Double-layer pipe overall buckling simulation experiment device and method

A technology for simulating experimental devices and double-layer pipes, applied in measuring devices, using stable bending force to test material strength, instruments, etc., which can solve problems such as incomplete consistency of pipeline project evaluation criteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

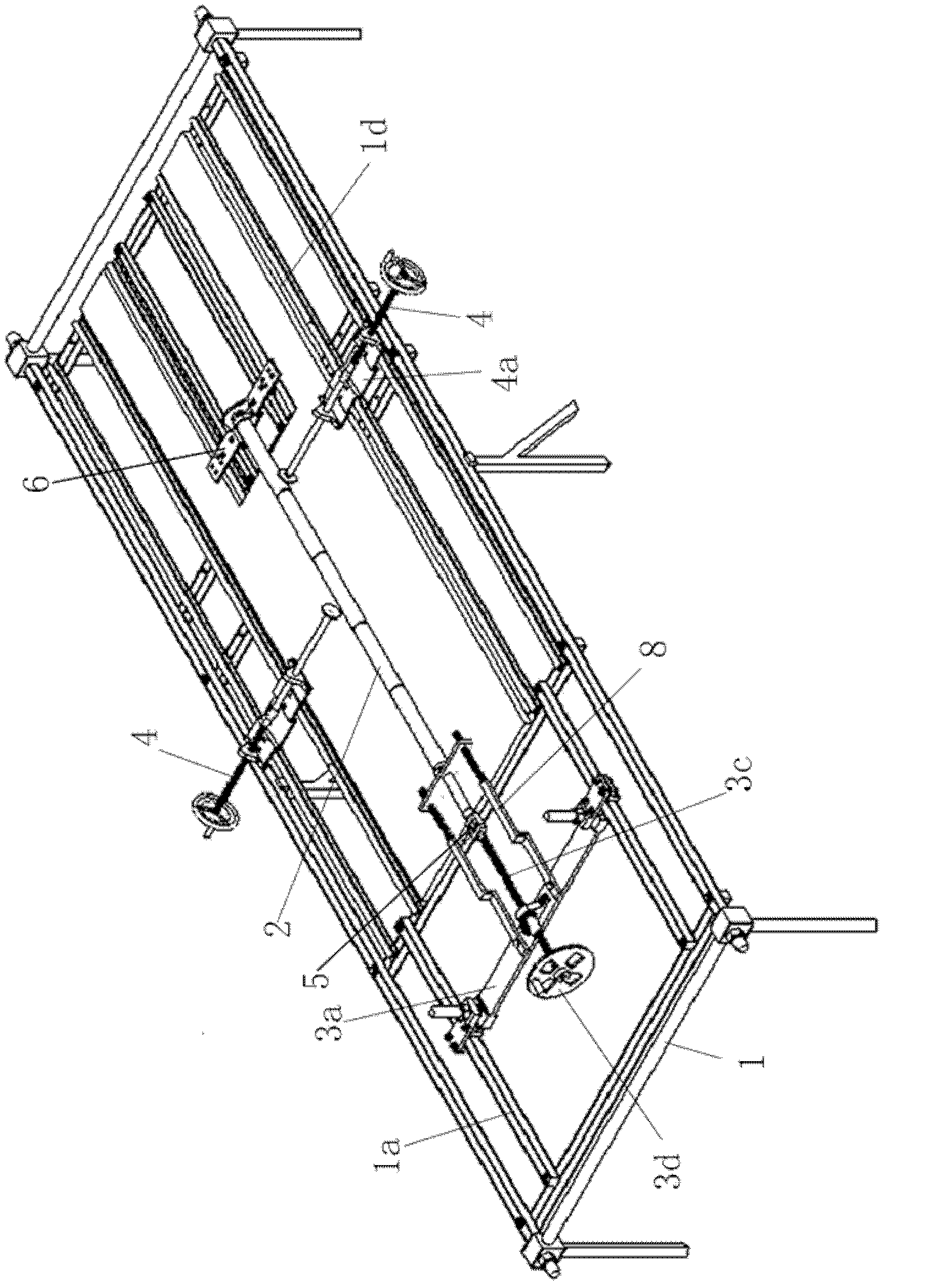

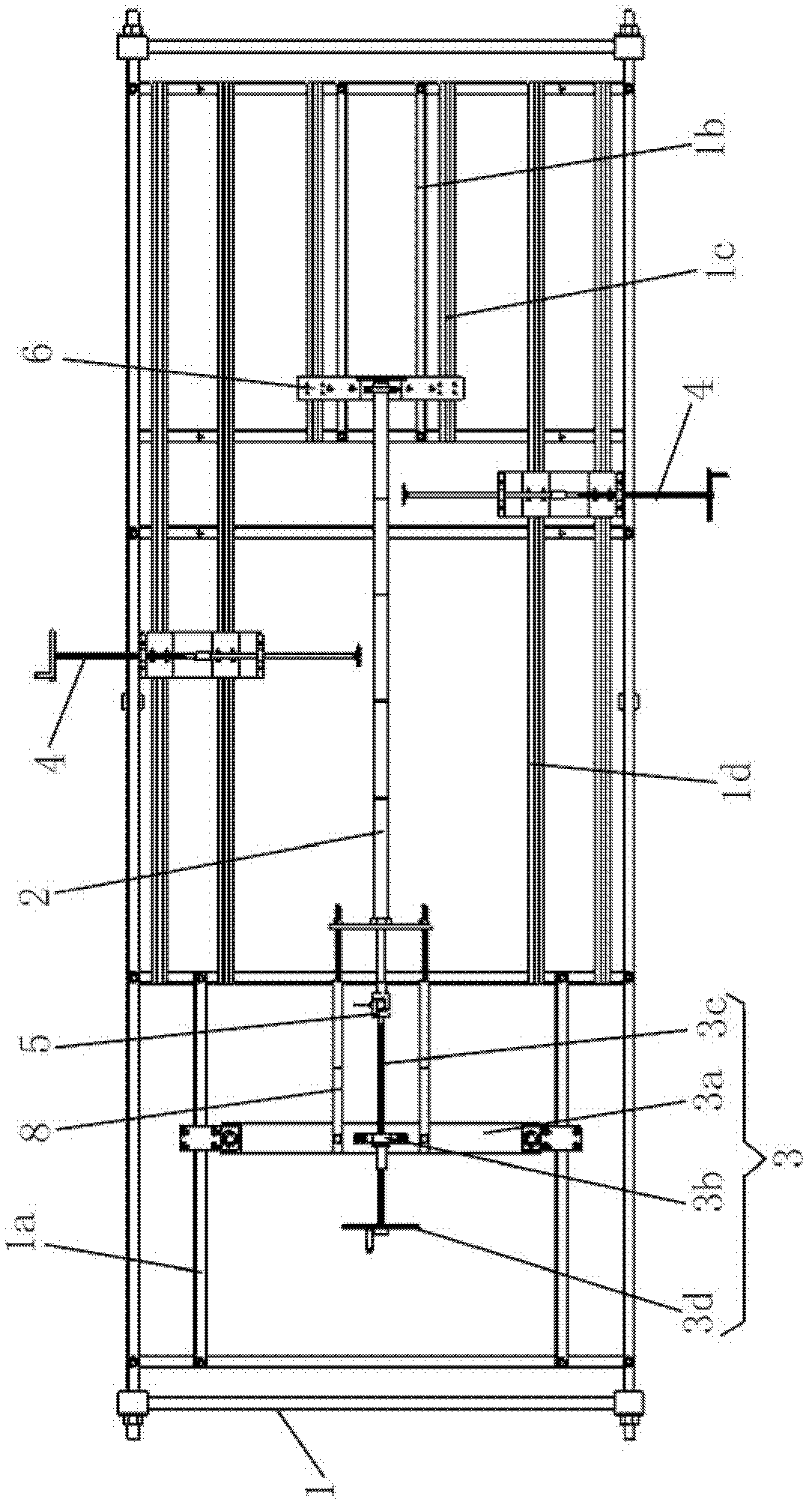

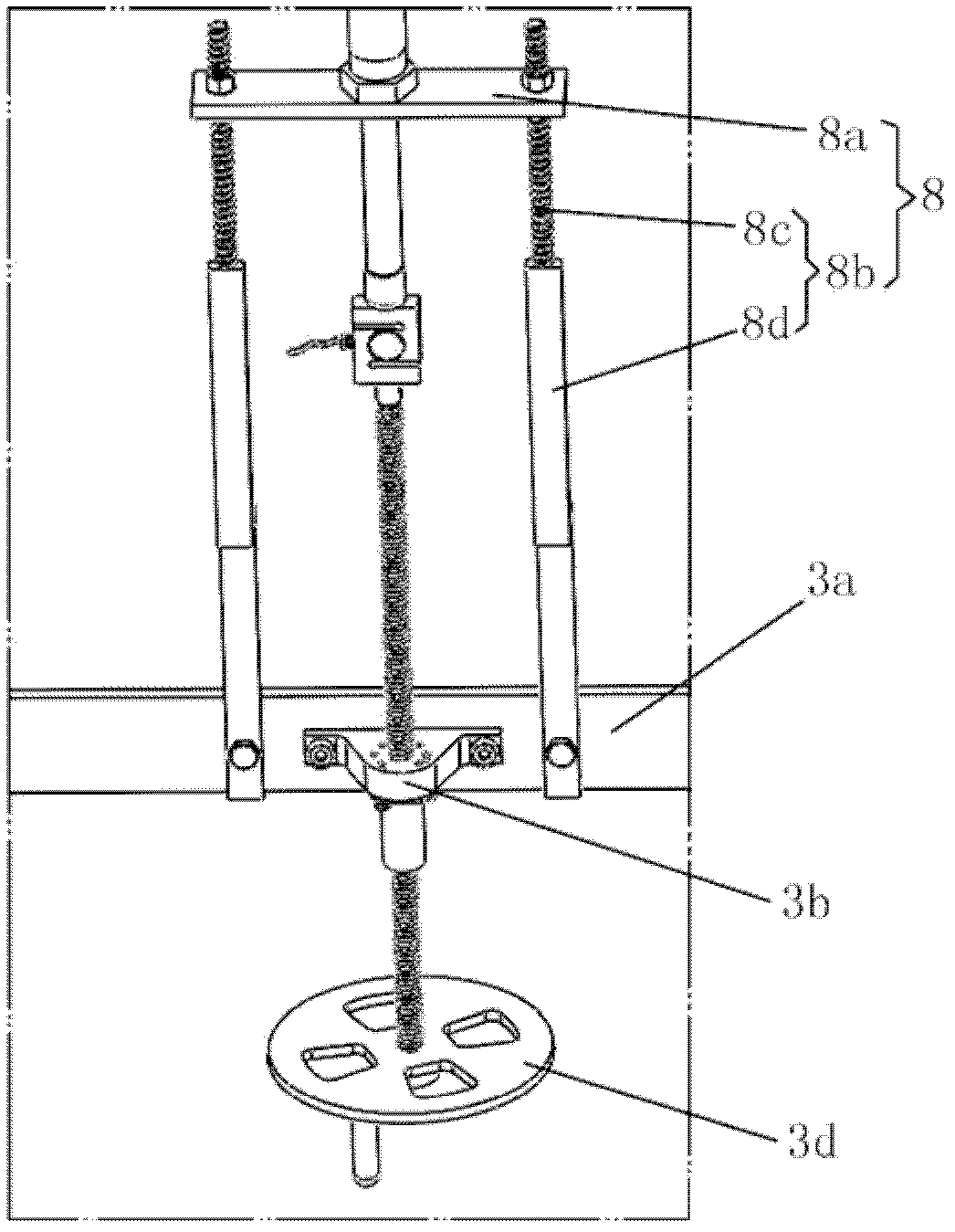

[0045] Such as Figure 1 to Figure 2 As shown, the overall buckling simulation experiment device of the double-layer pipe proposed by the embodiment of the present invention includes a base 1 , a double-layer pipe 2 , an axial loading device 3 and two