Patents

Literature

65results about "Vacuum tube vessels/containers/shields" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

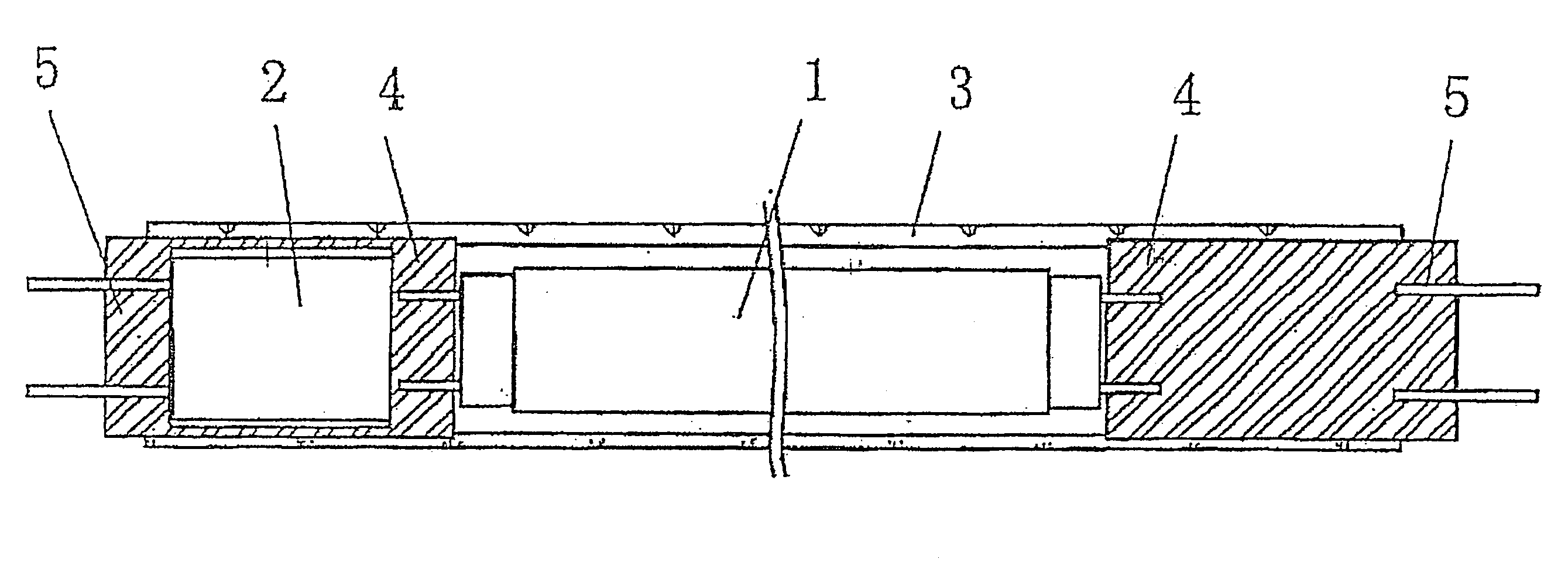

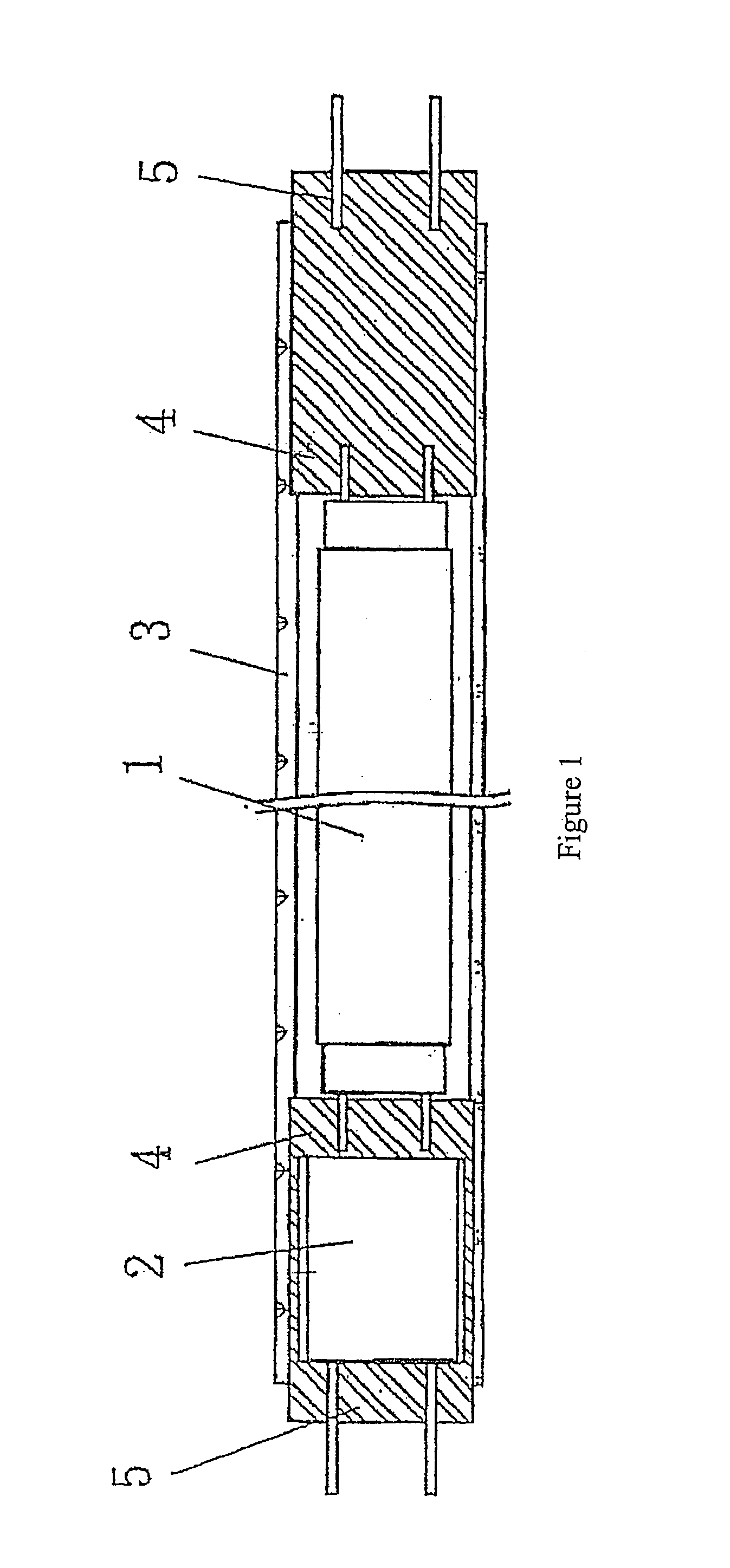

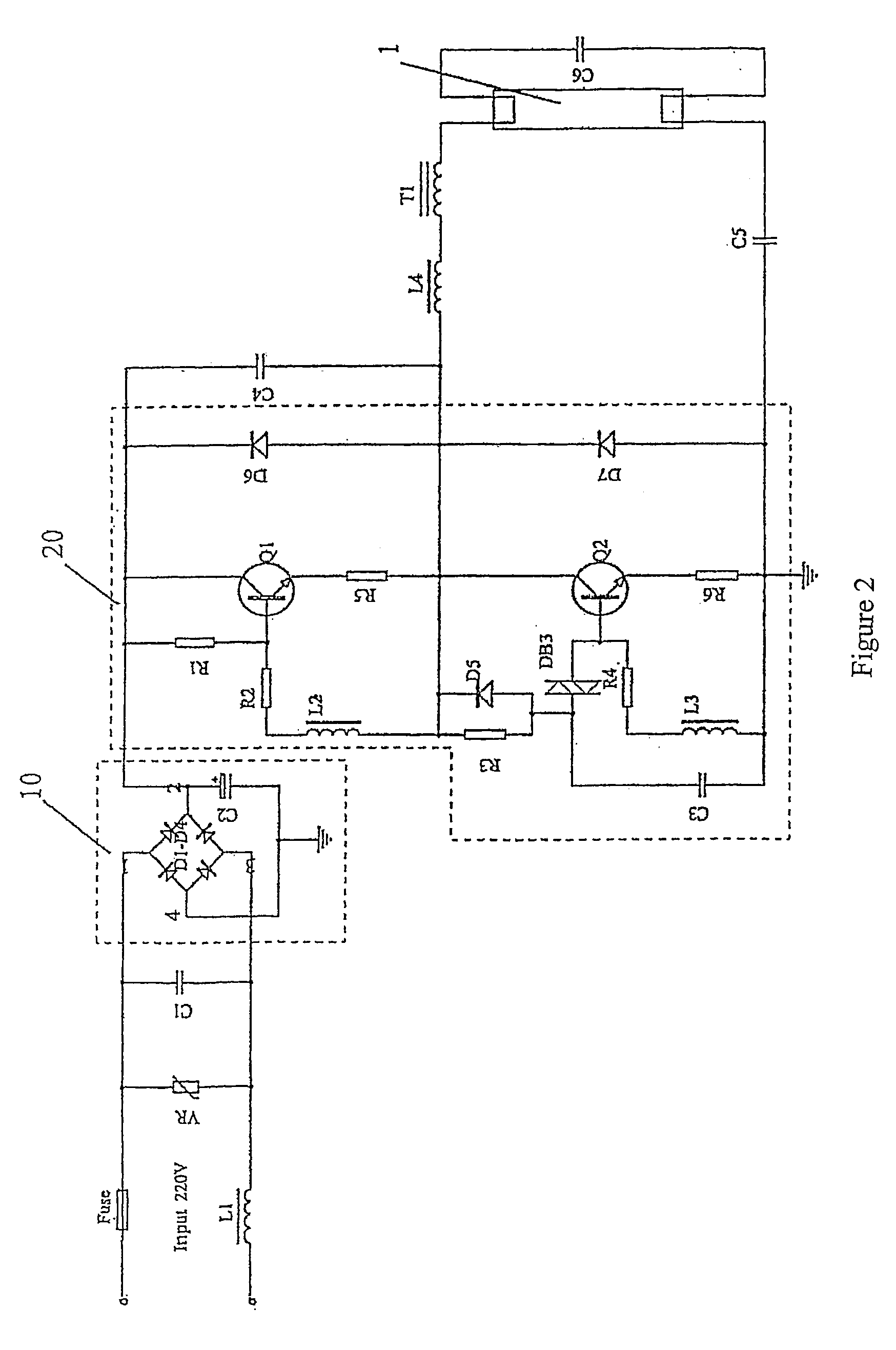

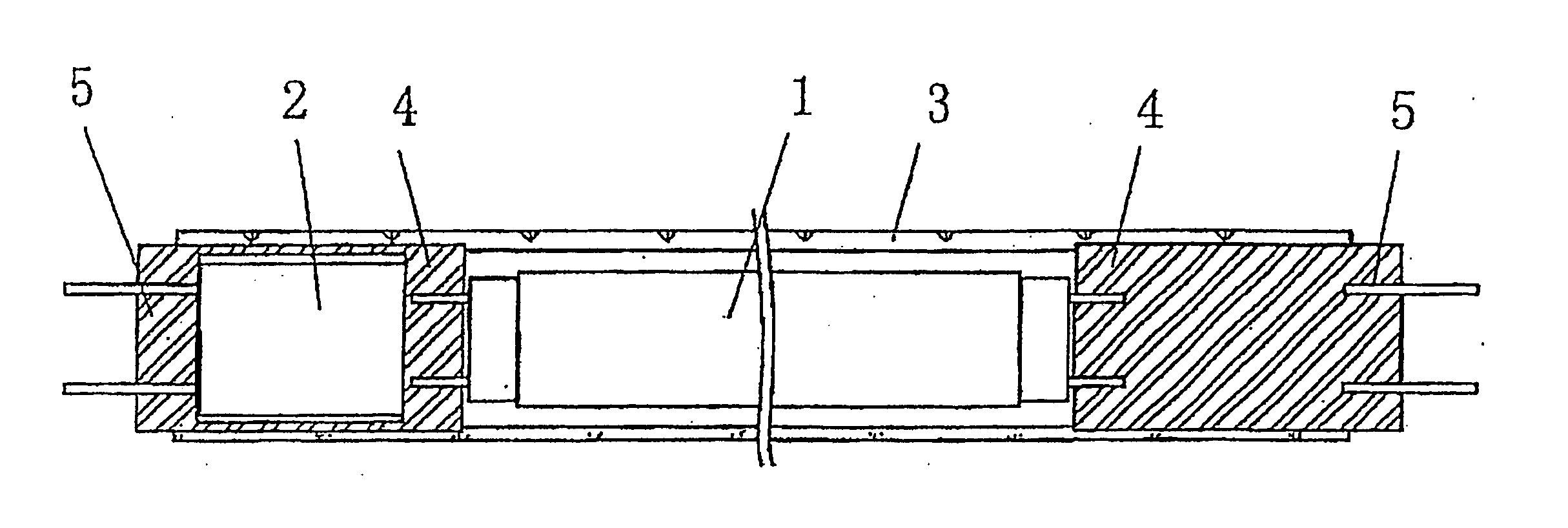

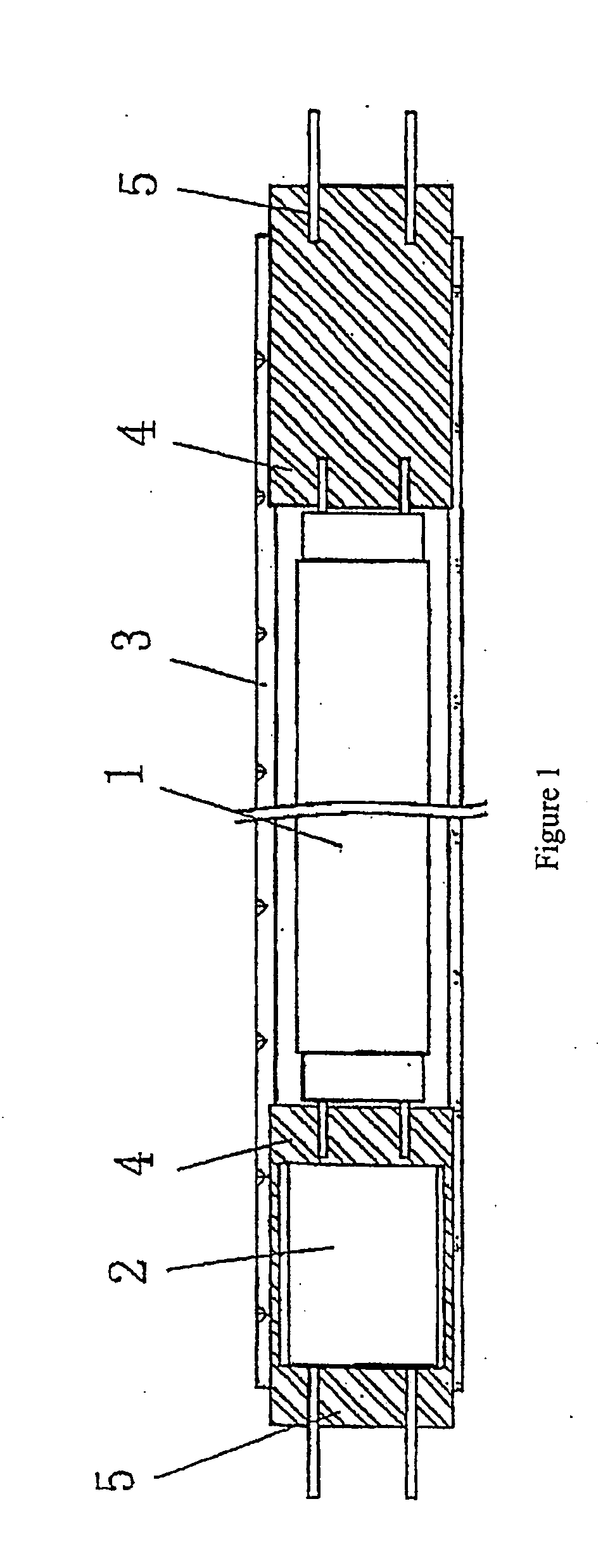

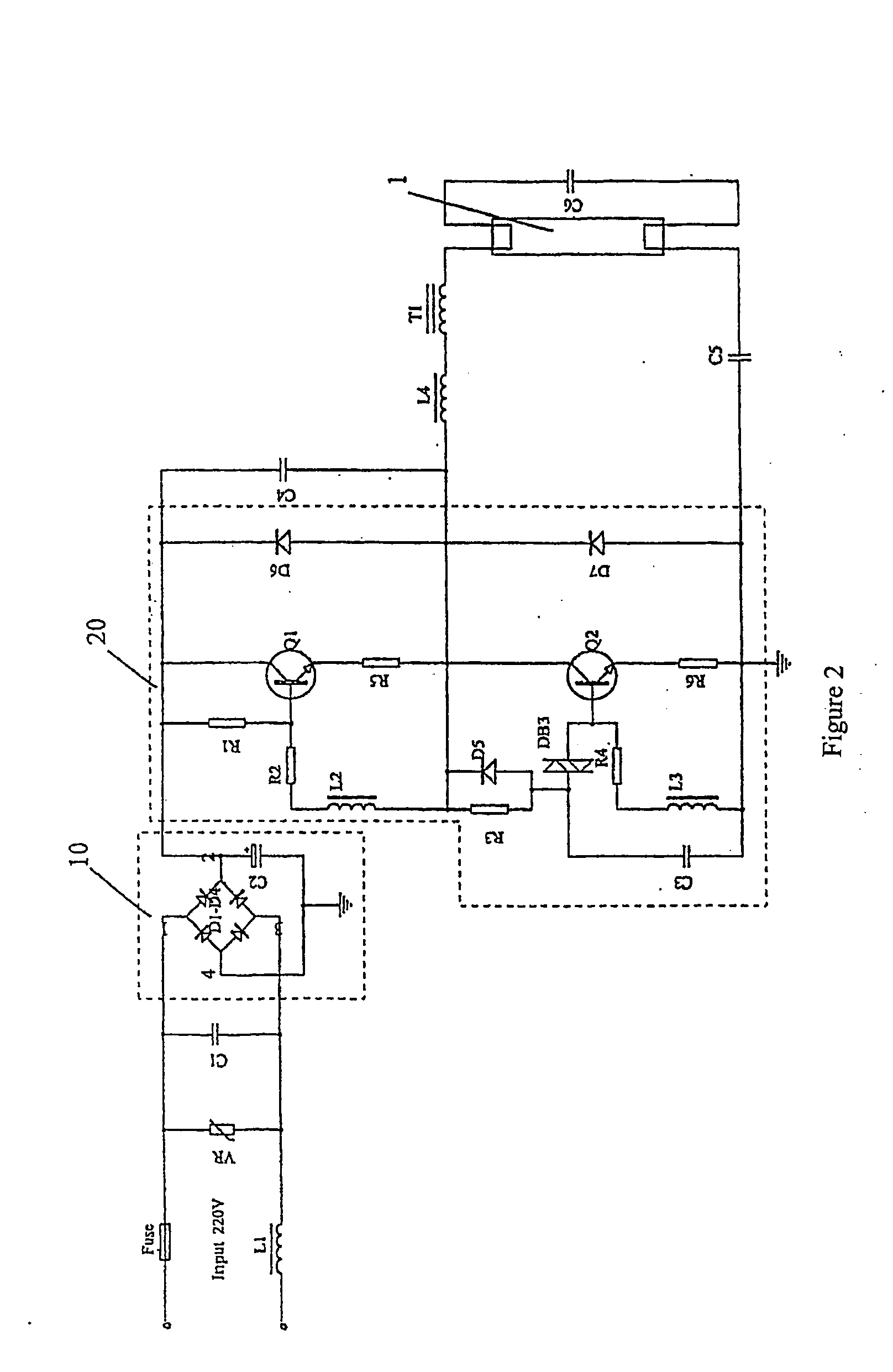

Fluorescent lamp tube having integrated electronic ballast

InactiveUS7083309B2Simply replacedOvercomes shortcomingLighting support devicesElongate light sourcesPower factorColor rendering index

A new fluorescent lamp comprises a lamp tube and an electronic ballast, it is characterized in that it is provided with an outer tube, there are respectively an outer plug at both ends of the outer tube, in which inserts a socket for the lamp tube. The electronic ballast is between the outer plug and the socket for the lamp tube at one end, said lamp tube is disposed between two sockets for the lamp tube. There are advantages as follows: an urgent lighting, the electronic ballast and the compact lamp tube are integrated as one whole; it is convenient for mounting and exchanging, a cost for mounting is greatly reduced; it is possible for repacking to maintain an original means, to reduce a contamination of waste; its weight is light; its power factor is high, more than 95%, it is economical in power, a cost for transporting is low; the color rendering index (CRI) is more than 80%; it is ignited immediately after it is turned on, it does not flash; it is applied to lamps having deferent power; the life of the lamp tube is prolonged by 50%; its output brightness is higher than existing lamps by twice or more; the lamp tube still steadily operates when a power supply is unexpected to be shut off, which reduces accident cases; the whole distortion of a resonant wave becomes smaller than 30%.

