Eight-station rotary fixed-point spraying cleaning machine

A spray cleaning and rotary technology, which is applied to dryers, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of large occupied area, low cleaning efficiency, and inability to clean, and achieve short rotation cycle , to meet the effect of high production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

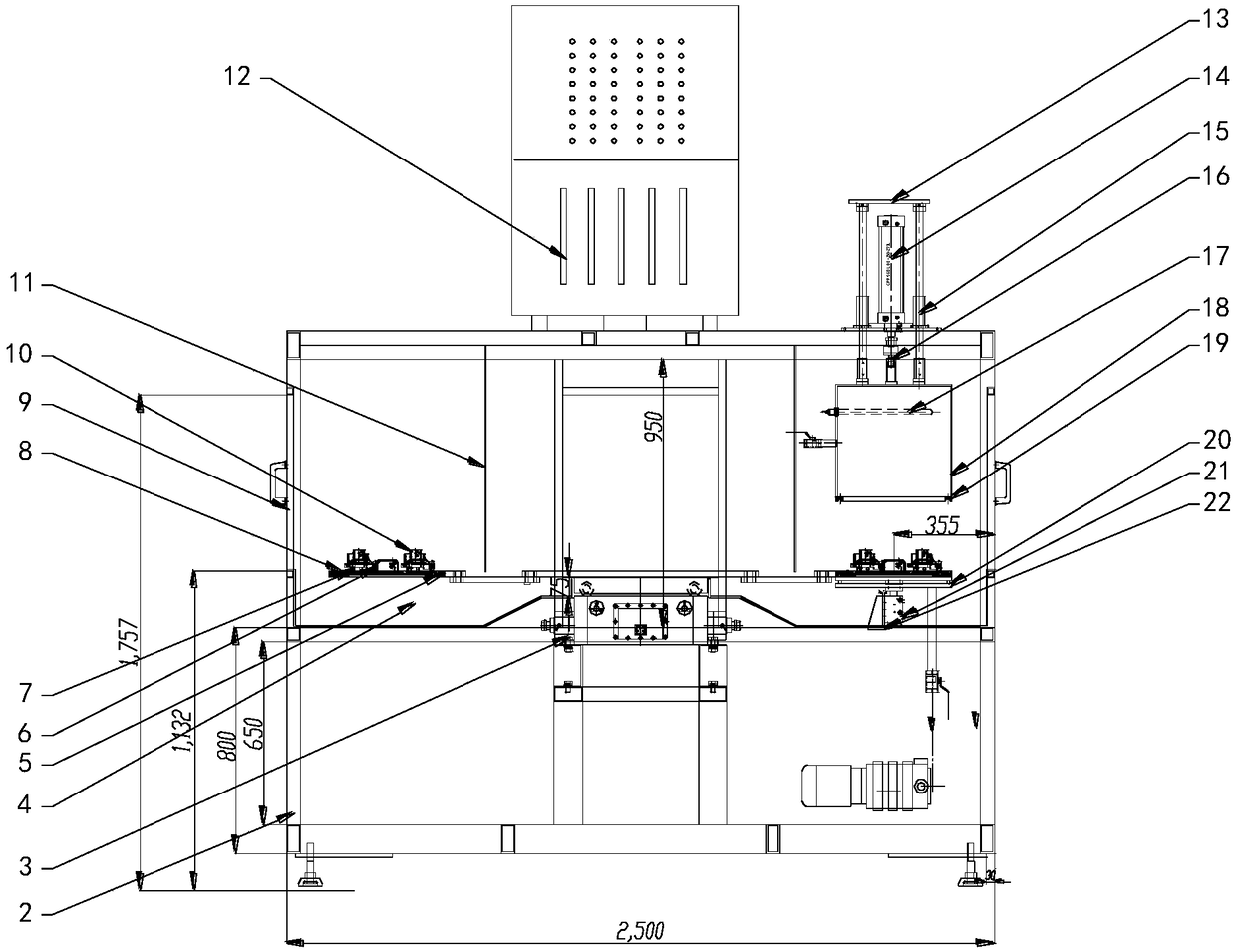

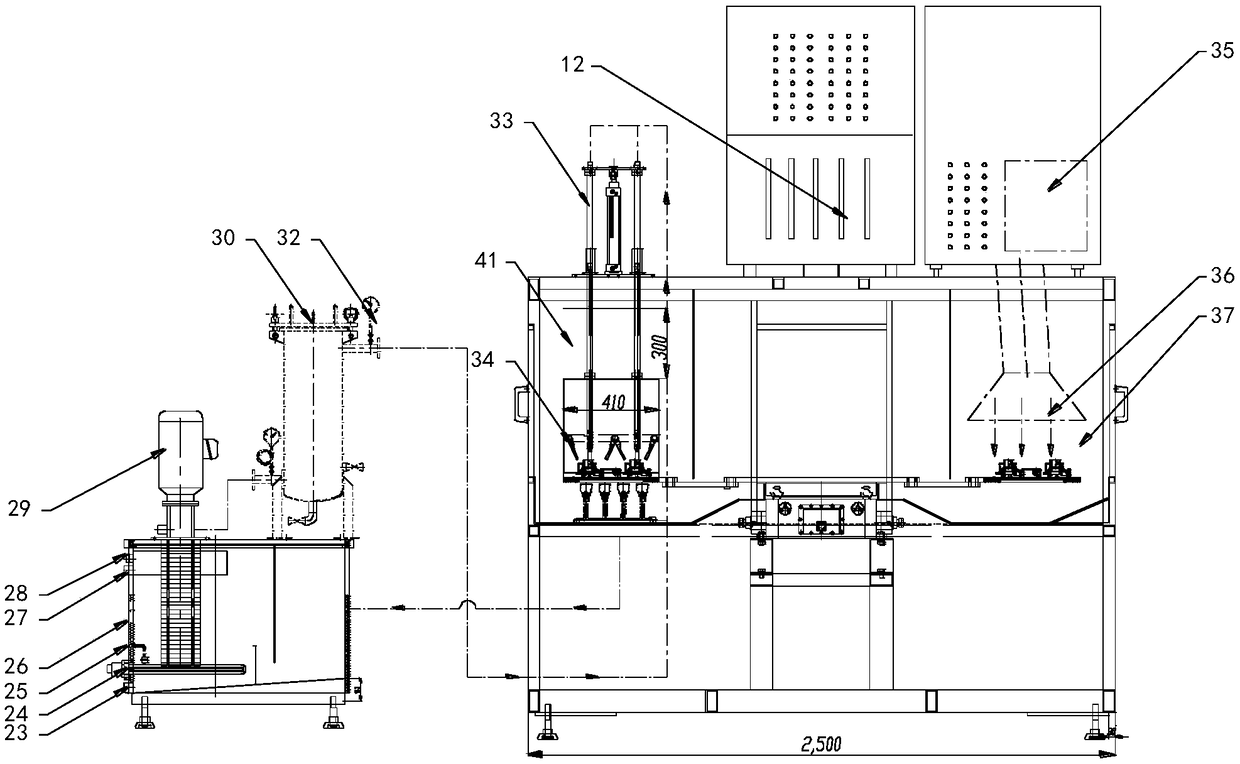

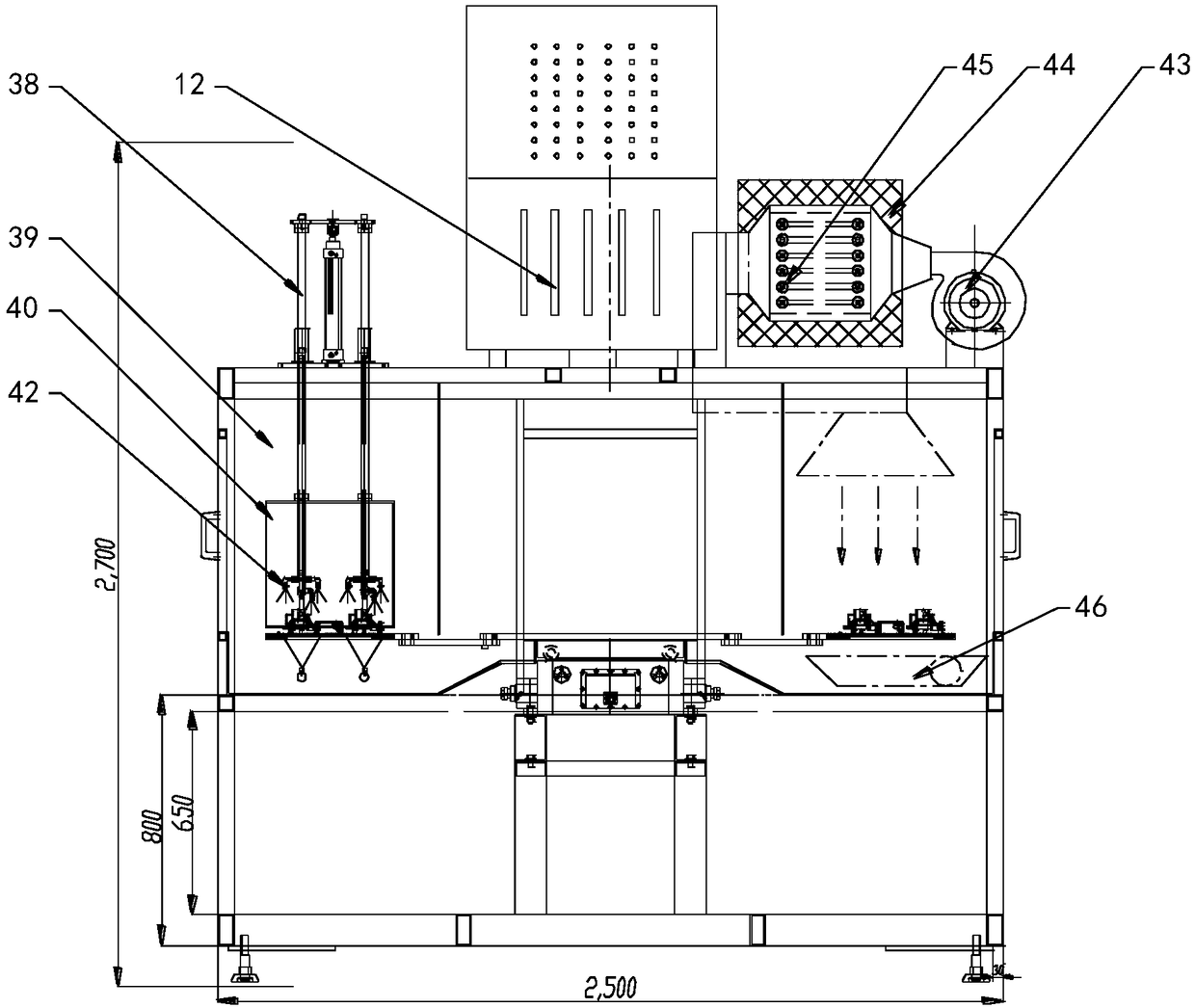

[0031] like Figure 1-4 As shown, the present invention discloses an eight-station rotary fixed-point spray cleaning machine. Specifically, the cleaning machine includes a hydraulic turntable, a rotary structure connected to the hydraulic turntable, and eight stations set by the ring rotary structure; The three stations are the first spraying station, the second spraying station, the third spraying station, the wind cutting station, the drying station, the vacuum drying station, the cooling station and the loading and unloading station. And the first spraying station, the second spraying station and the third spraying station are all equipped with a spraying system, the wind cutting station is provided with a wind cutting device, and the drying station is provided with a drying device, vacuum drying The station is equipped with a vacuum drying device, the cooling station is equipped with a cooling device, and the loading and unloading station is provided with a mechanical arm;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com