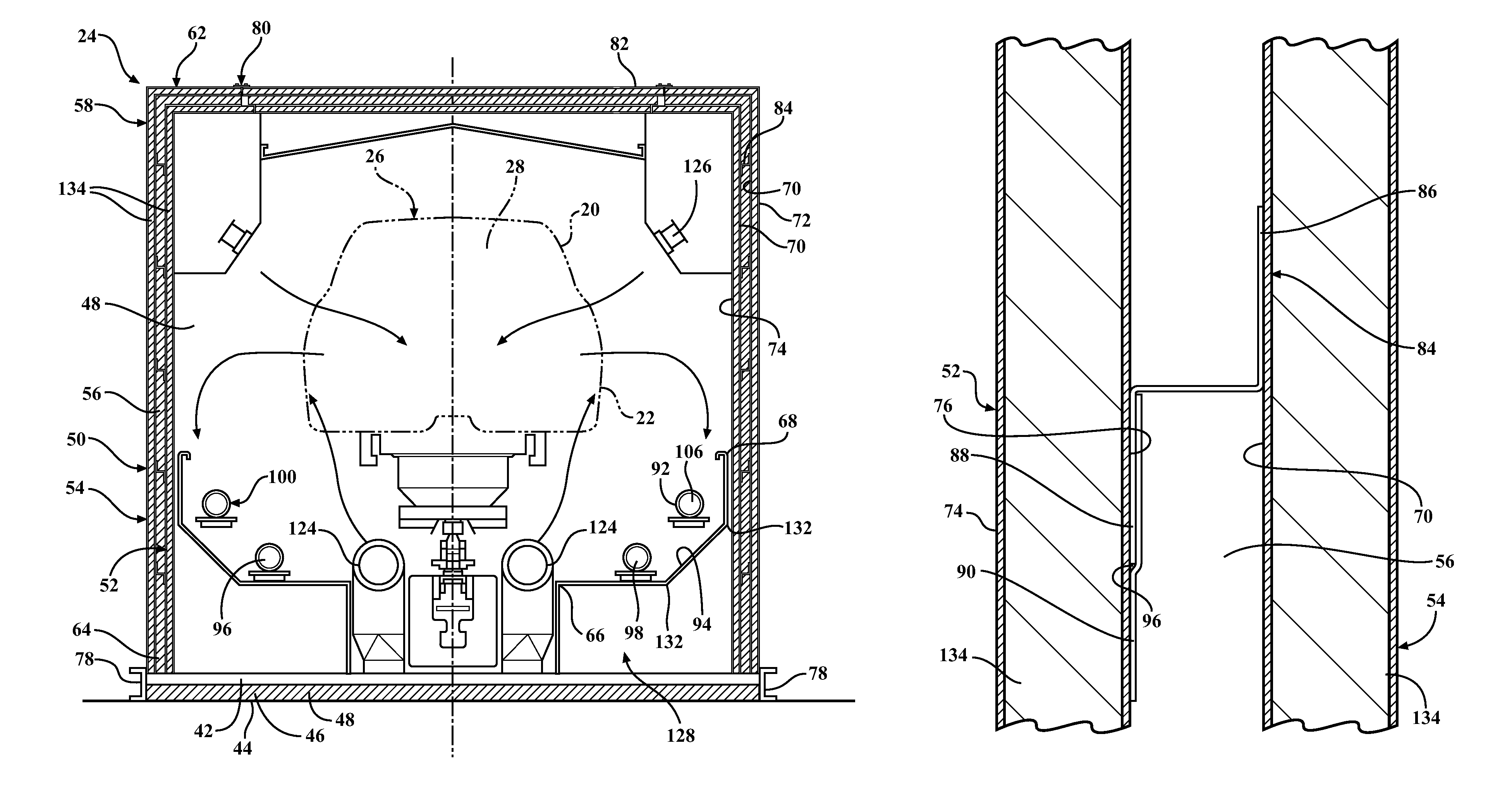

Tumble dryer having a fire extinguishing system

InactiveUS20130139404A1Simple but nevertheless safe constructionAvoid unnecessary lossDrying machine combinationsDrying gas arrangementsLaundryCavity wall

A tumble dryer includes a drum which has an interior for holding laundry items, and at least one container which is received in the interior of the drum. The container has a cavity which is filled with an extinguishing medium. At least one release device is arranged in a cavity wall of the container for the extinguishing medium and is activated in the event of a fire starting or having started in the drum to thereby provide an opening to the cavity of the container.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

Drying device for heat insulation plate

InactiveCN108800873ADry evenlyImprove drying effectDrying solid materials with heatDrying gas arrangementsMicrowaveEngineering

The invention discloses a drying device for a heat insulation plate. The drying device includes a box body, a base and a transmission mechanism; the box body is located at the top of the base, an inner cavity of the box body is divided into a pre-drying room, a drying room and a heat dissipation room through a partition plate, a feeding opening is formed in the left side wall of the pre-drying room, a discharging opening is formed in the right side wall of the heat dissipation room, motor boxes are arranged in the top of the box body and the base, a heat dissipation motor is arranged in an inner cavity of each motor box, and a rotating shaft is arranged at the power output end of each heat dissipation motor; and a fan blade is arranged at the end, located in the inner cavity of the box body, of each rotating shaft, electric telescopic rods are symmetrically arranged at the top and the bottom of the inner cavity of the drying room, base seats are arranged on the side, attached to each other, of the two sets of electric telescopic rods, microwave generators are arranged on the sides, attached to each other, of the base seats, heat exchange fans are arranged on the left and right sidewalls of the pre-drying room and the right side wall of the heat dissipation room, and a supporting column is arranged in the base. The drying device can reuse the heat discharged by electromagneticheating to dry the heat insulation plate for the first time, the drying effect is better, and the energy is saved.

Owner:吴江市金搏保温材料厂(普通合伙)

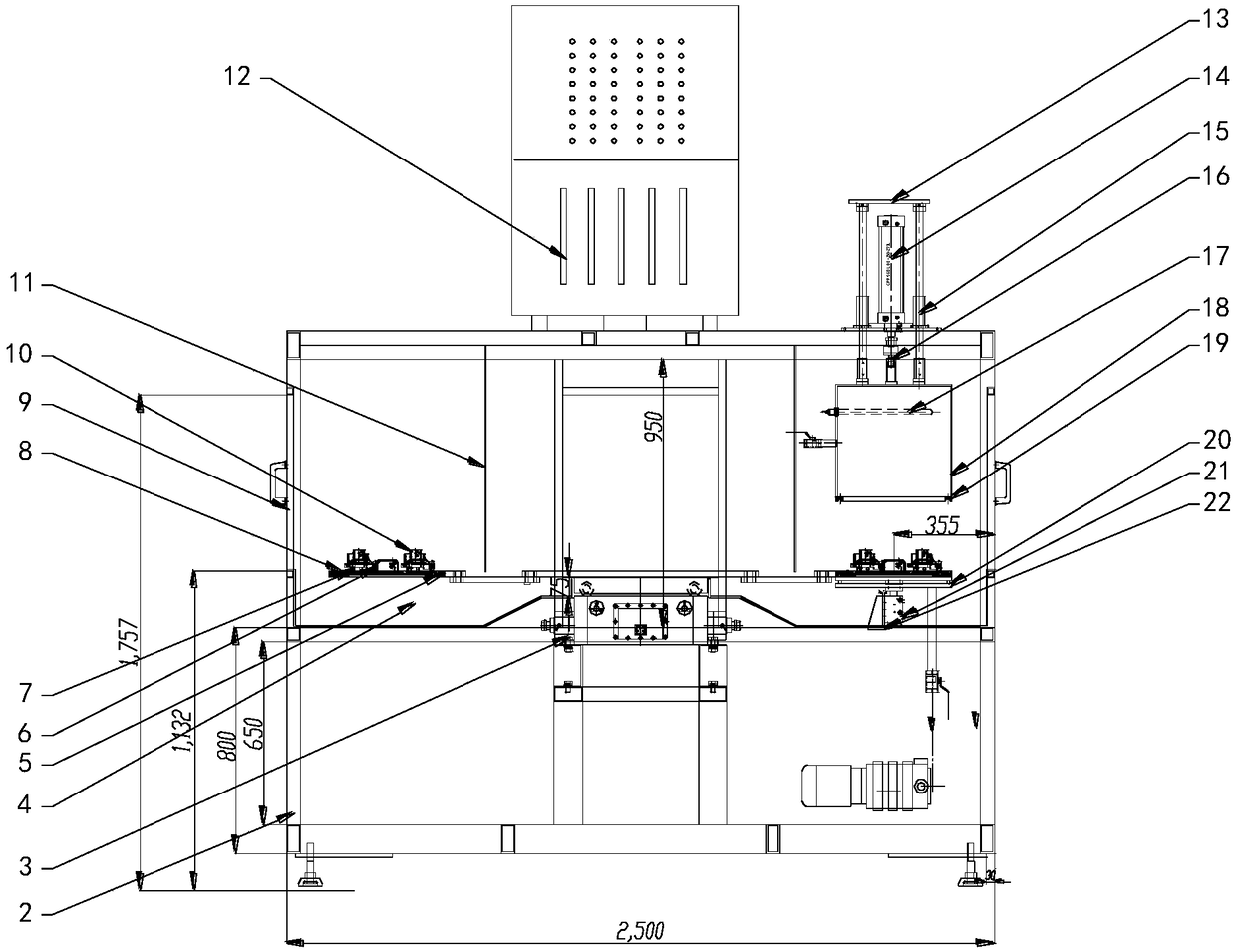

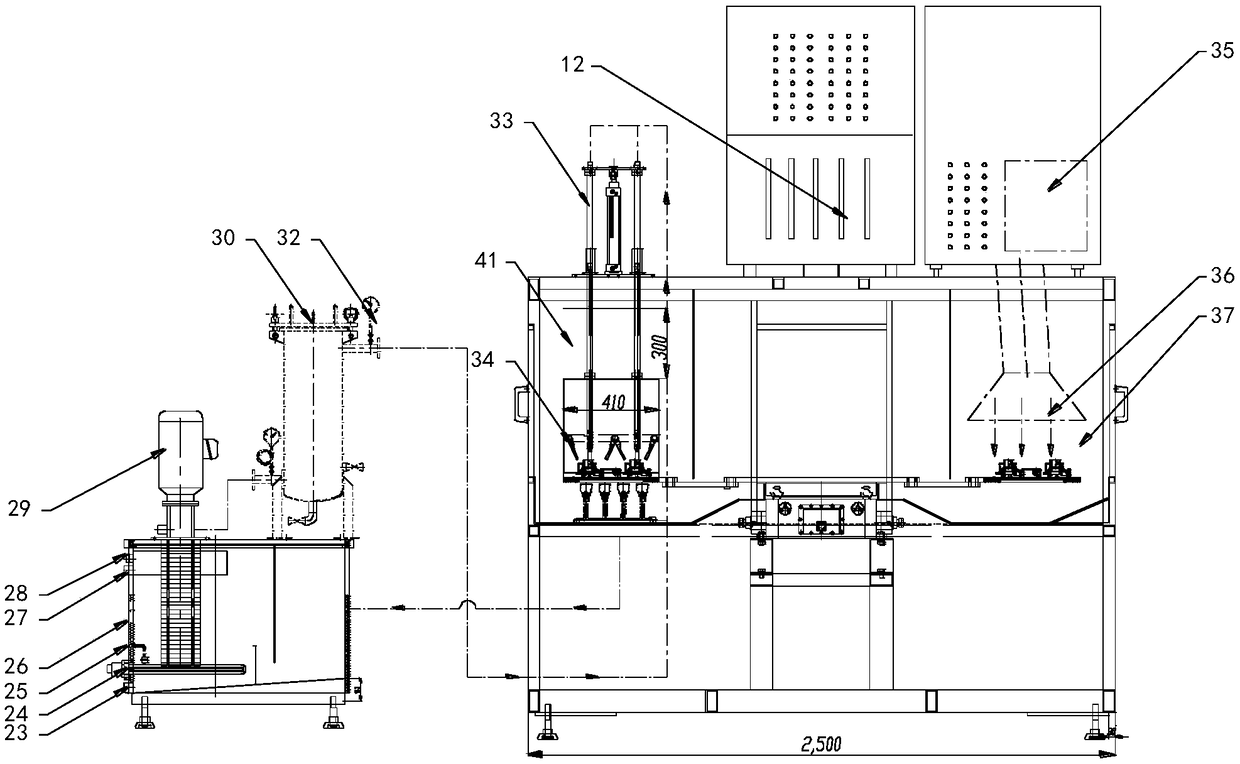

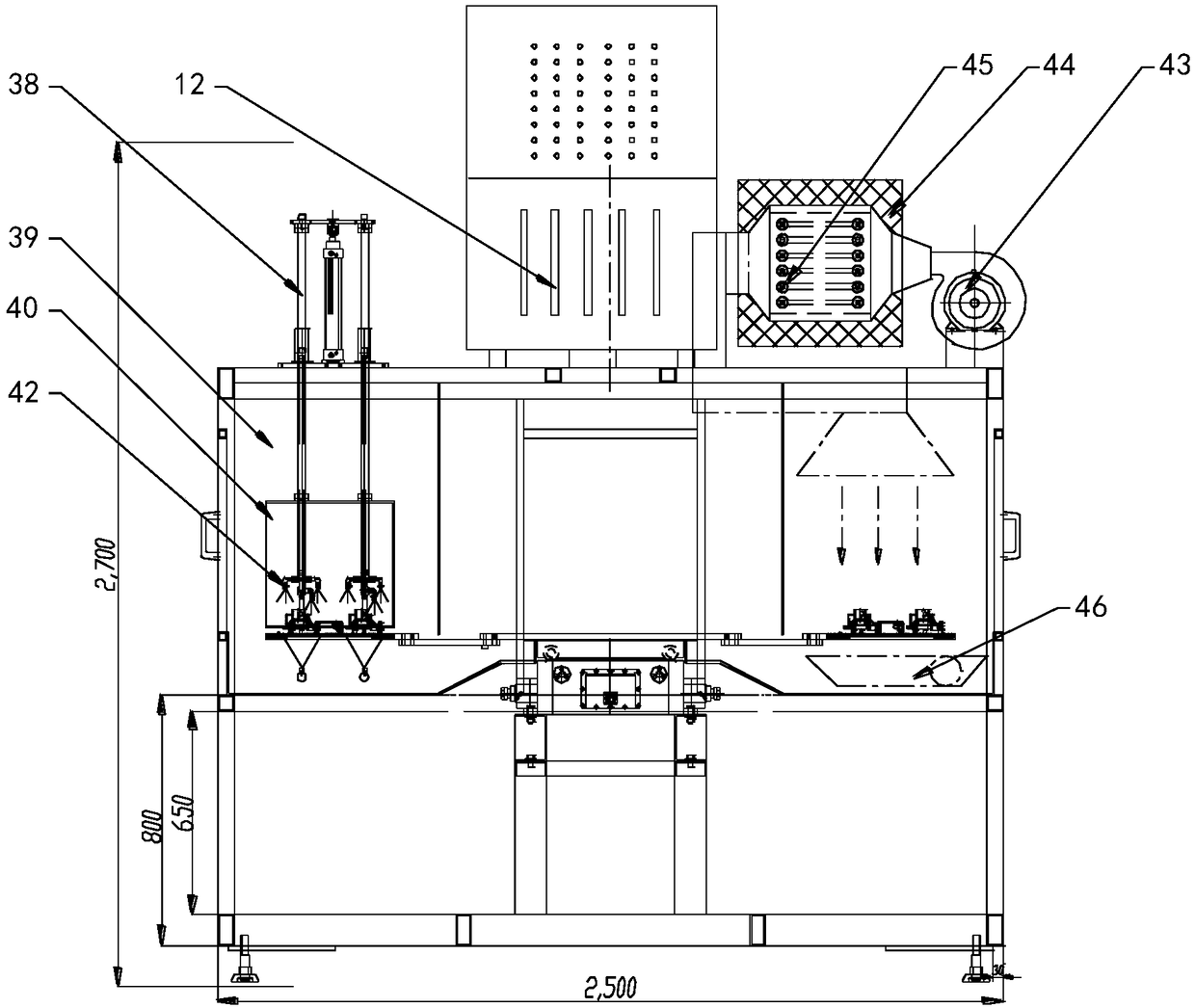

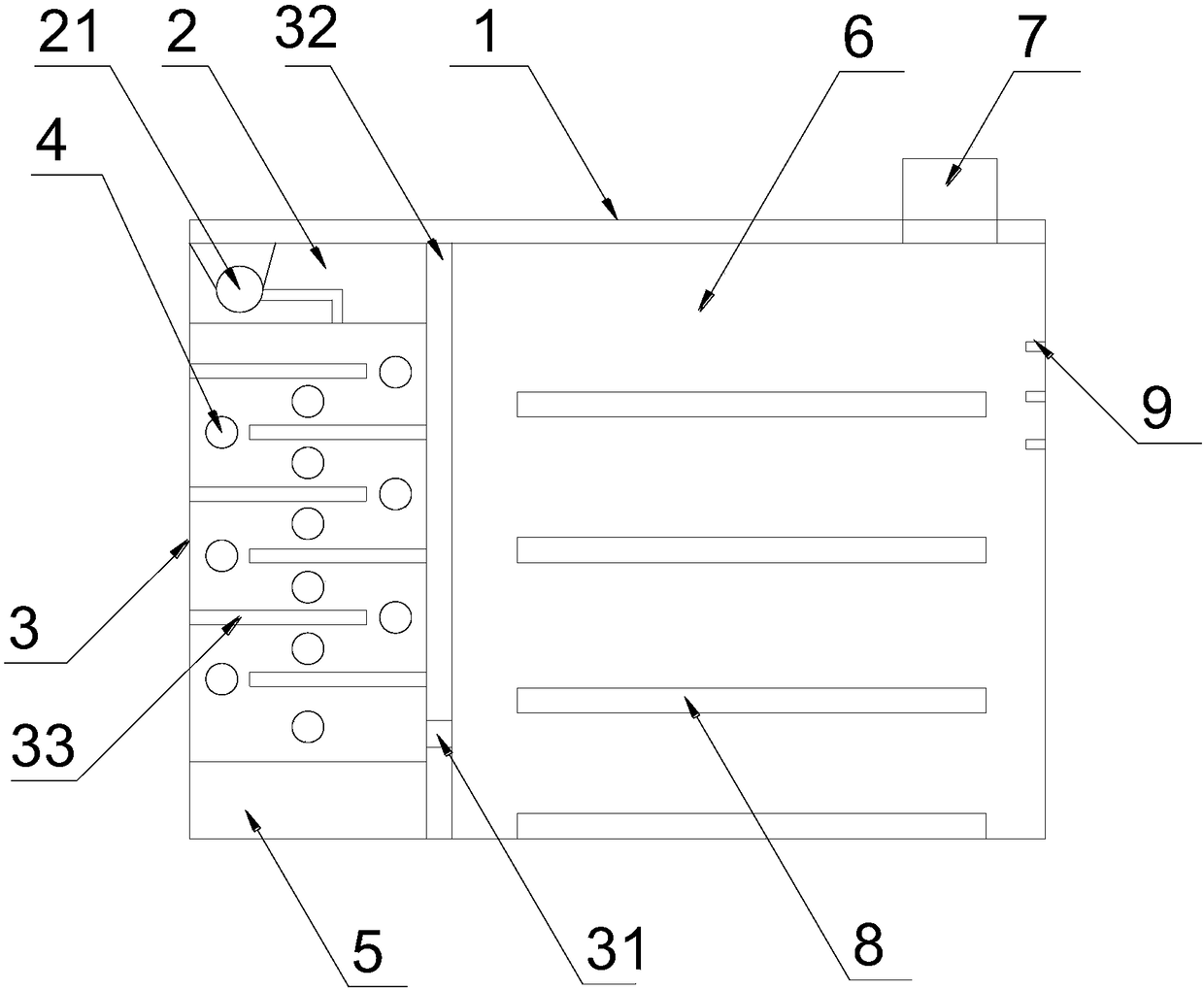

Eight-station rotary fixed-point spraying cleaning machine

InactiveCN109261601AMeet the needs of high production capacityDrying solid materials without heatDrying gas arrangementsWind shearEngineering

