Thin film field emitting cathode with gradually changed electronic transmission layer component

A technology of electron transport layer and field emission cathode, which is applied in the direction of discharge tube/lamp parts, cathode ray tube/electron beam tube, circuit, etc., can solve the problem that the emission current of large-screen high-brightness flat-panel display devices cannot be satisfied, Achieve the effect of low device capacitance and large emission current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

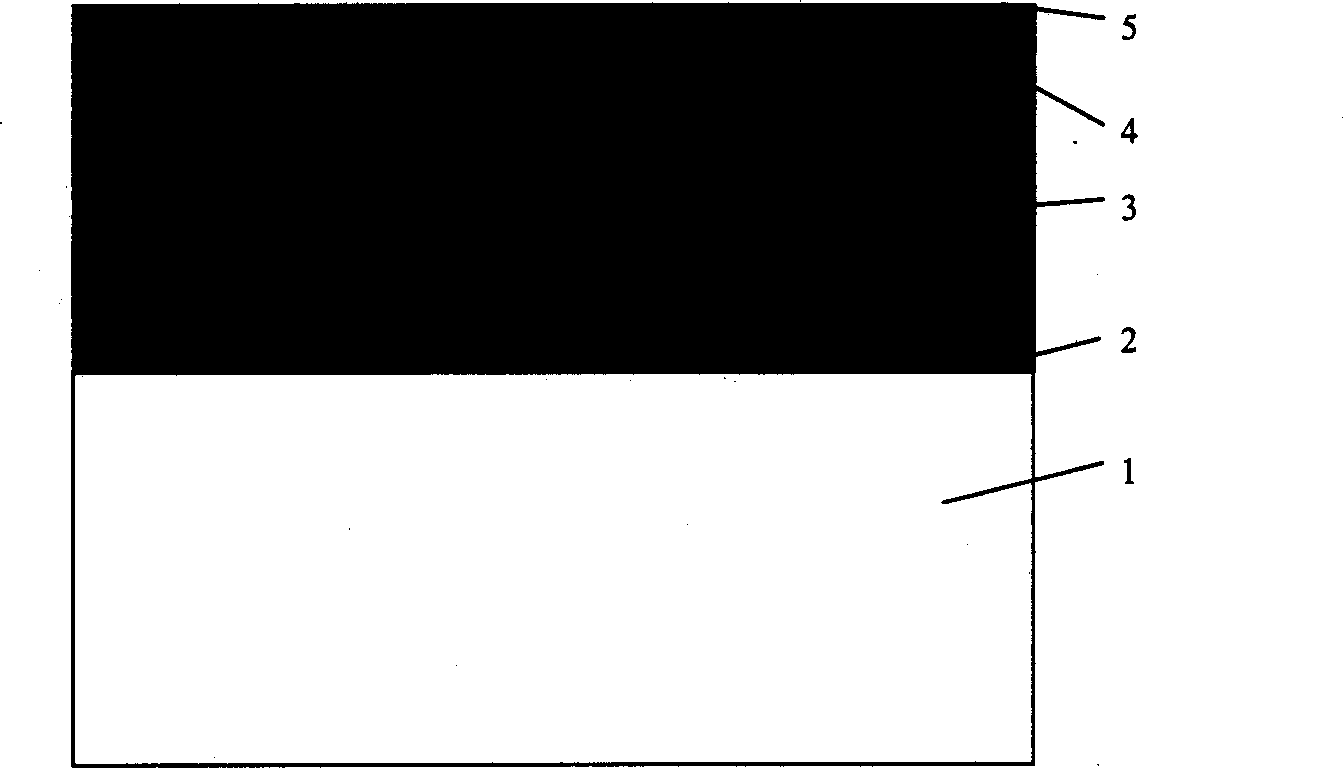

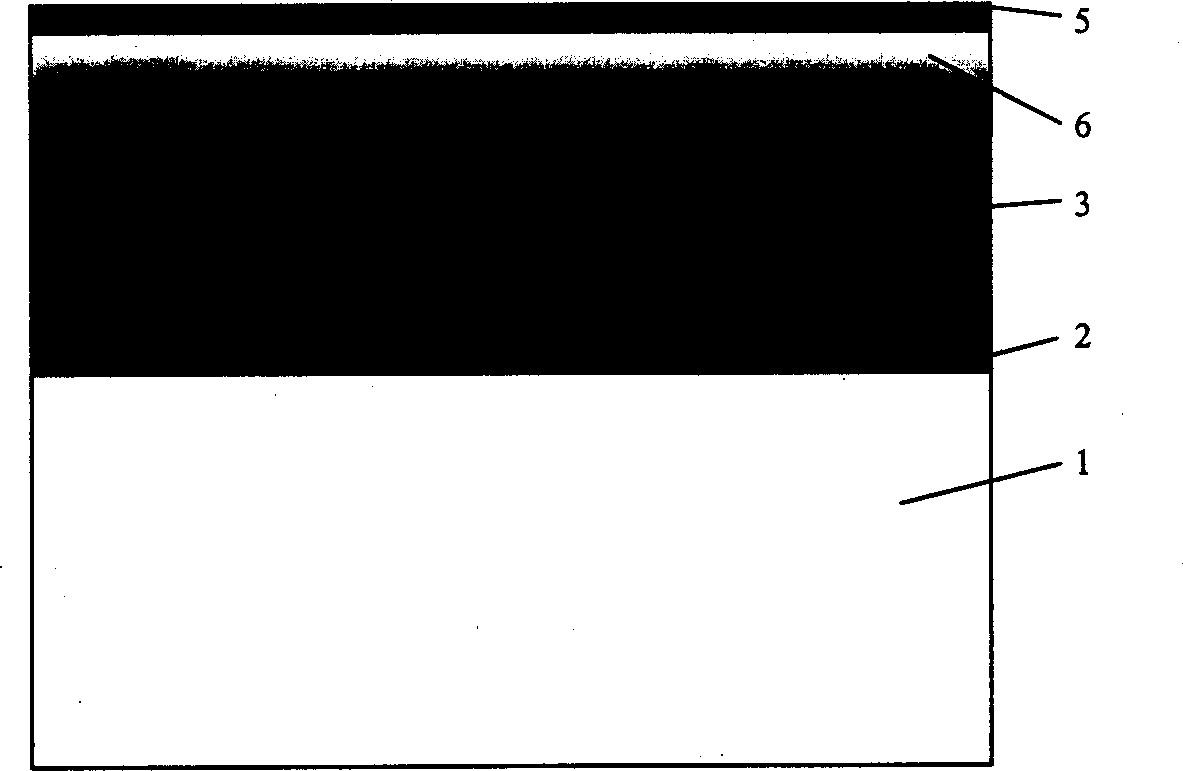

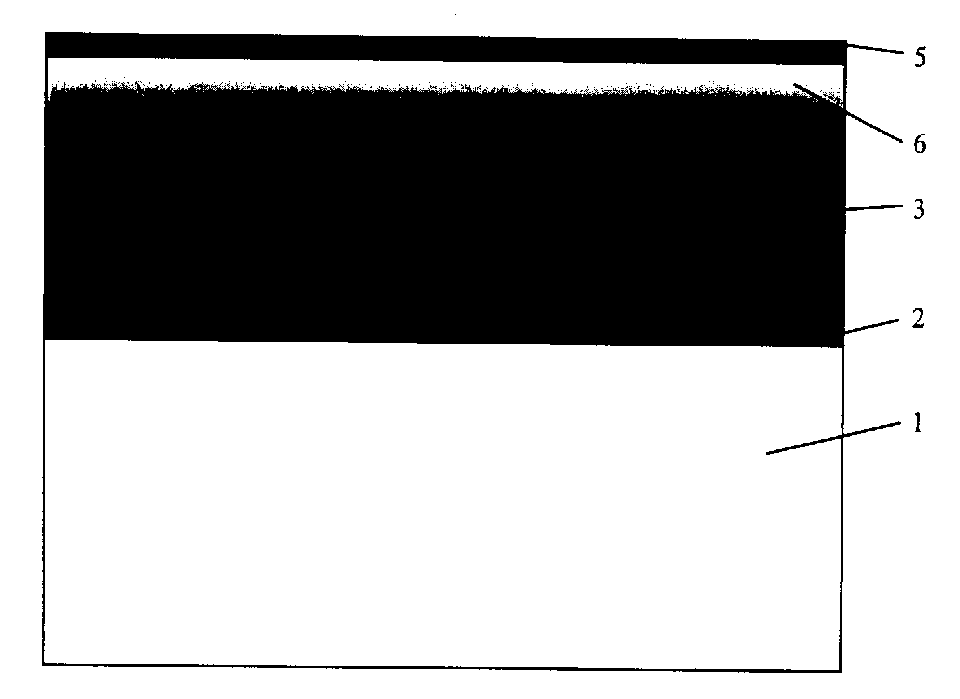

[0018] The electronic transport layer composition graded thin film field emission cathode of the present invention comprises a substrate glass 1 , a lower electrode 2 , a single component insulating layer 3 , a composition graded electron transport layer 6 and an upper electrode 5 .

[0019] In this structure, when a reverse voltage is applied between the upper and lower electrodes, electrons are injected from the upper electrode into the conduction band of the electron transport layer, and finally reach the interface between the electron transport layer and the single-component insulating layer. These electrons cannot enter the single-component insulating layer, but form electrons on the interface state energy level. When a forward voltage is applied between the electrodes, the electrons in the interface state return to the electron transport layer of the graded component and are accelerated there to obtain sufficient kinetic energy. Since the electron affinity of the materia...

Embodiment 1

[0021] The lower electrode uses a metal molybdenum film with a thickness of 100 nanometers, the single-component insulating layer 3 is a tantalum pentoxide film with a thickness of 400 nanometers, and the composition-graded electron transport layer 6 adopts 100 nanometers of semiconductor zinc sulfide with high electron affinity to low electron affinity. Potential for semiconducting magnesium sulfide graded transition films. The upper electrode 5 adopts a semiconductor hafnium nitride film with a thickness of 10 nanometers and a low work function. If the ratio of the emission current to the current between the electrodes is defined as the emissivity, at a driving voltage of 80 volts, a field emission current with an emissivity greater than 0.5% is obtained.

Embodiment 2

[0023] The lower electrode uses a metal chromium film with a thickness of 100 nanometers, the single-component insulating layer 3 is a tantalum pentoxide film with a thickness of 400 nanometers, and the composition-gradient electron transport layer 5 adopts a film with a gradual transition from zinc sulfide to magnesium sulfide with a thickness of 50 nanometers. The upper electrode 5 adopts a metal silver film with a thickness of 10 nanometers. Under a driving voltage of 120 volts, a field emission current with an emissivity greater than 0.5% is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com