Method and apparatus of manufacturing grooved pipe, and structure thereof

a manufacturing method and groove technology, applied in the direction of indirect heat exchangers, lighting and heating apparatus, other domestic articles, etc., can solve the problems of uneven length of pipe, product quality is not stable, and the forming range of grooves in the longitudinal direction of inner pipes is not stable, so as to achieve the effect of manufacturing a grooved pip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

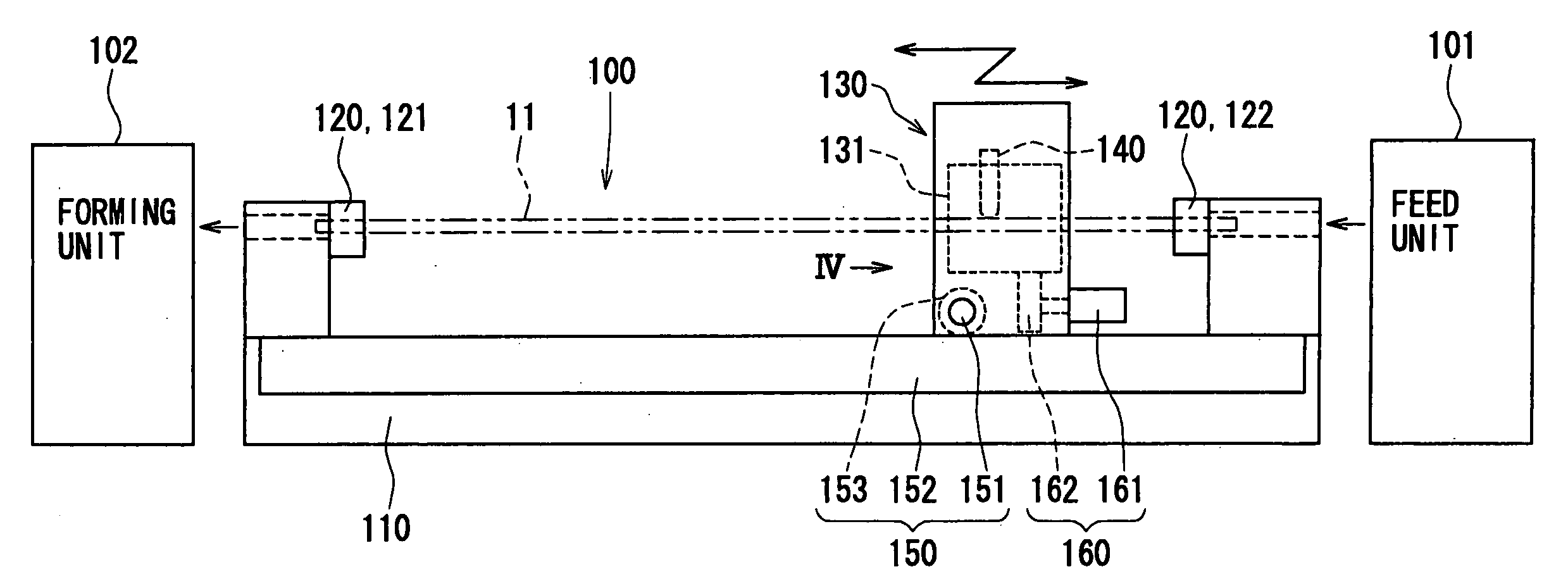

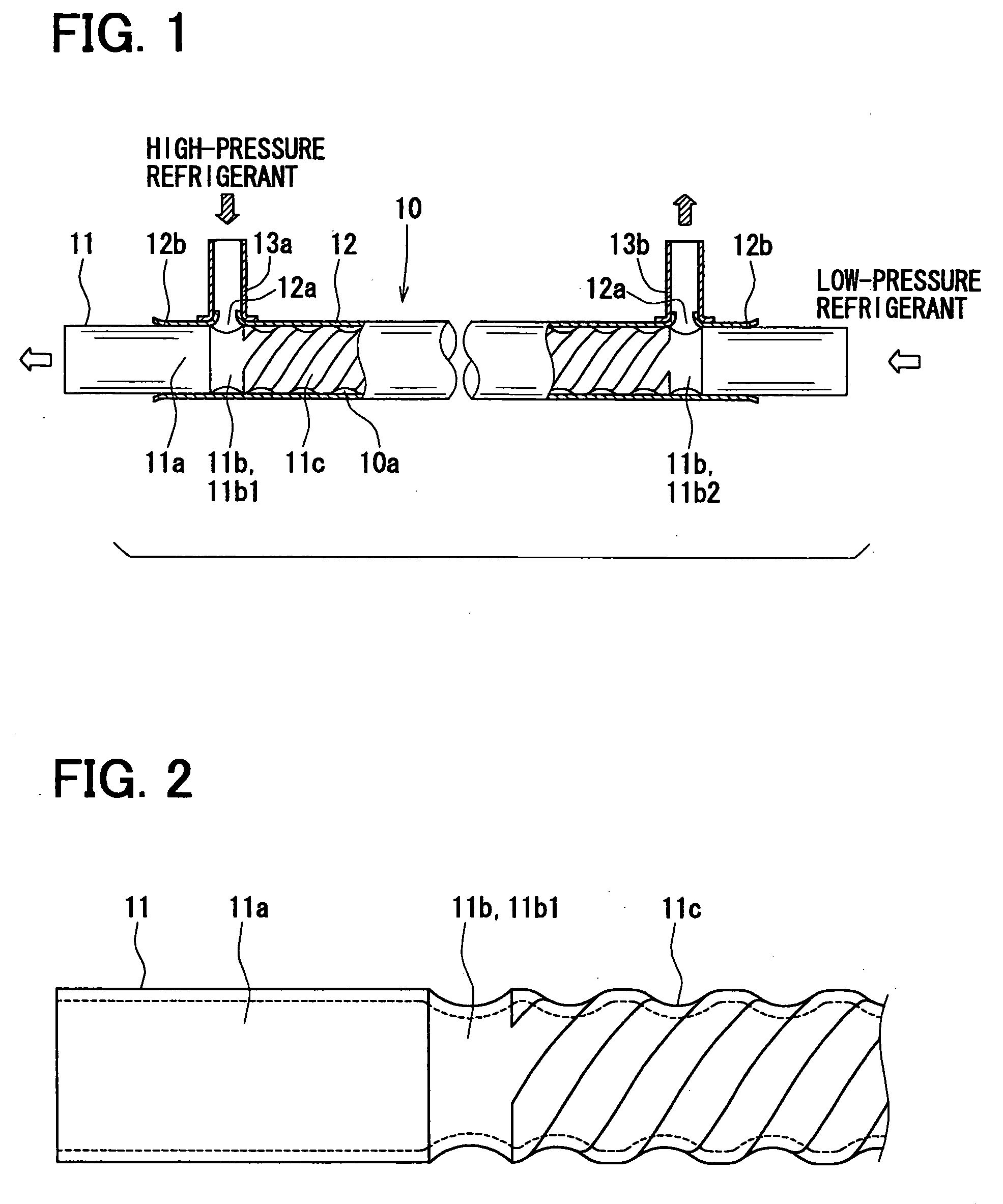

[0035] In this embodiment, a double-wall pipe 10 according to the present invention is typically used for a refrigeration cycle of a vehicle air conditioning apparatus. The double-wall pipe 10 serves as a pipe for a refrigerant. The double-wall pipe 10 also serves as an internal heat exchanger for exchanging heat between a high-temperature high-pressure refrigerant from a condenser of the refrigeration cycle and a low-temperature low-pressure refrigerant from an evaporator. The double-wall pipe 10 is constructed with an outer pipe 12 and an inner pipe 11 inserted into the outer pipe 12. The low-temperature low-pressure refrigerant flows through inside the inner pipe 11. The high-temperature high-pressure refrigerant flows through a passage between the inner pipe 11 and the outer pipe 12. The inner pipe 11 of the double-wall pipe 10 includes grooves 11b, 11c. The grooves 11b, 11c are formed to be recessed from a wall surface 11a of the inner pipe 11. The grooves 11b, 11c are formed b...

