Viscous flow type pyrotechnic composition drying room

A technology of pyrotechnic powder and drying room, which is applied in drying, drying machines, lighting and heating equipment, etc. It can solve the problems of potential safety hazards, safety accidents, and the origin of dangerous accidents of pyrotechnic powder and dust, and achieve zero emissions and enhanced thermal The effect of transmitting and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

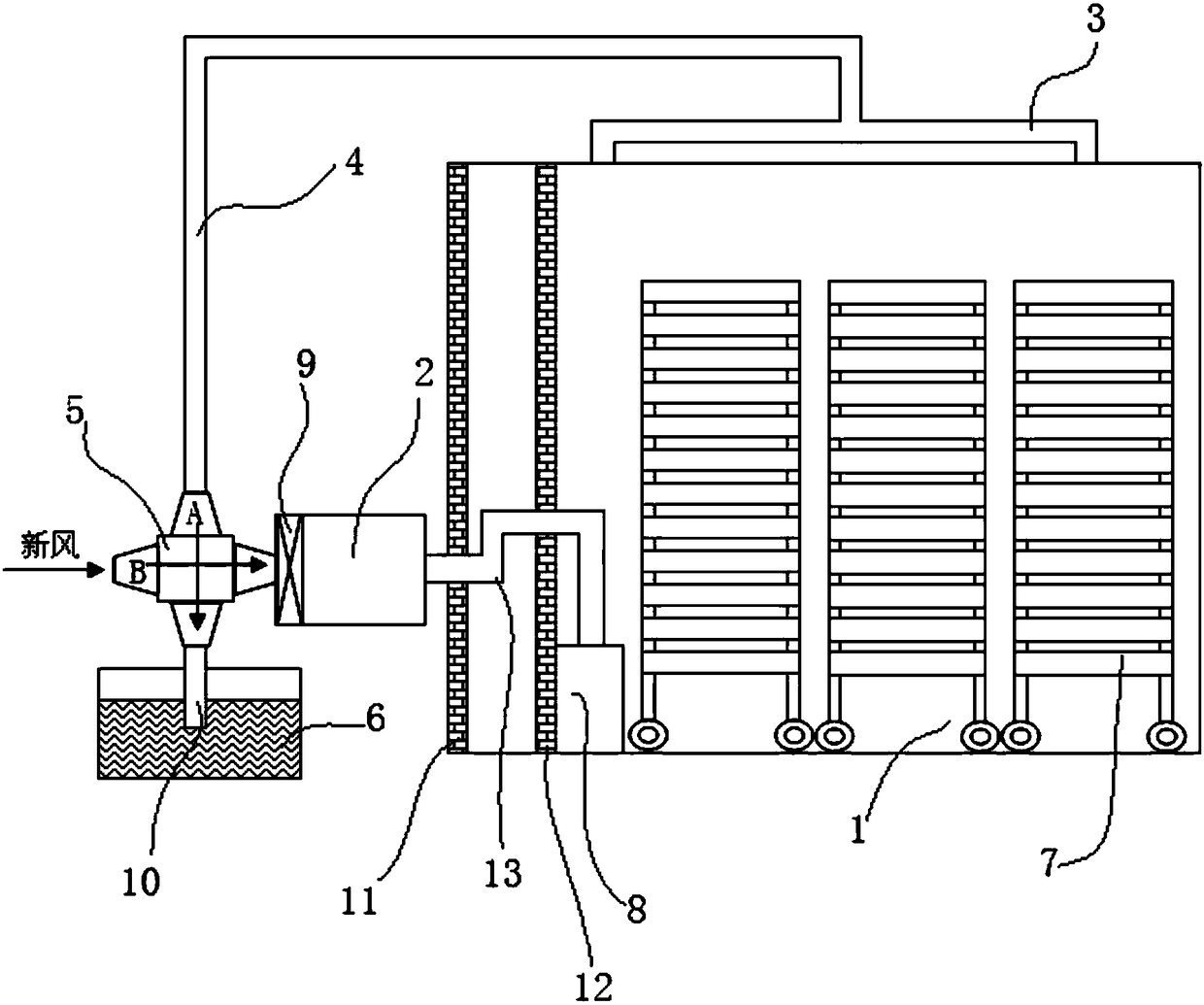

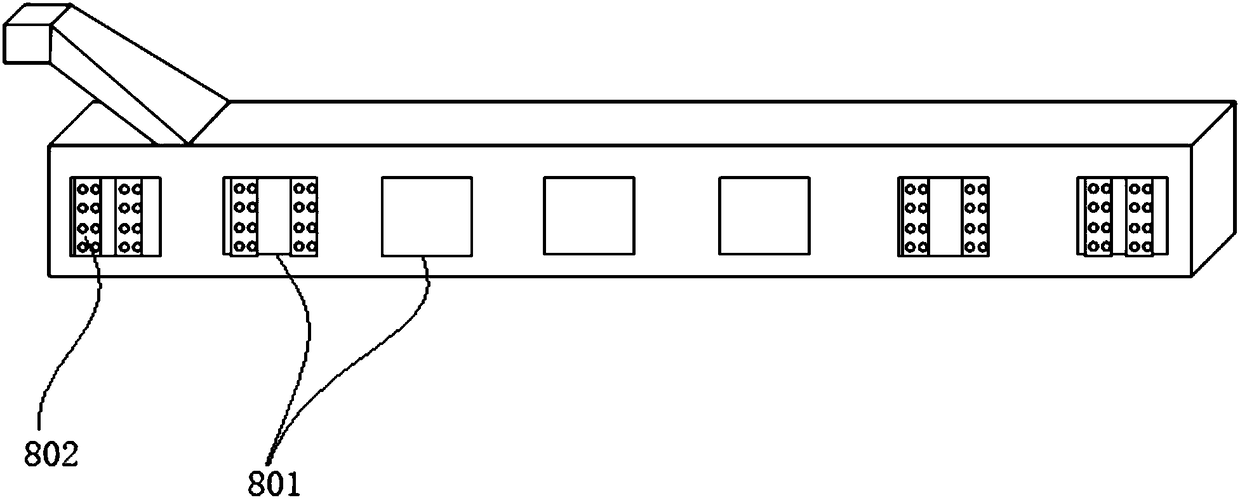

[0016] Referring to the accompanying drawings, reflecting a specific structure of the present invention, in the stagnation type pyrotechnic powder drying room, the hot air inlet at the bottom of the drying room 1 is connected to the air outlet of the hot air supply mechanism 2; the hot air supply mechanism 2 uses an air source heat pump to heat the air . The hot air inlet at the lower part of the drying room 1 is provided with an equalizing air duct 8, and seven air outlet holes 801 are evenly distributed on the equalizing air duct 8, and an air outlet 801 near both ends with a larger air volume is provided with a damper. The damper adopts a multi-leaf structure, and each hinged door 802 can move laterally along the air outlet hole 801. The more hinged doors 802 that close the air outlet hole 801, the smaller the air outlet channel of the air outlet hole 801. In this way, the balanced supply of hot air in each section of the drying room can be realized.

[0017] The moisture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com