Patents

Literature

389 results about "Double-walled pipe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A double-walled pipe is a secondary contained piping system. It is a pipe within a pipe, or encased in an outer covering, with an annulus (interstitial space) between the two diameters. The inner pipe is the primary or carrier pipe and the outer pipe is called the secondary or containment pipe. The great majority of double-walled piping applications involve wastewater, groundwater, and process safety.

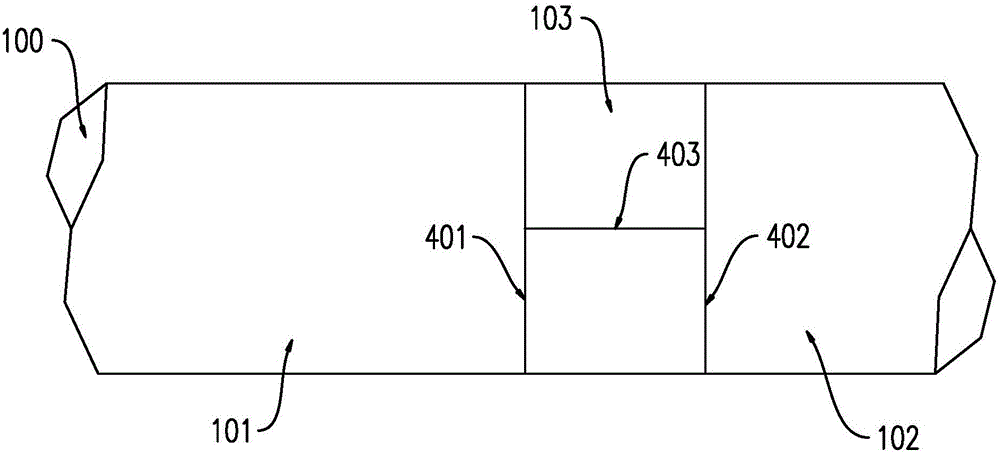

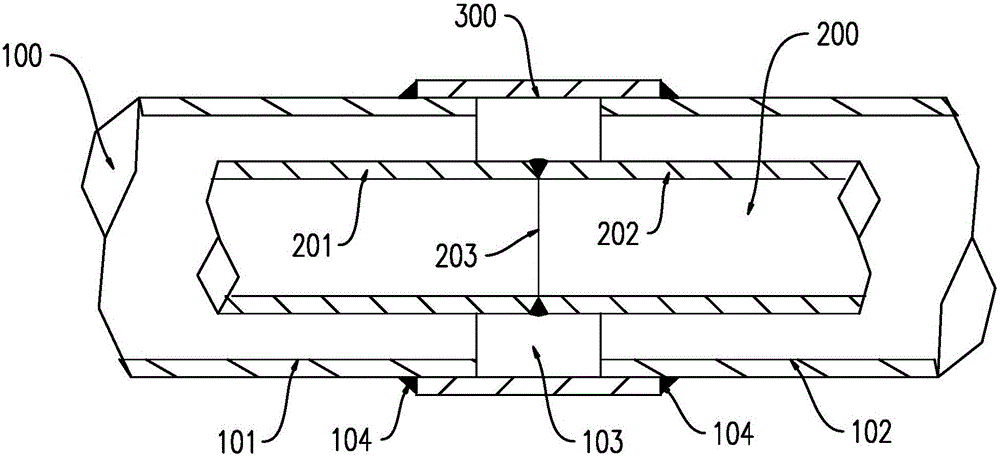

Reinforced double-walled pipe and manufacturing method

InactiveUS20090000681A1Good mechanical resistanceReduce steel thicknessThermal insulationMetal-working apparatusMechanical resistanceDouble-walled pipe

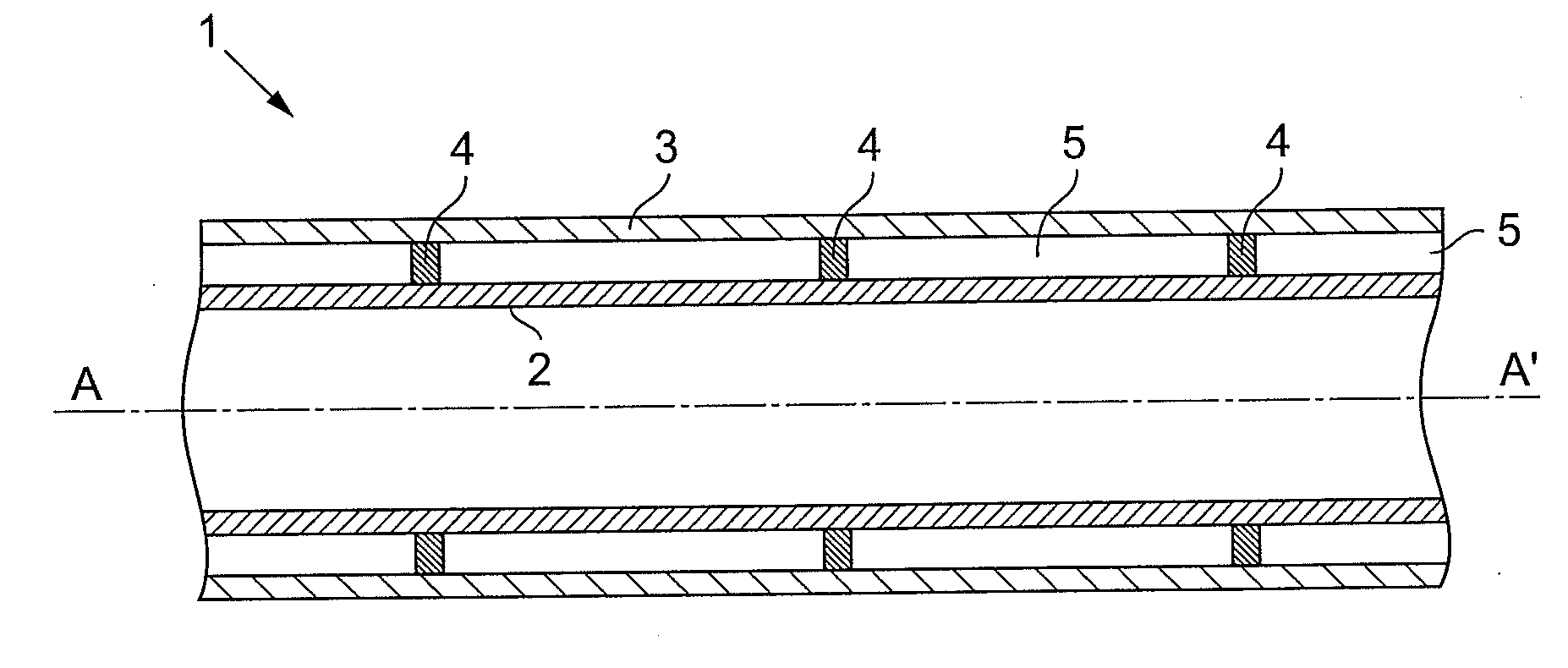

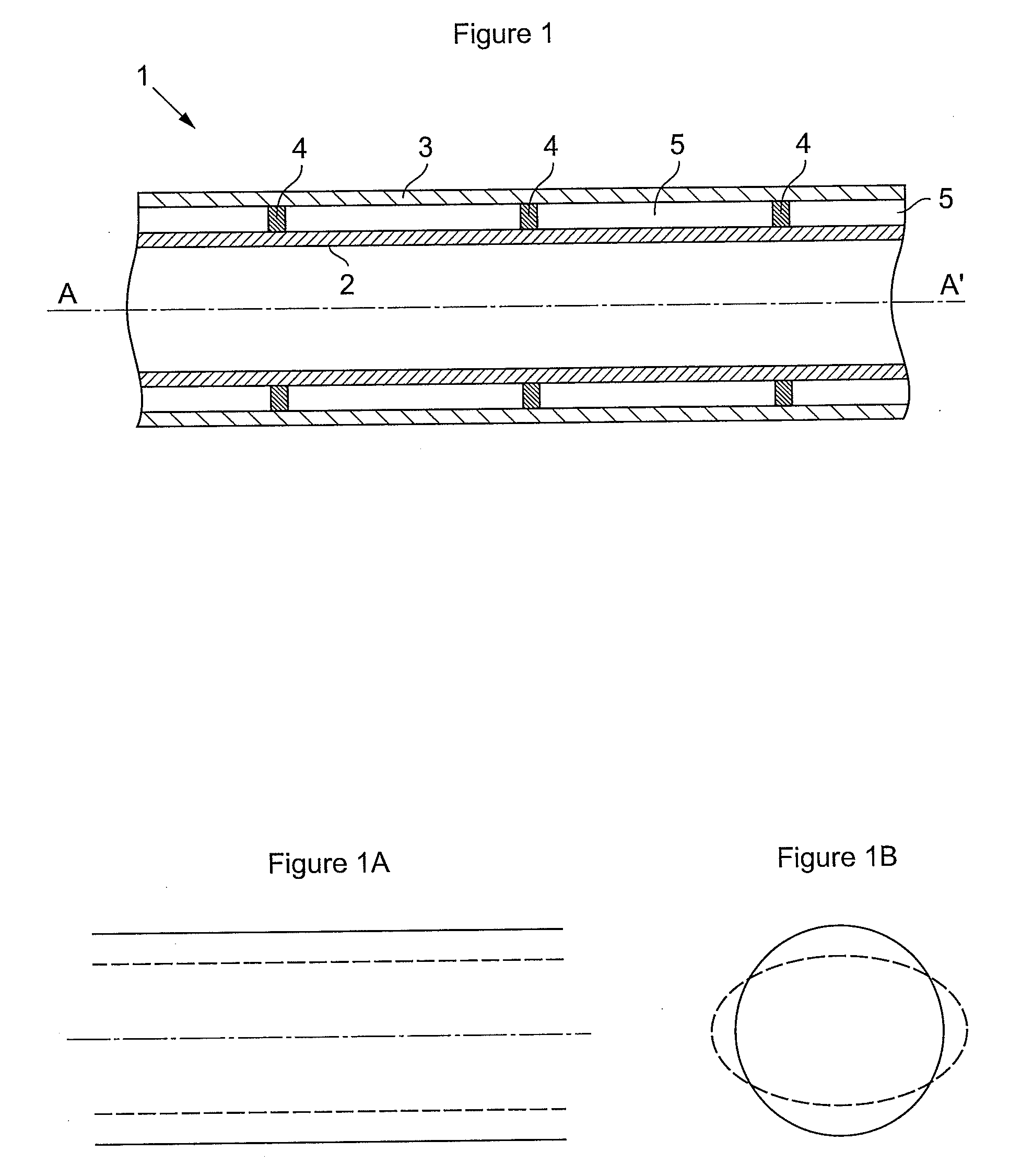

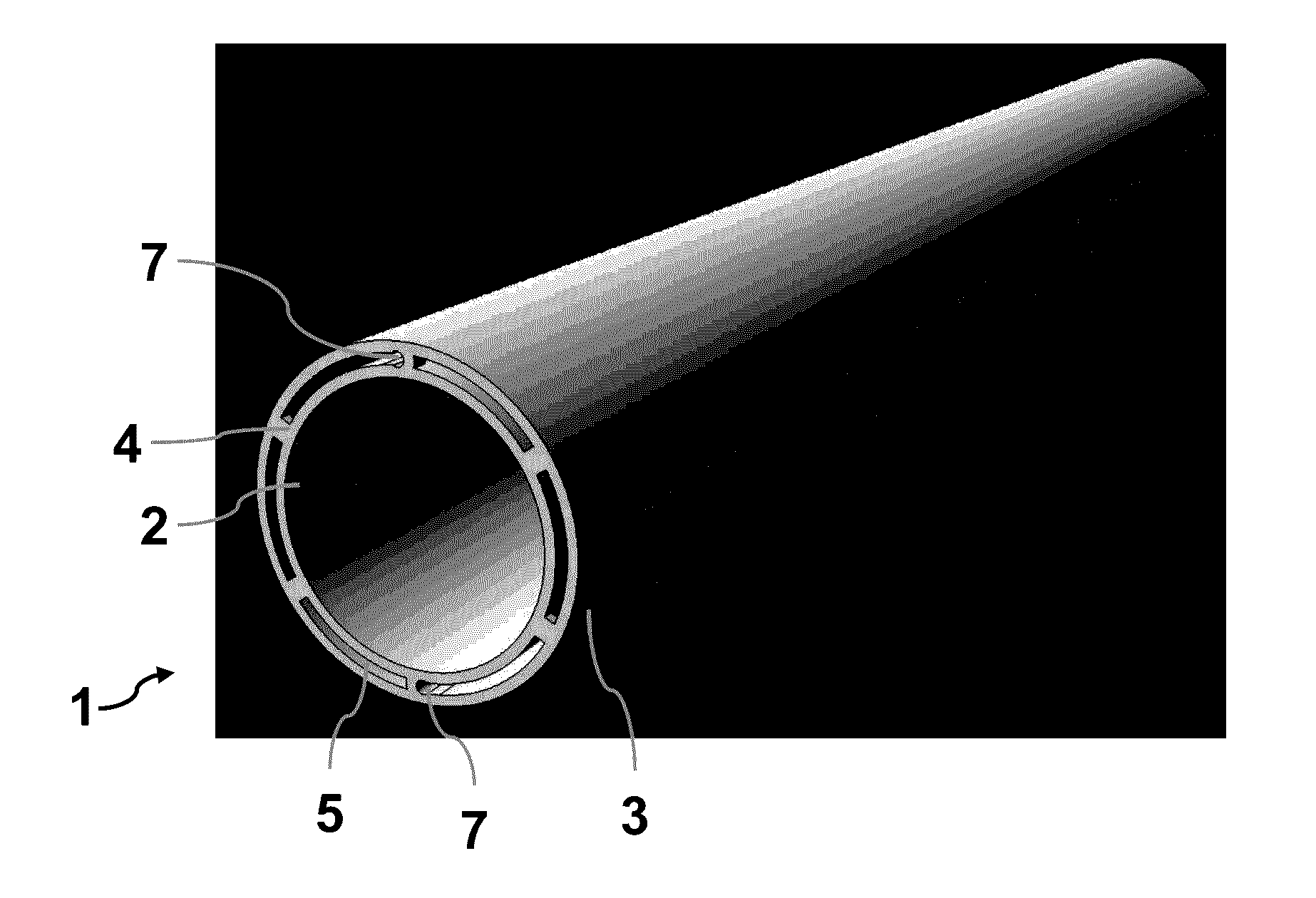

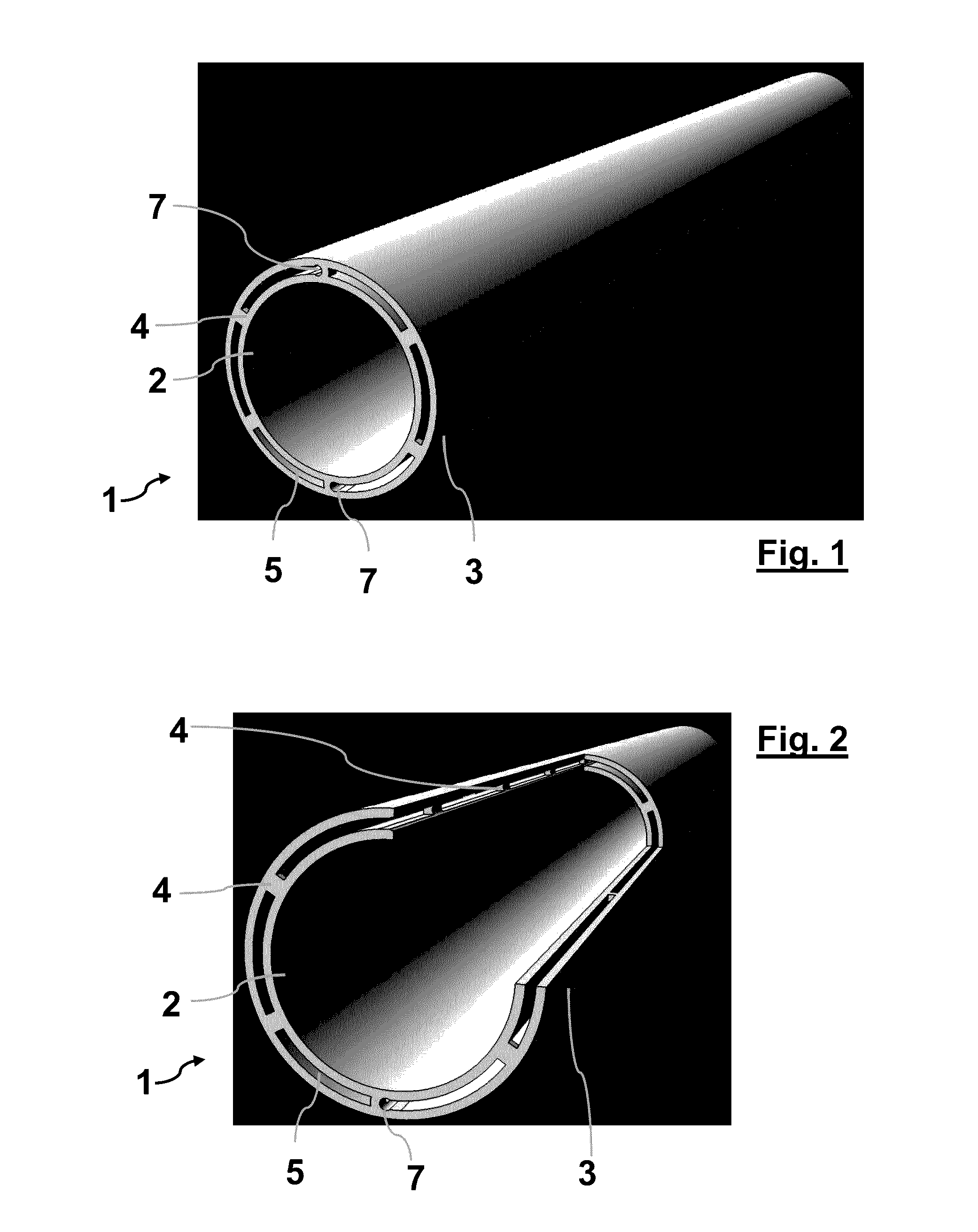

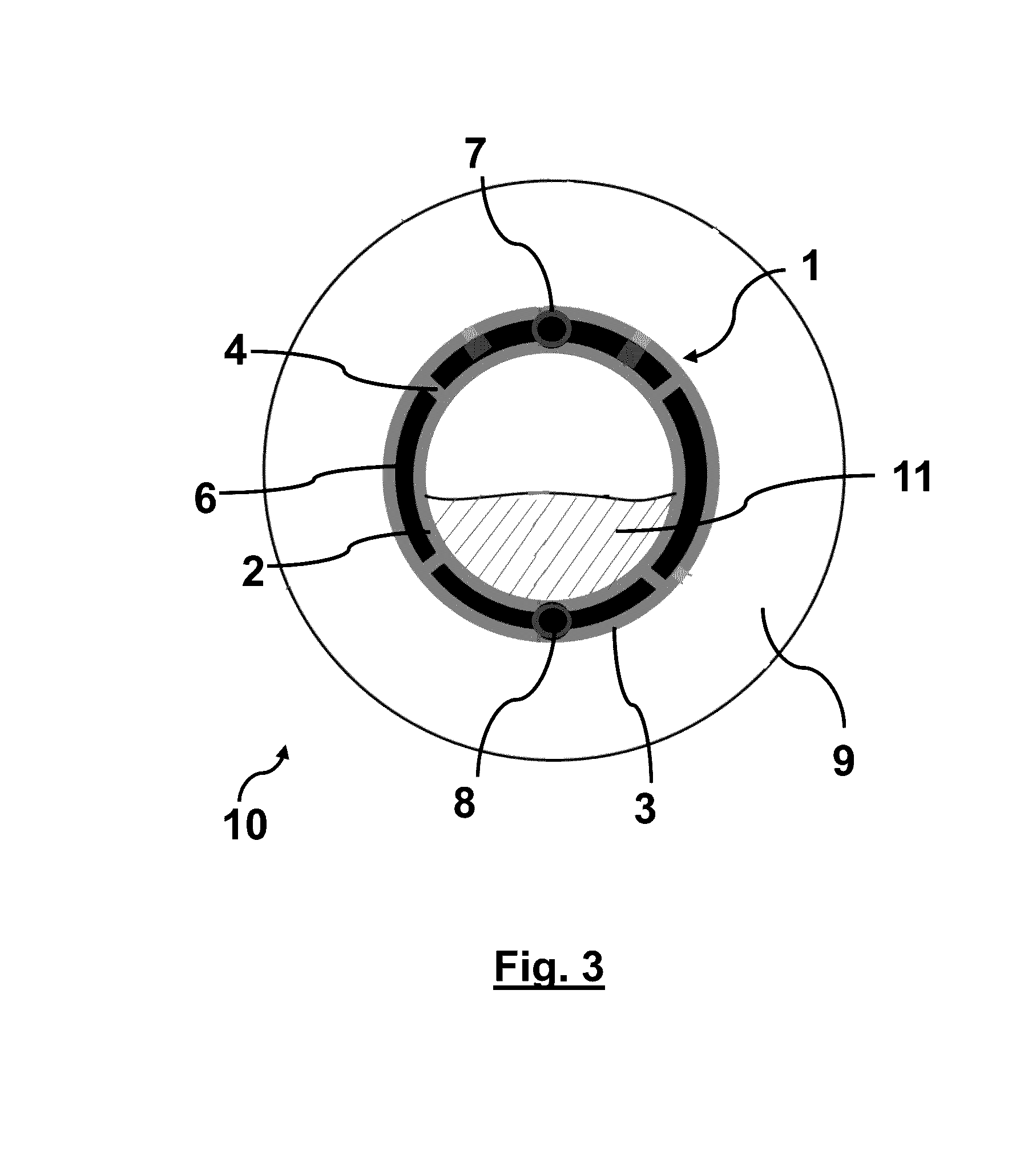

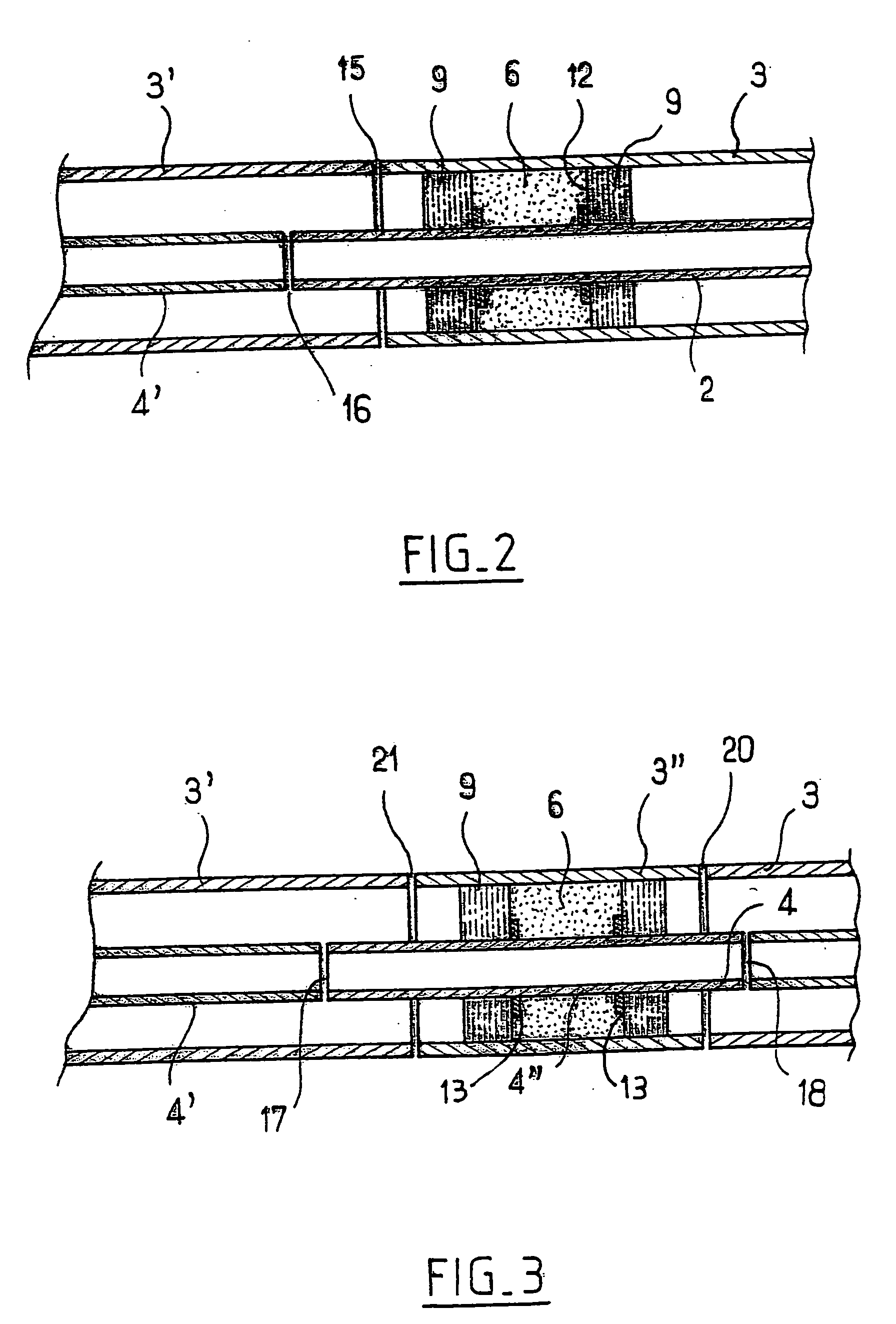

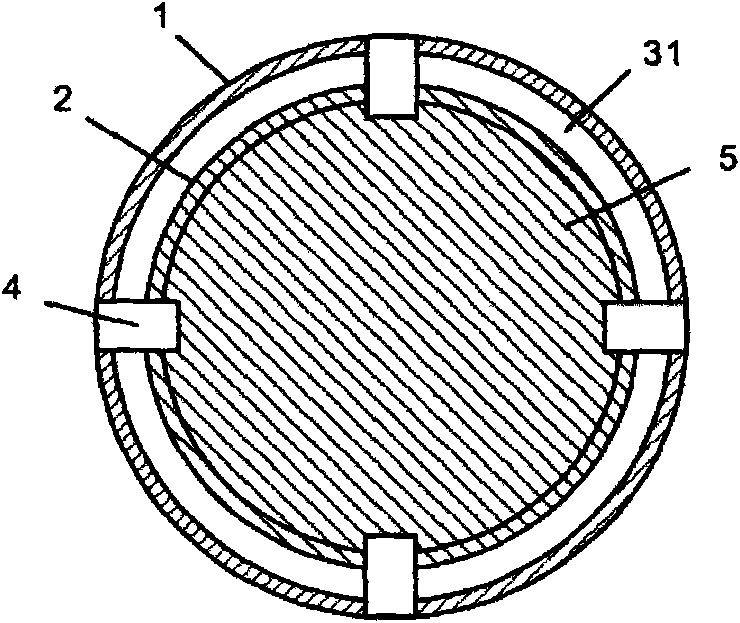

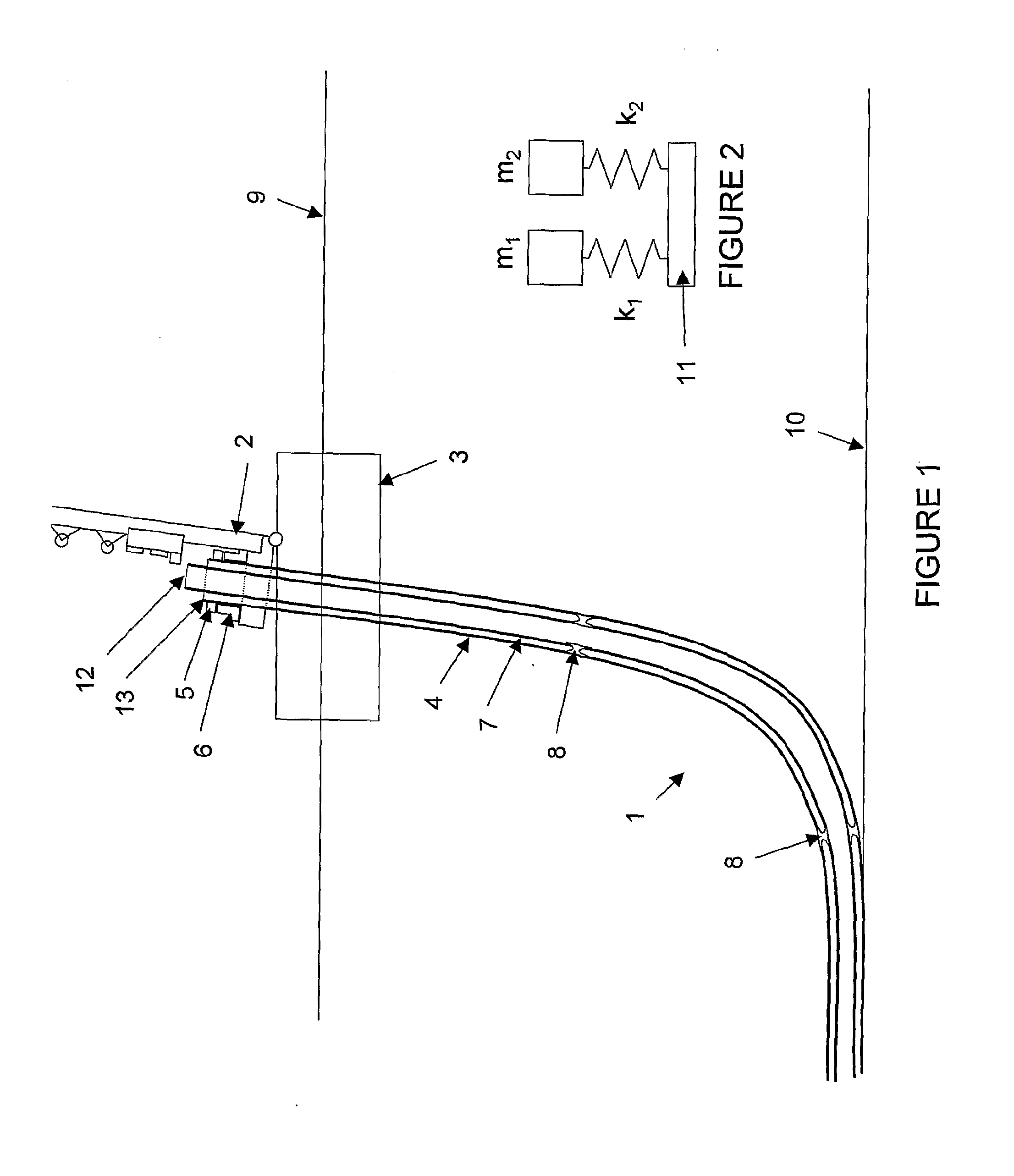

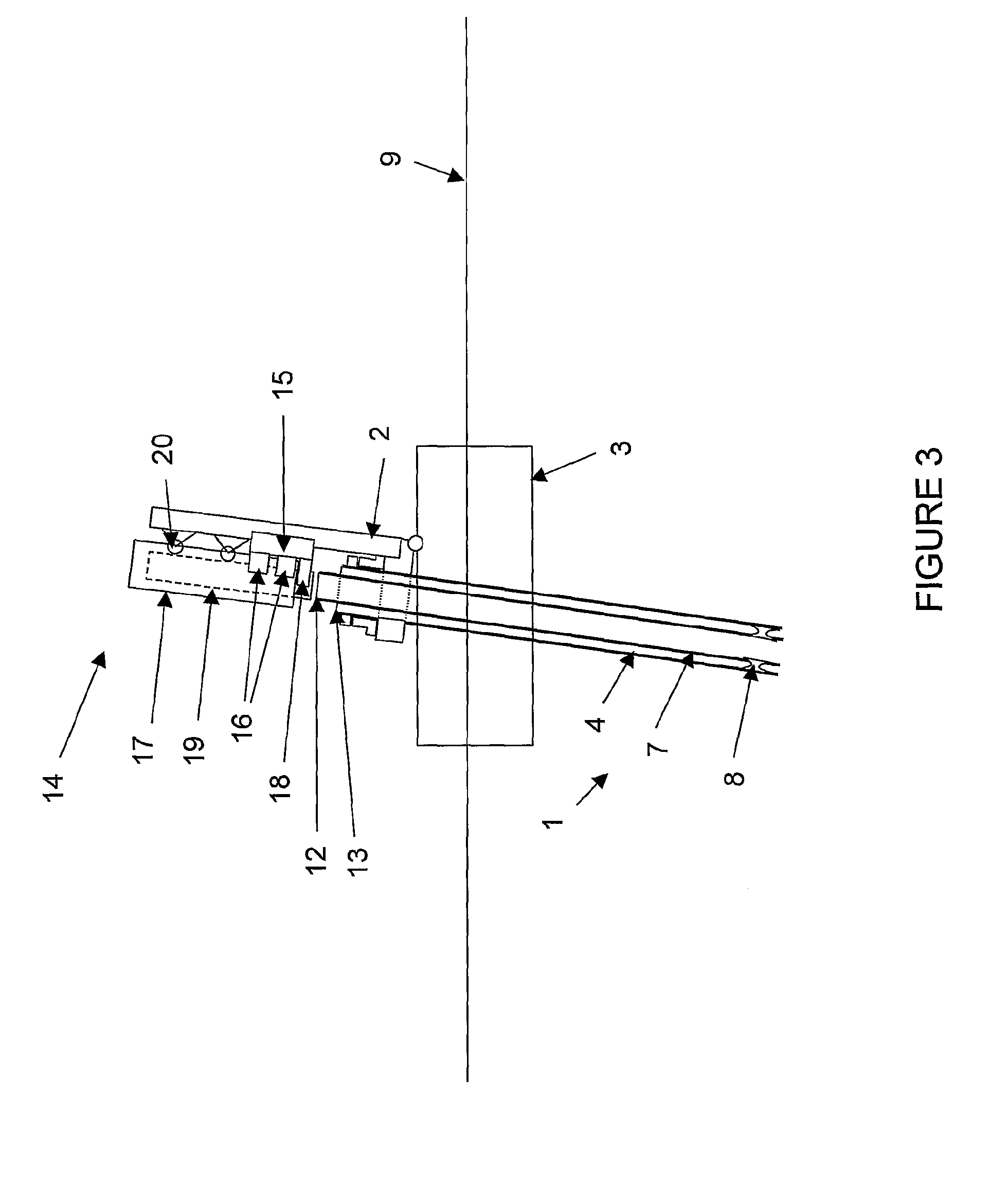

The double-walled pipe comprises a rigid internal tube 2 arranged in a rigid external tube 3, the tubes being separated by an annular space, centering elements holding the internal tube in position in relation to the external tube.External tube 3 withstands alone an external pressure at least above 50 bars.The mechanical resistance of the pipe to the external pressure is reinforced by placing centering elements 4 in contact with internal tube 2 and with external tube 3.

