A single carbon nano electronic field emission cathode and its making method

A technology of carbon nanotubes and emission cathodes, which is applied in the field of preparation of such carbon nanotube electron field emission cathodes, can solve the problems of small current and difficulty in obtaining single-walled tubes, and achieve the effects of large current, easy acquisition, and low turn-on voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

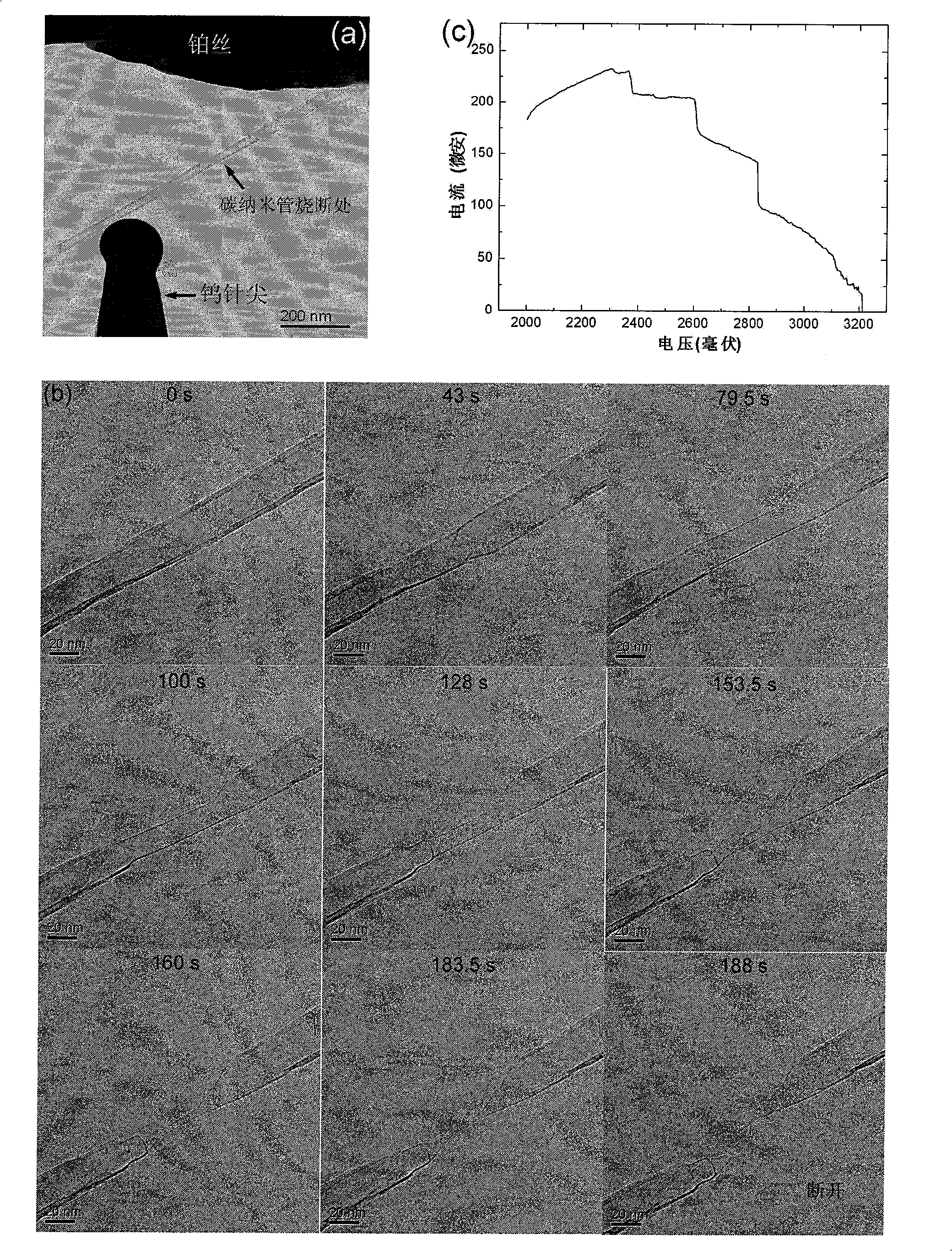

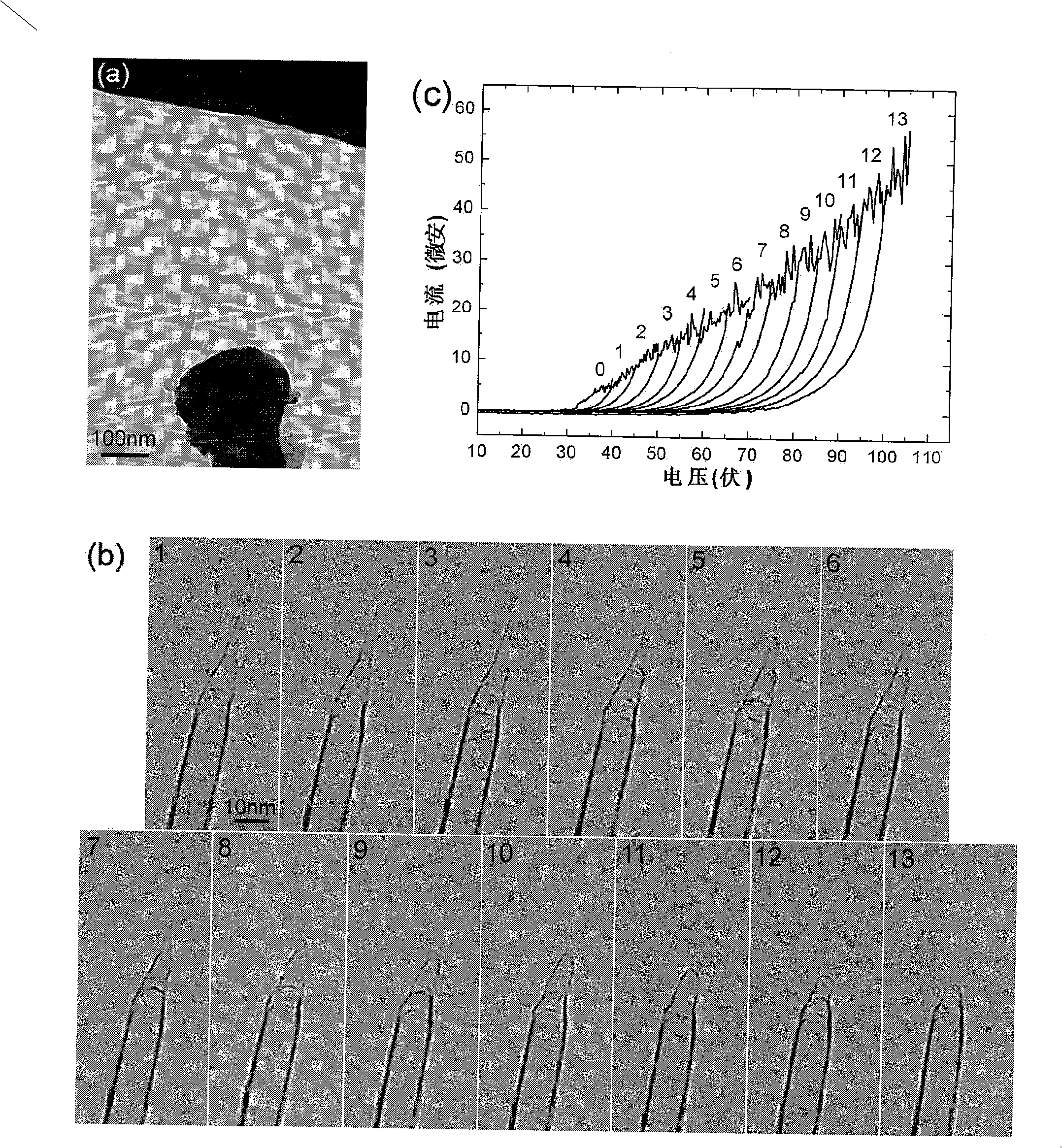

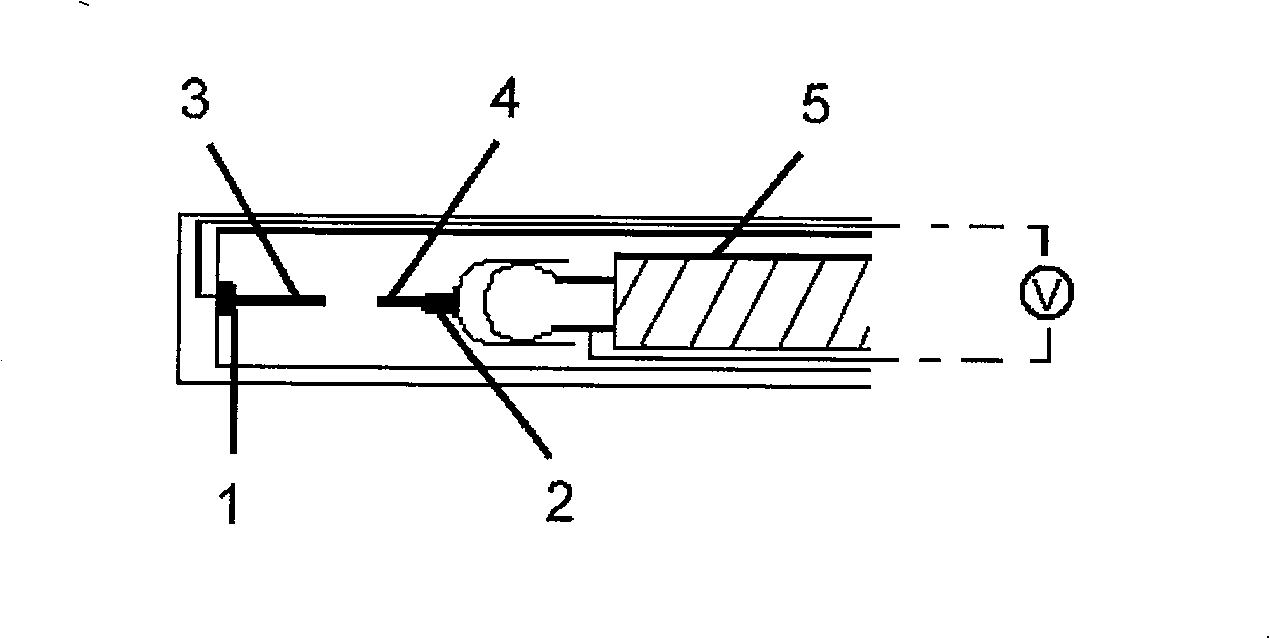

[0033] The invention adopts the method of in-situ electrifying a single carbon nanotube in a transmission electron microscope to prepare the carbon nanotube with a conical tip. The conical tip of this carbon nanotube has the diameter and the number of tube walls of an ordinary multi-walled carbon nanotube, while the conical tip is composed of a closed single-walled or double-walled tube, and its topmost curvature radius is equivalent to that of an ordinary single-walled carbon nanotube. wall pipe. refer to figure 1 , a single multi-walled carbon nanotube rides on two metal wires, such as figure 1 As shown in (a), under the action of electric heating, the middle part of the carbon nanotube gradually becomes thinner, and finally breaks into two carbon nanotubes with conical tips, as shown in figure 1 Shown in (b). figure 1 (c) records the current-voltage curve of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com