The invention relates to the technical field of cleaning devices, in particular to an eight-station rotary fixed-point spraying cleaning machine. The spraying cleaning machine is provided with a rotating structure and eight stations arranged on a ring rotation structure, the eight stations sequentially include a first spraying station, a second spraying station, a third spraying station, a wind shear station, a drying station, a vacuum drying station, a cooling station and a feeding and discharging station, eight rotating arms are correspondingly arranged on the eight stations a rotating mechanism, the free end of each rotating arm is fixed with a fixture for fixing a workpiece to be cleaned, a hydraulic rotary table drives the rotating mechanism to rotate to drive the eight rotating armsto rotate, so that the workpiece to be cleaned on each rotating arm sequentially passes the eight stations, the workpieces to be cleaned can be sequentially sprayed and cleaned for three times, blownby compressed air, circularly dried by hot wind, vacuumized, cooled and highly accurately abutted to a mechanical arm in the feeding and discharging processes, and high-productivity requirements can be met as a rotating takt is short.

Owner:苏州司达夫超声科技有限公司

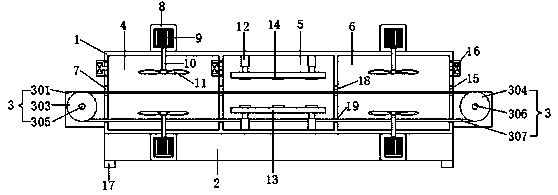

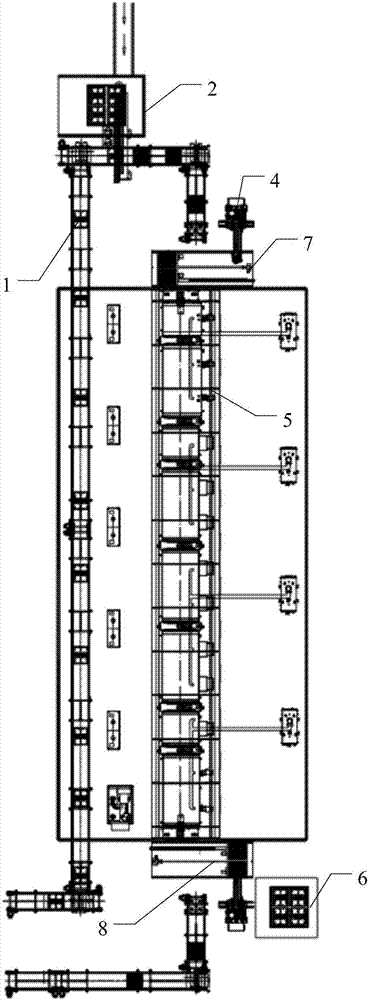

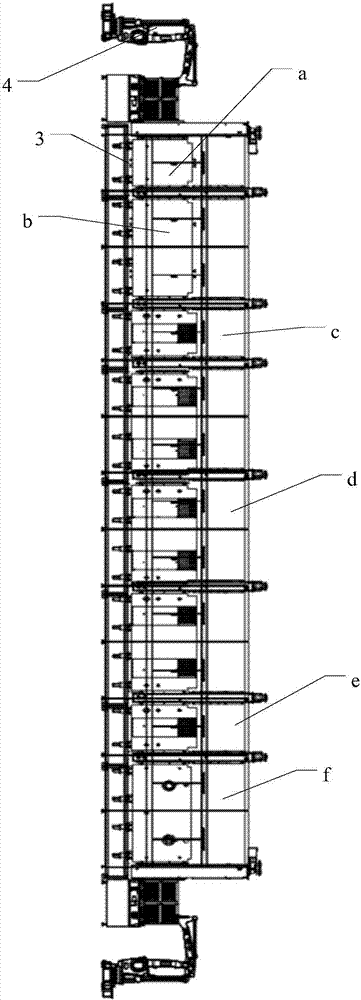

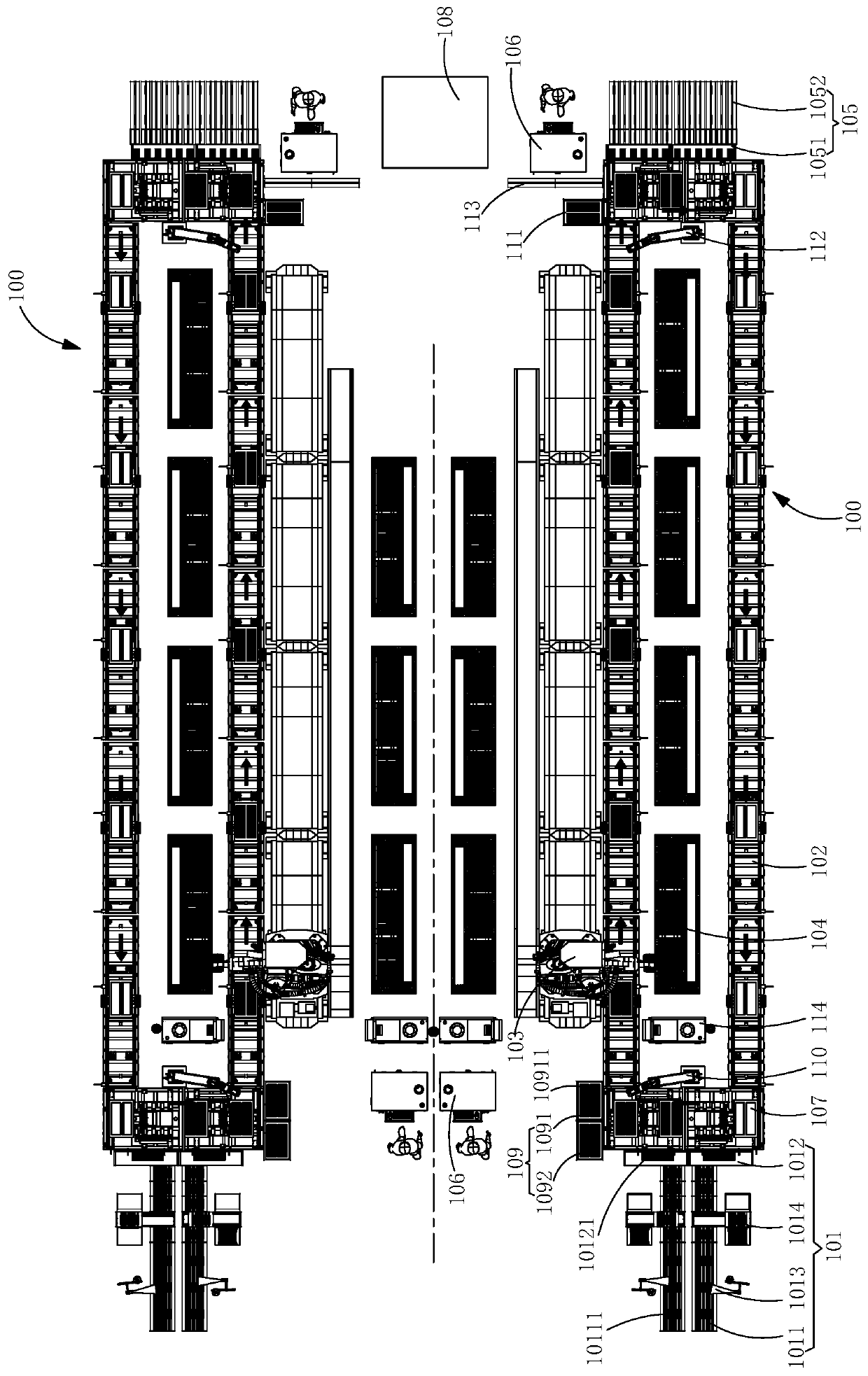

High-vacuum intelligent tunnel type baking line

ActiveCN106895663ARealize mechanized automatic conveyingImprove performanceDrying gas arrangementsDrying machines with progressive movementsProduction lineAssembly line

The invention provides a high-vacuum intelligent tunnel type baking line which comprises preposition conveying lines, a full-load logistics line and work units; the full-load logistics line comprises a front end feeding segment, a middle baking segment and a tail end discharging segment which are connected in sequence; the work units operate independently, the work units are provided with work cavities, the work units are provided with automatic sealing doors for sealing the two ends of the work cavities, and the work units are configured with temperature adjustment systems and vacuum systems. The high-vacuum intelligent tunnel type baking line is a professional battery production line, temperature raising, constant temperature and temperature lowering are divided into independent functional segments, each functional segment always maintains a state, the high vacuum degree, high temperature uniformity and the low dew point are achieved, and performance parameters of a lithium battery are greatly improved; and meanwhile, energy consumption is greatly lowered. By means of the high-vacuum intelligent tunnel type baking line, automatic, intelligent and large-scale production are achieved, work efficiency is improved, and the capacity advantage is improved; and all processes are subjected to professional assembly line division of labor, battery performance and consistency are improved completely, and the quality advantage is enhanced.

Owner:湖北番中工业装备科技有限公司

Textile drying machine

InactiveCN107525387ATimely exclusionImprove work efficiencyDrying gas arrangementsDrying chambers/containersExhaust valvePulp and paper industry

The invention relates to the technical field of textile processing and in particular relates to a textile drying machine. The textile drying machine dries a textile repeatedly, so that the work efficiency is relatively high; the textile drying machine is not closed inside during work, so that residual gas in a working cavity can be immediately removed and is unlikely to burst, and therefore, the service life of the textile drying machine is guaranteed, and the using reliability of the textile drying machine is improved; the textile drying machine comprises a box body, a placing plate and a fan. The working cavity is formed in the box body, an opening is formed in the left side wall of the box body, a door plate is arranged on the opening, and a handle is arranged on the door plate; the textile drying machine also comprises a servo motor, a left supporting rack, a right supporting rack and a conveyor belt; the textile drying machine also comprises a heating box, two silicon carbide rods, a fan supporting rack, a plurality of fans and a temperature controller. A heating cavity is formed in the heating box. The textile drying machine also comprise a one-way exhaust valve, an exhaust cavity is formed in the one-way exhaust valve, and a lower exhaust baffle plate, an upper exhaust baffle plate, an exhaust spring and an exhaust baffle plate are arranged in the exhaust cavity.

