A method of monitoring a spray dryer and a spray dryer comprising one or more infrared cameras

An infrared camera, spray dryer technology, applied in drying solid materials, drying safety systems, heating to dry solid materials, etc., can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

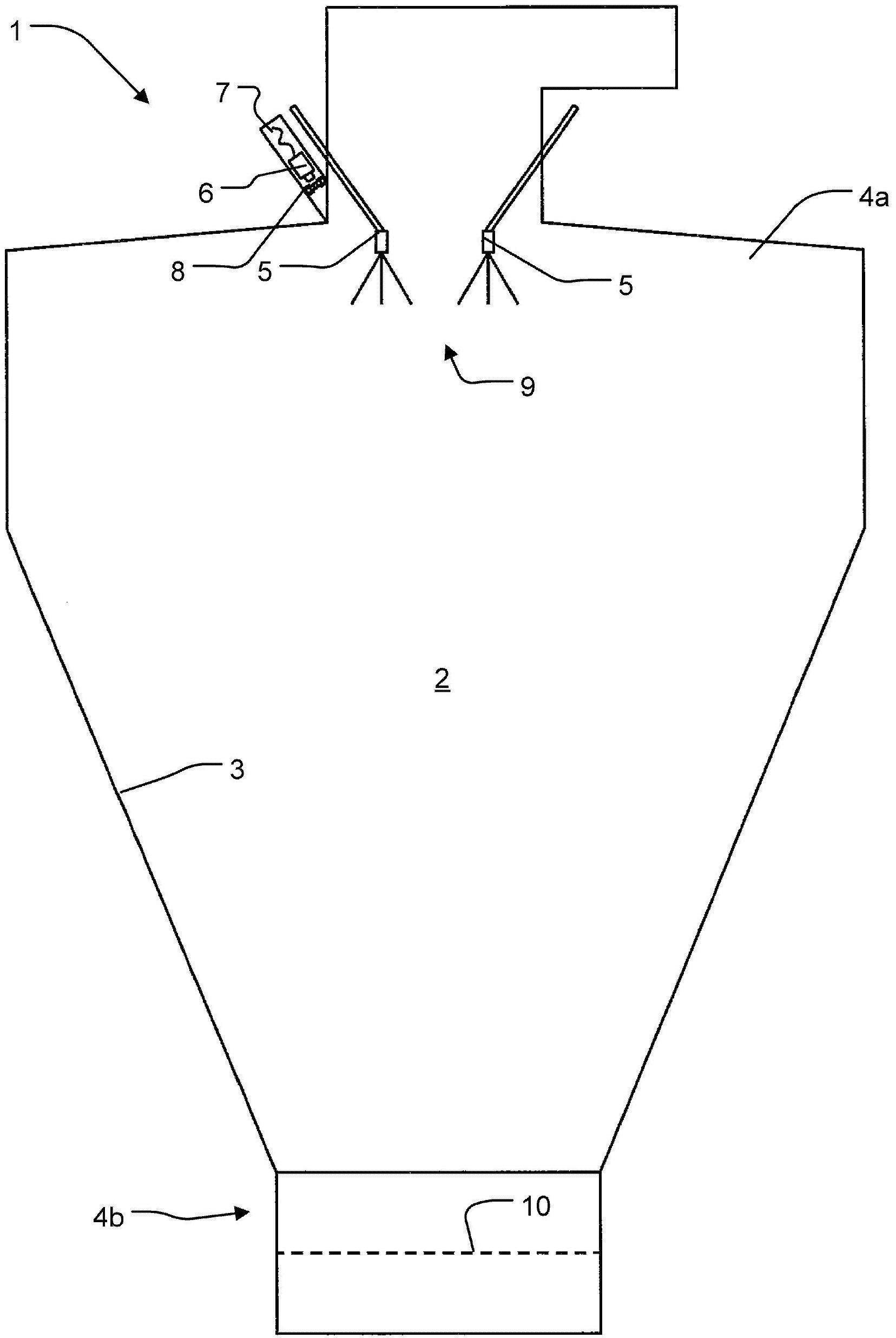

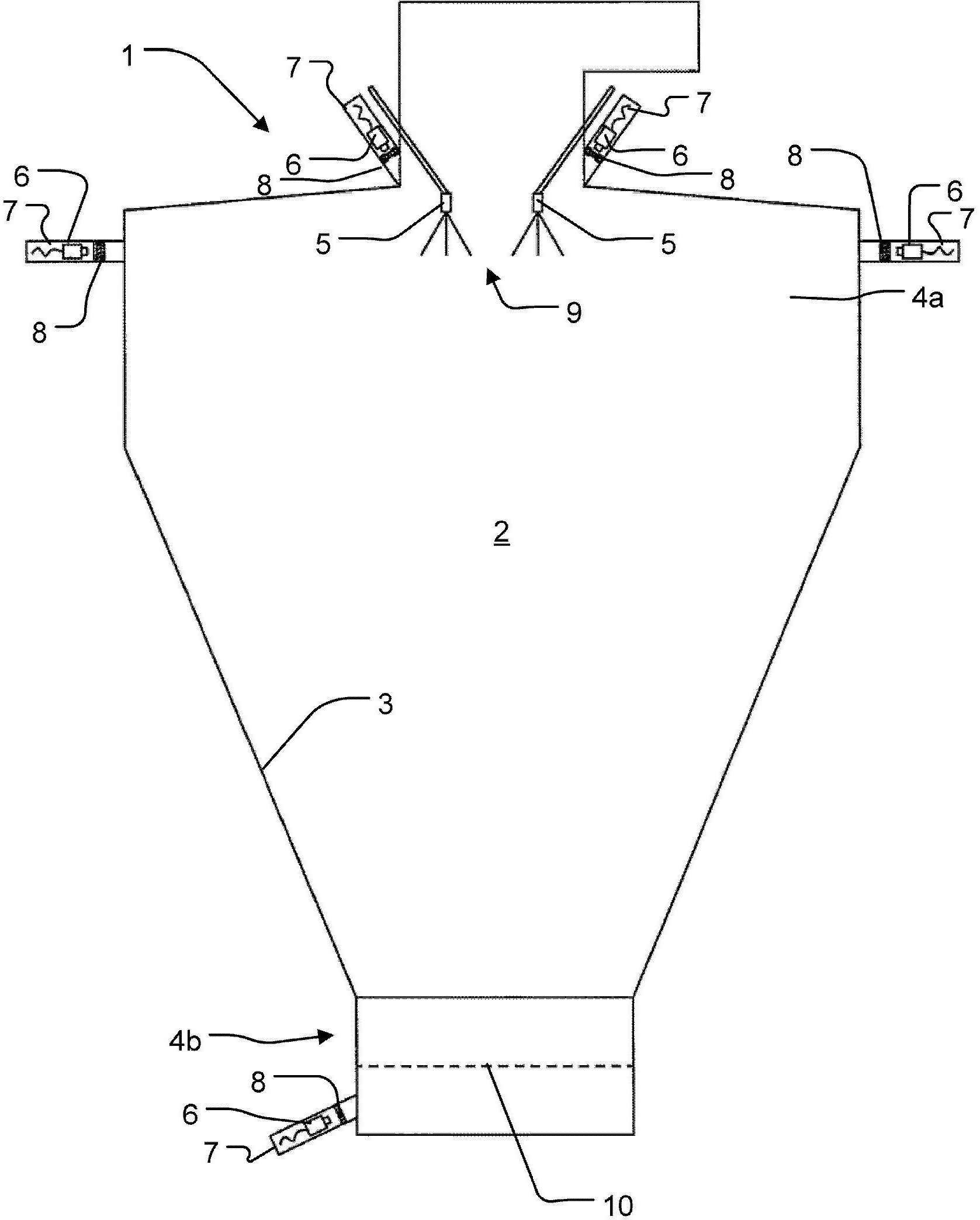

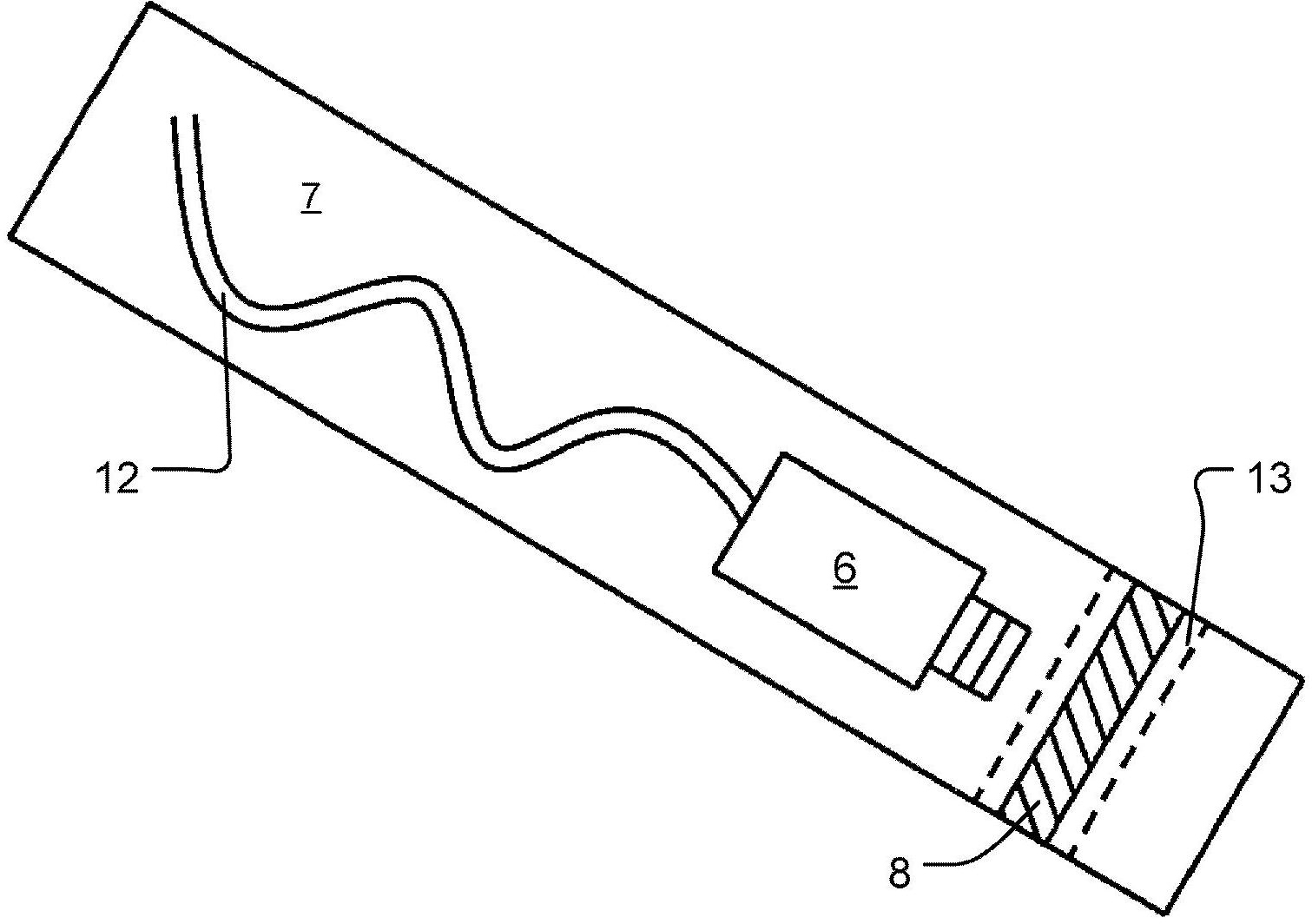

[0031] figure 1 An example of a spray dryer 1 with a spray drying chamber 2 is shown, which includes a substantially cylindrical top portion 4a, a conical wall 3, and a narrow lower portion 4b. An atomizing device 9 is provided in the top 4a. An air diffuser connected to the air inlet, which may be a straight air inlet, a radial inlet, or a tangential inlet, is provided in the top of the spray drying chamber (not shown). The air diffuser may, for example, have the form described in the applicant's co-pending international application No. WO2007 / 071238 or PCT / DK2009 / 050277, or may be similarly designed as other conventional air diffusers.

[0032] The spray dryer 1 comprises a supply device to the atomization device 9 in a manner known per se. The air diffuser may be installed above or in the ceiling of the drying chamber 2 of the spray dryer 1, or installed in the top 4a of the drying chamber 2, for example. Depending on the size of the drying chamber 2, there may be more than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com