Owner:INST FR DU PETROLE

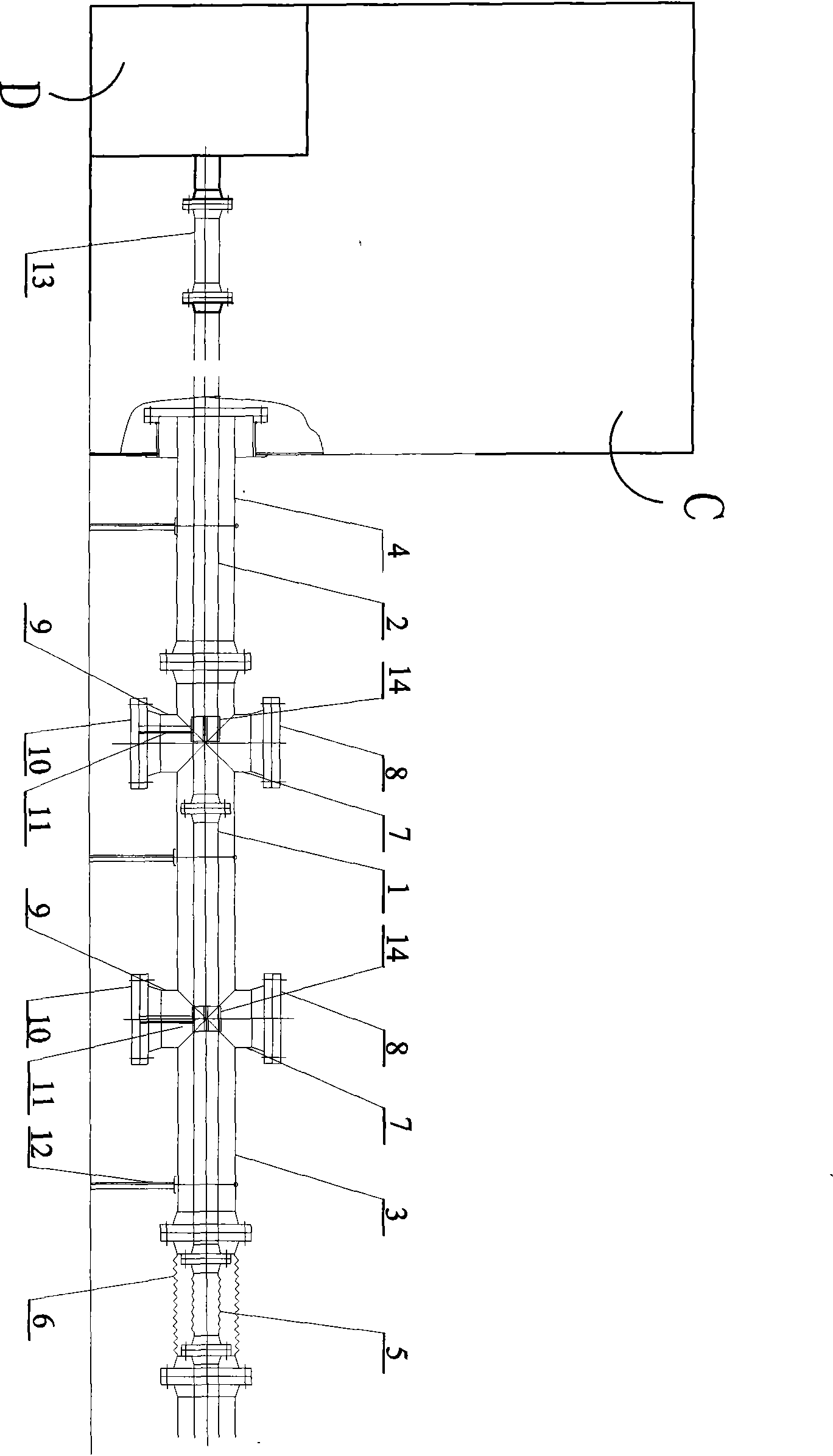

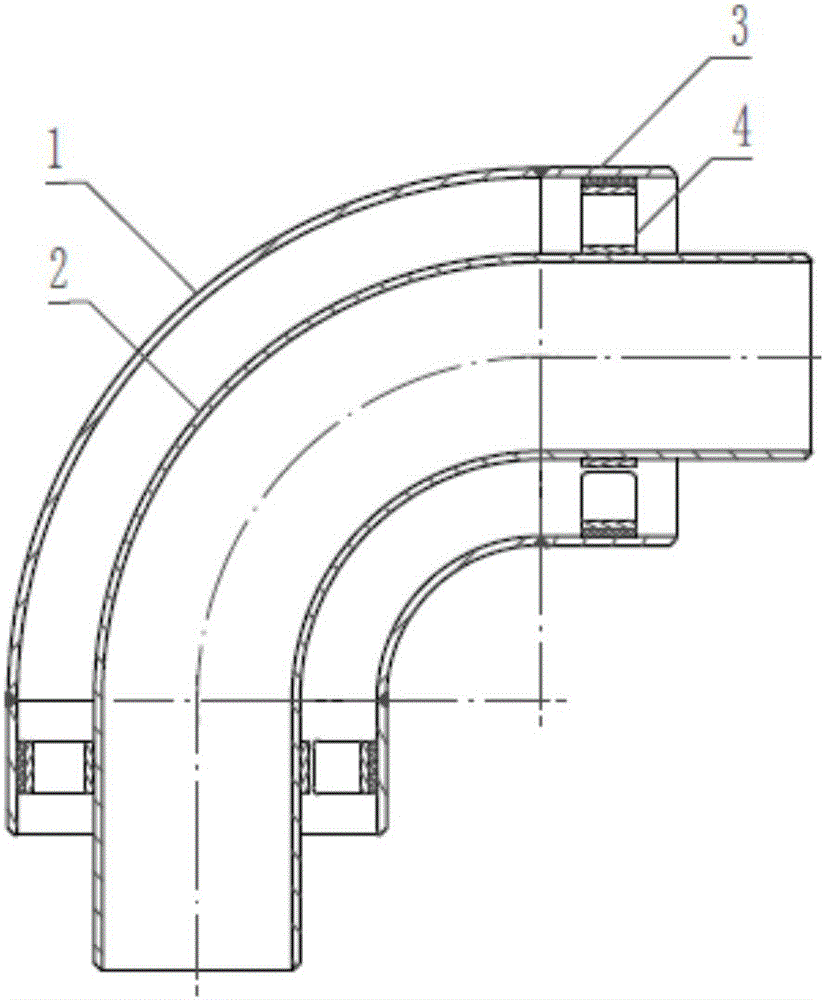

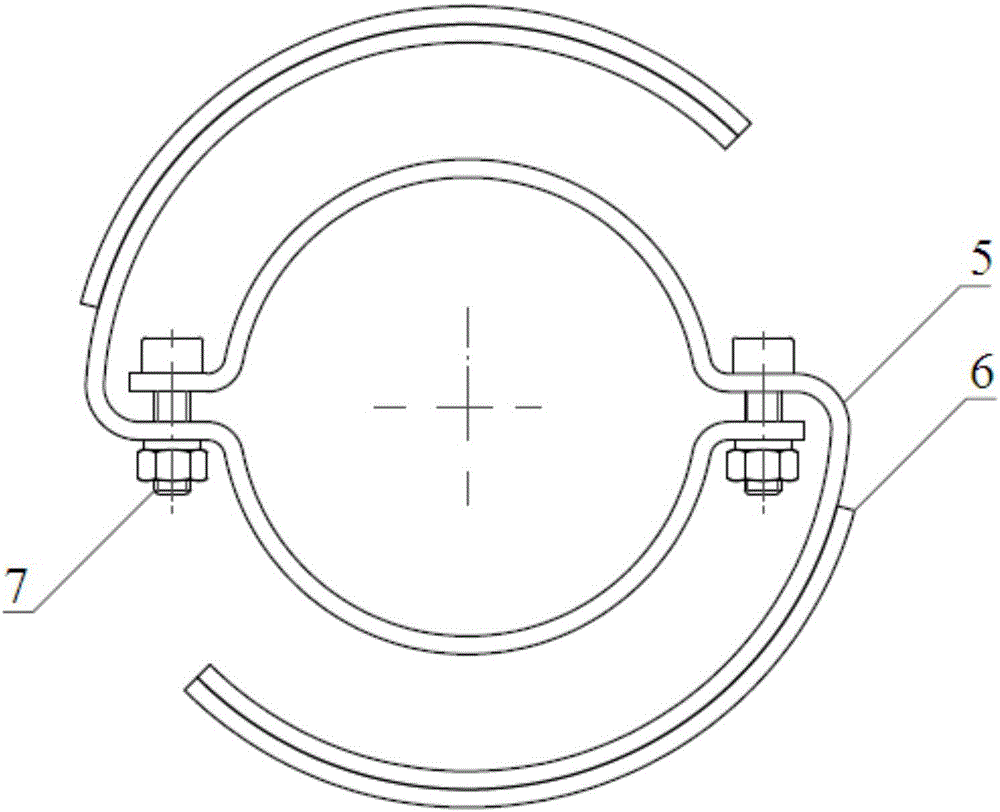

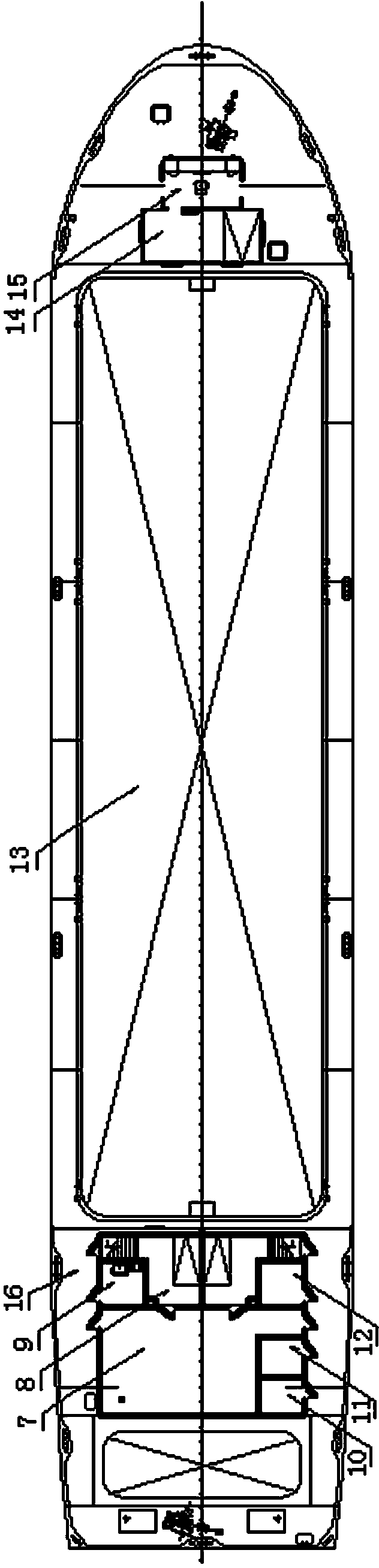

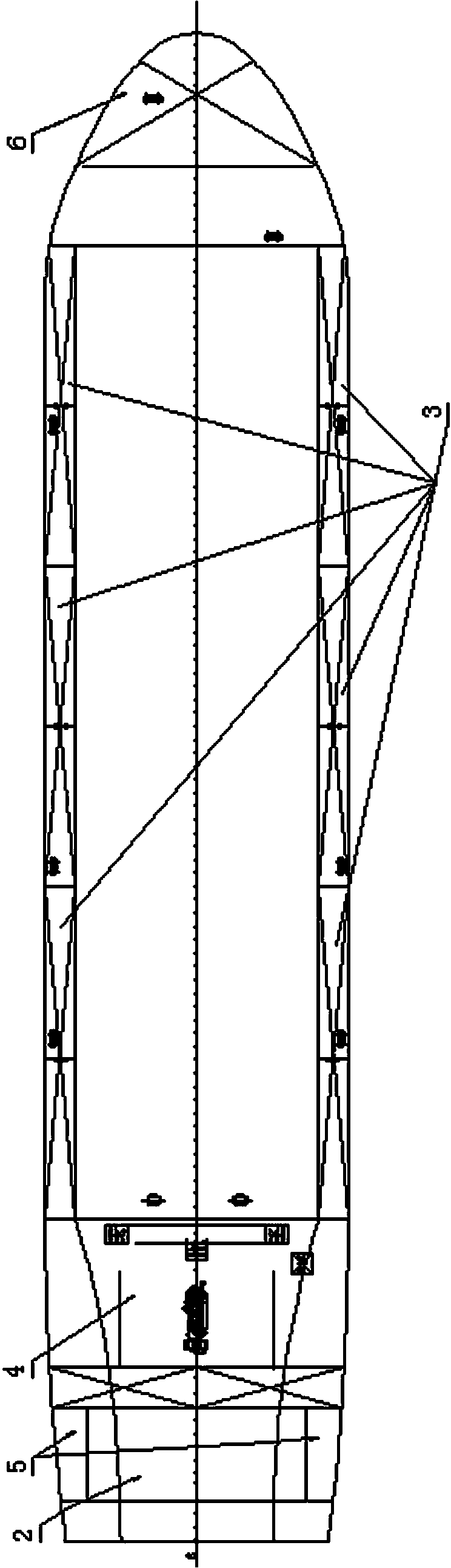

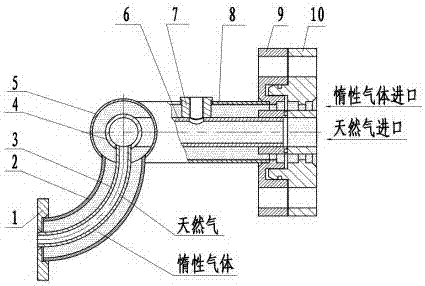

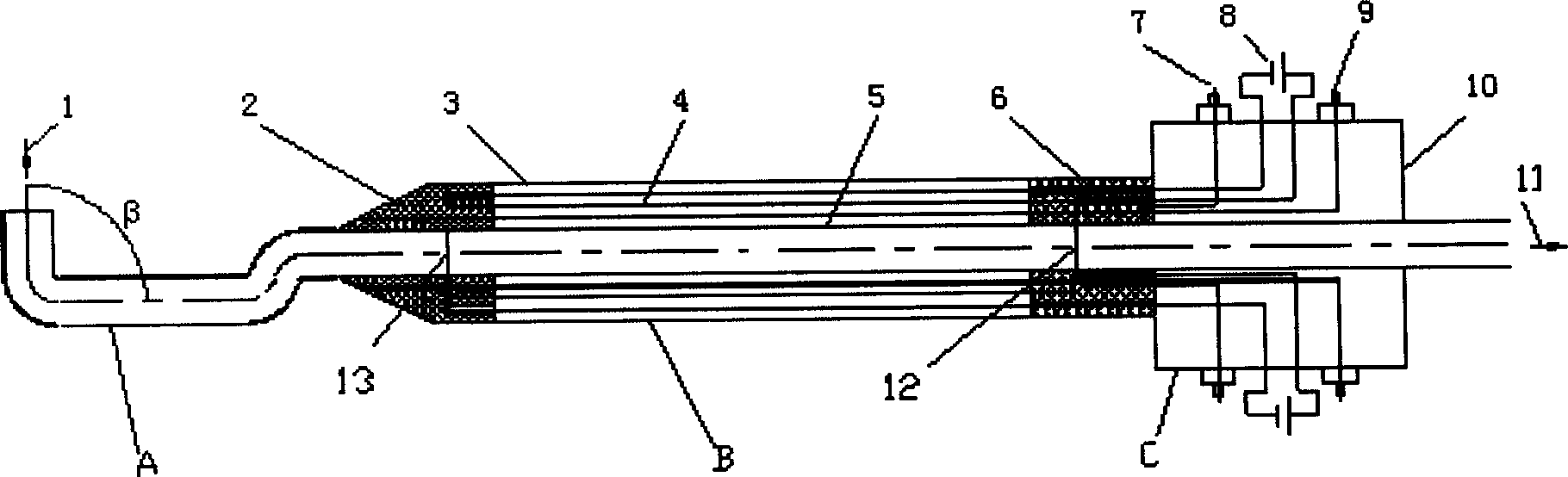

Double-wall pipeline for the connection of fuel-gas valve set and engine on LNG ship and installation method of double-wall pipeline

ActiveCN101525048ASimple structureEasy to manufactureInternal combustion piston enginesFuel supply apparatusDouble-walled pipeDouble wall

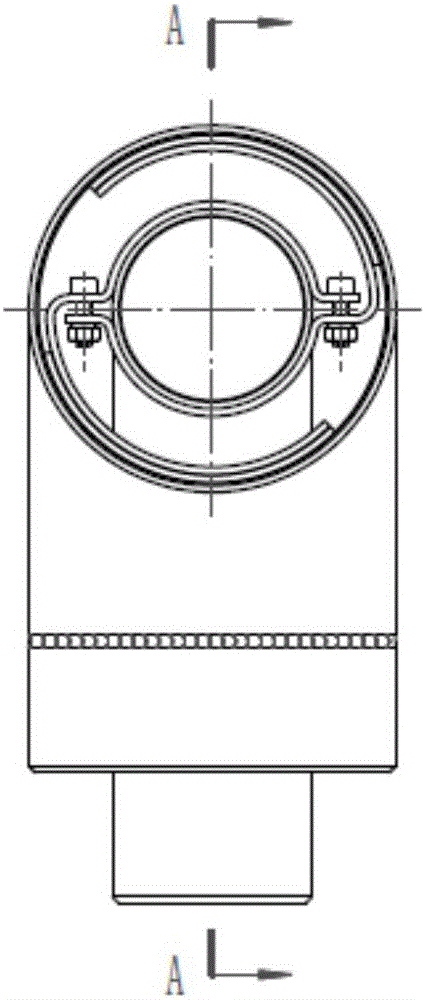

The invention relates to a double-wall pipeline for the connection of a fuel-gas valve set and an engine on an LNG ship, which comprises an internal pipe and an external pipe, wherein the internal pipe and the external pipe are coaxially sleeved and supported by a plurality of detachable clips, one end of the external pipe is fixed on the side wall of a fuel-gas valve set chamber provided with the fuel-gas valve set, one end of the internal pipe is communicated with the fuel-gas valve set by a transitional connection pipe, the other end of the internal pipe is communicated with the air inlet of a double fuel-gas engine by an internal corrugated pipe, the aperture of the internal pipe is the same as that of the air inlet of the engine, and a circular chamber is arranged between the internal pipe and the external pipe and communicated with the fuel-gas valve chamber to together realize air change. The double-wall pipe of the invention has simple and practical structure, uses common material of easy production and low cost, and can be rapidly and conveniently assembled and disassemble by using common tools when being applied on the LNG ship.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

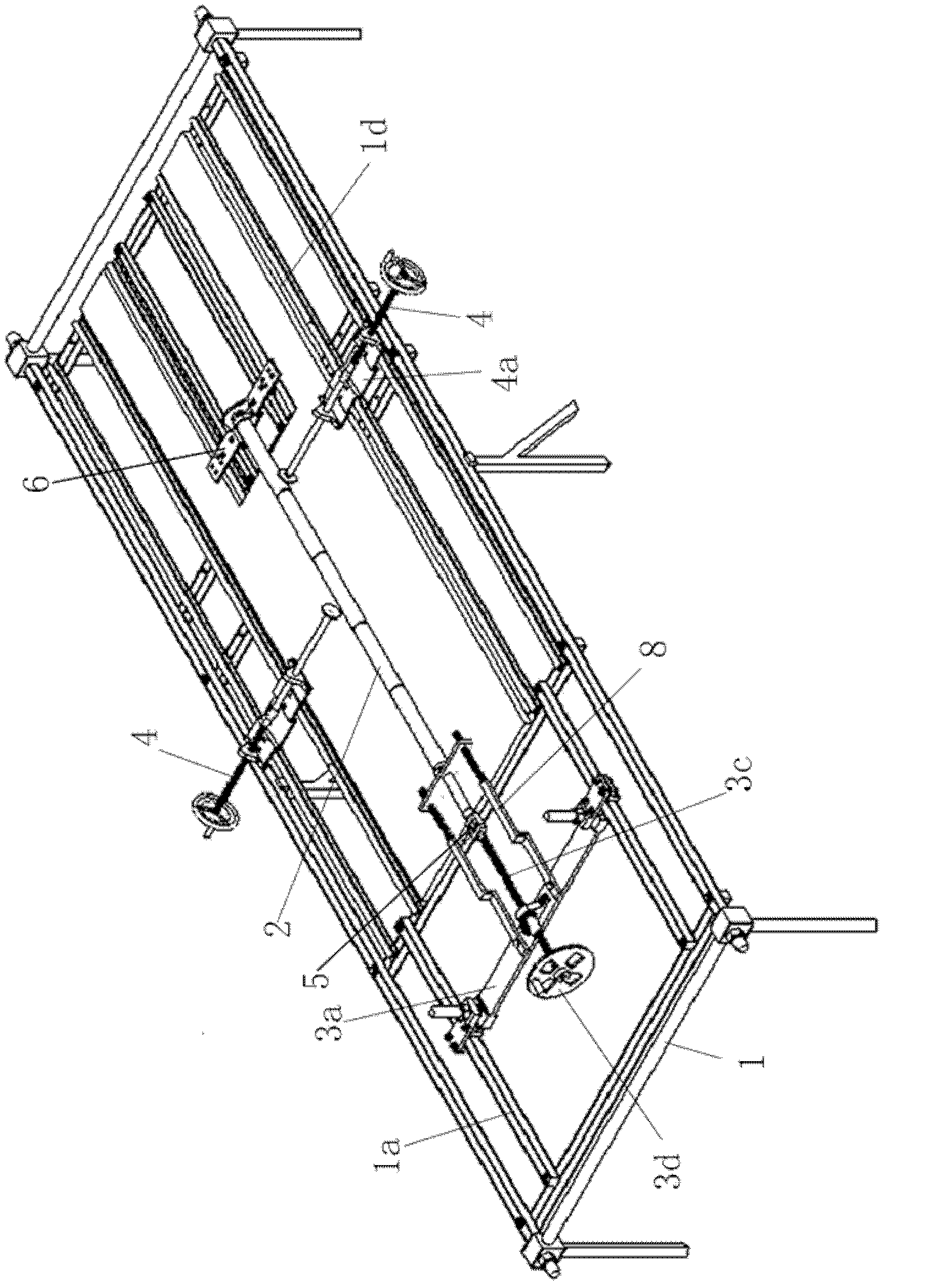

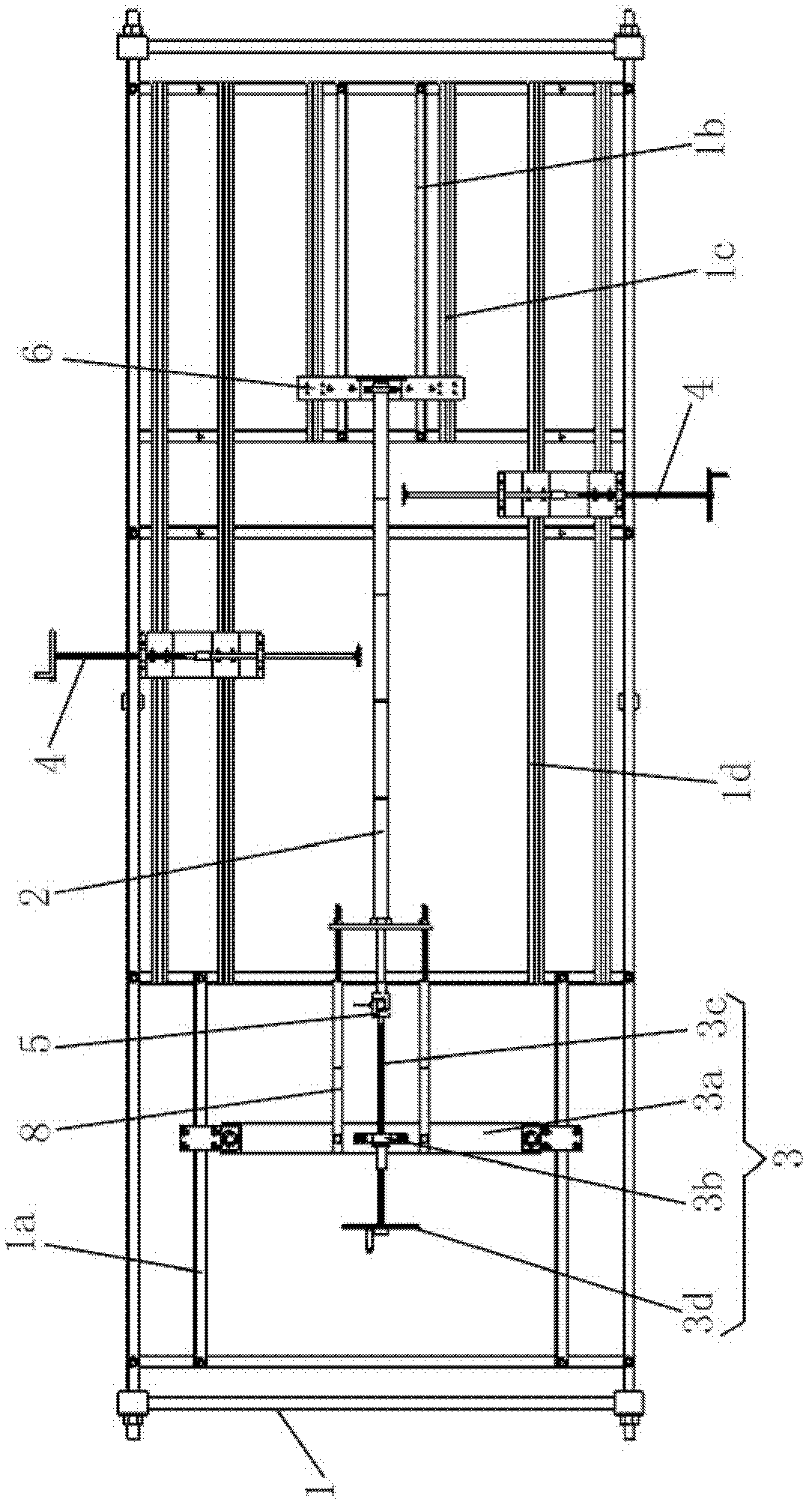

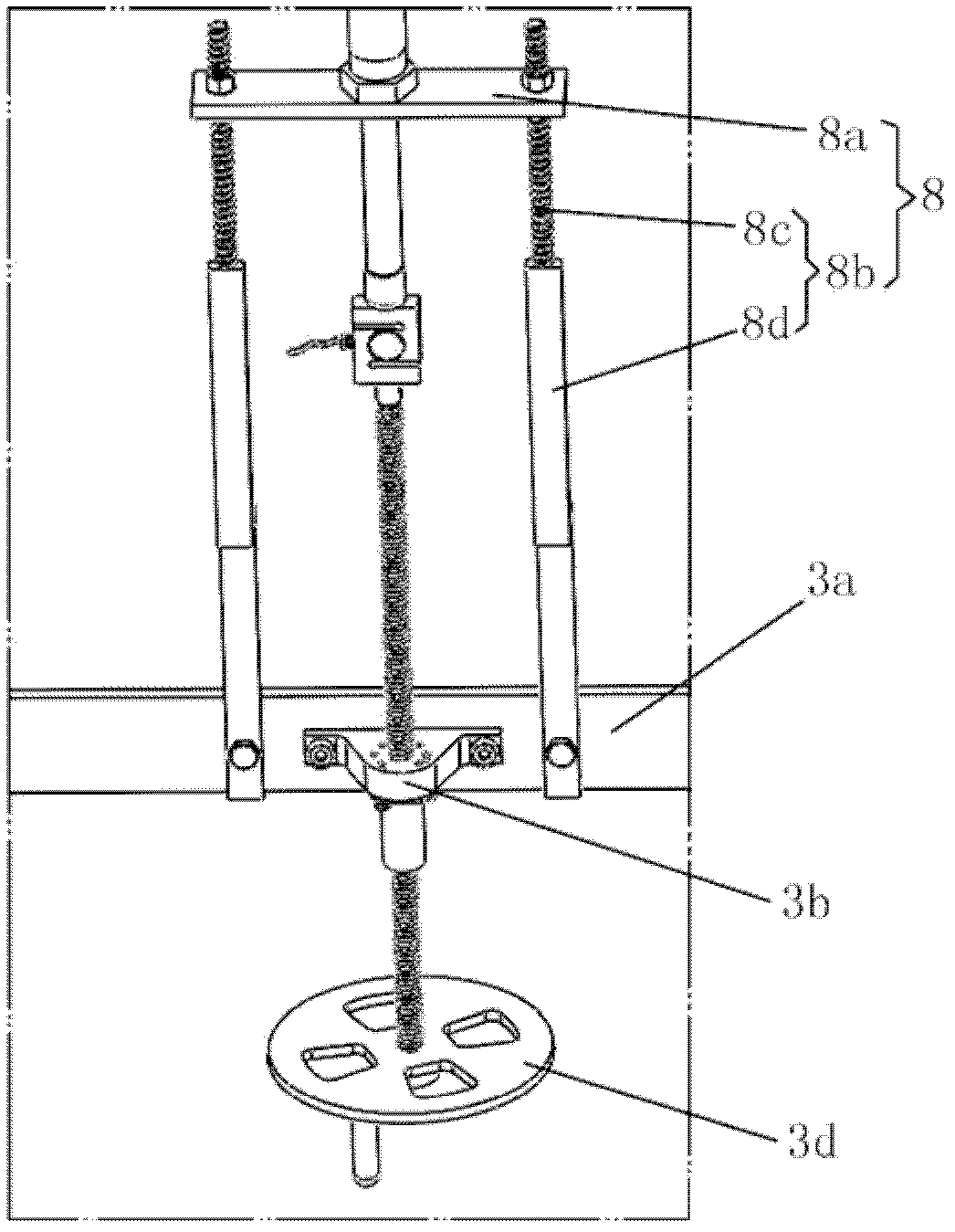

Double-layer pipe overall buckling simulation experiment device and method

The invention discloses a double-layer pipe overall buckling simulation experiment device and method. The experiment device comprises a base, loading devices, a fixing device, a measuring device and the like. The double-layer pipe consists of an inner pipe and an outer pipe sleeved outside the inner pipe at an interval, and the tail end of the double-layer pipe is fixed by a fixing device; the axial loading device can axially slide and is connected to the base; the axial loading device is connected with the front end of the inner pipe; a pressure sensor is connected between the axial loading device and the inner pipe; two lateral loading devices are located on the two sides of the double-layer pipe respectively; and the two lateral loading devices are staggered.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

