Adjustable cloth drying device

A cloth drying and adjustable technology, applied in drying, drying machines, progressive drying machines, etc., can solve the problems of drying cloth damage, difficulty in drying, deformation, etc., to reduce deformation and ensure drying quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

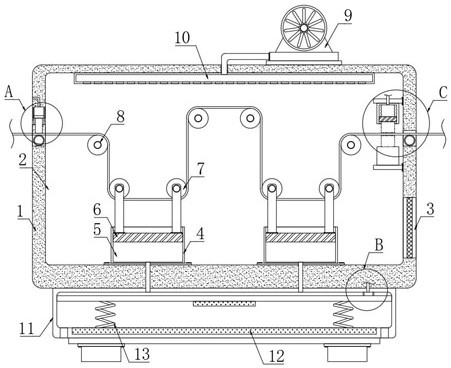

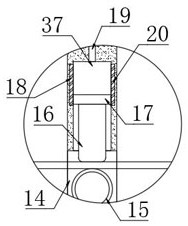

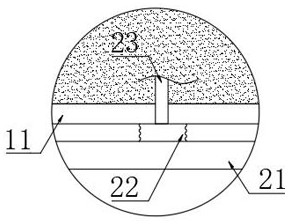

[0029] refer to Figure 1-4 , an adjustable cloth drying device, including a box body 1, a drying chamber 2 is arranged in the box body 1, openings 14 are provided on the left and right inner walls of the drying chamber 2, and the inner bottom of each opening 14 is provided with Guide roller 15, a plurality of fixed winding rollers 8 are arranged in the drying chamber 2, and the front and rear end rotating shafts of the fixed winding rollers 8 are respectively connected to the front and rear inner walls of the drying chamber 2 in rotation. The inner bottom of the drying chamber 2 is symmetrically provided with two adjusting block 4, the upper end of each adjustment block 4 is provided with an adjustment groove 5, and each adjustment groove 5 is provided with a slide plate 6 for sliding up and down, and an annular limit block can be set at the notch of the adjustment groove 5, To avoid the situation that the slide plate 6 moves up too far and slides out from the notch of the ad...

Embodiment 2

[0039] refer to Figure 5-7 The difference between this embodiment and Embodiment 1 is that the upper end of the opening 14 on the right side is provided with a plurality of second trigger grooves 34, and each second trigger groove 34 is provided with a second piston for sliding up and down. plate 35, the lower end of each second piston plate 35 is provided with a second block 36, and the lower end of each second block 36 extends into the opening 14 on the right side;

[0040] As an embodiment of the present invention, in order to remind the staff in time when the cloth is damaged or wrinkled after drying, the upper end of the box body 1 is equipped with a connecting bar 29, and the upper end part of the connecting bar 29 is connected with a trigger through a rotating shaft. Box 30, two load-bearing blocks 32 are symmetrically arranged in the trigger box 30, two hoses 33 are communicated with the space on the left and right sides of the trigger box 30 respectively, and the oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com