Modified polyethylene pipe and preparation method thereof

A polyethylene pipe and polyethylene resin technology, applied in the field of modified polyethylene pipes and their preparation, can solve the problems of poor ring stiffness, increased carbon emissions, and insufficient toughness of double-walled pipes, and achieve good impact resistance and super strength Chemical corrosion resistance, the effect of improving the ability of foundation settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of above-mentioned modified polyethylene pipe, comprises the following steps:

[0035] a. Polyethylene resin, 50% chlorinated polyethylene, chlorinated polypropylene, 50% coupling agent, 50% compatibilizer, color masterbatch, light stabilizer , antioxidant, and anti-cracking resin were weighed in parts by weight, kneaded at 60-100°C for 5-20 minutes, cooled to 30-43°C, and spare material A was obtained;

[0036] b. Combine chlorinated polyvinyl chloride, lead-free stabilizer, lubricant, calcium stearate, remaining chlorinated polyethylene, processing aid, remaining compatibilizer, nanomaterial, and remaining coupling agent at 110 Stir at ~135°C for 15-30 minutes, then cool to 35-43°C, and obtain spare material B after granulation;

[0037] c. Blend spare material A and spare material B for 5-10 minutes, cool to 30-38°C after the temperature reaches 30-60°C, and extrude to obtain a modified polyethylene pipe.

[0038] Wherein, in the preparation ...

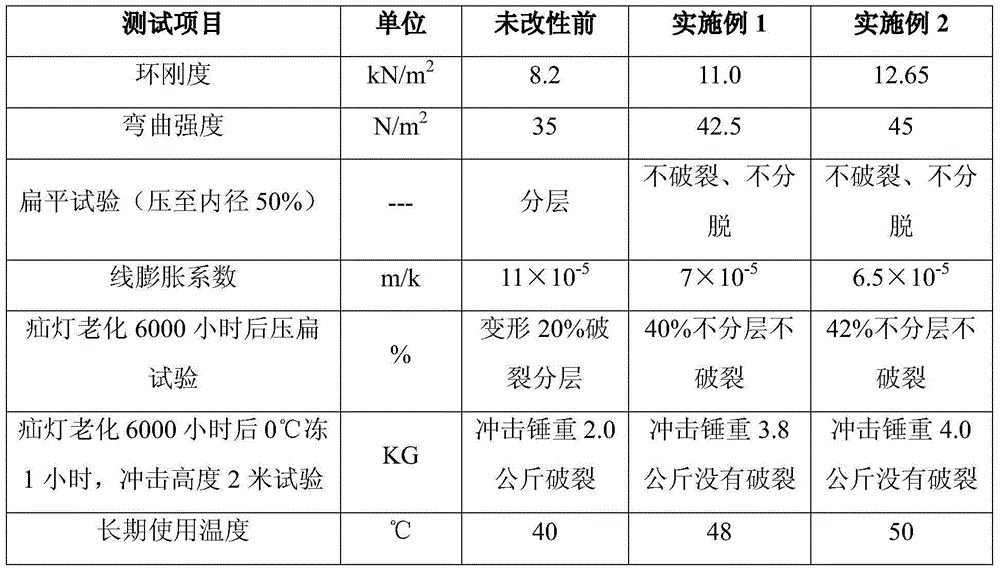

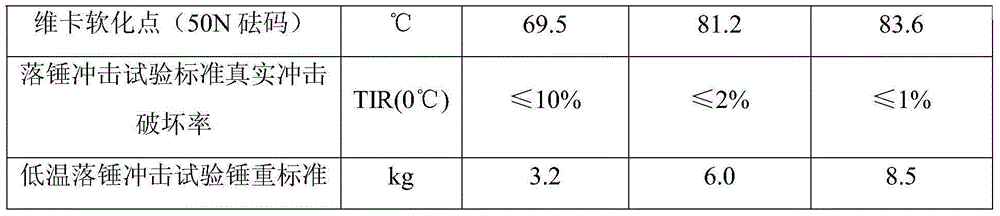

Embodiment 1

[0047] Modified polyethylene pipes with the following weight ratios:

[0048] 100 parts of polyethylene resin, 50 parts of chlorinated polyethylene, 20 parts of chlorinated polyvinyl chloride, 10 parts of chlorinated polypropylene, 5 parts of ethylene-propylene copolymer, 20 parts of activated nano calcium carbonate, 0.5 parts of white masterbatch, calcium 4 parts of zinc stabilizer, 2 parts of hindered amine light stabilizer, 1 part of maleic anhydride graft copolymer, 2 parts of phenolic antioxidant 1076, 2 parts of titanate coupling agent, 0.5 part of calcium stearate, 0.1 part of polyethylene wax, 3 parts of ethylene-octene copolymer.

[0049] Adopt following preparation method:

[0050] a, polyethylene resin, chlorinated polyethylene (50% of total parts), chlorinated polypropylene, titanate coupling agent (50% of total parts), maleic anhydride graft copolymer (total parts 50% of the number), white masterbatch, antioxidant 1076, hindered amine light stabilizer, ethylene-...

Embodiment 2

[0056] Modified polyethylene pipes with the following weight ratios:

[0057] 100 parts of polyethylene resin, 30 parts of chlorinated polyethylene, 25 parts of chlorinated polyvinyl chloride, 15 parts of chlorinated polypropylene, 20 parts of active nano mica, 0.5 parts of black color masterbatch, 2 parts of organotin stabilizer, diphenyl 2 parts of ketone light stabilizer, 5 parts of acrylic resin, 5 parts of acrylonitrile-butadiene-styrene graft, 5 parts of ethylene-vinyl acetate copolymer, 2 parts of phosphite antioxidant 168, silane 2 parts of coupling agent, 0.5 part of calcium stearate, 0.1 part of polyethylene wax, 0.1 part of paraffin wax, 3 parts of ethylene-hexene copolymer.

[0058] The preparation method and process parameters are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com