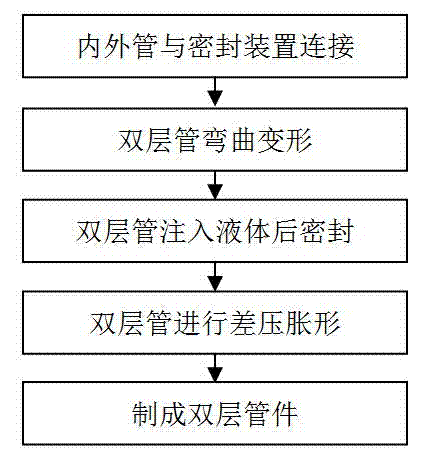

Complicated-shape double-layer pipe manufacturing method and sealing device

The invention discloses a complicated-shape double-layer pipe manufacturing method and belongs to the field of double-layer pipe manufacturing technologies. The manufacturing method comprises the following steps: coaxially putting pipe blanks with different diameters, welding and reinforcing the two ends of the pipe blanks and a sealing device, then performing bending deformation; secondly, injecting a high-pressure liquid into an inner pipe and a gap between the inner pipe and an outer pipe, simultaneously pressuring in the inner pipe and the gap between the inner pipe and the outer pipe, increasing the gap between the inner pipe and the outer pipe by controlling the liquid pressure difference between the two so that the inner pipe reaches a needed shape; at last, releasing the high-pressure liquid, performing vacuum-pumping on the gap between the inner pipe and the outer pipe, simultaneously sealing the inner pipe and outer pipe at the two ends of the double-layer pipe to obtain the double-layer pipe. According to the complicated-shape double-layer pipe manufacturing method, by performing vacuum-pumping heat insulation on the gap between the inner pipe and the outer pipe, the weight of a heat insulation pipe is obviously reduced, the manufacturing cost is reduced, and various complicated-shape double-layer pipe fittings can be produced to be suitable for the requirements of different industries. The invention also discloses a sealing device for manufacturing the complicated-shape double-layer pipe.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Pipe joint assembly

InactiveUS20030090112A1Active connectionReducing amount and difficultySleeve/socket jointsFluid pressure sealed jointsDouble-walled pipeDouble wall

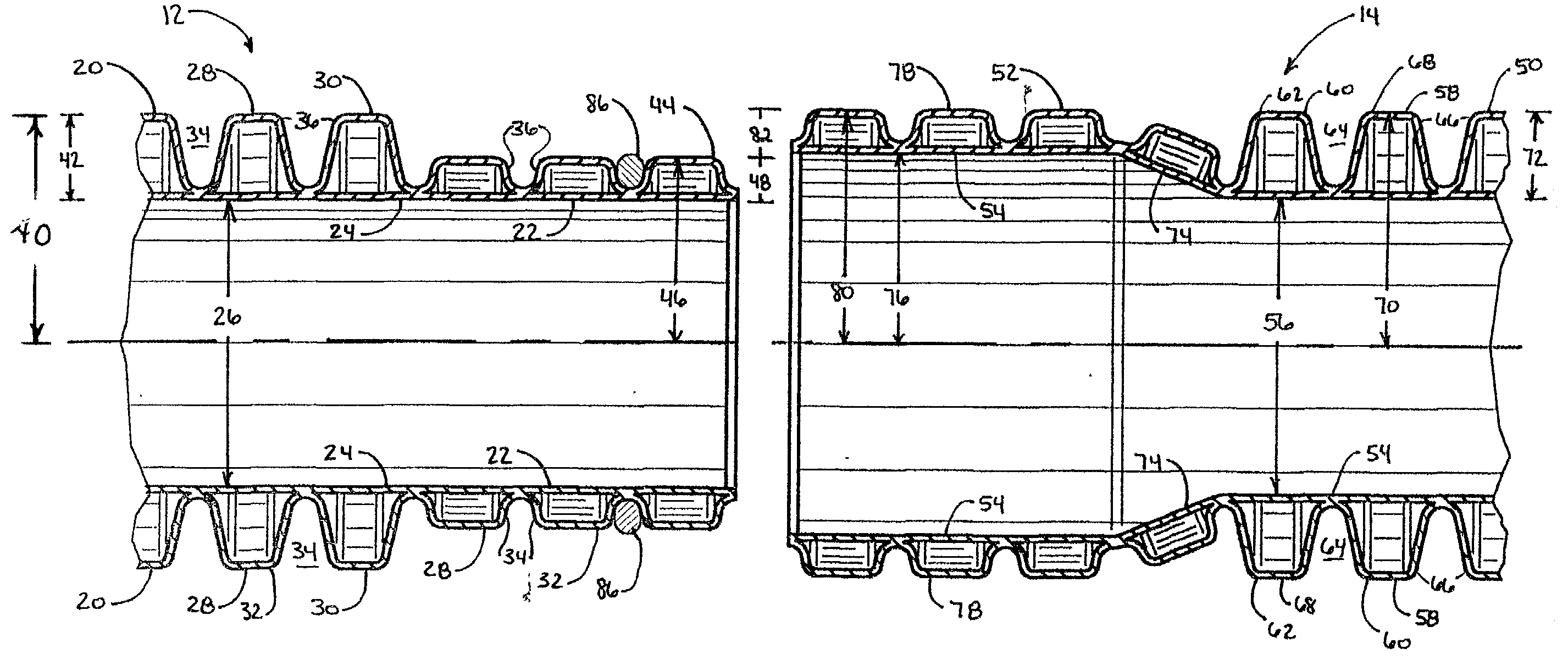

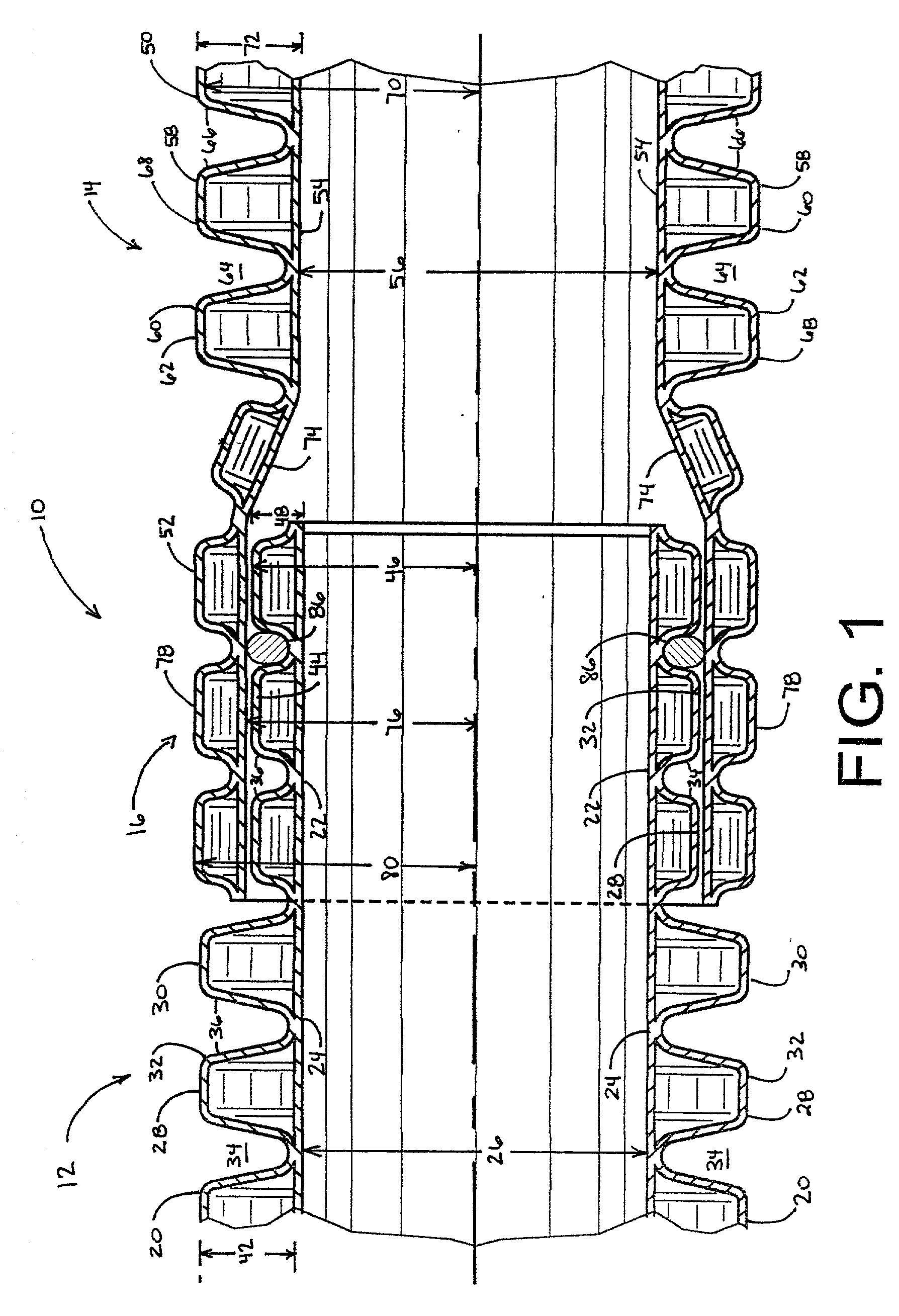

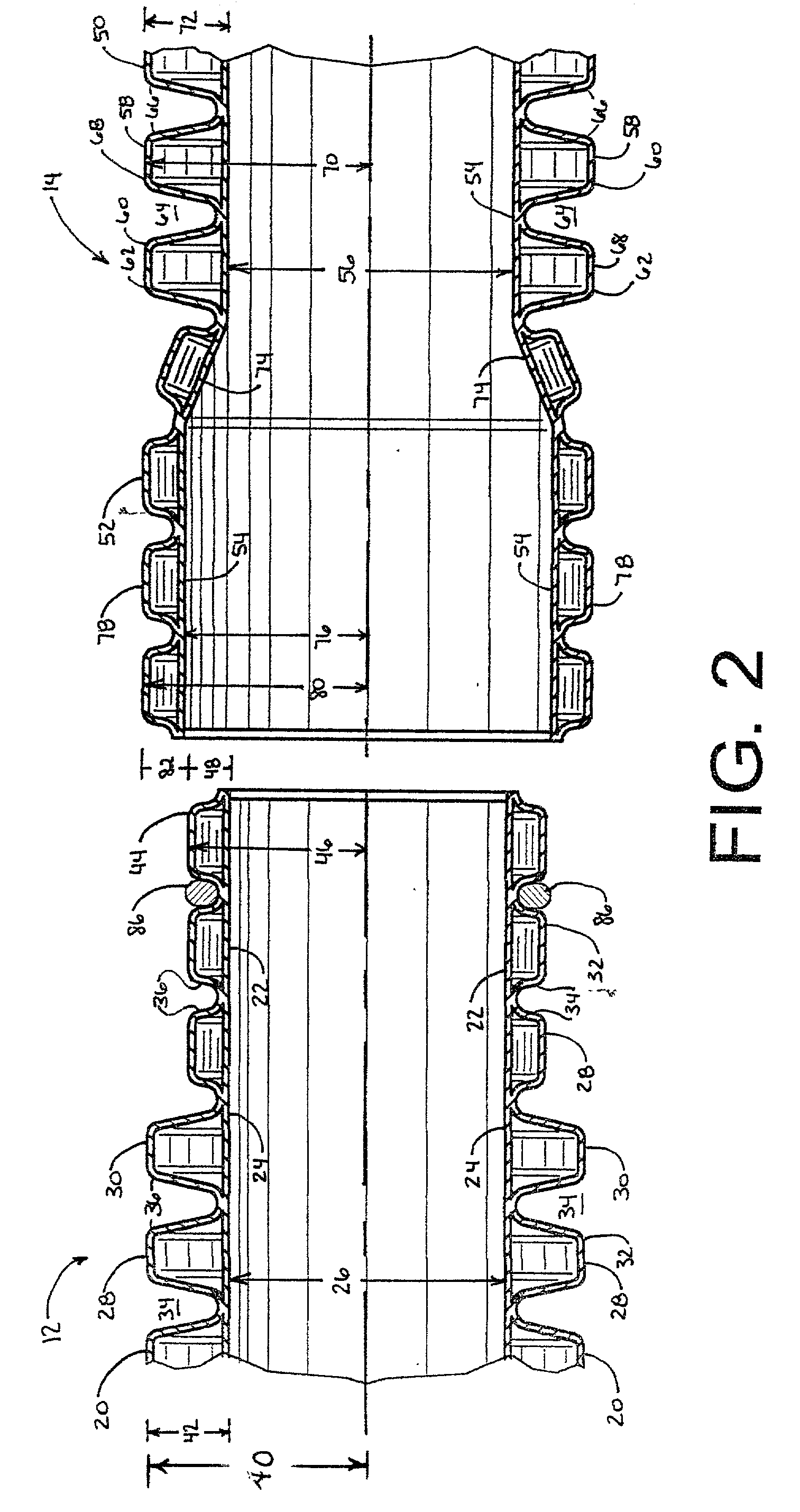

A pipe joint assembly joins two double wall pipe sections together. The pipe joint assembly includes a first pipe section having at least one double wall corrugation on an end portion, a second pipe section having at least one double wall corrugation on an end portion and a joint formed by locating the first pipe section end portion and the second pipe section end portion in an overlapping relationship. The pipe joint assembly substantially increases the strength of the joint relative to conventional pipe assemblies.

Owner:BAUGHMAN TILE

Modified polyethylene pipe and preparation method thereof

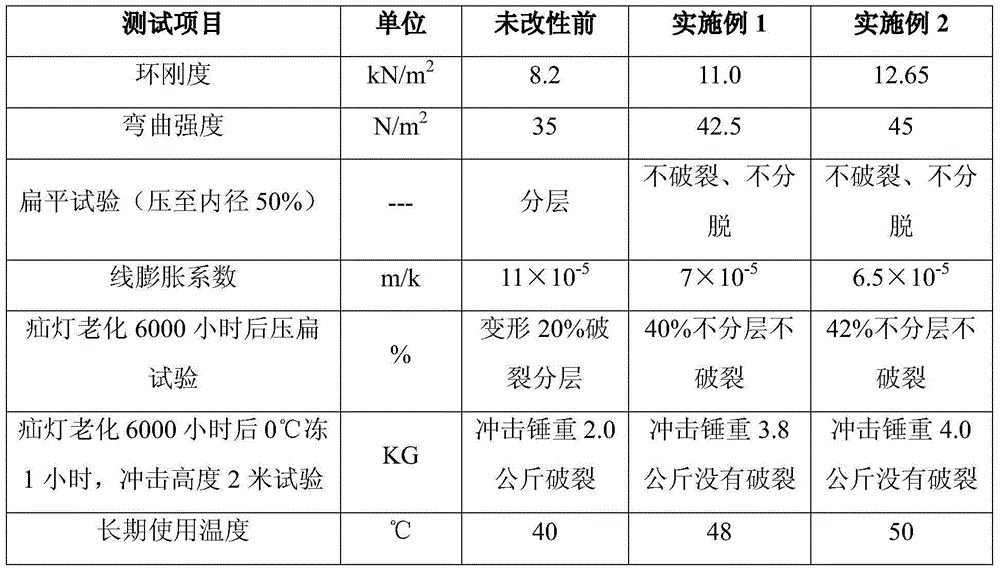

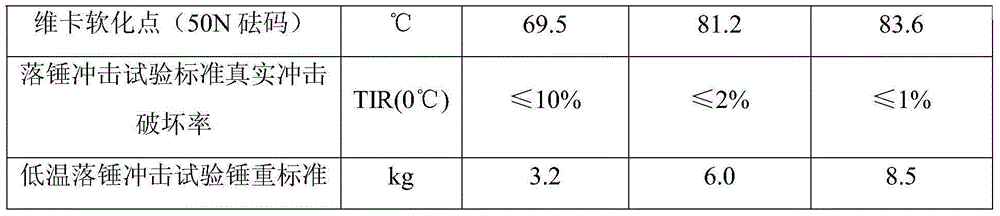

The invention belongs to the field of a blowdown pipe and particularly relates to a modified polyethylene pipe and a preparation method thereof. The invention aims to solve the technical problems of poor ring stiffness, insufficient toughness, resource waste and increase of carbon emission of a double-wall pipe processed by polyethylene. To solve the technical problems, the adopted scheme is to provide the modified polyethylene pipe which comprises the following components by weight: 100 parts of polyethylene resin, 5 to 50 parts of chlorinated polyethylene, 5 to 50 parts of chlorinated polyvinyl chloride, 1 to 30 parts of chlorinated polypropylene, 1 to 50 parts of nano material, 0.1 to 3 parts of color masterbatch, 1 to 20 parts of processing aid, 0.1 to 5 parts of calcium stearate, 0.1 to 1 part of lubricant, 0.5 to 5 parts of light stabilizer, 0.5 to 5 parts of antioxidant, 1 to 15 parts of compatibilizer, 0.5 to 8 parts of lead-free stabilizer and 1 to 15 parts of anti-cracking resin. The invention also provides the preparation method of the modified polyethylene pipe. According to the modified polyethylene pipe provided by the invention, the ring stiffness is greatly improved and the modified polyethylene pip has good toughness and aging resistance.

Owner:KANGTAI PLASTIC SCI & TECH GRP

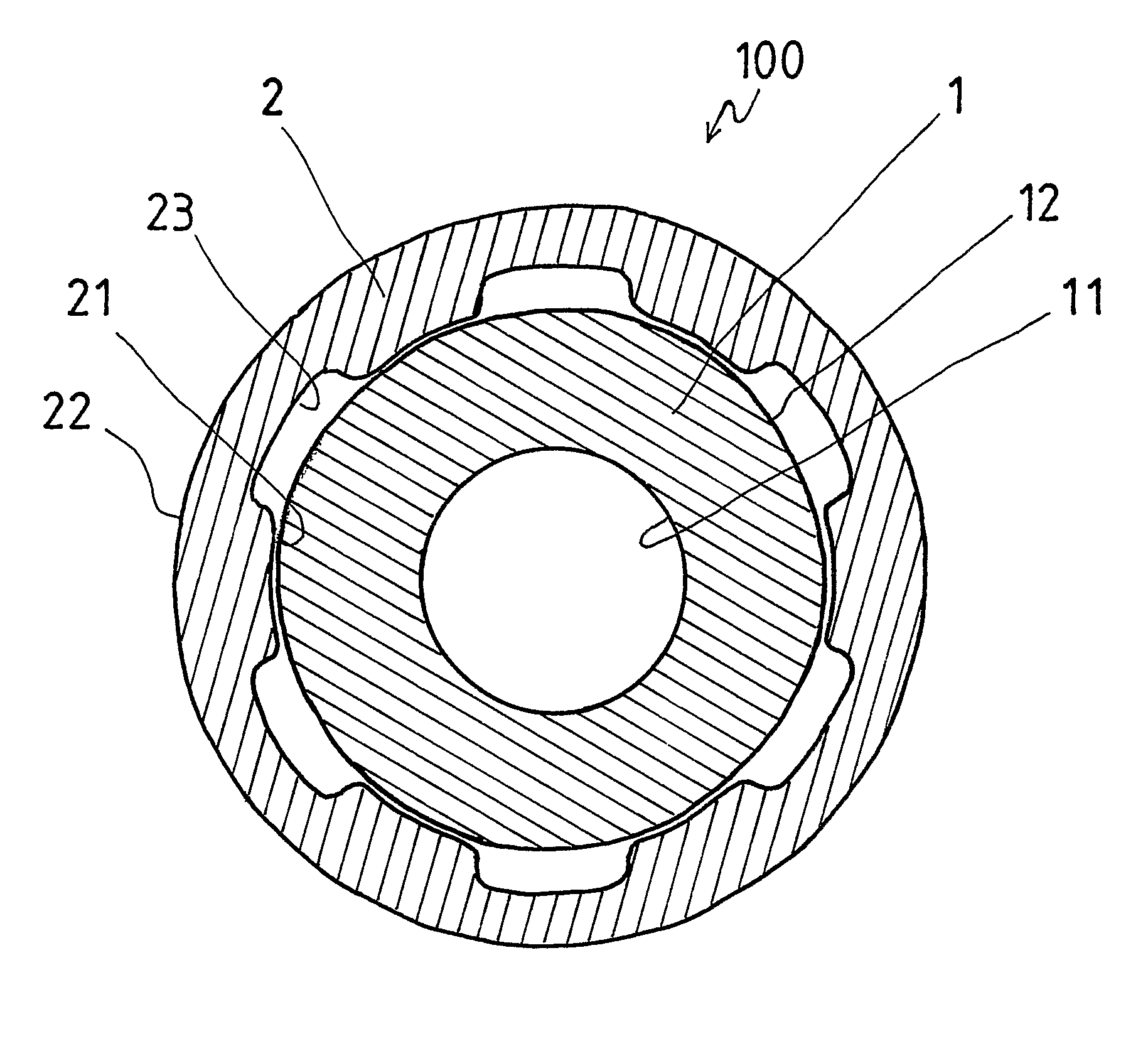

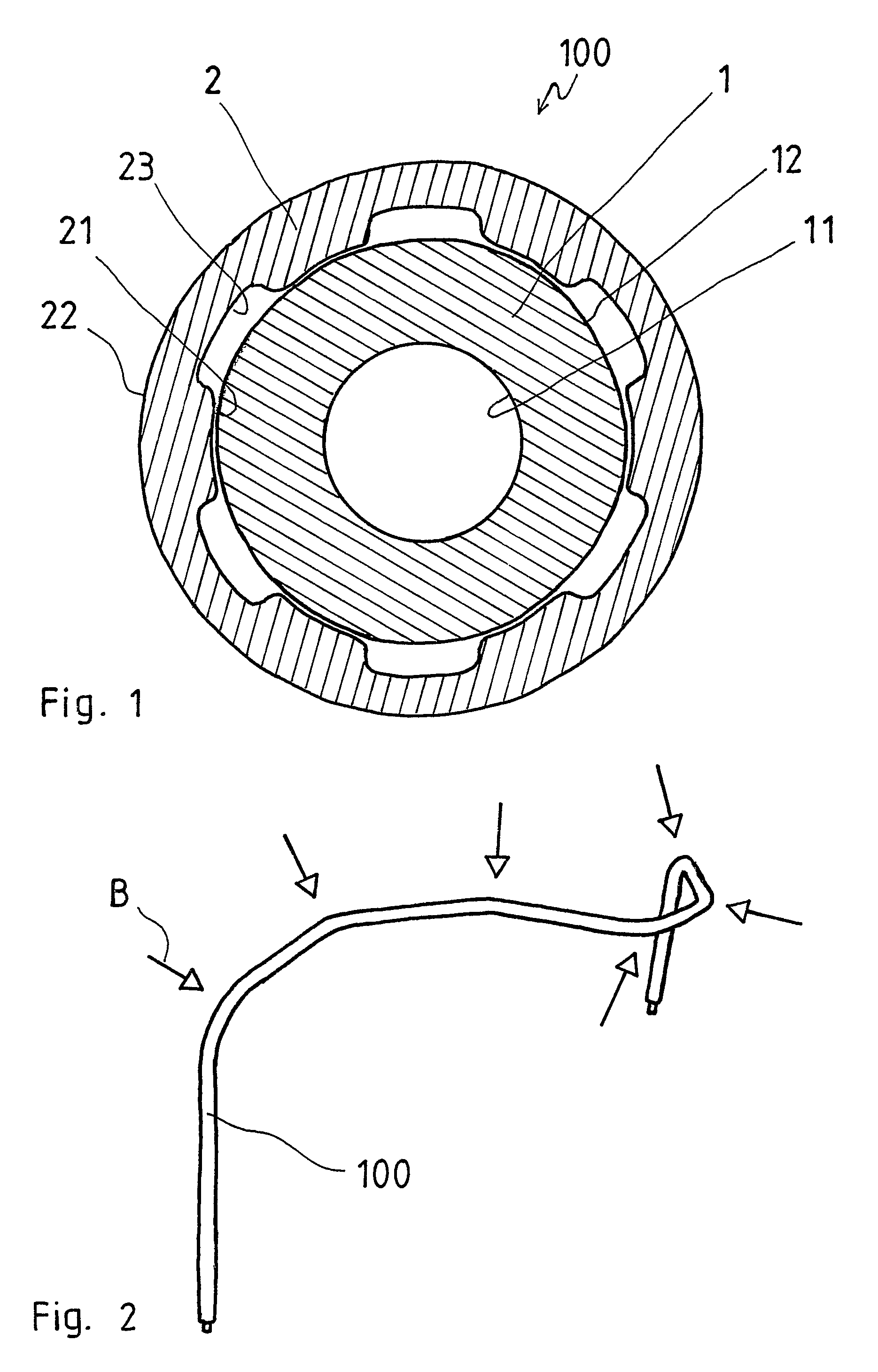

Double wall pipe

InactiveUS7770602B2Cut-out easierExtended service lifePipe elementsFlexible pipesDouble-walled pipeDouble wall

The present invention relates to a double wall pipe with an inner high pressure pipe (1) having an inner flow space for harmful and / or flammable liquids, particularly fuel to be infected or hydraulic oil, and with an outer protection pipe (2) coaxially arranged around the inner pipe, having an enter flow space between inner pipe and outer pipe, for possibly leaking or spilling liquid from the inner pipe, wherein the protection pipe (2) has several substantially longitudinal arranged grooves (23) throughout its inner surface (21); the inner high pressure pipe (1) is fitted tightly into the protection pipe (2); and after bending the double wall pipe (100), the double wall pipe (100) is unified by surface pressure due to deformation of bending process.

Owner:GALL & SEITZ SYSTEMS GMBH

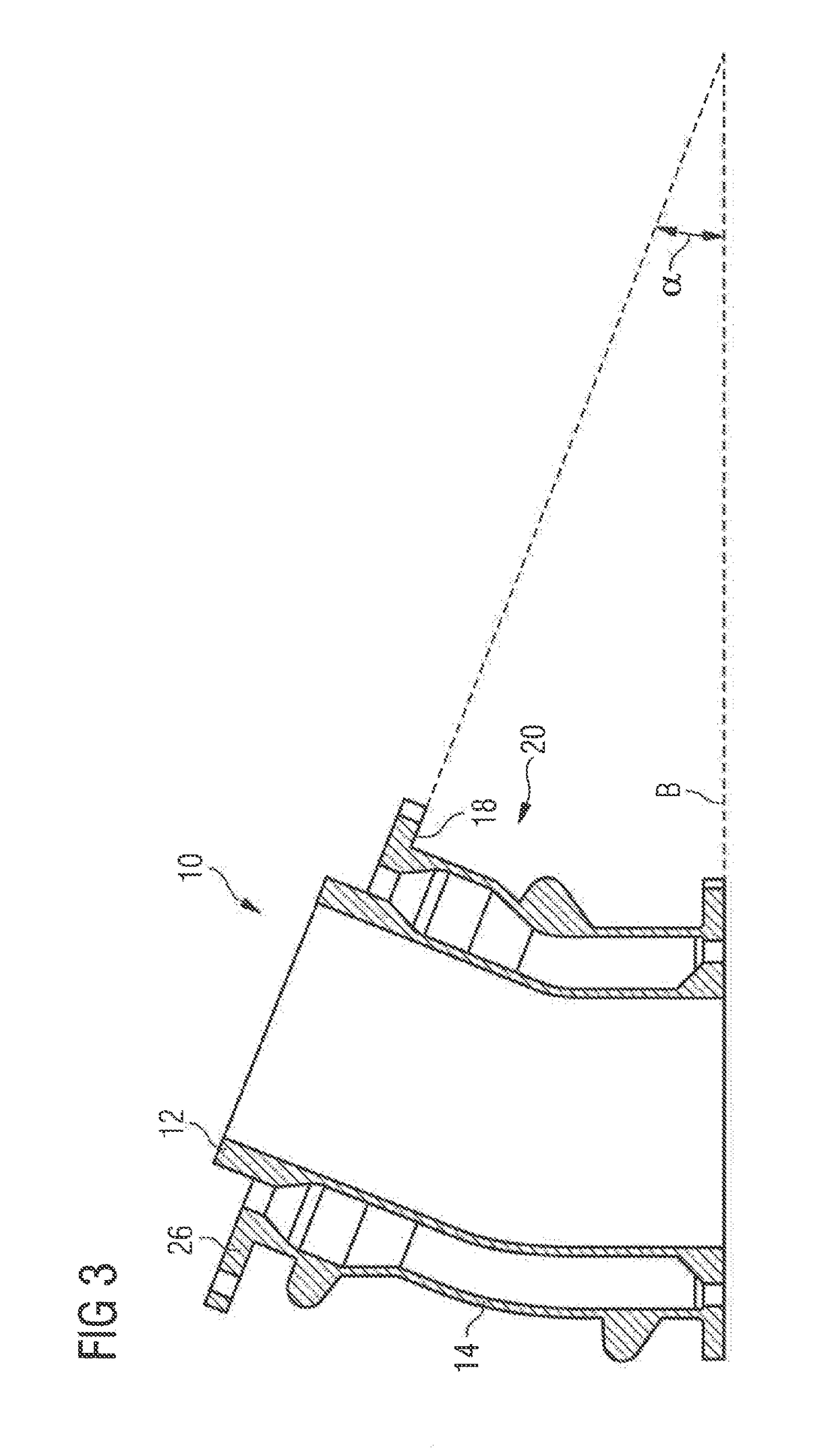

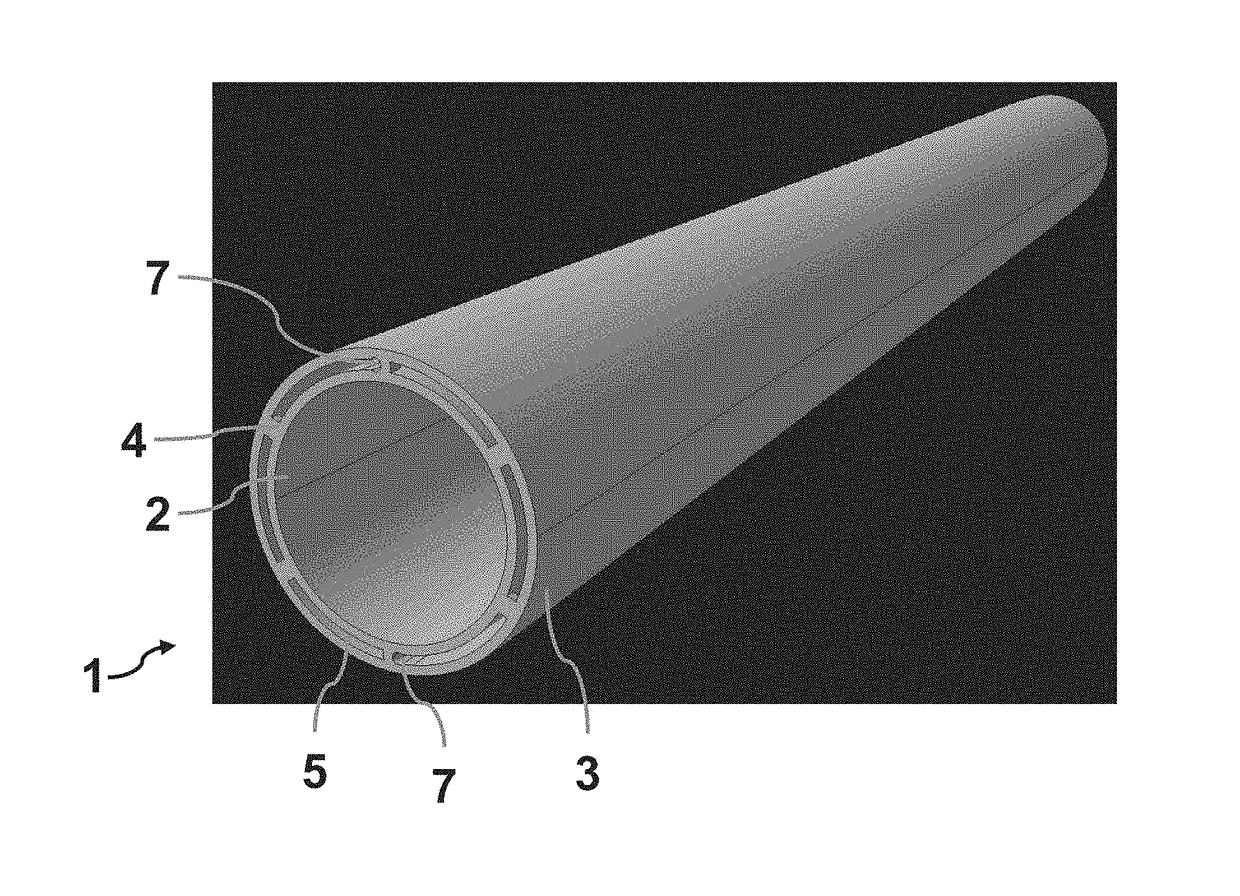

Double-walled pipe element and method for producing a double-walled pipe element

InactiveUS20170219134A1Producible simply and cost-effectivelyProduced simply and cost-effectivelyAdditive manufacturing apparatusPower plant fuel supplyDouble-walled pipeAirplane

Owner:AIRBUS DEFENCE & SPACE

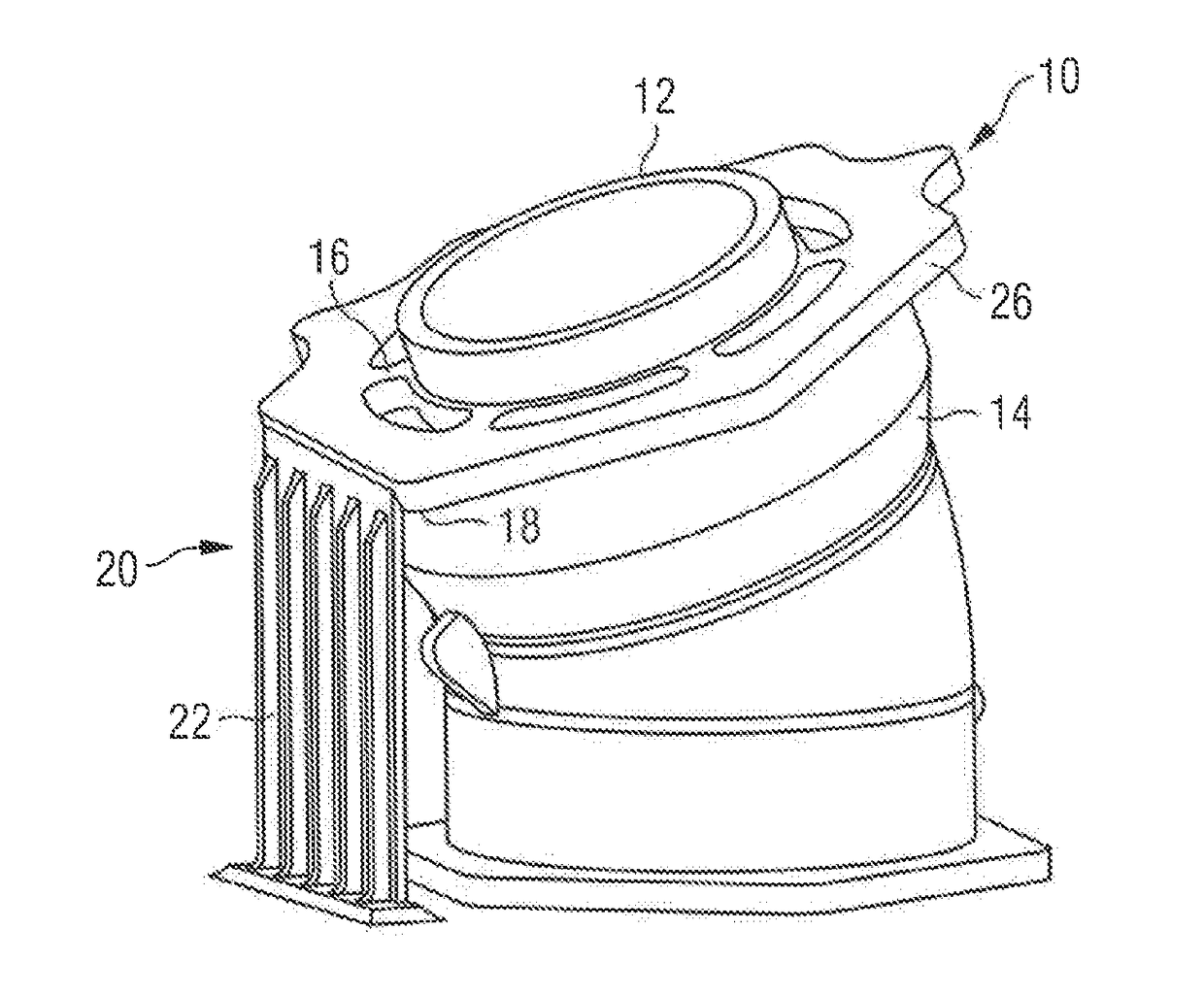

Double-walled pipe with integrated heating capability for an aircraft or spacecraft

ActiveUS9939087B2Lightweight and efficient designEase of installation and productionAdditive manufacturing apparatusThermal insulationDouble-walled pipeIntermediate space

A double-walled pipe with integrated heating capability for an aircraft or spacecraft includes a pipe body rigidly formed from plastic in one piece with an inner wall, with an outer wall and with a plurality of wall supports, the wall supports connecting the inner wall to the outer wall, the inner wall and the outer wall defining an intermediate space. The double-walled pipe further includes an electrically conductive coating surrounding the inner wall within the intermediate space and configured to heat up under application of an electric current such that heat is transferred to the inner wall.

