Platform conveying drying device for fabric processing

A drying device and platform technology, which is applied in the field of garment processing, can solve the problems of affecting the drying efficiency of the cloth, and the cloth cannot be completely dried, and achieve the effects of facilitating the evaporation of water, shortening the processing time, and prolonging the drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

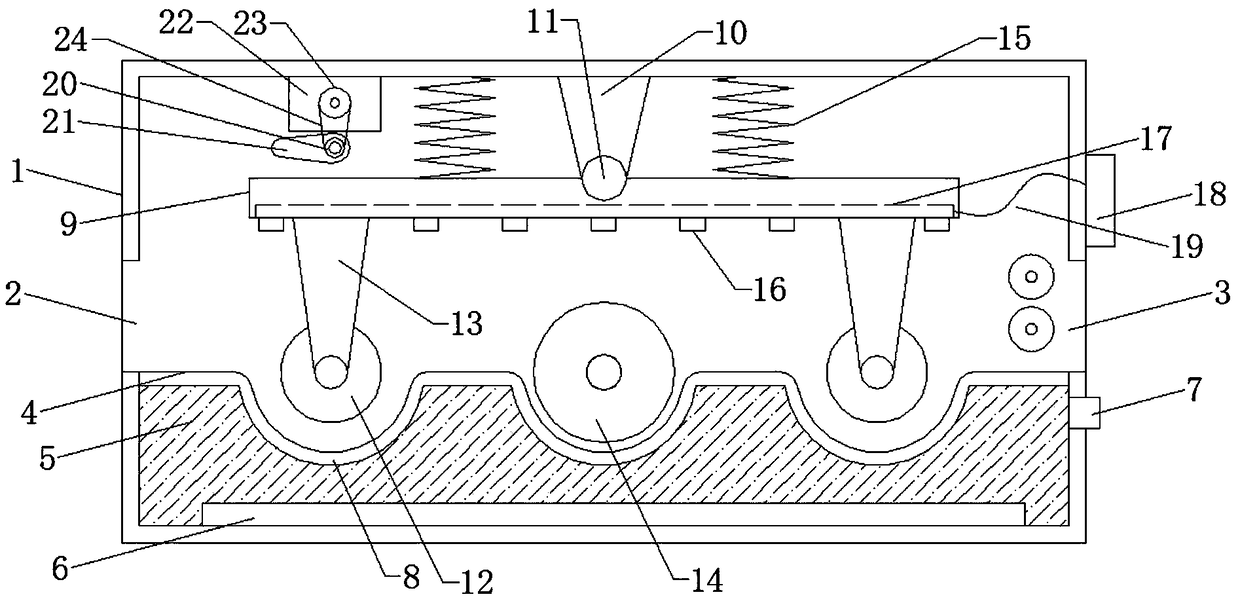

[0016] Please refer to the figure, in the embodiment of the present invention, a platform conveying and drying device for cloth processing includes a housing 1, a feed port 2, a discharge port 3, a heating element 6 and a conveying guide wheel; the feed port 2, The discharge port 3 is set at the left and right ends of the housing 1 respectively, and the feed port 2 and the discharge port 3 are arranged horizontally opposite to each other. A conveying guide wheel for sending the cloth is installed in the discharge port 3 to provide the cloth inside. Tension to move the cloth from left to right.

[0017] A horizontal platform 4 is fixedly welded on the lower side of the corresponding feed port 2 and discharge port 3 in the housing 1, and a plurality of downwardly recessed arc-shaped plates 8 are distributed equidistantly in the horizontal platform 4. The arc-shaped plates 8 and the horizontal platform 4 are integrally structured, and the smoothness is excessive, so that the clot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com