Water-controlling sand prevention device and method used for fracturing horizontal gas well

A gas well and horizontal technology, which is applied in earth-moving drilling, wellbore/well components, and production fluids, etc., can solve the problems of inability to control water and sand at the same time, inconvenient operation, and complicated equipment, and achieve the effect of ensuring continuous and efficient production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

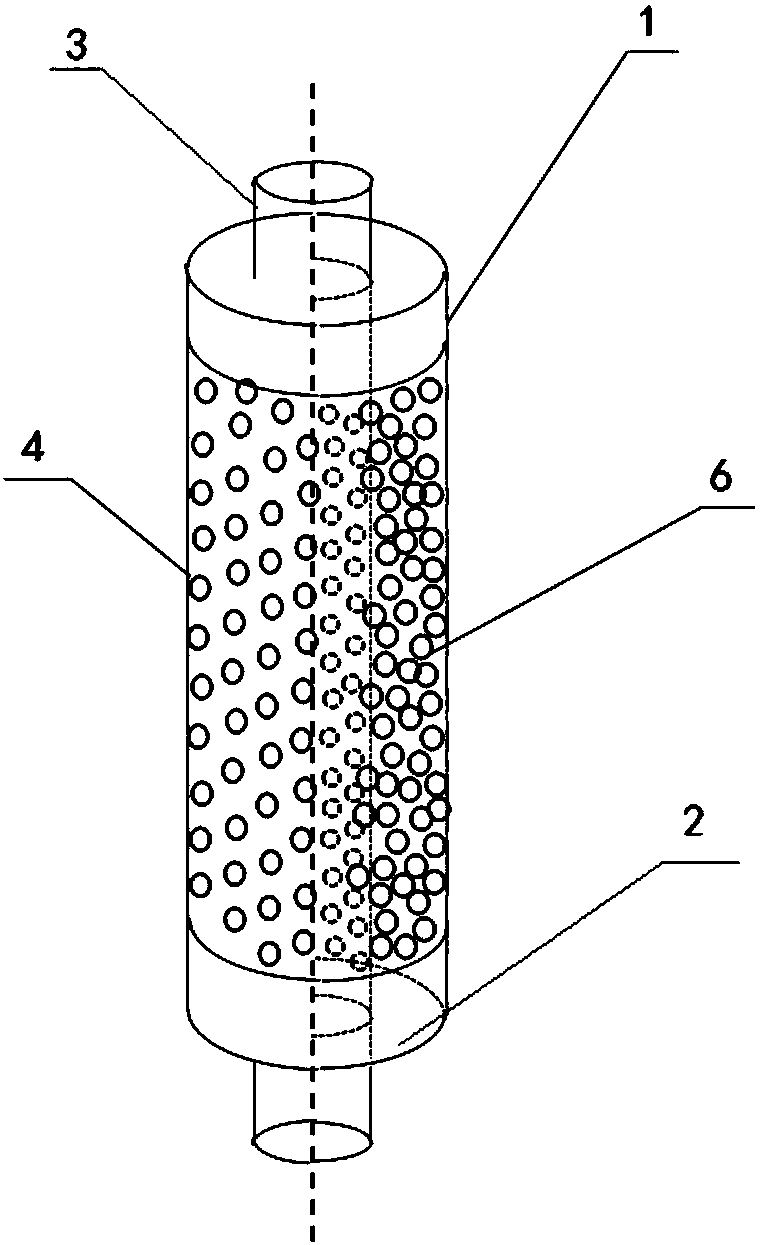

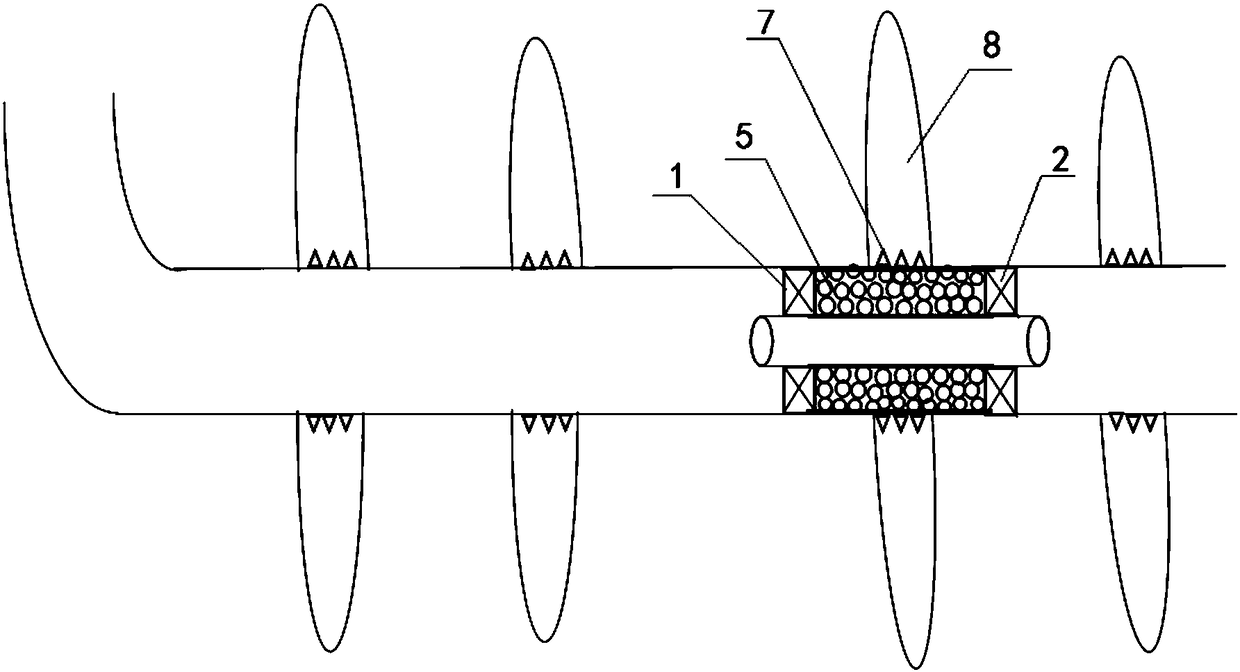

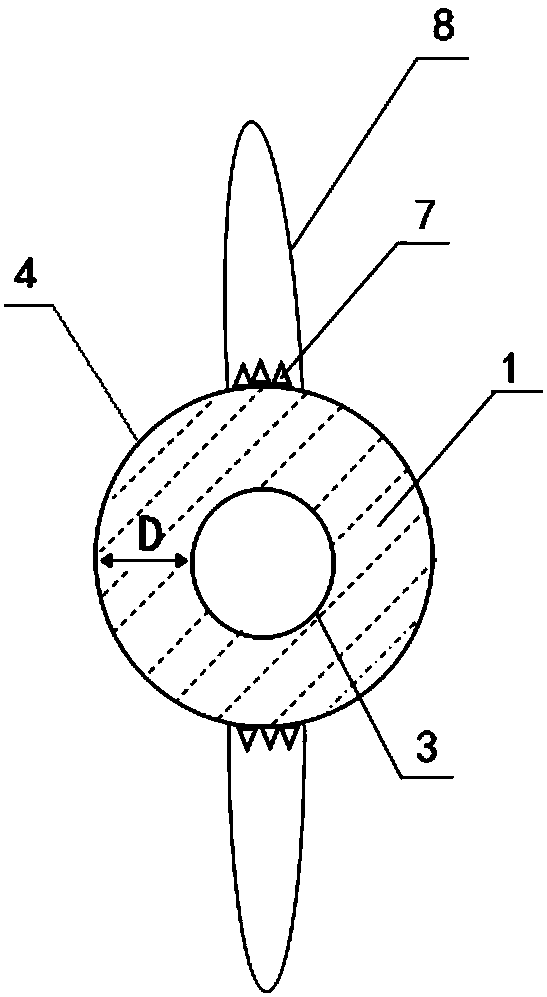

[0057] figure 1 A perspective view showing a water and sand control device according to an embodiment of the present invention, figure 2 A schematic diagram showing the installation of a water and sand control device according to an embodiment of the present invention, image 3 It shows the left view of the installation of the water and sand control device according to the embodiment of the present invention.

[0058] Such as Figure 1-3 As shown, the water and sand control device for fracturing a horizontal gas well according to an embodiment of the present invention includes:

[0059] Double-layer pipe, the double-layer pipe includes an inner pipe 3 and an outer pipe 4 sleeved outside the inner pipe, an annular space is formed between the inner pipe 3 and the outer pipe 4, and the inner pipe 3 and the outer pipe 4 Pipe holes 6 are provided on the pipe walls, wherein the length of the inner pipe 3 is greater than the length of the outer pipe 4;

[0060] The proppant 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com