Owner:JIANGSU GUANGSHENGYUAN TECH DEV

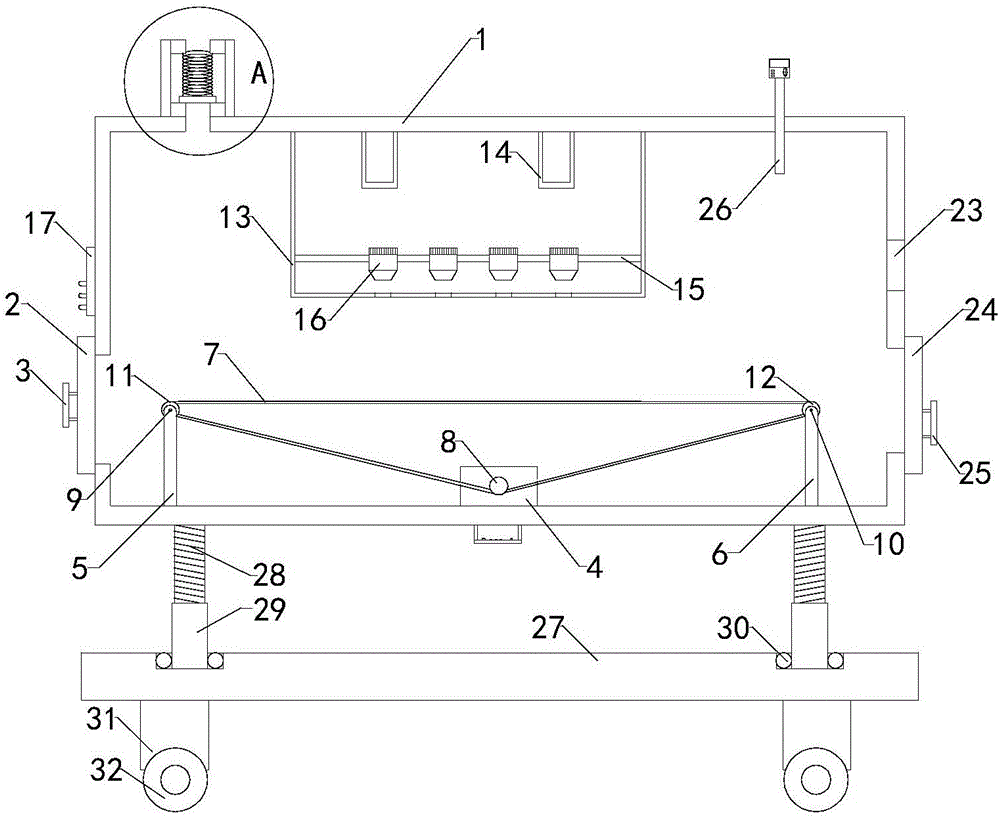

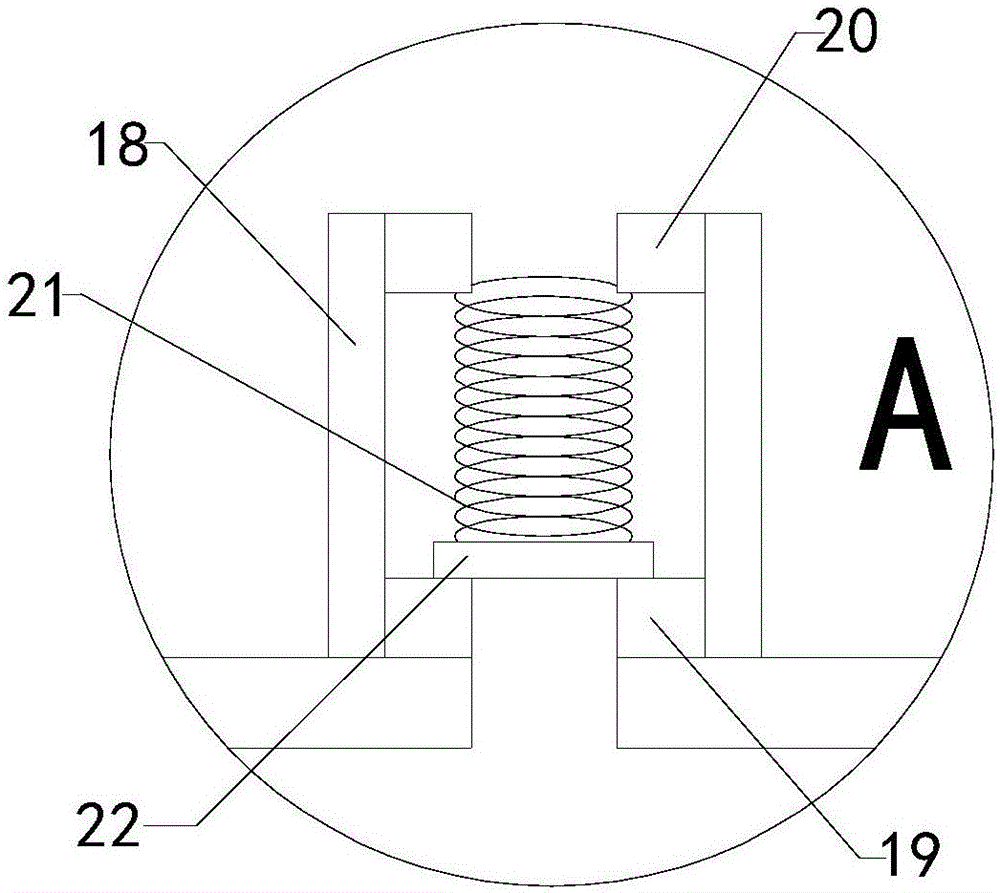

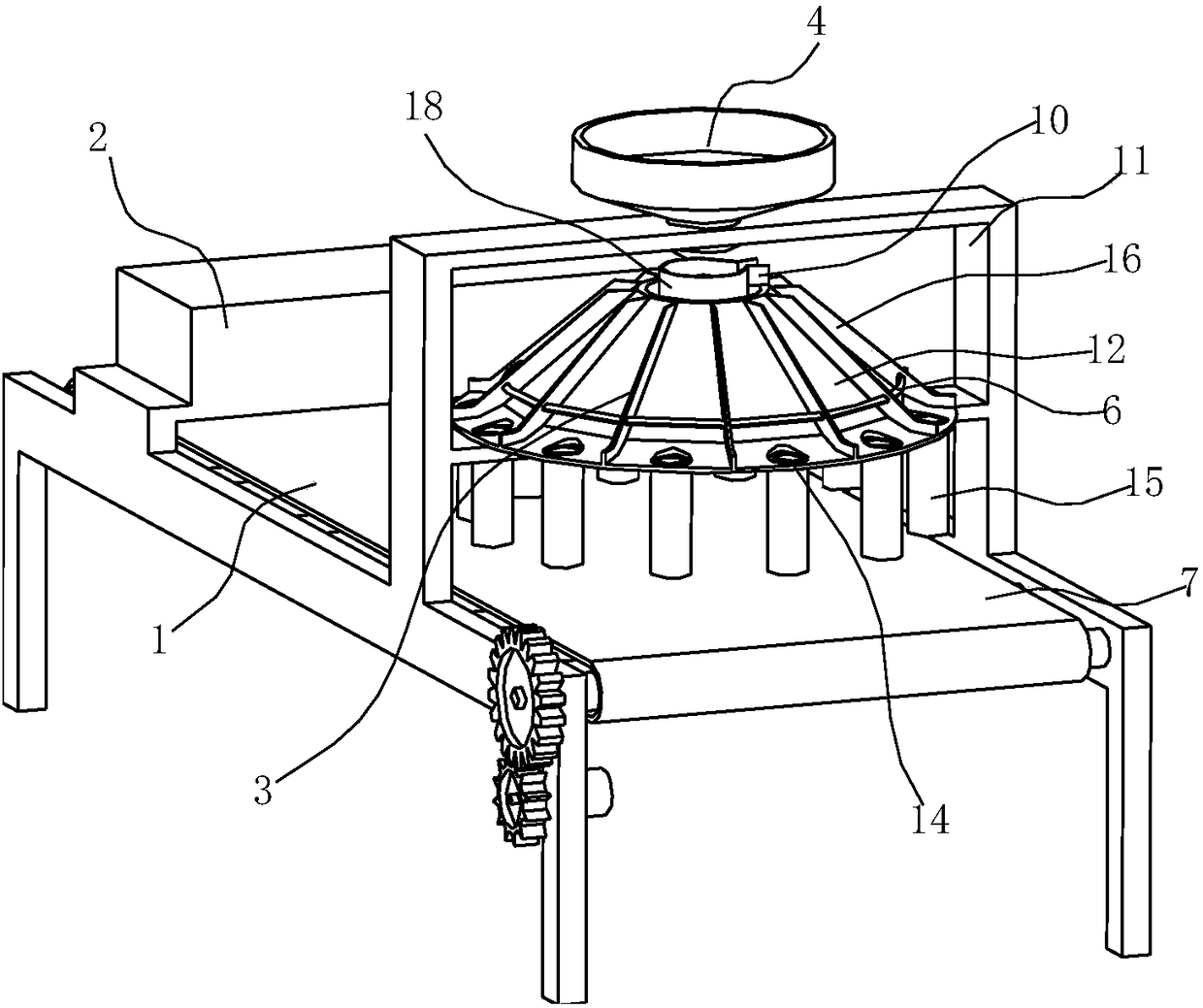

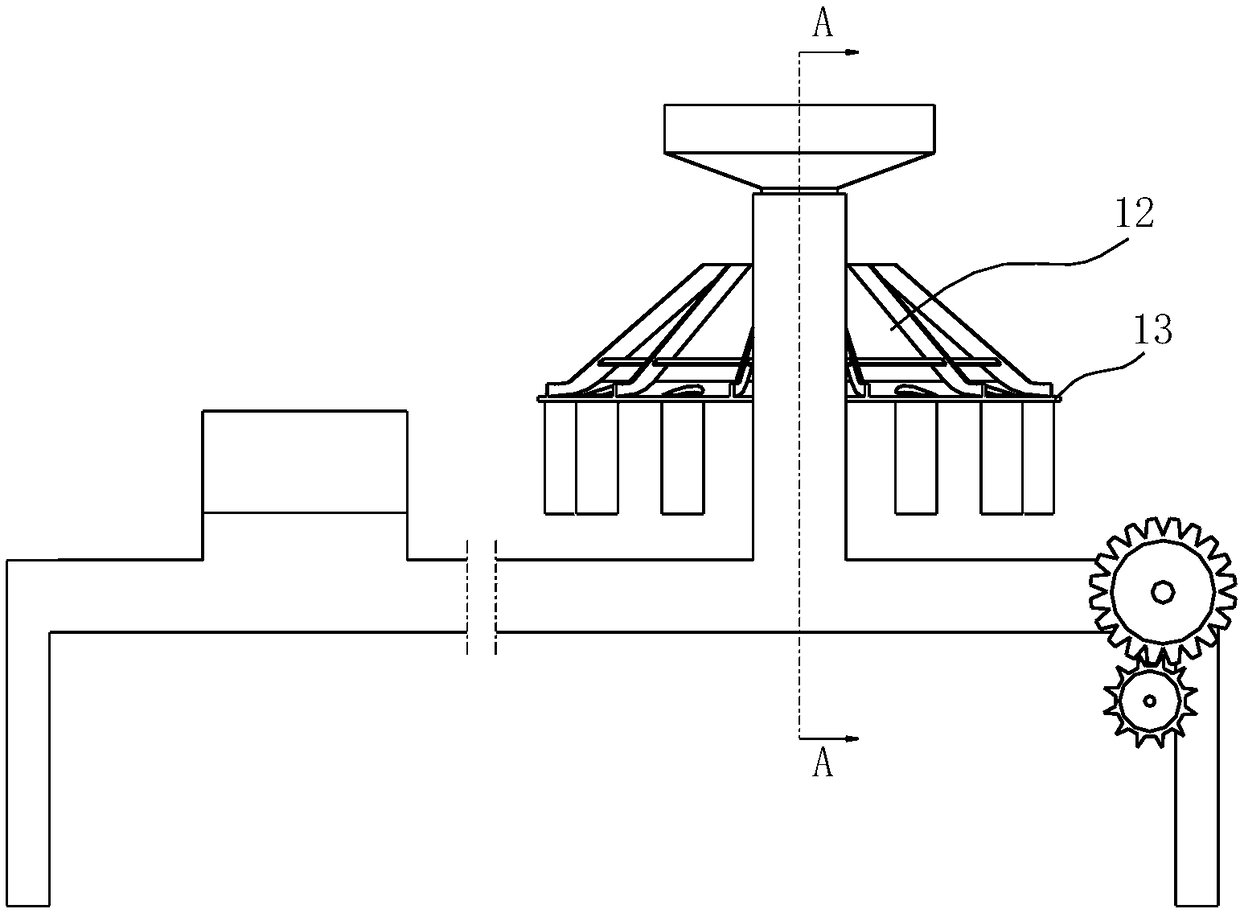

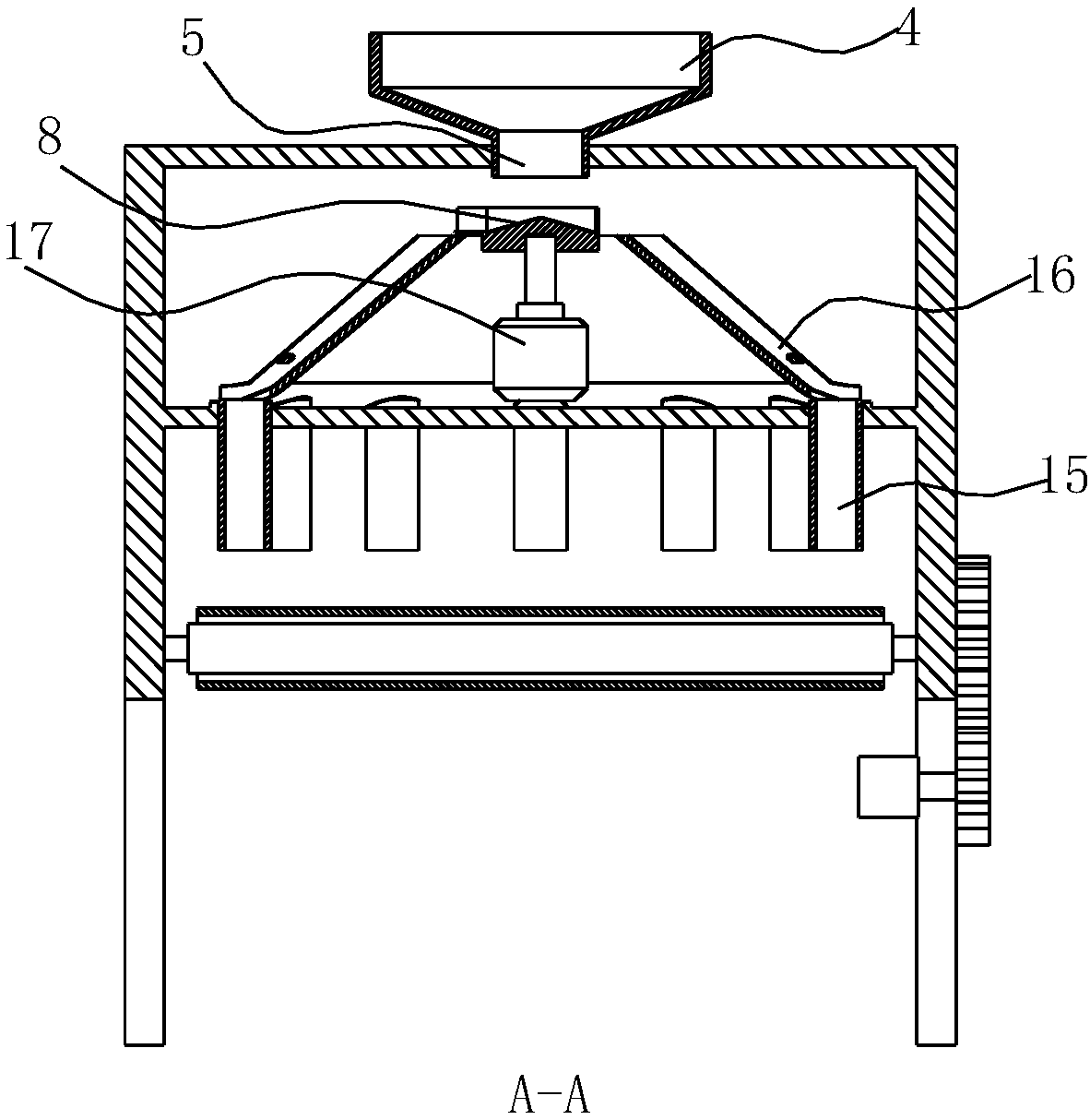

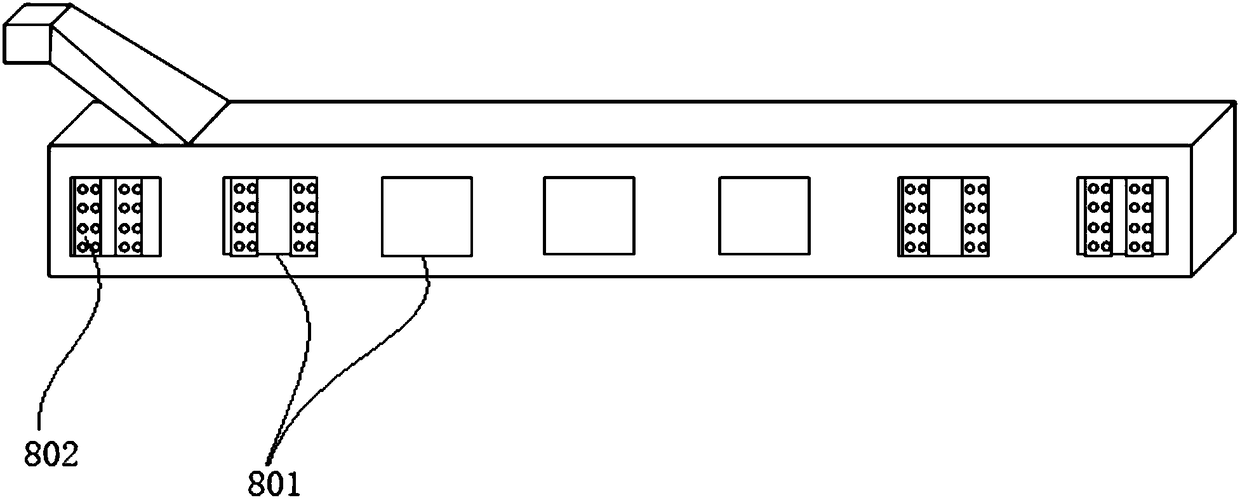

Traditional Chinese medicine decoction piece uniformly spreading and drying equipment and using method thereof

ActiveCN108195181ASpread evenlySpread quicklyDrying machines with progressive movementsDrying safety systemsBiochemical engineeringChinese drug

The invention relates to traditional Chinese medicine decoction piece uniformly spreading and drying equipment and a using method thereof, and belongs to the technical field of traditional Chinese medicine processing equipment. The equipment comprises conveying equipment, wherein a drying box is arranged on the rear side of the conveying equipment, and a spreading mechanism is arranged above the front side of the conveying equipment; and a discharging hopper is arranged above the spreading mechanism, and a 2mm-4mm distance is formed between the discharging hopper and the spreading mechanism. The using method comprises the following three steps of initially adjusting, starting a drying box, and starting a motor I and a motor and the like. According to the using method, the distance betweena baffle ring and the surface of a shell body is determined according to the thickness of the traditional Chinese medicine decoction piece, and the situation that only one traditional Chinese medicinedecoction piece can pass through the space between the baffle ring and the shell body one time prevails; adjustment of the distance between the discharging hopper and the spreading mechanism is subjected to the situation that the traditional Chinese medicine decoction pieces are not stacked and blocked on the spreading mechanism; and the lengths of cylinders are adjusted, so that distance betweenthe lower ends of the cylinders and a conveying belt does not exceed the thickness of the two traditional Chinese medicine decoction pieces, and the influence of the cylinders on conveying of the traditional Chinese medicine decoction pieces is avoided.

