Double-pipe pipeline connection flange of hazardous gas delivery system

A technology for connecting flanges and conveying systems. It is applied in the direction of pipes/pipe joints/fittings, flange connections, passing components, etc. It can solve problems such as inability to achieve ventilation penetration, so as to ensure ventilation continuity, increase service life, and facilitate construction. The effect of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

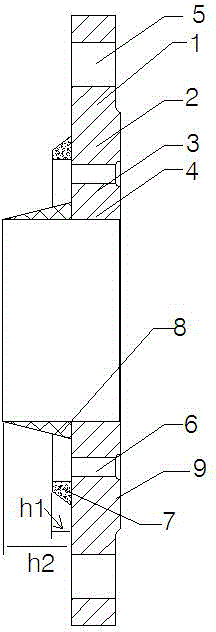

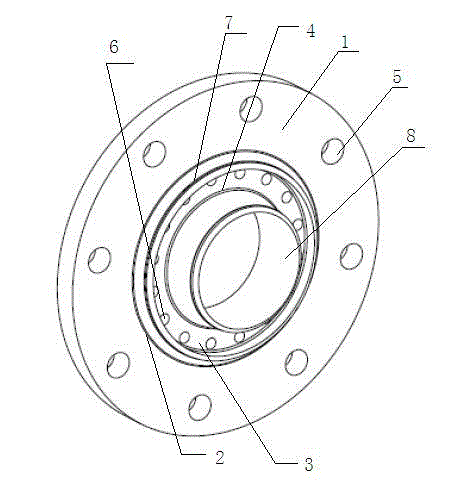

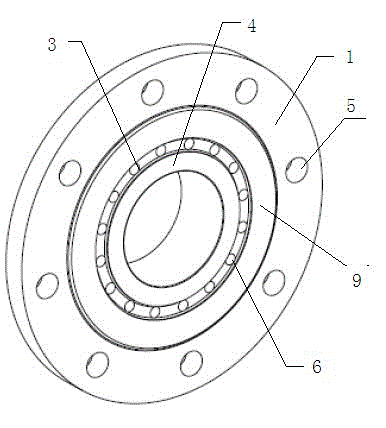

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] As shown in the figure, a double-pipe pipeline connection flange for a dangerous gas delivery system includes two connection flange main bodies 1 with hollow ring structures, and the connection flange main body 1 is provided with outer pipes from outside to inside. The connection area 2, the transition area 3 and the inner pipe connection area 4, the flange body 1 is evenly provided with a number of bolt connection holes 5, and the bolt connection holes 5 are circumferentially distributed outside the outer pipe connection area 2, and the outer pipe connection area 2. Just 1-2 gears larger than the inner pipe connection area 4, a number of ventilation holes 6 are evenly provided on the transition area 3, and an outer pipe shoulder 7 with a ring structure is provided on the outer pipe connection area 2, and the outer pipe shoulder The cross-sectional shape of 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com