Drying room structure and drying method

A drying room and area technology, applied in the direction of drying, drying machine, drying solid materials, etc., can solve the problems of fluctuating drying conditions, time-consuming and extensive, easy to break, etc., and achieve the effect of small cooking loss and not easy to muddy soup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

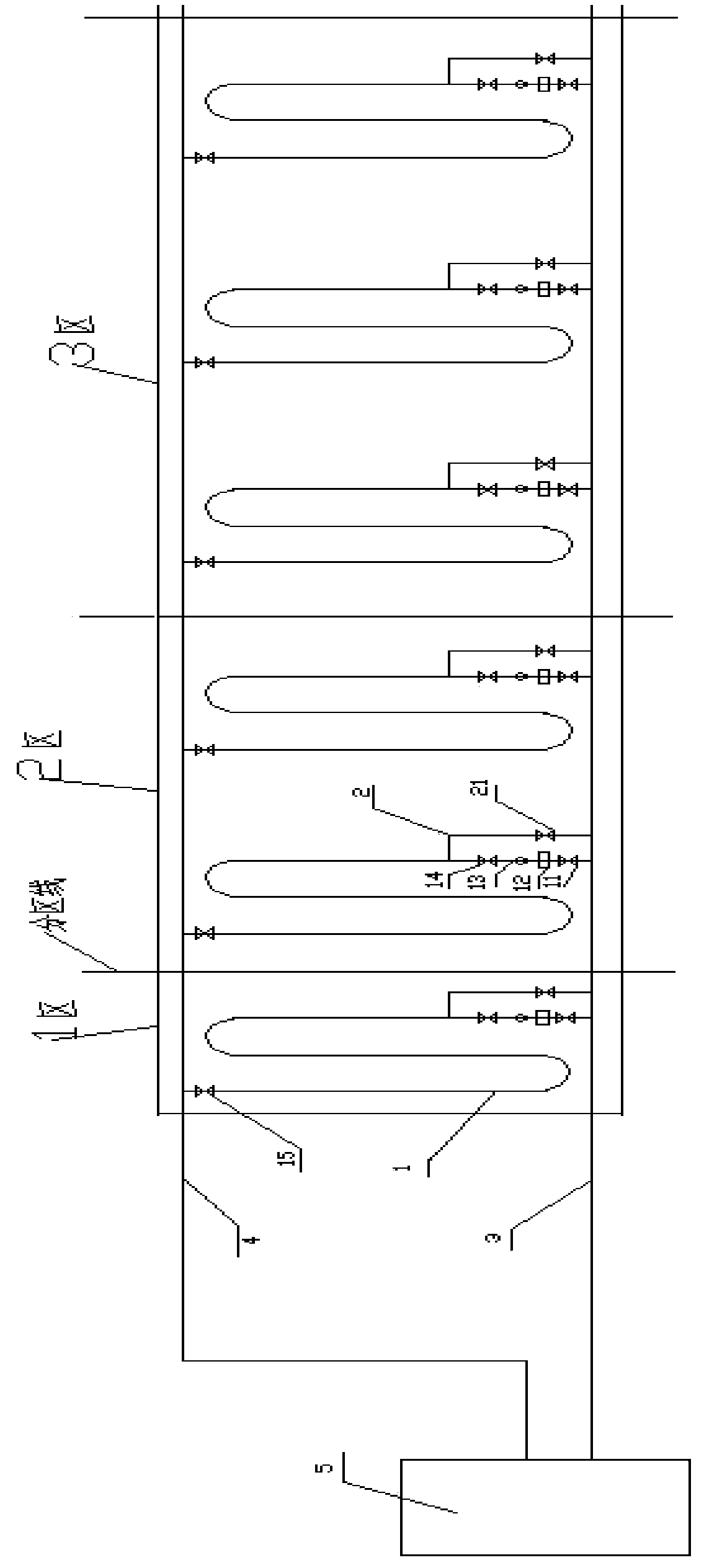

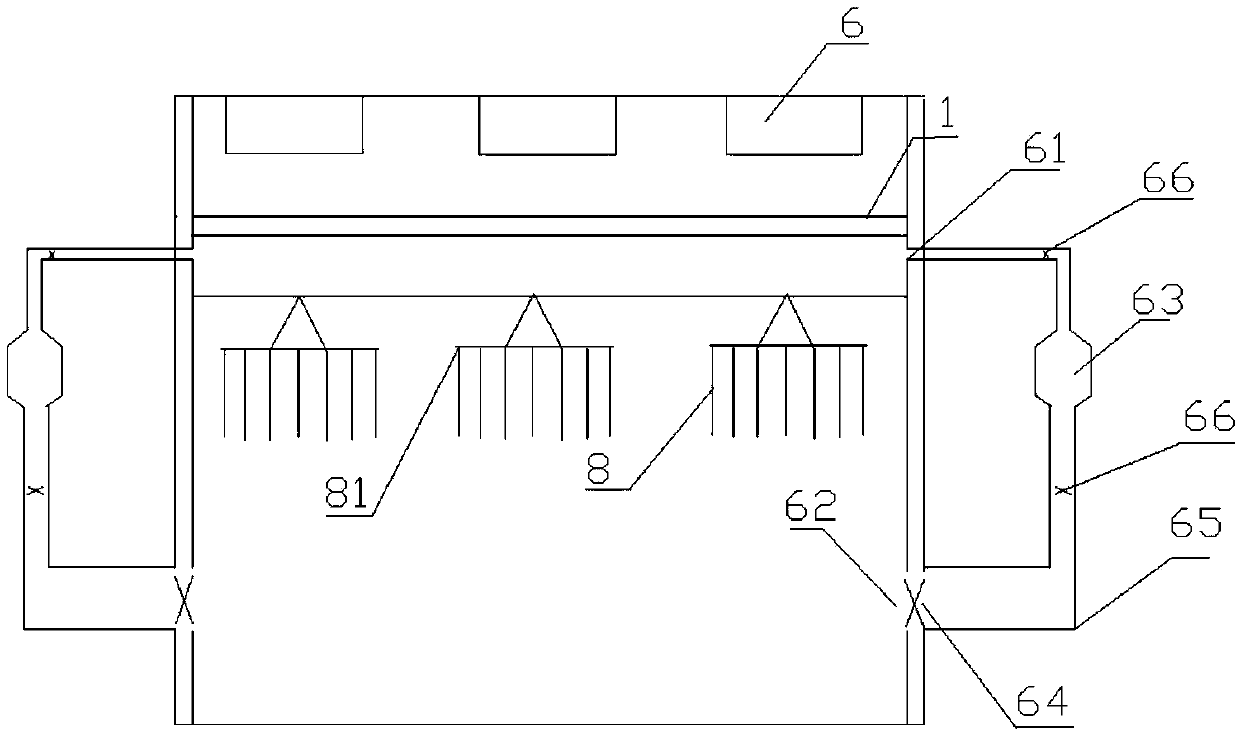

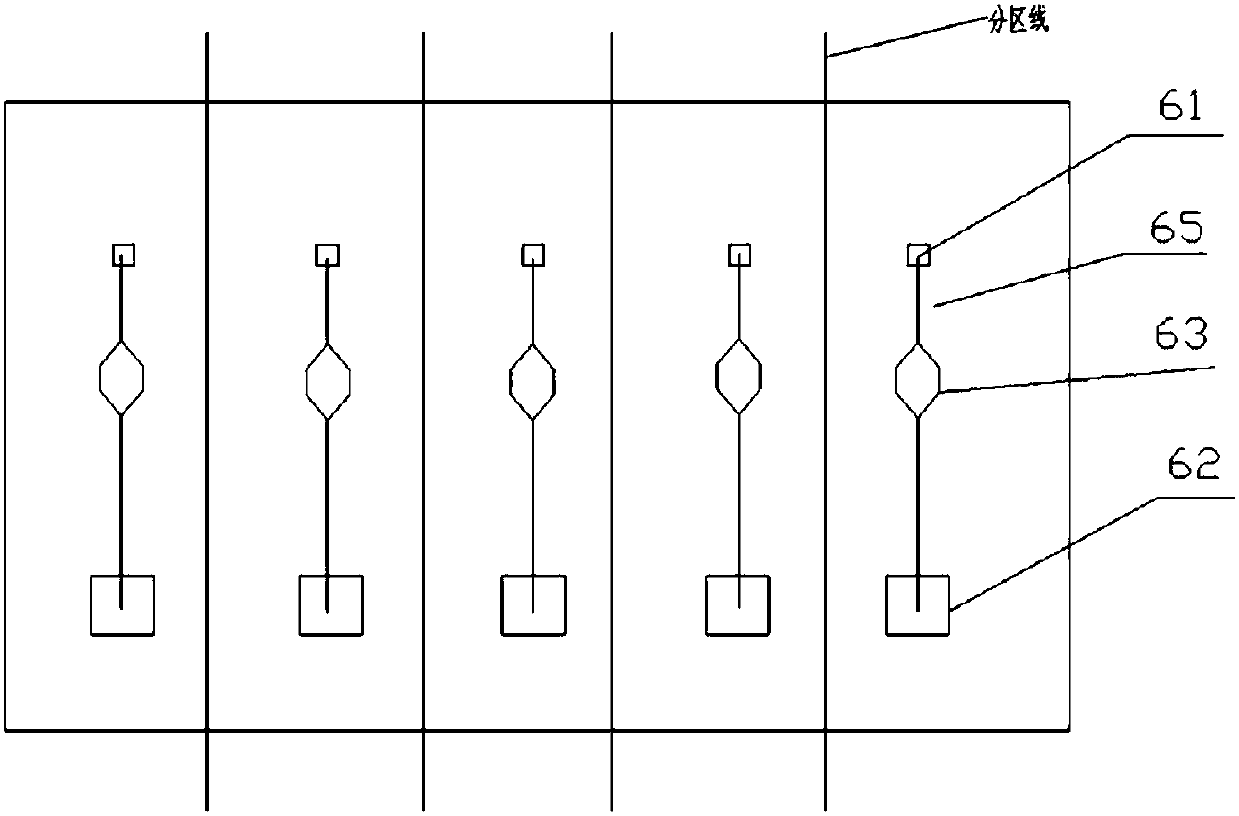

[0035] Such as Figure 1-5 As shown, this embodiment provides a drying room structure. The drying room structure can be a room-shaped closed structure with a length of about 60-90 meters, a width of 5 meters, and a height of about 5 meters. It is provided with an entrance and an exit. The dried noodles enter the drying room through the