Owner:AIRBUS OPERATIONS GMBH

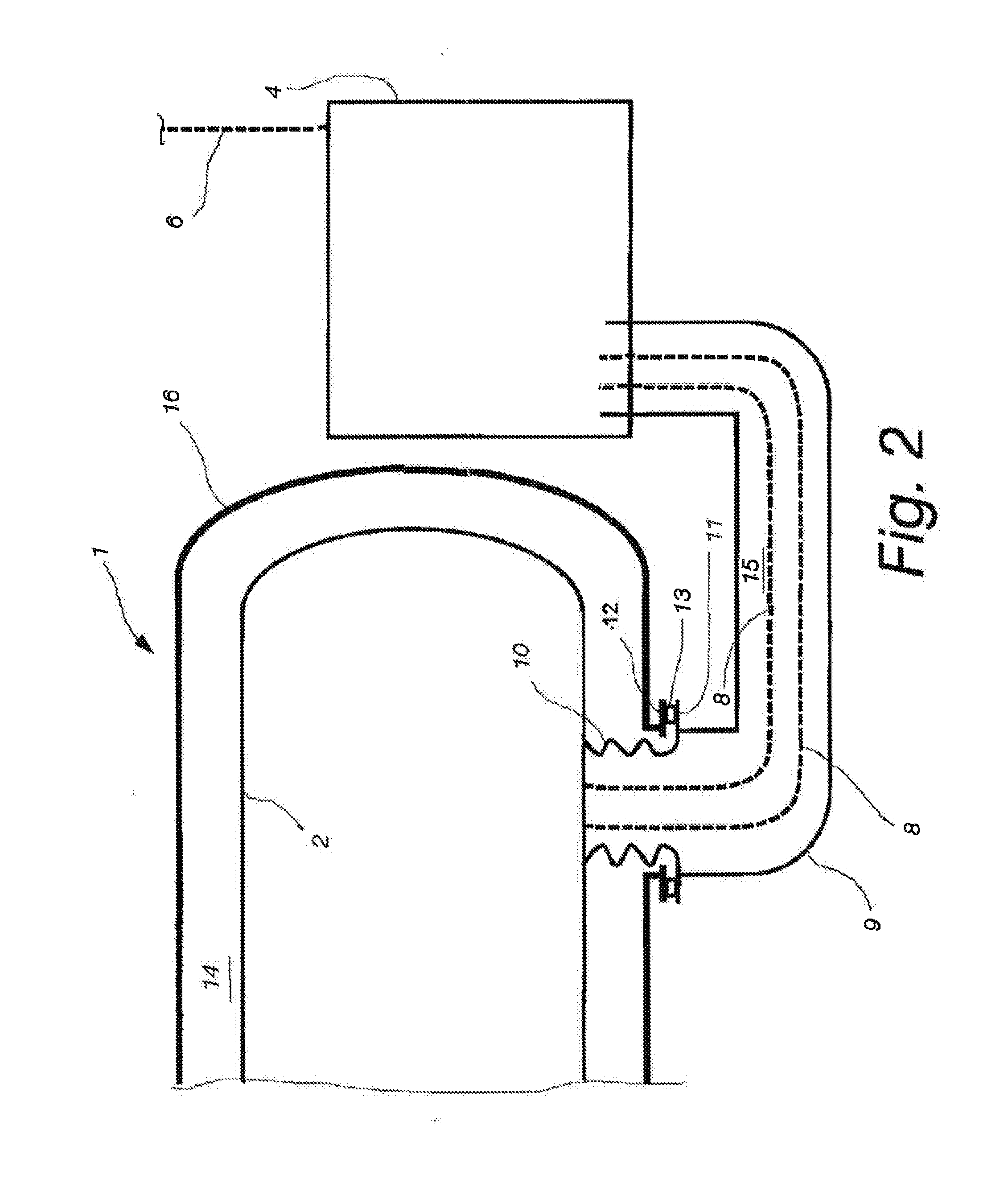

Connection of double-walled pipes

A double-walled pipe connection for an aircraft fuel line includes a first outer pipe surrounding a first inner pipe, a second outer pipe surrounding a second inner pipe, a pipe coupling joining the inner pipes together, a securing fixture on the first inner pipe, a sleeve-shaped outer pipe bushing bolted to the securing fixture by bolts oriented parallel to a radial direction, and an outer pipe sleeve that is axially slidable over the second outer pipe and onto the outer pipe bushing. The first outer pipe is plugged into the outer pipe bushing, which is plugged into the outer pipe sleeve, which seals onto the second outer pipe. The inner pipe coupling is covered or exposed by axially moving the outer pipe sleeve, while the outer pipe bushing remains bolted to the first inner pipe, and mechanically secured and electrically grounded to a metal structure.

Owner:AIRBUS OPERATIONS GMBH

Double-walled pipe with integrated heating capability for an aircraft or spacecraft

ActiveUS20160312924A1Solve the quick installationEase of productionAdditive manufacturing apparatusThermal insulationDouble-walled pipeIntermediate space

A double-walled pipe with integrated heating capability for an aircraft or spacecraft includes a pipe body rigidly formed from plastic in one piece with an inner wall, with an outer wall and with a plurality of wall supports, the wall supports connecting the inner wall to the outer wall, the inner wall and the outer wall defining an intermediate space. The double-walled pipe further includes an electrically conductive coating surrounding the inner wall within the intermediate space and configured to heat up under application of an electric current such that heat is transferred to the inner wall.

Owner:AIRBUS OPERATIONS GMBH

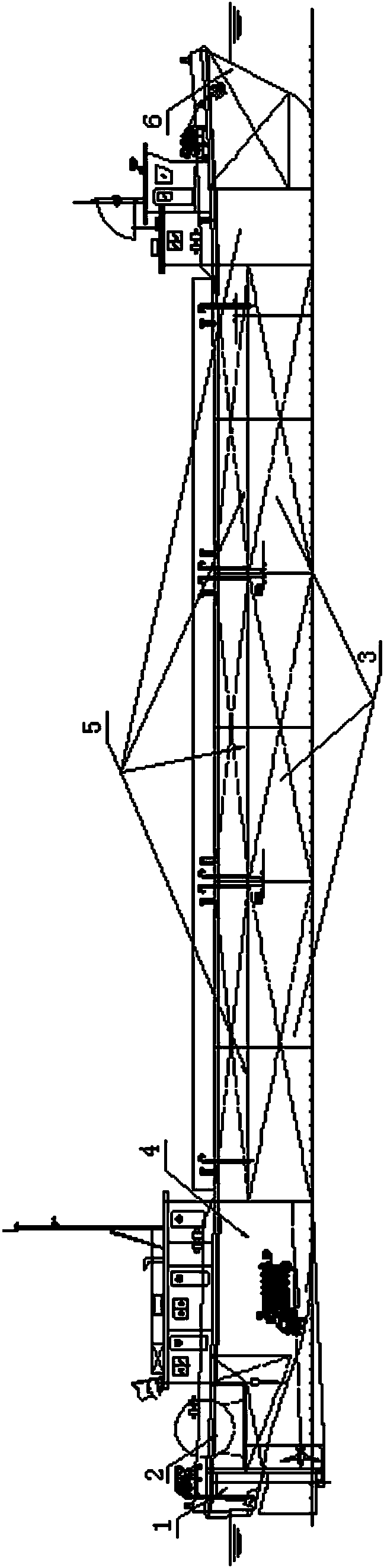

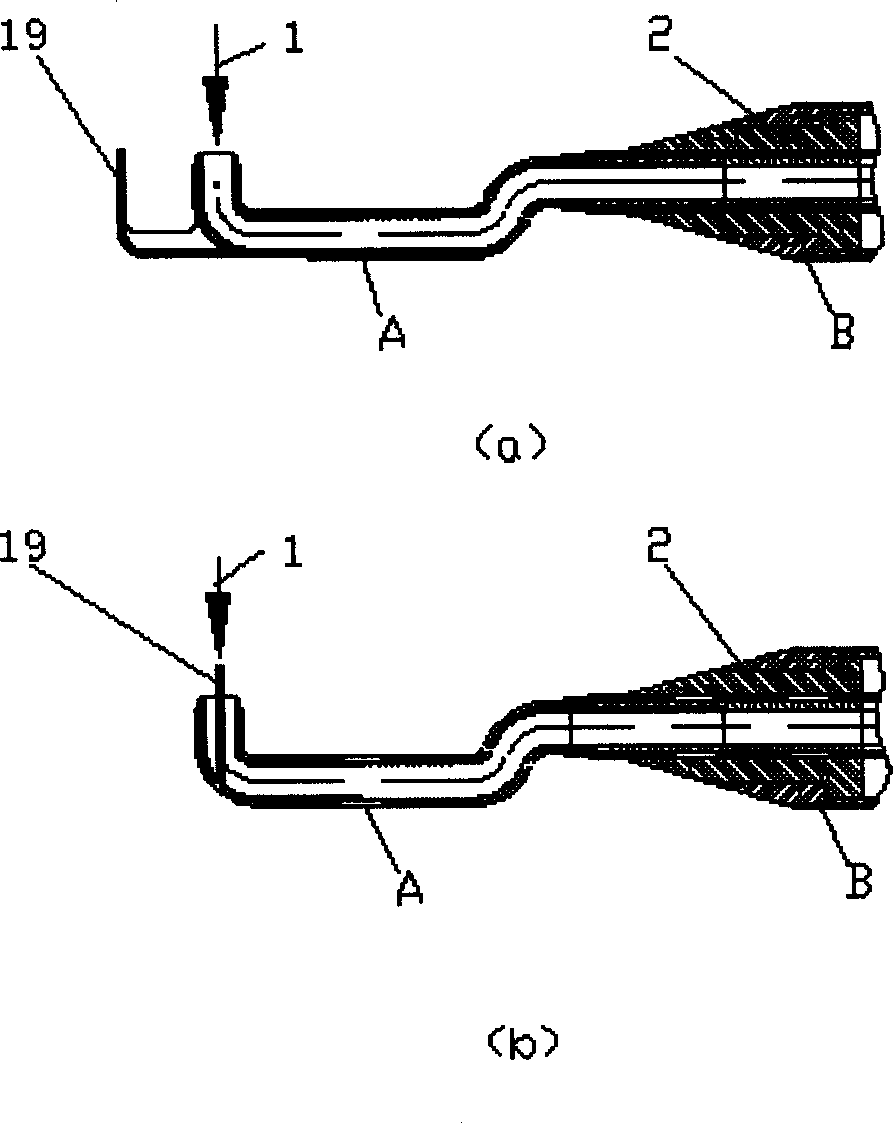

Liquefied natural gas power driving vessel gas supply system double-wall pipe construction process

ActiveCN106322000AImprove construction efficiencyQuality assuranceRigid pipesDouble-walled pipeConstruction design

The invention discloses a liquefied natural gas power driving vessel gas supply system double-wall pipe construction process. An internal field construction process includes the steps: 1) completing a construction design scheme and drawing according to a liquefied natural gas supply system drawing; 2) purchasing right-angled bends and manufacturing inner pipes, outer pipes and supporting devices according to the construction design drawing; 3) manufacturing double-wall pipe right-angled bend prefabricated parts. An external field construction process includes the steps: 1) manufacturing double-wall pipe straight sections by a pre-nesting process; 2) welding and closing the double-wall pipe right-angled bend prefabricated parts and the inner pipes of the double-wall pipe straight sections, and performing 100% radiographic inspection for welds; 3) performing air pressure test under design pressure; 4) actually measuring inner pipe closure welds and the length of a shooting position, manufacturing outer pipes at the shooting position, mounting the outer pipes, welding joints and performing routine inspection for the welds. Reworking is decreased, vessel construction efficiency is greatly improved, and construction cost is reduced.

Owner:NO 711 RES INST CHINA SHIPPING HEAVY IND GRP

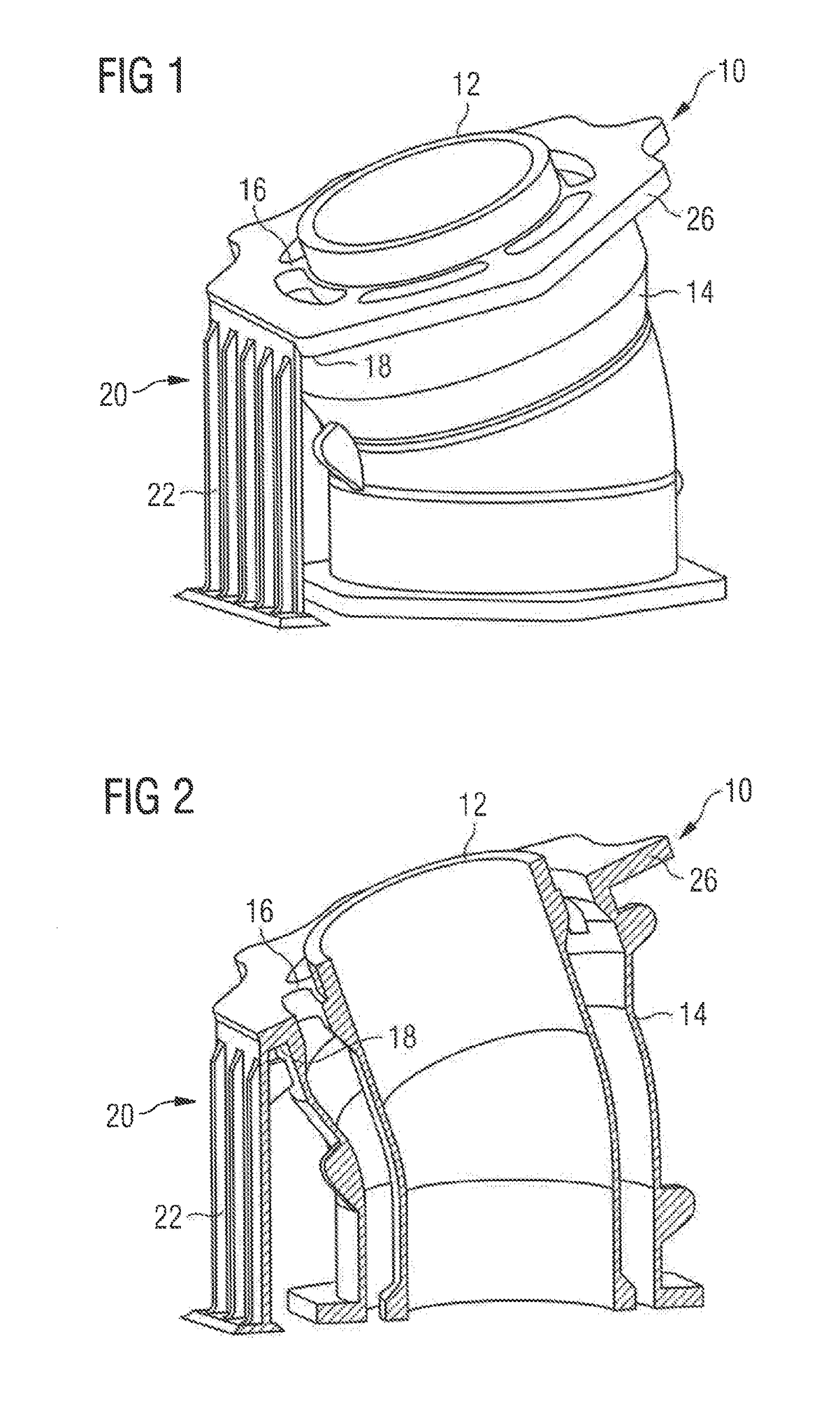

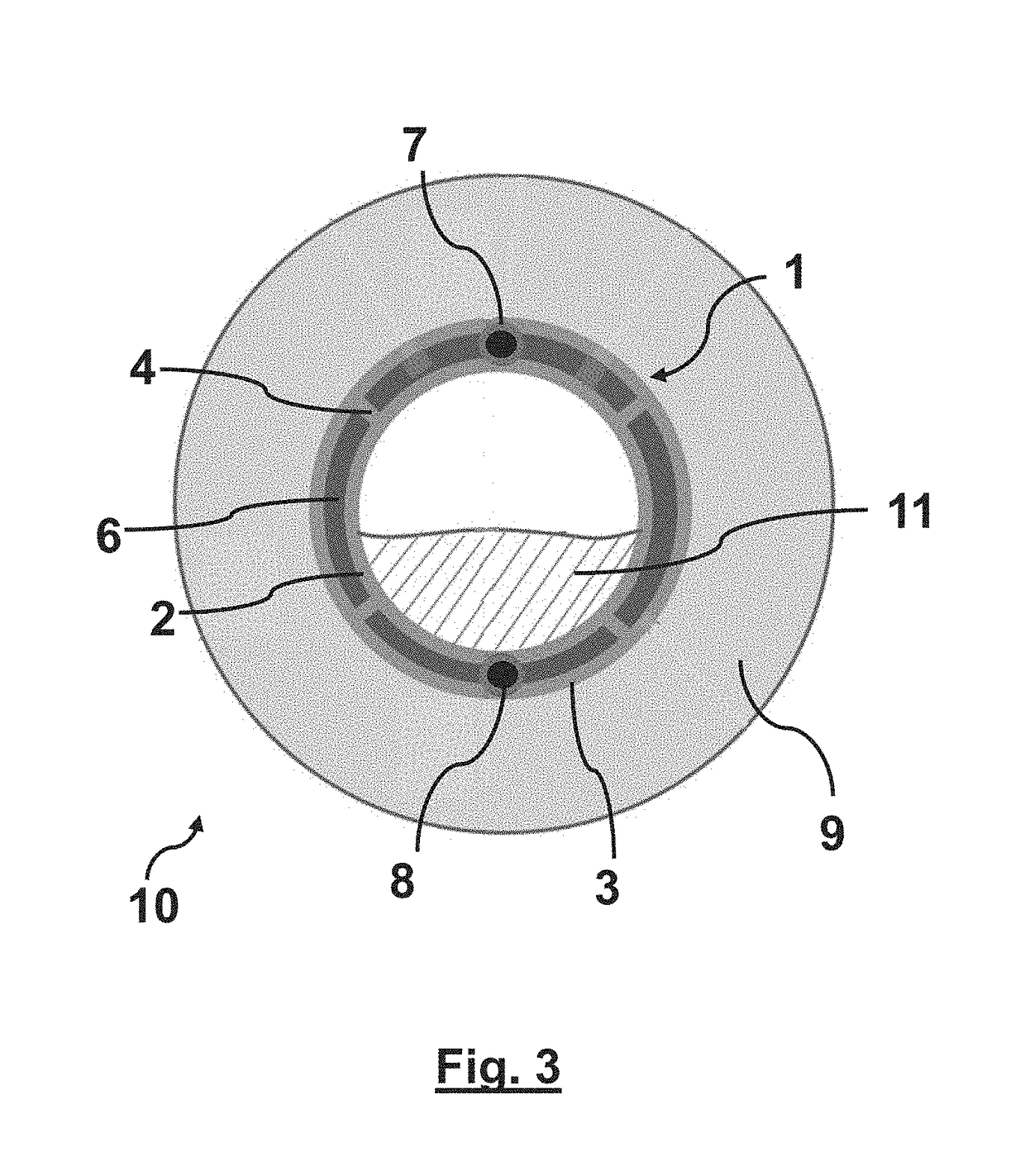

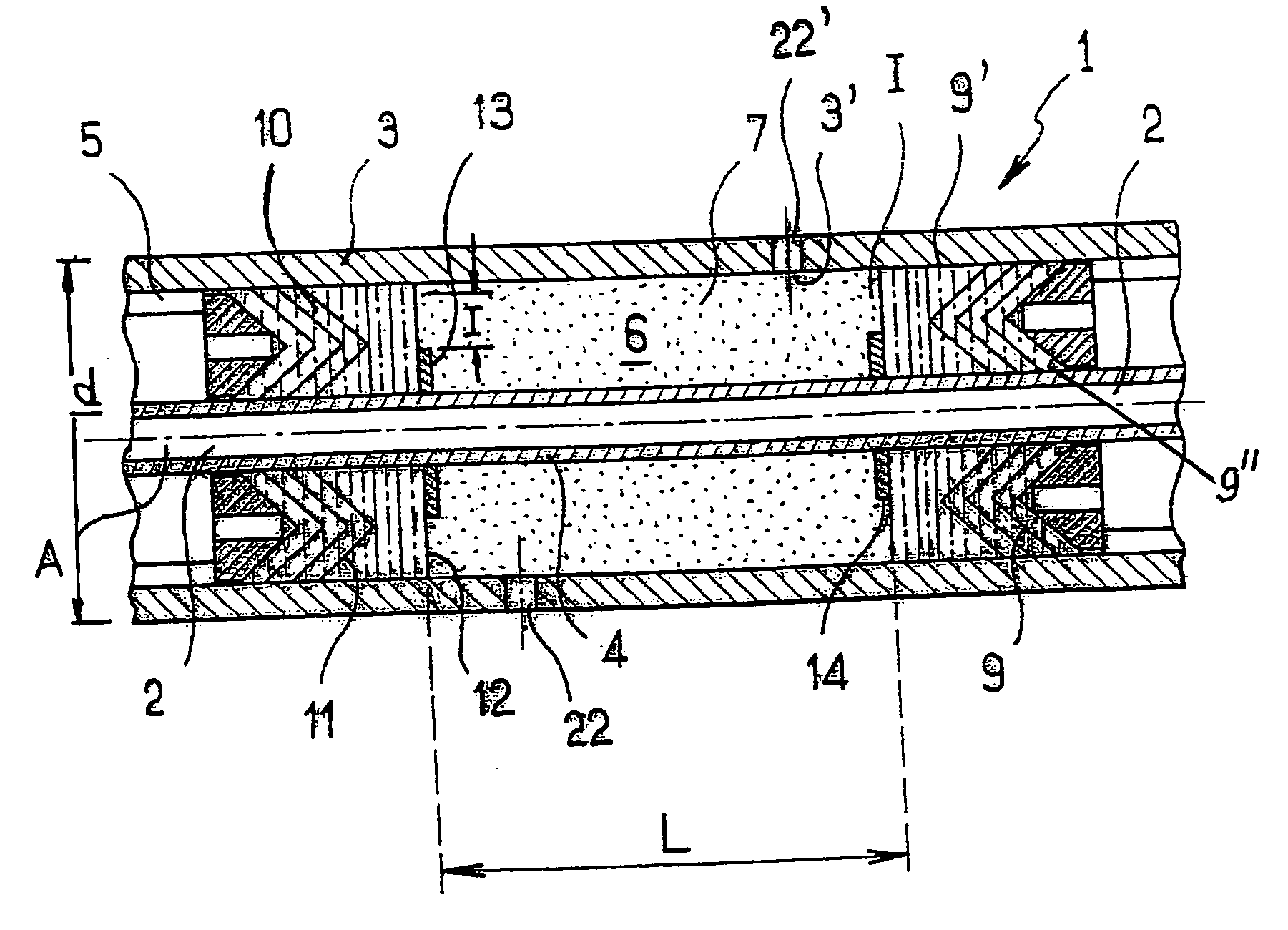

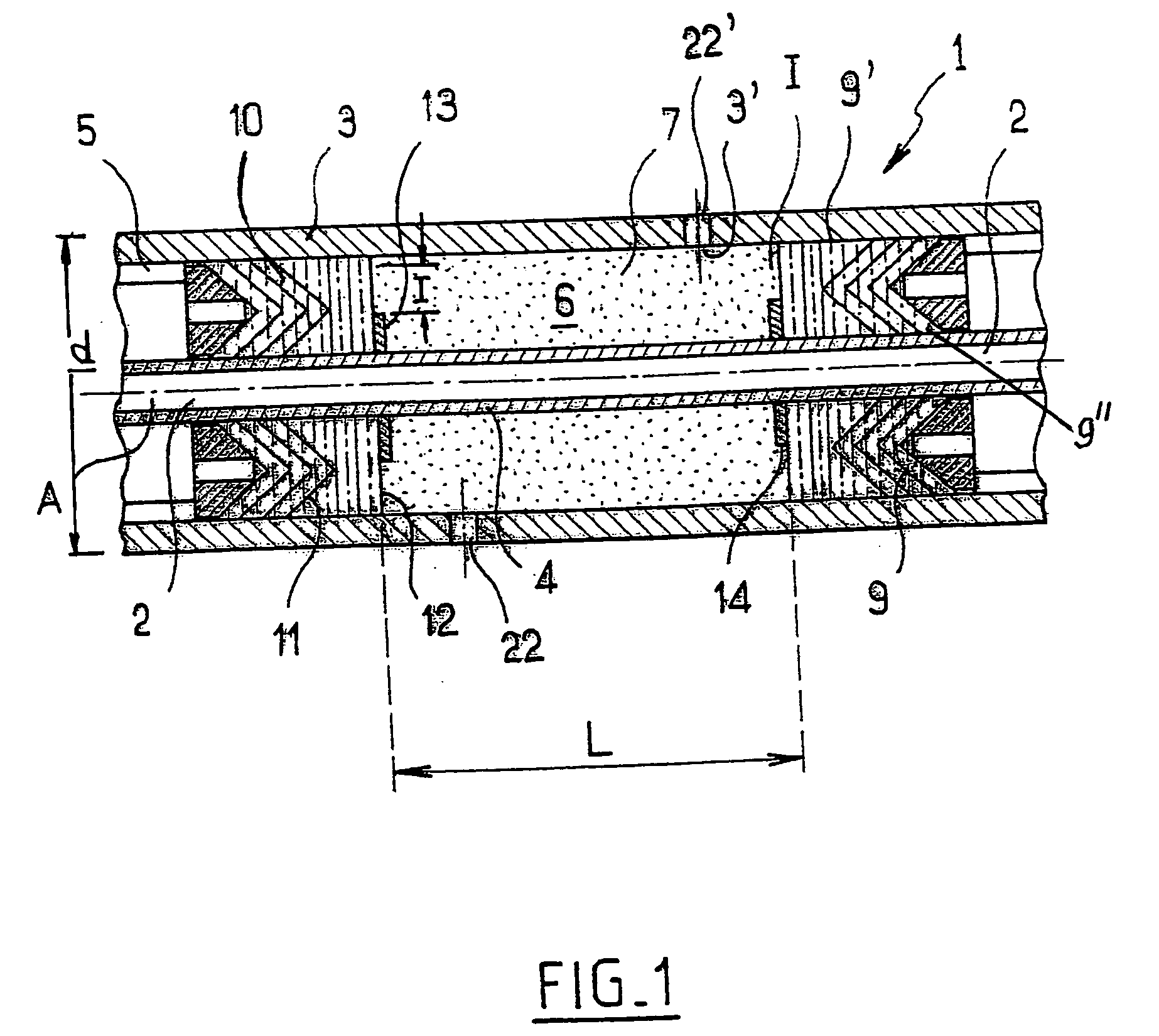

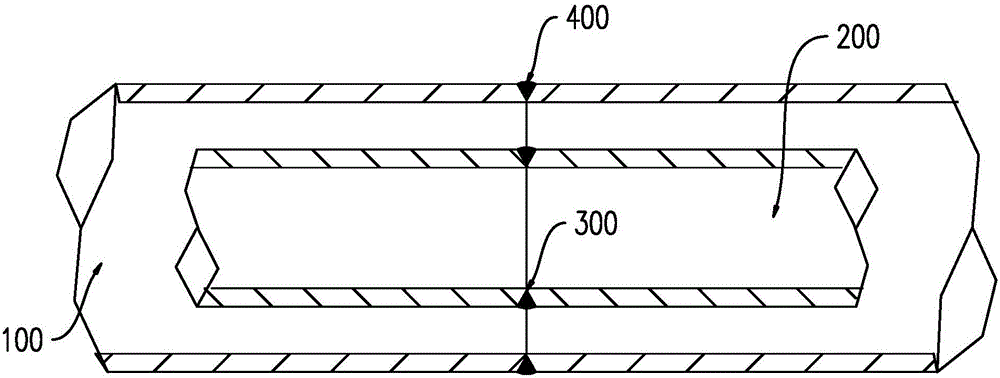

Device for arresting the propagation of a buckle in a double-walled pipe

InactiveUS20060032036A1Shorter and long curing timeEasy to producePipe laying and repairLaminationDouble-walled pipeCompound (substance)

Device for arresting the propagation of a buckle in a double walled pipe. The device comprising an outer pipe wall having a defined external diameter and placed around an inner pipe wall, defining an annular space between the said outer and inner walls; providing predetermined regions in the annular space which are bounded between two sealing blocks with radially opposed faces which are in contact with the outer and inner pipes; placing a curable compound in each region and curing it the length of each region is at least equal to 0.5 times the external diameter of the outer wall.