Owner:SYNERGY LIGHTING GRP LTD

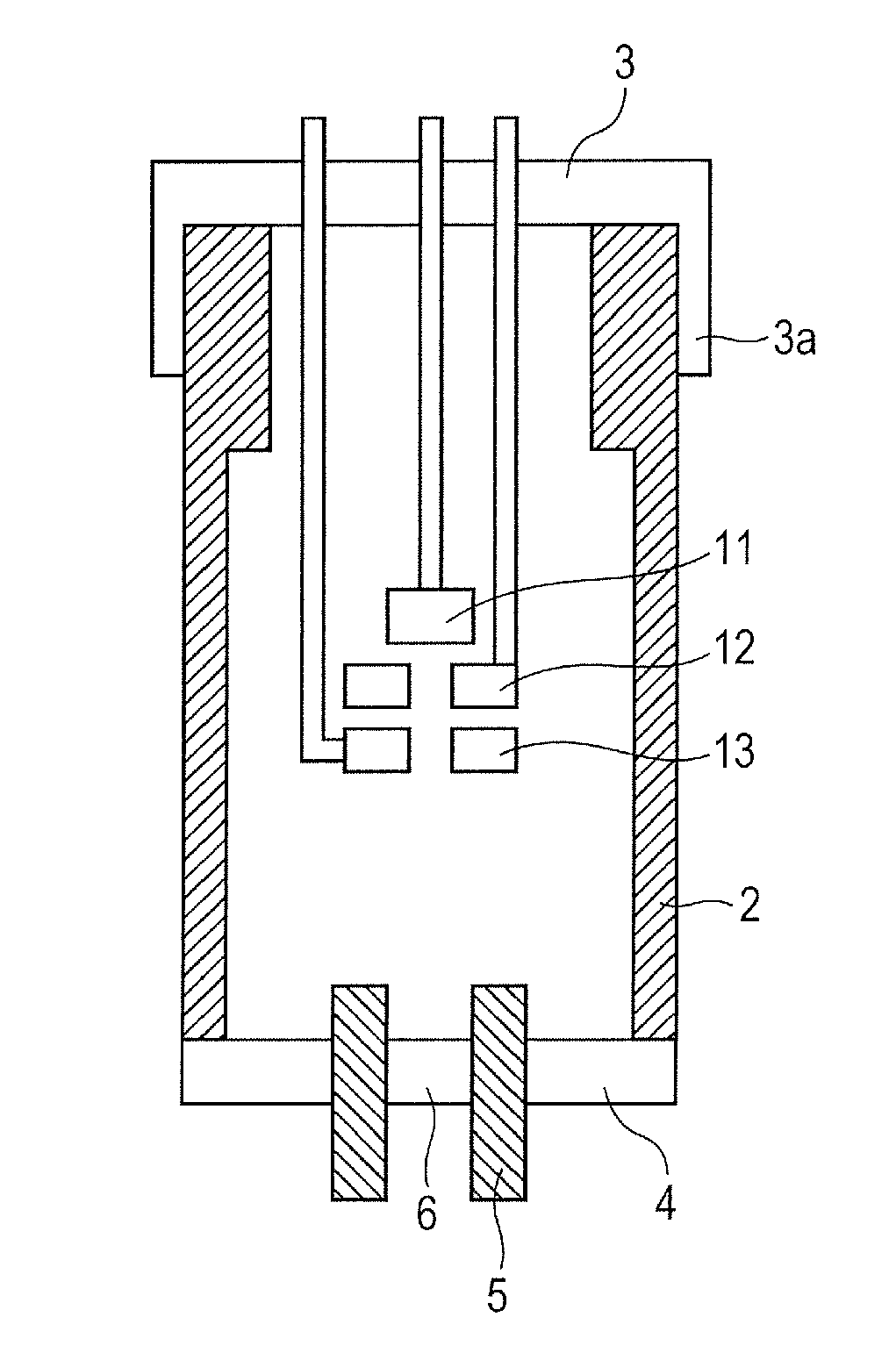

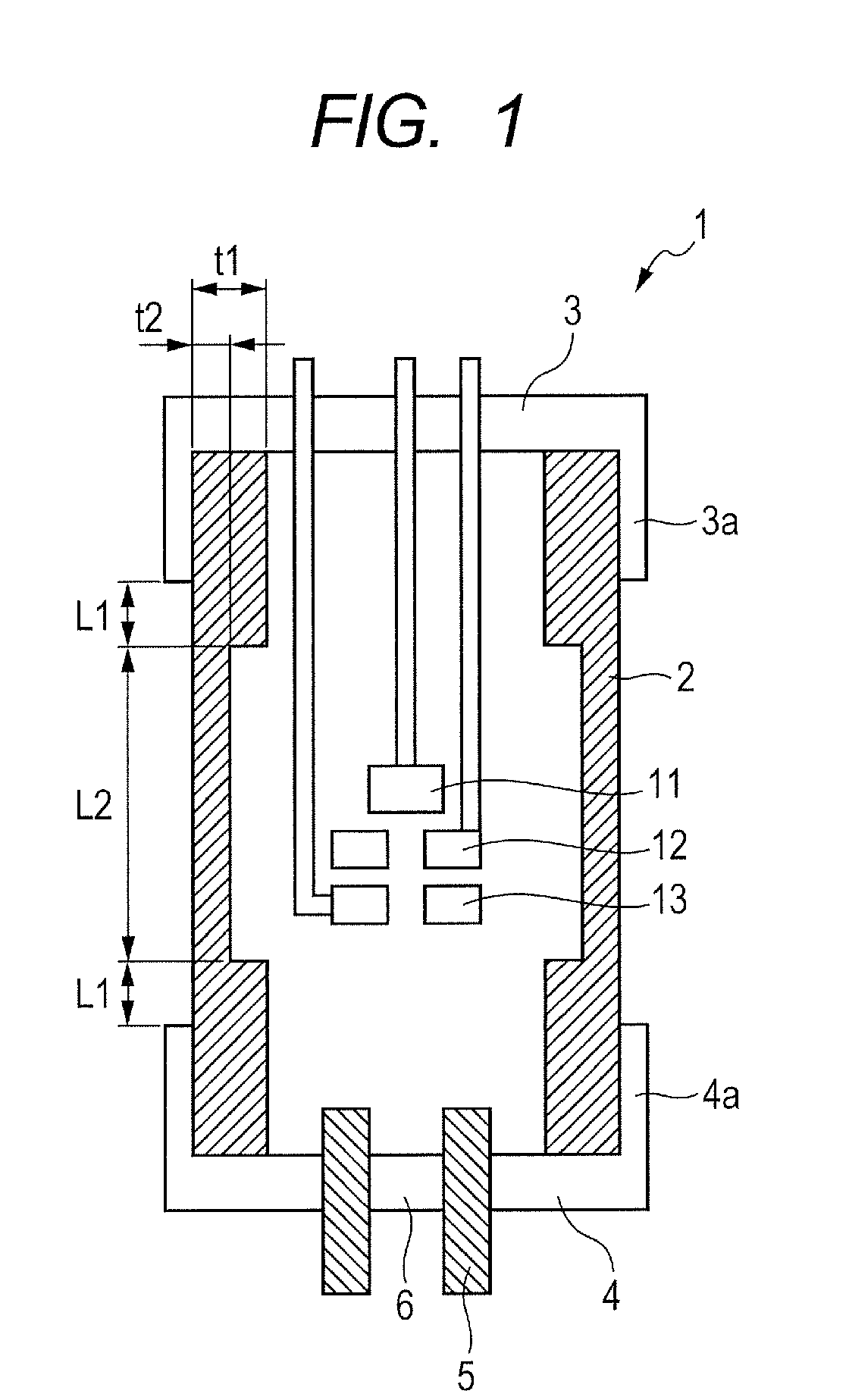

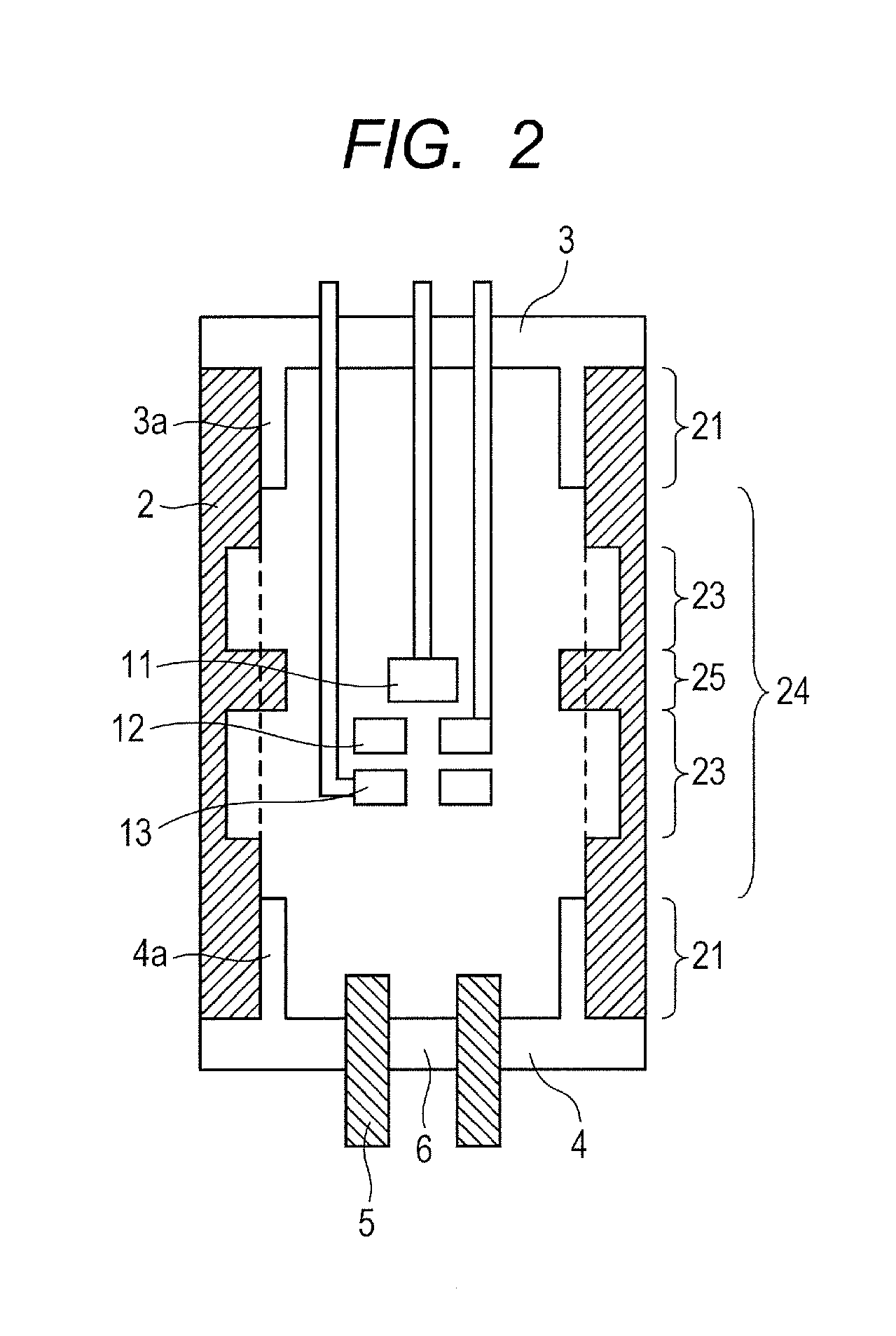

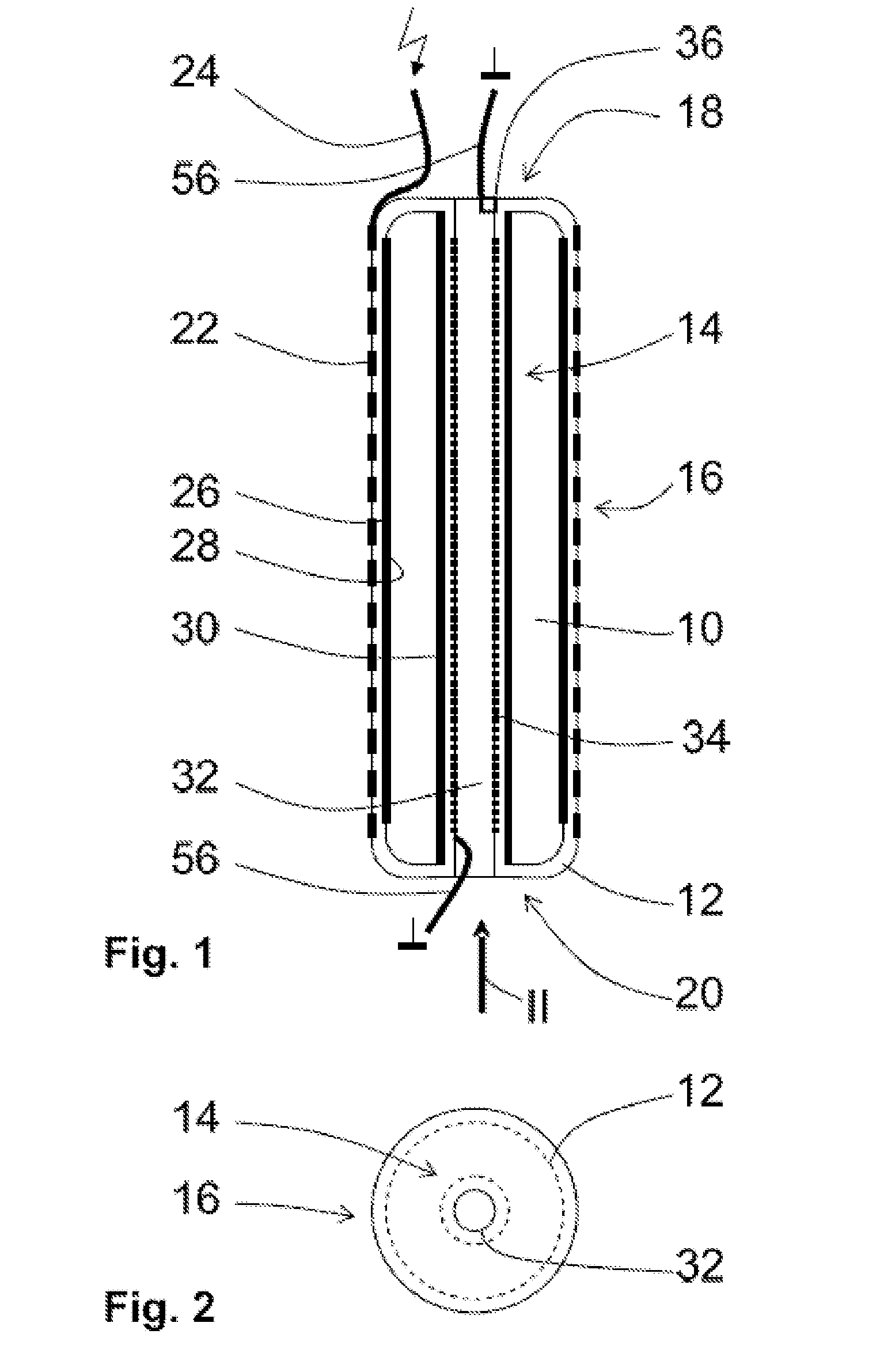

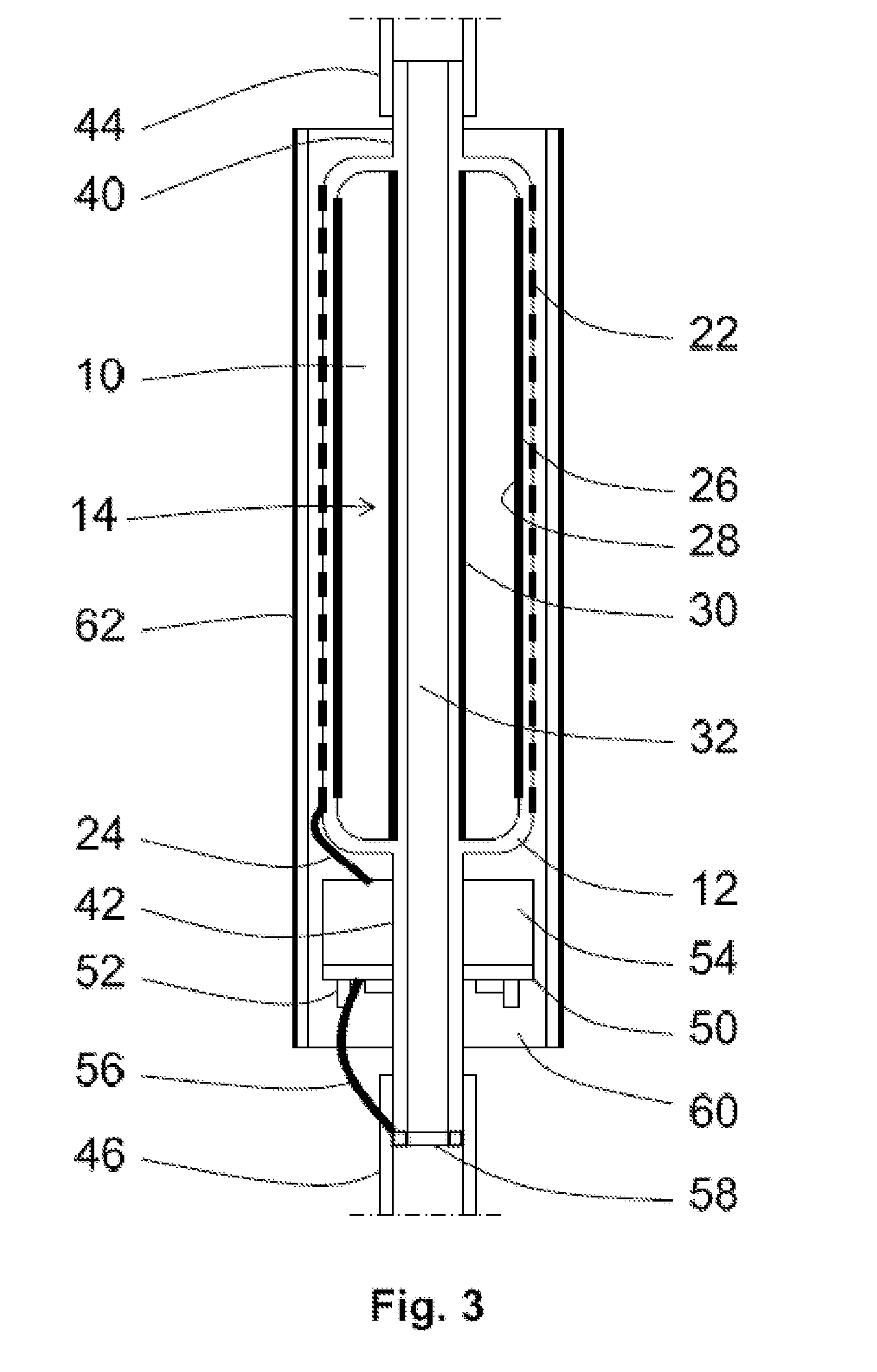

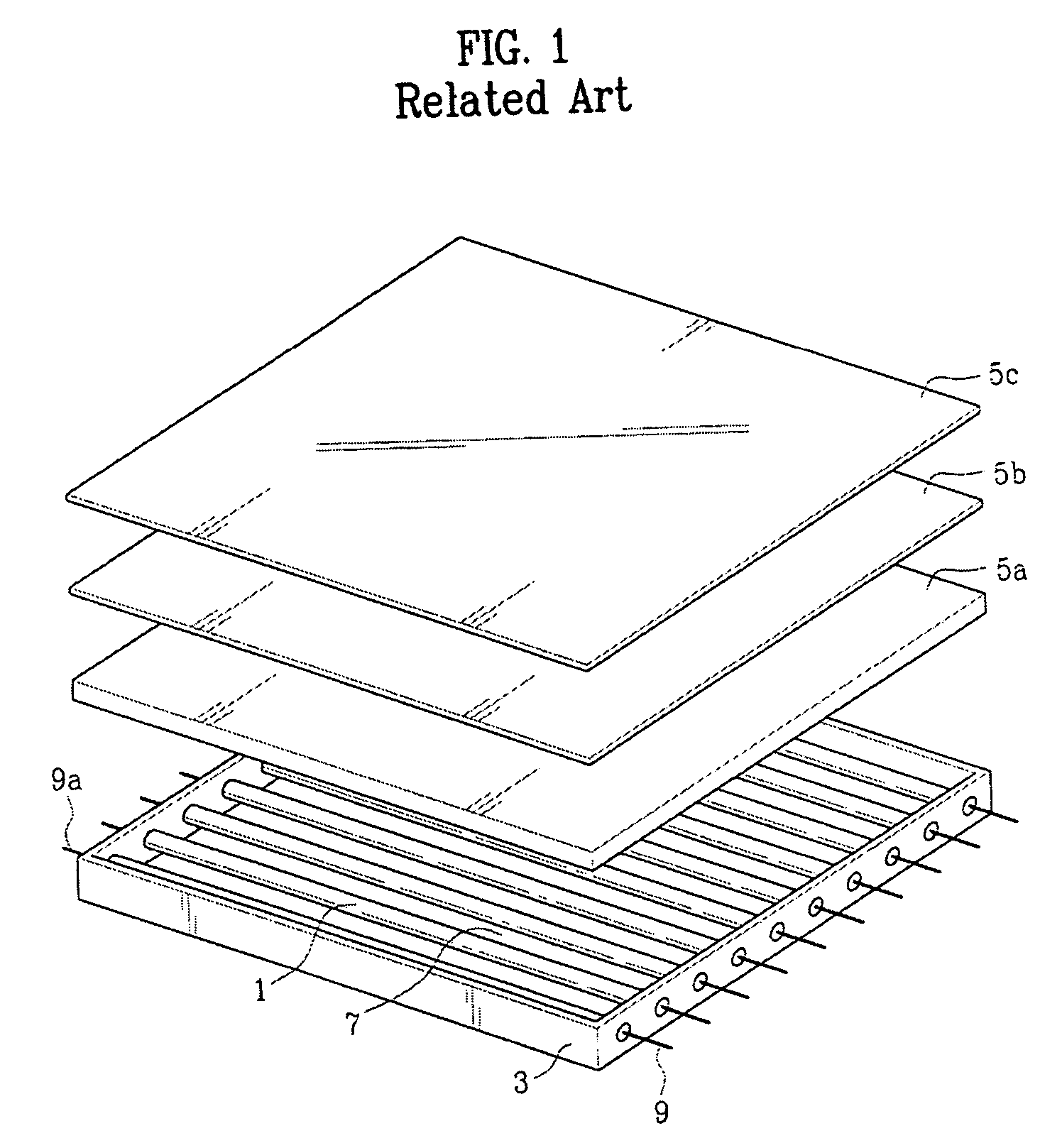

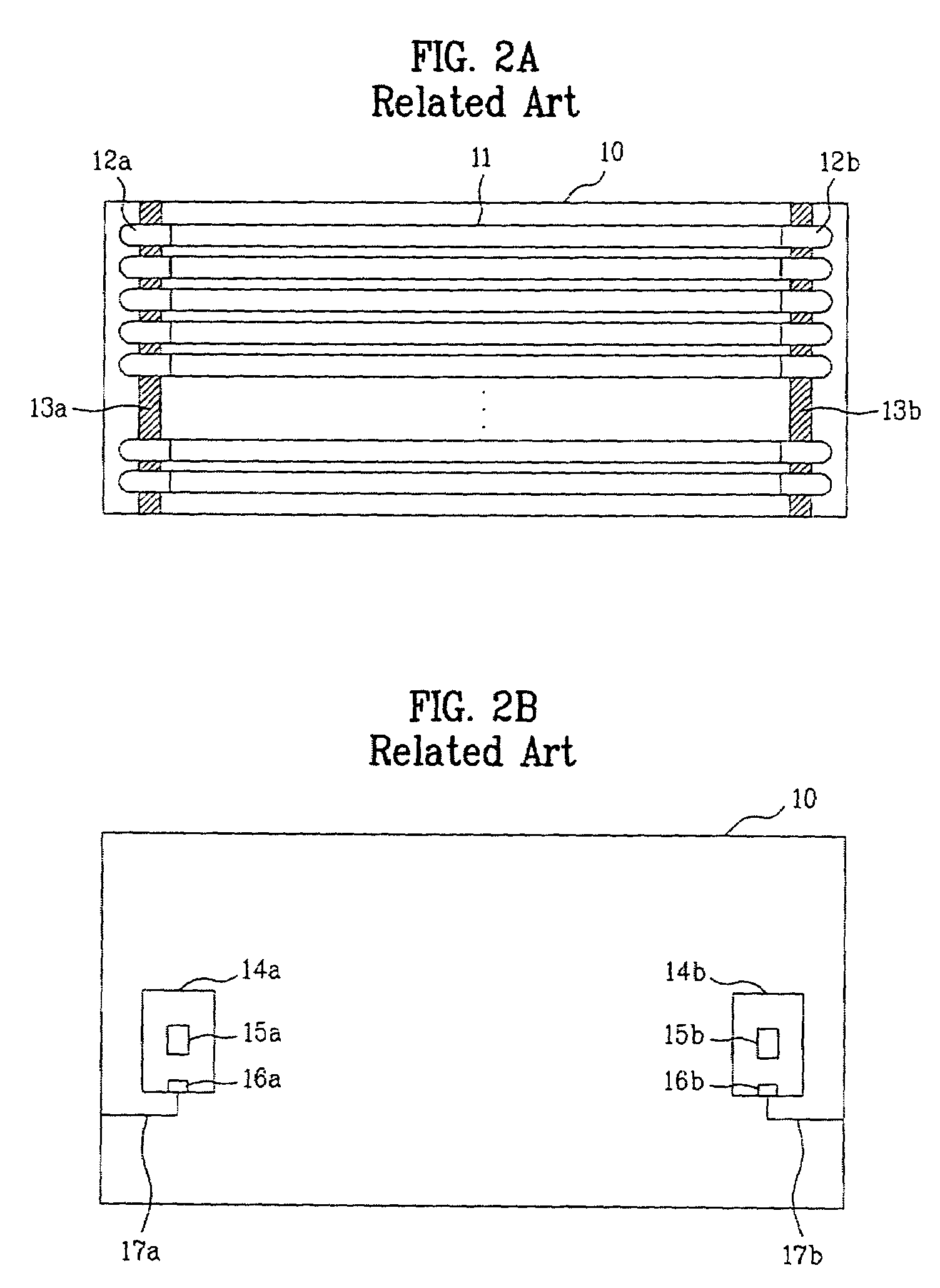

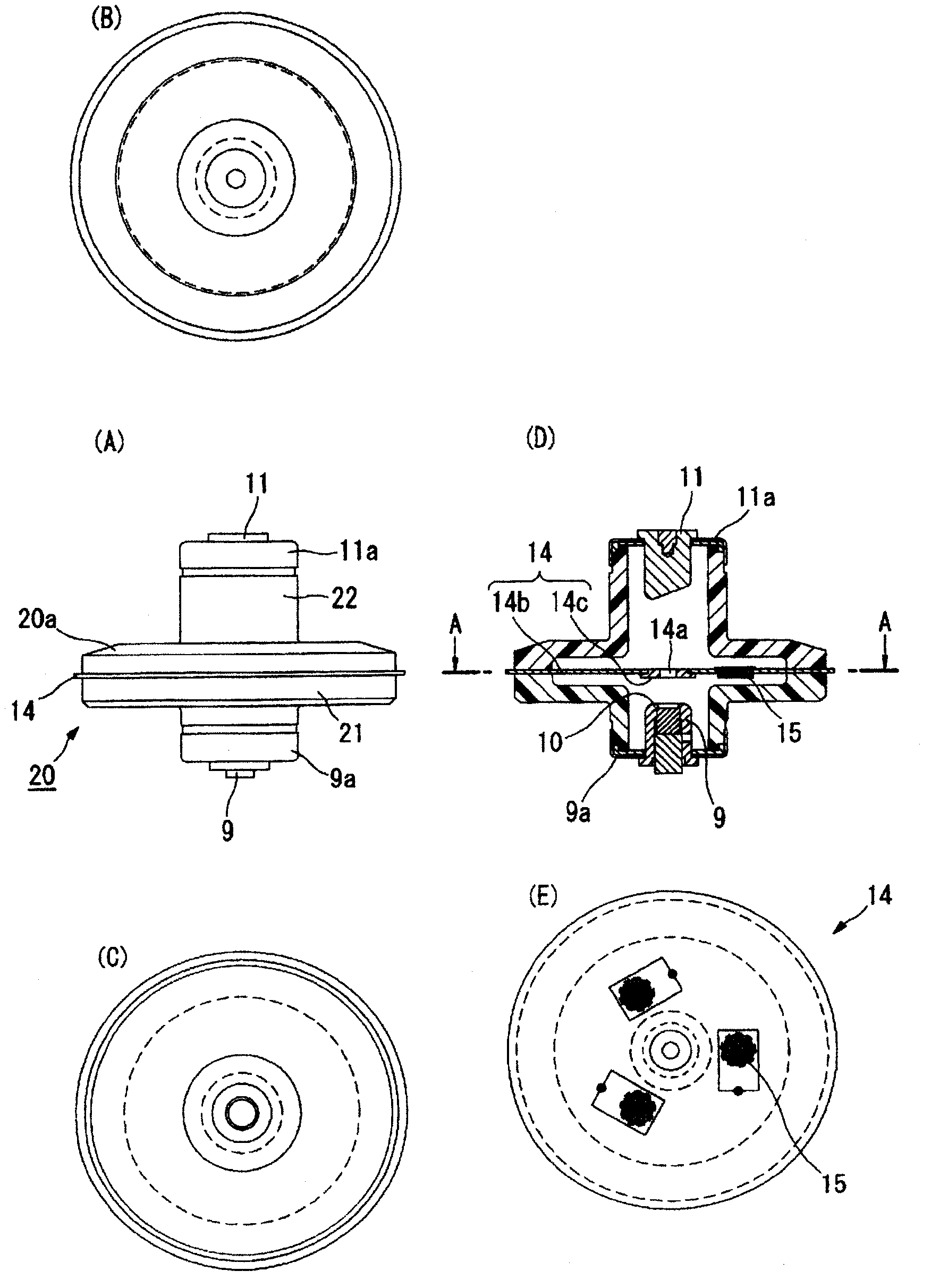

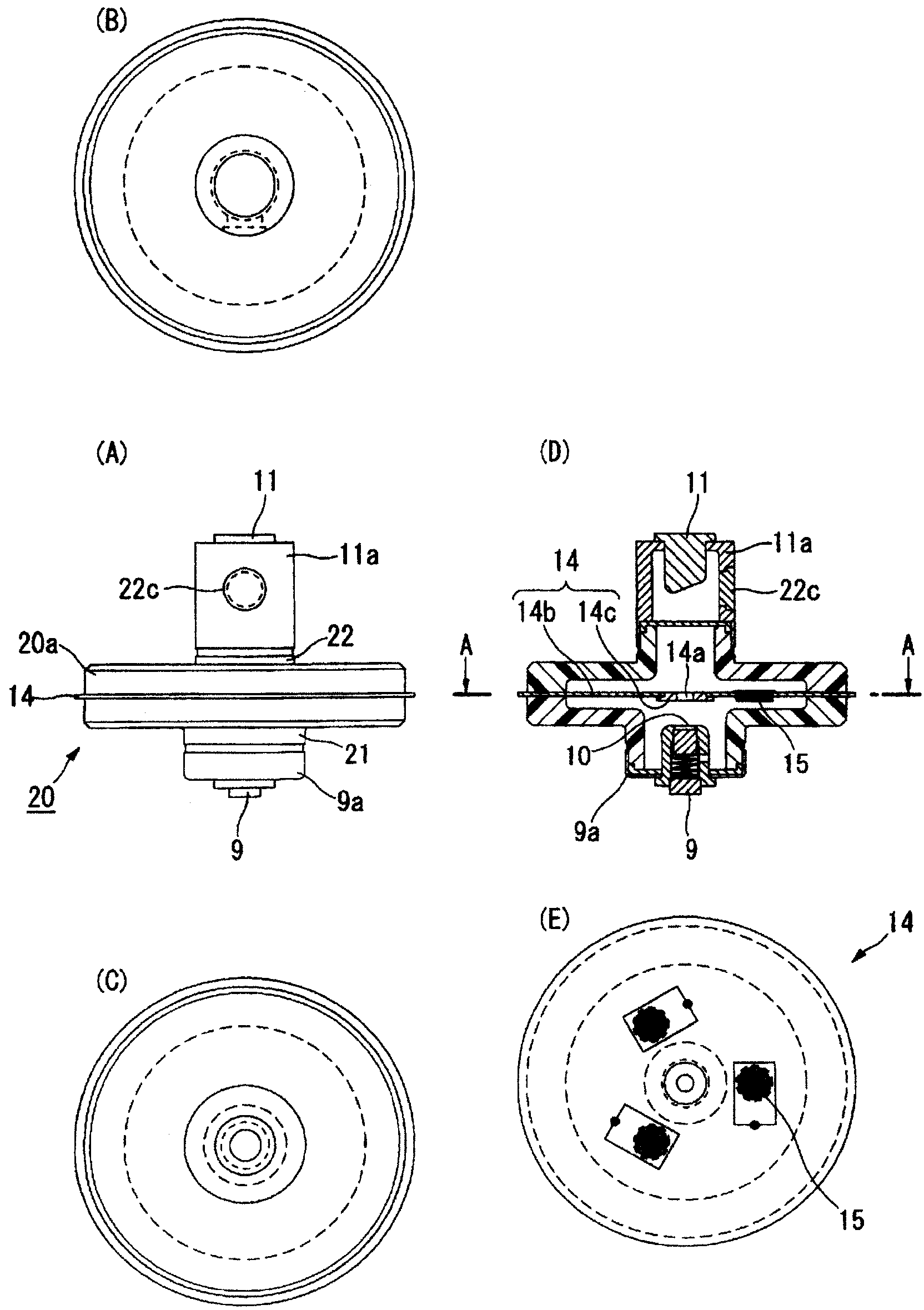

Fluorescent lamp for cold environments

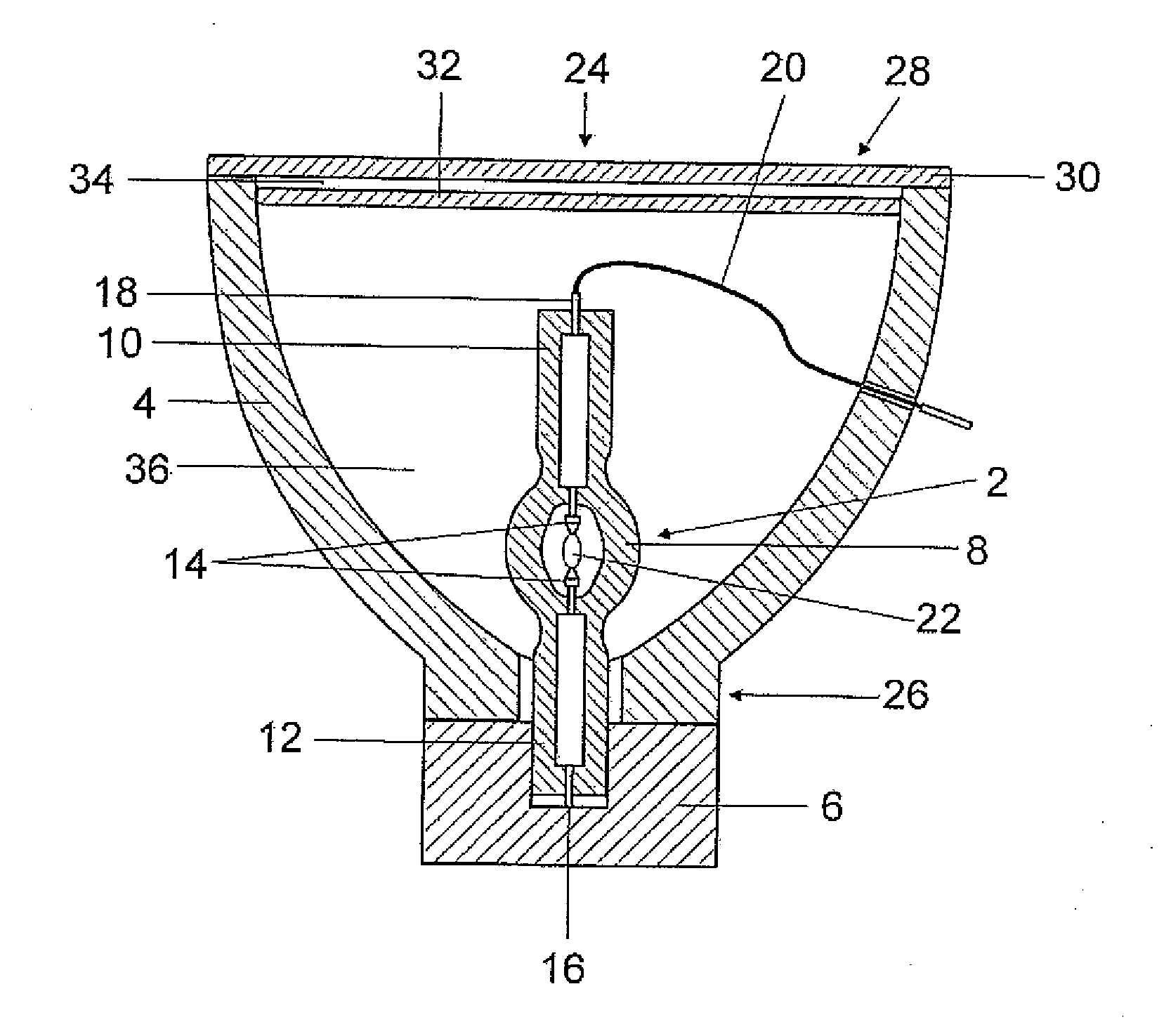

InactiveUS8456075B2Reduce heat transferLow thermal conductivityElectrode assembly support/mounting/spacing/insulationVacuum tube vessels/containers/shieldsEngineeringFluorescent lamp