entrance, and after drying in the drying room , is sent to the next process through the export. The drying room structure includes a plurality of drying areas. According to the embodiment of the present invention, it is assumed that the drying room structure of the present embodiment is divided into 5 areas as an example to describe the present invention. According to the embodiment of the present invention, it is preferably distributed by length, Zone 1 accounts for 14% of the length, that is, about 8.4 meters to 12.6 meters, Zone 2 accounts for 20%, Zone 3 accounts for 32%, Zone 4 accounts for 20%, and Zone 5 accounts for 14%. Wherein, zone ...

Embodiment 2

[0052] Based on the drying room structure of Embodiment 1, the embodiment of the present invention provides a drying method, which includes the following steps:

[0053] Step 601, the dried noodles are input from the entrance close to zone 1, and go through zones 2, 3, 4, and 5 in sequence until the exit, where the dried noodles are dried and then enter the next process.

[0054] Step 602 , adjust the temperature according to the measured value and the set value of the temperature, adjust the humidity according to the measured value and the set value of the humidity, and adjust the wind speed according to the measured value and the set value of the wind speed.

[0055] The control method for temperature, humidity and wind speed is as follows: When the temperature deviates from the set value to a predetermined value, adjust the electric control valve to control the flow of heat transfer medium to adjust the temperature to the set value; when the humidity deviates from the set va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com