Owner:TECH FRANCE SA

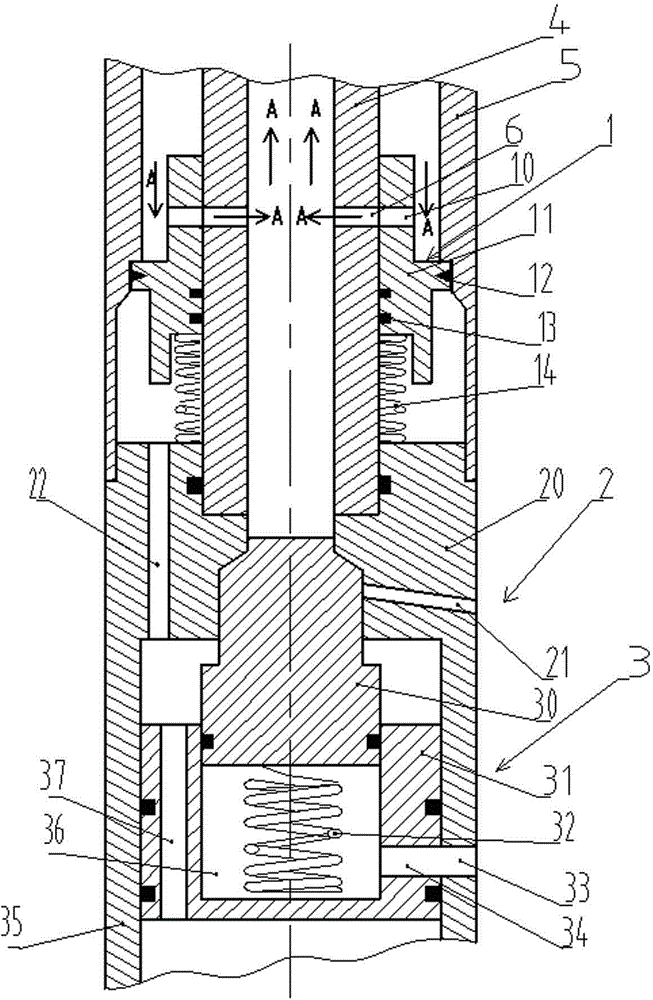

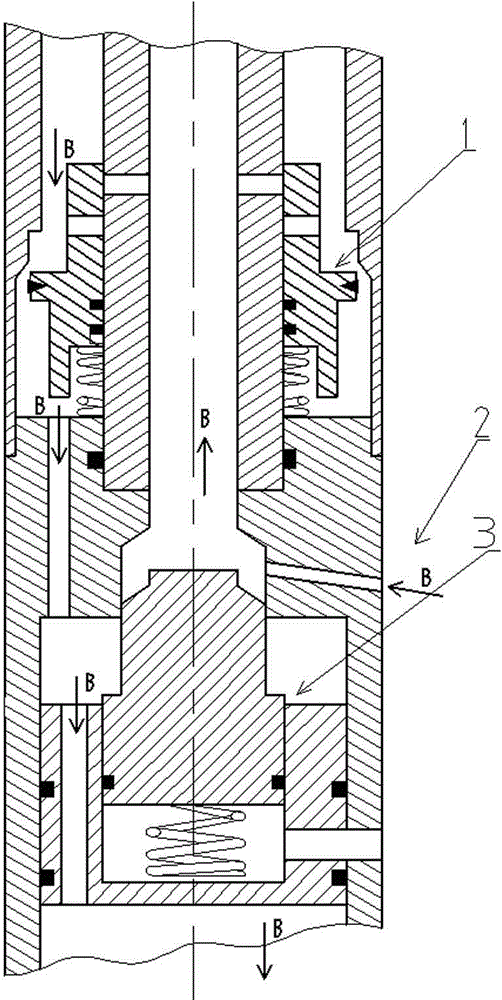

Double-flow-channel direction control short connection device

The invention discloses a double-flow-channel direction control short connection device. The device is connected to the lower ends of an inner-layer pipe and an outer-layer pipe of a double-layer pipe. The device comprises an outer-layer flow channel one-way valve, a fluid steering short connector and an inner-layer flow channel one-way valve, wherein the outer-layer flow channel one-way valve comprises a valve core A, an outer-layer sealing ring A, an inner-layer sealing ring A and a spring A, and can be used for realizing direction control of fluid in an outer-layer flow channel; the fluid steering short connector can be used for realizing communication of an inner-layer flow channel with an annulus space; the inner-layer flow channel one-way valve comprises a valve core C, a valve seat C, a valve body C and a spring C, and can be used for realizing direction control of fluid in an inner-layer flow channel. By adopting the device, fluid entering the annulus space through the outer-layer flow channel can be guided into the inner-layer flow channel, and isolation of the inner-layer flow channel and the outer-layer flow channel from the shaft bottom fluid can be realized. The device has the advantages of simple structure, reliability in direction control and reduction of shaft bottom pressure fluctuation during pump opening.

Owner:CHINA PETROCHEMICAL CORP +1

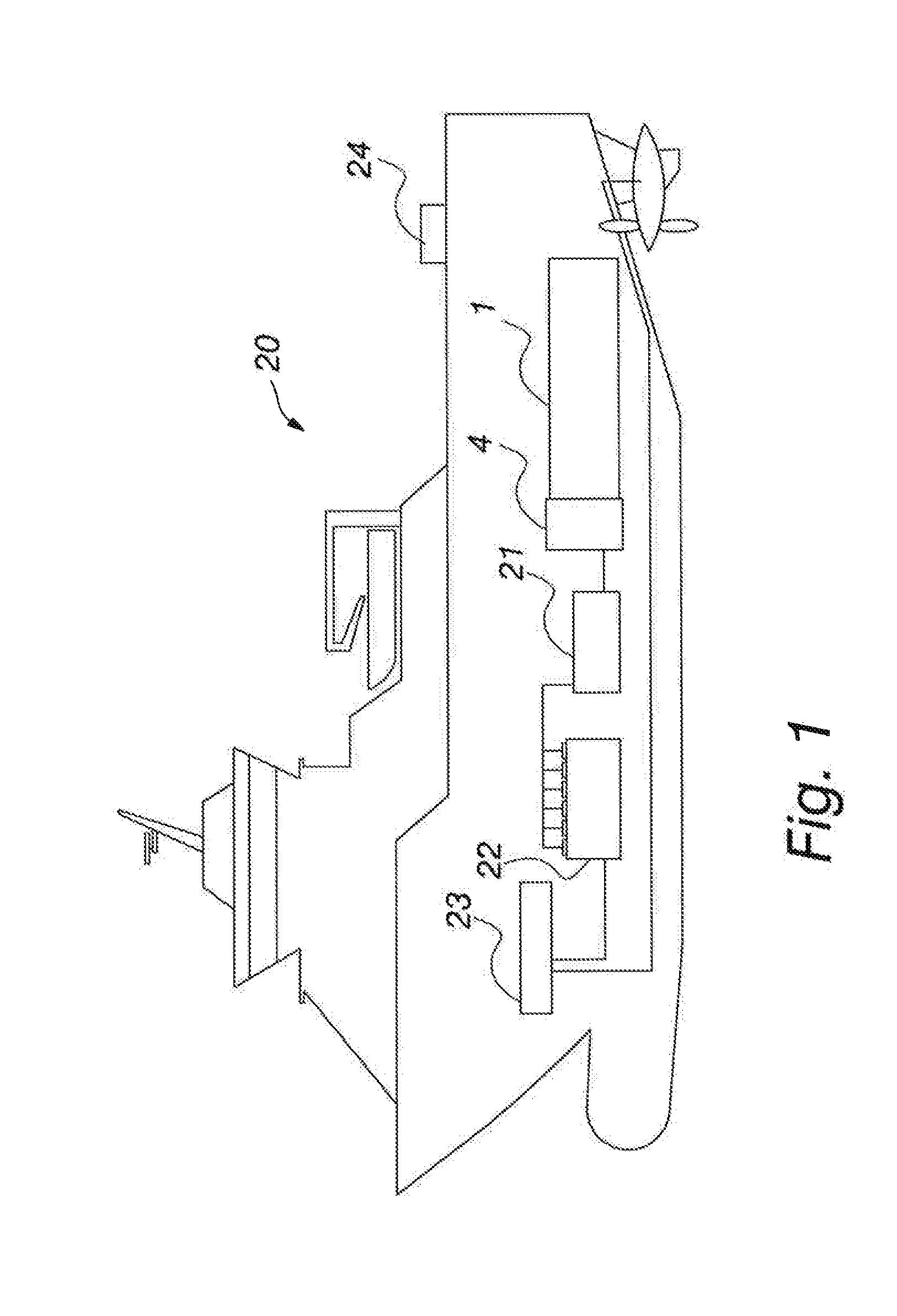

LNG single-fuel ship

ActiveCN104015913AReasonable useNot conducive to agglomerationPropulsion power plantsPropulsive elementsEngineeringSafety valve

The invention provides an LNG single-fuel ship and belongs to the technical field of ship engineering. According to the structure of the LNG single-fuel ship, a hole is formed in a main deck of a storage tank cabin, the storage tank cabin is designed to be of a sunken structure, one part of a gas storage tank is located above the main deck, the other part of the gas storage tank is located below the main deck, a double-wall pipe in an engine room is adopted as a fuel gas delivery pipe, a rectangular ventilation guide pipe is arranged on the periphery of the tail segment, close to an engine, of the fuel gas delivery pipe, and a round ventilation guide pipe is arranged on the periphery of the segment, on the upstream of the rectangular ventilation guide pipe, of the fuel gas delivery pipe; a liquid outlet pipe on the downstream of a flowmeter is divided into a main path and an auxiliary path, wherein the main path is finally connected to a mixer, and the auxiliary path is connected to the portion, between a second-stage pressure reducing valve and a downstream manual drainage pipe, of the main path through a fault opening type electromagnetic pneumatic valve and an auxiliary path safety valve; the mixer is connected with a supercharger, and the supercharger is connected with the fuel gas delivery pipe. Due to the design, the strength and the stability of the LNG single-fuel ship are improved; fuel adding, fuel feeding and safety protection are achieved, and the safety of a ship power system is guaranteed.

Owner:SHANDONG HANGYU SHIPPING IND GRP

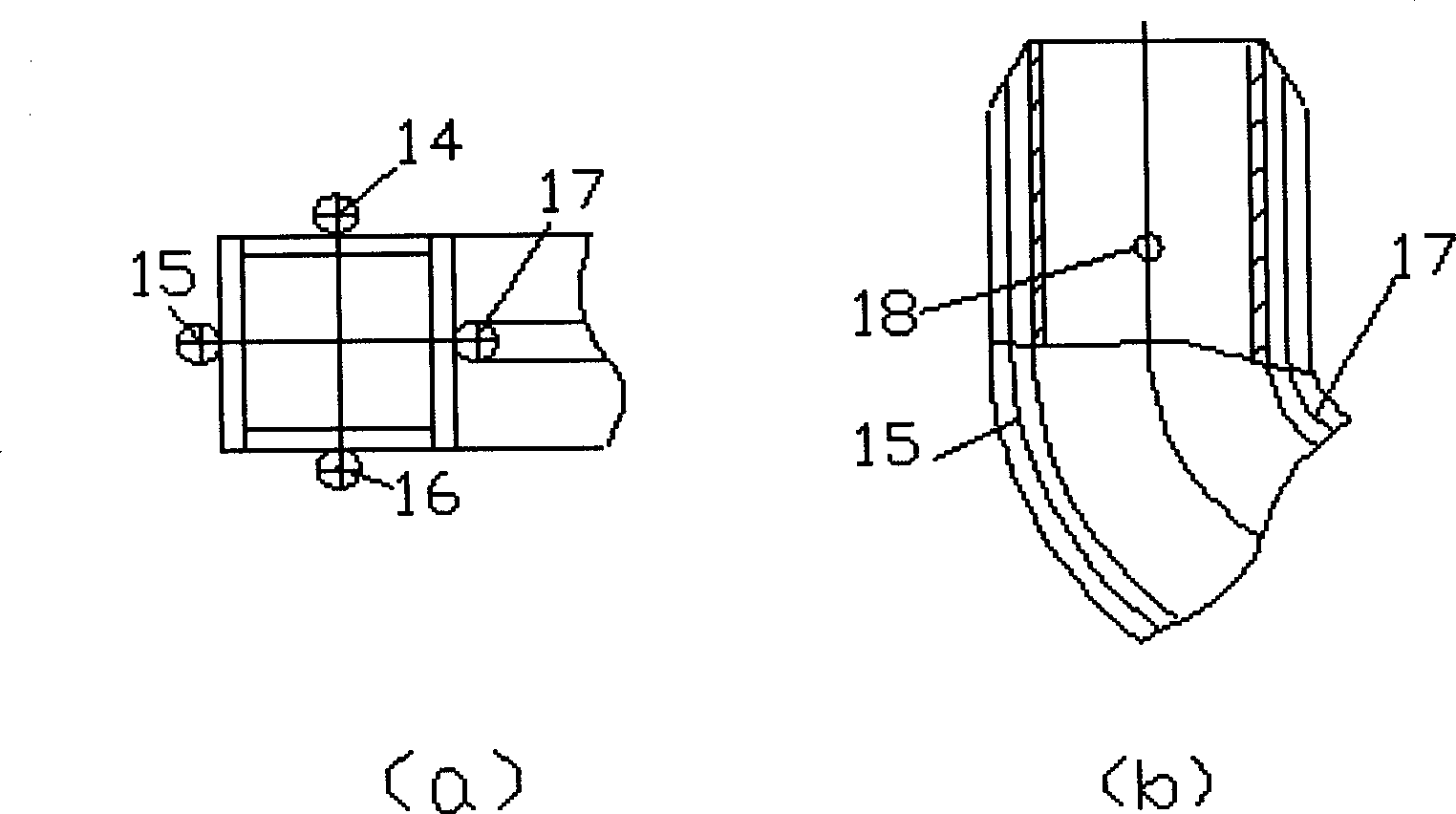

Bending process of double-layer pipe

InactiveCN101804429AWill not cause severe corrosionConducive to environmental requirementsDouble-walled pipeEngineering

The invention relates to a bending process of a double-layer pipe, which comprises the following steps that: an outer layer pipe is fed; an inner layer pipe is fed; one end of the inner layer pipe is made into a flared end; the other end of the inner layer pipe is plugged to form a plugging end; the inner and the outer layer pipes are assembled and welded; special solid stuffing for bending pipe is filled inside the pipes; the inner and the outer layer pipes are bent; the special solid stuffing for bending pipe is dissolved; the pipes are cut; and the double-layer pipes are examined. The bending process has the advantages that the solid stuffing is filled between the two layers of pipe, so the stuffing between the two layers of the pipe is free from being smashed during the pipe bending process, effective supporting between the two layers of the pipe can be realized, a satisfactory distance between the outer side surface of the inner layer pipe and the outer layer pipe after the pipe is bent can be maintained, the shape of the bending part is smooth and aesthetic, and the function of the double-layer pipe can be adequately played in the application.

Owner:东莞市旗丰消声器有限公司

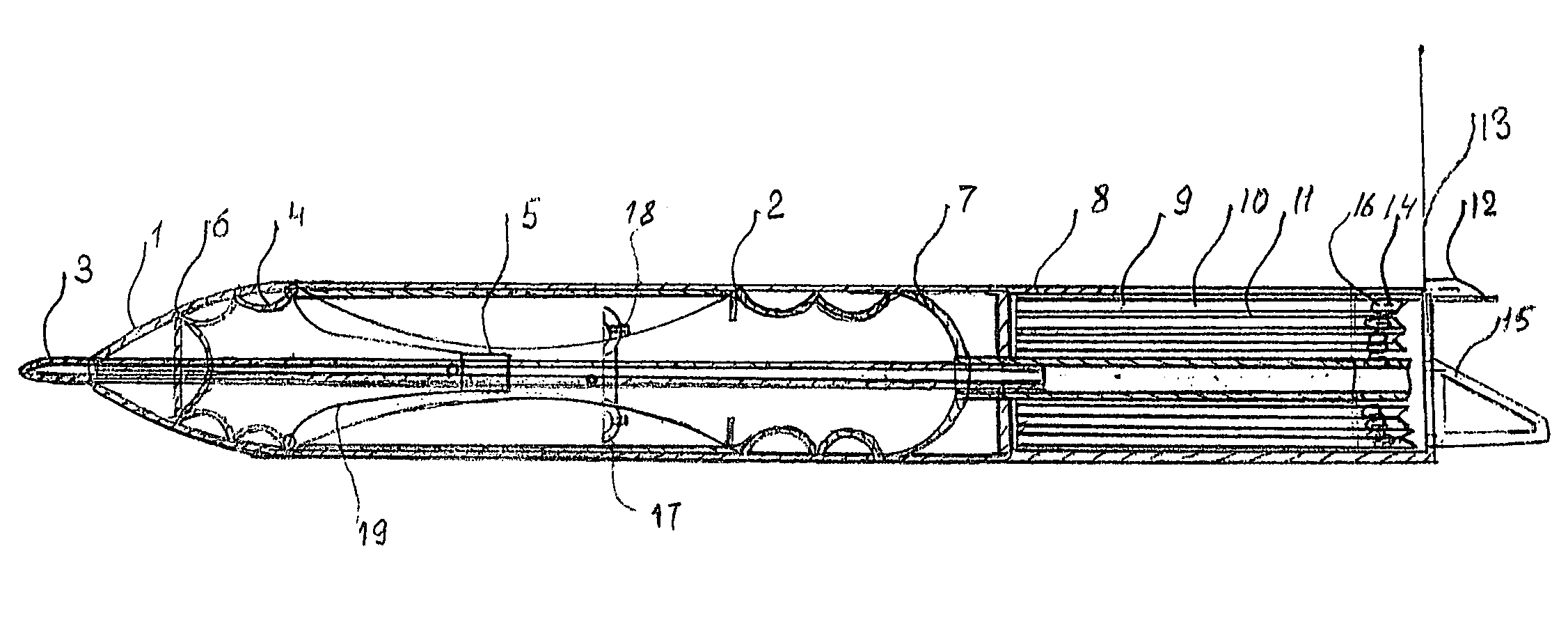

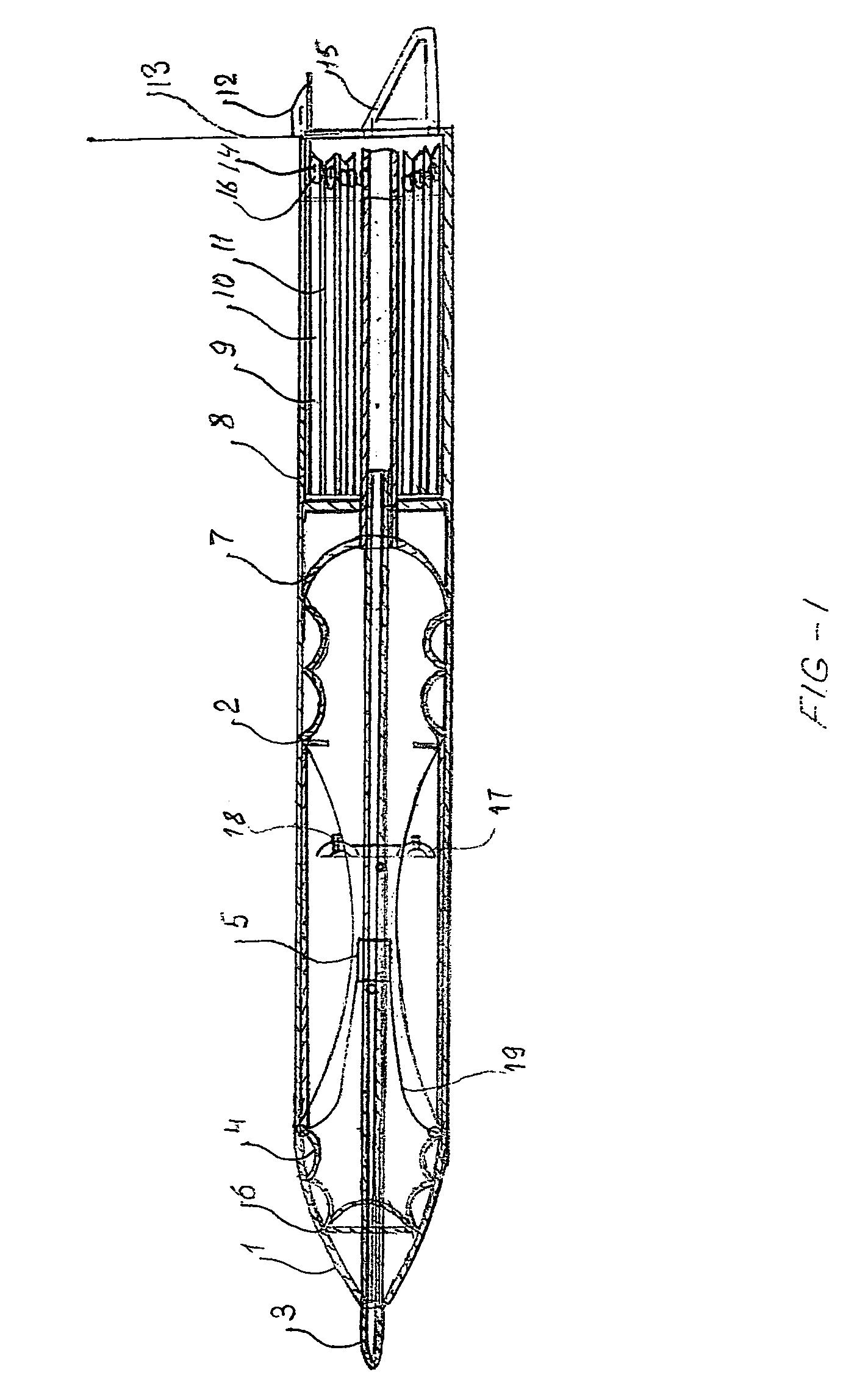

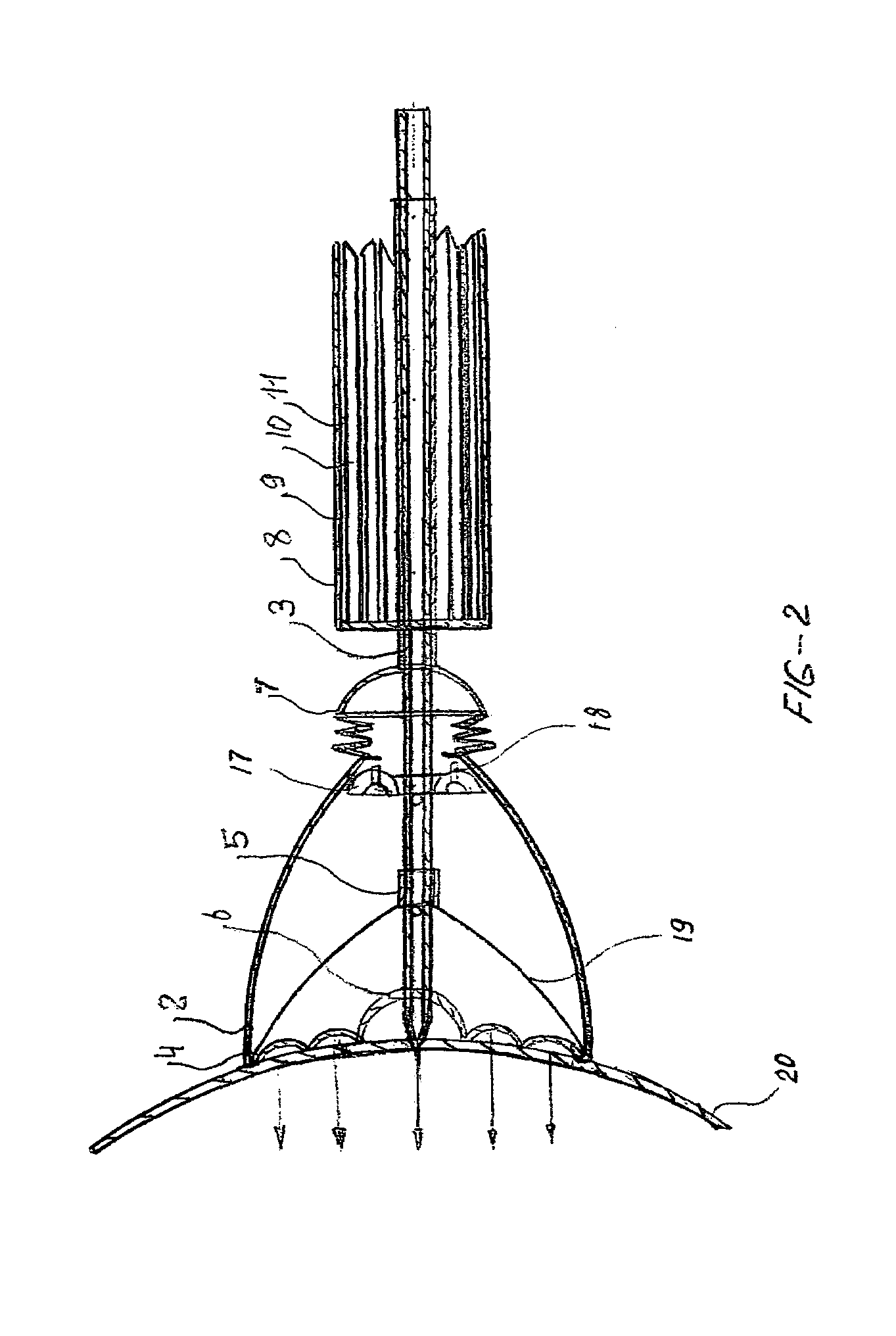

Fast-moving cumulative torpedo-mine "present"

An embodiment of torpedo, providing increased explosive energy, comprises: a casing encapsulating a rubber container, having frontal cumulative cavities with peripheral magnetic rings, said container containing an elongated type explosive charge, an axle, a bushing slidely mounted on the axle, spokes associated with the bushing and container's front, cumulative cups with press-detonators; a formatter, joined with the container's rear portion, slidely disposed on the axle, capable to displace the charge from the rear to the middle of container thereby converting it into a cumulative type charge; a magnetic cup slidely disposed on the axle; an engine unit including a cylindrical shell, fixed to the casing, the shell containing aluminum thin double-wall pipes furnished with ignition detonators. The pipes are innerly stuffed with compressed pyroxylin gunpowder; the internal space between the pipes' double-walls is filled with water, gasified during the torpedo's launch and outlet from the rear, increasing the torpedo's speed.

Owner:YATSENKO YURIY

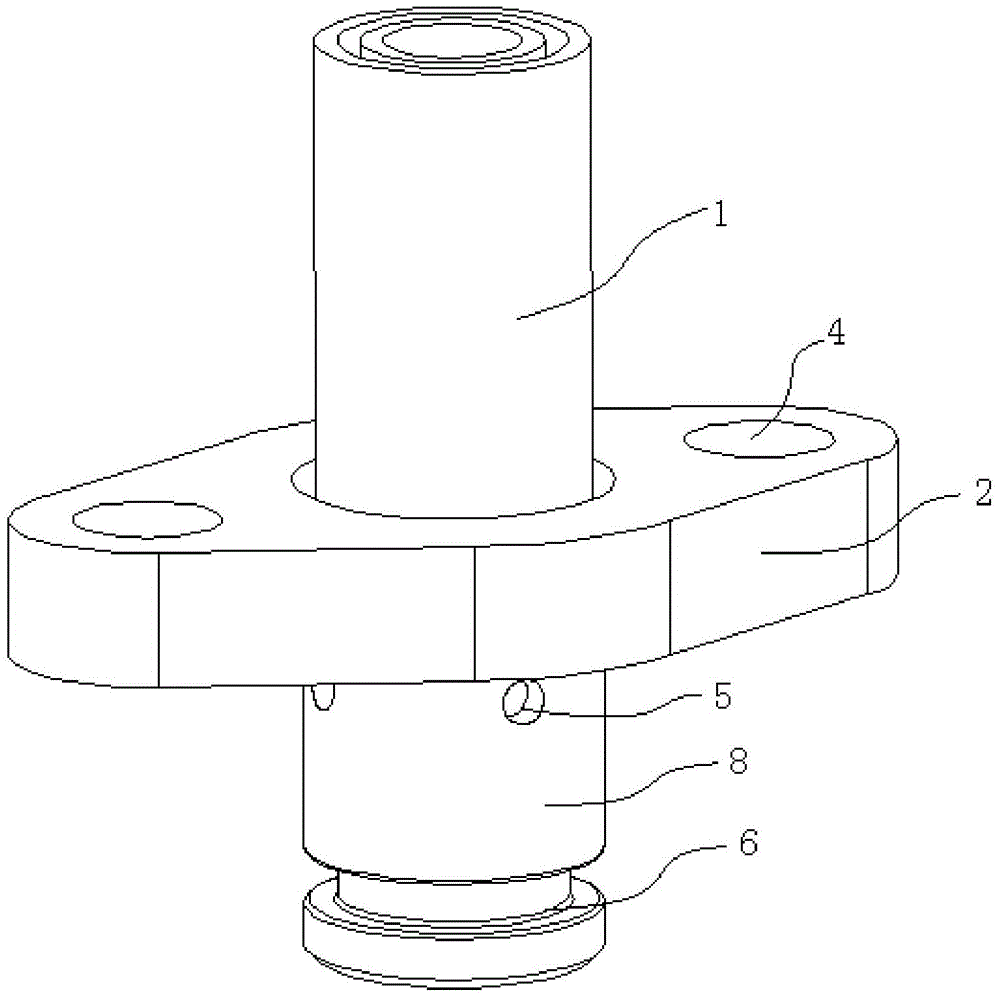

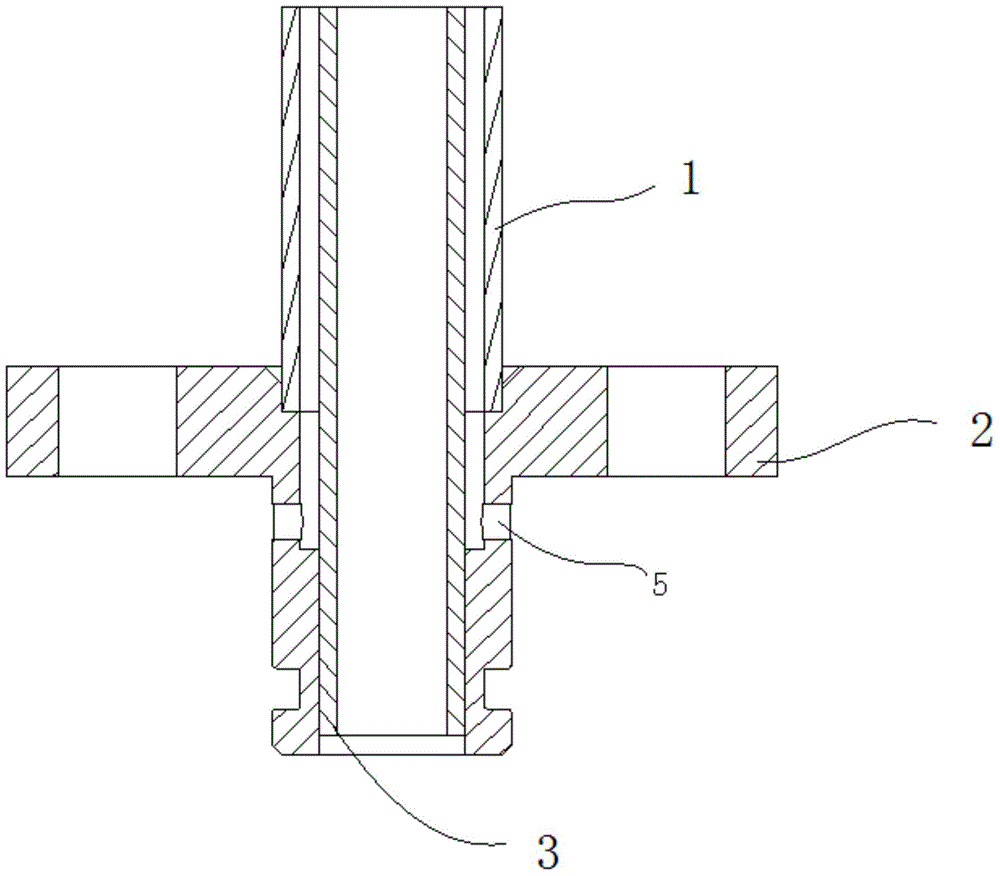

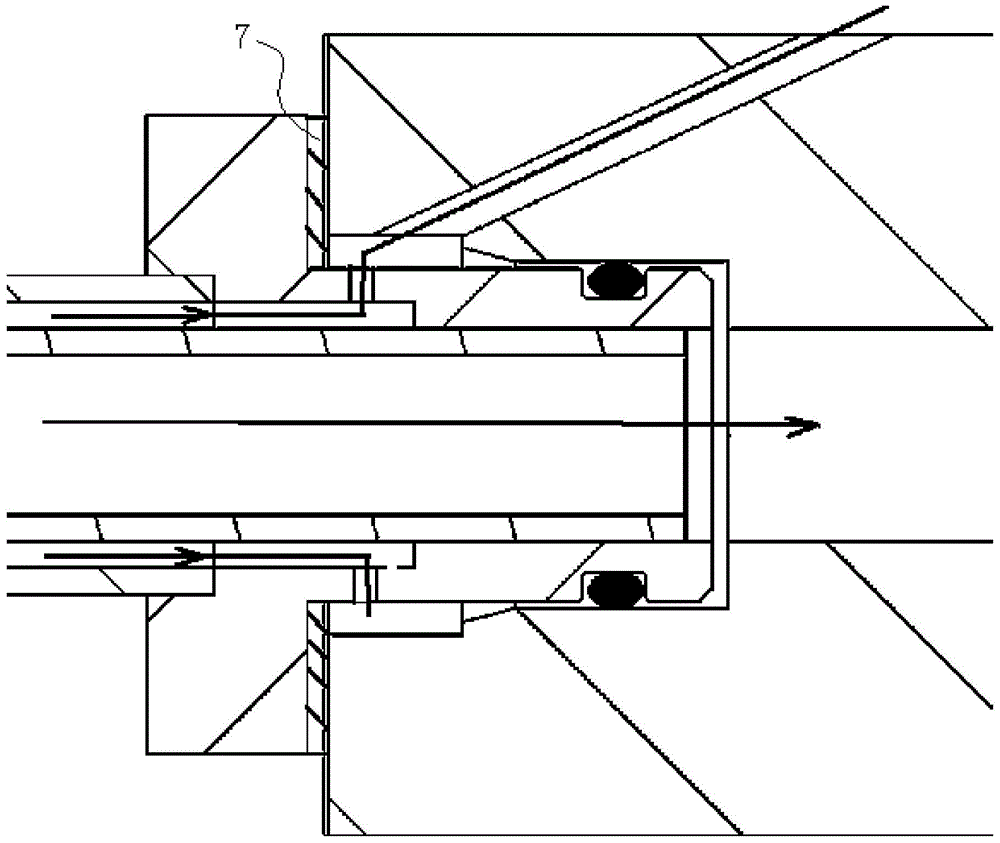

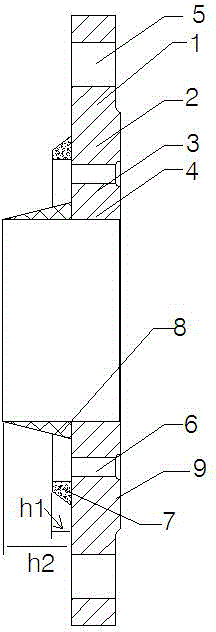

Double-layer pipe joint for engine gas supply system

ActiveCN104989558ASave installation spaceImprove sealingInternal combustion piston enginesFuel supply apparatusDouble-walled pipeControl engineering

The invention discloses a double-layer pipe joint for an engine gas supply system. The double-layer pipe joint for the engine gas supply system comprises an outer pipe, an inner pipe and a flange. The upper section of the inner pipe is arranged in an inner cavity of the outer pipe to form a ventilation interlayer. The flange comprises a flange plate and an inner pipe sleeve. An inner pipe penetrating hole is formed in the center of the flange plate. An outer pipe welding groove is formed in the upper end of the inner pipe penetrating hole. The lower section of the inner pipe is inserted in the inner pipe penetrating hole to form a ventilation gap. The ventilation interlayer is communicated with the ventilation gap. Multiple vent holes are formed in the peripheral side of the upper side of the inner pipe sleeve at intervals and communicated with the ventilation gap. By the adoption of the double-layer pipe joint for the engine gas supply system, the vent holes communicated with the ventilation interlayer of a double-layer pipe are formed in the peripheral side of the flange, the installation positions of the double-layer pipe joint are reduced, a double sealing structure of a gasket and an O-shaped ring is adopted in the double-layer pipe joint, and sealing performance is good.

