Multi-pole multi-electron injection radiation source based on cold cathode

A multi-electron injection and radiation source technology, applied in the field of longitudinal multi-pole multi-electron injection radiation sources, can solve the problems of limited energy absorbed by modulated electron injection, fast electron injection speed, difficult manufacturing and assembly, etc. The effect of improving the interaction efficiency, improving the injection-wave interaction efficiency, and reducing the emission voltage requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

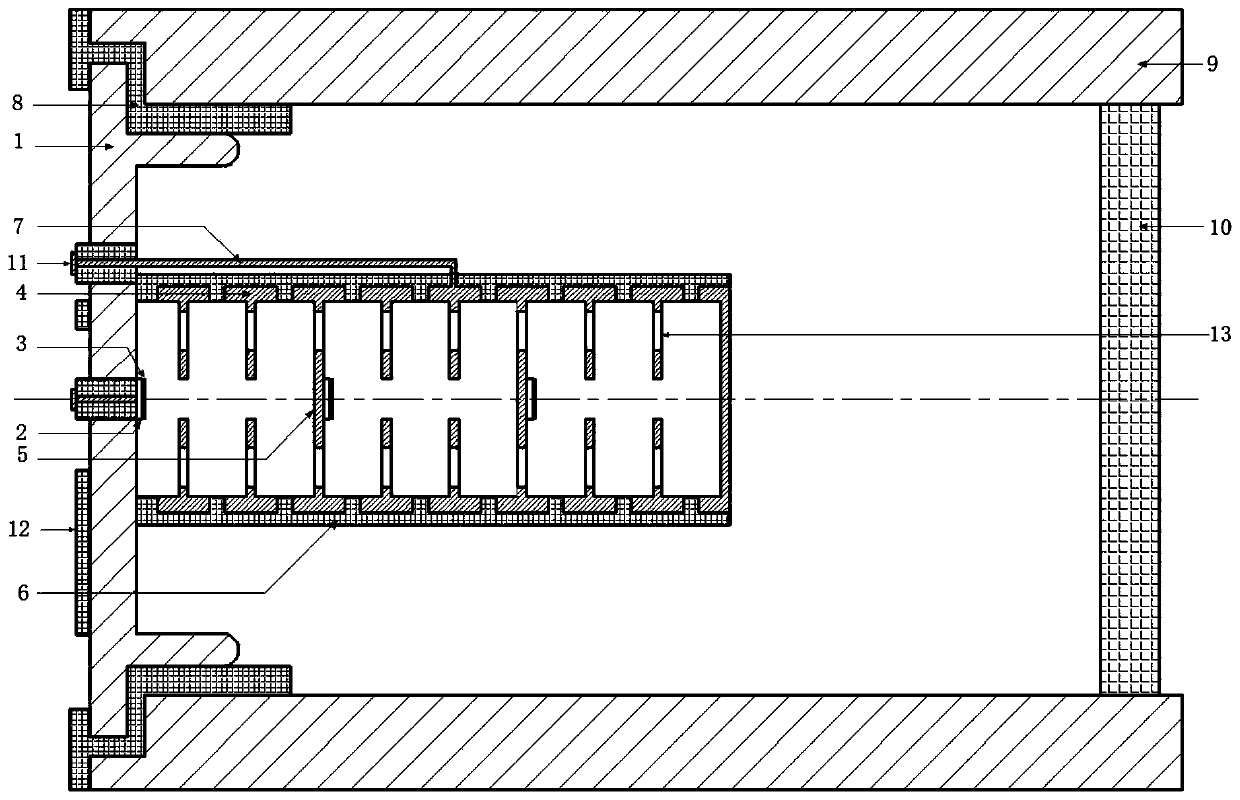

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

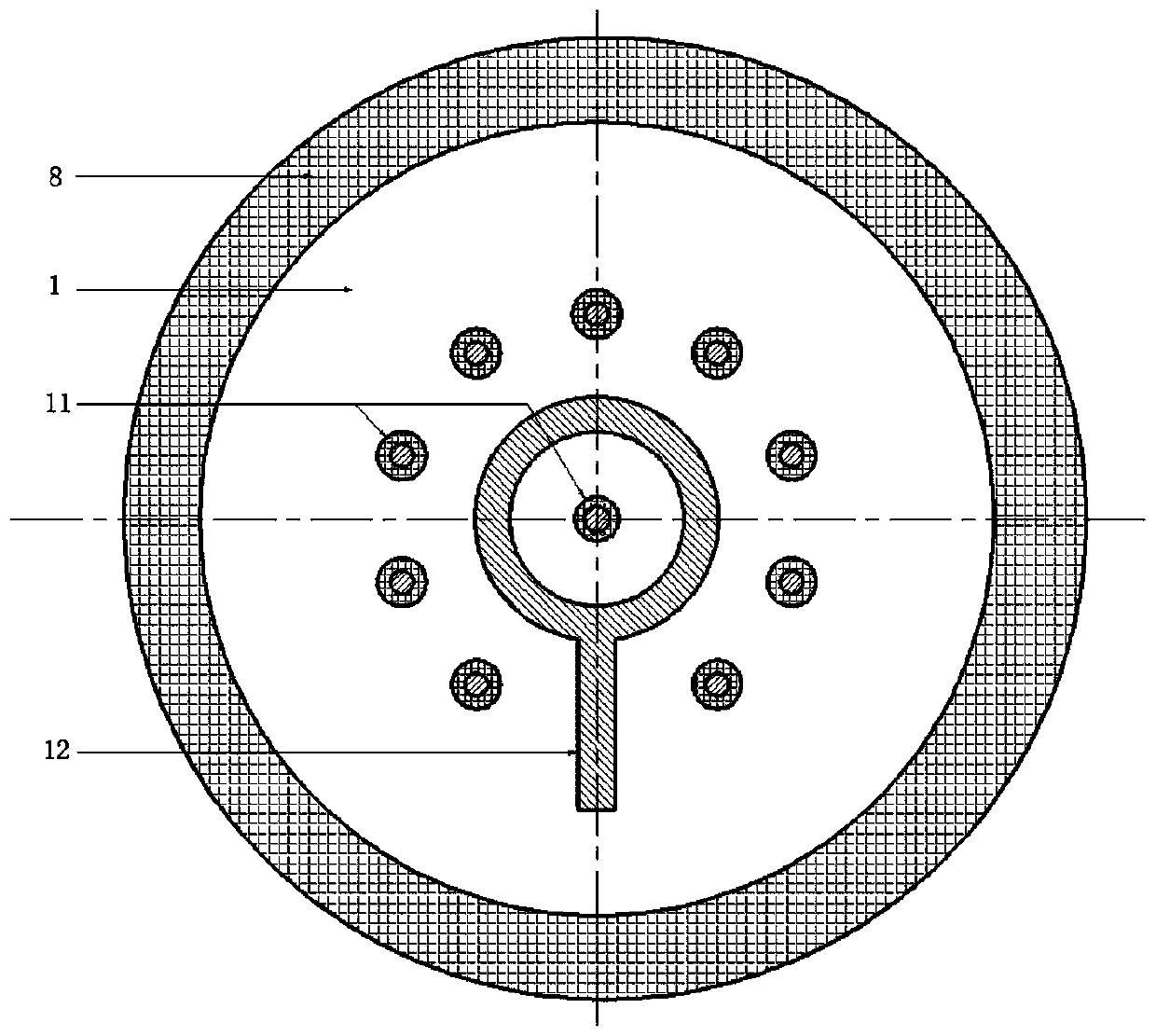

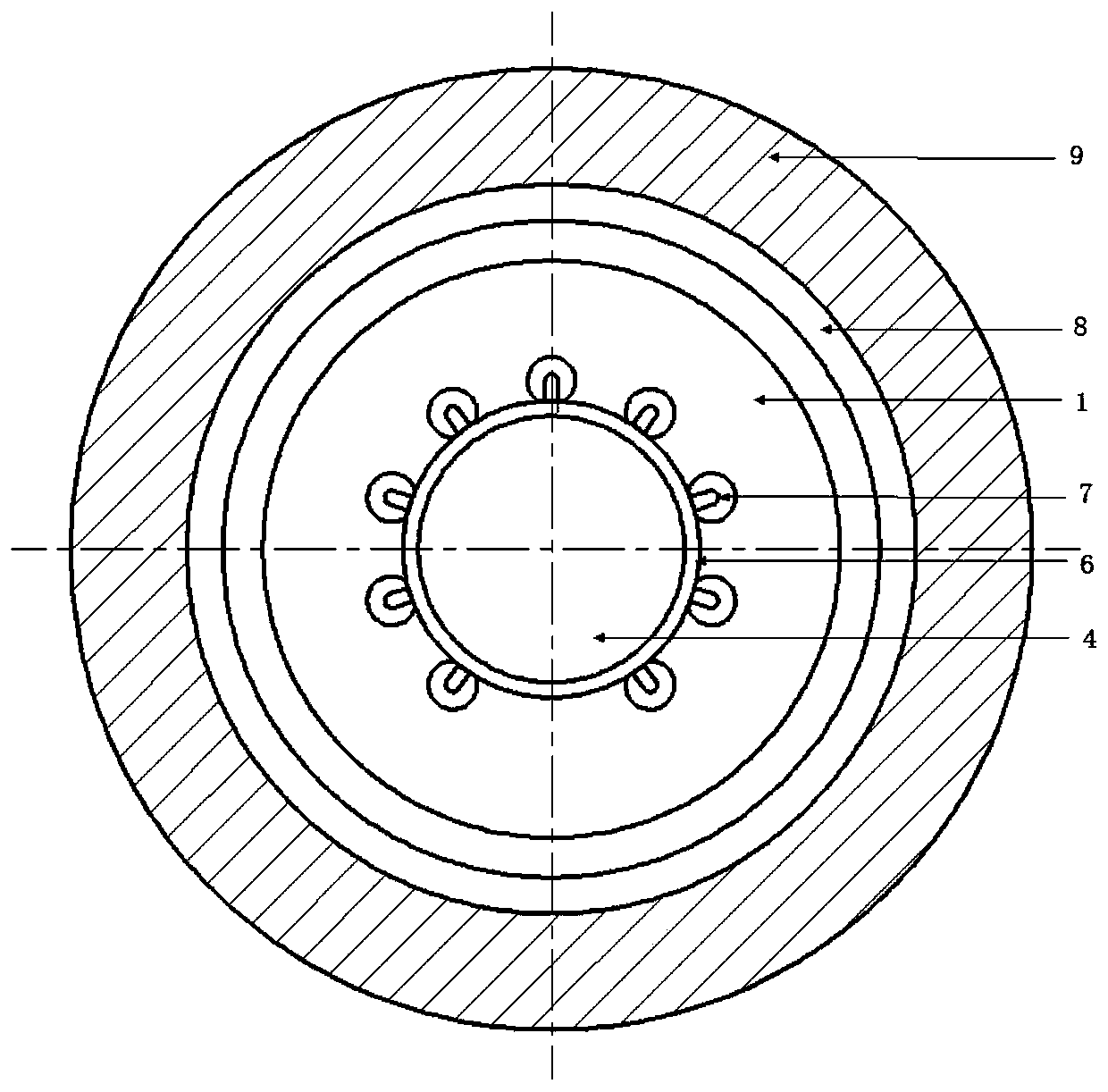

[0029] This embodiment provides a multi-pole and multi-electron injection radiation source based on cold cathode, its structure is as follows figure 1 ~As shown in 4; specifically include: cathode baffle, radiation source core, feed system, metal casing and output window; among them,

[0030] The material of the cathode baffle 1 is metal, the center is connected to the radiation source core, and the periphery is connected to one end of the metal shell 9 through an insulator 8, and the output window is packaged at the other end of the metal shell 9;

[0031] The feed system includes a metal wire 7, an electrode 12 and an insulating medium. There are several small holes on the cathode baffle, and one end of the metal wire passes through the small hole to connect the radiation source core and the other end to the electrode. The metal wire and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com