Owner:宁夏明德中药饮片有限公司

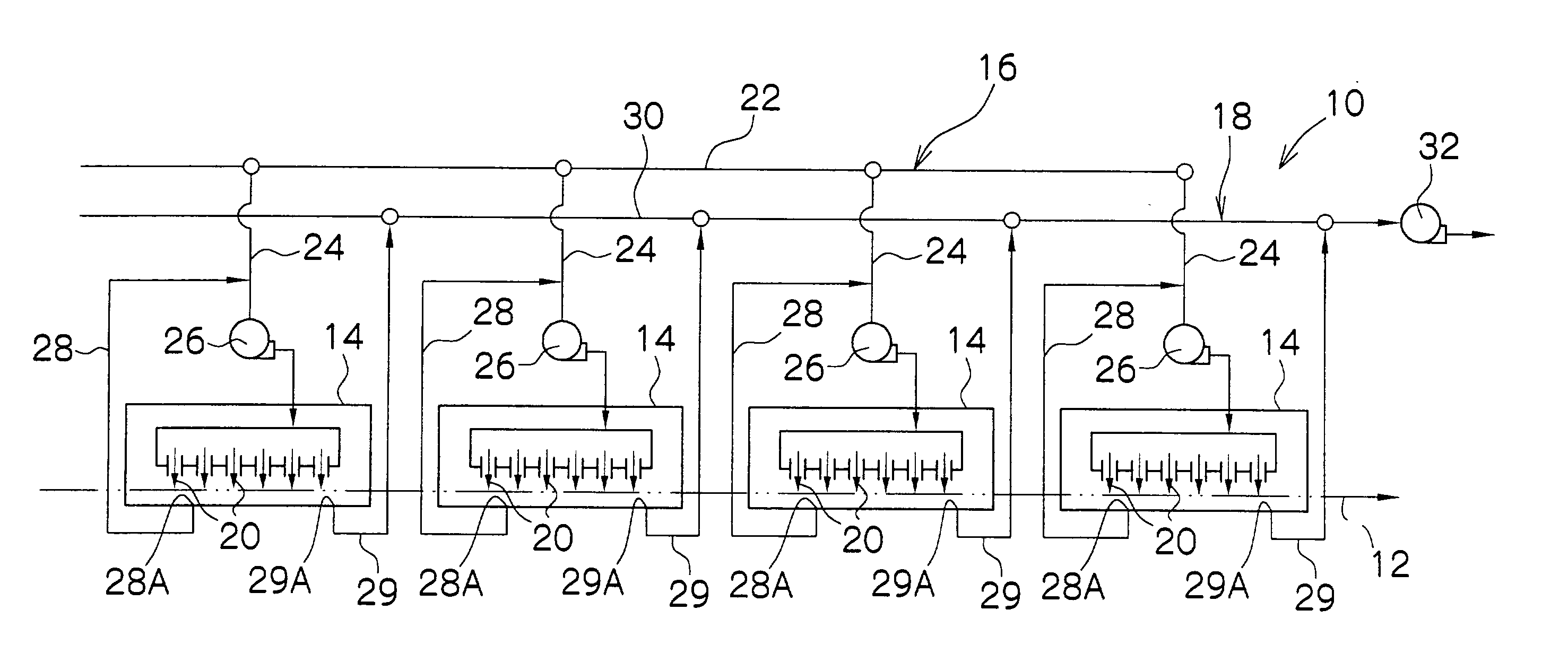

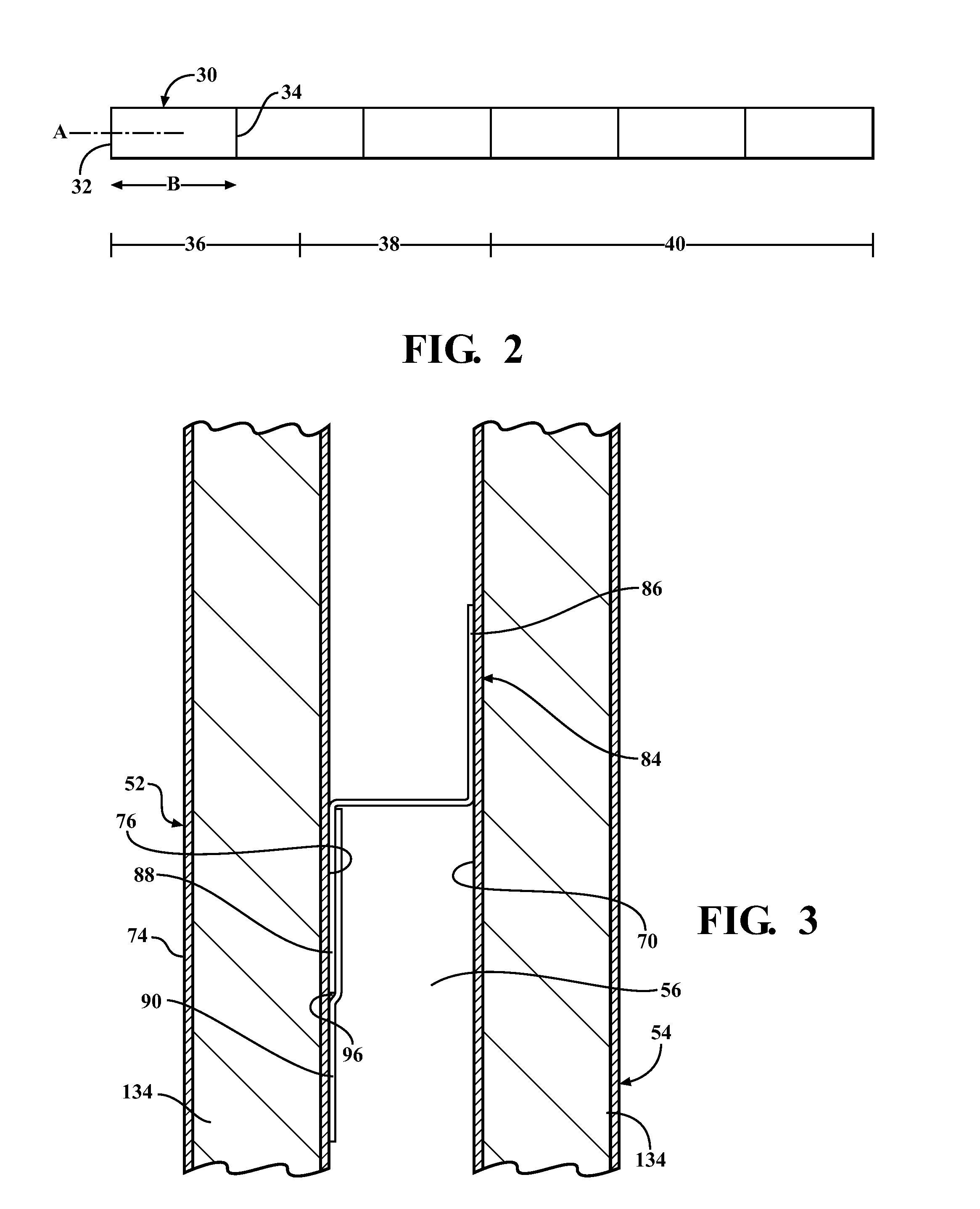

Modular paint oven using radiant and convection heat

Owner:GK LICENSING

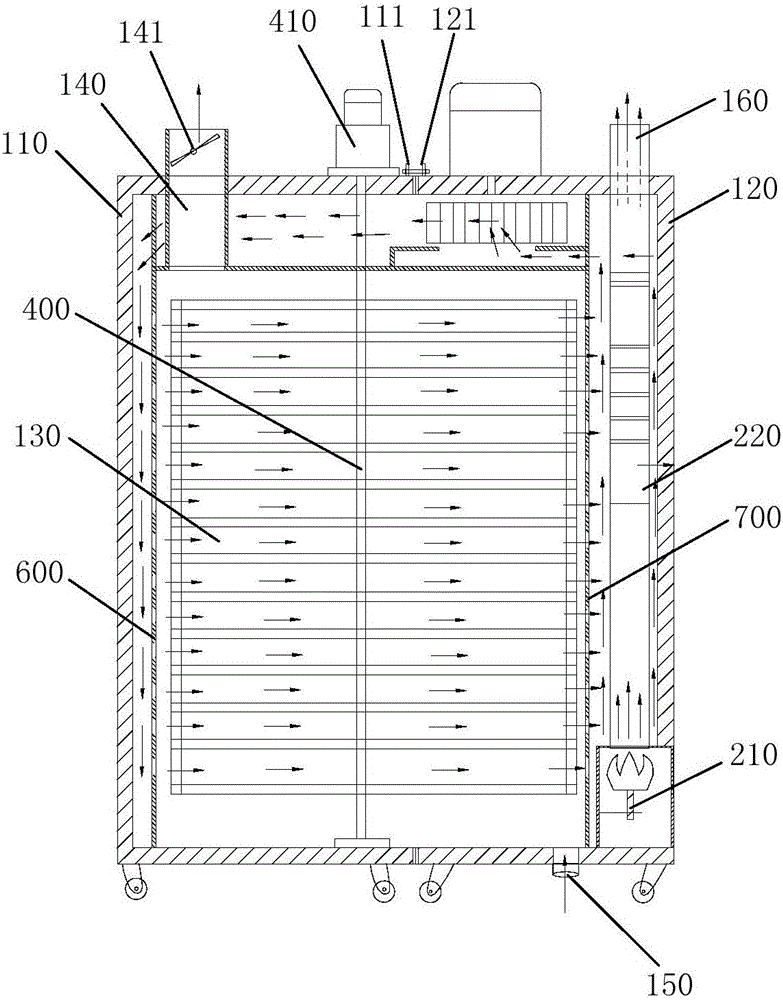

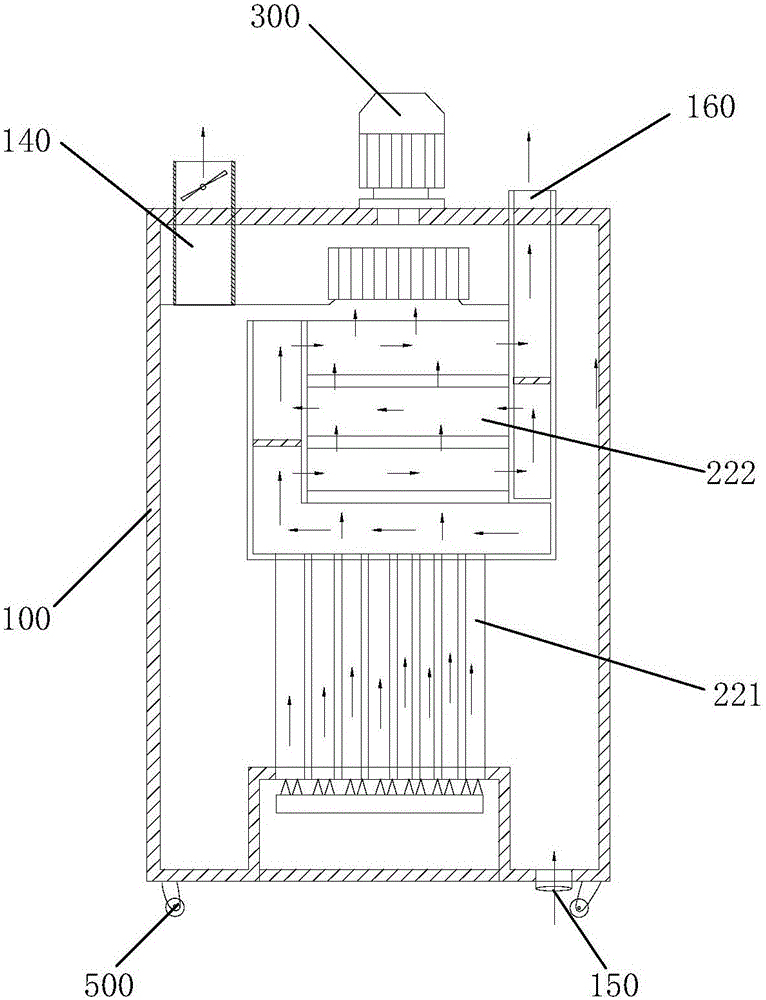

Energy-saving drying box

InactiveCN108204716AImprove the heating effectIncrease distanceDrying gas arrangementsDrying safety systemsDry boxUtilization rate

The invention discloses an energy-saving drying box. The energy-saving drying box comprises a box body, an equipment bin, a heating bin, a control bin and a drying bin; a box door, a display screen and a control panel are arranged on the outer side of the box body, and the control bin is located at the bottom of the box body; a partition plate is arranged in the box body, the equipment bin, the heating bin and the control bin are located on the left side of the partition plate, the drying bin is located on the right side of the partition plate, a vent hole is formed in the bottom of the partition plate, and the heating bin communicates with the drying bin through the vent hole; the equipment bin is located on the upper portion of the interior of the box body, and the heating bin is locatedbetween the equipment bin and the control bin; baffles are arranged in the heating bin, and the ends of the baffles are fixed to the inner wall of the heating bin and the partition plate; an S-shapedair channel is formed in the heating bin; multiple heating assemblies are arranged in the flowing direction of air in the S-shaped air channel; and multiple rows of storage racks are fixedly installed in the drying bin, an exhaust port is arranged on the top of the drying bin, and a one-way valve is arranged at the exhaust port. According to the energy-saving drying box, the drying effect is good, the heat exchange efficiency is high, the energy utilization rate is increased, energy waste is avoided, and use is safe.

Owner:安徽依诺格实验室设备有限公司

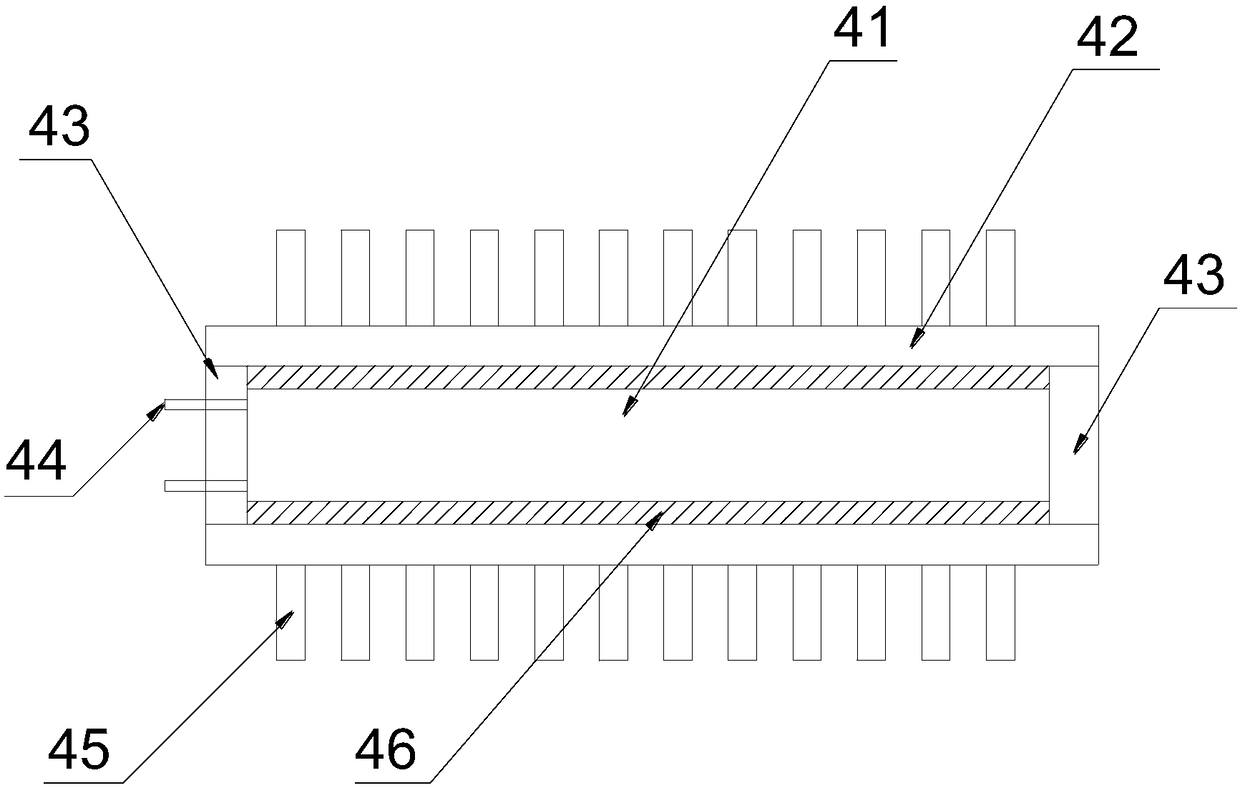

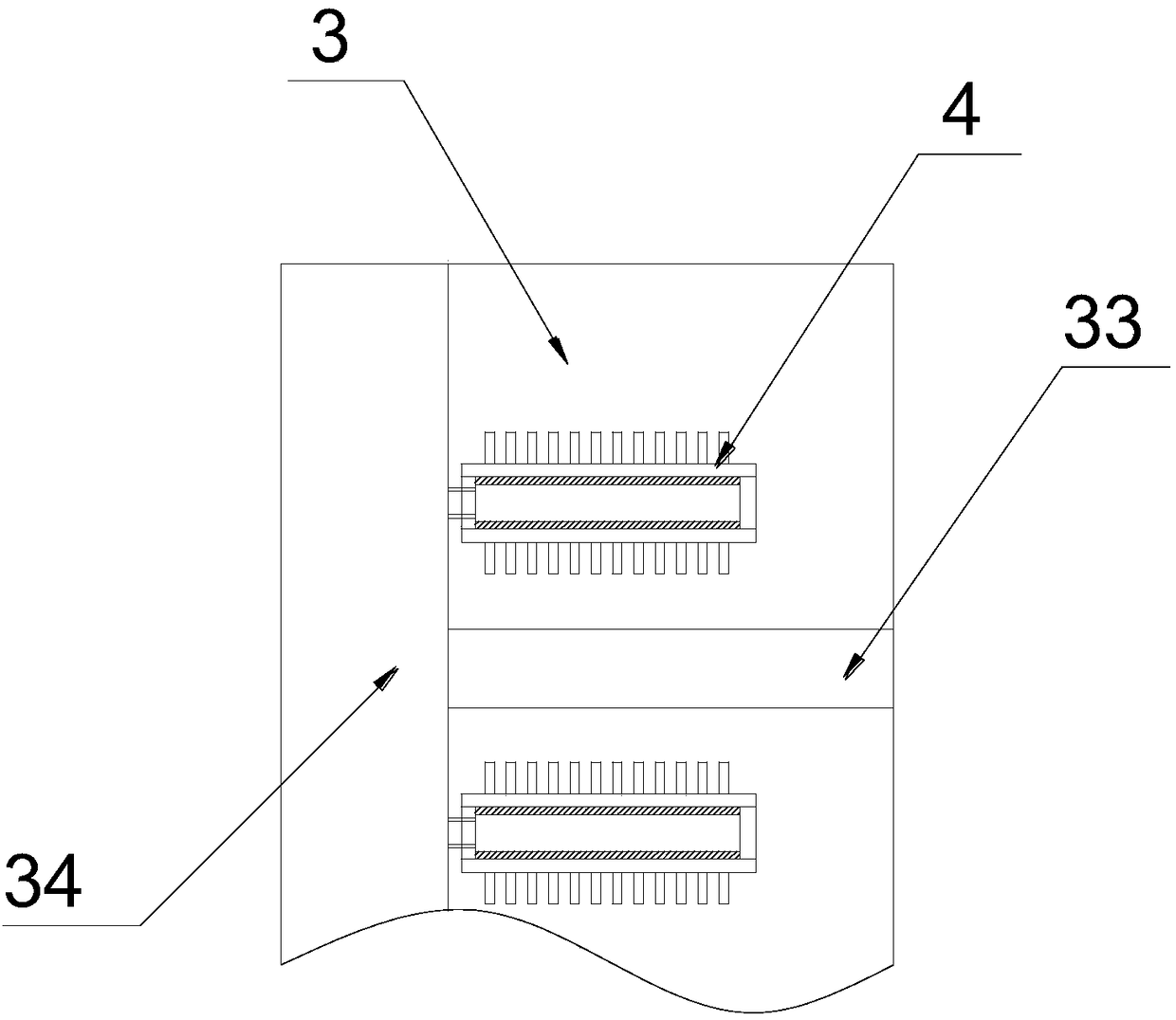

Square tube type four-return metal hot-blast-furnace gas drier

PendingCN106705608AExtended circulation timeImprove heat exchange efficiencyTea dryingDrying gas arrangementsCombustion chamberEngineering

The invention relates to a square tube type four-return metal hot-blast-furnace gas drier. The square tube type four-return metal hot-blast-furnace gas drier is provided with an insulation machine cabinet which is square shaped and capable of being dissembled from the middle into left and right parts, a left-side guide plate and a right-side guide plate are arranged in the insulation machine cabinet, a drying chamber is formed between the left-side guide plate and the right-side guide plate, a combustion chamber is formed between the right-side guide plate and the right wall of the insulation machine cabinet and at the lower portion in the insulation machine cabinet, a heating chamber is formed above the combustion chamber, furnace ends are accommodated in the combustion chamber, a furnace body which is of a four-return metal hot-blast furnace body is accommodated in the heating chamber, and the furnace body comprises a plurality of vertical square tubes and four horizontal square tubes connected with the vertical square tube and horizontally folded and arrayed in a zigzag manner. Compared with an ordinary gas dryer, the square tube type four-return metal hot-blast-furnace gas drier has the advantages of high heat transfer efficiency, easiness in carry and good popularization value.