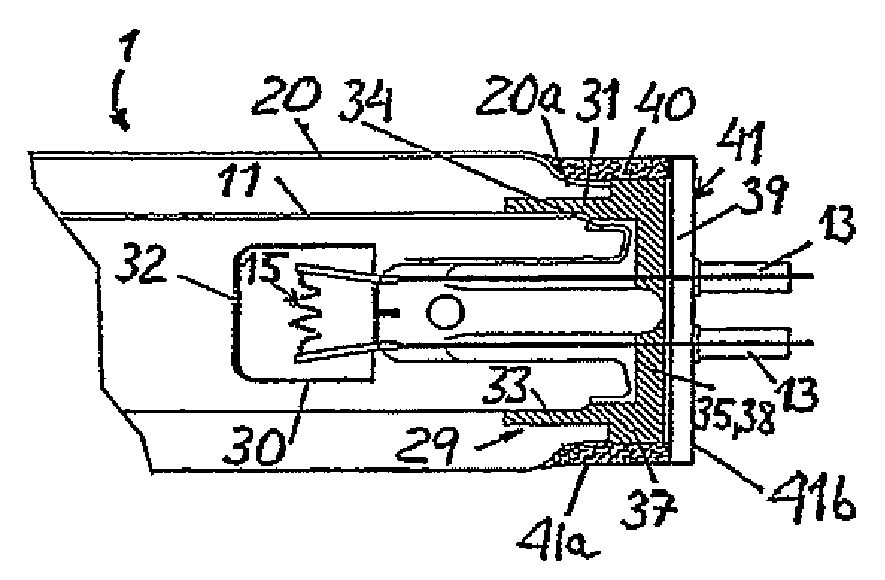

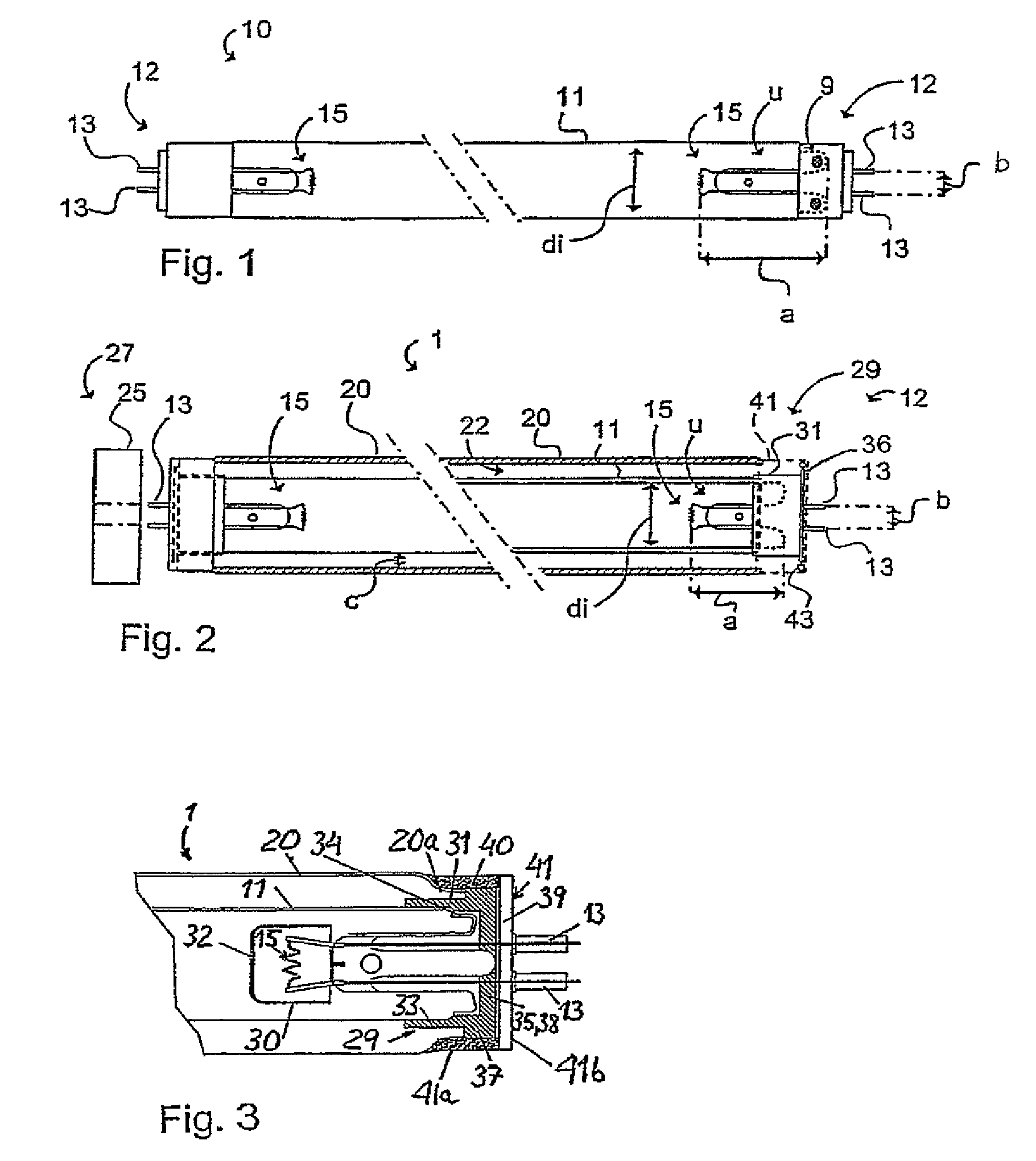

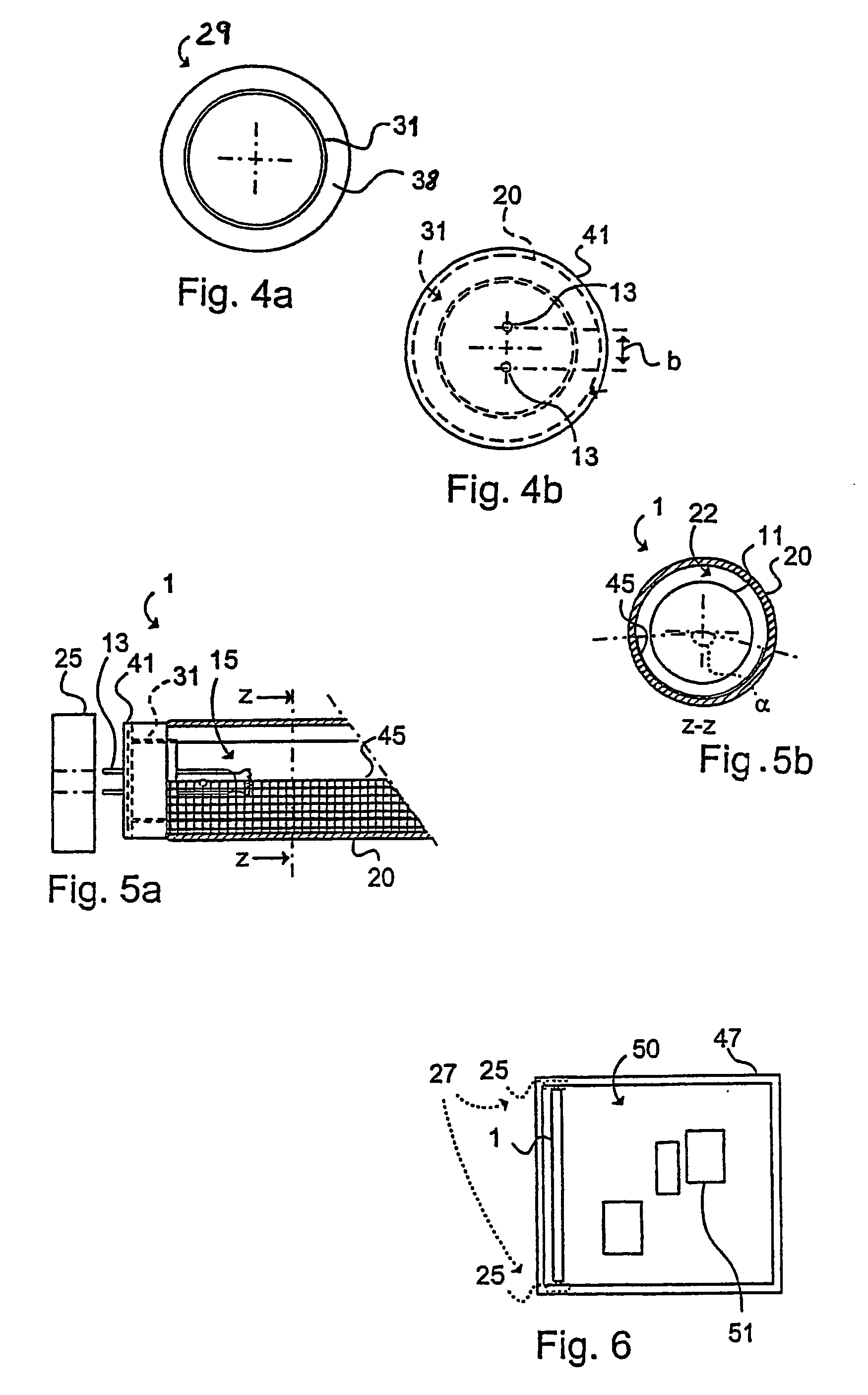

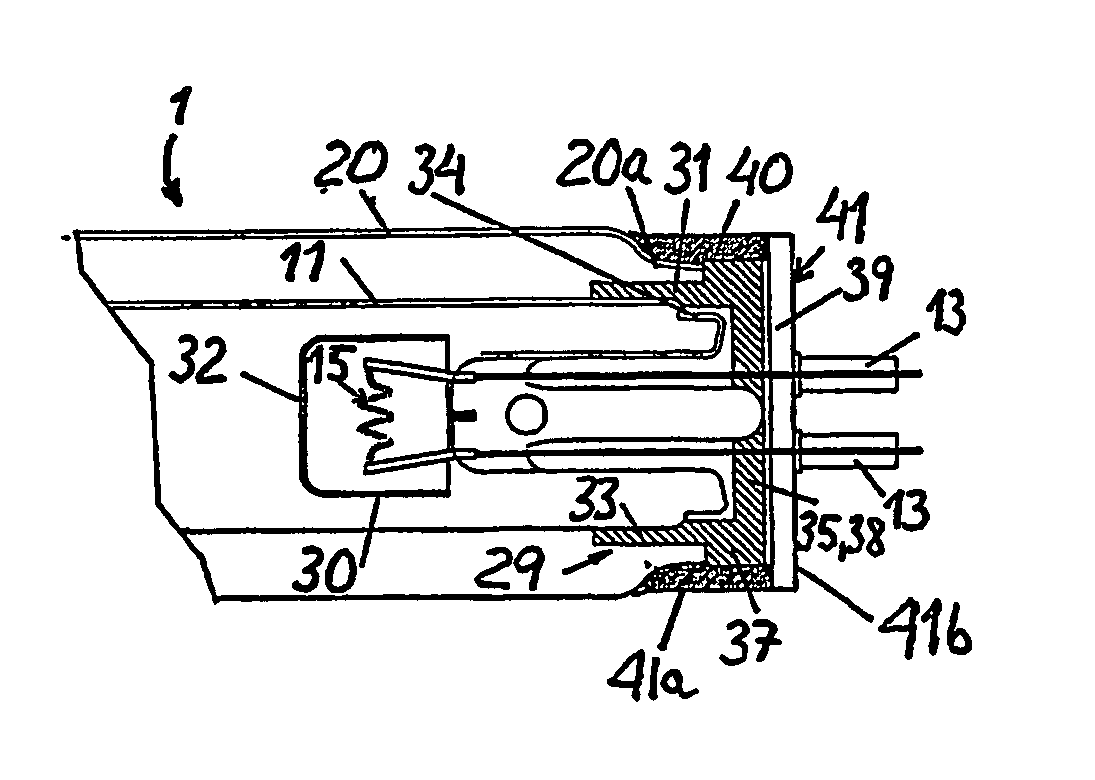

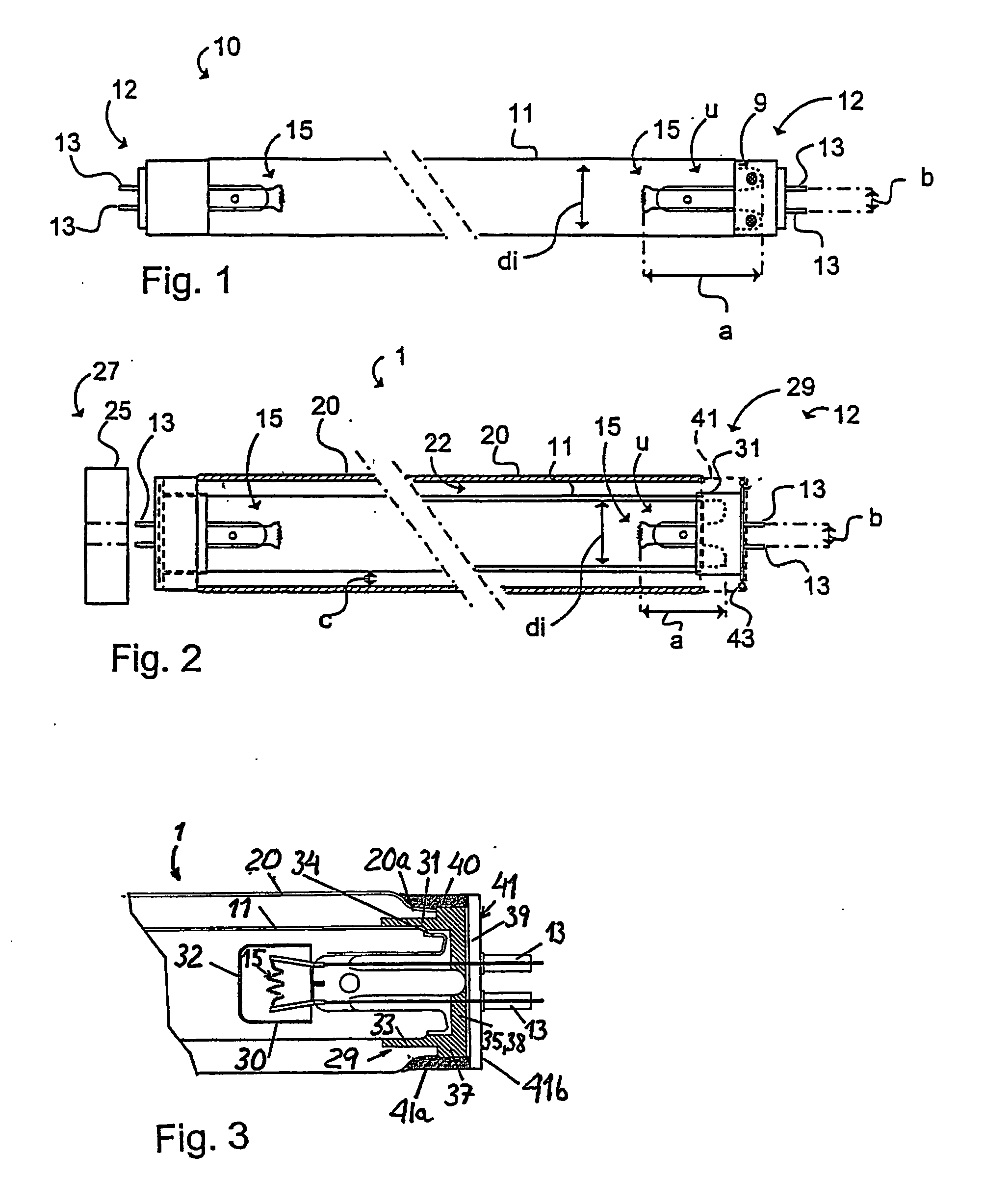

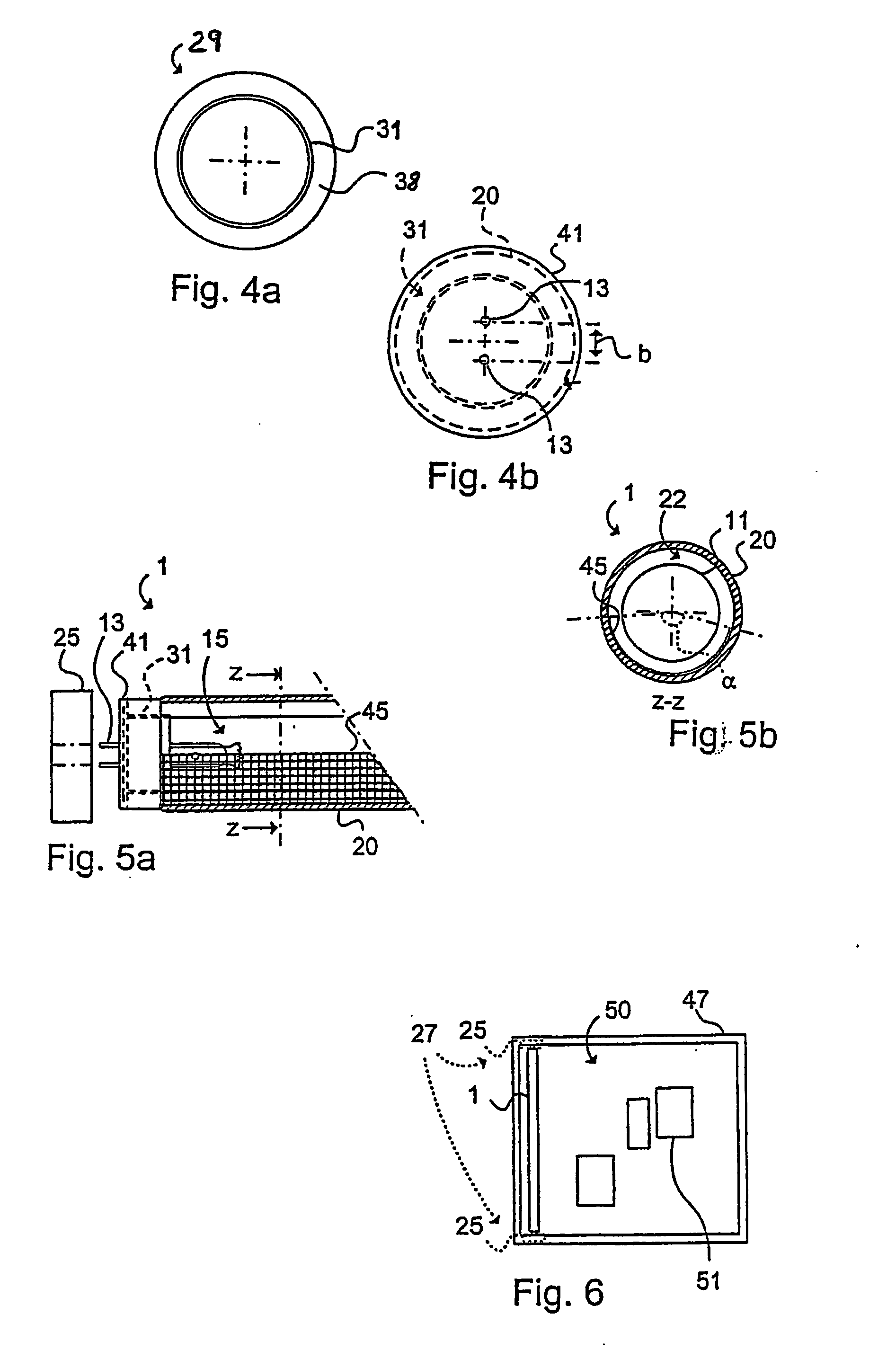

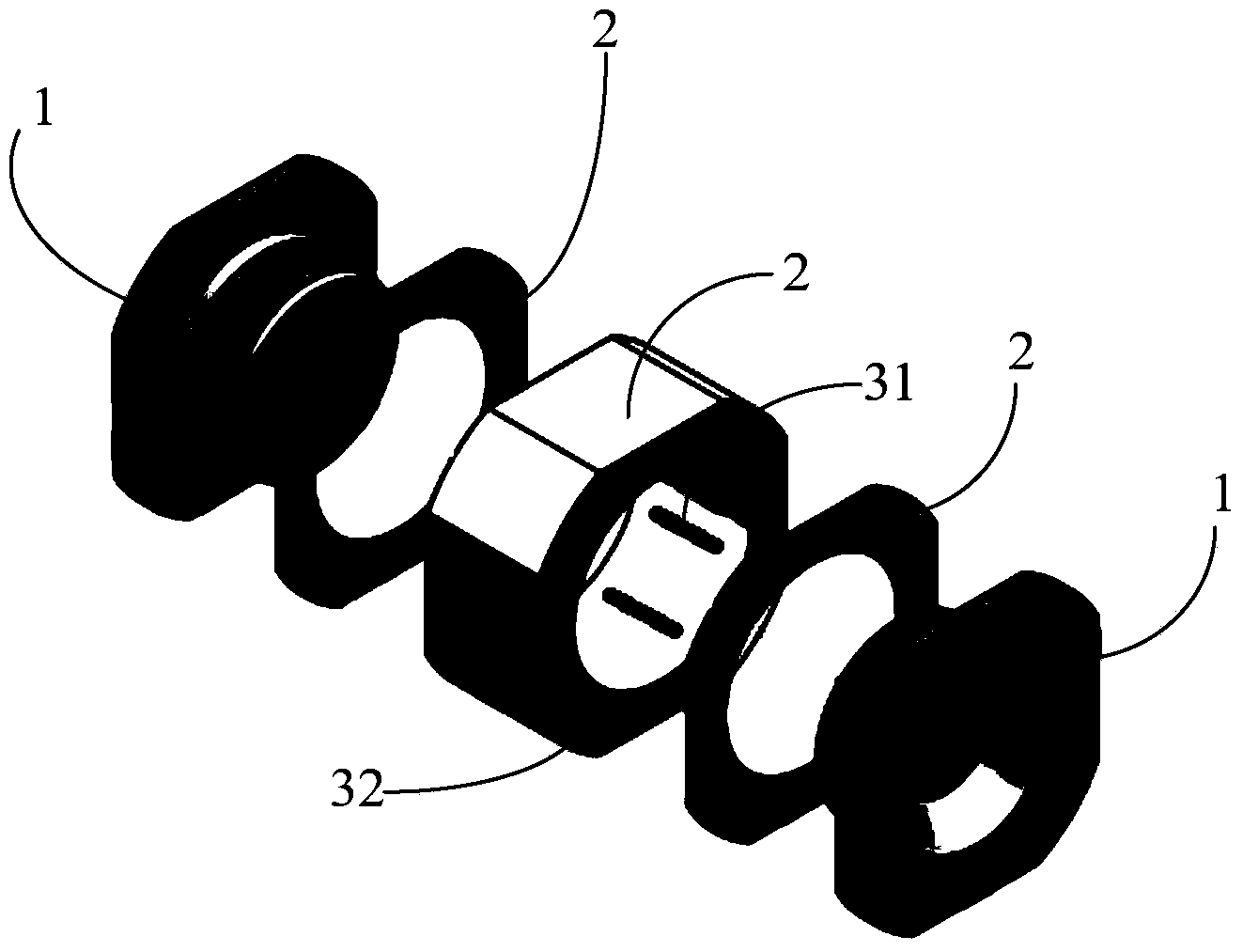

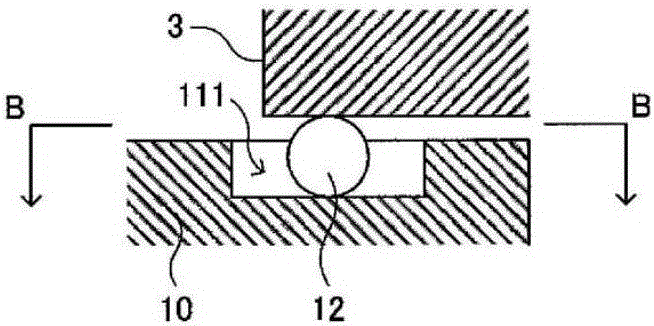

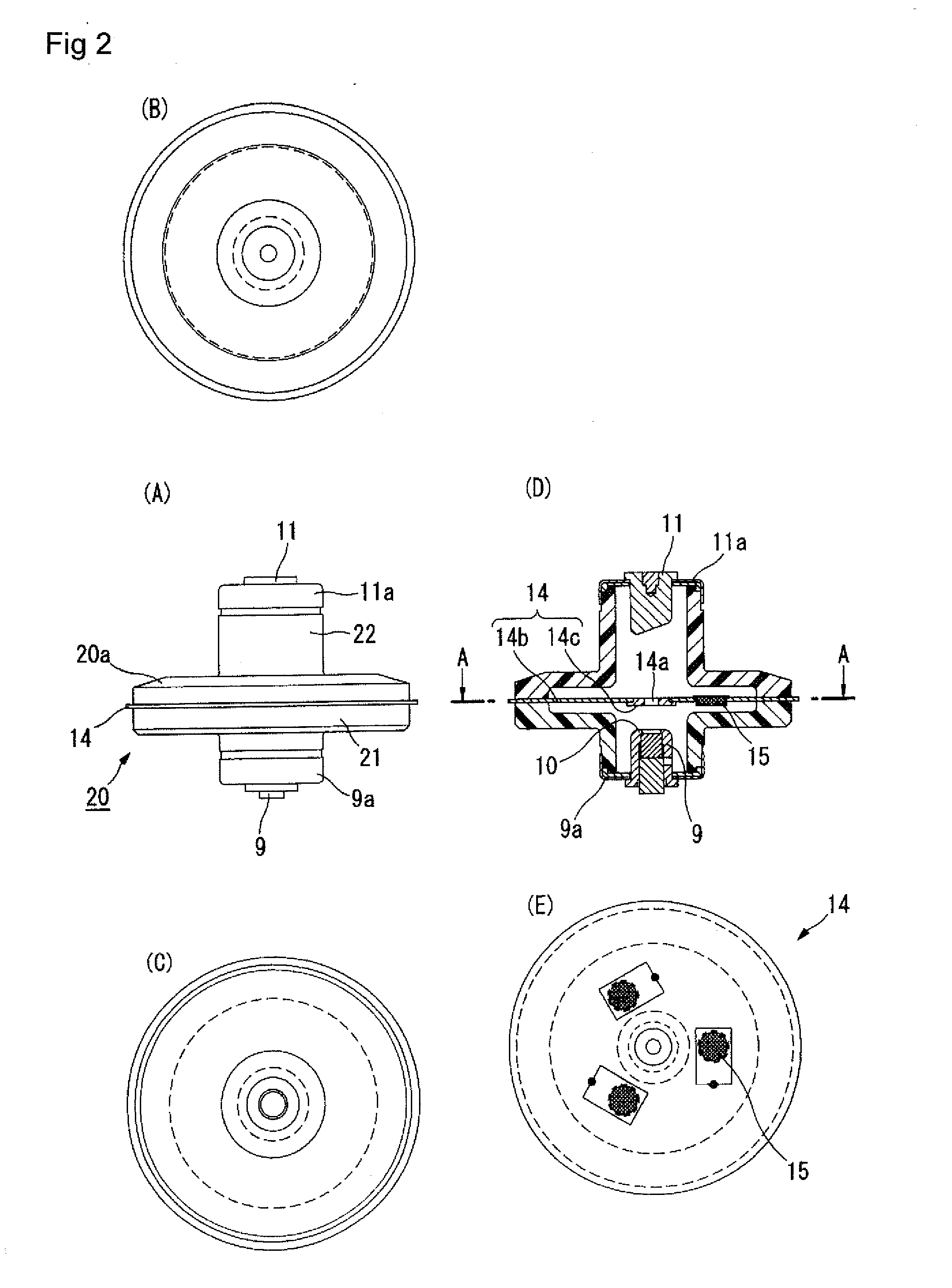

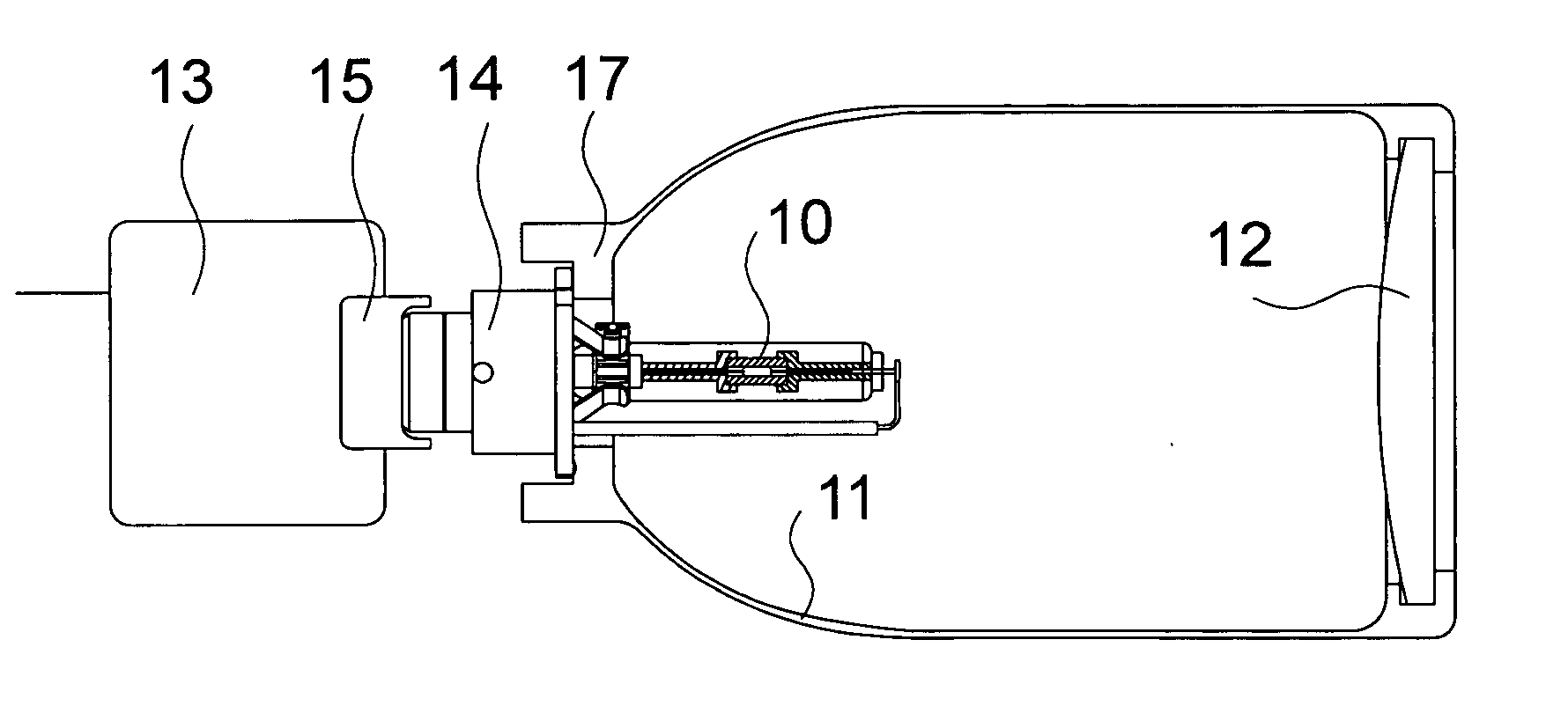

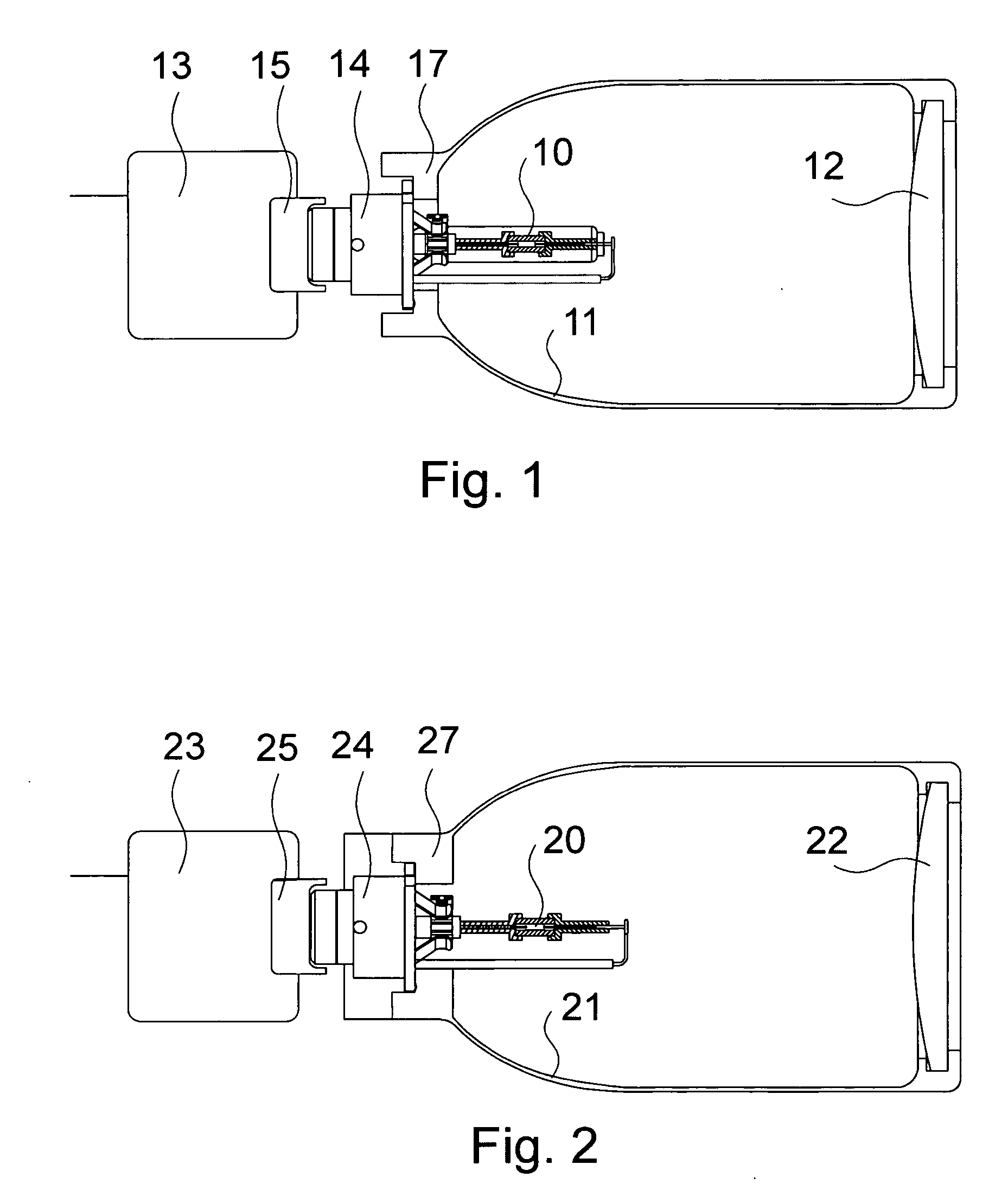

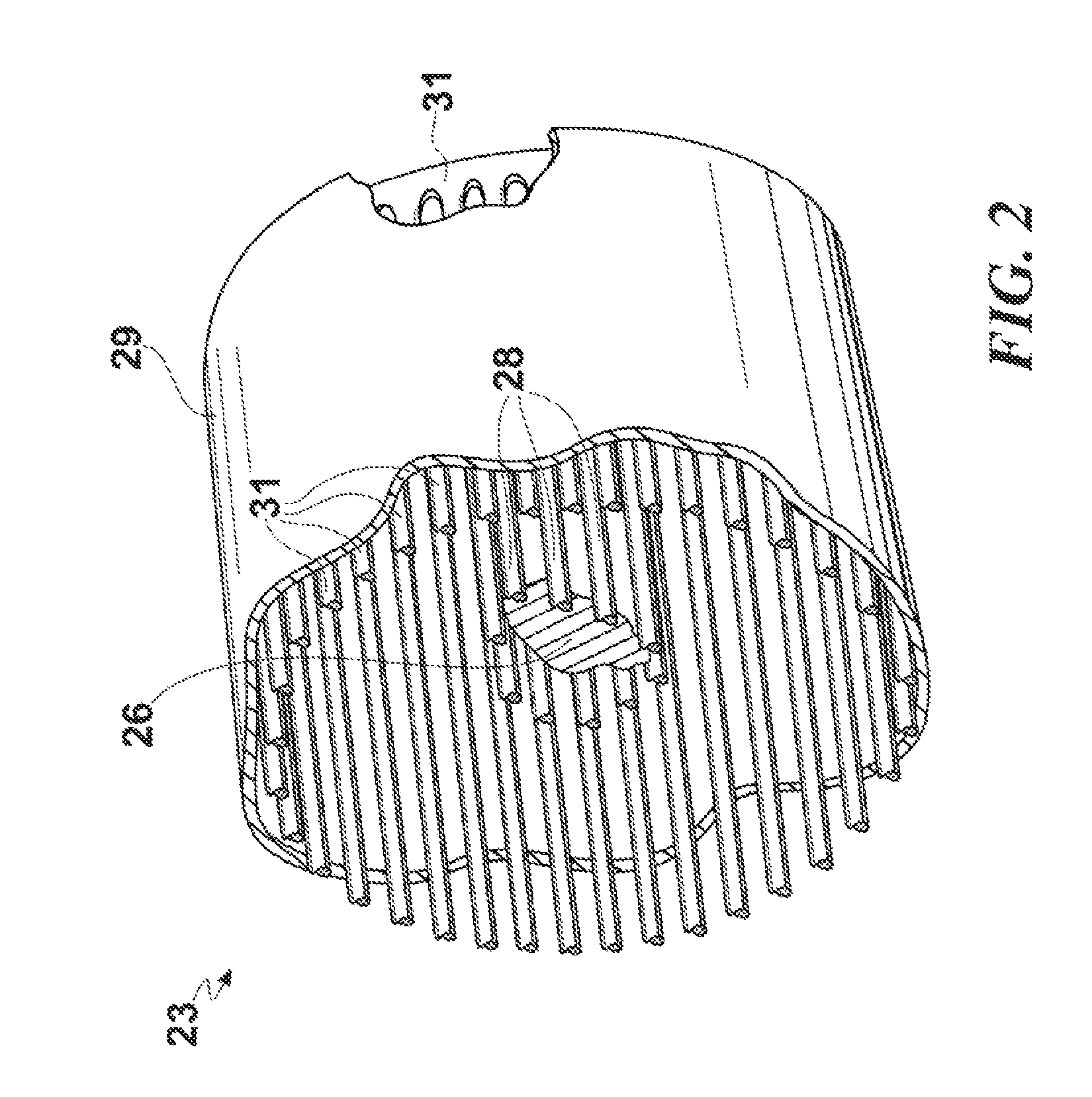

The invention relates to a fluorescent lamp (1) adapted for cold environments, which comprises an elongated main tube (11), fixing devices (12) at each end of the fluorescent lamp (1) for fixing the fluorescent lamp (1) in a light fitting (27), two electrodes (15) placed inside the main tube (11), a heat-insulating outer tube (20) that surrounds the main tube (11) and creates an airspace (22) between the main tube (11) and the outer tube (20). Each fixing device (12) comprises an end cap (41) with a radial part (41b), that delimits an outer end plane of the fluorescent lamp (1), and with an axial peripheral part (41a), that is connected to an end of the outer tube (20). An axial spacer (29, 31) with low heat conductivity has a first end part (33) that is connected to an end (34) of the main tube (11) and a second end part (38) that adjoins the outer end plane and keeps the main tube (11) separate from the end cap (41) in order to reduce the transmission of heat from the main tube (11) to the end cap (41) and the outer tube (20).

