Hermetic sealing program control testing stand

A technology of air sealing and test bench, which is applied in the direction of liquid tightness measurement by using liquid/vacuum degree, and by measuring the increase and deceleration rate of fluid, etc. It can solve the problems of inconvenient operation and use, influence of pipe fitting quality, and low test accuracy. Achieve the effects of intuitive detection results, quality assurance, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

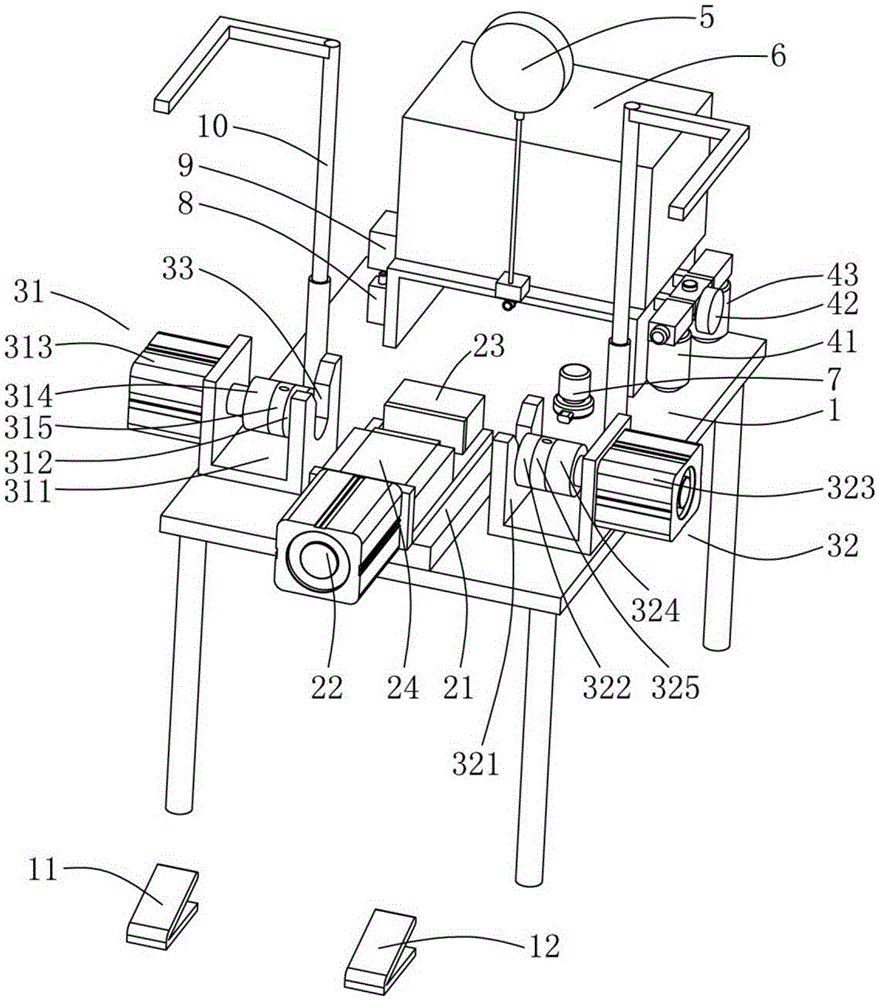

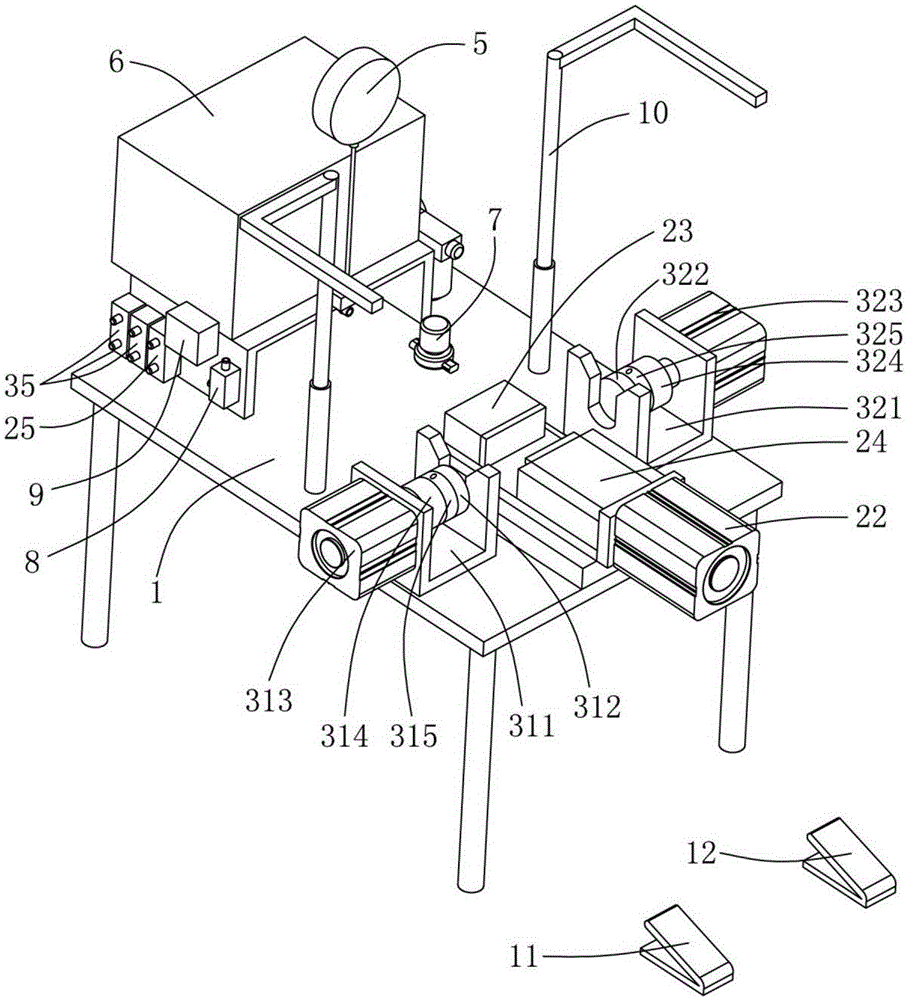

[0024] like Figure 1 to Figure 3 The air-tight program-controlled test bench shown includes a workbench 1 on which a clamping and positioning device, a sealing and sealing device, an air source processing device, a pressure gauge 5 and an electric control box 6 are respectively arranged.