Owner:林美娟

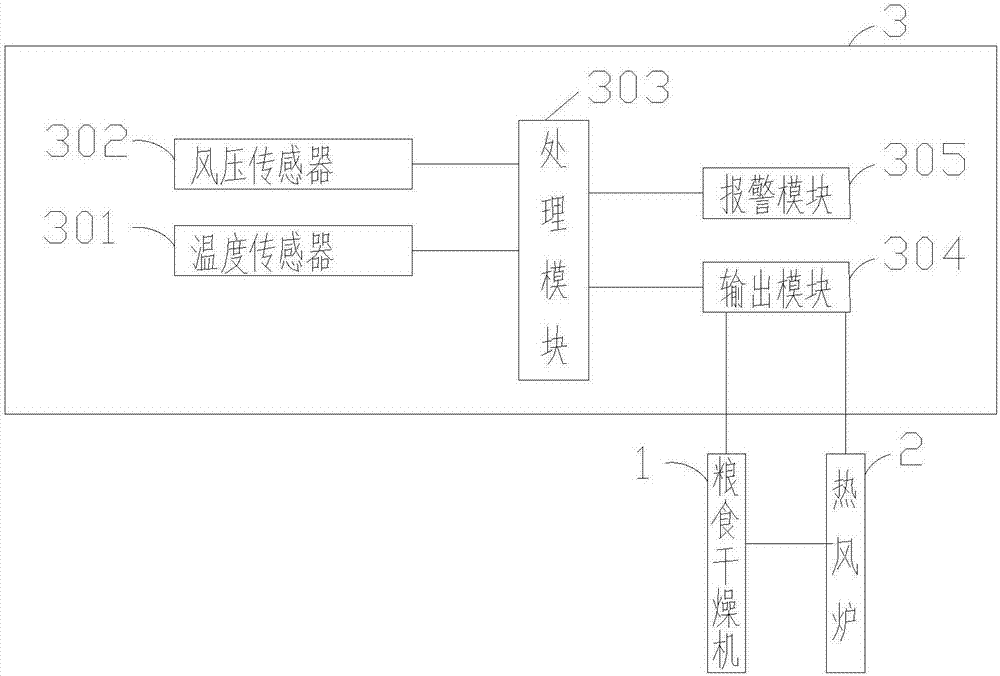

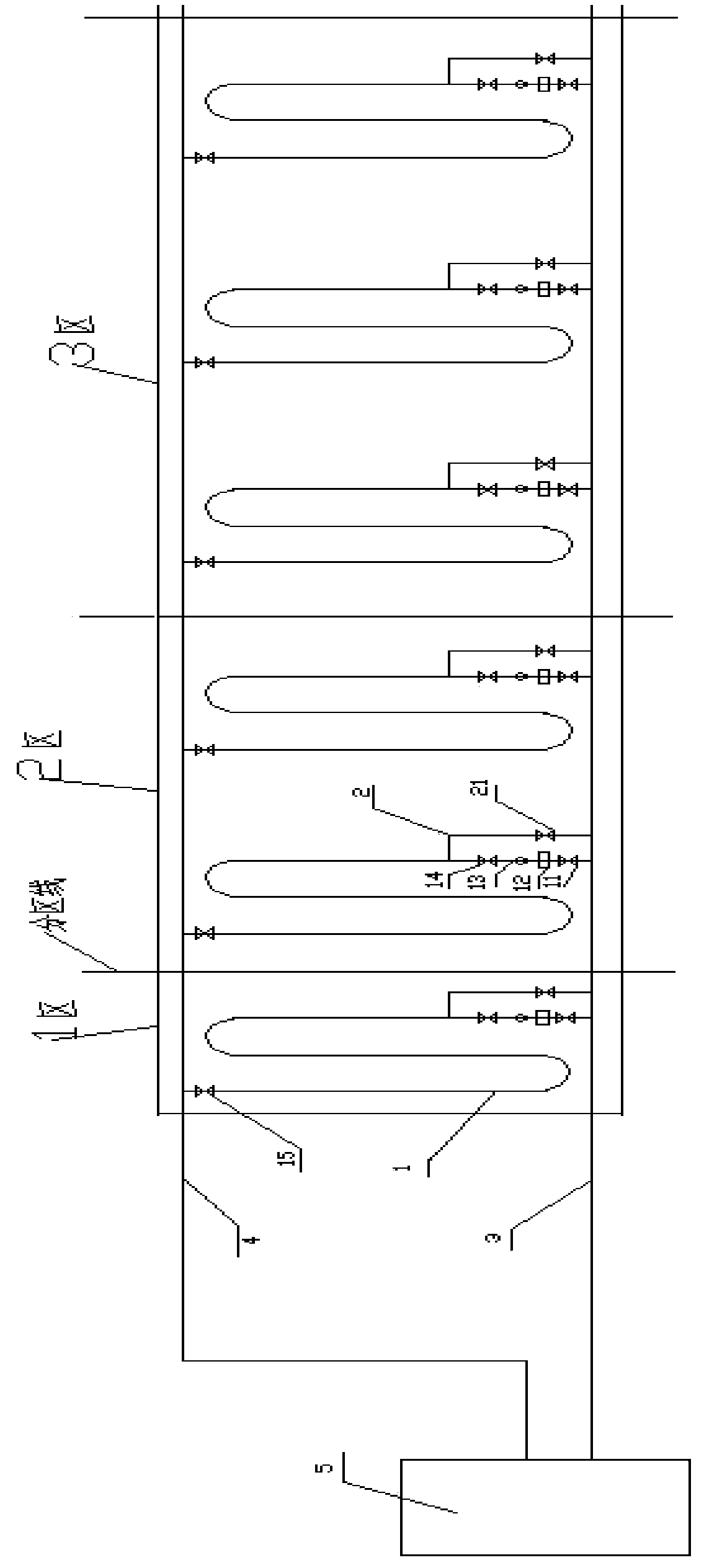

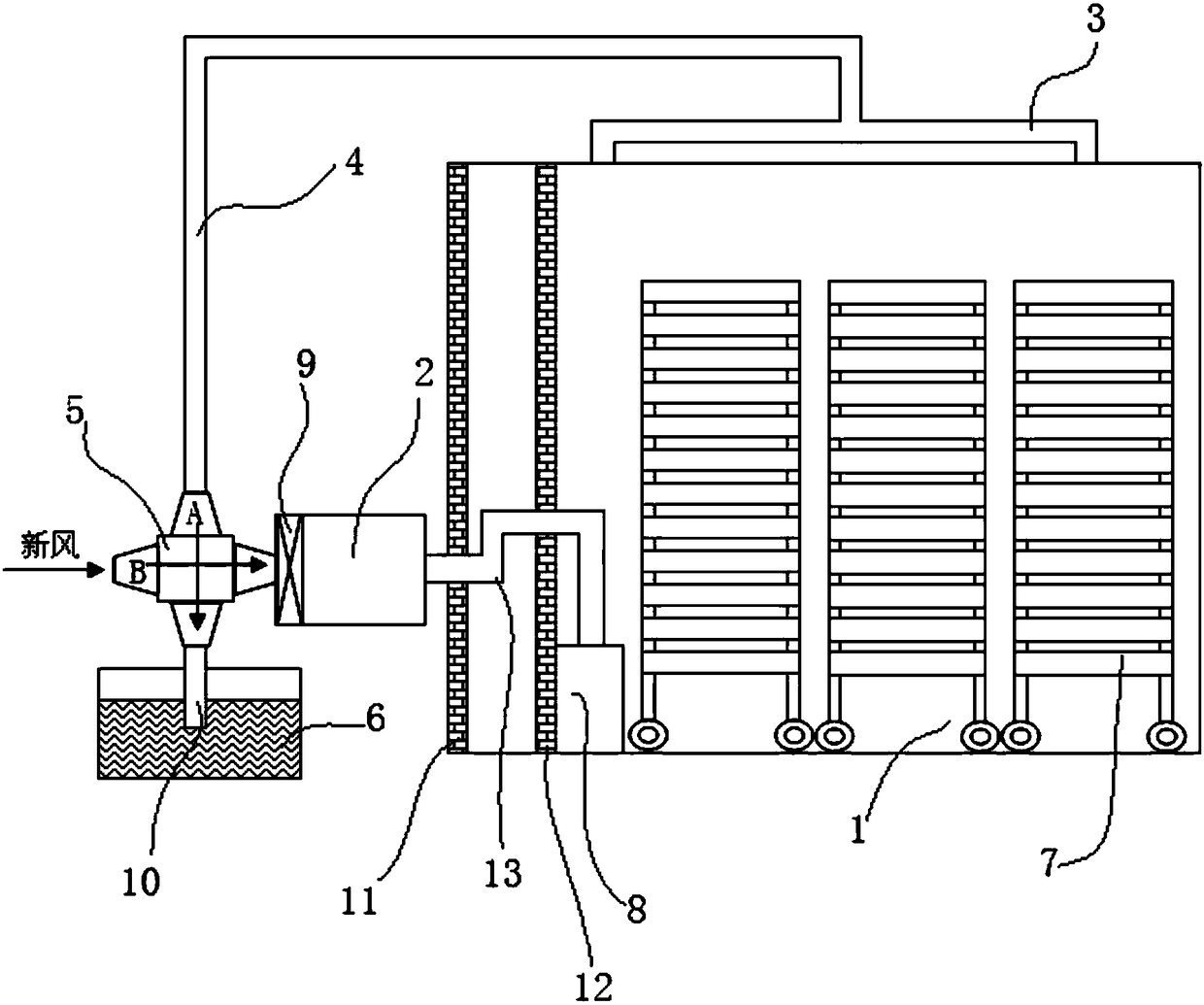

Grain drying system

PendingCN106907918AGuaranteed drying efficiencyReduce humidityDrying gas arrangementsDrying safety systemsControl systemAgricultural engineering

The invention provides a grain drying system, which includes a grain dryer, a hot air stove and a grain drying control system; the grain drying system includes a humidity sensor for detecting the humidity of hot air, a wind pressure sensor for hot air pressure, a processing module and an output module; The temperature sensor, the wind pressure sensor and the output module are respectively connected to the processing module; the grain dryer is connected to the hot stove, and the grain dryer is provided with an exhaust fan; the output module is connected to the The hot blast stove and the exhaust fan. This scheme can improve the drying efficiency of grain.

