Double-flow-channel direction control short connection device

A technology of directional control and dual channels, which is applied in earthwork drilling, wellbore/well components, flushing wellbore, etc., can solve problems such as ball valve spool wear, ball valve half-opening and half-closing, affecting sealing reliability, etc., to ensure Reliability, increase reliability, reduce stress agitation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

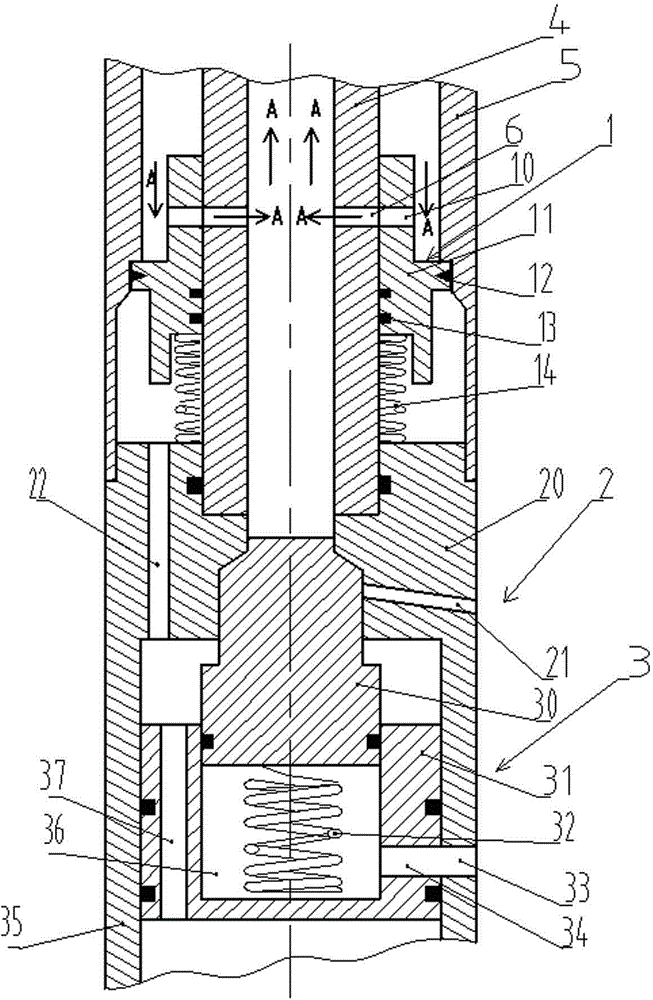

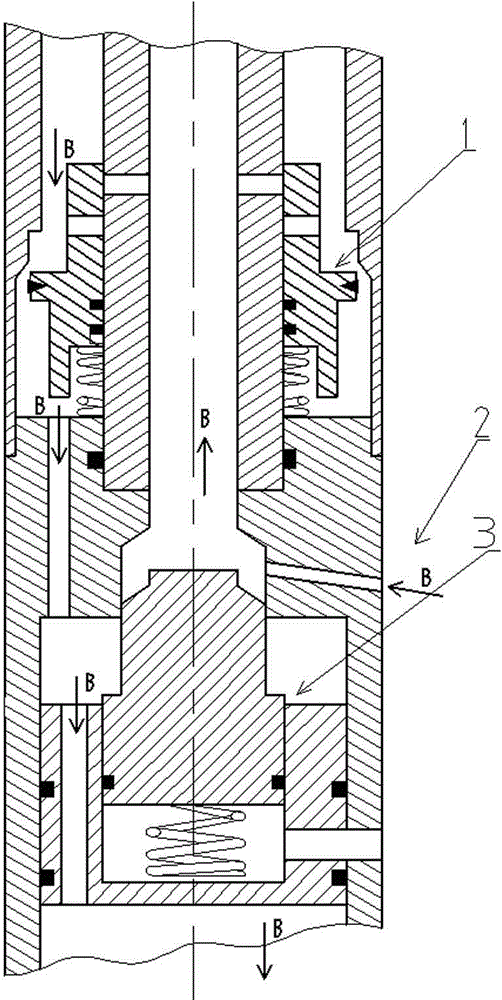

[0020] A double channel direction control shorting device includes an outer channel check valve 1 , a fluid turning short circuit 2 and an inner channel check valve 3 . The device is connected to the lower ends of the inner tube 4 and the outer tube 5 of the double-layer tube, the inner tube 4 forms an inner flow channel, and the inner tube 4 and the outer tube 5 form an outer flow channel.

[0021] Outer channel check valve 1 includes spool A11, outer sealing ring A12, inner sealing ring A13 and spring A14; spool A11 is installed between inner tube 4 and outer tube 5; The layer tubes 4 are sealed by the inner layer sealing ring A13; when the double-layer tube outer flow channel check valve 1 is closed, the valve core A11 and the outer layer tube 5 are sealed by the outer layer sealing ring A12; the valve core A11 Spring A14 is installed at the lower part; the inner tube 4 is radially processed with a through hole D6, and the valve core A11 is radially processed with a through...

Embodiment 2

[0027] In Embodiment 2, the fluid steering short-circuit is connected separately to the shell of the inner layer channel check valve (ie, the body 20 and the valve body 35 ).

Embodiment 3

[0028] In embodiment 3, the sealing ring in embodiment 1 is simplified or omitted, and the sliding and sealing cooperation between the upper and lower valve cores and their joint surfaces is achieved through fine processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com