[0025] The clamping and positioning device includes a base 21 fixed on the workbench 1. The base 21 is respectively provided with a clamping cylinder 22 and a limit block 23. Block 24, the clamping cylinder 22 is electrically connected with the electric control box 6 through the clamping solenoid valve 25, and the clamping solenoid valve 25 is used to directly control the clamping cylinder 22 to perform clamping and loosening actions.

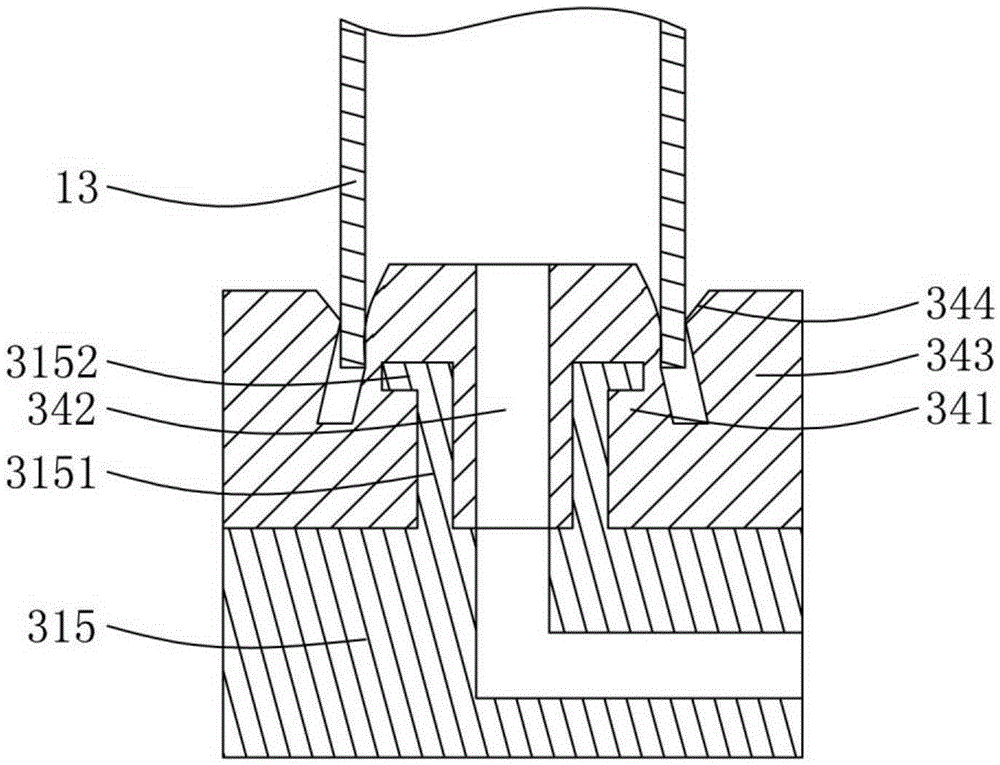

[0026] The sealing and blocking device includes two blocking mechanisms with the same structure, that is, a left blocking mechanism 31 and a right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com