Fluidization cabinet type delivery pump and method thereof

A fluidization and conveying pump technology, used in conveyors, conveying bulk materials, transportation and packaging, etc., can solve the problems of weakened sealing performance, slow fluidization speed of a single intake, environmental pollution, etc., to achieve enhanced sealing ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

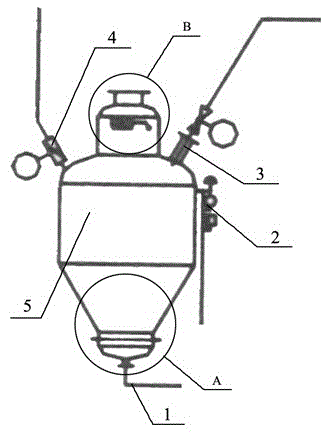

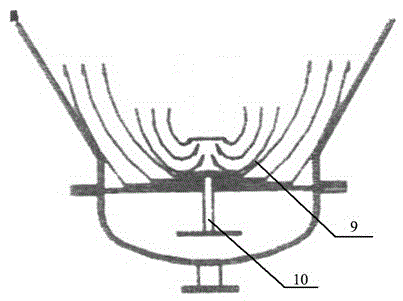

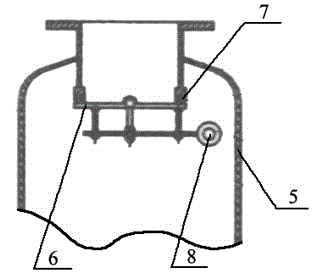

[0016] Such as figure 1 , 2 , 3, the fluidized silo-type conveying pump includes a main air intake device 1, a secondary air intake device 2, a tertiary air intake device 3, a ventilation device 4, a pump body 5, a feeding device, and a fluidization device; the pump body 5. There is a main air intake device 1 outside the bottom of the pump body 5. A fluidization device is provided inside the bottom of the pump body 5. A secondary air intake device 2 is provided on the outer wall of the middle part of the pump body 5. A tertiary air intake device is provided on the top of the pump body 5. 3. Ventilation Device 4, feeding device; the feeding device includes a cover plate 6, a sealing gasket 7, and a rotating shaft 8, the cover plate 6 is rotatably connected to the pump body 5 through the rotating shaft 8, and the opening between the cover plate 6 and the pump body 5 passes through the sealing gasket 7 Sealing; a fluidization device is provided in the bottom of the pump body 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com