Owner:广西玉柴船电动力有限公司

Welding method for double-layered tube

ActiveCN105710551AReduce the overall length of the weldReduce construction difficultyWelding apparatusButt weldingDouble-walled pipe

The invention discloses a welding method for a double-layered tube. The welding method comprises the following specific steps of preparing the double-layered tube, wherein the double-layered tube comprises an inner tube and an outer tube, the outer tube is sleeved with an outer tube sleeve, the inner tube comprises a left inner tube and a right inner tube, and the outer tube comprises a left outer tube and a right outer tube; attaching and aligning end faces of the left inner tube and the right inner tube, reserving a gap between the left outer tube and the right outer tube, moving the outer tube sleeve onto the left outer tube or the right outer tube, and exposing the gap between the left outer tube and the right outer tube; performing application for inspection before welding on the left inner tube and the right inner tube according to the butt welding requirement; welding a connected part of the left inner tube and the right inner tube; polishing and cleaning a weld joint of the welded inner tube; performing application for inspection before welding on the left outer tube and the right outer tube according to the overlap welding requirement; moving the outer tube sleeve to the outer side of the gap in the first step, and separately welding a connected part between the left outer tube and the outer tube sleeve as well as a connected part between the right outer tube and the outer tube sleeve; and separately polishing and cleaning a weld joint between the left outer tube and the outer tube sleeve as well as a weld joint between the right outer tube and the outer tube sleeve.

Owner:JIANGNAN SHIPYARD GRP CO LTD

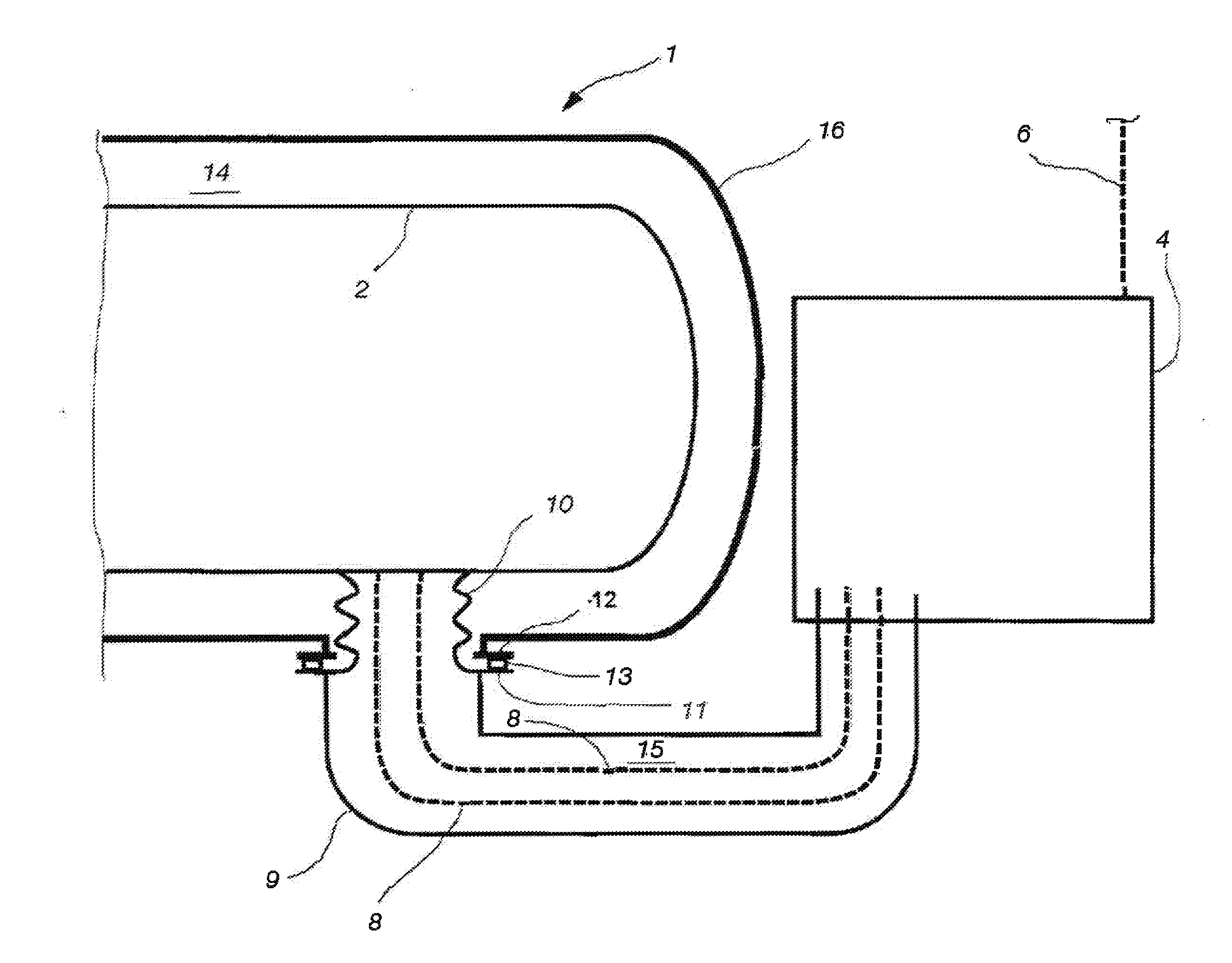

Arrangement for connecting a pipe to a LNG tank

ActiveUS20130187374A1Container filling methodsGas handling/storage effectsDouble-walled pipePipe fitting

An arrangement is disclosed for connecting at least one double-walled pipe of stainless steel to a LNG tank having an inner shell of stainless steel and an outer shell spaced at a distance from the inner shell, the inner and outer shells defining an isolation space therebetween. The at least one double-walled pipe includes a common outer wall and at least one inner pipe. The outer wall of the pipe is connected to the inner shell of the tank in such a way that the outer wall and / or a pipe fitting of cold resistant material between the inner shell and the outer wall is arranged to compensate for changes in the length of the outer wall of the pipe and / or of the pipe fitting due to temperature differences between the outer wall of the pipe and the inner shell of the tank.

Owner:WARTSILA FINLAND OY

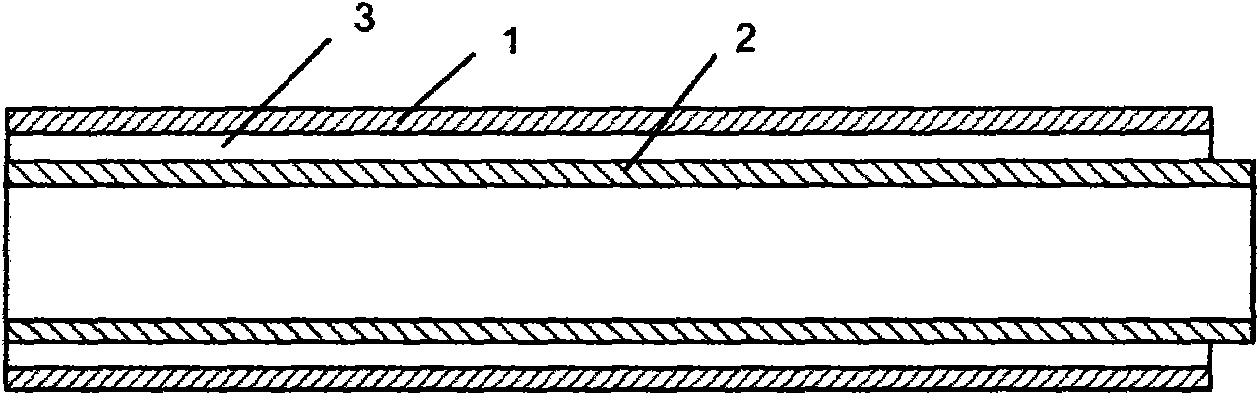

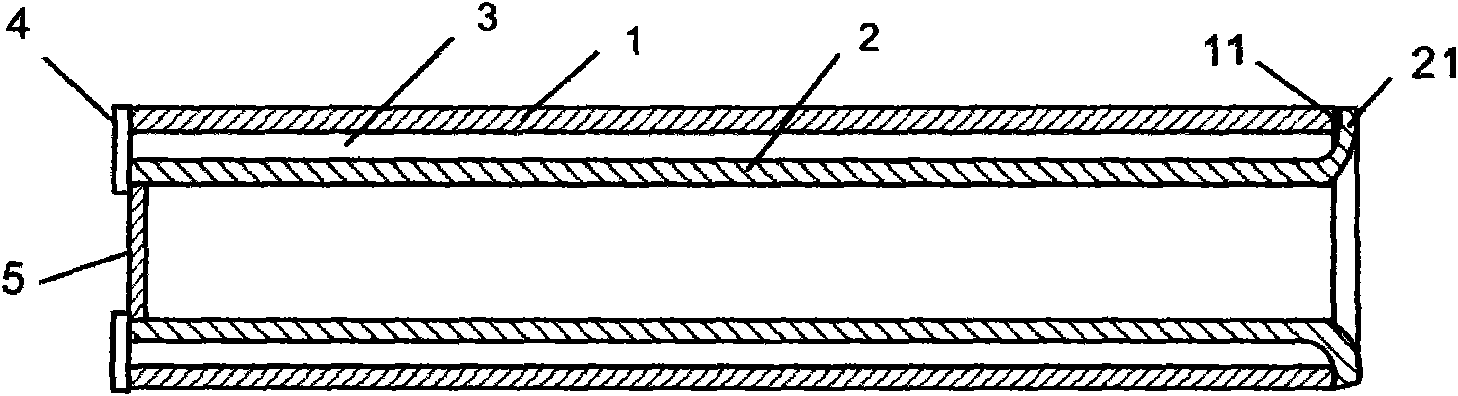

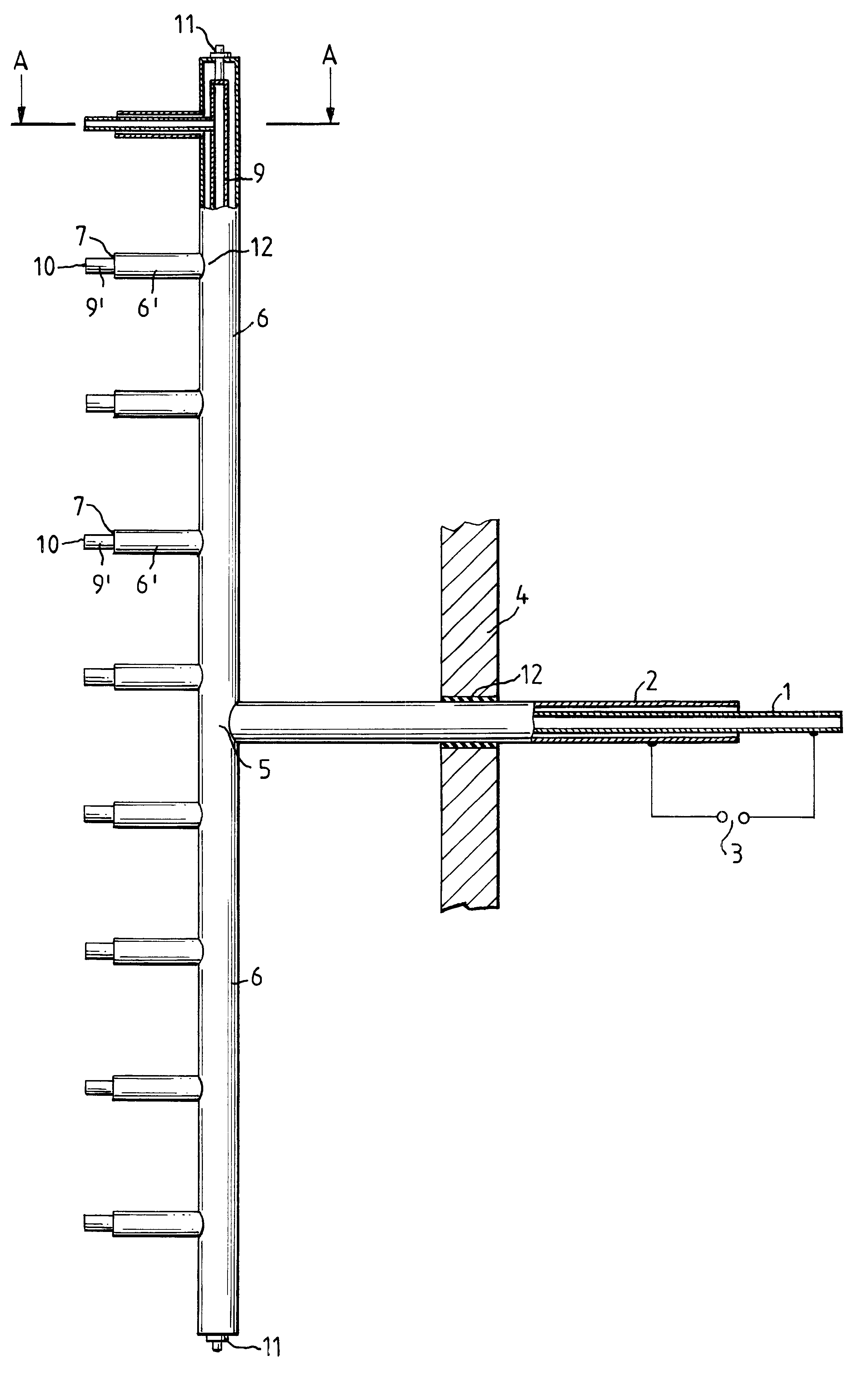

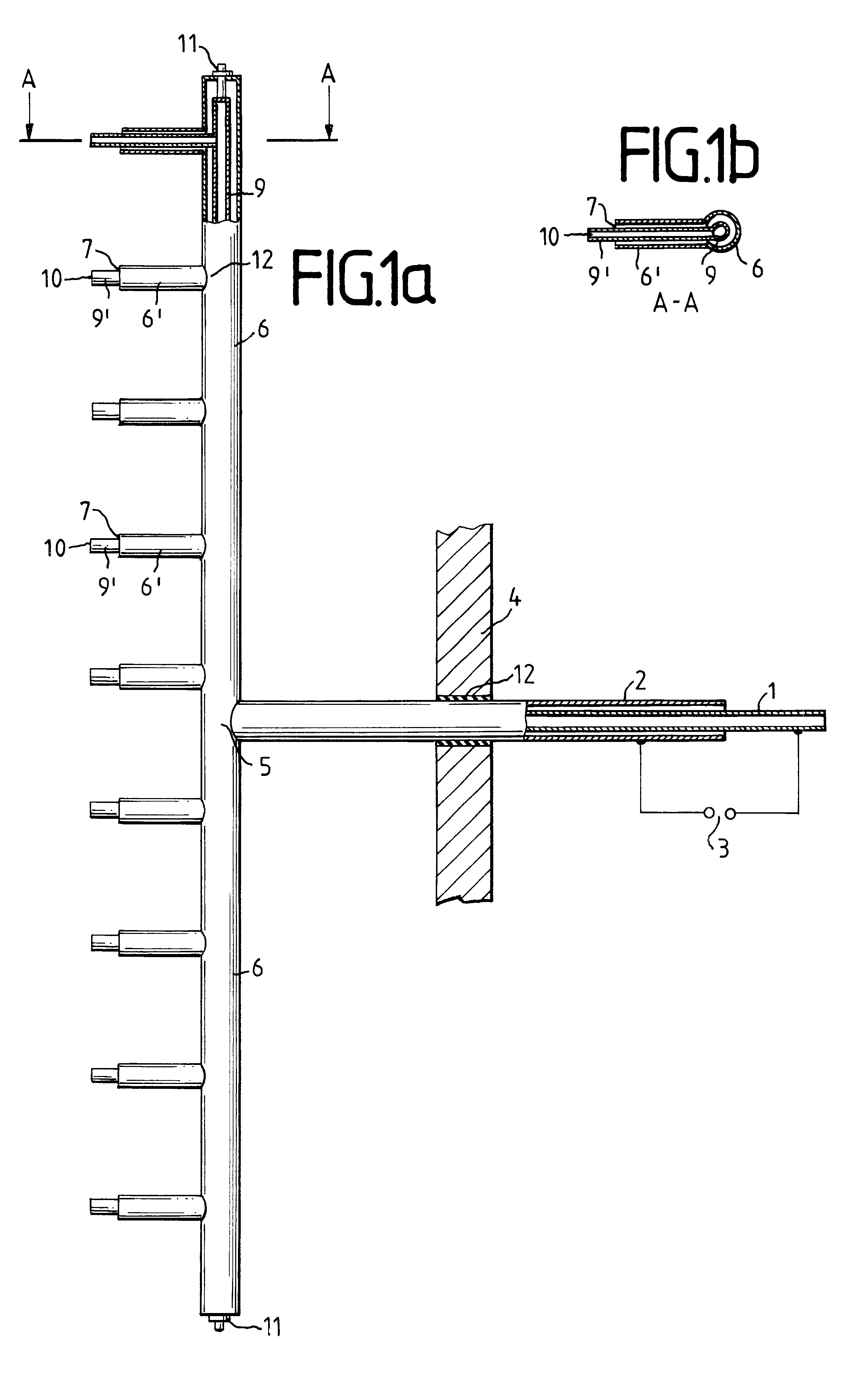

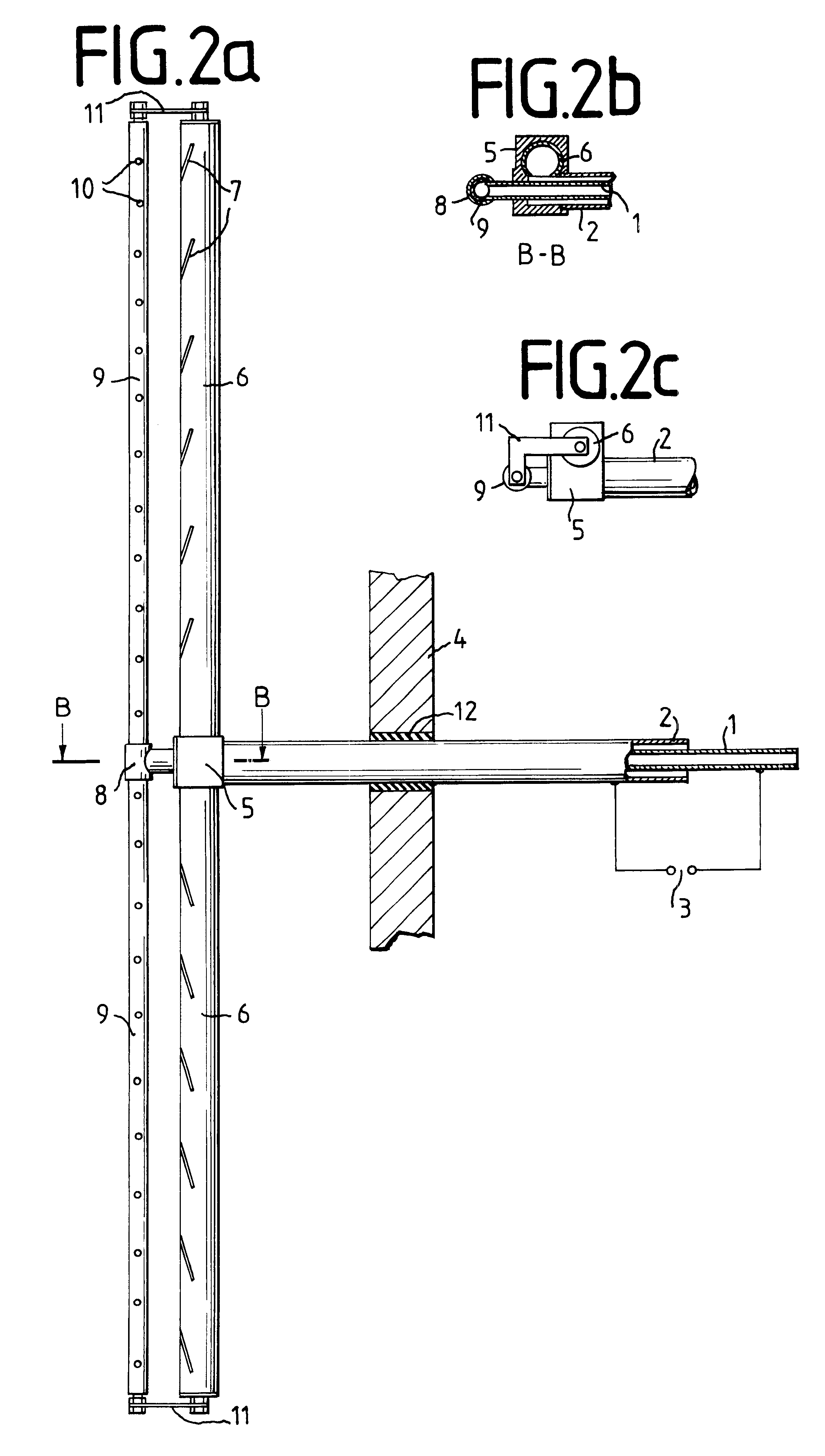

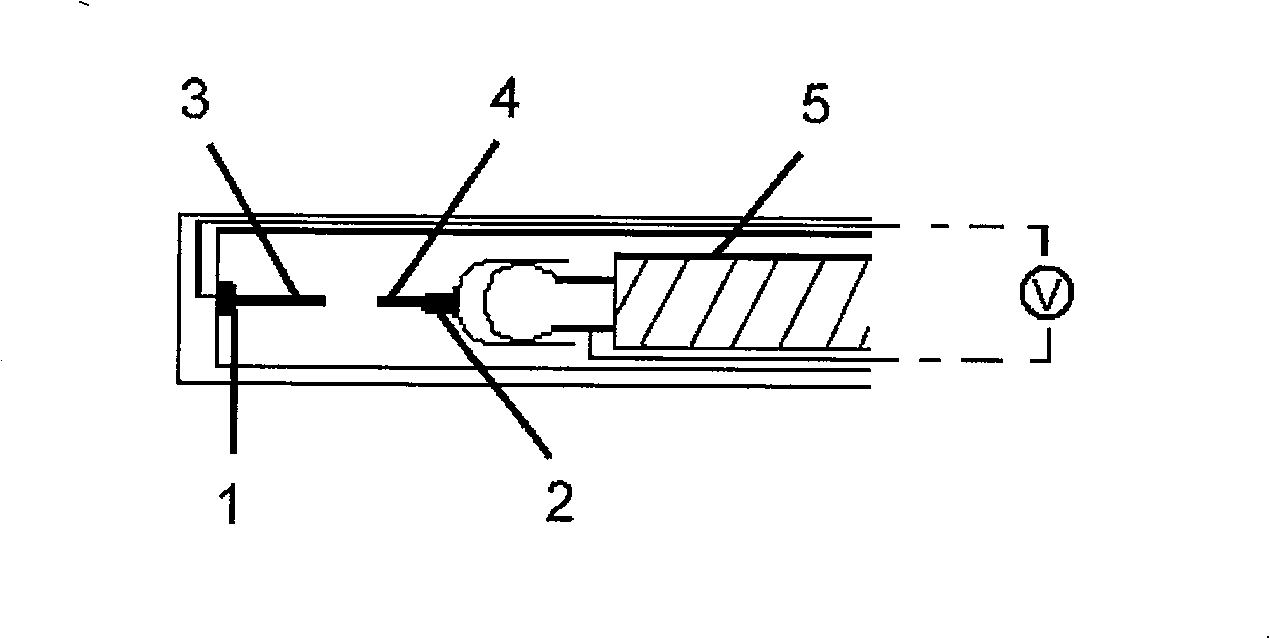

Method for transporting at least one vaporous substance through the wall of a vacuum chamber and into the vacuum chamber and a device for executing and utilizing the method

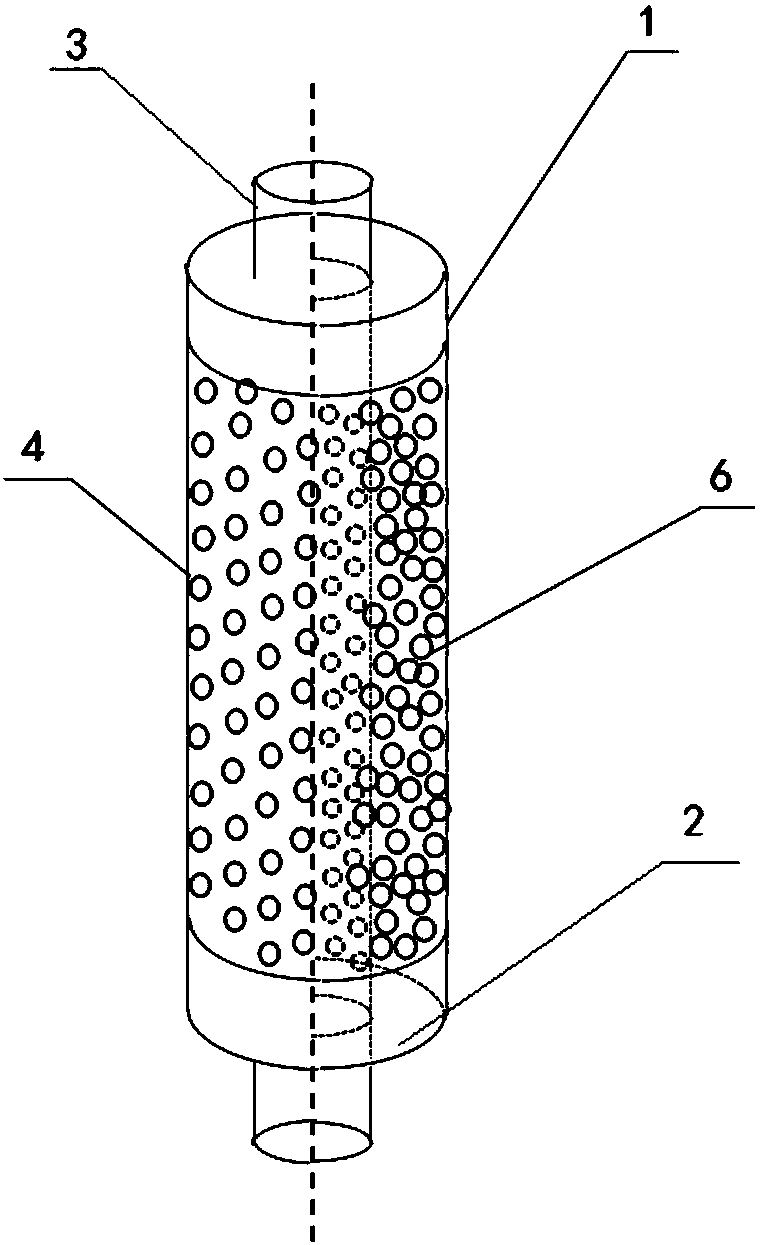

Method for transporting at least one vaporous substance through the wall (4) of a vacuum chamber and into the vacuum chamber and device for executing and utilizing the method. In the method, a vaporous substance is introduced from the outside through an interior pipe (1) of a double-walled pipe into the vacuum chamber, with electric current from a power supply (3) applied to the interior pipe (1) and exterior pipe (2) of the double-walled pipe.

