Energy-saving drying box

A technology of drying oven and drying warehouse, which is applied in drying solid materials, drying safety system, drying gas arrangement, etc., can solve problems such as inability to effectively control heating temperature, poor drying efficiency of drying oven, and high energy consumption of electric heating resistance wires. , to achieve the effect of prolonging the heat exchange time, good heat dissipation effect and good insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

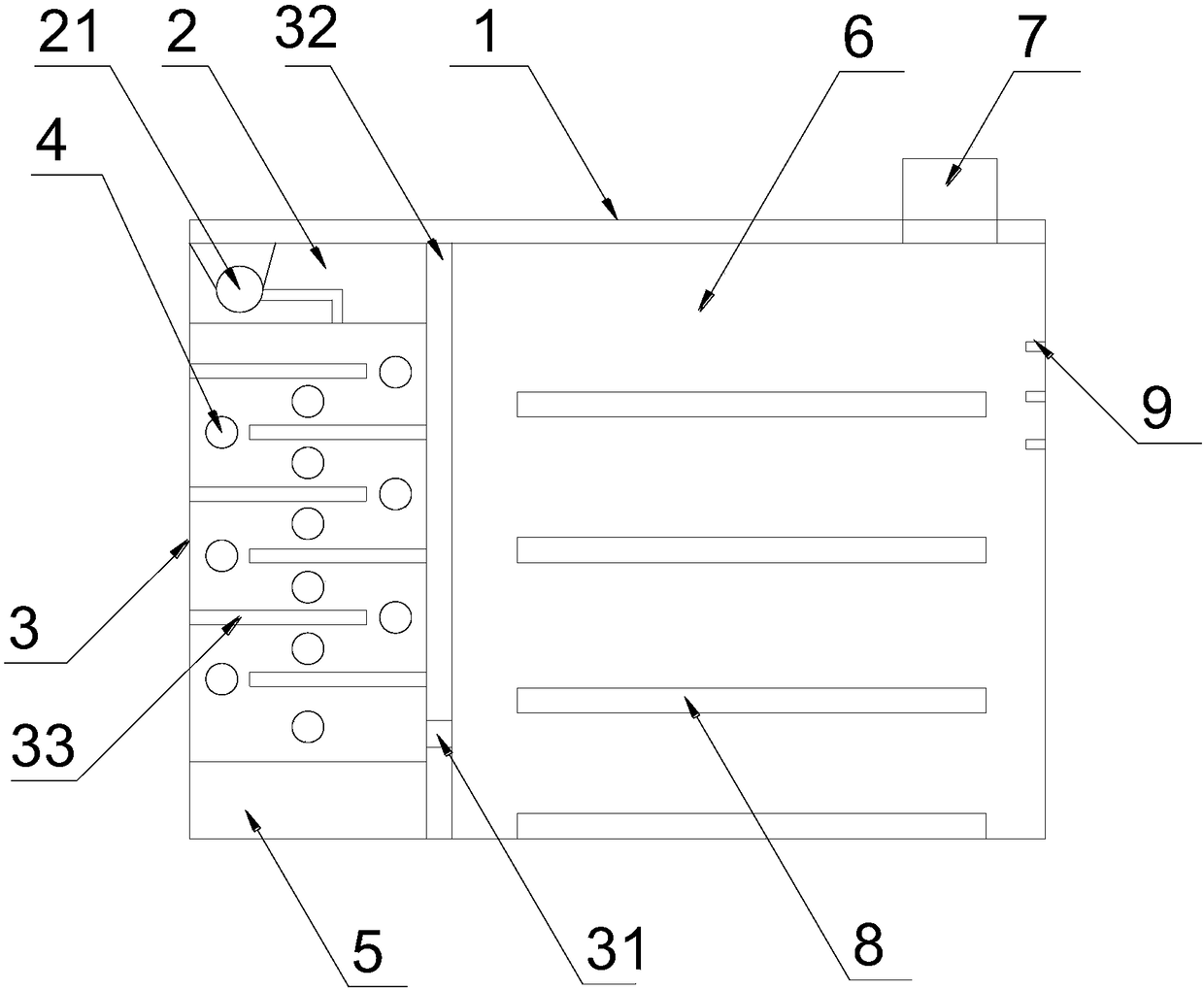