Owner:AURALIGHT INT

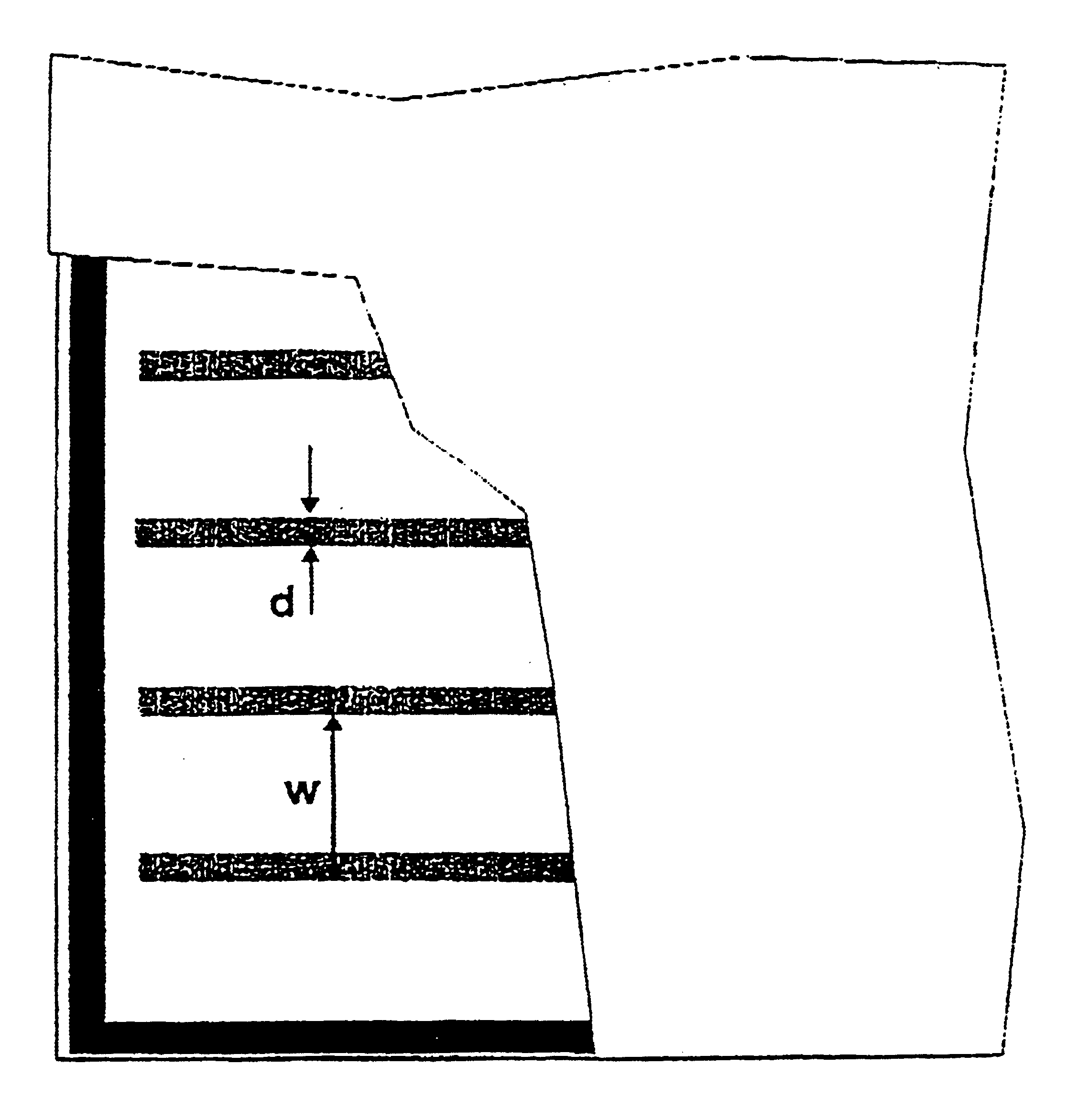

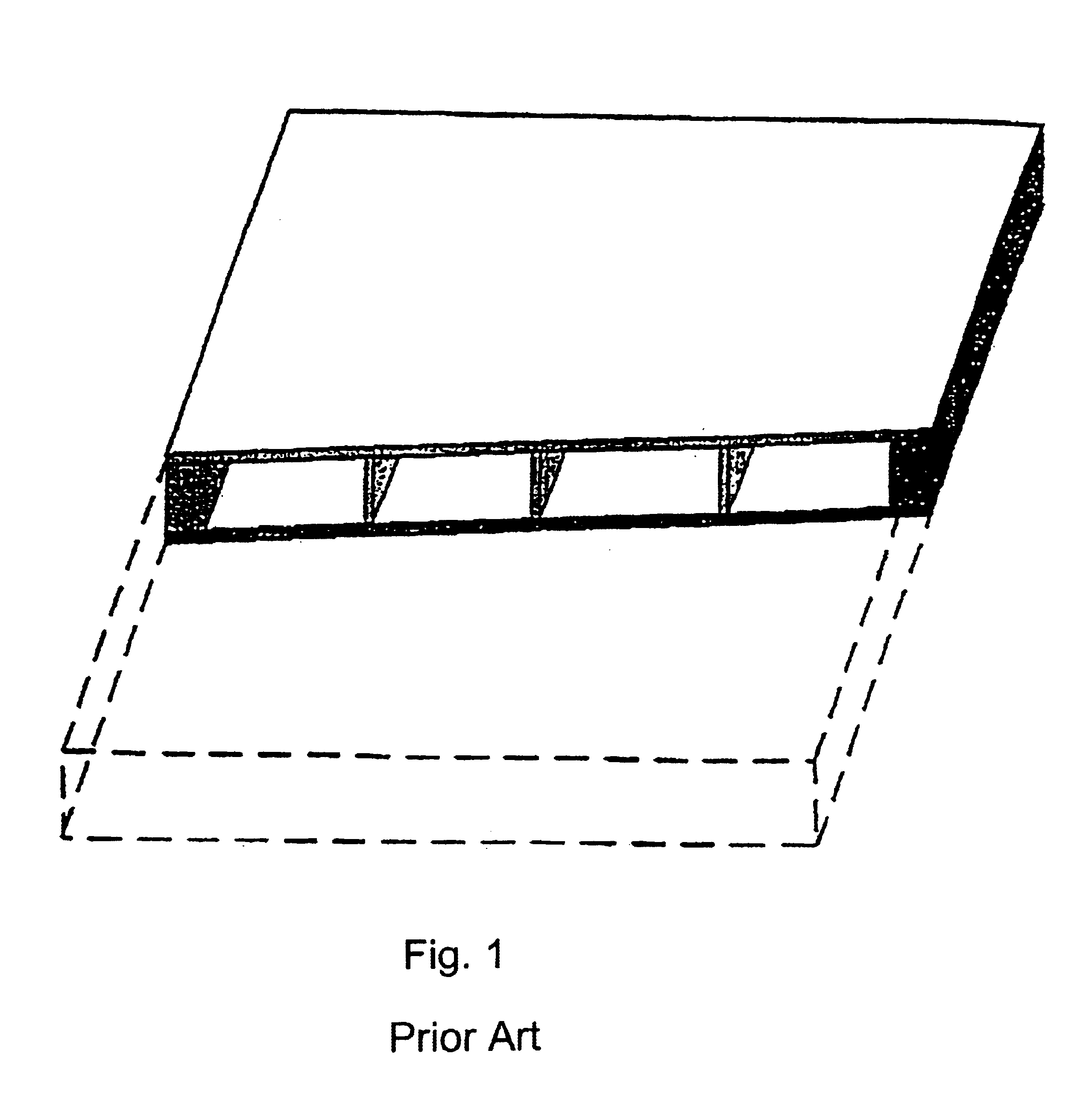

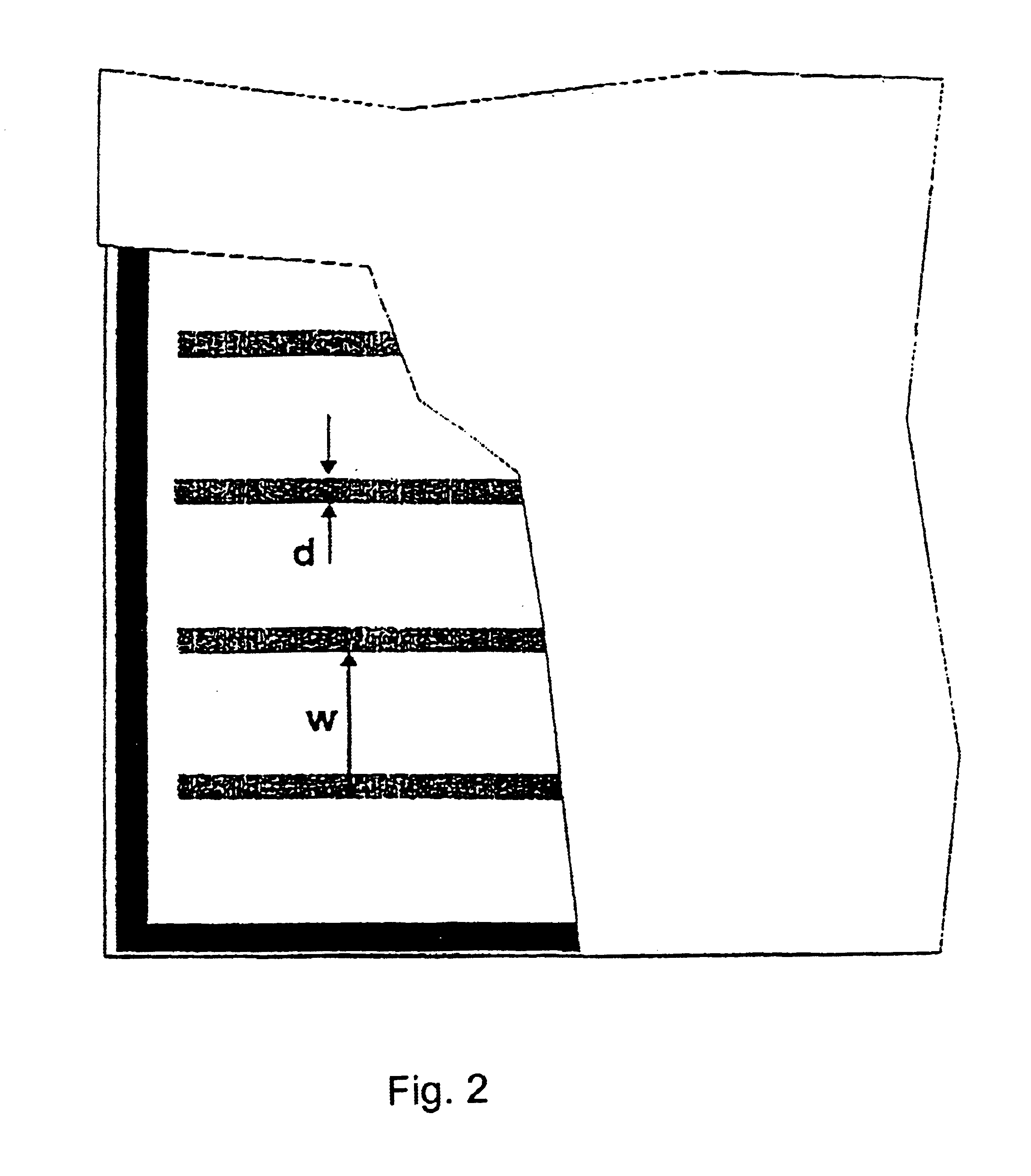

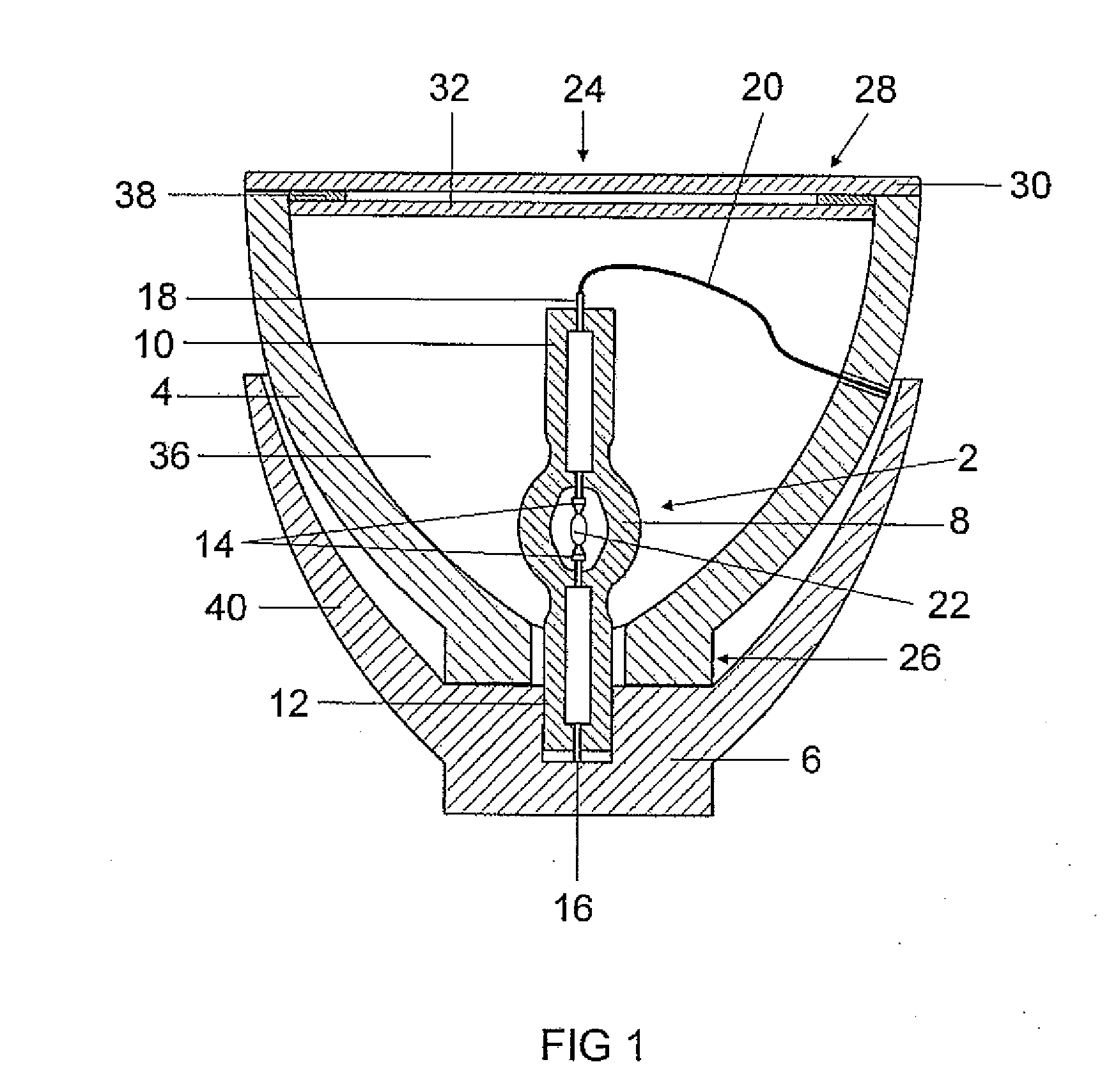

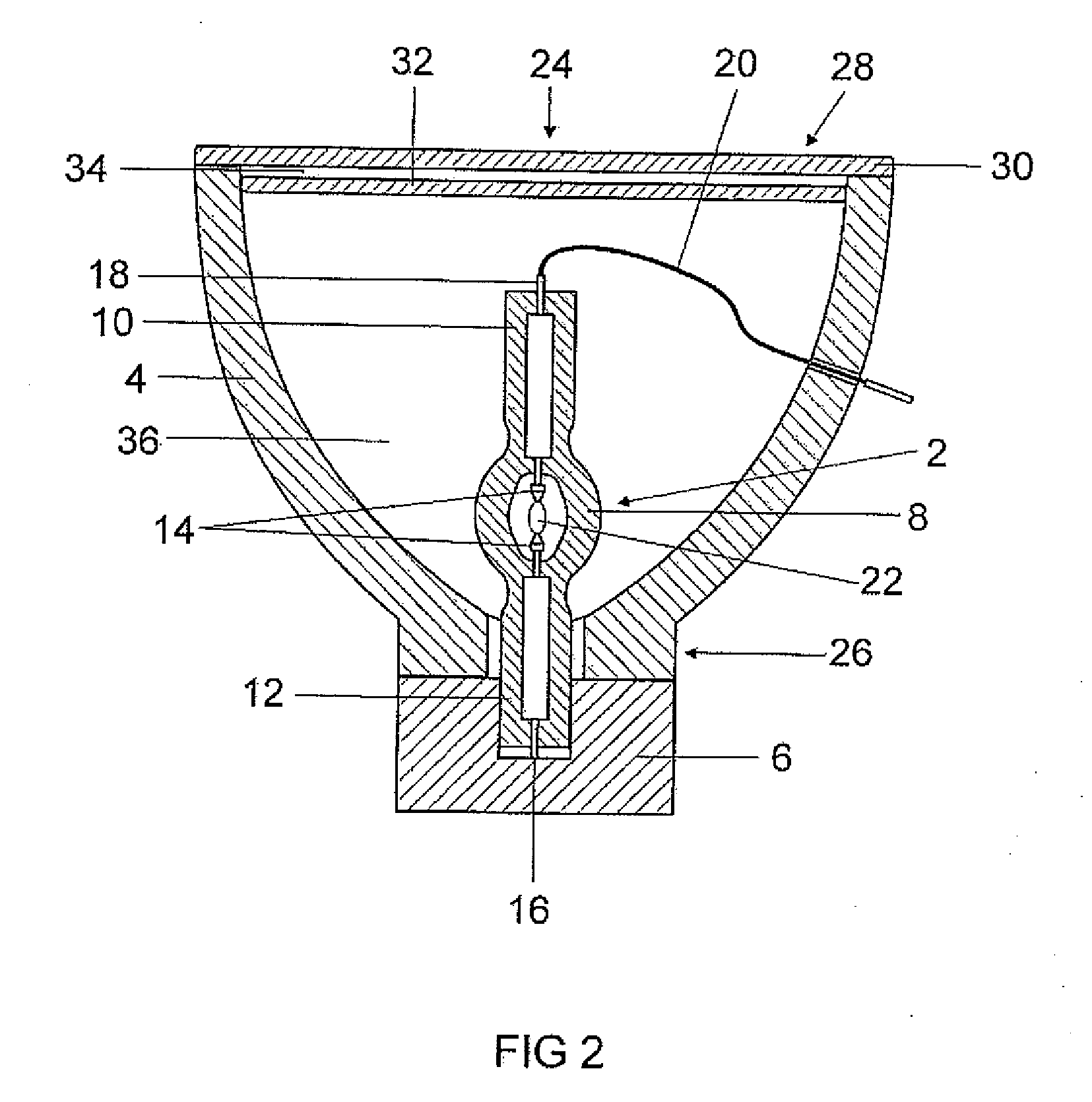

Fluorescent Lamp for Cold Environments

InactiveUS20070210687A1Reduce heat transferLow thermal conductivityElectrode assembly support/mounting/spacing/insulationVacuum tube vessels/containers/shieldsEngineeringFluorescent lamp

The invention relates to a fluorescent lamp (1) adapted for cold environments, which comprises an elongated main tube (11), fixing devices (12) at each end of the fluorescent lamp (1) for fixing the fluorescent lamp (1) in a light fitting (27), two electrodes (15) placed inside the main tube (11), a heat-insulating outer tube (20) that surrounds the main tube (11) and creates an airspace (22) between the main tube (11) and the outer tube (20). Each fixing device (12) comprises an end cap (41) with a radial part (41b), that delimits an outer end plane of the fluorescent lamp (1), and with an axial peripheral part (41a), that is connected to an end of the outer tube (20). An axial spacer (29, 31) with low heat conductivity has a first end part (33) that is connected to an end (34) of the main tube (11) and a second end part (38) that adjoins the outer end plane and keeps the main tube (11) separate from the end cap (41) in order to reduce the transmission of heat from the main tube (11) to the end cap (41) and the outer tube (20).

Owner:AURALIGHT INT

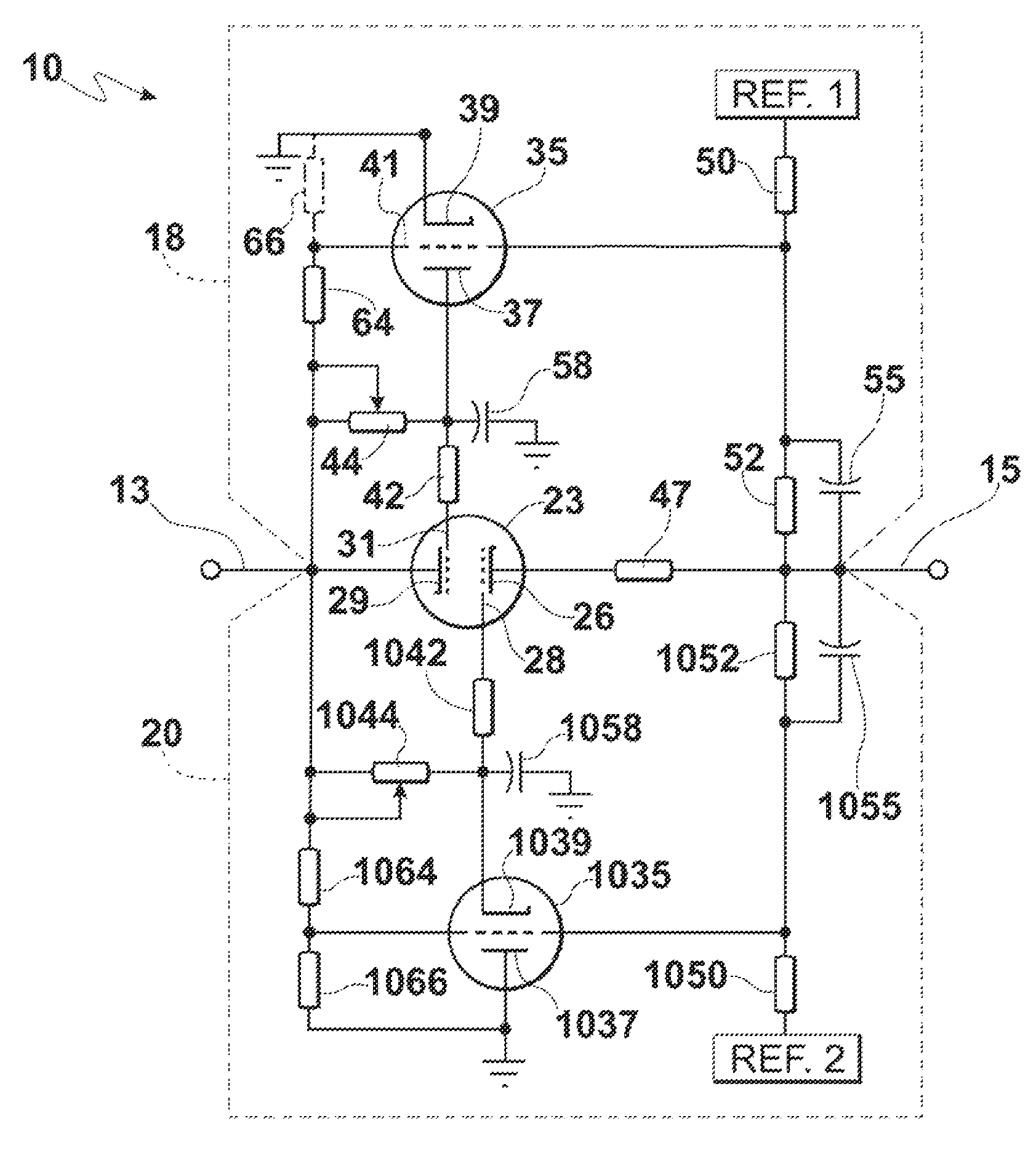

High Voltage High Current Regulator

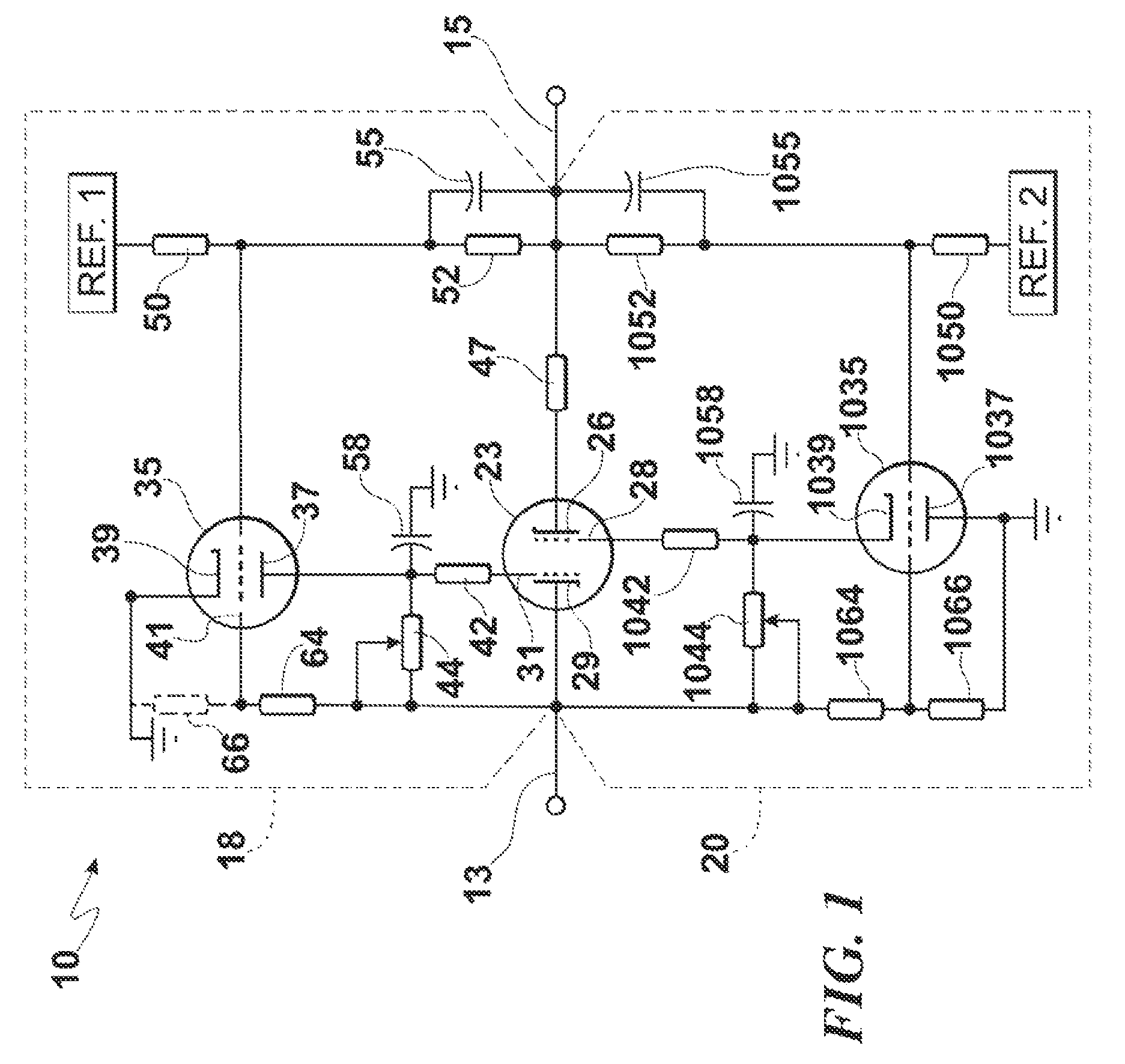

ActiveUS20120081097A1Minimized size requirementPreventing internal electrical short circuitAnti-noise capacitorsElectrode assembly support/mounting/spacing/insulationHigh voltage igbtControl signal