Owner:安徽省沃昇机电科技有限公司

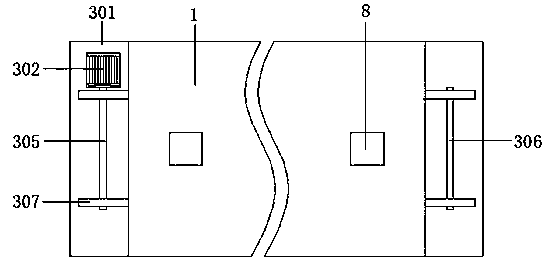

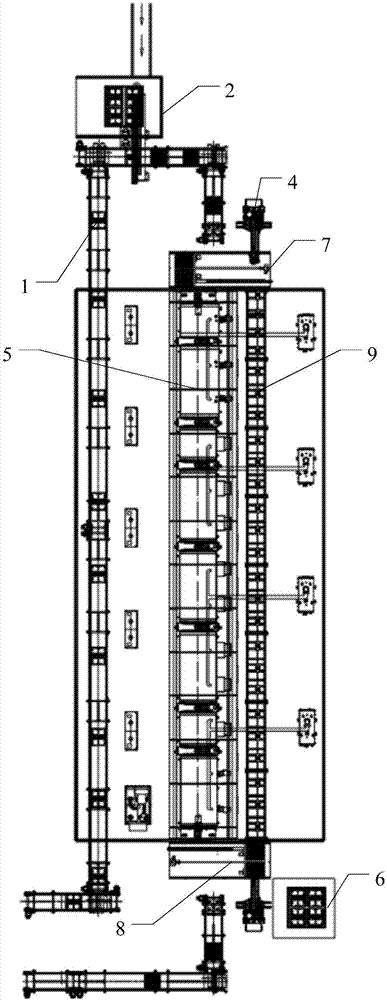

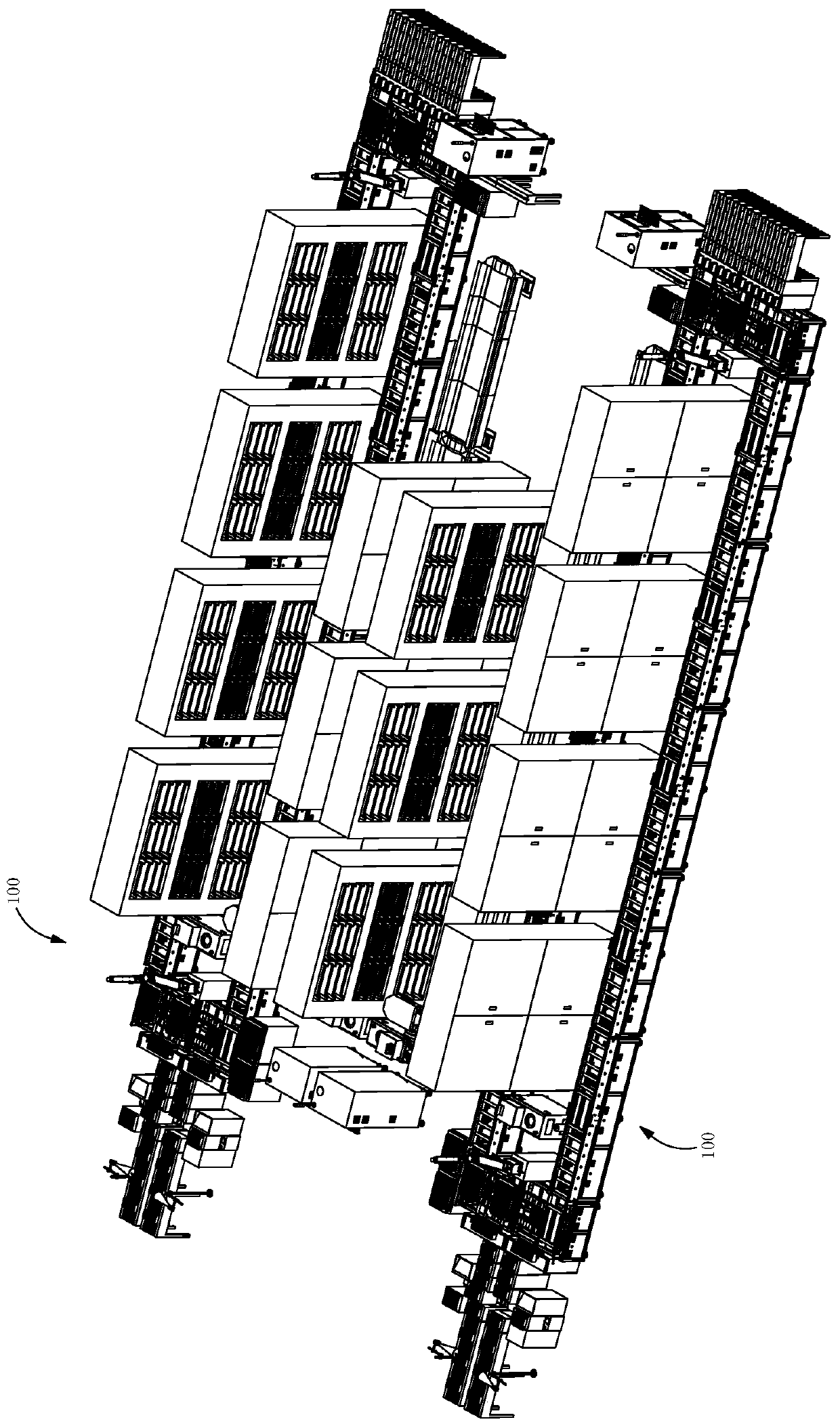

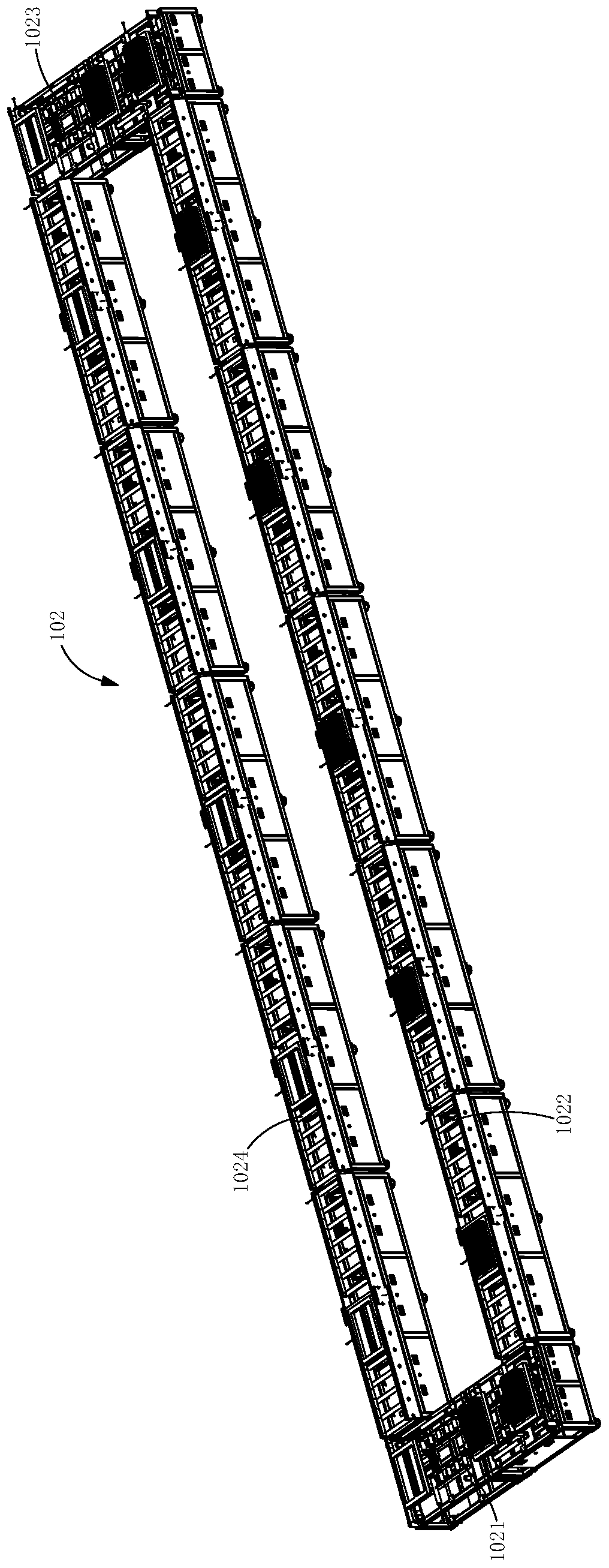

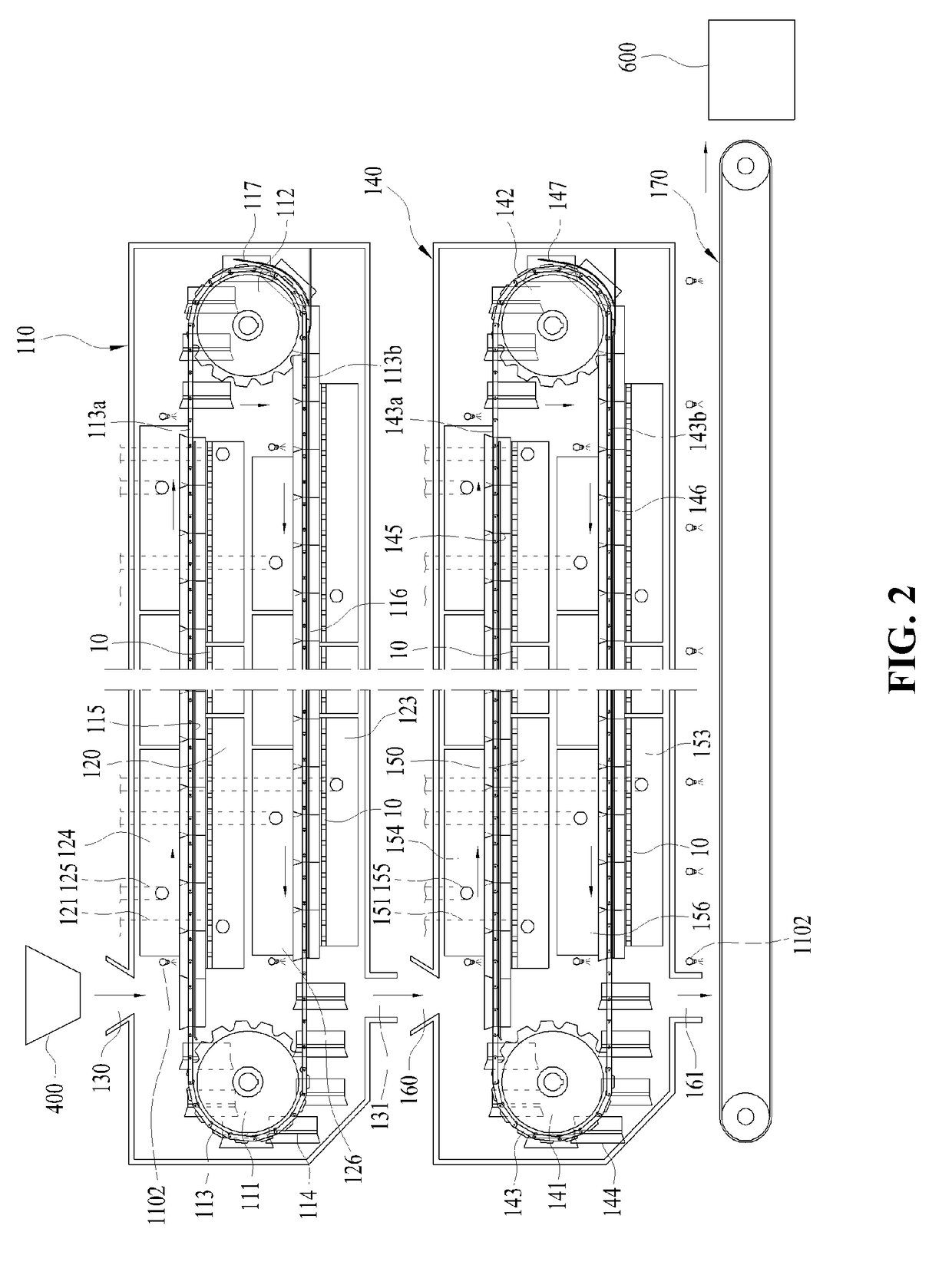

Automatic lithium battery drying line

PendingCN110044162AReal-time monitoring of running statusGuarantee stabilityDrying solid materials without heatFinal product manufactureAutomationLithium battery

The invention relates to the technical field of lithium battery drying and provides an automatic lithium battery drying line. The automatic lithium battery drying line comprises at least one independent drying line which comprises an incoming material position, a clamp circular conveying line, a scheduling unit, a drying unit, a discharging position and a controller. The incoming material position, the clamp circular conveying line, the scheduling unit, the drying unit and the discharging position are connected to the controller. A clamp is arranged on the clamp circular conveying line, and the clamp can operate on the clamp circular conveying line. The incoming material position is arranged at one end of the clamp circular conveying line and the discharging position is arranged at the other end of the clamp circular conveying line. The scheduling unit is also arranged between the incoming material position and the discharging position. The scheduling unit is arranged on one side of the clamp circular conveying line for scheduling the clamp. The drying unit is arranged on at least one side of the scheduling unit. The drying unit is arranged separated from the clamp circular conveying line. The automatic lithium battery drying line can monitor the operating states of parts in real time to guarantee the stability and the safety of system operation, so that the automation level oflithium batteries in processing industry is improved.

Owner:深圳市山村联合实业有限公司

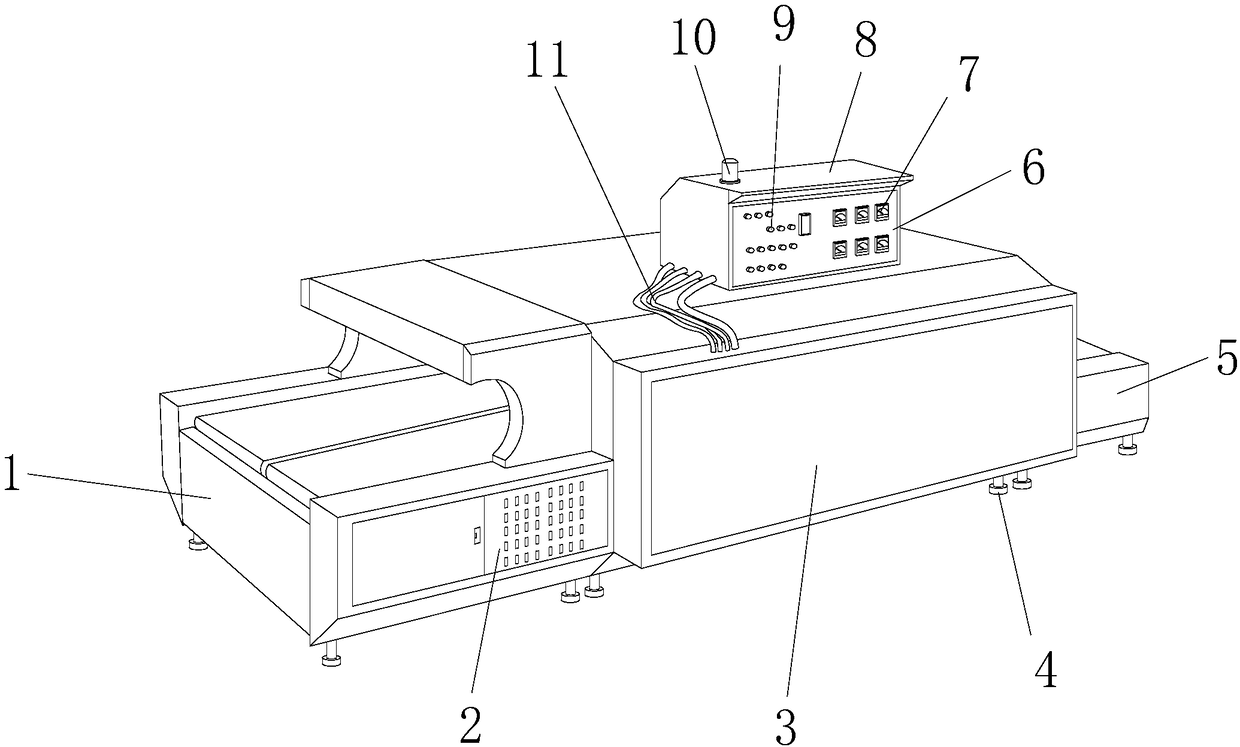

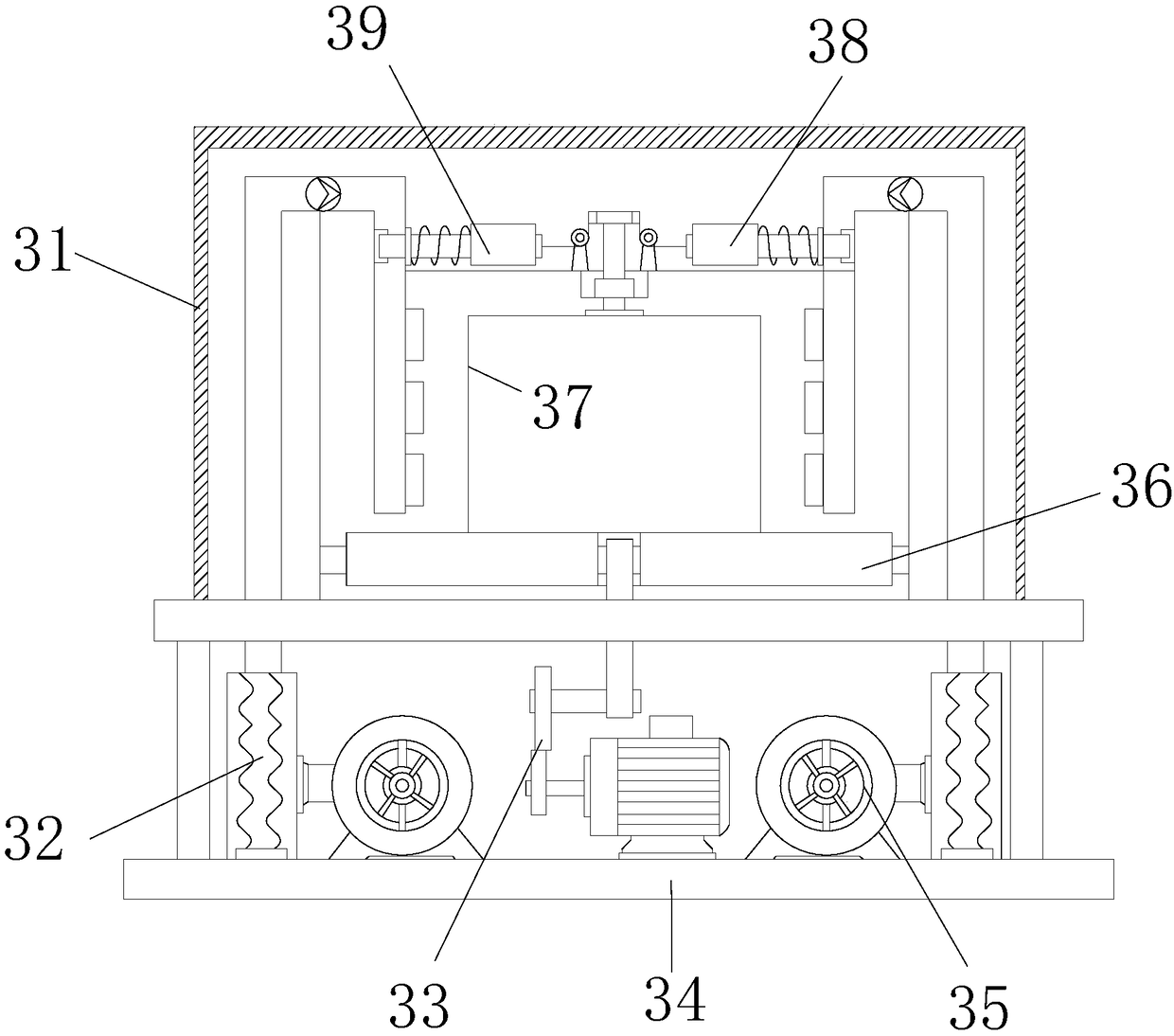

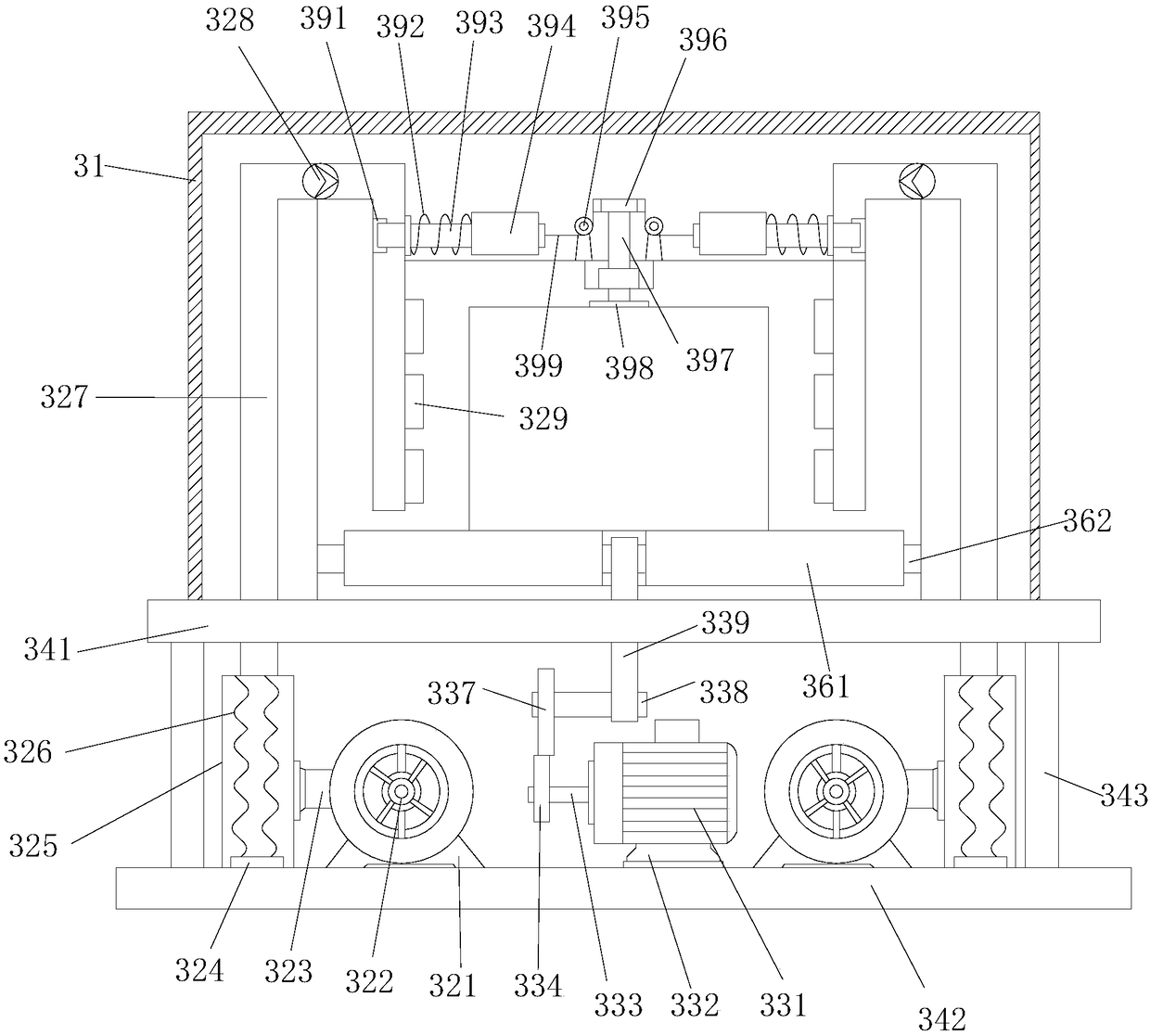

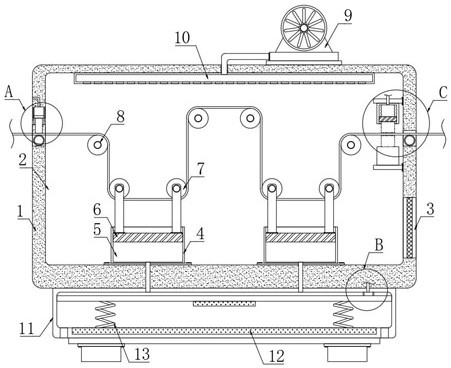

Intermittent drying device for automobile accessories

InactiveCN108224929AImprove drying efficiencyRealize intermittent dryingDrying gas arrangementsDrying safety systemsThermal insulationEngineering

The invention discloses an intermittent drying device for automobile accessories. The intermittent drying device structurally comprises a front conveying base, a heat dissipation opening, a drying box, foot cups, a rear conveying base, a control panel, a display instrument, a main control cabinet, control buttons, a fault warning lamp and connecting lines; the front conveying base and the rear conveying base are arranged on the front side and the rear side of the drying box separately. According to the intermittent drying device for the automobile accessories, a thermal insulation box body, adrying mechanism, a Maltese mechanism, a mounting base, a conveying mechanism and a sensing mechanism are arranged in the drying box, so that intermittent conveying of the automobile accessories in the conveying process can be realized, the automobile accessories have sufficient drying time in the drying box, in addition, the positions of the automobile accessories on a conveying belt can be sensed, intermittent drying can be carried out on the automobile accessories, and therefore the drying effect can be improved.