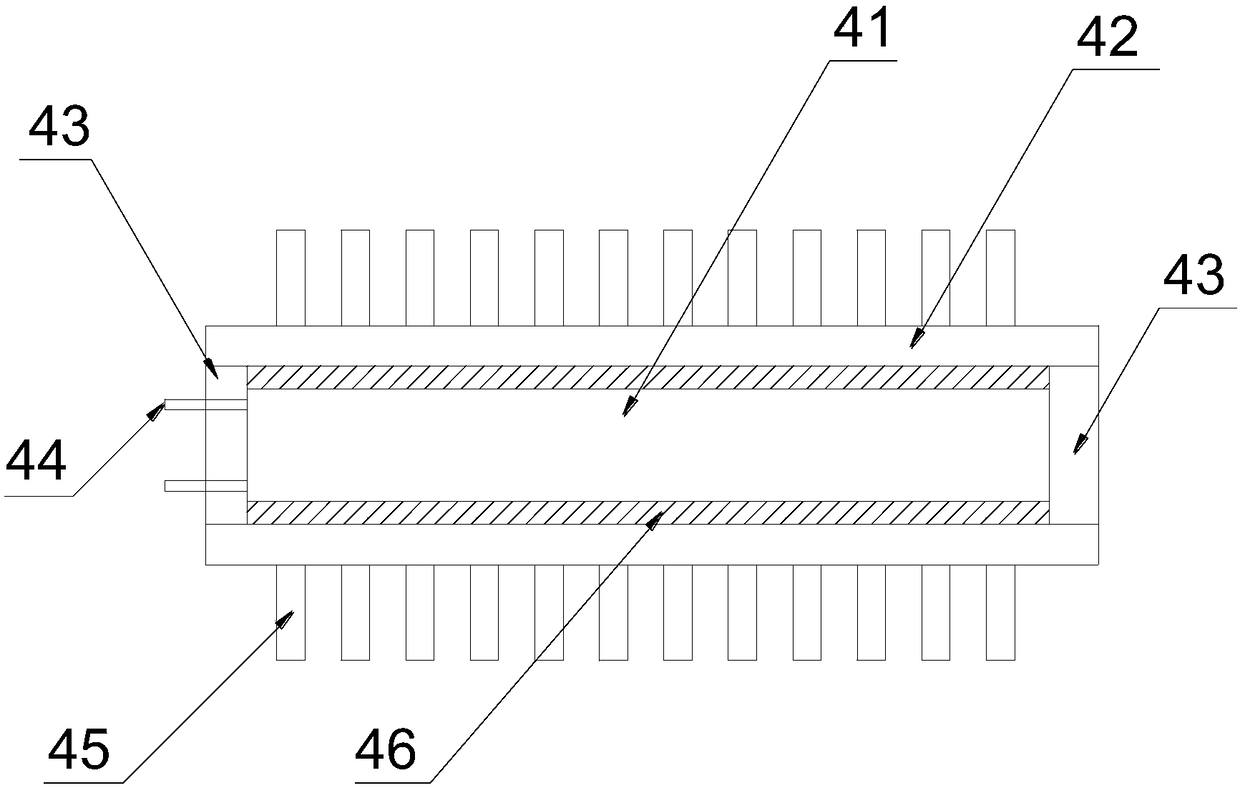

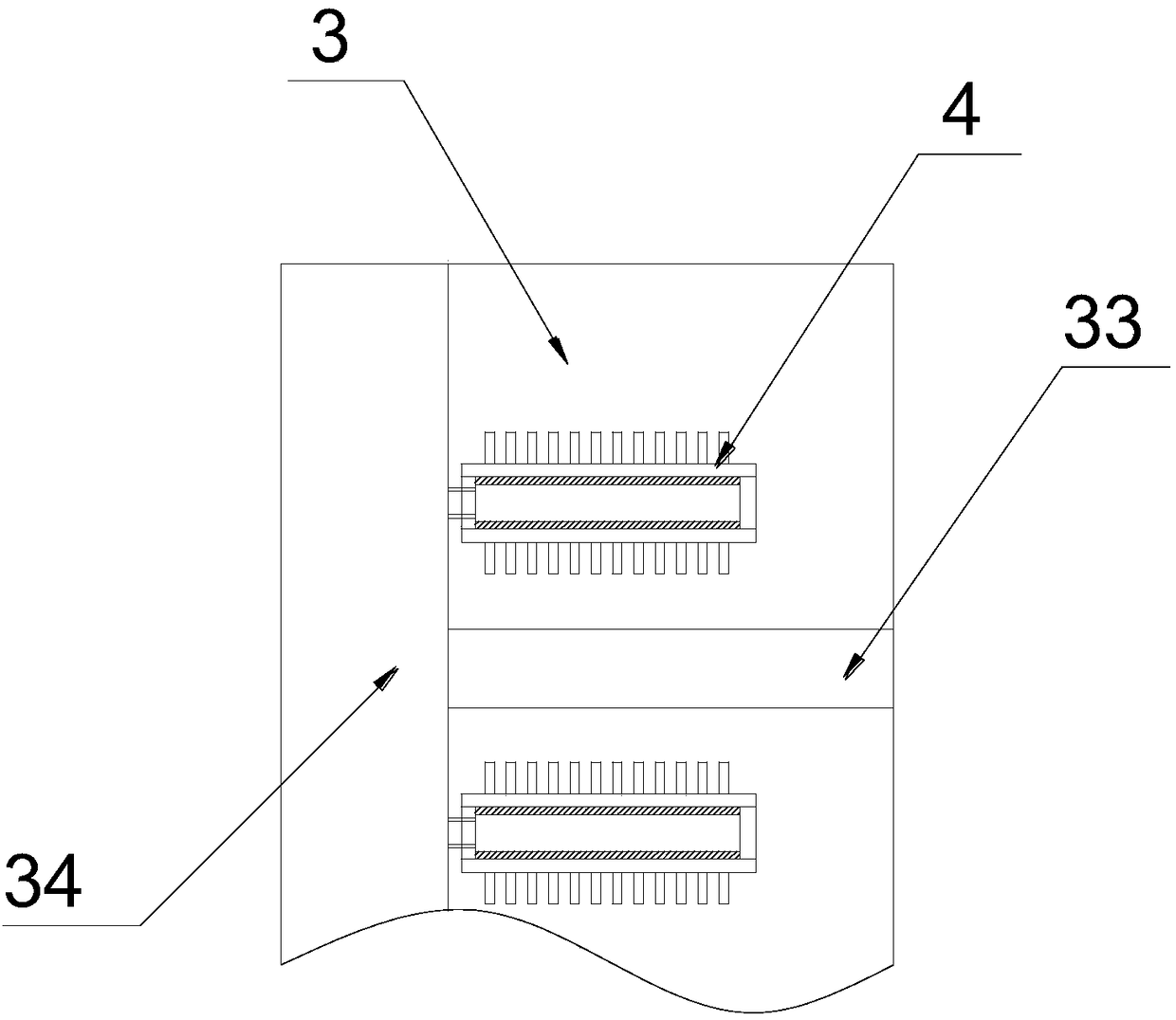

[0021] Such as Figure 1-4 as shown, figure 1 A schematic structural view of an energy-saving drying oven proposed by the present invention figure 2 It is a structural schematic diagram of the heating assembly in the energy-saving drying box proposed by the present invention, image 3 It is a schematic diagram of the partial structure of the drying chamber in the energy-saving drying oven proposed by the present invention, Figure 4 It is a schematic diagram of the outer structure of the energy-saving drying box proposed by the present invention.

[0022] refer to Figure 1-4 An energy-saving drying box proposed by the present invention includes a box body 1, an equipment bin 2, a heating bin 3, a control bin 5 and a drying bin 6; When the door 11 is closed, it forms a sealed structure with the box body 1, and the signal of the display screen 12 and the control panel 13 are connected to the PLC control system installed inside the control compartment 5, and the control com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com