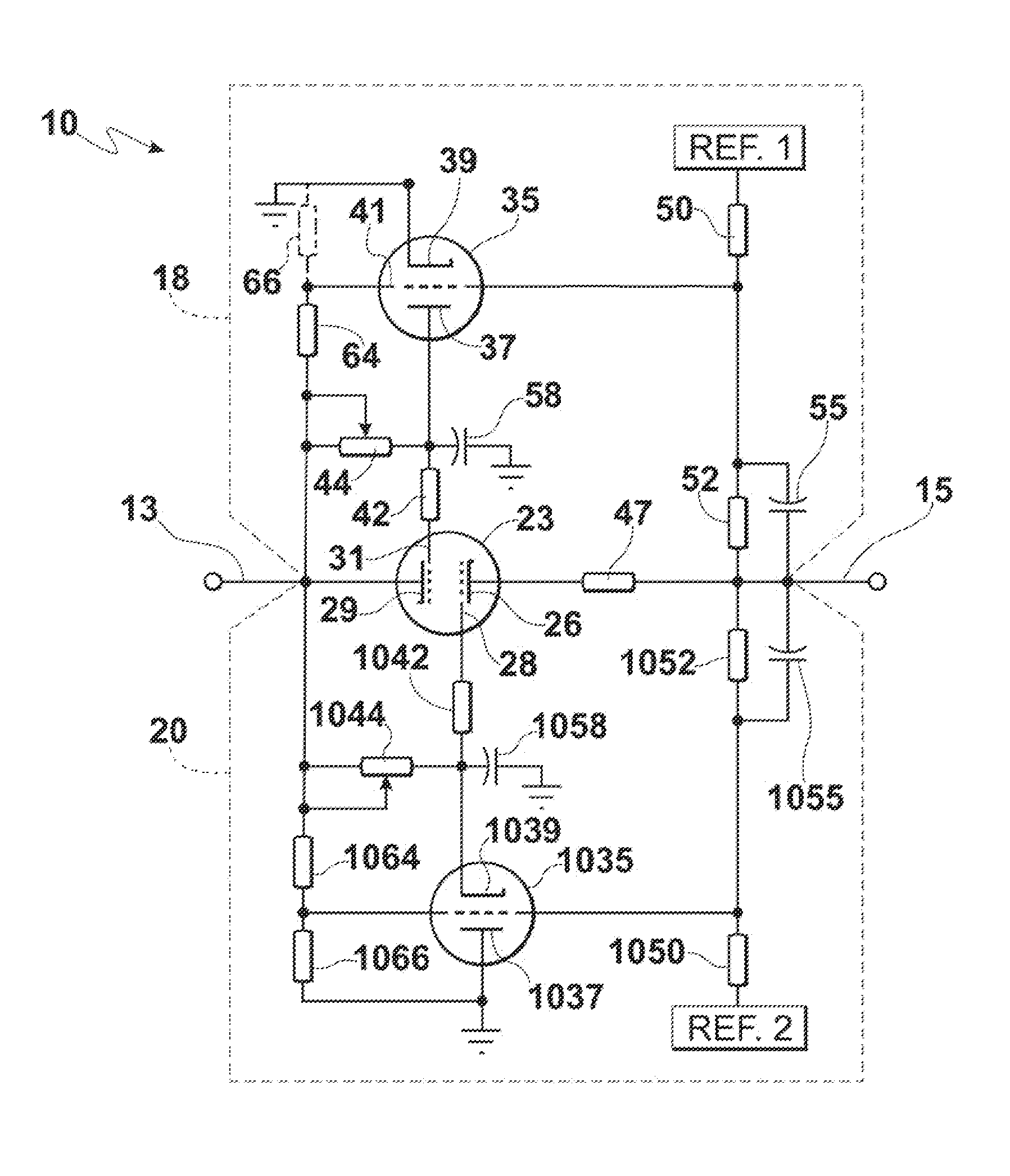

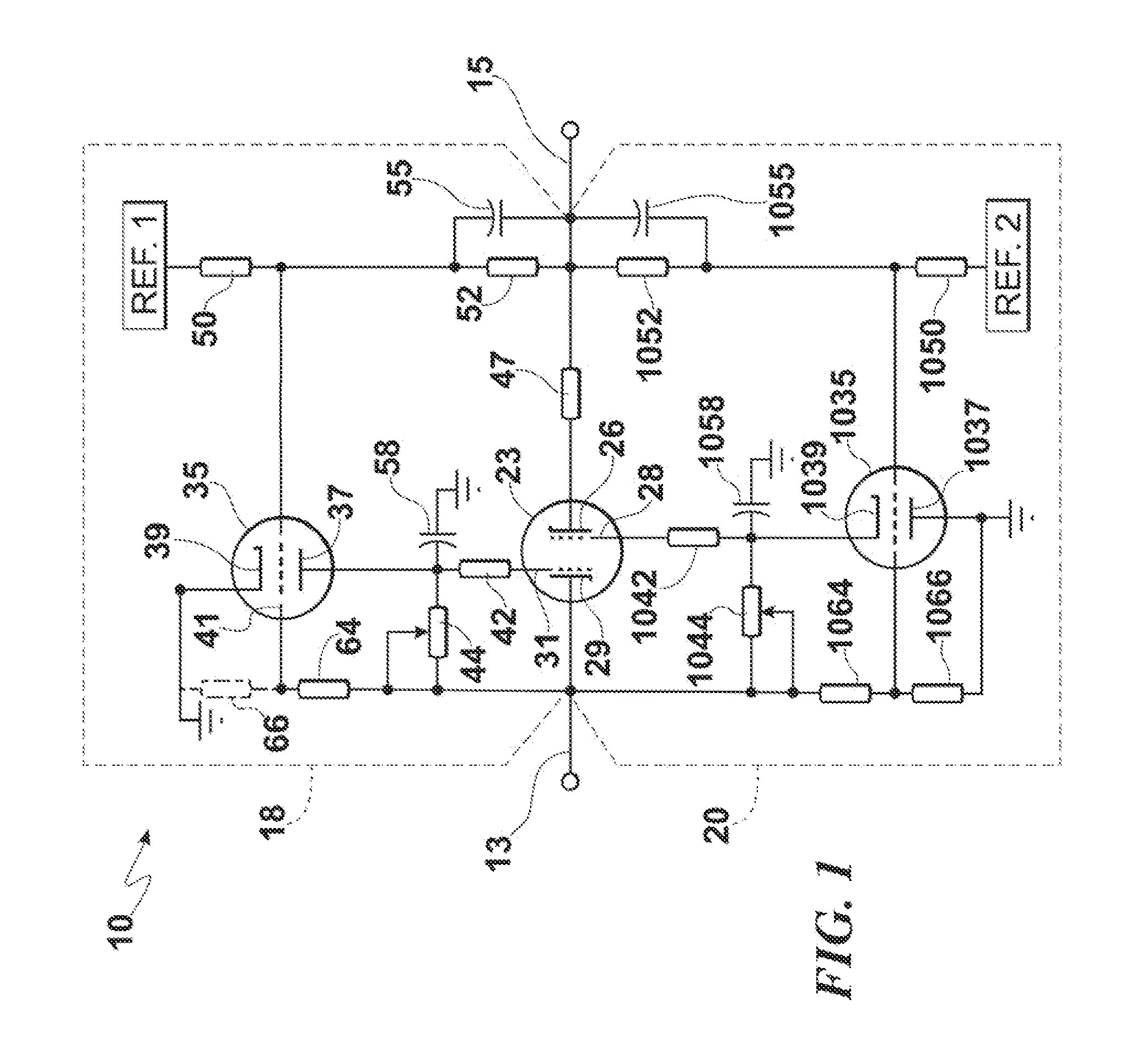

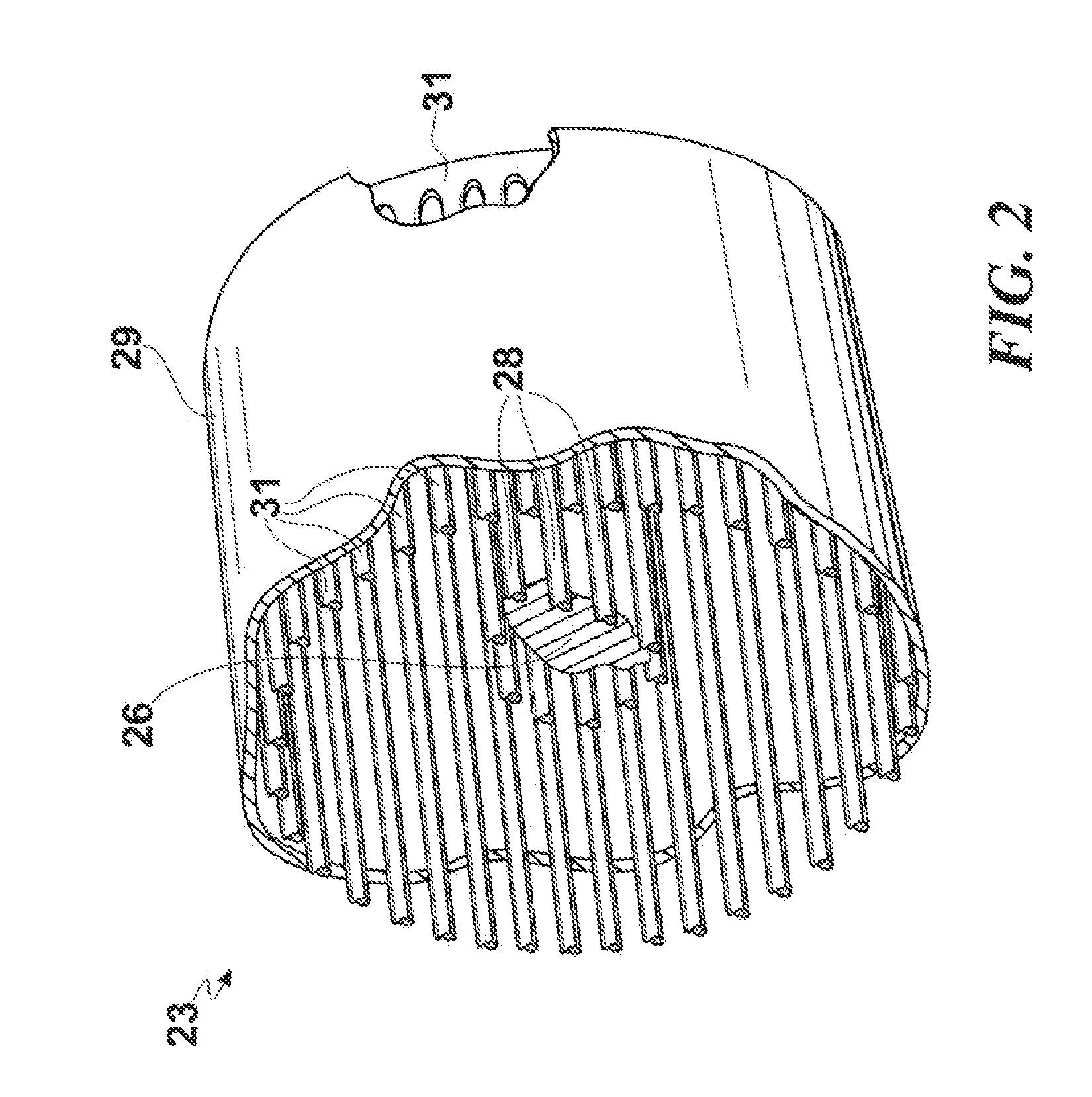

High voltage high current regulator circuit for regulating current is interposed between first and second terminals connected to an external circuit and comprises at least one main-current carrying cold-cathode field emission electron tube conducting current between the first and second terminals. First and second grid-control cold-cathode field emission electron tubes provide control signals for first and second grids of the at least one main-current carrying cold-cathode field emission electron tube for positive and negative excursions of voltage on the first and second terminals, respectively. The current regulator circuit may be accompanied by a voltage-clamping circuit that includes at least one cold-cathode field emission electron tube. At least two cold-cathode field emission electron tubes, configured to operate at high voltage and high current, are preferably contained within a single vacuum enclosure and are interconnected to provide a circuit function, so as to form a high voltage high current vacuum integrated circuit.

Owner:ADVANCED FUSION SYST LLC

Flat light source

InactiveUS6853123B1High strengthUnder load is increasedDischarge tube luminescnet screensCathode-ray/electron-beam tube vessels/containersEngineeringAtmospheric pressure

A flat light source having a front plate and a rear part. The front plate is held at a distance from the rear part by spacers. A gaseous filling which is under a pressure lower than the ambient atmospheric pressure is introduced into the intermediate space between the front plate and rear part, and the front plate is of a glass material. To be able to produce flat light sources of this type which have a low intrinsic weight, according to this invention the front plate and / or the rear part can be configured as an at least partly thermally or chemically tempered glass pane or the front plate and / or the rear part can be configured as a glass pane which at least in areas is coated with ductile polymer material.

Owner:SCHOTT AG

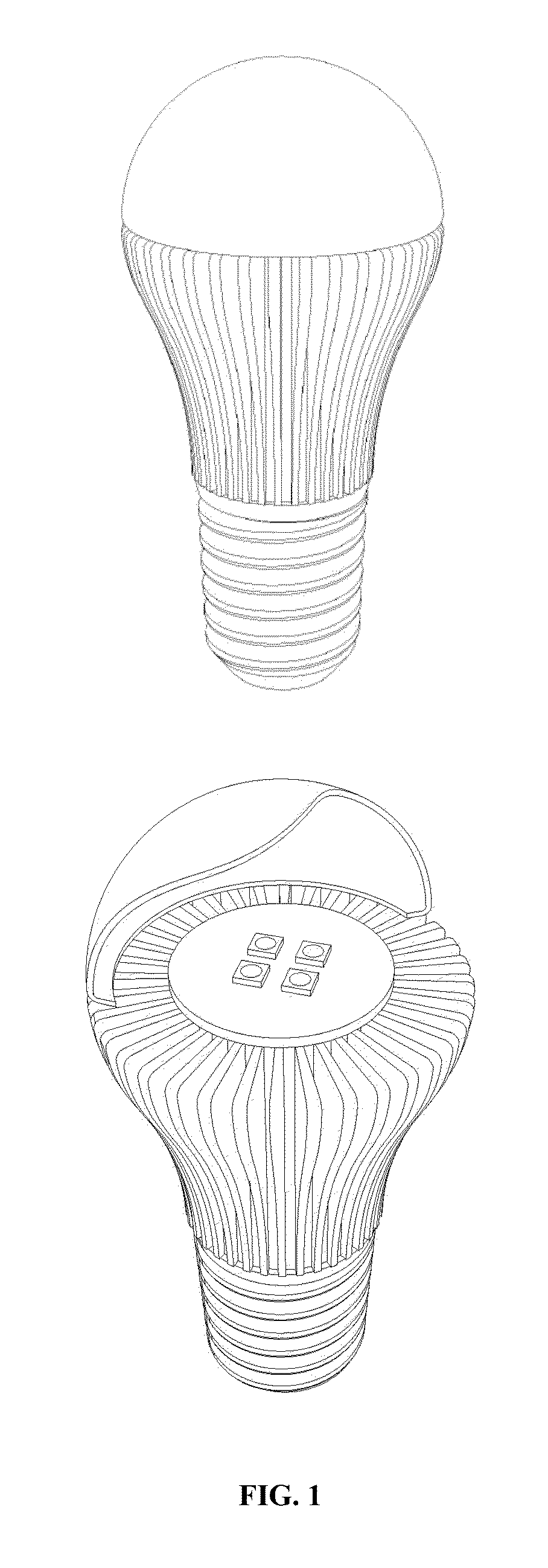

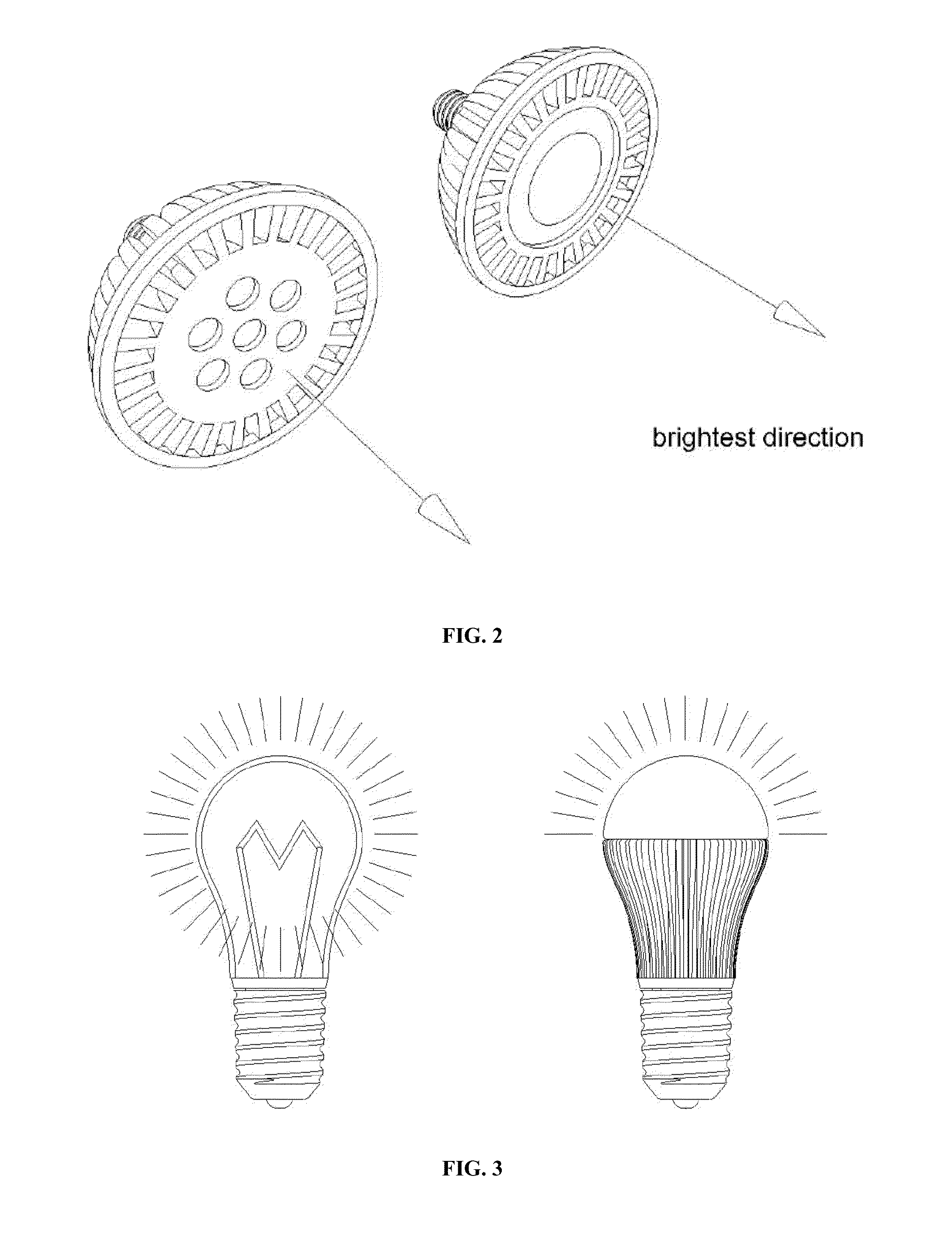

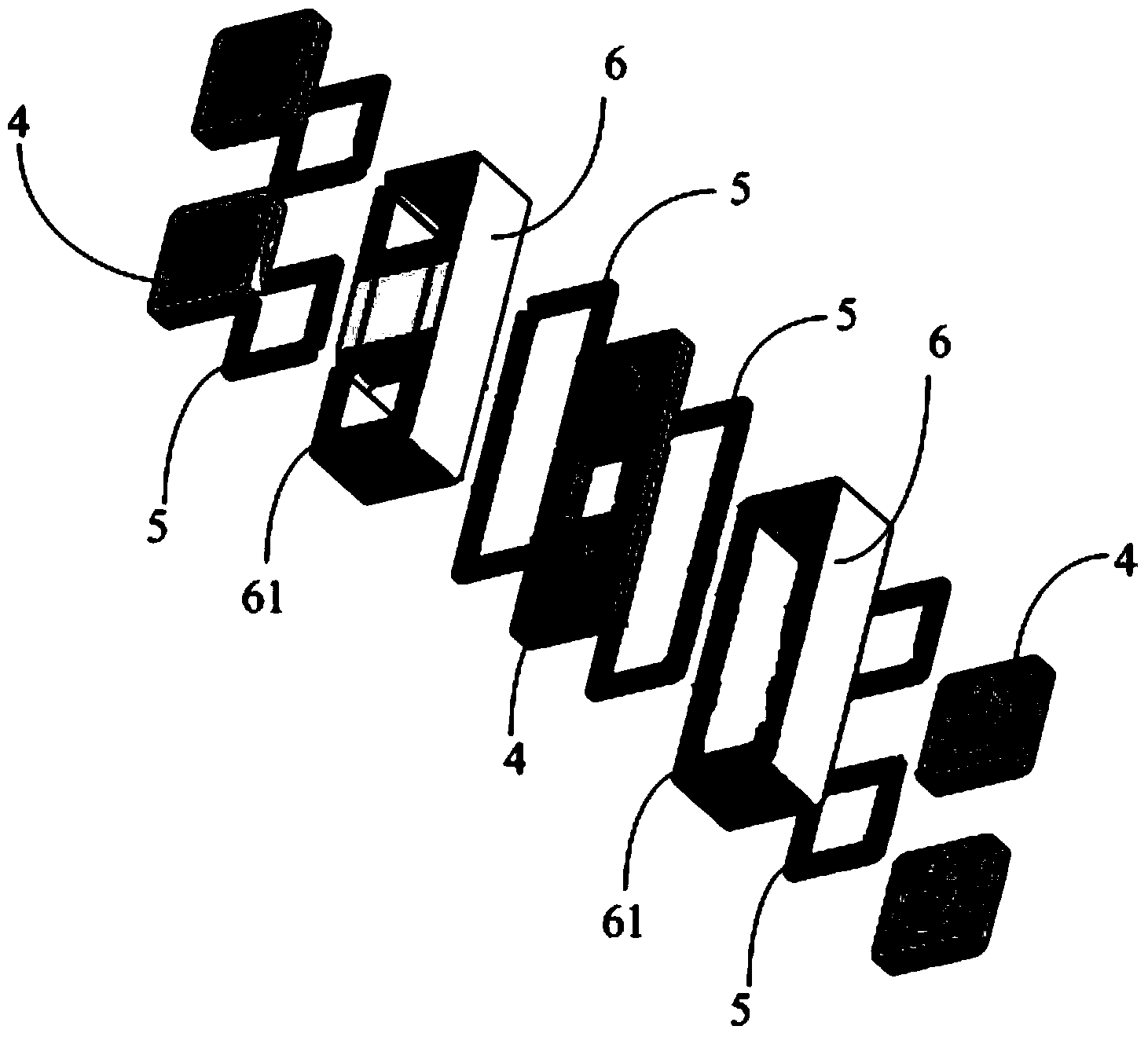

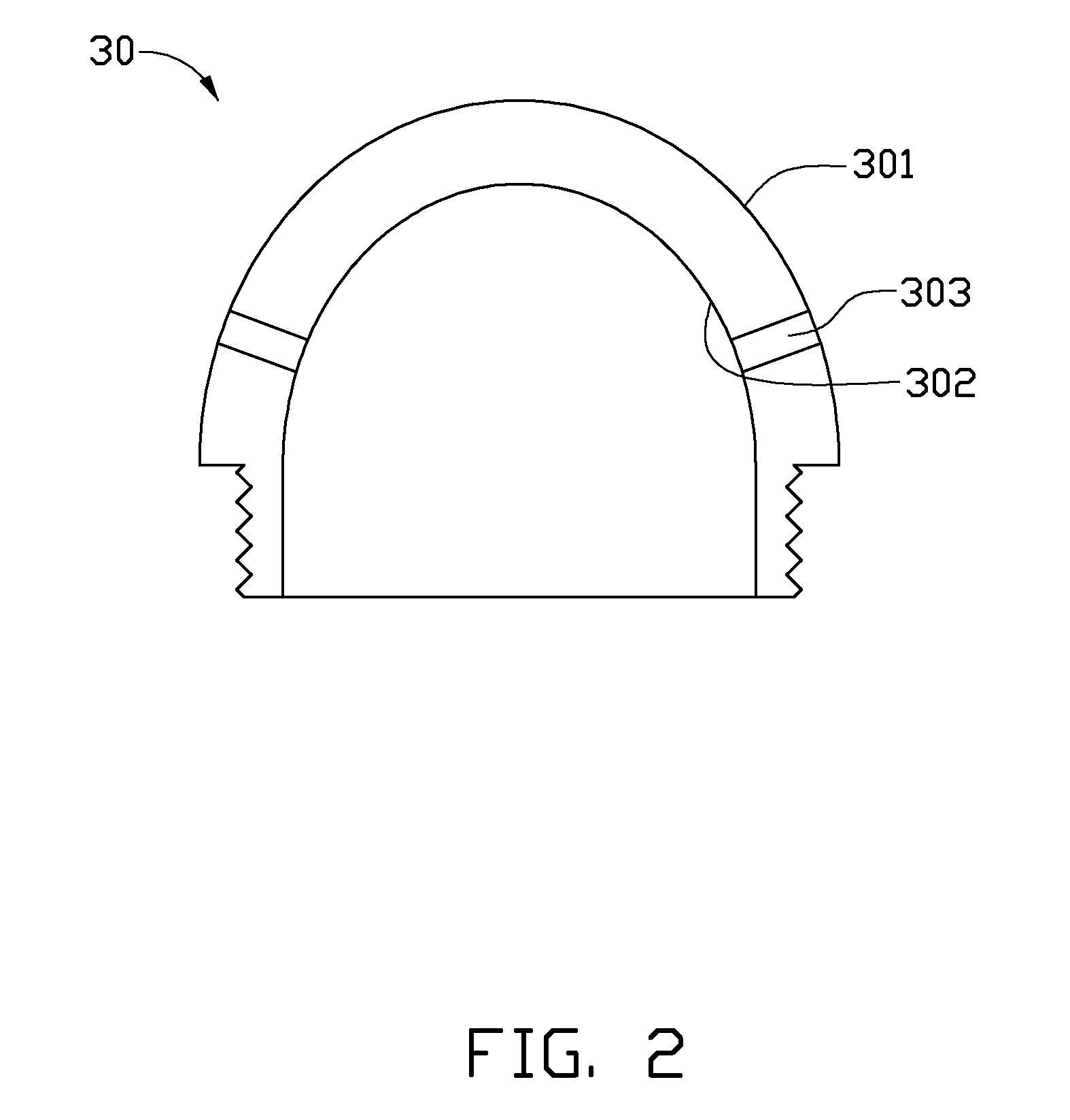

LED bulbs with adjustable light emitting direction

InactiveUS20130278132A1Reliable lockingPlanar light sourcesLight source combinationsOptoelectronicsLED lamp

