Drying system in radioactive solid waste furnace and drying method

A technology of solid waste and drying system, which is applied in the direction of drying safety system, drying solid material, drying machine for static material, etc. It can solve the problem of air discharge of radioactive materials without proper solution, increase evaporation speed, and does not mention the drying process Split cooling and other issues to achieve the effect of avoiding emissions, avoiding efflux, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments.

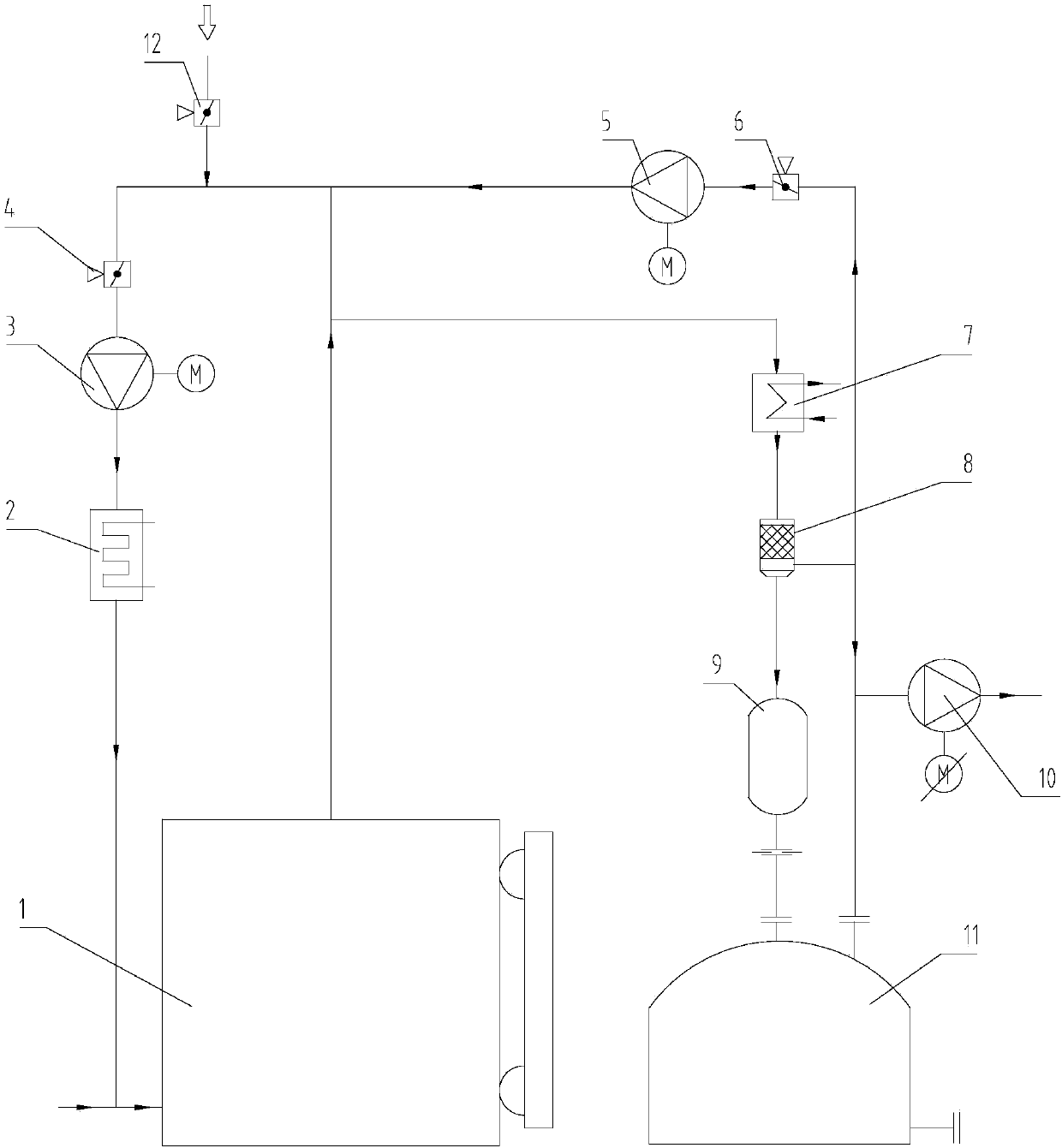

[0019] The radioactive solid waste in-furnace drying system of this embodiment is as follows: figure 1 As shown, the drying furnace 1 has a main circulation loop connected to the side of the drying furnace 1 through the heating fan 3 and the heater 2 connected in series at the top, and is connected to the condensate through the cooler 7, the steam-water separator 8 and the metering device 9. Split line for box 11. A hot blast regulating valve 4 is arranged before the heating blower 3, the heater 2 can be an electric heater, and various heat exchangers can also be used as the heater, and the cooler 7 can adopt various heat exchangers.

[0020] The gas outlet of the steam-water separator 8 is connected to the main circulation loop through the cooling fan 5 to form a return gas pipeline. Before the cooling fan ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com