second embodiment

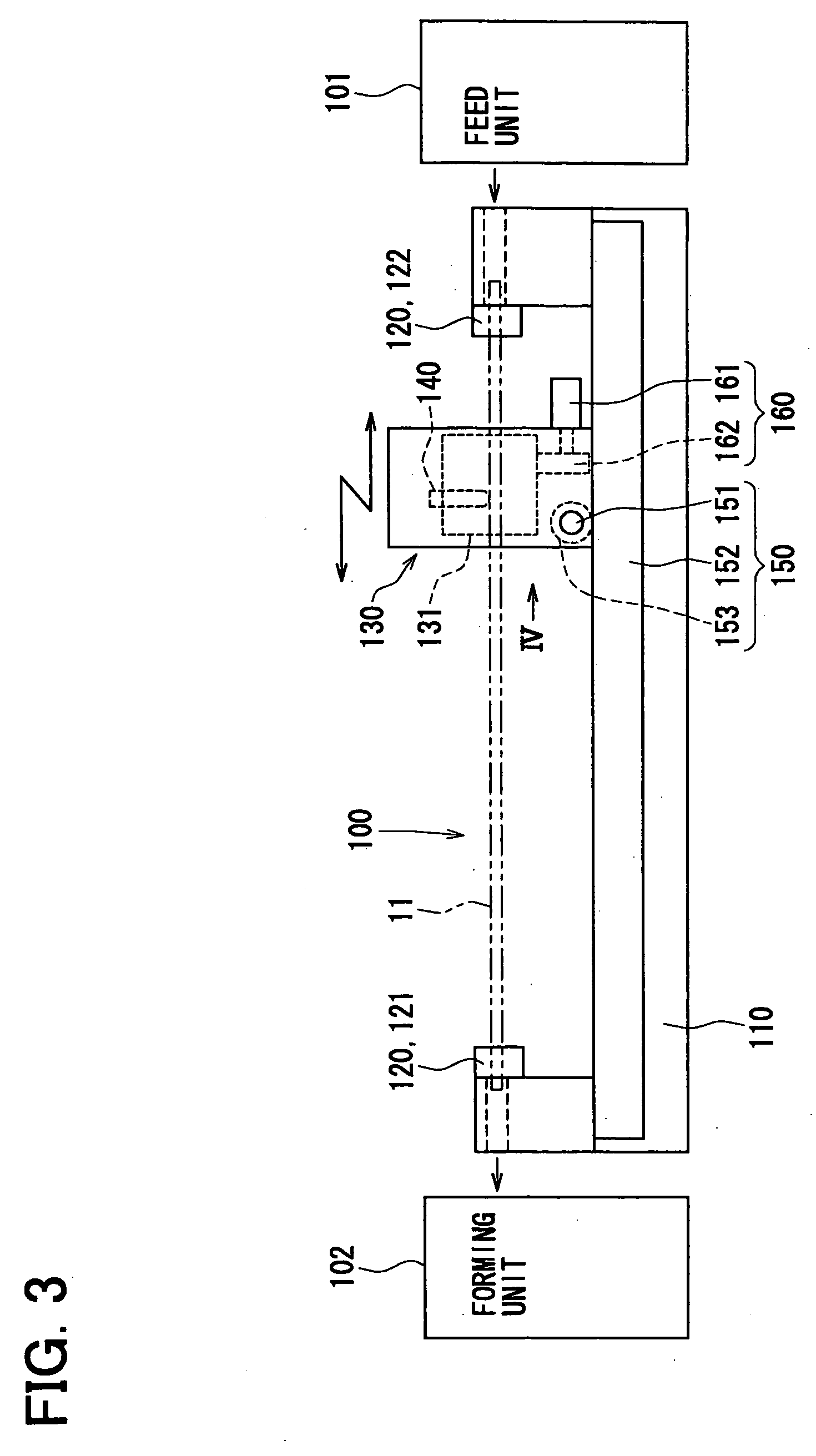

[0062] A second embodiment of the present invention will be described with reference to the accompanying drawings. Similar components of a production apparatus forming a grooved pipe of the present embodiment, which are similar to the components of the production apparatus of the grooved pipe of the first embodiment, will be indicated by the same numerals.

[0063]FIG. 7 is a block diagram of a production method for manufacturing the grooved pipe according to the second embodiment. In the present embodiment, the production apparatus 100 shown in FIGS. 3, 4 can be used, and a displacement of the blocks 131 in the radial direction is driven by a driving device, such as a motor.

[0064] In a feeding step 710, a pipe material to be processed for forming the inner pipe 11 is fed. In a cutting and forming step 711, a predetermined length of the pipe material is cut from a pipe coil. The cut pipe material is formed into a tubular shape to be fed. In a feeding and inserting step 712, the pipe ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| inner diameter | aaaaa | aaaaa |

| outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com