Owner:APPLIED FILMS GMBH & CO KG

Heat exchange type ventilator

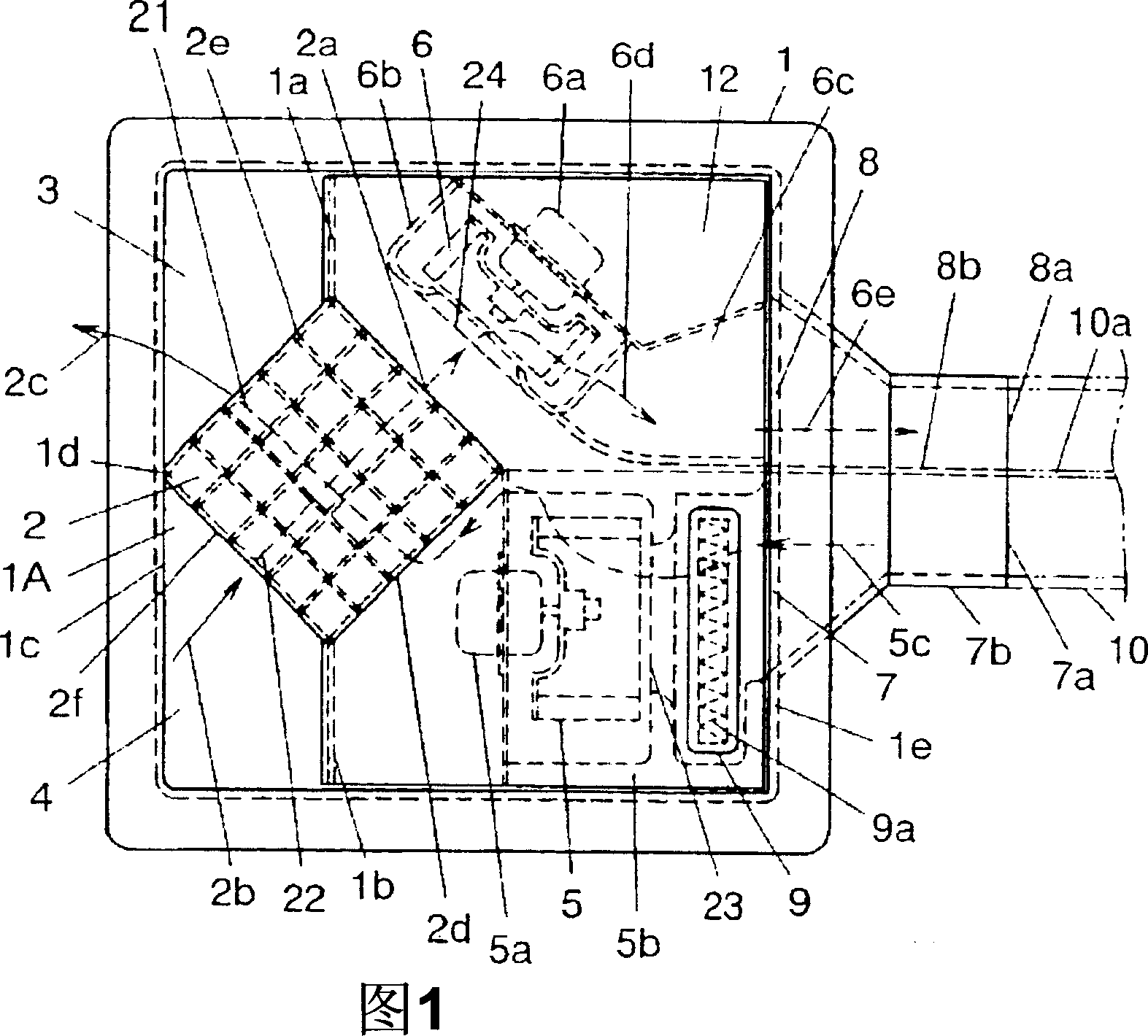

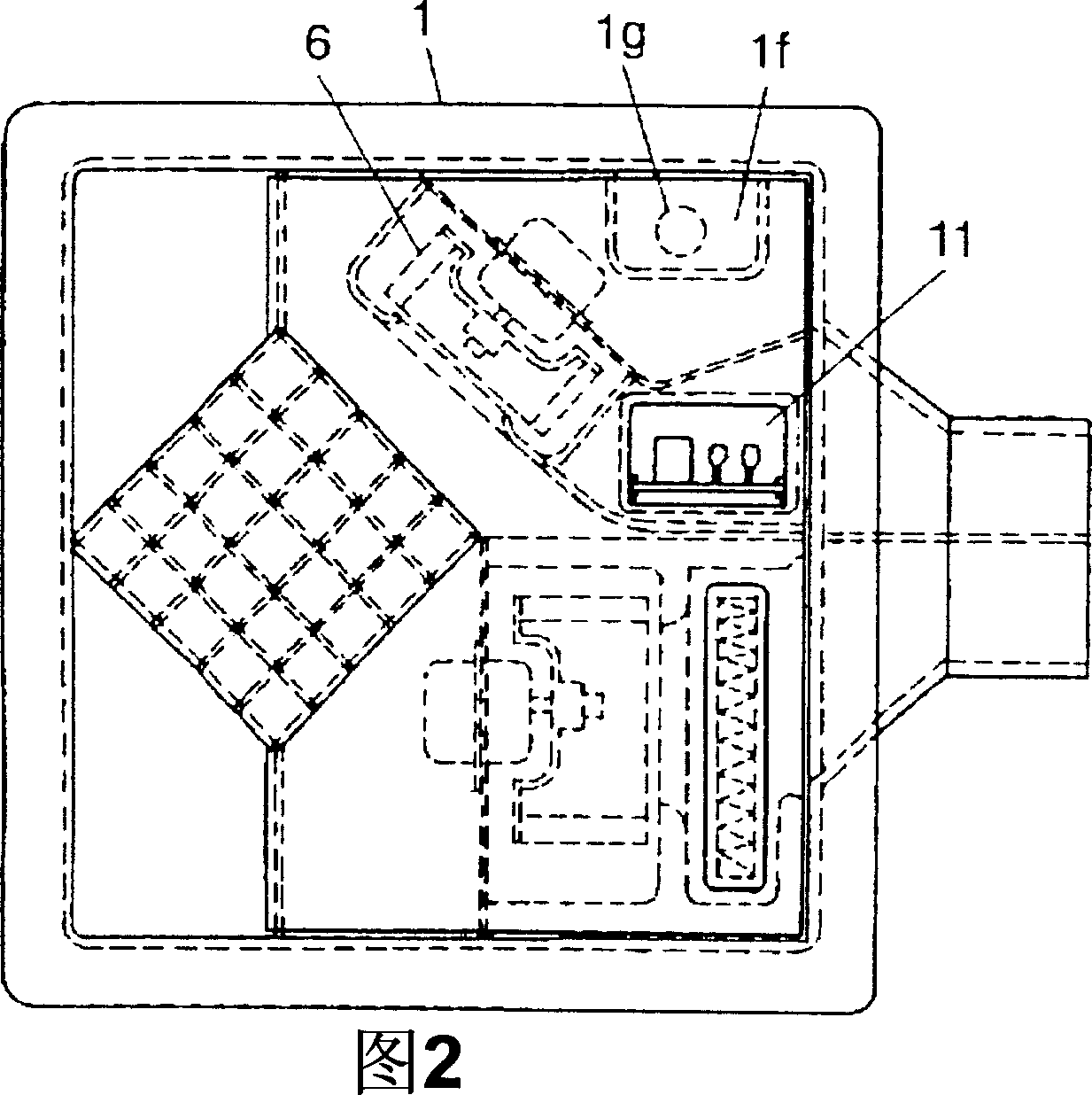

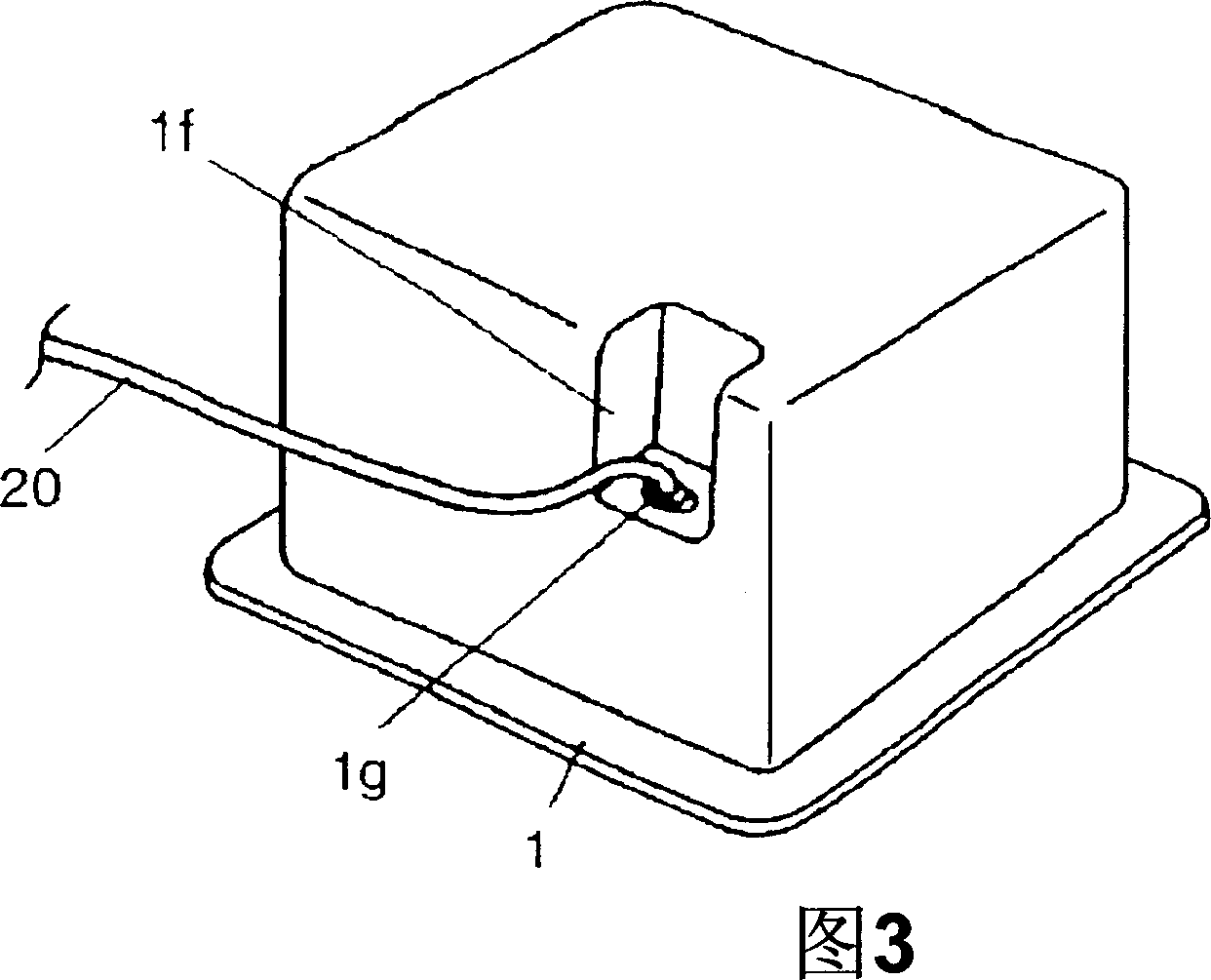

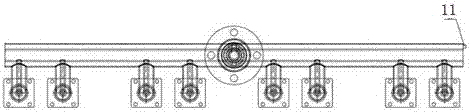

InactiveCN1969152AImprove gas supply capacityEliminate spaceEnergy recovery in ventilation and heatingHeat recovery systemsDouble-walled pipeEngineering

A heat exchange type ventilator enabling a reduction in the size of a device body, comprising a box (1) installed on the surface of a ceiling, having an opening part (1A) in the lower surface thereof, and having a cross section of square shape. A large number of exhaust flow passages (22) and intake flow passages (21) are alternately stacked on each other in the depth direction of the box body (1) so that the exhaust flow passages (22) and the intake flow passages (21) are allowed to cross each other through heat exchange boards. The box also comprises a heat exchange element (2) exchanging heat between an intake flow and an exhaust flow and an intake blower (5) communicating with the intake flow inflow surface (2d) of the heat exchange element (2). The box further comprises an exhaust blower (6) communicating with the exhaust flow outflow surface (2a) of the heat exchange element (2) and an outdoor side intake flow passage inlet (7) formed in the side face of the box on the opposite side of an indoor side intake flow passage outlet (3) on the upstream side of the intake blower (5). In addition, the box comprises, on the downstream side of the exhaust blower (6), an indoor side exhaust flow passage inlet (4) and an outdoor side exhaust flow passage outlet (8) formed in the side face of the box on the opposite side of the indoor side exhaust flow passage inlet, and the outdoor side intake flow passage inlet (7) and the outdoor side exhaust flow passage outlet (8) are positioned adjacent to each other and allowed to communicate with the inside of a bimetallic tube (10) formed by dividing the inside of the tube into two flow passages.

Owner:PANASONIC CORP

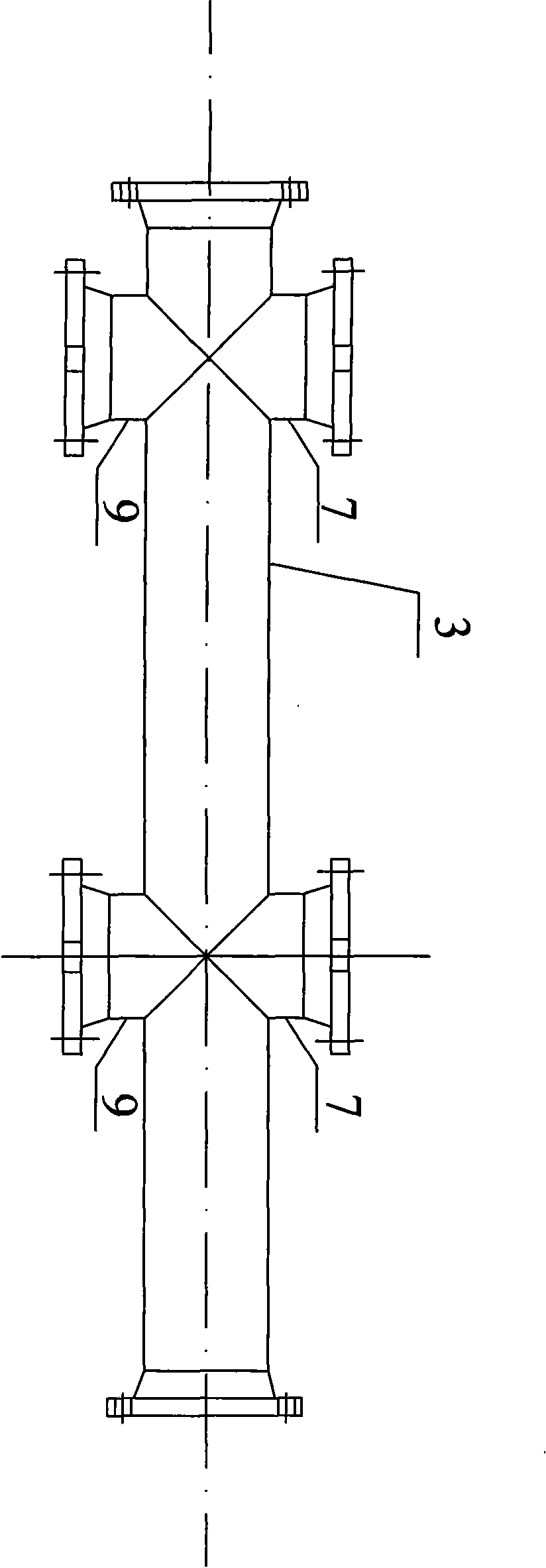

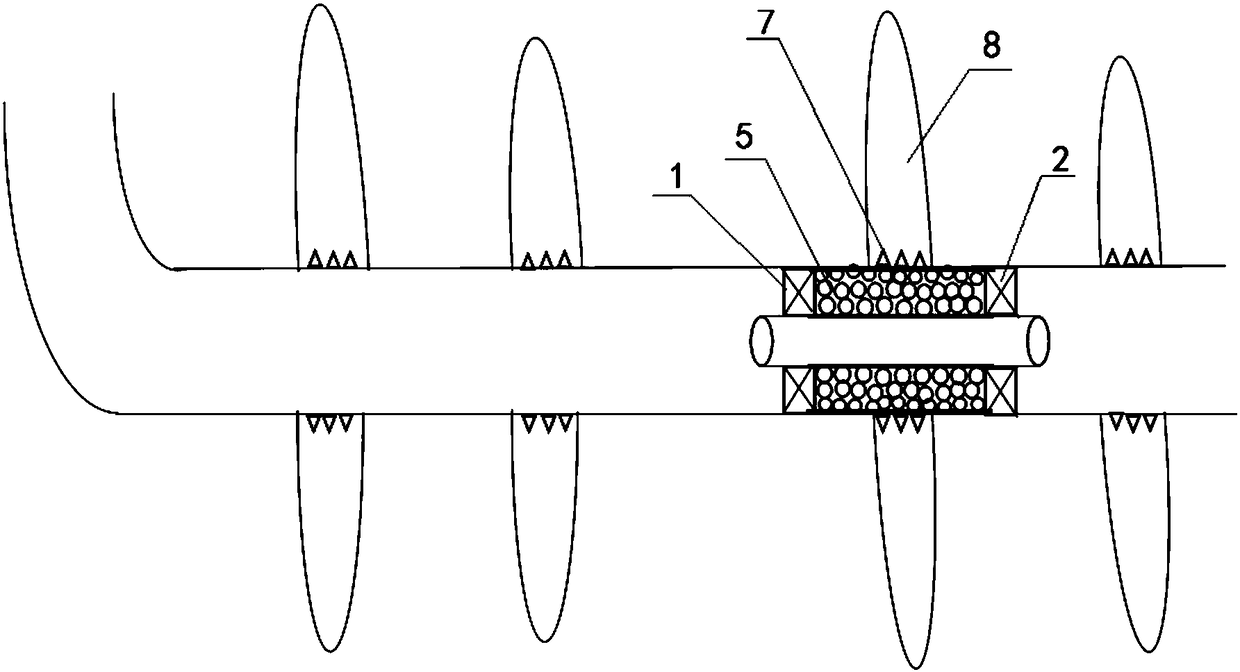

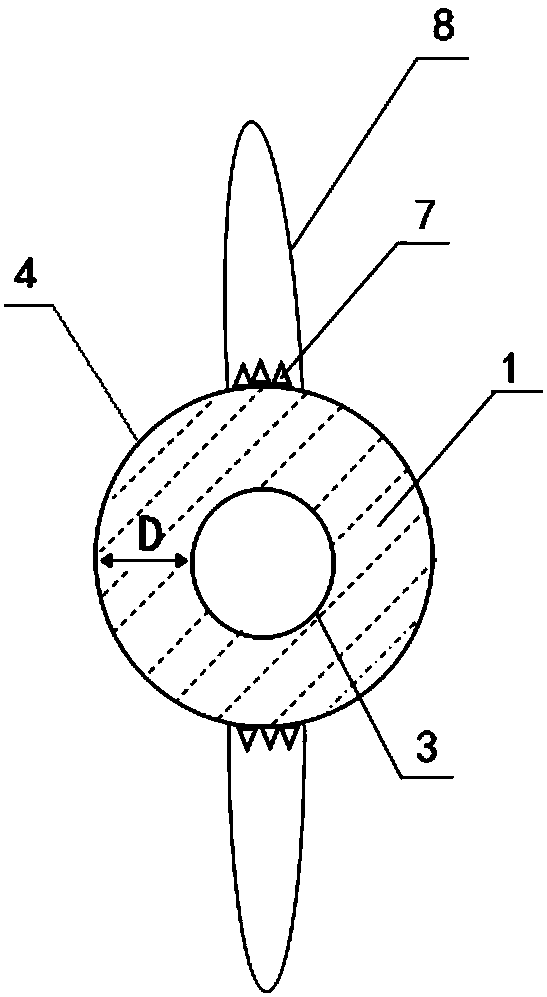

Ship gas engine double-wall pipe

The invention belongs to the technical field of gas engines, and relates to a ship gas engine double-wall pipe. The provided ship gas engine double-wall pipe is provided with a straight-pipe-shaped main air inlet pipe. The main air inlet pipe is provided with a main air inlet pipe inner pipe and a main air inlet pipe outer pipe which are coaxially arranged, and an annular cavity is formed between the main air inlet pipe inner pipe and the main air inlet pipe outer pipe. The main air inlet pipe is provided with a plurality of sets of air inlet branch pipes. Two air inlet branch pipes are arranged in each set of air inlet branch pipes. Each air inlet branch pipe is composed of an air inlet branch pipe outer pipe and an air inlet branch pipe inner pipe which are coaxially arranged. The upper ends of the air inlet branch pipe inner pipes and the air inlet branch pipe inner pipes are welded to the lower portions of the main air inlet pipe outer pipe and the main air inlet pipe inner pipe, and the lower ends of the air inlet branch pipe outer pipes and the air inlet branch pipe inner pipes are welded to connecting flanges. Annular cavities between the air inlet branch pipe outer pipes and the air inlet branch pipe inner pipes communicate with the annular cavity between the main air inlet pipe inner pipe and the main air inlet pipe outer pipe. According to the ship gas engine double-wall pipe, the purpose of direct supply of natural gas to cylinders is achieved, and it is ensured that natural gas does not leak on an engine gas supply pipeline.

Owner:HENAN DIESEL ENGINE IND

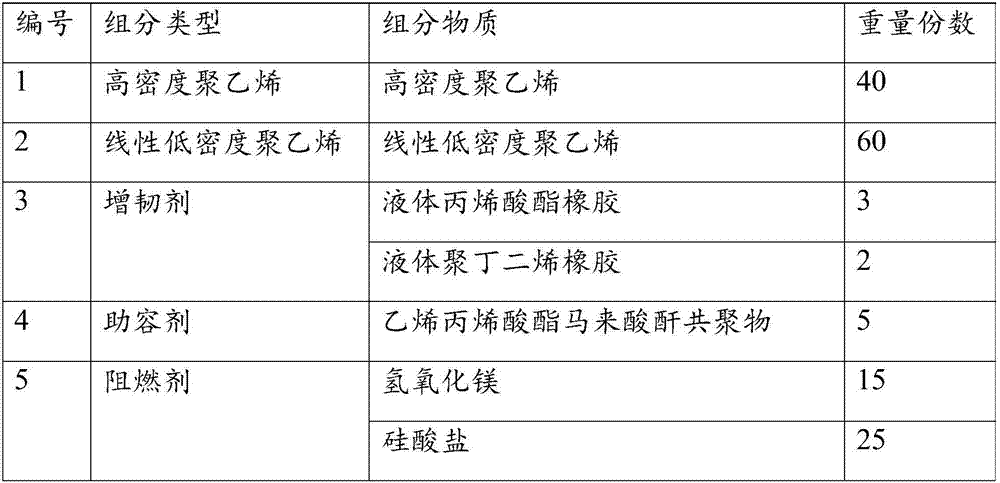

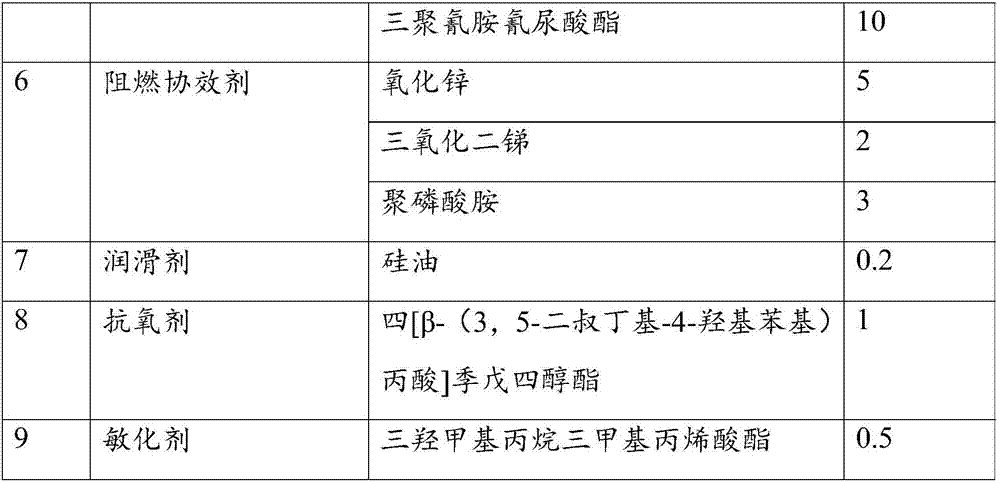

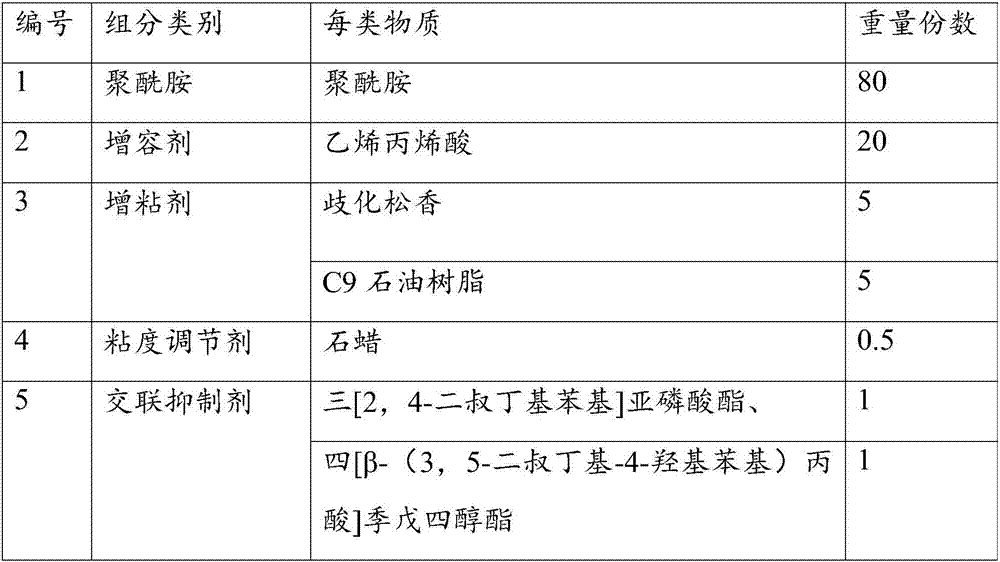

Puncture-resistant heat-shrinkable double-wall pipe and preparation method thereof

InactiveCN107973972AStrong retractive forceHigh mechanical strengthLinear low-density polyethylenePolyamide

The invention discloses a puncture-resistant heat-shrinkable double-wall pipe. The puncture-resistant heat-shrinkable double-wall pipe comprises an outer skin and an inner adhesive, wherein the outerskin material comprises the following components in parts by weight: 40-80 parts of high-density polyethylene, 20-60 parts of linear low-density polyethylene, 5-20 parts of a toughening agent, 2-5 parts of a cosolvent, 20-50 parts of a flame retardant, 10-25 parts of a flame retardant synergist, 0.2-1 part of a lubricant, 0.5-1 part of an antioxidant and 0.5-2 parts of a sensitizing agent; the inner adhesive material comprises the following components in parts by weight: 60-80 parts of polyamide, 20-40 parts of a compatibilizer, 2-10 parts of a tackifier, 0.5-3 parts of a viscosity regulator and 0.5-2 parts of a crosslinking inhibitor. The puncture-resistant heat-shrinkable double-wall pipe has excellent mechanical strength and puncture resistance and can effectively protect internal electric wires, and the inner adhesive has good fluidity and excellent sealing performance.

Owner:SHANGHAI CHANGYUAN ELECTRONICS MATERIAL

Flow wet, team humidity measuring instrument of bilayerpipe direct heating type

A flowing wet ¿C steam humidity measurer of double layer tube direct ¿C heating type is prepared as connecting inlet section to heating section being connected to outlet section, setting middle layer heating tube in outer jacket of internal layer heating tube at heating section, setting external layer support tube in outer jacket of middle layer heating tube, insulating said tubes to each other and holding gap between them, connecting inlet section to one end of heating section by left connection component and outlet section to another end of heating section by right connecting component, setting directional needle tube in inlet section and connecting said needle tube to piping connection box of outlet section.

