Universal shaft connector of double-layer structure power drilling tool

A power drilling tool, double-layer structure technology, applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problem that the screw drilling tool cannot be applied, and achieve the effect of increasing the sealing capacity, reducing wear and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The cardan shaft connector of a power drill with a double-layer structure described in this embodiment is used for a screw motor.

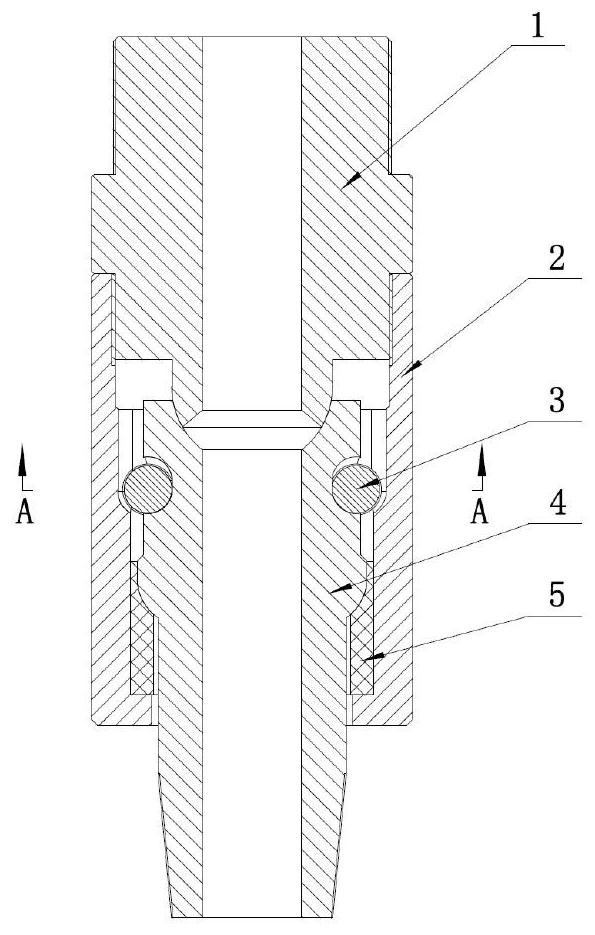

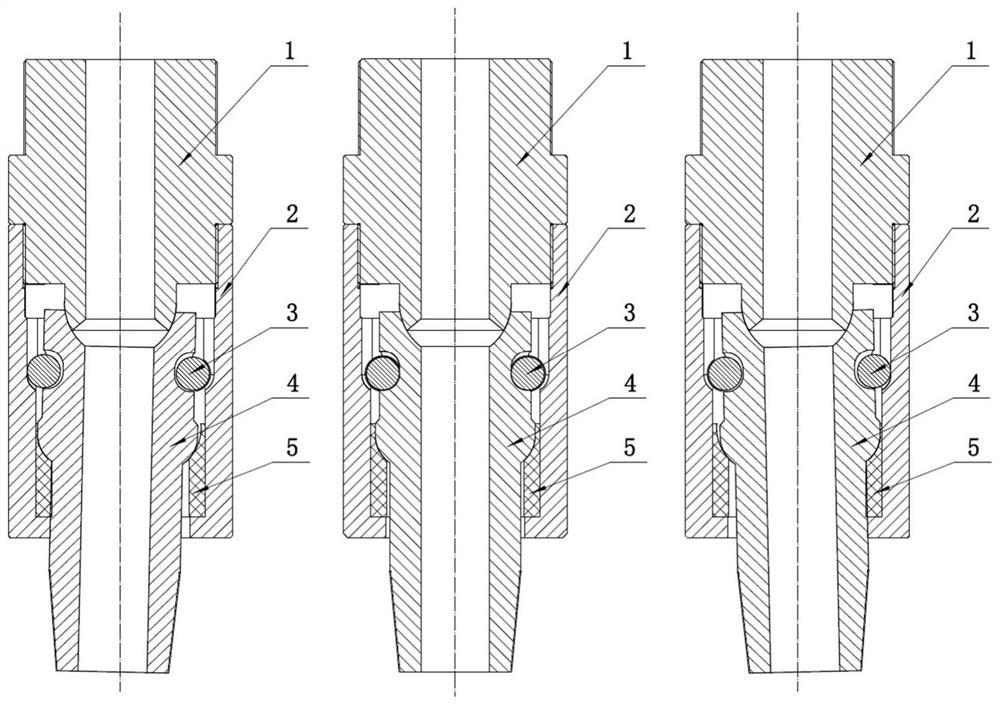

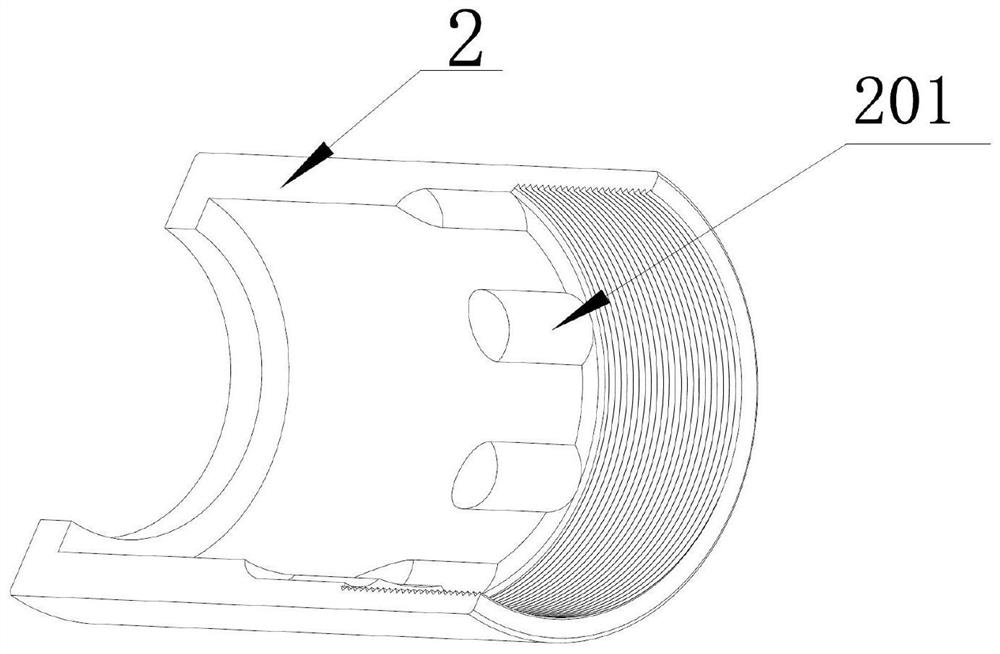

[0022] As shown in the figure, a double-layer structure power drilling tool cardan shaft connector is composed of an upper joint 1, a casing 2, a transmission ball 3, a screw joint 4, and a sealing plug 5. The screw joint 4 is connected to the screw rotor 6. The upper joint 1 is connected with the outer shell 2, and the other end is connected with the inner pipe 9. There is a transmission ball 3 and a sealing plug 5 between the screw joint 4 and the outer shell 2. The transmission ball 3 can realize the transmission of torque, and the transmission ball 3 and the outer shell 2 There is a radial gap between them, the sealing plug 5 can be compressed, and the screw joint 4 can swing around the upper joint through the spherical contact surface.

[0023] The above-mentioned double-layer structure power drill cardan shaft connector is characteriz...

Embodiment 2

[0028] The cardan shaft connector of a double-layer structure power drilling tool described in this embodiment is used in a screw pump.

[0029] As shown in the figure, a double-layer structure power drilling tool cardan shaft connector is composed of an upper joint 1, a casing 2, a transmission ball 3, a screw joint 4, and a sealing plug 5. The screw joint 4 is connected to the screw rotor 6. The upper joint 1 is connected with the outer shell 2, and the other end is connected with the inner pipe 9. There is a transmission ball 3 and a sealing plug 5 between the screw joint 4 and the outer shell 2. The transmission ball 3 can realize the transmission of torque, and the transmission ball 3 and the outer shell 2 There is a radial gap between them, the sealing plug 5 can be compressed, and the screw joint 4 can swing around the upper joint through the spherical contact surface.

[0030] The above-mentioned double-layer structure power drill cardan shaft connector is characterize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com