Owner:YUAN ZENGGUANG +1

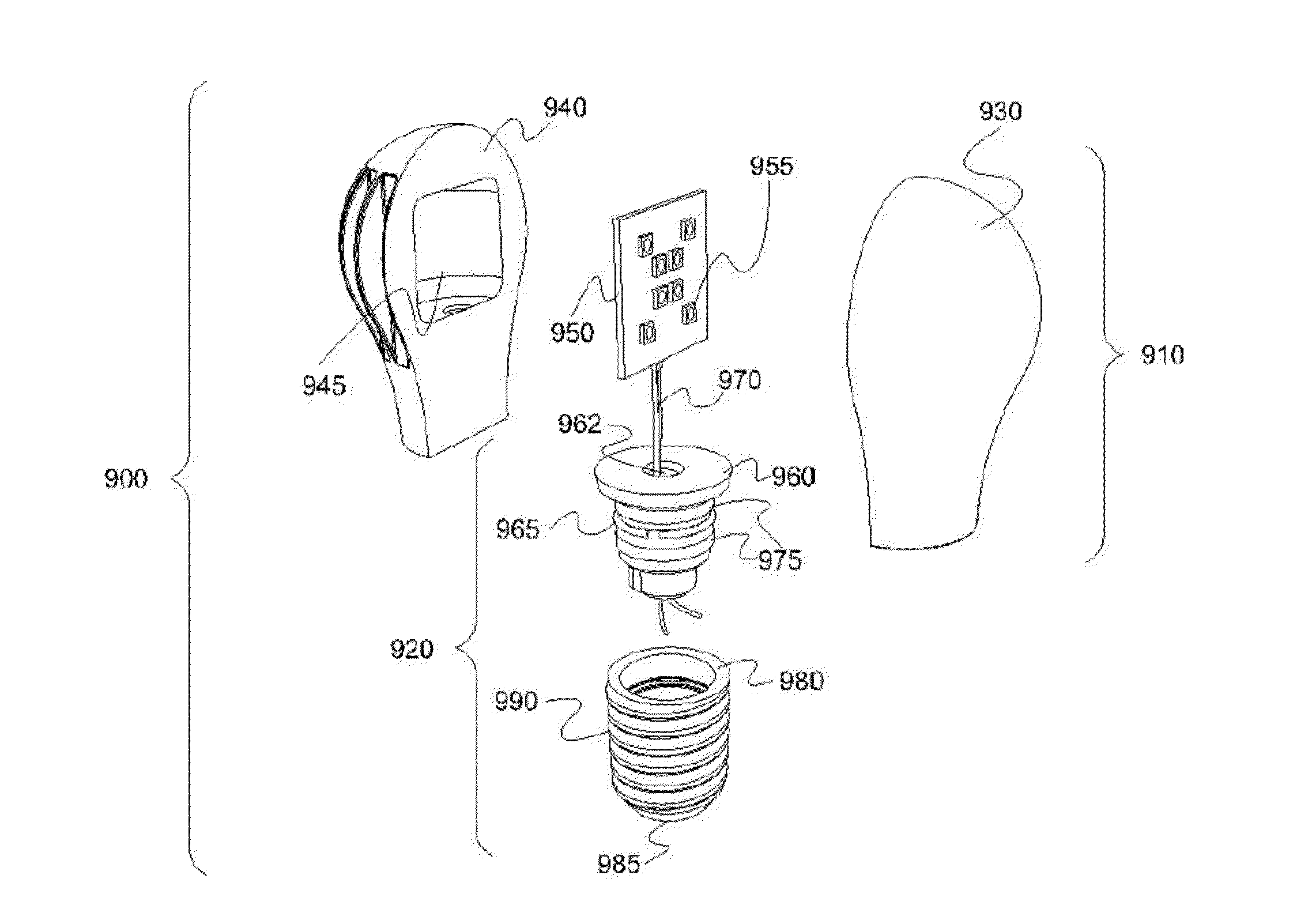

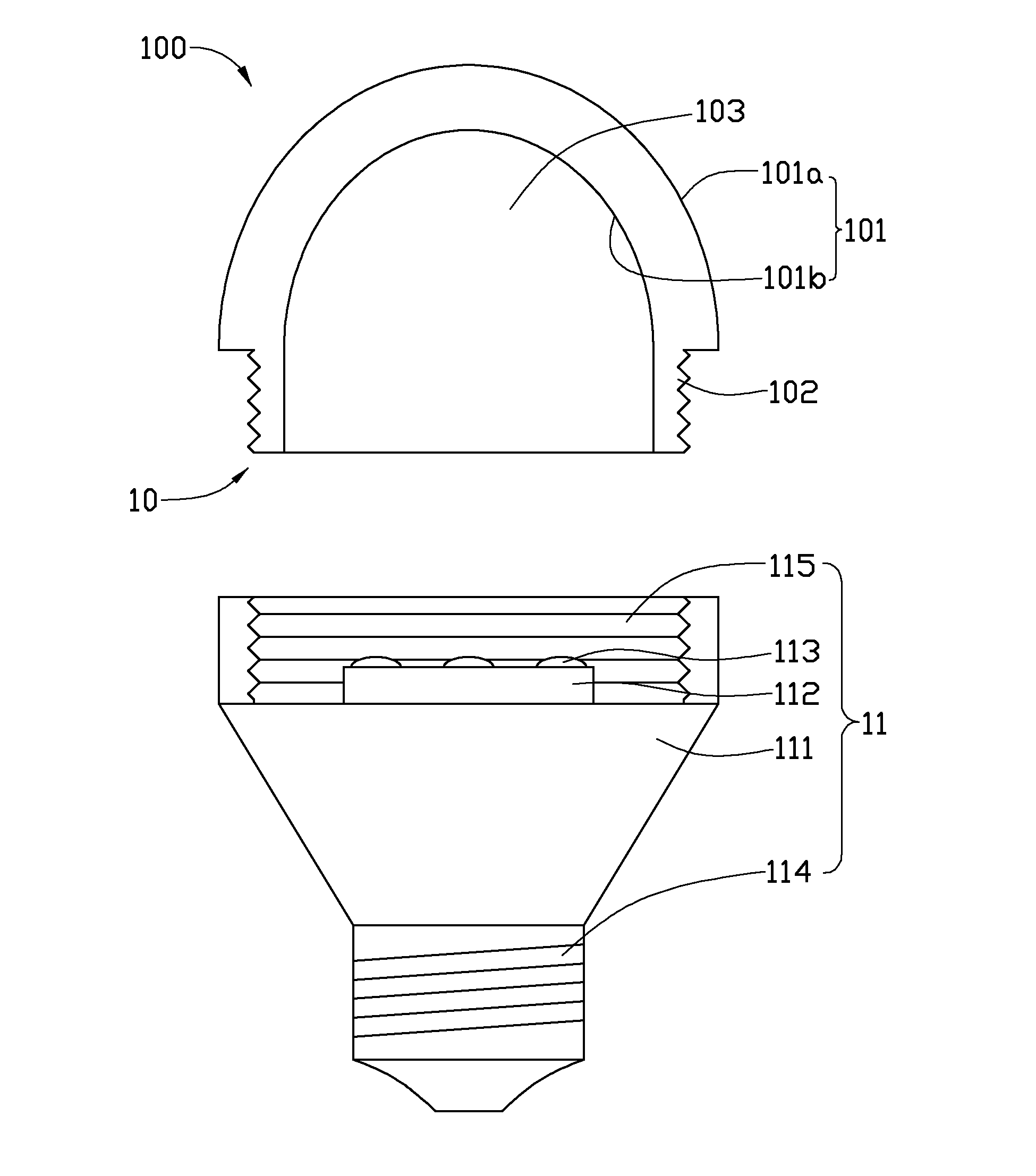

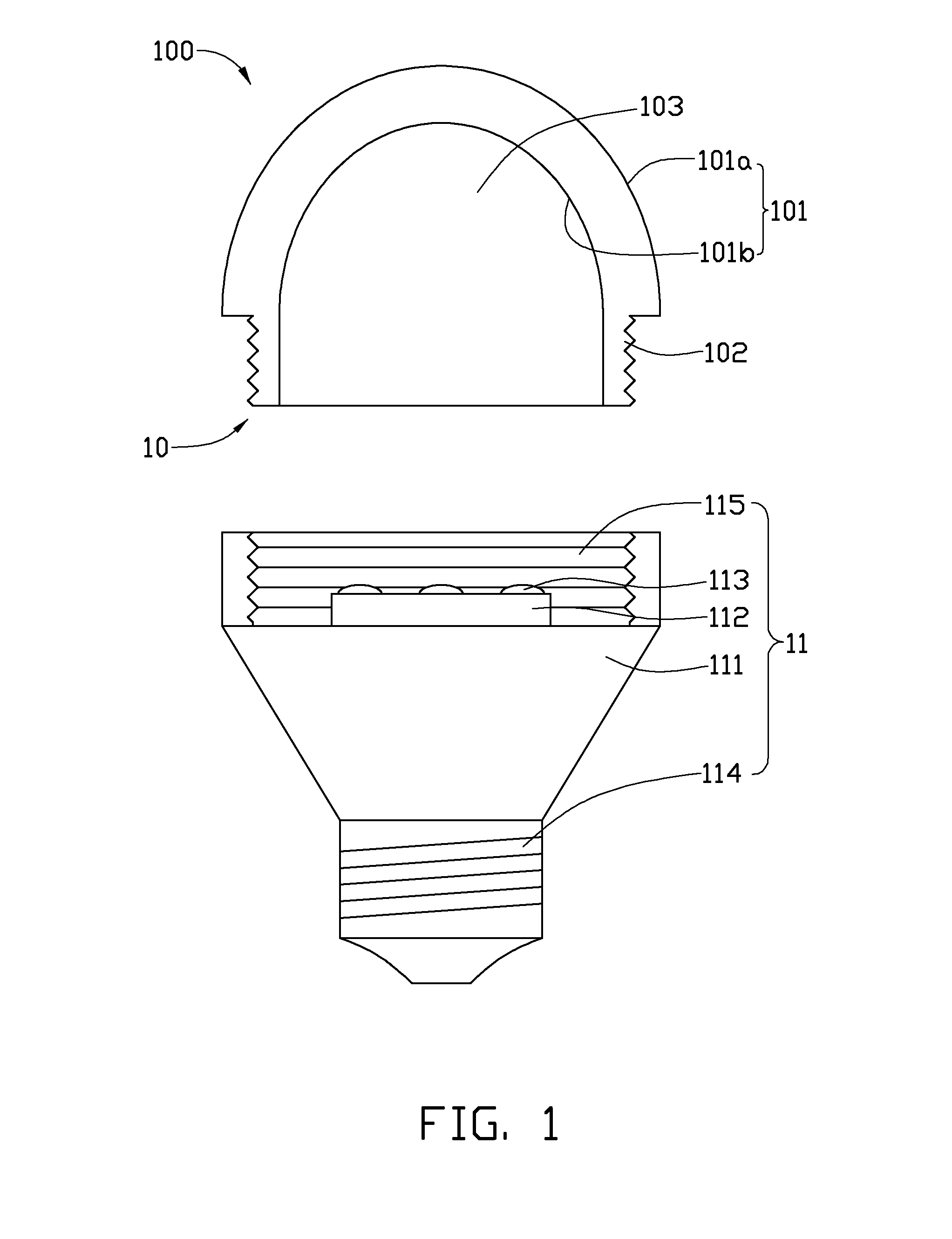

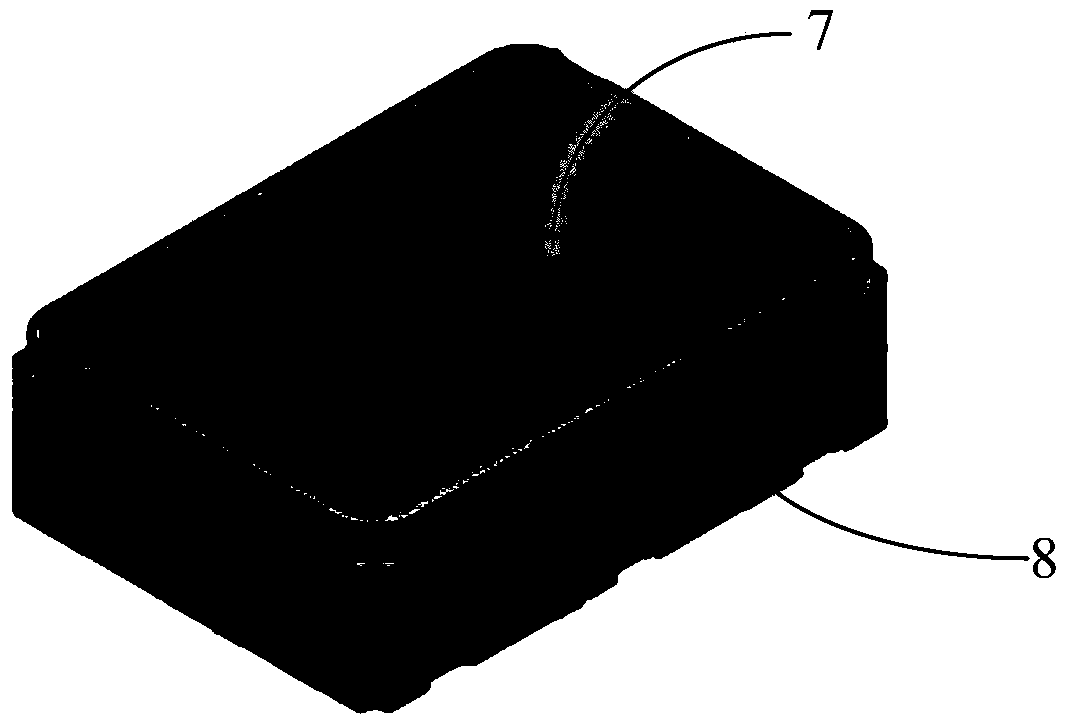

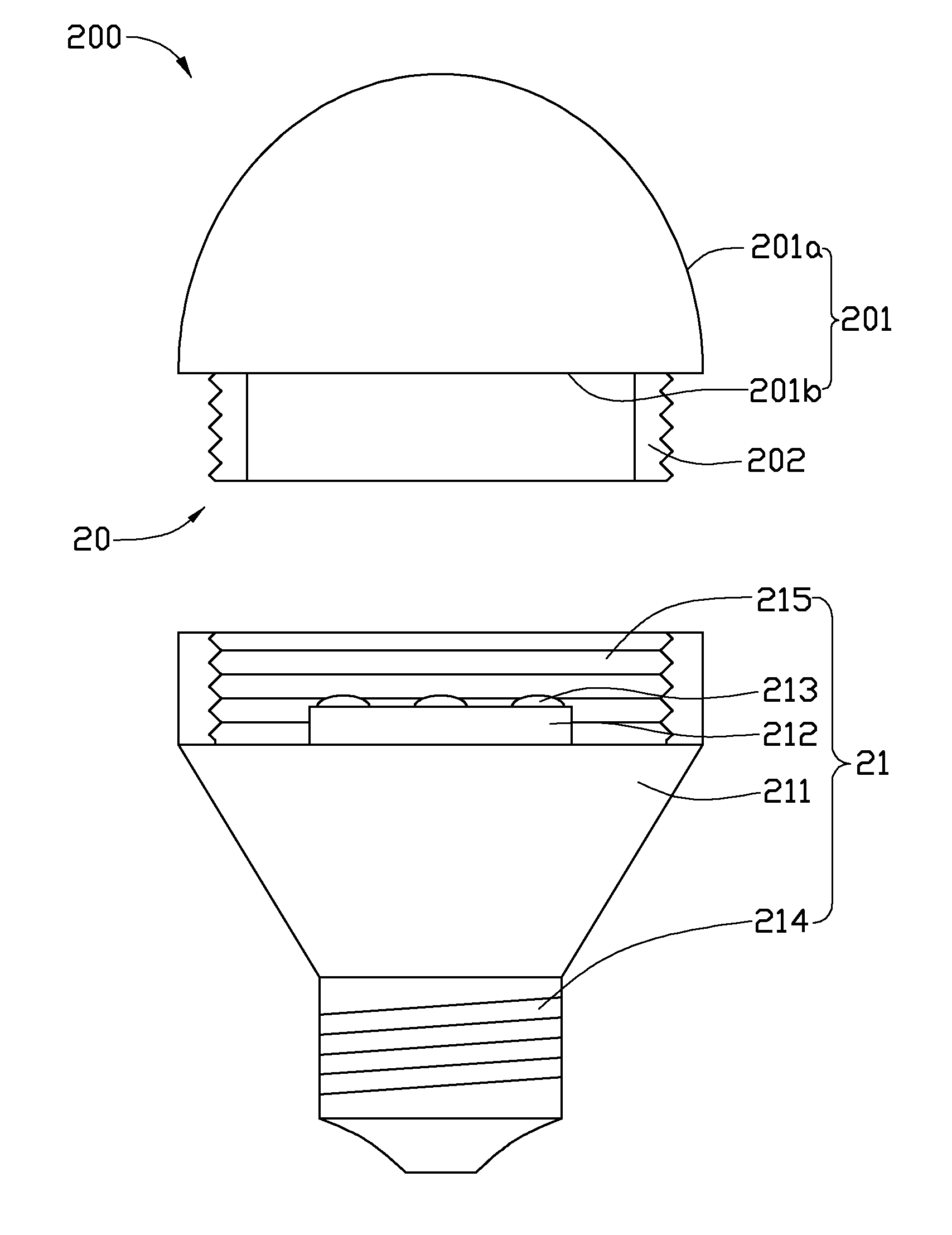

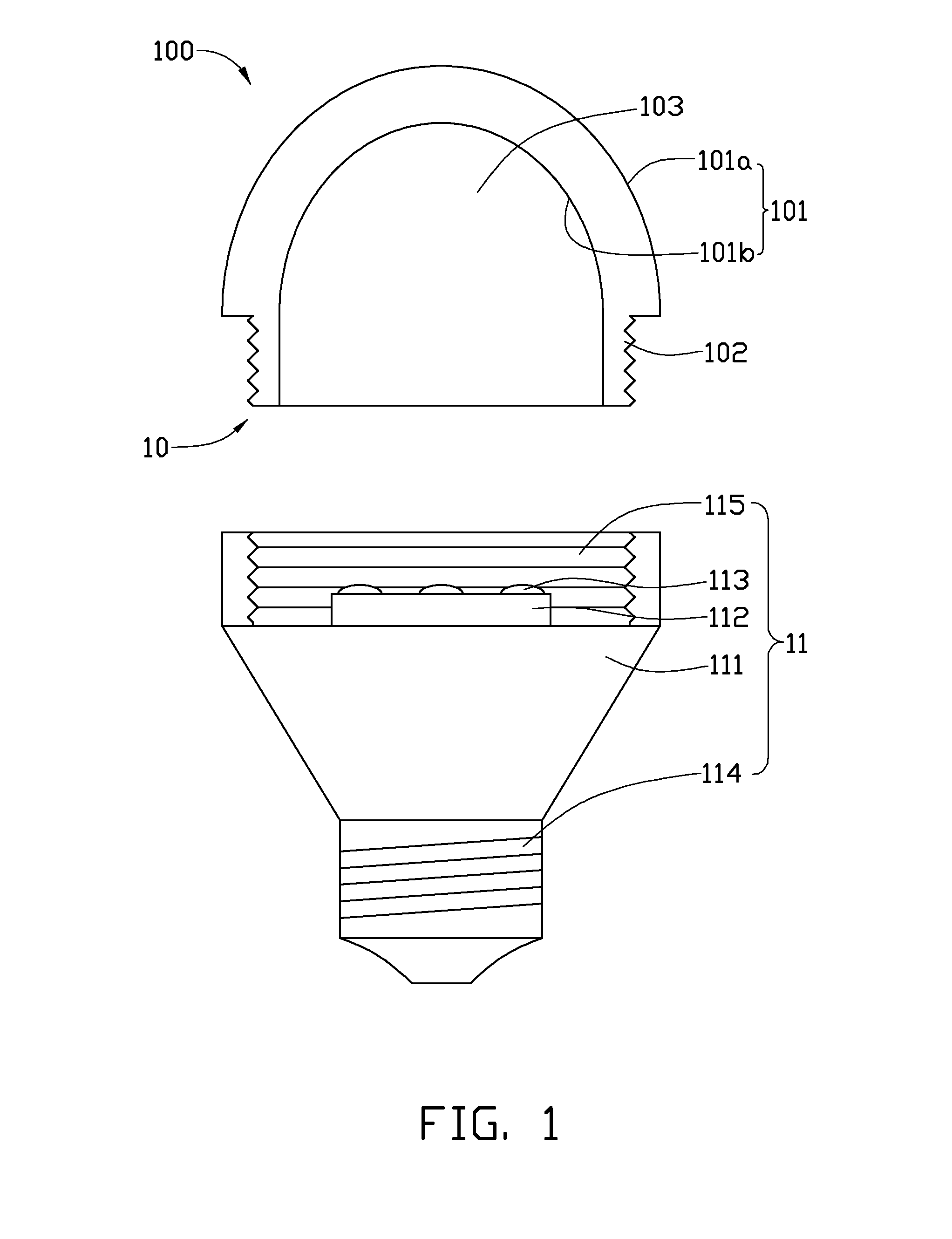

Lamps with replaceable covers

InactiveUS20110031871A1Discharge tube luminescnet screensPoint-like light sourceEngineeringPrinted circuit board

A lamp includes a main body and a removable cover, and the main body includes a lamp housing, a printed circuit board (PCB), at least one light emitting element, and a threaded base. The lamp housing defines a socket configured for receiving the PCB and the at least one light emitting element, and the PCB is electrically connected to the at least one light emitting element and fixed in the socket. The removable cover includes a light-transmission portion and a connection portion, the connection portion connects to the end of the lamp housing with the socket, and the light-transmission portion is opposite to the socket. Light from the at least one light emitting element is emitted from the light-transmission portion.

Owner:FOXSEMICON INTEGRATED TECH INC

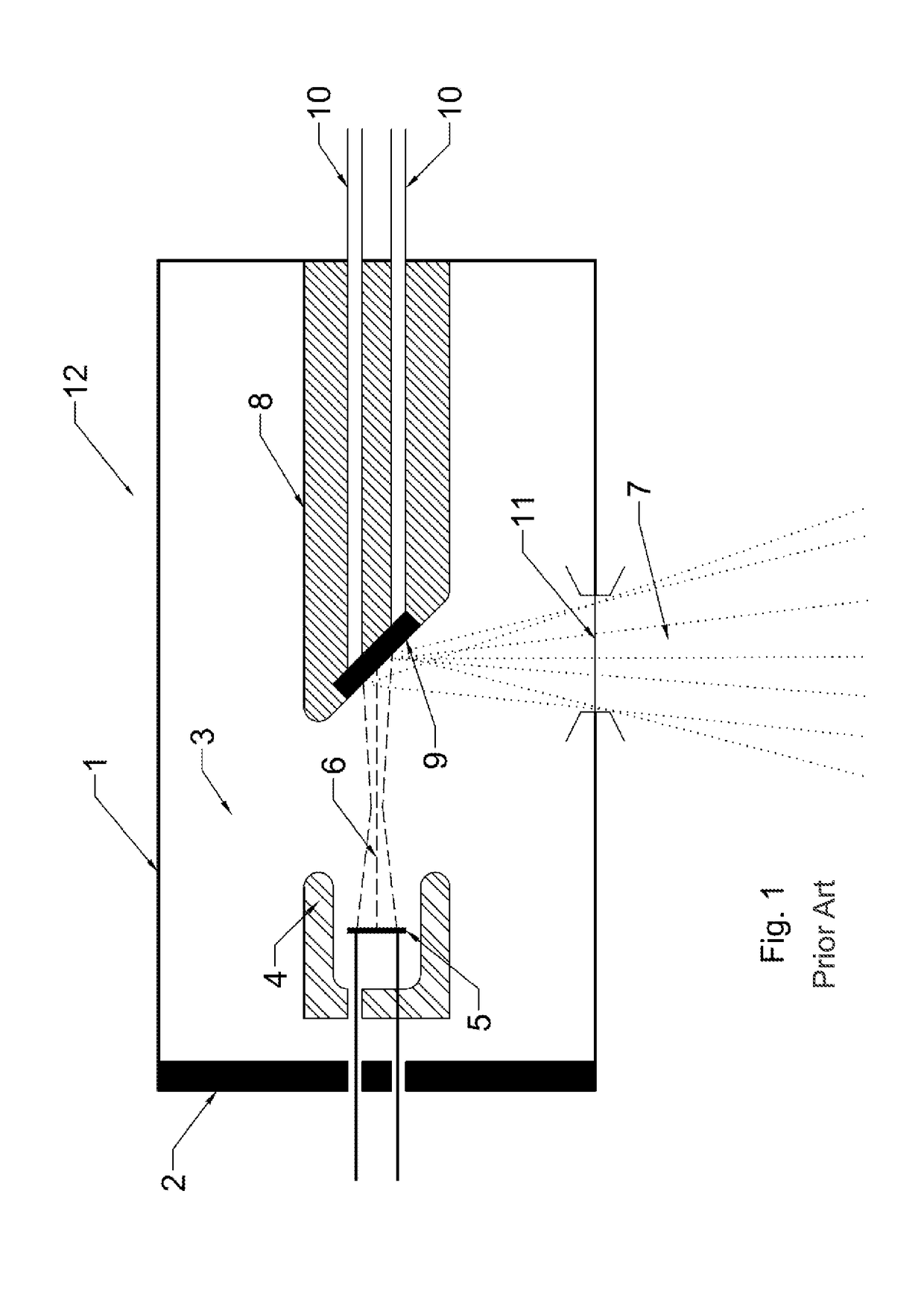

Radiation generating tube, and radiation generating apparatus and radiation imaging system using the same

ActiveUS20140369470A1High resolutionElectrode assembly support/mounting/spacing/insulationCathode ray tubes/electron beam tubesStress concentrationRadiation imaging

Provided is a radiation generating tube in which an insulating tube is prevented from being damaged by heat generation of a target or an electron emitting source during drive. Extending portions extending along an outer periphery of an insulating tube are provided to a cathode and an anode, respectively, and the insulating tube is joined to the extending portions to enhance the strength of joint portions. At the same time, the insulating tube can be deformed easily by setting a tube wall thickness of the insulating tube at a central portion in a longitudinal direction to be smaller than a tube wall thickness of an opening end, and thus the concentration of thermal stress on the joint portions caused by an increase in temperature of the cathode and the anode is alleviated.

Owner:CANON KK

Phosphor, Method For Manufacturing Same, Light Emitting Device, And Image Display Device

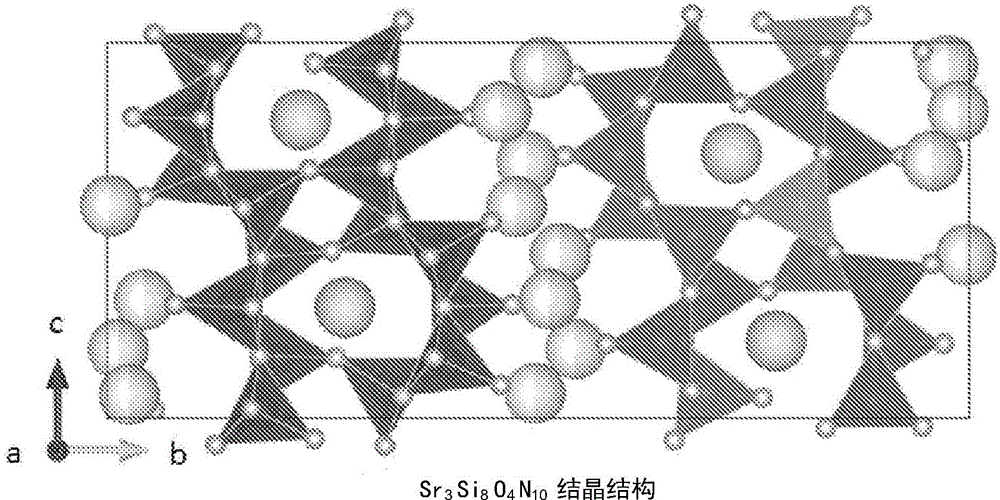

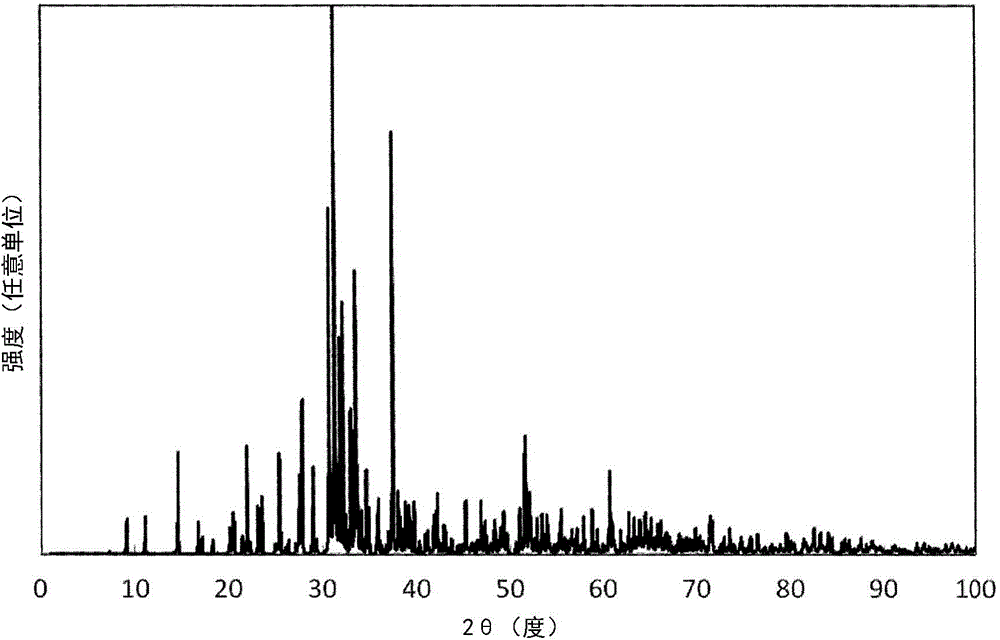

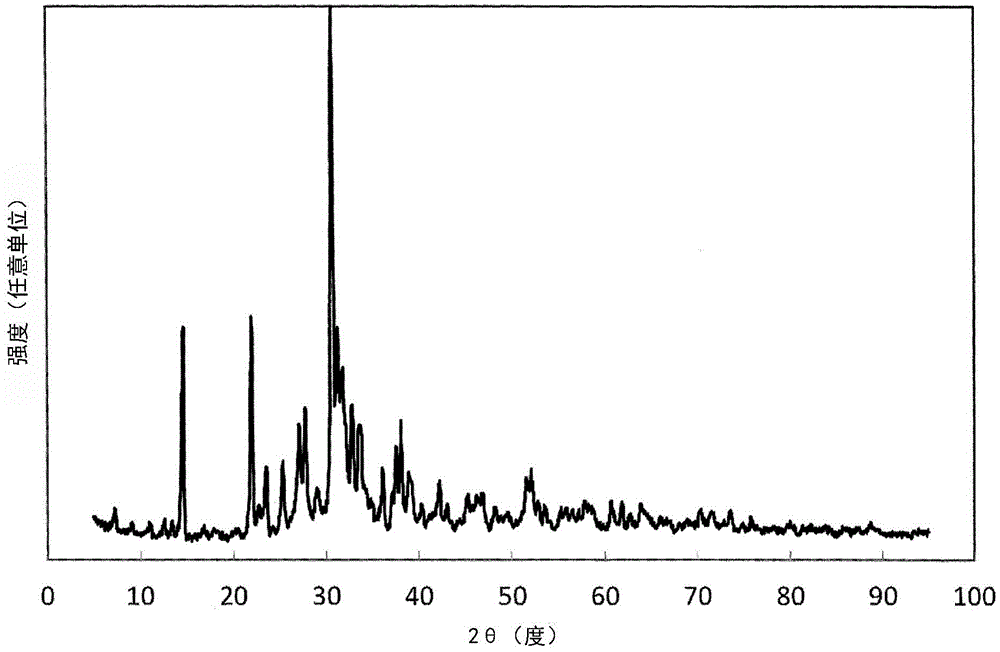

ActiveCN104024375AIncrease brightnessFrom solid stateVacuum tube vessels/containers/shieldsLuminous intensityDisplay device

According to the present invention, a chemically and thermally stable phosphor having unconventional light emitting properties, and having high light emitting intensity even when combined with an LED at 470 nm or less, contains crystals expressed by A3(D,E)8X1 4 that contain: element A, element D, and element X (where A represents one or more element selected from Li, Mg, Ca, Sr, and Ba; D represents one or more element selected from Si, Ge, Sn, Ti, Zr, Hf, and X represents one or more elements selected from O, N, and F), and if necessary element E (where E represents one or more elements selected from B, Al, Ga, In, Sc, Y, and La); crystals expressed by Sr3Si8O4N1 0; inorganic crystals having the same crystalline structure as the crystals expressed by Sr3Si8O4N1 0; or an inorganic compound in the form of a solid solution of element M (where M represents one or more elements selected from Mn, Ce, Pr, Nd, Sm, Eu, Tb, Dy, and Yb) in these solid-solution crystals.