Owner:XI AN JIAOTONG UNIV

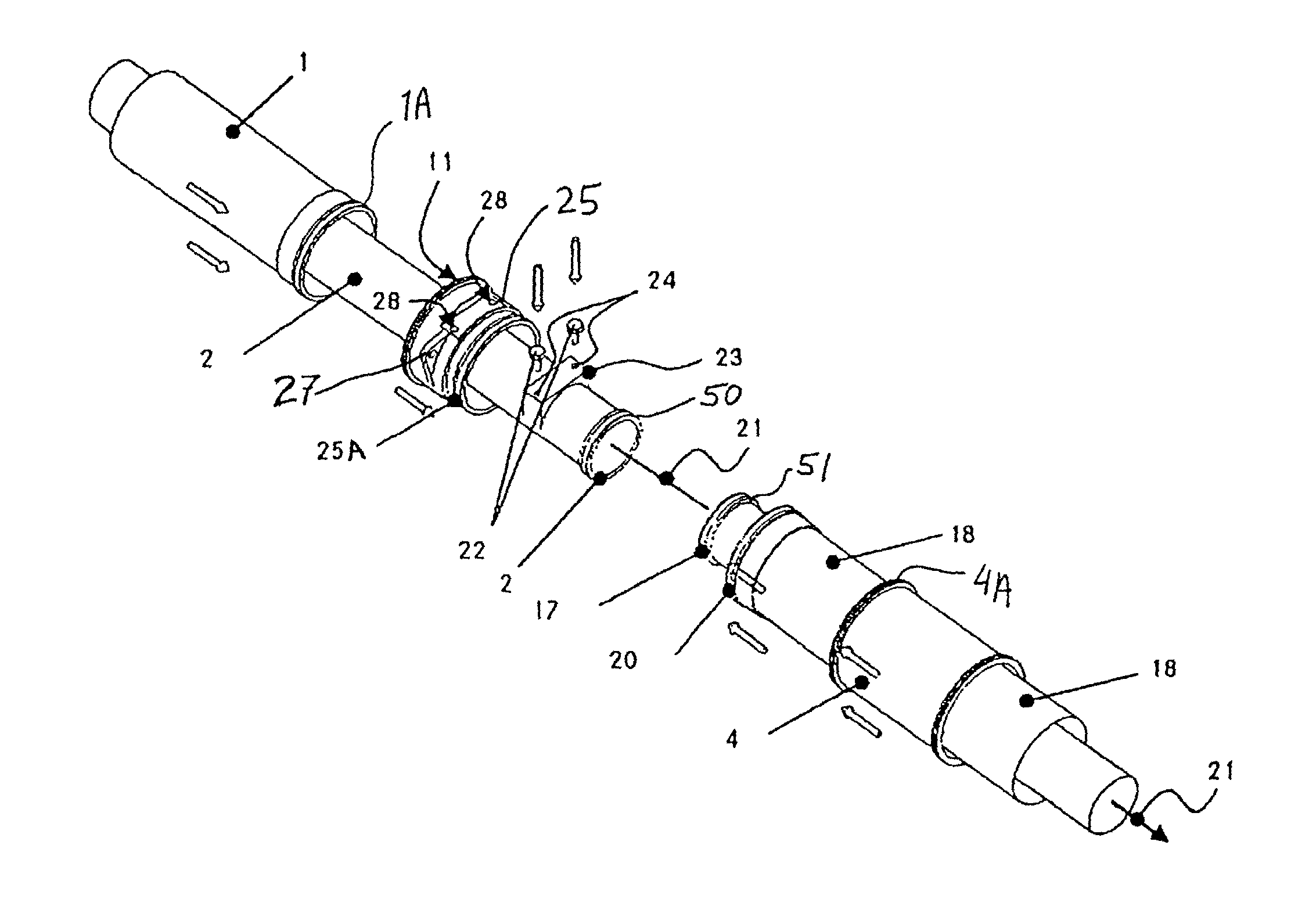

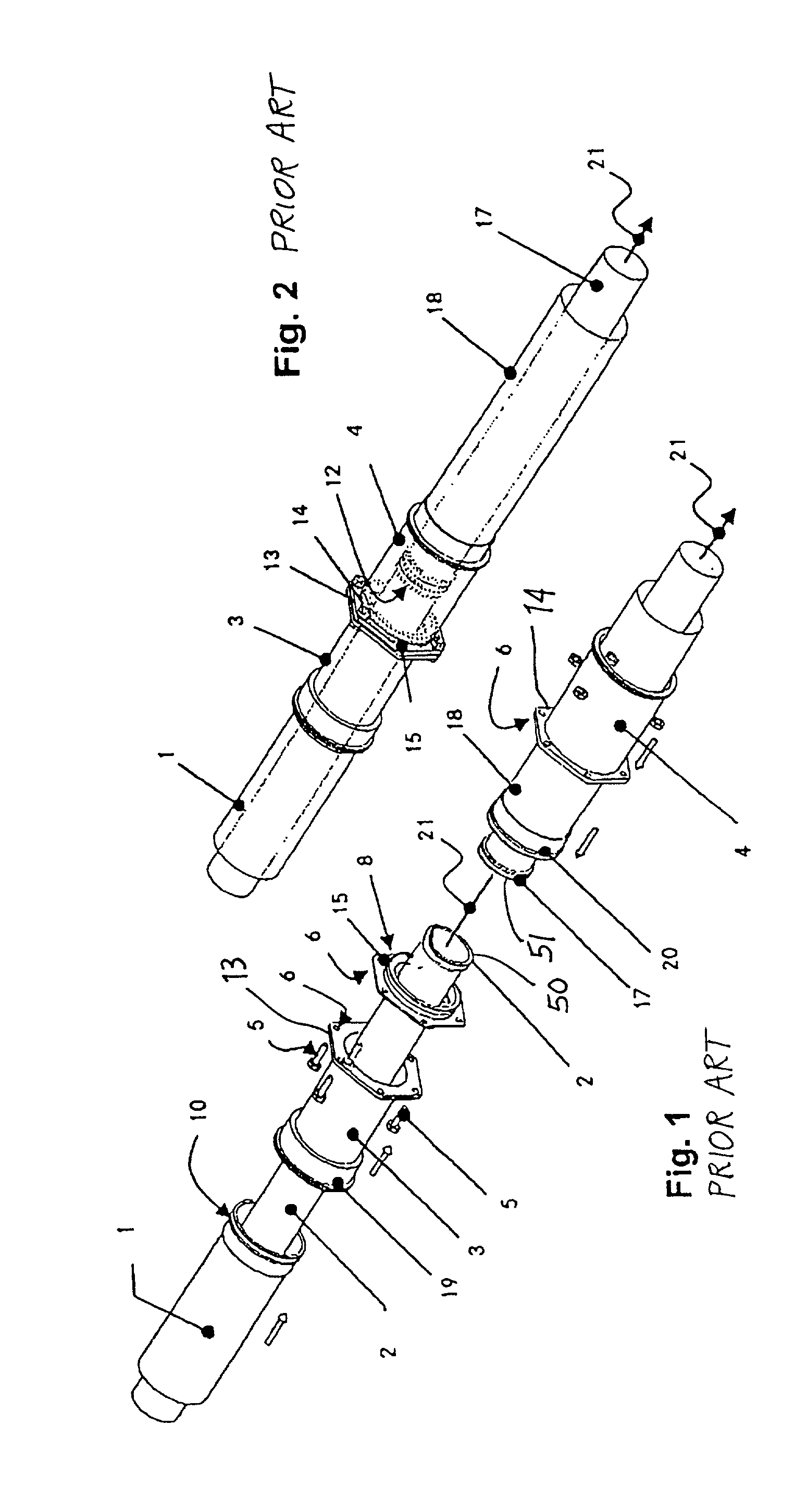

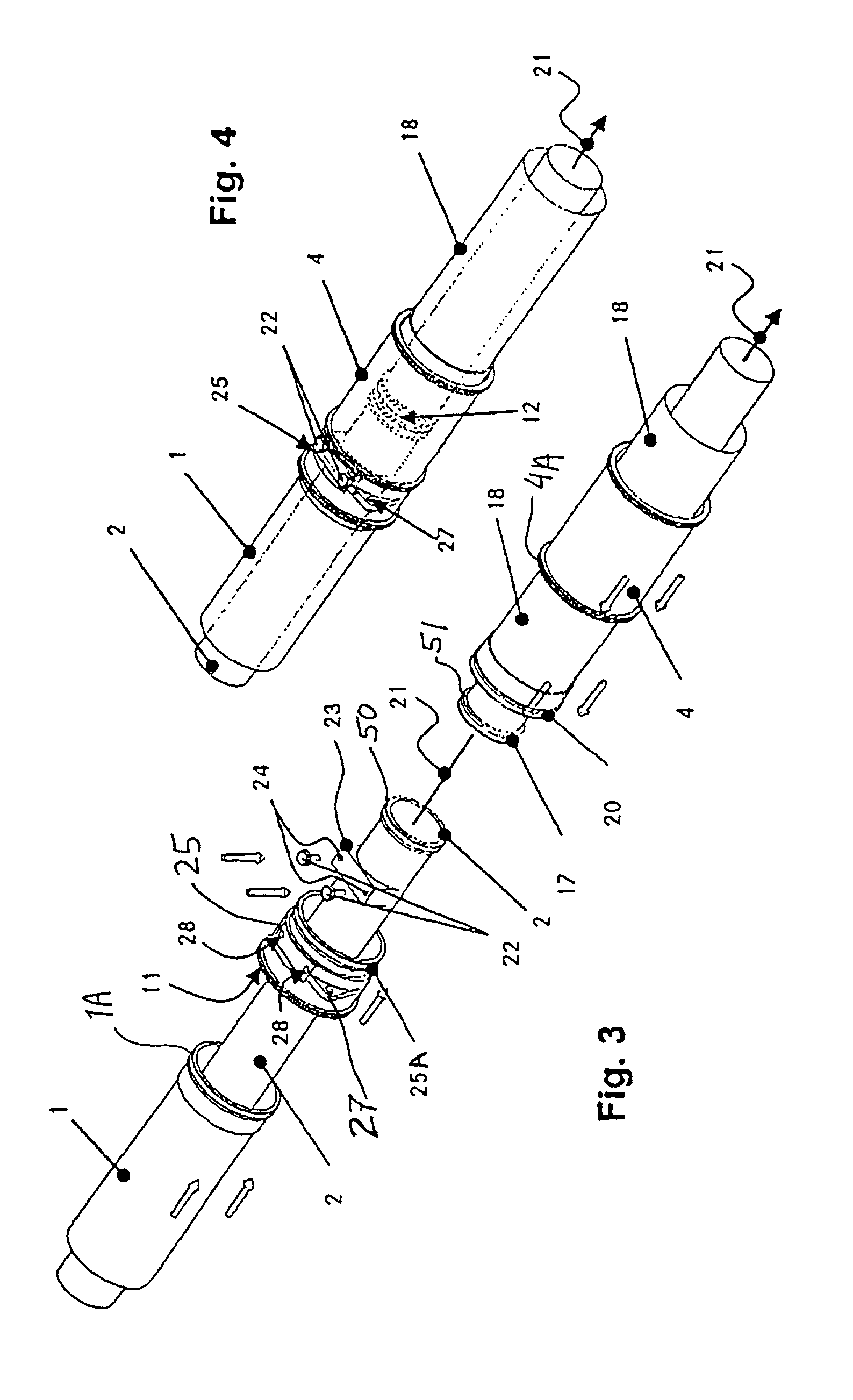

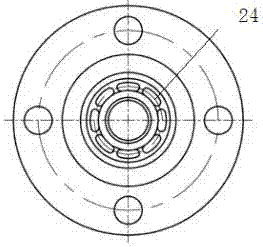

Inner Pipe Fixation Device

InactiveUS20100104370A1Improve accuracyEasy to followPipe laying and repairWaterborne vesselsDouble-walled pipeEngineering

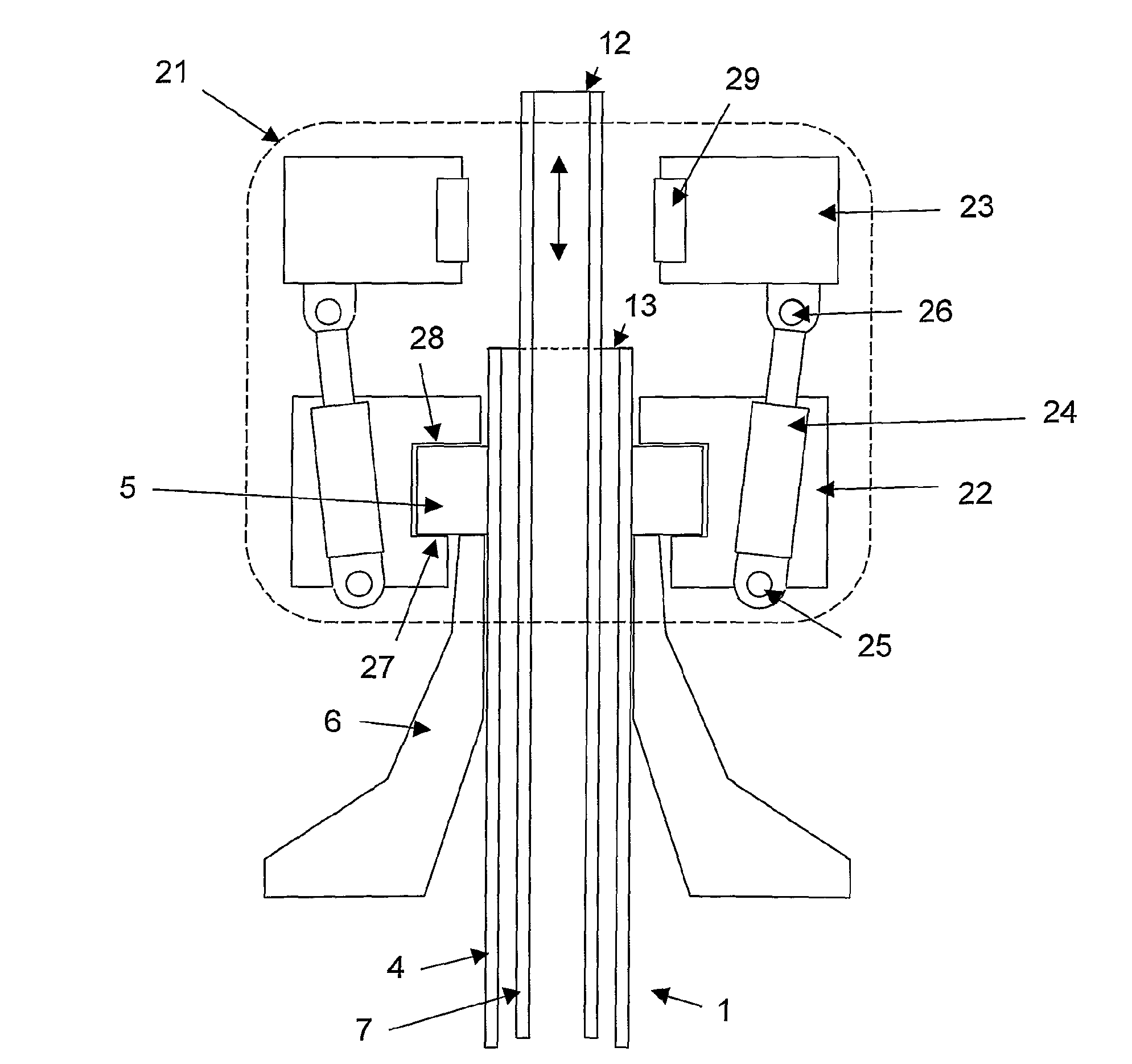

The present invention relates to a fixation device for fixation of a position of an inner pipe of a double-walled pipe with respect to a pipe laying structure and / or an outer pipe of said double-walled pipe, said fixation device comprising: an inner pipe gripping device (23) configured to grip said inner pipe, and a connection device (24,25,2S) configured to connect said inner pipe gripping device with said pipe laying structure and / or said outer pipe, said connection device having a flexible state in which, during use, the inner pipe gripping device is movable with respect to said pipe laying structure and / or said outer pipe, and a fixation state in which, during use, the inner pipe gripping device is fixated with respect to the pipe-laying structure and / or said outer pipe.

Owner:HEEREMA MARINE CONTRACTORS NEDERLAND

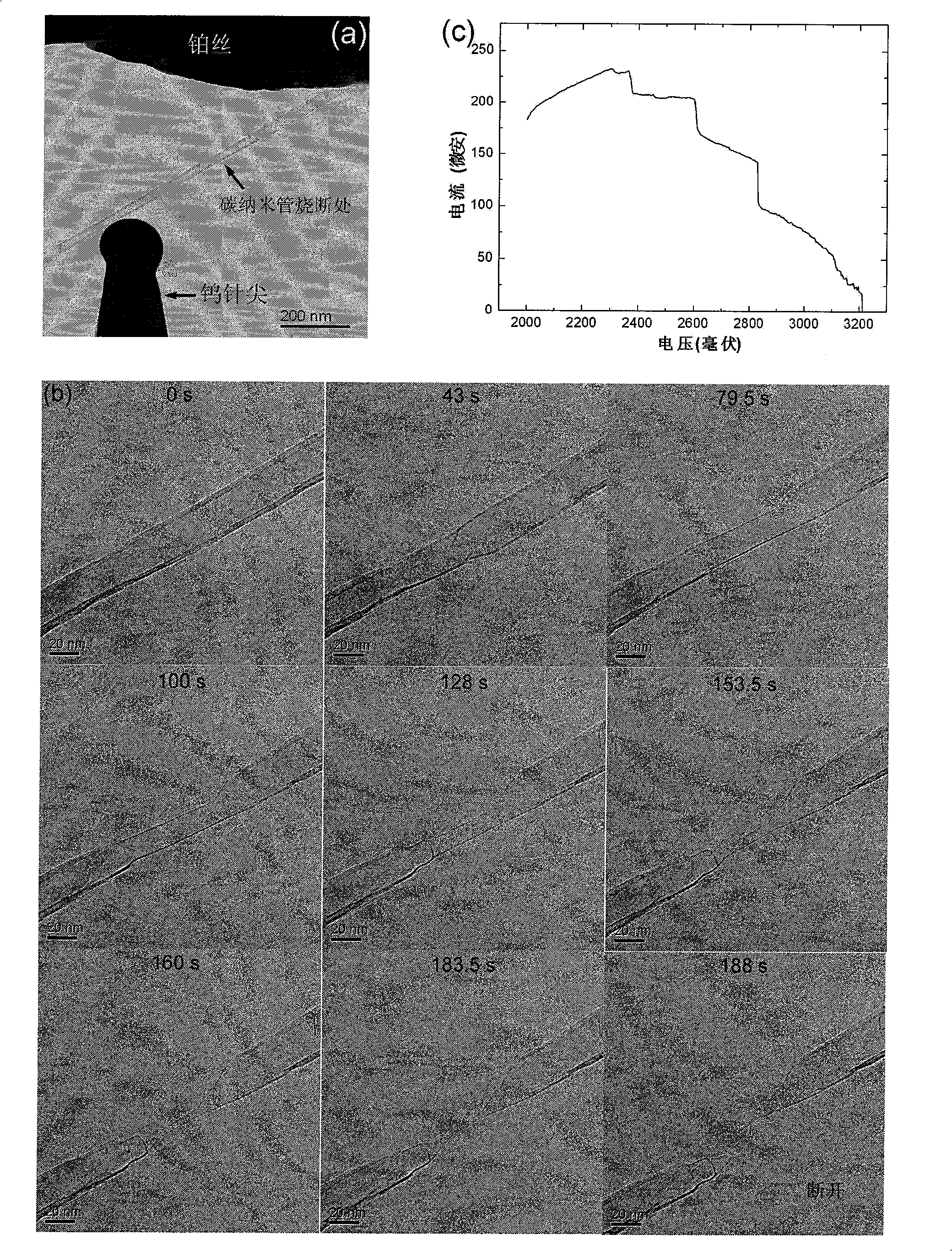

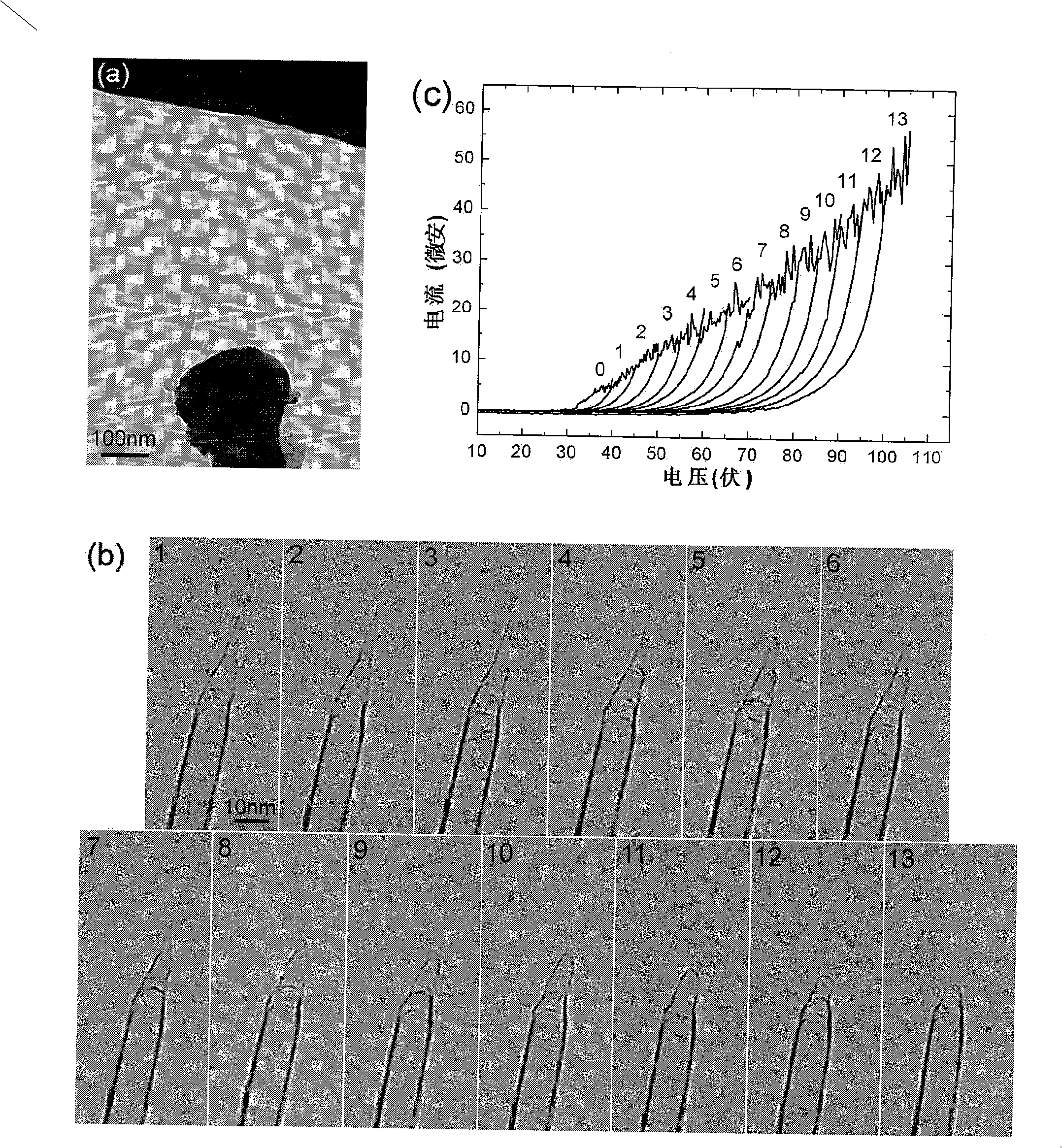

A single carbon nano electronic field emission cathode and its making method

InactiveCN101261916ALaunch stableLower turn-on voltageDischarge tube/lamp detailsCold cathode manufactureDouble-walled pipeNanotube

The invention provides an electron field emission cathode of a single carbon nanotube and a method for the preparation thereof, belonging to the application field of the carbon nanotubes. The nanotube used as the field emission cathode is provided with a cone-shaped end part that is in structure of a sealed sing-wall or double-wall pipe; multi-wall pipe structure is arranged at the lower part of the cone-shaped structure. The manufacturing method of the carbon nanotubes comprises the steps as follows: a multi-wall carbon nanotube is acquired through a metal wire; one multi-wall carbon nanotube on the metal wire is contacted through a metal needle tip; evenly increasing voltage is added between the metal wire and the metal needle tip, which leads the single carbon nanotube to become thinner and even to break up as a result of the electric current effects, so as to obtain the carbon nanotube with the cone-shaped end part. The carbon nanotube, with the advantages of the single-wall tubes and the multi-wall tubes on the emission performance, also has the advantages of stable emission, and low threshold voltage, can bear higher electric current and is also relatively easy to obtain. In addition, the curvature radius of the cone-shaped tip is controllable and can be enlarged; therefore, the corresponding maximum electric current to be borne can be increased constantly.

Owner:PEKING UNIV

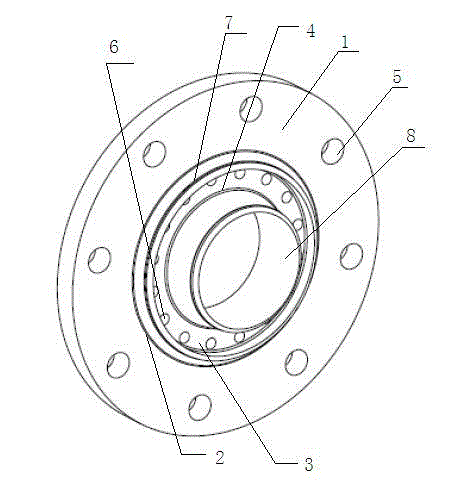

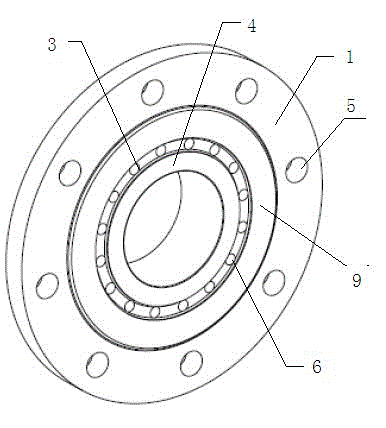

Double-pipe pipeline connection flange of hazardous gas delivery system

The invention provides a double-pipe pipeline connection flange of a hazardous gas delivery system. The double-pipe pipeline connection flange comprises two connection flange bodies of a hollow circular ring structure, each connection flange body is sequentially provided with an outer pipe connection region, a transition region and an inner pipe connection region from outside to inside, a plurality of ventilation holes are uniformly formed in each transition region, each outer pipe connection region is provided with an outer pipe convex shoulder of a circular ring structure, each inner pipe connection region is provided with an inner pipe convex shoulder of a circular ring structure, and each inner pipe convex shoulder and the corresponding outer pipe convex shoulder are arranged in the same direction. The connection flange is applied to design a gas pipeline, a conventional marine seamless steel pipe can be adopted as an outer pipe, the specification of the outer pipe only needs to be one or two grades higher than that of an inner pipe, the boundary dimension of the whole hazardous gas delivery system pipeline can be reduced greatly, and the discharge capacity of a draught fan drawing air from a negative pressure machine with double wall pipes is reduced. Ventilation continuity between the double wall pipes is guaranteed, the inner pipe and the outer pipe are connected through the flange, building construction is facilitated, and building efficiency is improved.

Owner:JIANGSU DAJIN HEAVY IND

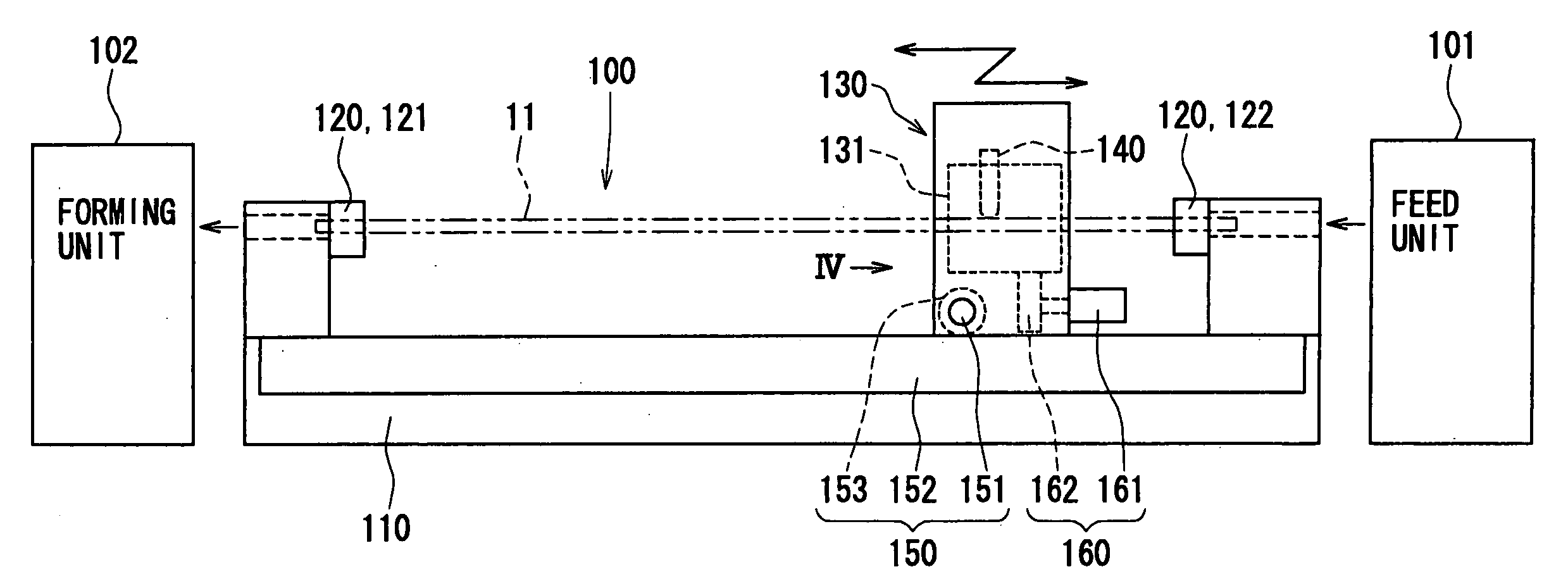

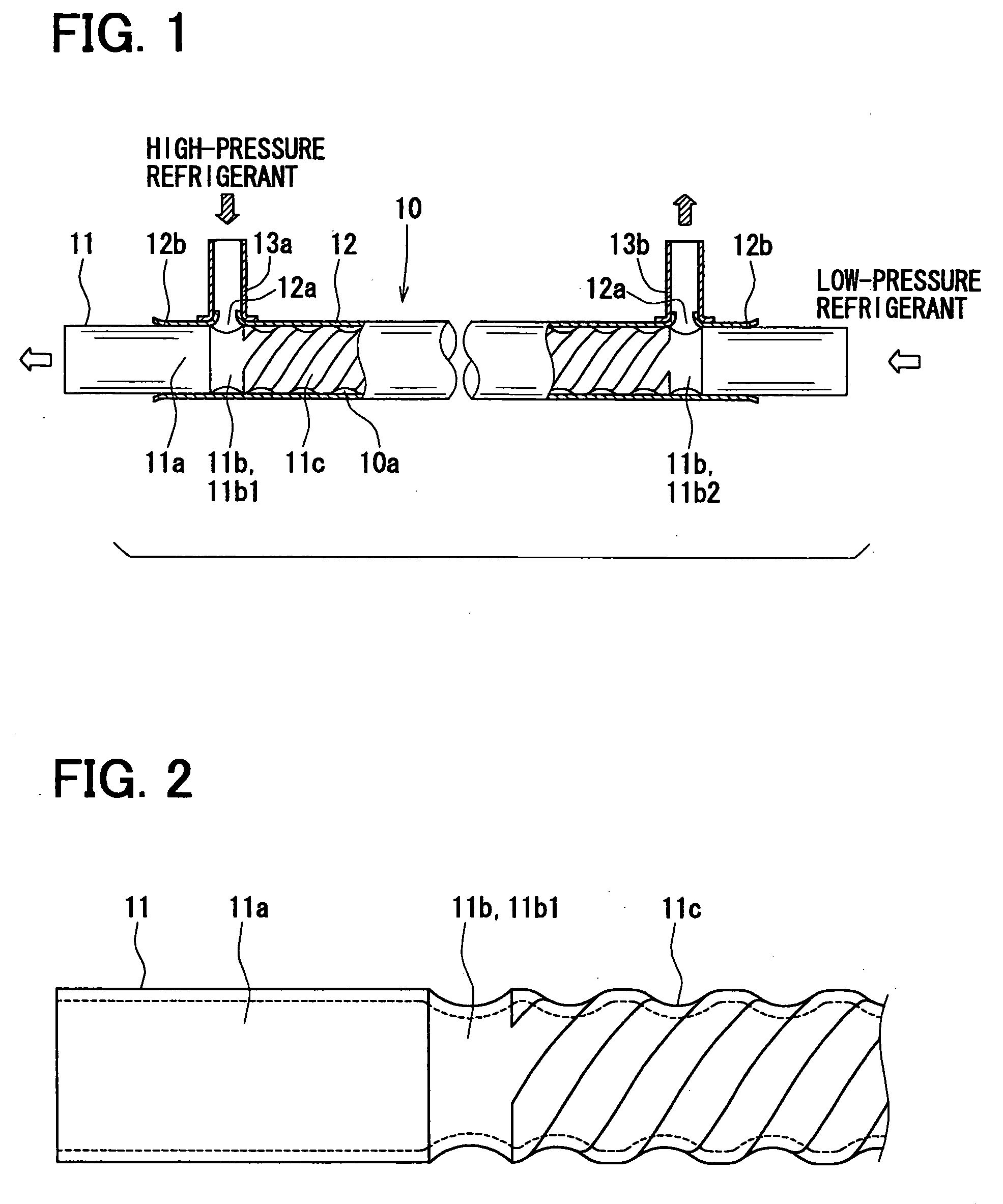

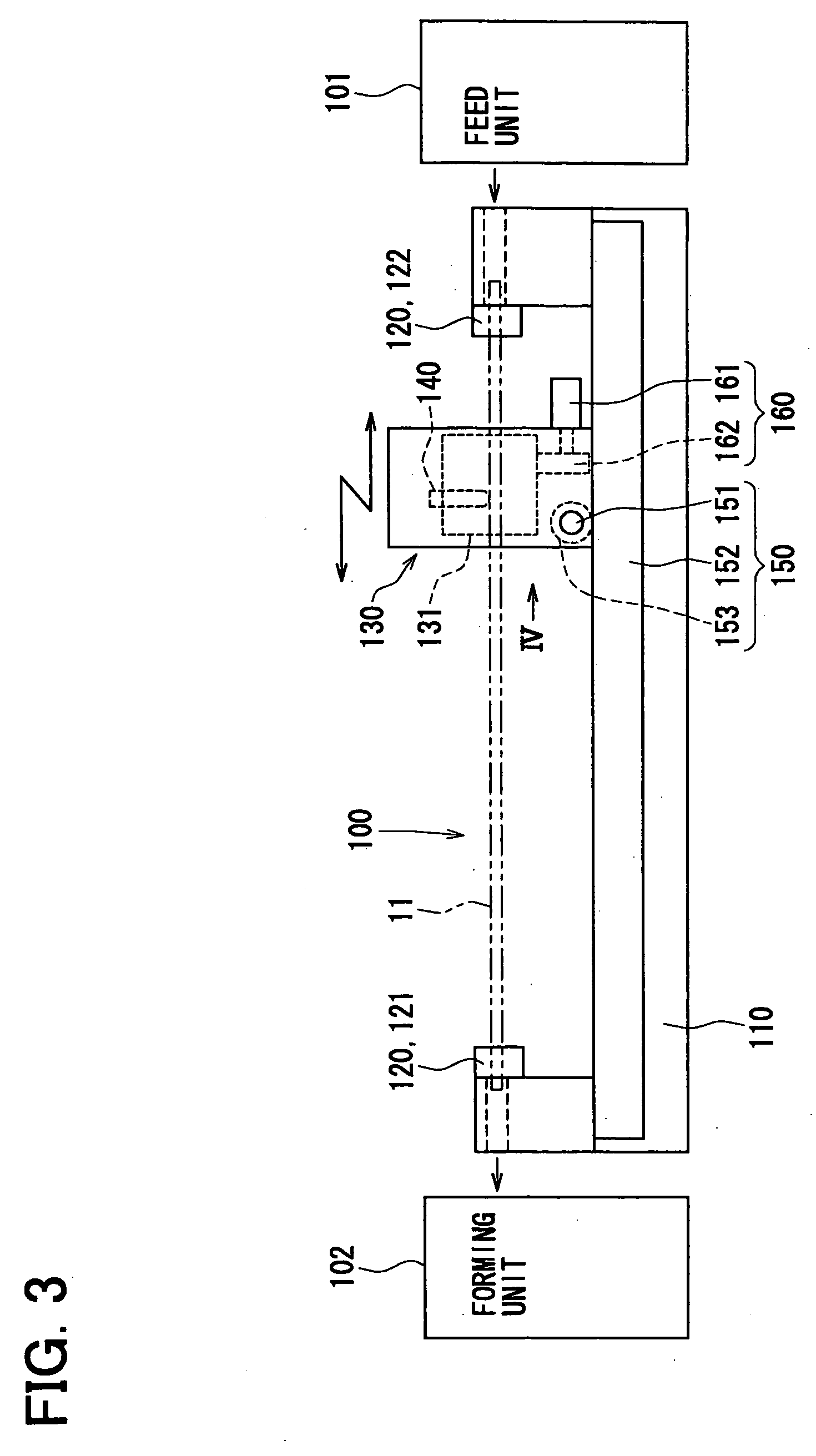

Method and apparatus of manufacturing grooved pipe, and structure thereof

InactiveUS20060112556A1Efficient preparationWell formedPipe supportsCompression machines with non-reversible cycleDouble-walled pipeMechanical engineering

Owner:DENSO CORP +1

Water-controlling sand prevention device and method used for fracturing horizontal gas well

InactiveCN109098694APrevent void spaceProduction does not affect each otherFluid removalSealing/packingEnvironmental geologyDouble-walled pipe

The invention discloses a water-controlling sand prevention device and method used for a fracturing horizontal gas well. The water-controlling sand prevention device comprises a double-layer tube, a supporting agent, a first packer and a second packer, wherein the double-layer tube comprises an inner layer tube body and an outer layer tube body sleeving the exterior of the inner layer tube body, an annular space is formed between the inner layer tube body and the outer layer tube body, and tube holes are formed in the tube walls of the inner layer tube body and outer layer tube body respectively; the supporting agent is arranged in the annular space and is a hydrophobic supporting agent, and the maximum particle size of the supporting agent is smaller than the average value of stratum separated particle sizes; the first packer and the second packer are annular and are arranged at the two ends of the double-layer tube respectively to close the supporting agent in the annular space. Withthe water-controlling sand prevention device and method, stratum particles and the supporting agent are controlled to enter a shaft, at the same time, water production of the gas well is controlled,production among all fracturing layers is not affected, and continuous efficient production of the horizontal gas well is guaranteed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com