Owner:伊方昱

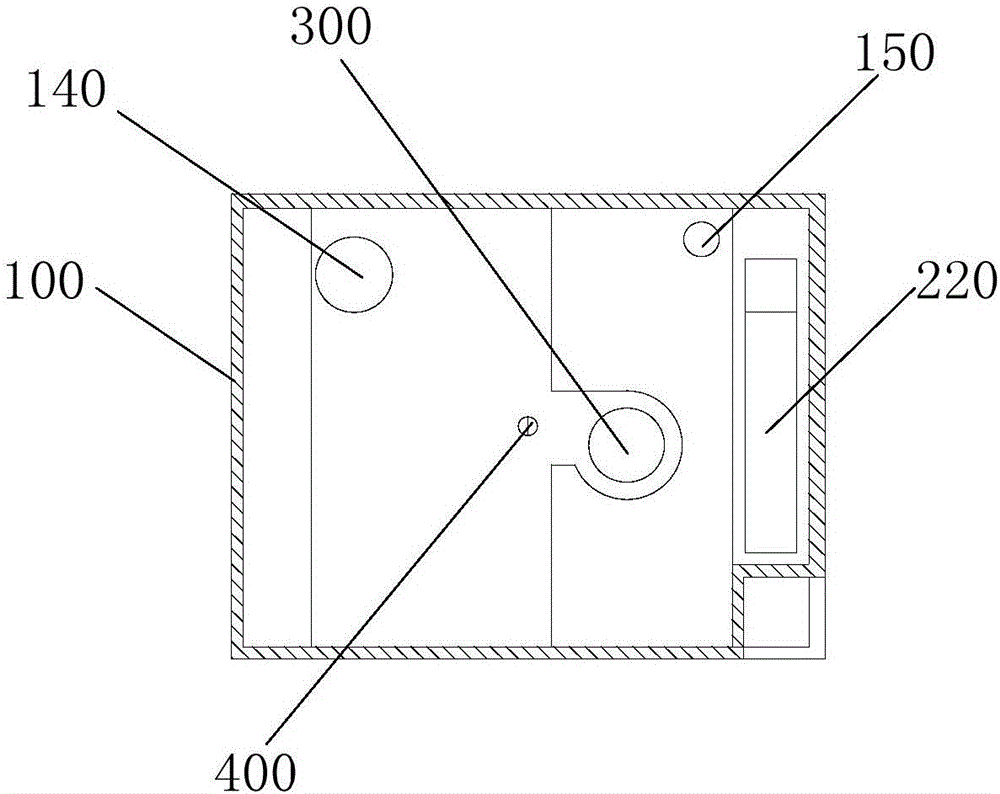

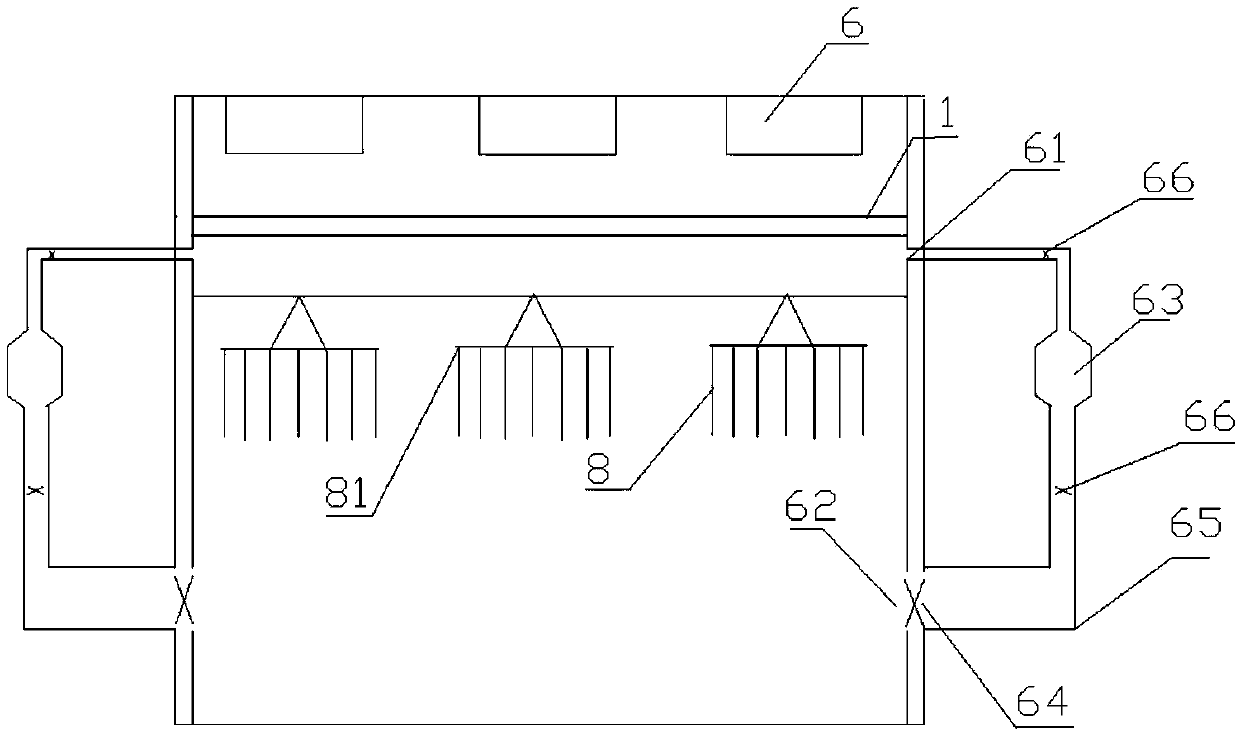

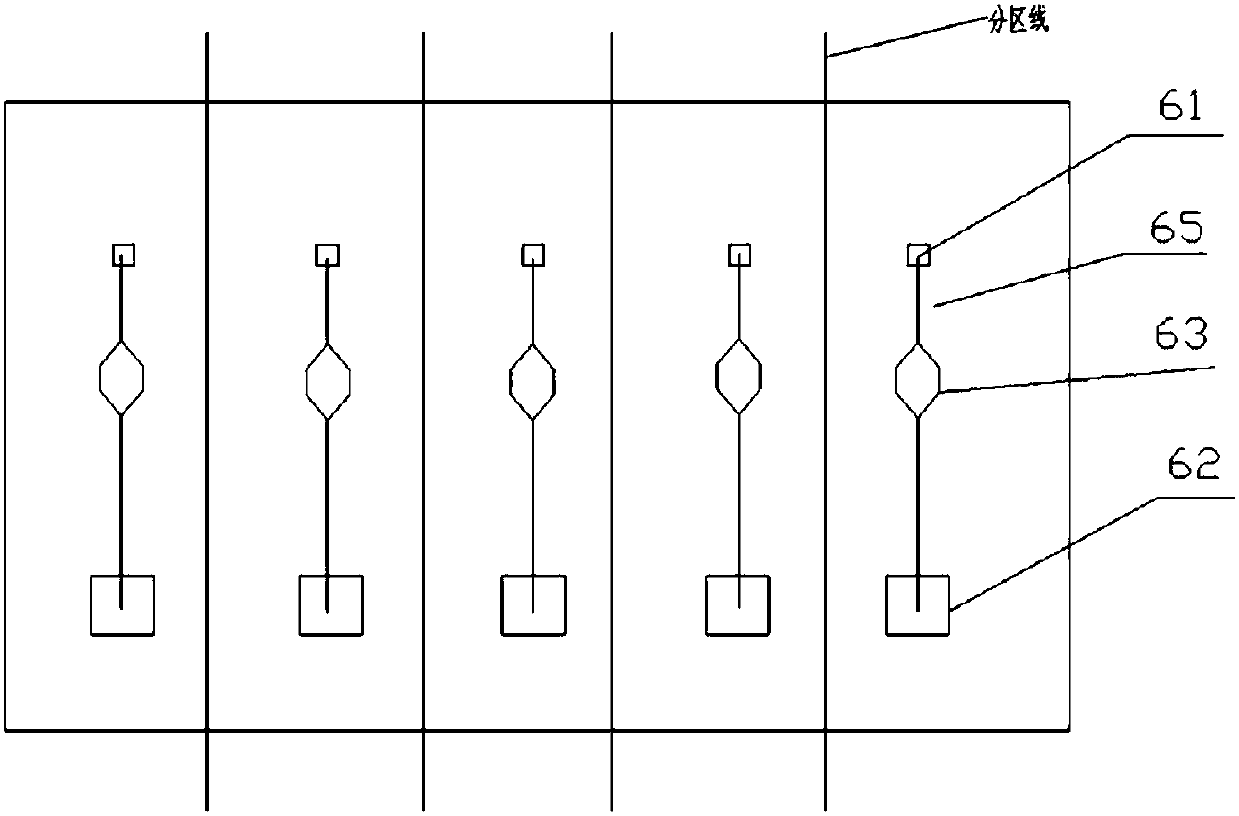

Drying room structure and drying method

PendingCN110388805ANot easy muddy soupReduce cooking lossDrying solid materials with heatDrying gas arrangementsControl systemMonitoring system

The embodiment of the invention provides a drying room structure and a drying method. A drying method in the prior art can be optimized. The drying room is of a room-shaped structure and comprises anentrance and an exit, wherein the interior of the drying room is divided into a plurality of areas, and the areas communicate with one another; and the drying room comprises a conveying system, a heating system, a circulation system, a moisture removal system, a monitoring system and a control system, wherein the control system is used for correspondingly controlling the heating system, the circulation system and the moisture removal system according to the temperature, the humidity and the air speed monitored by the monitoring system. According to the embodiment of the invention, through appropriate drying conditions, a good structure can be formed between the inner protein and the starch molecules of fine dried noodles, so that the fine dried noodles are not easy to muddy in the cookingprocess, the cooking loss is small, and the fine dried noodles are chewy.

Owner:想念食品股份有限公司

Adjustable cloth drying device

ActiveCN113701481AGuaranteed drying qualityReduce distortionDrying machines with progressive movementsDrying safety systemsEngineeringDrying time

The invention discloses an adjustable cloth drying device. The adjustable cloth drying device comprises a box body, a drying cavity is formed in the box body, openings are formed in the inner walls of the left side and the right side of the drying cavity, a guide roller is arranged at the inner bottom of each opening, a plurality of fixed winding rollers are arranged in the drying cavity, two adjusting blocks are symmetrically arranged at the inner bottom of the drying cavity, an adjusting groove is formed in the upper end of each adjusting block, a sliding plate used for sliding up and down is arranged in each adjusting groove, two mounting frames are symmetrically arranged on each sliding plate, and a movable winding roller is mounted on each mounting frame. In the using process of the device, the cloth drying time can be adjusted according to the thickness of cloth, then the good cloth drying effect is achieved, and the device is further provided with a warning structure, so that an alarm can be given out when the cloth is damaged or wrinkled after being dried.

Owner:南通好心情家用纺织品有限公司

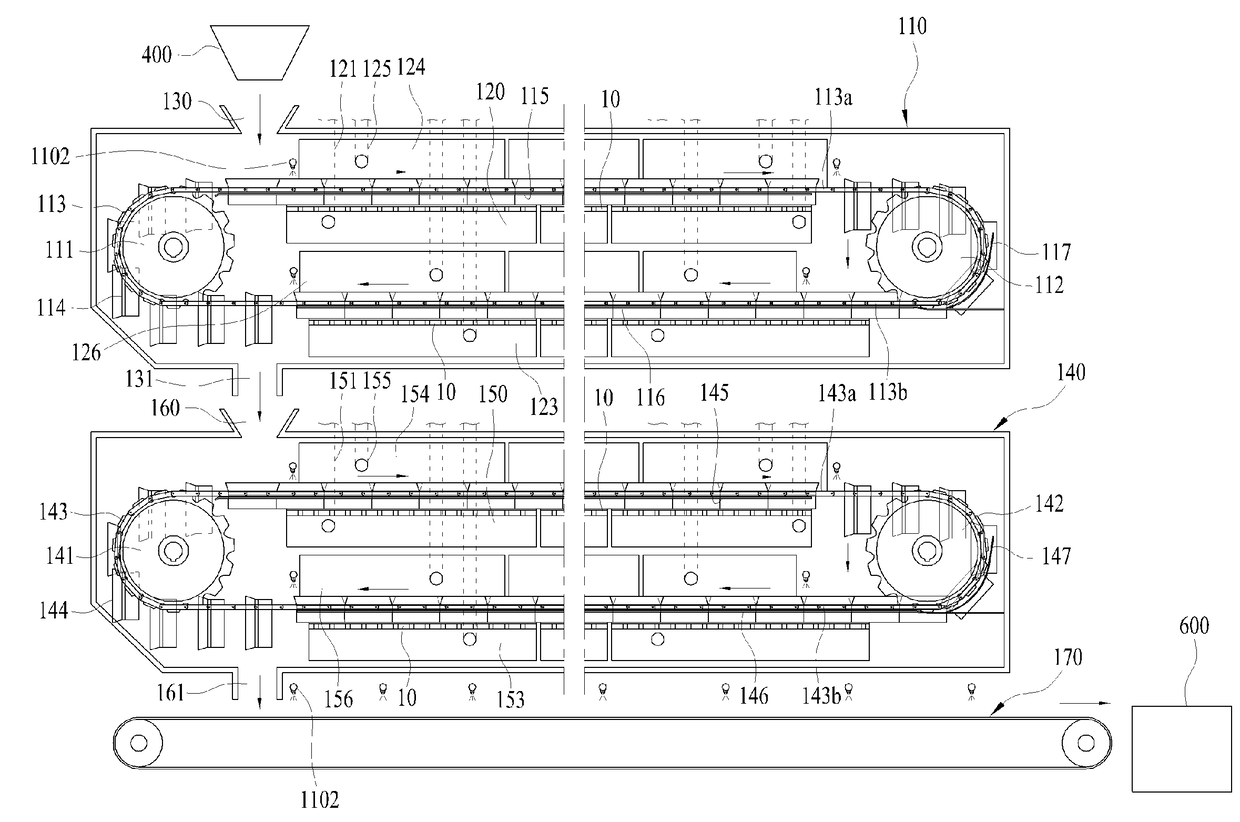

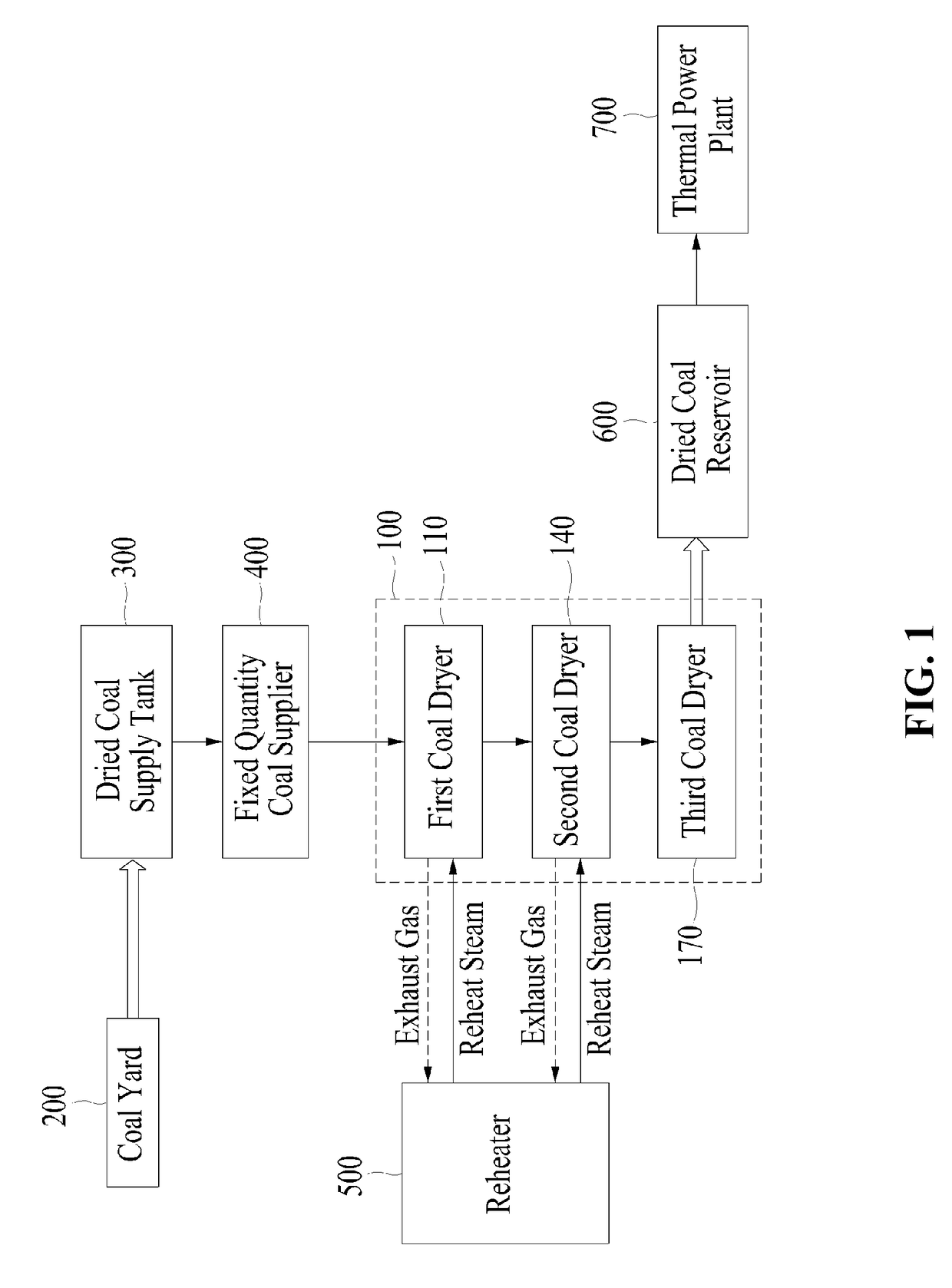

Apparatus for preventing spontaneous ignition of transferred coal in apparatus for drying coal using reheat steam

InactiveUS20170145315A1Maximize useMinimize occurrenceDrying solid materials with heatCoke ovensFour-way valveNitrogen

The present invention relates to an apparatus for preventing, in a multi-stage dryer for drying coal using reheat steam, spontaneous ignition caused by oxidation of coal when coal is transferred to the multi-stage dryer from a fixed quantity coal supplier by way of a pulverizer. The present invention relates to an apparatus for drying coal using reheat steam, the apparatus being configured so that coal which has been dried primarily in a first coal dryer is inputted into a second coal dryer and thus is secondarily dried, wherein reheat steam generated from a reheater is supplied through a reheat steam supply pipe; a nitrogen supplier supplies nitrogen through a nitrogen supply pipe; saturated steam generated from a saturated steam generator is supplied through a saturated steam supply pipe; the reheat steam supply pipe, the nitrogen supplier, and the saturated steam supply pipe are connected to a 4-way valve; and the 4-way valve supplies nitrogen and saturated steam, or nitrogen or saturated steam, along with reheat steam, to first to fourth steam chambers through the steam supply pipe, and injects steam into coal which is transferred to a first transfer plate and a second transfer plate so that spontaneous ignition of coal is prevented in the course of drying and transferring coal.