Owner:NAT INST FOR MATERIALS SCI

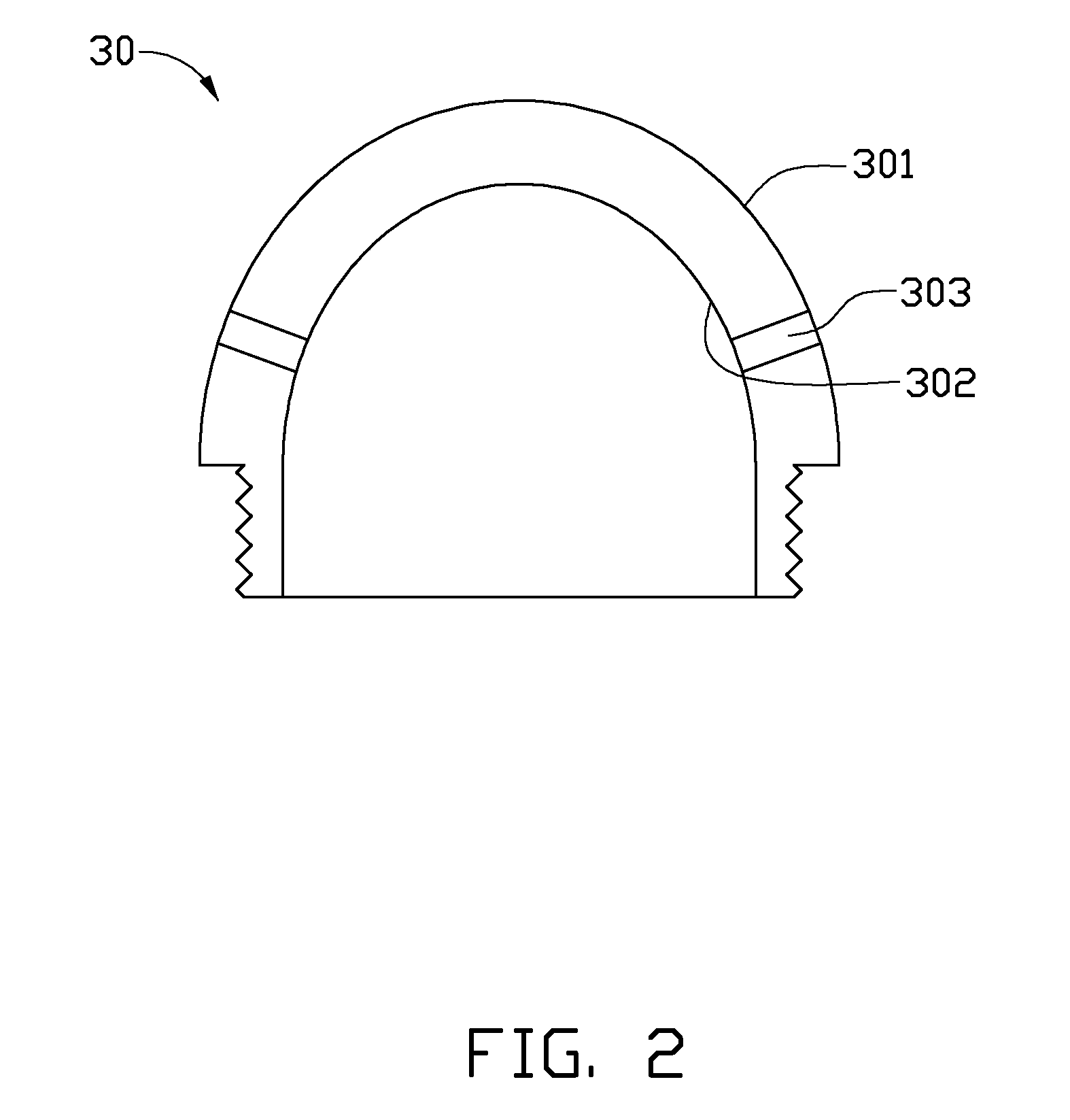

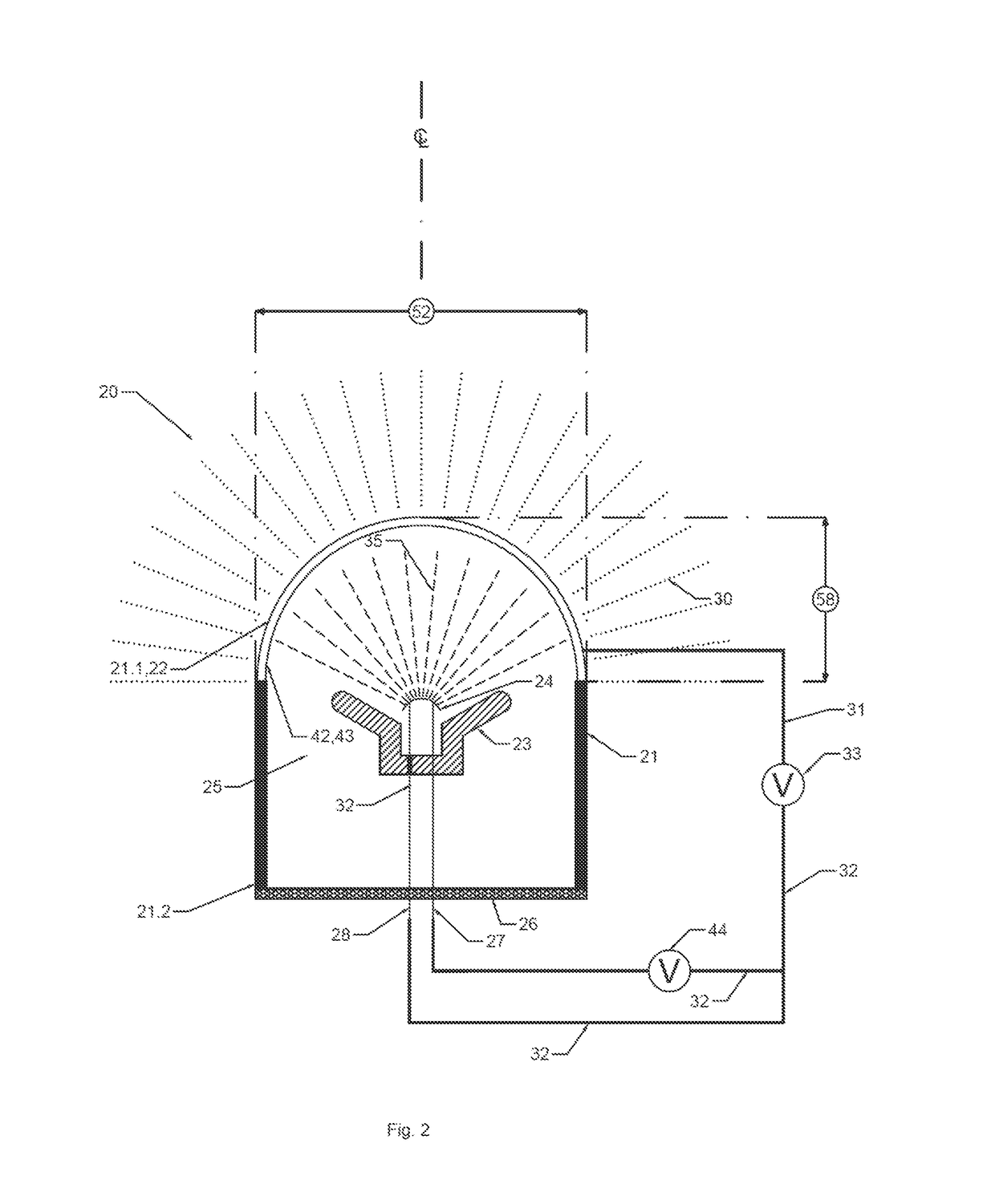

High dose output, through transmission target X-ray system and methods of use

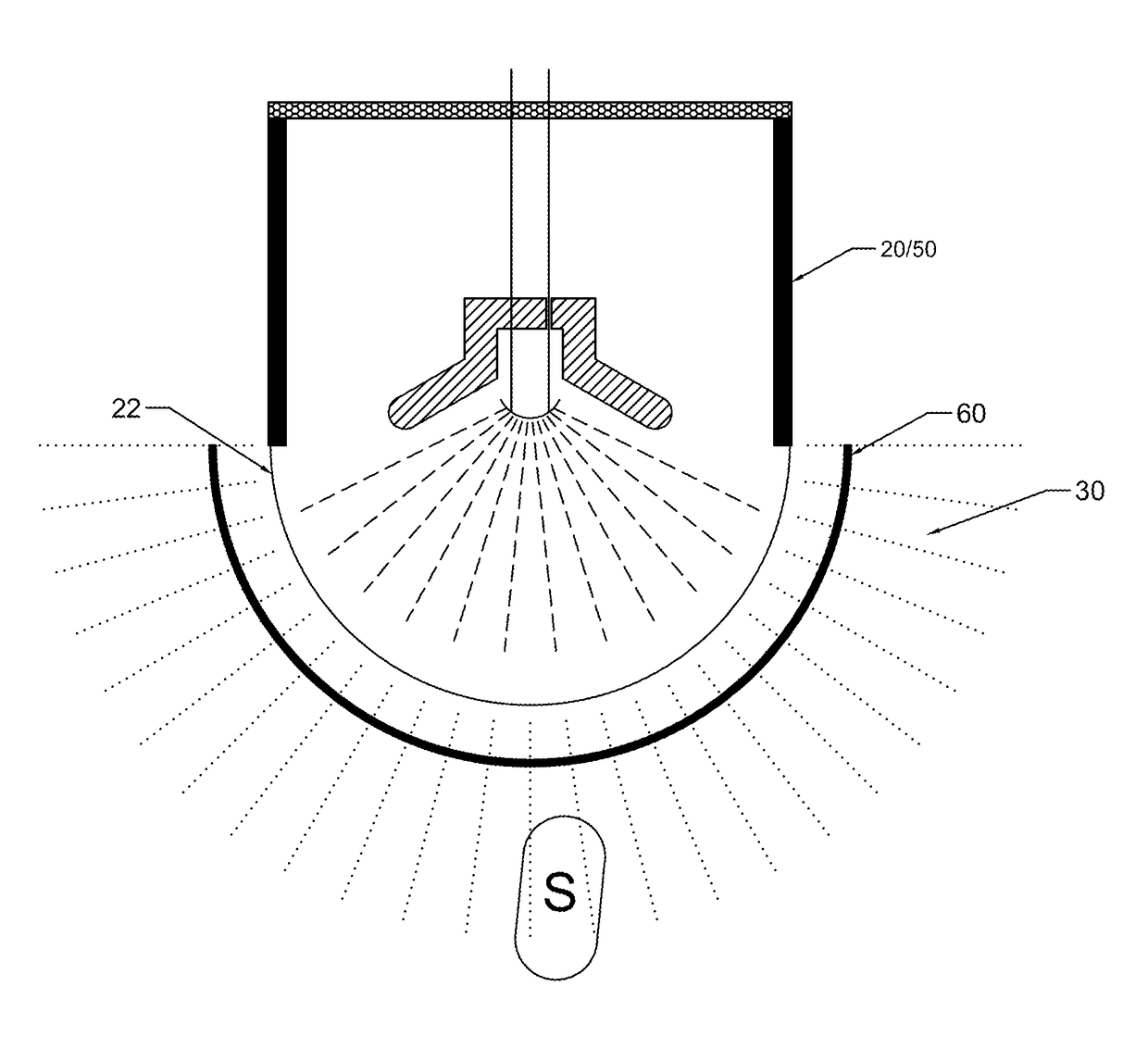

ActiveUS9818569B2Increase surface areaHigh outputX-ray tube electrodesVacuum tube vessels/containers/shieldsX-rayThrough transmission

A high dose output, through transmission target X-ray tube and methods of use includes, in general an X-ray tube for accelerating electrons under a high voltage potential having an evacuated high voltage housing, a hemispherical shaped through transmission target anode disposed in said housing, a cathode structure to deflect the electrons toward the hemispherical anode disposed in said housing, a filament located in the geometric center of the anode hemisphere disposed in said housing, a power supply connected to said cathode to provide accelerating voltage to the electrons.

Owner:RAD SOURCE TECH

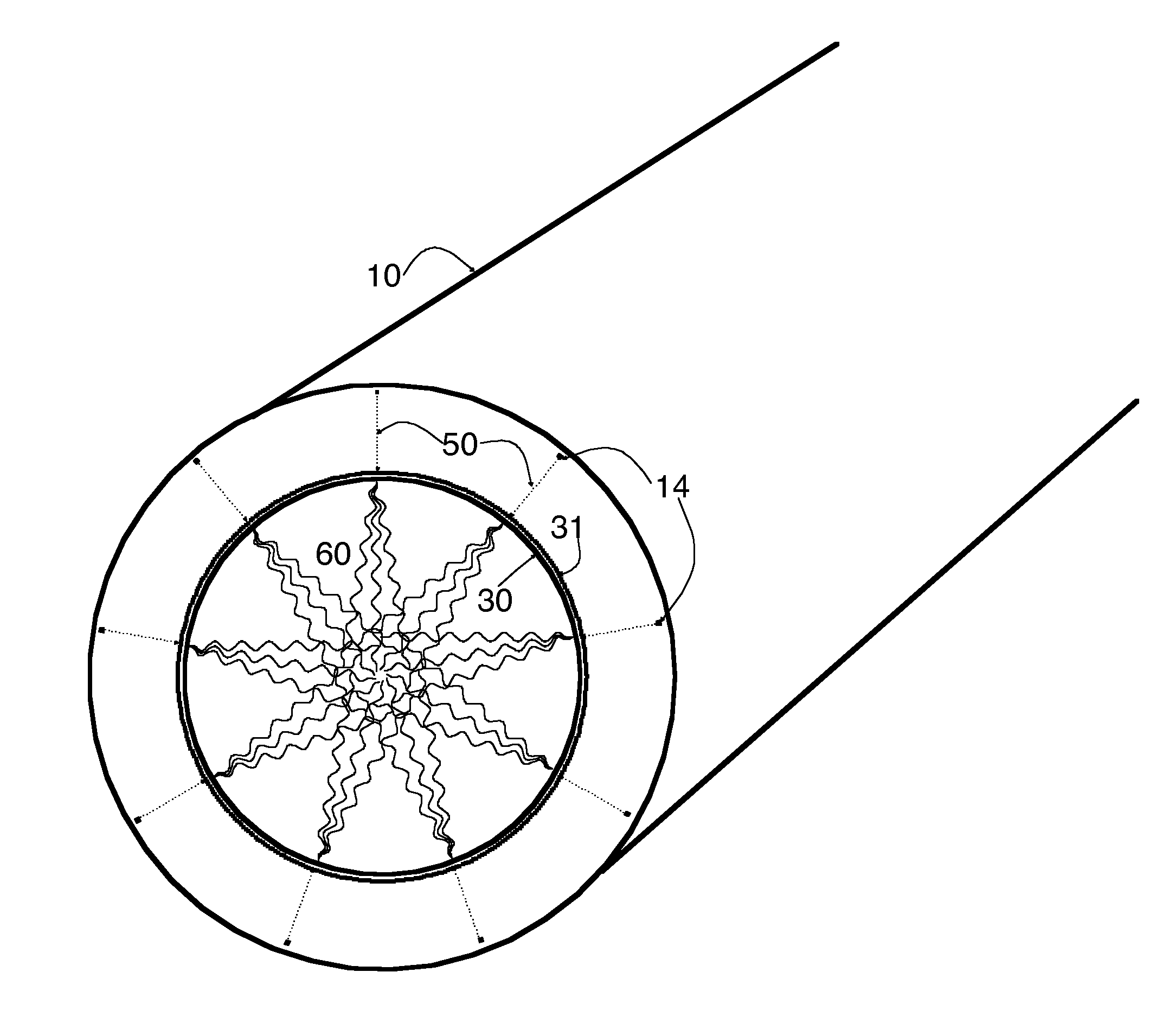

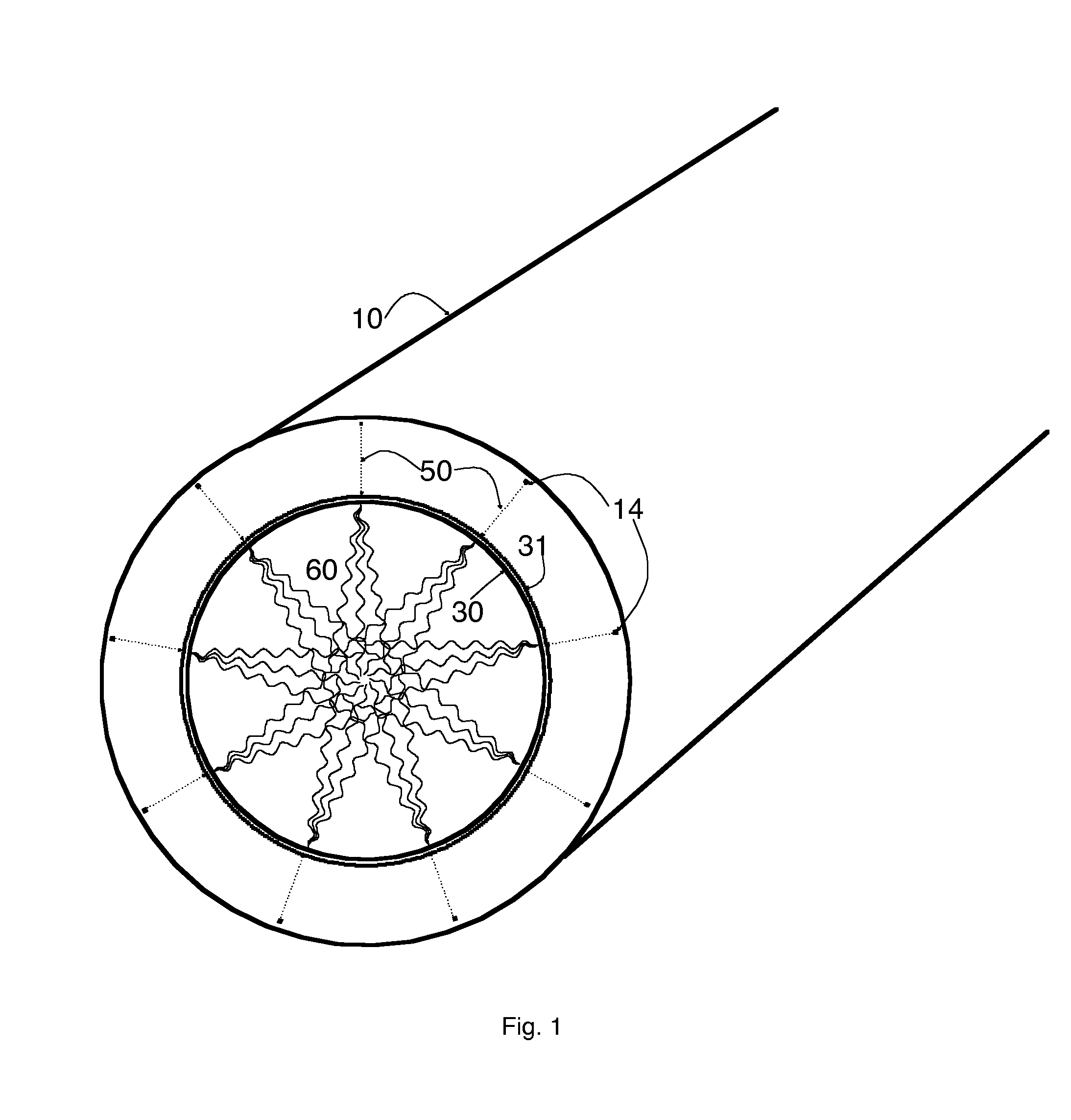

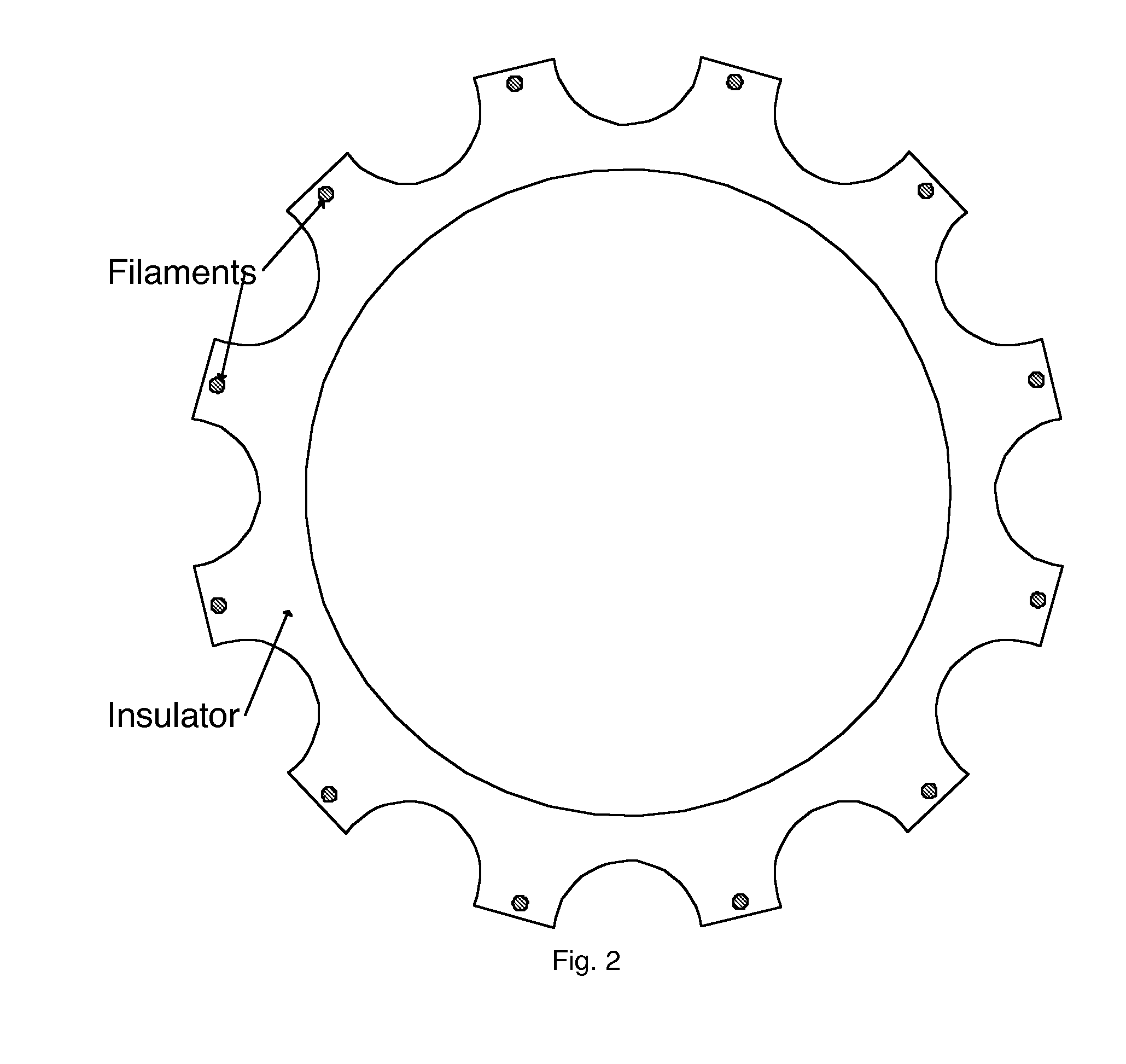

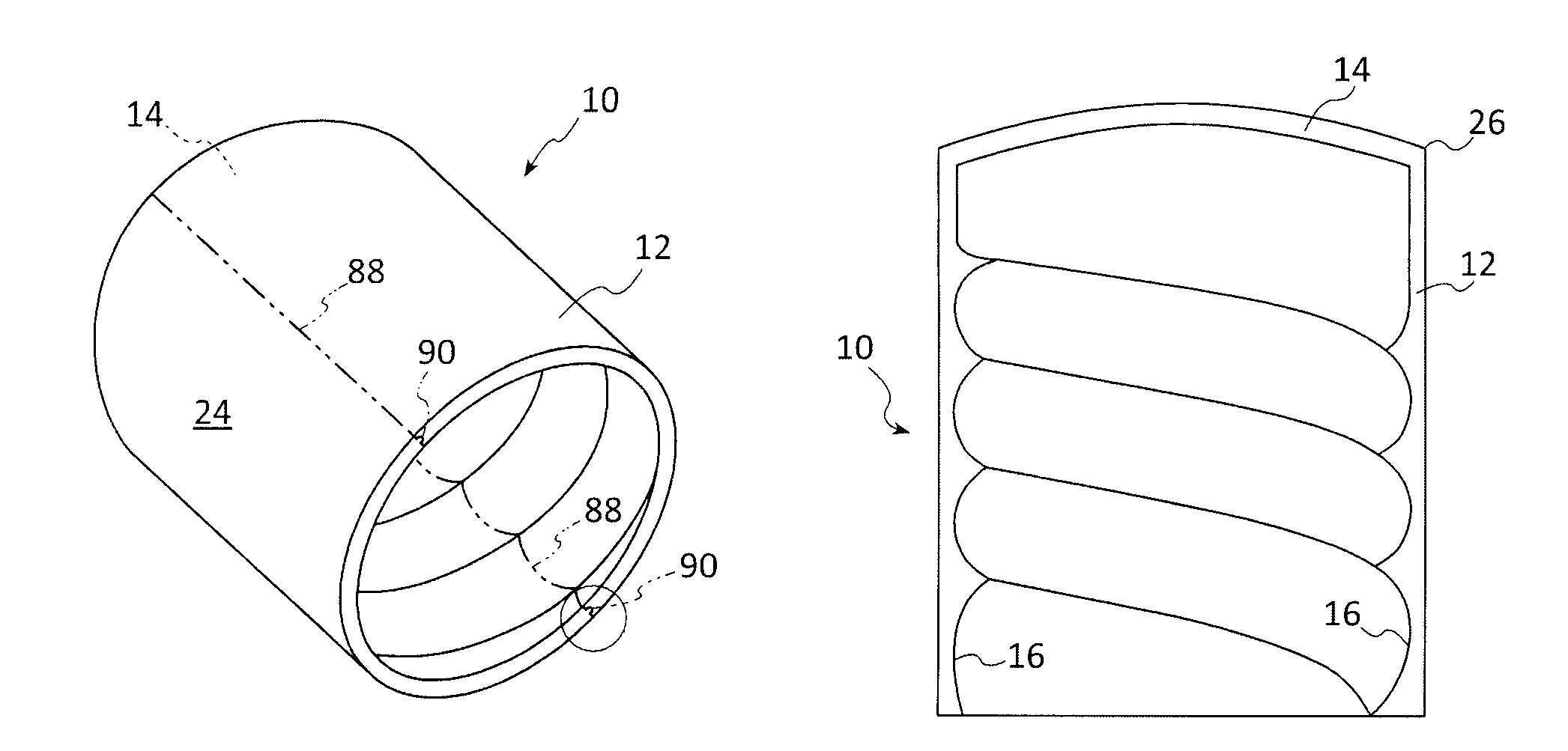

UV Pipe

ActiveUS20150262780A1Easy to scaleImprove power efficiencyDischarge tube luminescnet screensVacuum tube vessels/containers/shieldsDouble tubePower flow

A pipe source of UV flux has an inner pipe made of UV transmissive material and coated on its outer surface with a UV emitting phosphor. An outer pipe has a cathode array disposed on or near its inner surface, such as an array of thermionic filament cathodes mounted longitudinally or transverse to the length of the pipe, cold cathode arrays formed on the inner surface of the pipe or cold cathode arrays formed on separate substrates which are then attached to the inner surface of the outer pipe. The ends of this two-pipe assembly are hermetically sealed with flanges or end plates at either end of the pipe and evacuated to a pressure below 1×10−3 Torr. Internal spacing rings may be used to provide additional separation between the inner and out pipes. Current from the cathode arrays is accelerated by an anode voltage to strike the UV phosphors when then emit UV light flux which illuminates the inside of the pipe and the fluid material flowing through the inner pipe.

