Ship gas engine double-wall pipe

A gas engine and double-wall pipe technology, applied to pipes, pipe components, siphons, etc., can solve the problems of not having the online leak detection function, leaking gas residue, increasing flow resistance, etc., and achieve the goal of reducing resistance and leaking gas residue The effect of risk, maximization of circulation area, and guarantee of circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in conjunction with accompanying drawing and specific embodiment:

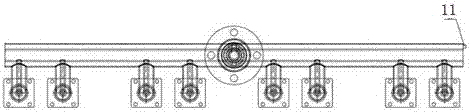

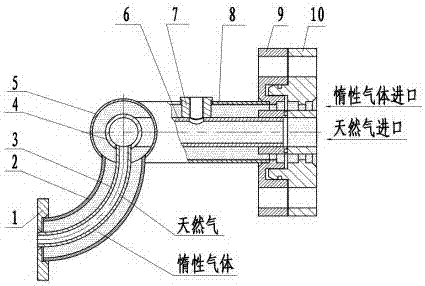

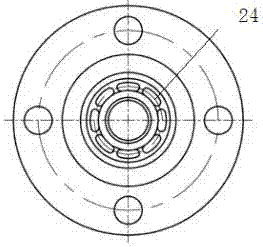

[0022] Such as figure 1 , figure 2 Shown, a kind of marine gas engine double-walled pipe, described double-walled pipe has the air intake main pipe that is straight pipe shape; Described air intake main pipe has the air intake main pipe inner pipe 4 and the air intake main pipe outer pipe that are nested and arranged 5; the inner tube 4 of the intake manifold is arranged coaxially with the outer tube 5 of the intake manifold, and there is an annular cavity between the two; the two ends of the intake manifold are respectively blocked by discs, and the intake manifold The circular plate at one end has a purge interface 11, and the purge interface 11 communicates with the annular cavity between the inner tube 4 of the intake manifold and the outer tube 5 of the intake manifold for purging the annular cavity Inert gas; the intake main pipe is provided with multiple grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com