lateral loading devices 4 . The double-layer pipe 2 is arranged on the base 1. The double-layer pipe 2 is composed of an inner pipe 2a and an outer pipe 2b which is sleeved outside the inner pipe 2a at intervals. The ends of the double-layer pipe 2 are fixed. The front ends of the outer tubes 2a and 2b are connected by an inner and outer tube coupling axial loading device 8, and multiple sets of strain gauges 2c are respectively attached to the inner tube 2a and the outer tube 2b for measuring the strain of the inner and outer tubes. An axial loading device 3 is axially slidably connected to the base 1 and connected to the front end of the inner tube 2a, and a pressure sensor 5 is connected between the axial loading device 3 and ...

Embodiment approach 2

[0092] This embodiment is modified on the basis of the experimental device of Embodiment 1, that is, a gasket 7 is added between the inner pipe 2a and the outer pipe 2b, as Figure 12 shown.

[0093] The experimental device of this embodiment can be used to verify the influence of the initial deflection of the washer, and its procedure is the same as that of the first embodiment.

[0094] Through this experimental setup, the influence of the initial deflection of the pipeline on the overall buckling of the pipeline can be studied, and the influence of the gasket spacing and height on the overall buckling of the pipeline can also be studied.

[0095] Other structures, working principles and beneficial effects of this specific embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com