Owner:HANKOOK TECH

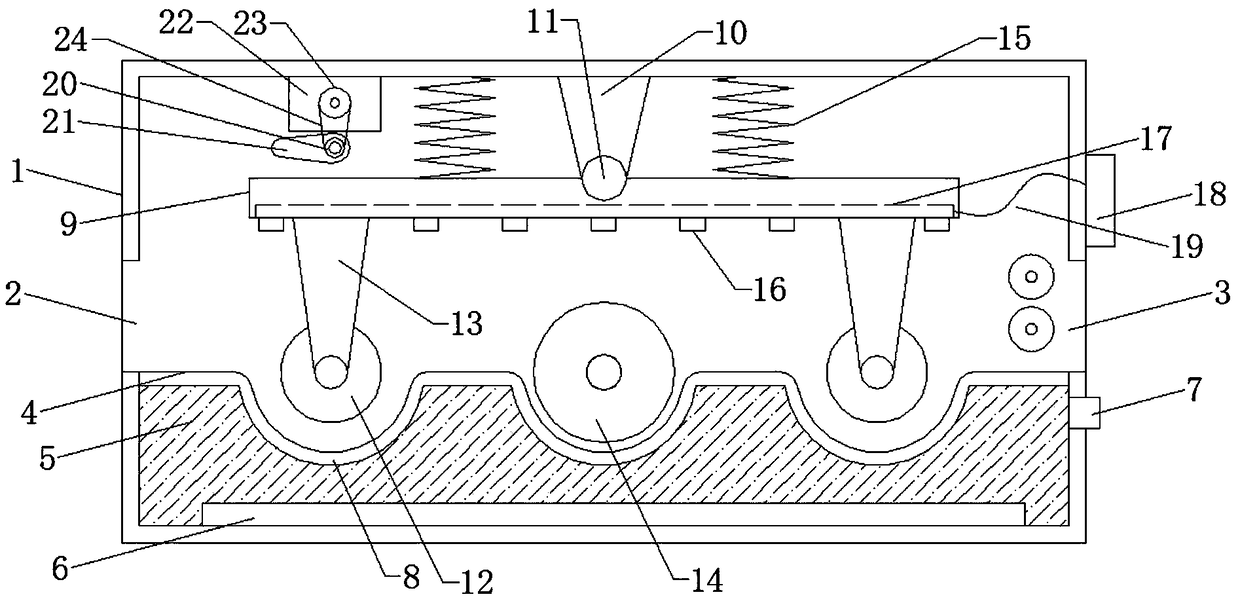

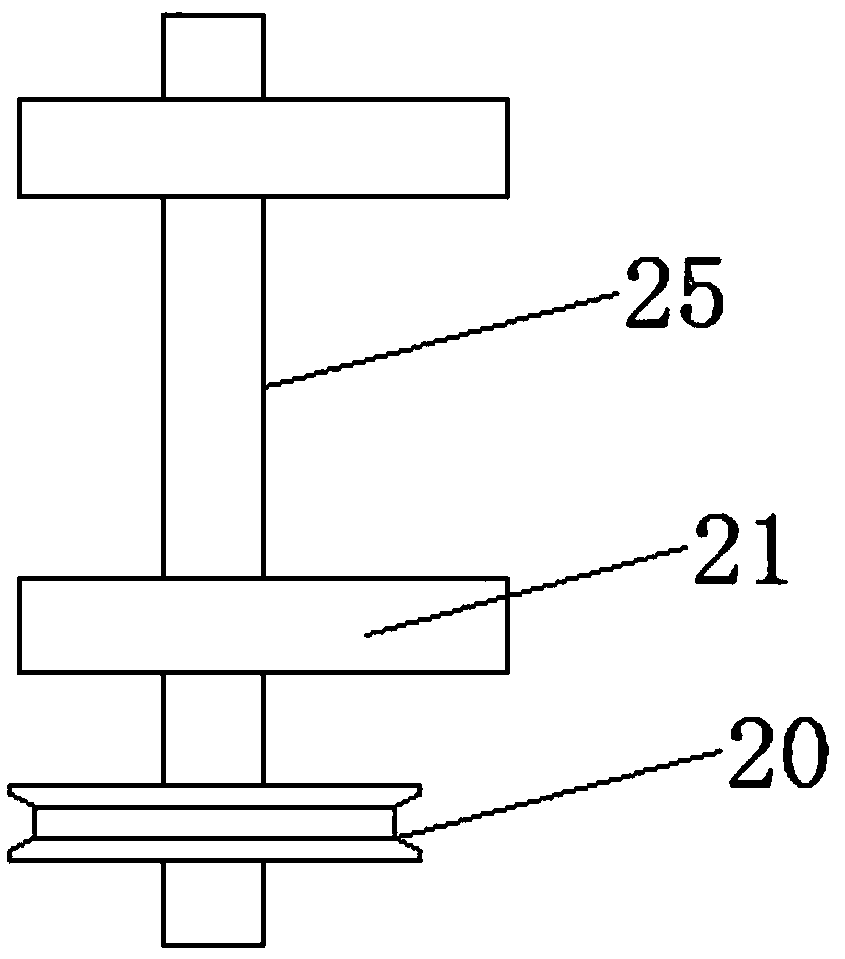

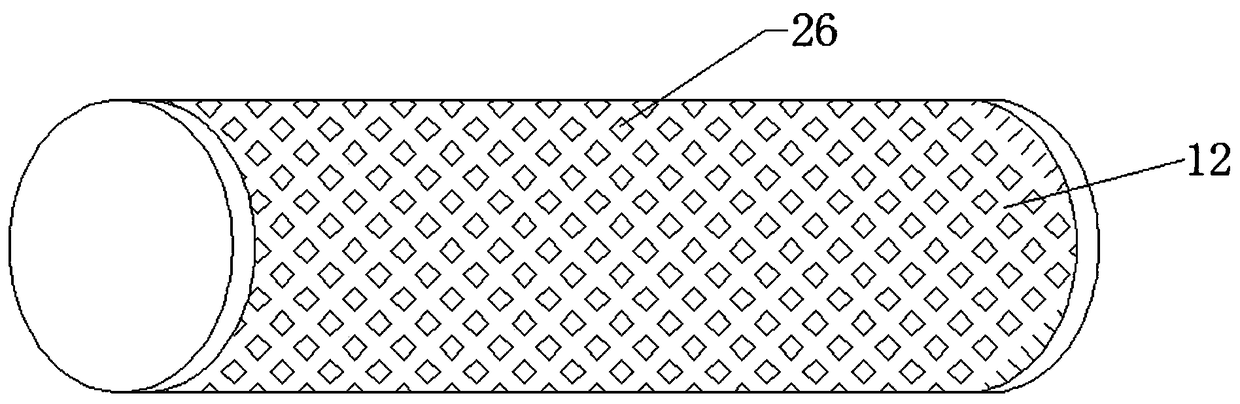

Platform conveying drying device for fabric processing

InactiveCN109028872ALong conveying distanceReduce the number of frequent feeds to the internalDrying machines with progressive movementsDrying safety systemsWater vaporEngineering

The invention discloses a platform conveying drying device for fabric processing. The platform conveying drying device comprises a shell, a feed inlet, a discharge hole, a heating element and conveying guide wheels. A horizontal platform which is horizontal is fixedly welded to the lower side of the corresponding feed inlet and discharge hole in the shell, and the horizontal platform is internallyprovided with a plurality of downwardly sunk curved plates at equal distance. A heating cavity is formed in the lower side of the horizontal platform and the curved plates in a sealed mode. The curved plates are internally provided with guide wheels, and the guide wheels comprise the swinging guide wheels which move up and down and the fixed guide wheel which is stationary. The platform conveyingdrying device conveys fabric on the surfaces of the horizontal platform and the curved plates, heats the fabric, evaporates water vapor in the fabric, and dries the fabric. The arranged curved platesextend the conveying distance of the fabric, prolong the drying time, reduce the number of times of frequent feeding into the interior of the fabric, and shortens the processing time; and the different guide wheels are arranged, and especially the swinging guide wheels shake the fabric to shake out moisture in the fabric to separate the moisture from the fabric.

Owner:陈敏珍

Clothes dryer exhaust device

ActiveUS9103589B2Provide convenienceImprove efficiencyDrying safety systemsDrying solid materialsPulp and paper industry

A clothes dryer exhaust line blower system is provided that assists a clothes dryer venting hot air and lint from the dryer interior and through the length of the dryer ducting to maintain a clear pathway and maintain the dryer's efficiency over time. A Y-pipe having a main exhaust line and an intermediate line is installed on the dryer exhaust port and connects the dryer exhaust outlet to an existing dryer duct that is adapted to communicate dryer exhaust from the dryer to the exterior of a dwelling. An intermediate section of the Y-pipe connection includes an electric blower assembly that functions as an auxiliary venting means, which generates air pressure to assist the dryer assembly vent the heated air through the exhaust conduit during the drying process. The blower is electrically driven and is controlled via a manual switch or timer switch that functions in conjunction with the drying cycles of the dryer.

Owner:SULLIVAN LOWELL R

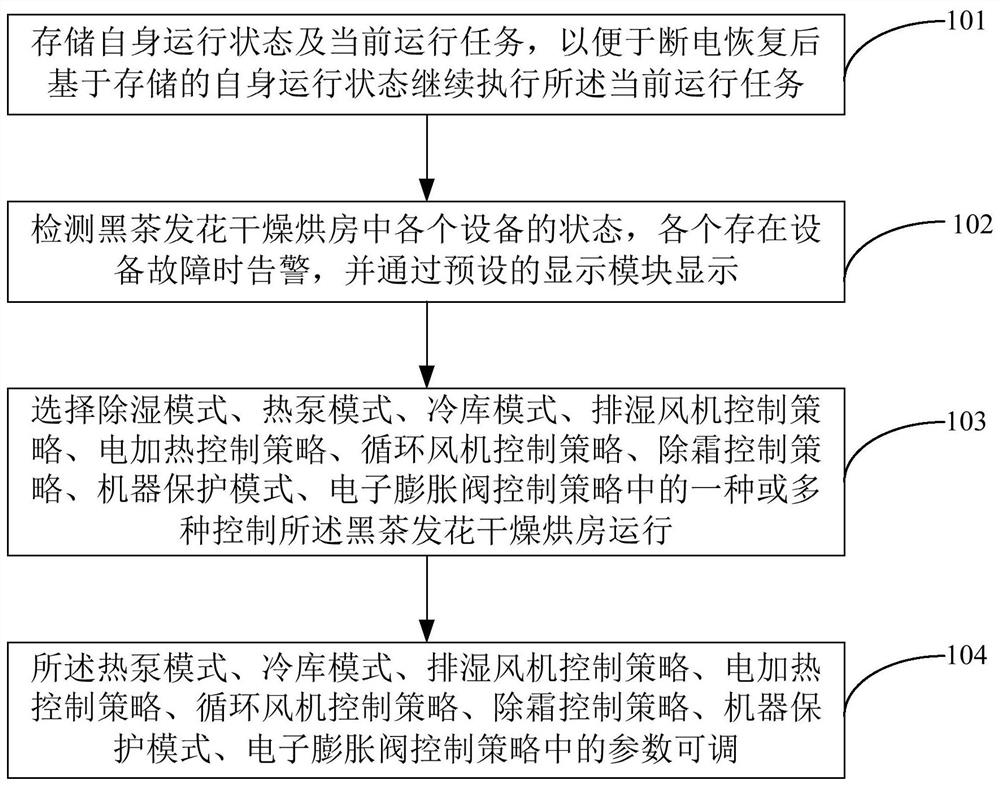

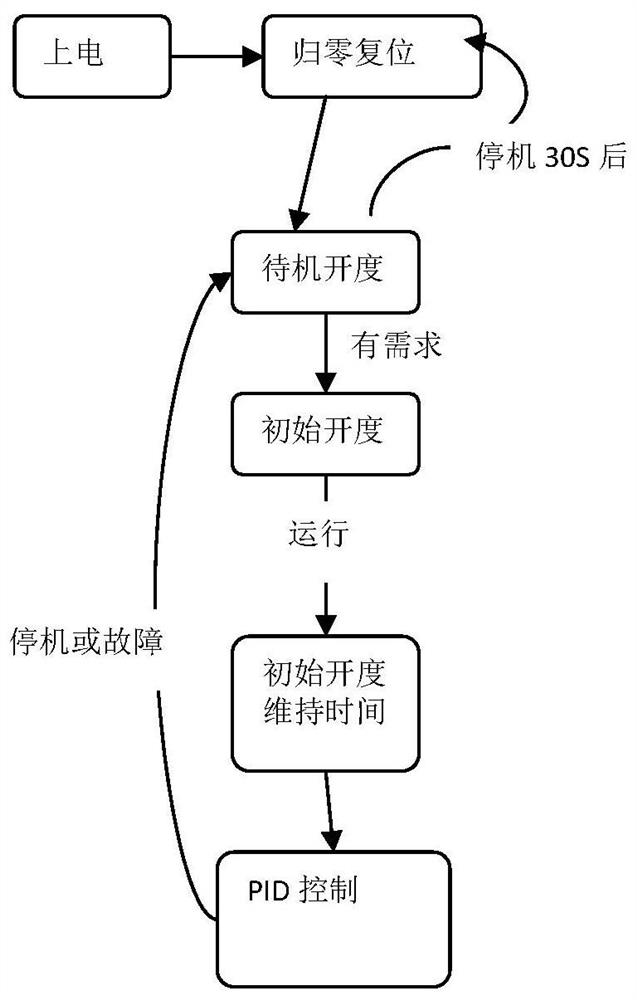

Dark tea eurotium cristatum growing and drying room and control method thereof

ActiveCN112460936AWith self-test functionWith power-off memory functionDrying gas arrangementsCorrosion preventionProcess engineeringRefrigeration

The invention provides a dark tea eurotium cristatum growing and drying room and a control method thereof. The control method of the dark tea eurotium cristatum growing and drying room comprises the following steps that a self running state and a current running task are stored, so that the current running task is executed continuously on the basis of the stored self running state after power failure recovery; the state of each piece of equipment in the dark tea eurotium cristatum growing and drying room is detected, an alarm is given when the equipment breaks down, and the alarm is displayedthrough a preset display module; one or more of a dehumidification mode, a heat pump mode, a refrigeration house mode, a dehumidification fan control strategy, an electric heating control strategy, acirculating fan control strategy, a defrosting control strategy, a machine protection mode and an electronic expansion valve control strategy are selected to control the black tea eurotium cristatum growing and drying room to operate; parameters of the heat pump mode, the refrigeration house mode, the dehumidification fan control strategy, the electric heating control strategy, the circulating fancontrol strategy, the defrosting control strategy, the machine protection mode and the electronic expansion valve control strategy are adjustable.

Owner:CHINATEA HUNAN ANHUA FIRST TEA FACTORY CO LTD

Viscous flow type pyrotechnic composition drying room

PendingCN108317813AImprove drying efficiencyOvercoming the common problem of slower dryingDrying gas arrangementsDrying safety systemsAlcoholFresh air

The invention discloses a viscous flow type pyrotechnic composition drying room. A hot air inlet of the lower portion of the drying room communicates with an air outlet of a hot air supply mechanism.One ends of a plurality of moisture exhaust branch pipes communicate with the upper portion of the drying room, and the other ends of the moisture exhaust branch pipes communicate with an air inlet ofan air channel A of a heat exchanger. An air outlet of the air channel A of the heat exchanger is inserted into water. An air inlet of an air channel B of the heat exchanger serves as a fresh air inlet, and an air outlet of the air channel B communicates with an air inlet of the hot air supply mechanism. The viscous flow type pyrotechnic composition drying room can improve drying efficiency, is beneficial for increasing the drying speed, achieves zero emission of ethyl alcohol and dust, and thoroughly eliminates potential safety hazards.

Owner:湖南省浏阳市择明热工器材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com