Owner:STELLARRAY

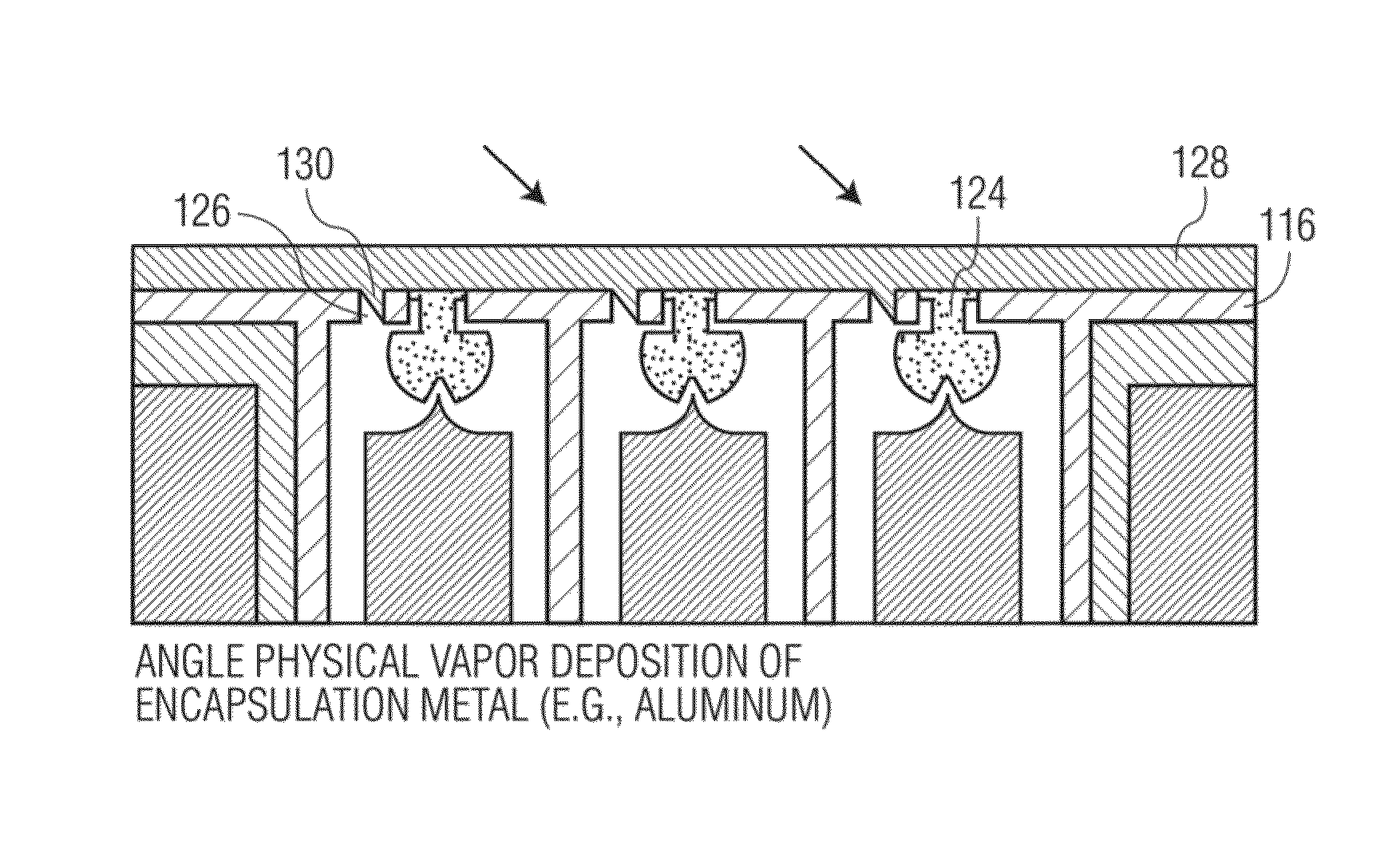

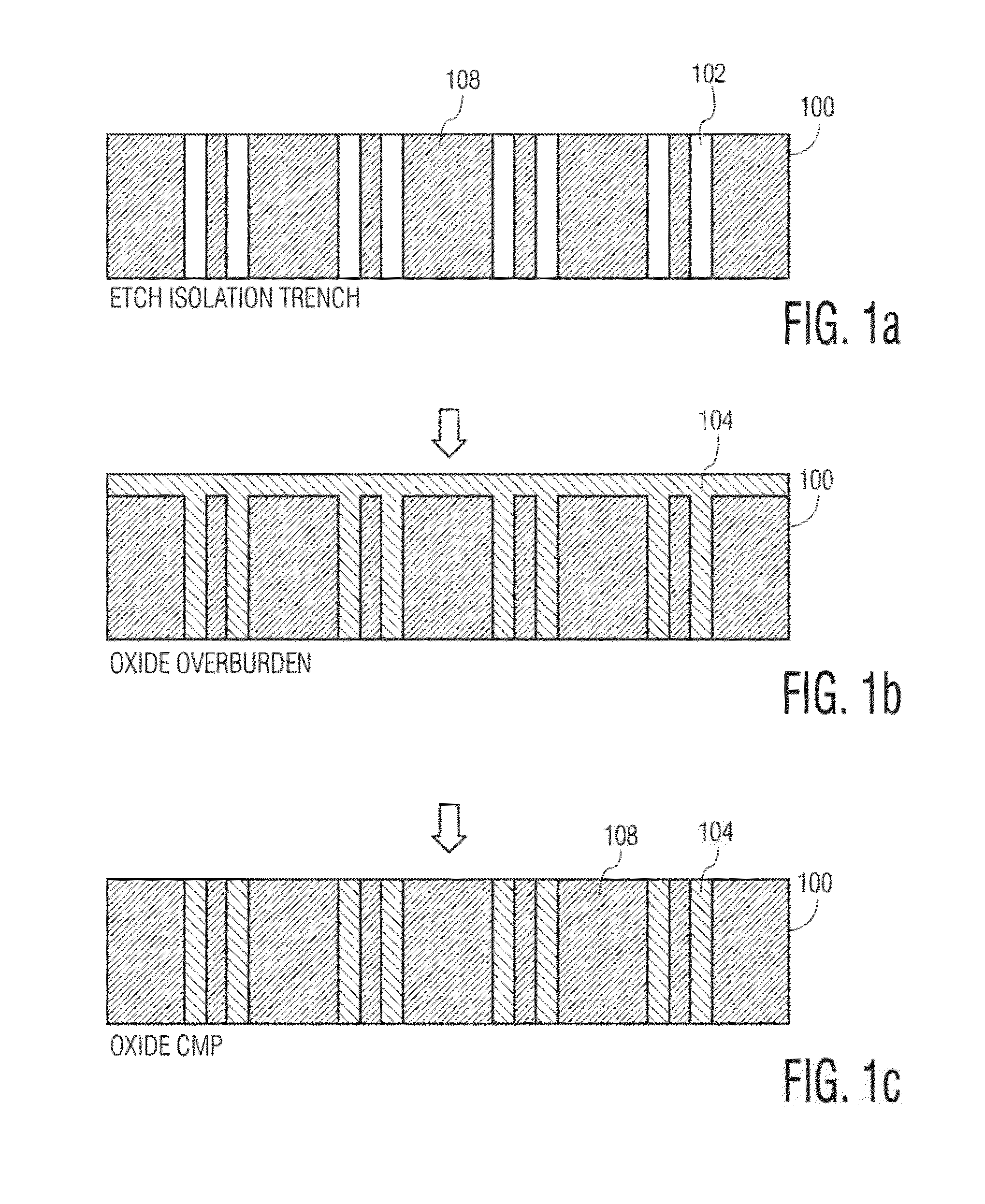

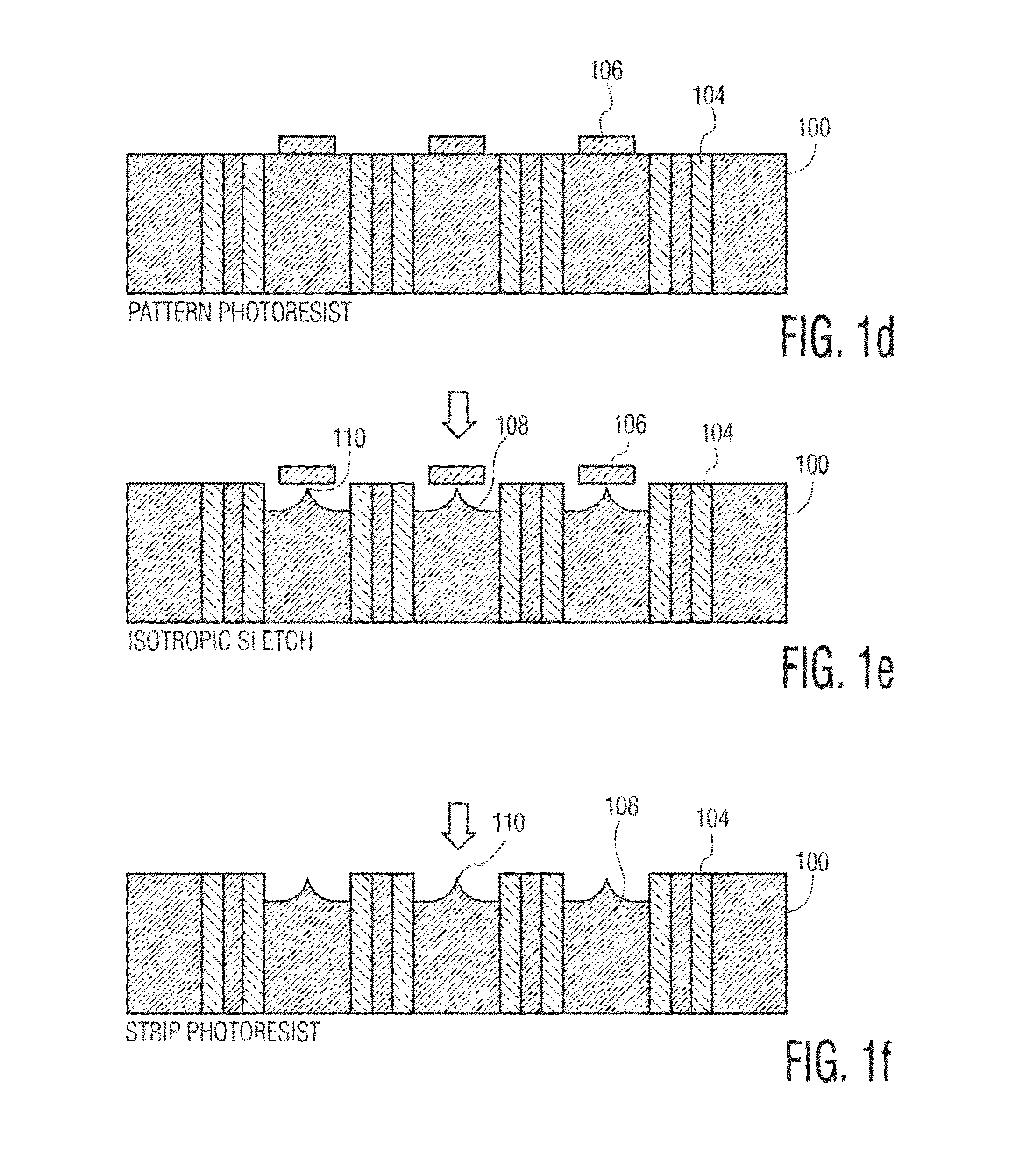

Method of manufacturing a fully integrated and encapsulated micro-fabricated vacuum diode

ActiveUS8814622B1Vacuum tube vessels/containers/shieldsThermionic cathodesConductive materialsEngineering

Disclosed is an encapsulated micro-diode and a method for producing same. The method comprises forming a plurality columns in the substrate with a respective tip disposed at a first end of the column, the tip defining a cathode of the diode; disposing a sacrificial oxide layer on the substrate, plurality of columns and respective tips; forming respective trenches in the sacrificial oxide layer around the columns; forming an opening in the sacrificial oxide layer to expose a portion of the tips; depositing a conductive material in of the opening and on a surface of the substrate to form an anode of the diode; and removing the sacrificial oxide layer.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

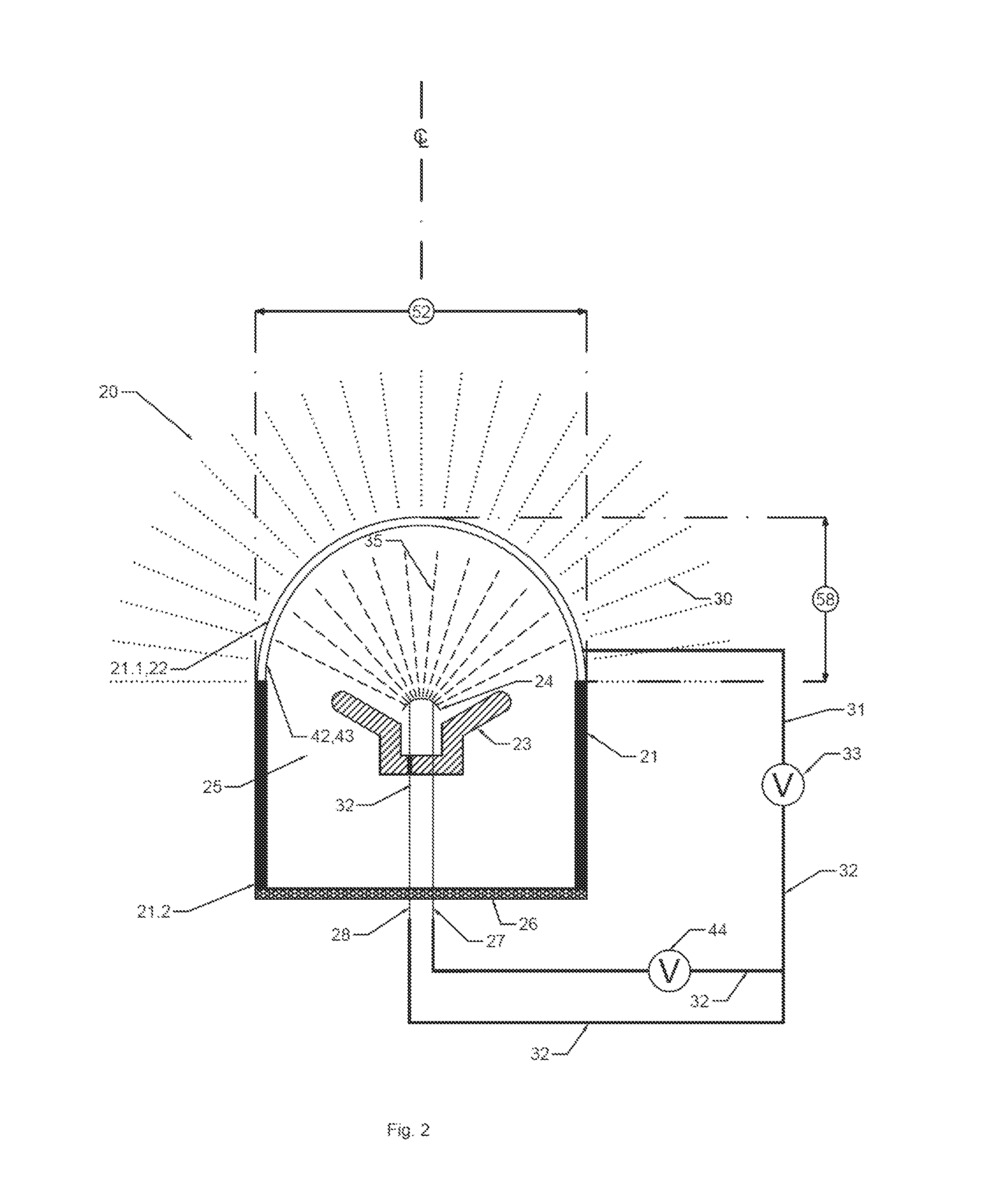

Explosion Protection System for a High Pressure Lamp

InactiveUS20110074273A1Improve explosion protectionEasy to catchIncadescent screens/filtersVacuum tube vessels/containers/shieldsExplosion protectionEngineering

A base for a high pressure lamp, such base having lateral walls enclosing the lamp bulb. Also disclosed are lateral walls for a base, and a lamp system comprising such base.

Owner:OSRAM OPTO SEMICONDUCTORS GMBH & CO OHG

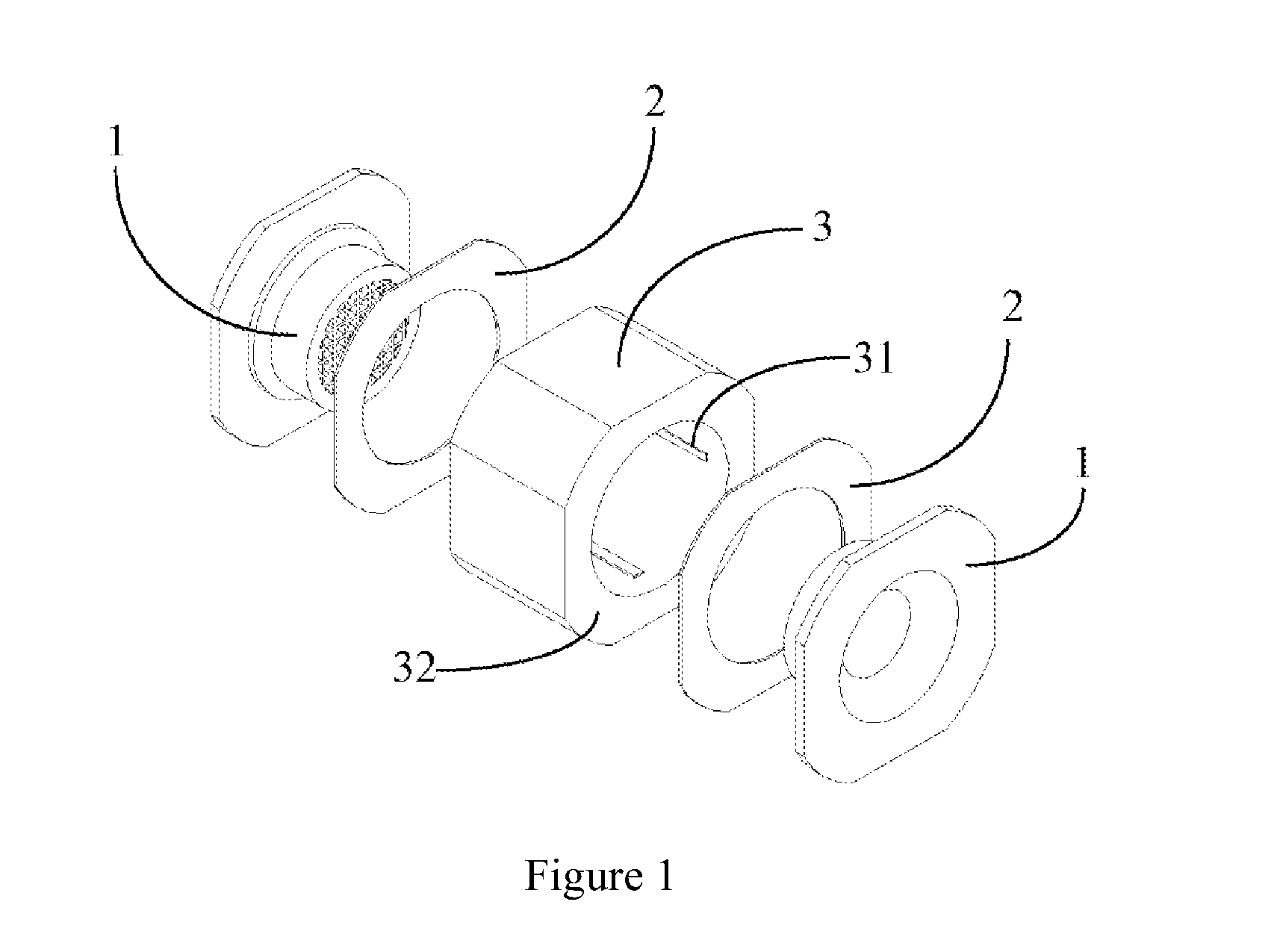

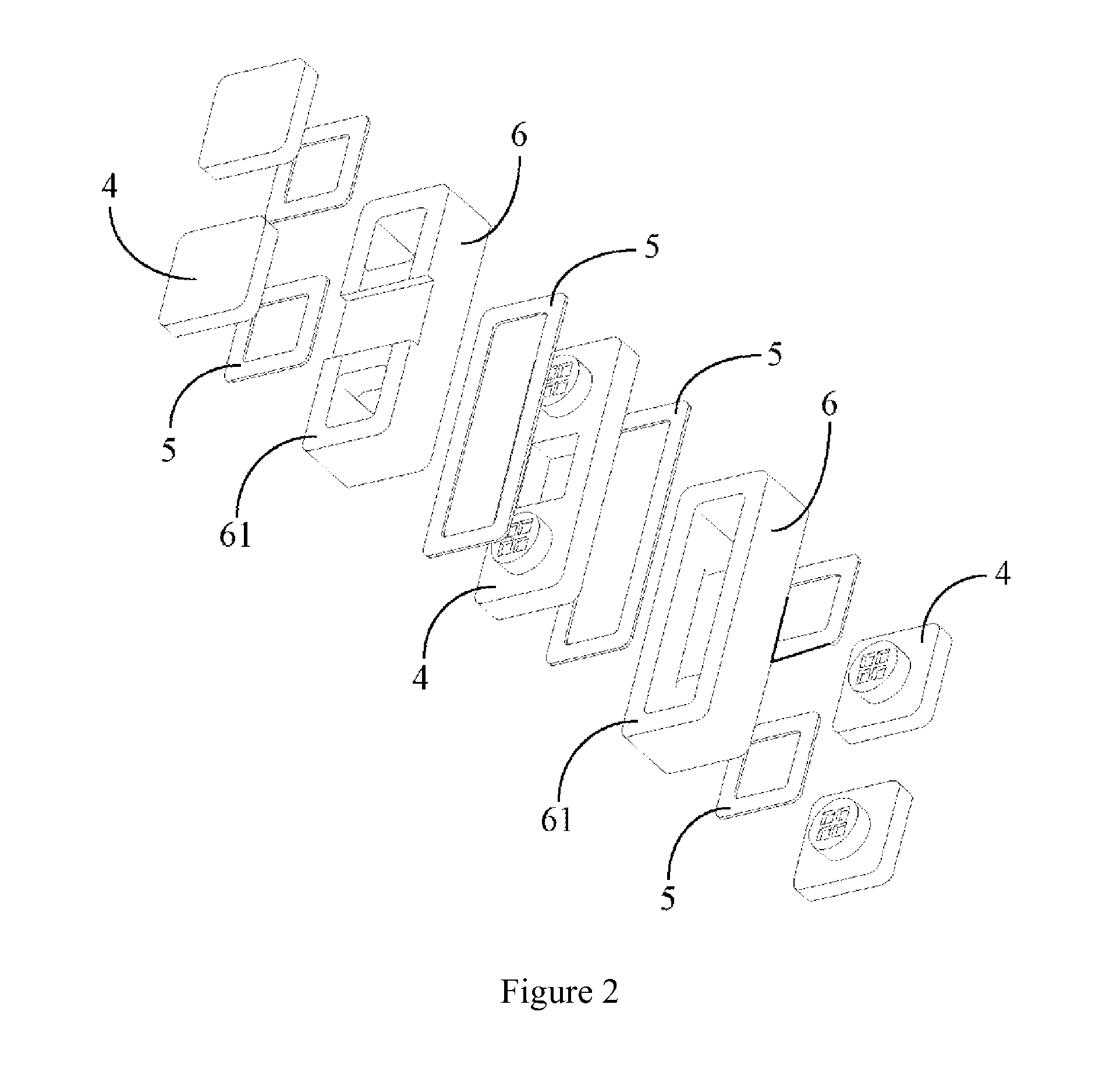

Integrated gas discharge tube and manufacturing method thereof

ActiveCN103441053AImprove discharge performanceIncrease production capacityVacuum tube vessels/containers/shieldsSolid cathode detailsElectric dischargeEnvironmental engineering

The invention provides an integrated gas discharge tube. According to the integrated gas discharge tube, a gas discharge tube structure is adjusted to comprises an upper cover and an insulation substrate, electrode integration is carried out on the inner side face and the outer side face of the bottom surface of the insulation substrate, the electric discharge effect of the gas discharge tube is effectively improved, the manufacturing procedure of the gas discharge tube with multiple ends to earth is greatly simplified, the manufacturing procedure is greatly simplified, and batch production and high integration of the gas discharge tube are achieved. The invention further provides a manufacturing method of the integrated gas discharge tube.

Owner:SHENZHEN BENCENT ELECTRONICS CO LTD

High dose output, through transmission target x-ray system and methods of use

ActiveUS20160189911A1Increase surface areaIncreased radiation outputX-ray tube laminated targetsX-ray tube anode coolingX-rayHigh doses

A high dose output, through transmission target X-ray tube and methods of use includes, in general an X-ray tube for accelerating electrons under a high voltage potential having an evacuated high voltage housing, a hemispherical shaped through transmission target anode disposed in said housing, a cathode structure to deflect the electrons toward the hemispherical anode disposed in said housing, a filament located in the geometric center of the anode hemisphere disposed in said housing, a power supply connected to said cathode to provide accelerating voltage to the electrons.

Owner:RAD SOURCE TECH

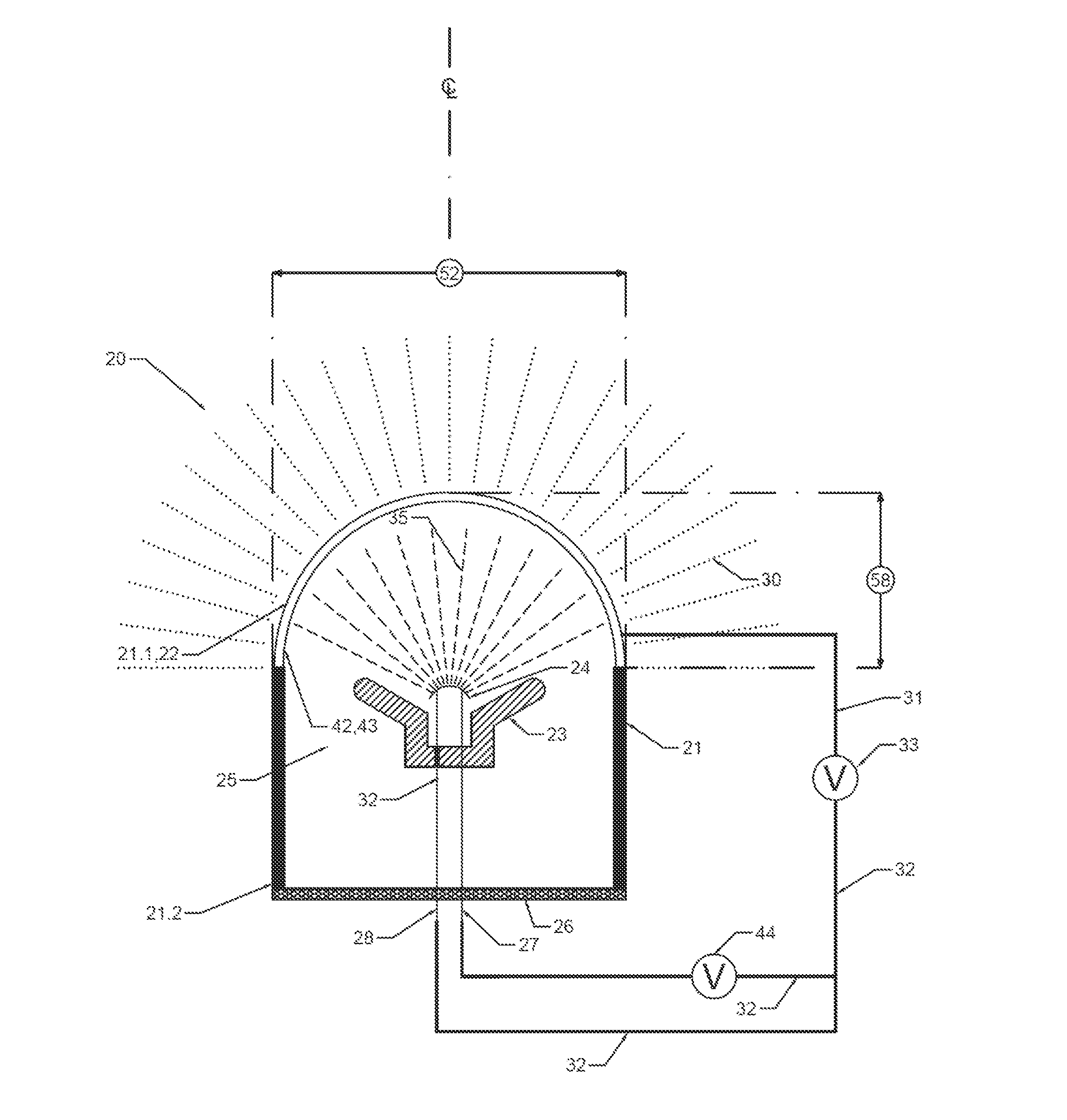

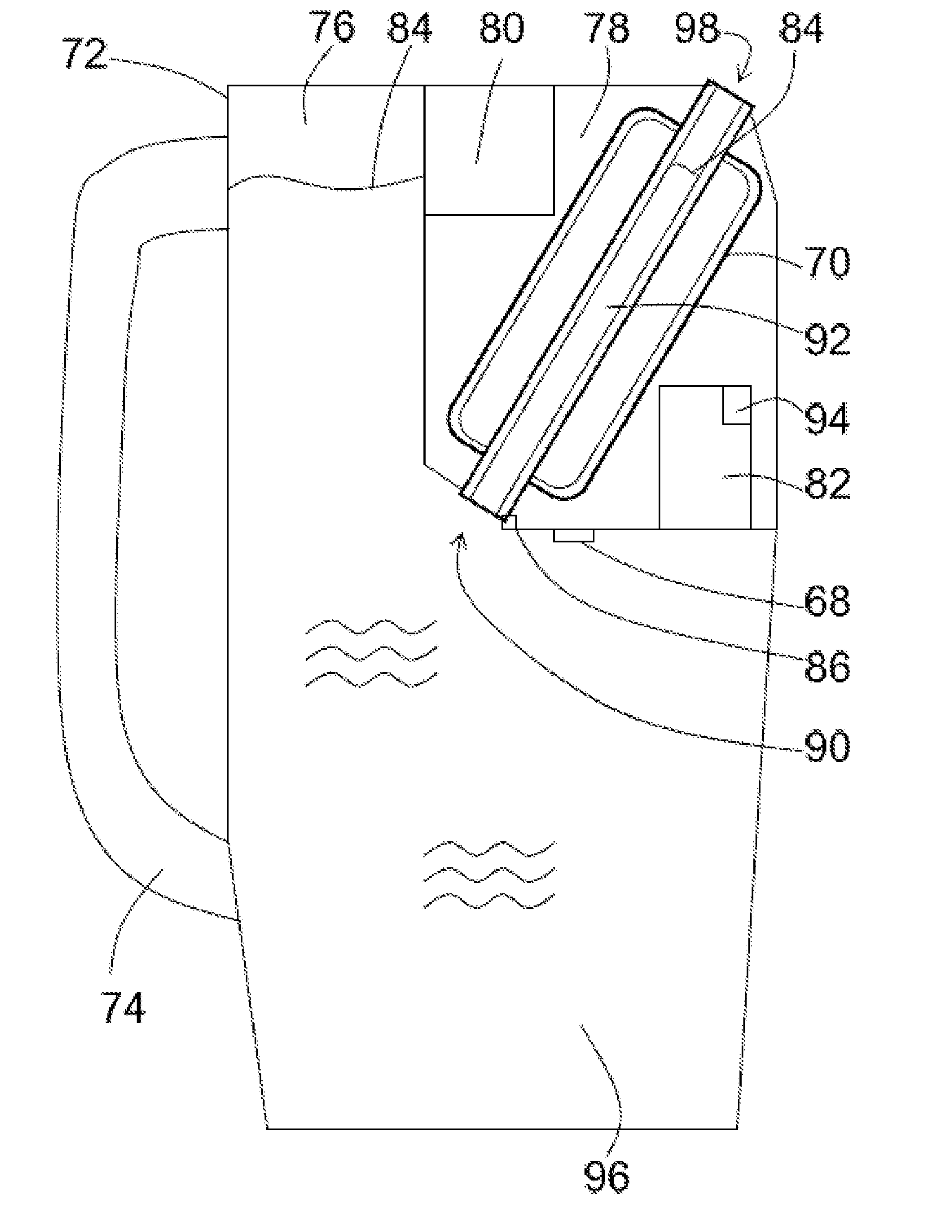

Dielectric barrier discharge lamp device, and optical fluid treatment device provided with the dielectric barrier discharge lamp device

ActiveUS20130221236A1Robust mechanical designRobust designVacuum tube vessels/containers/shieldsTreatment involving filtrationLow voltageBiomedical engineering

A dielectric barrier discharge, DBD, lamp device comprises a toroid shaped discharge chamber (10) having a discharge chamber wall (12). The discharge chamber wall comprises a tubular inner wall section (14), a tubular outer wall section (16), and two ring-shaped end wall sections (18, 20). Each of the end wall sections extend between an end of the outer wall section and an end of the inner wall section. A high voltage electrode (22) is provided at an outer surface of the outer wall section of the discharge chamber wall. A low voltage electrode comprises an electrically conducting fluid surrounded by the inner wall section of the discharge chamber wall. The DBD lamp device may be part of an optical fluid treatment device.

Owner:USHIO EURO

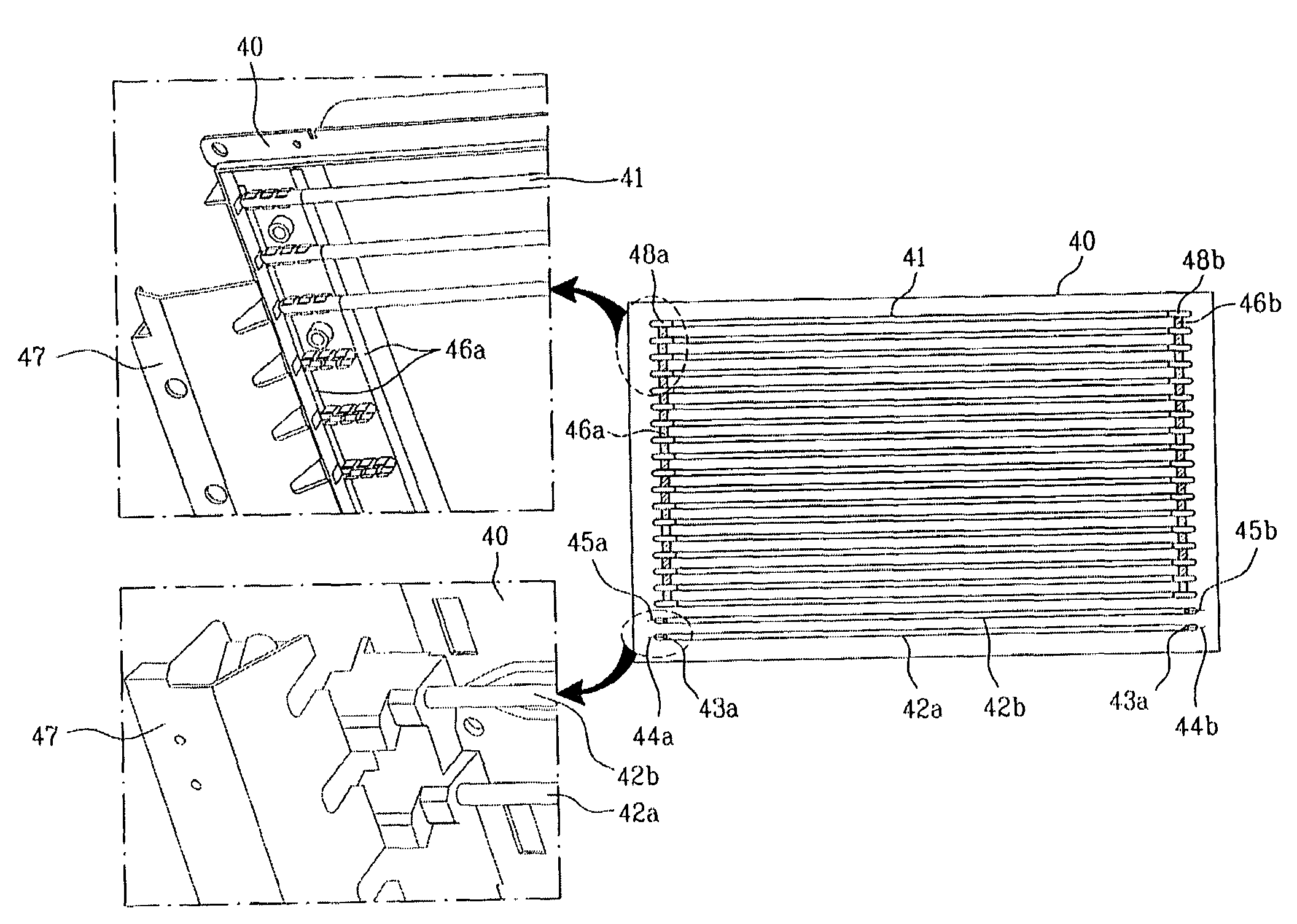

Backlight unit and method of driving the same

InactiveUS7441921B2Avoid Parasitic CapacitanceUniform backlight brightnessPoint-like light sourceStatic indicating devicesCold cathodeEngineering

Owner:LG DISPLAY CO LTD

Integrated gas discharge tube and preparation method therefor

ActiveUS20160049276A1Simple manufacturing processImprove discharge performanceVacuum tube vessels/containers/shieldsGas discharge lampsBatch productionProcess engineering

Provided is an integrated gas discharge tube. In the integrated gas discharge tube, the structure of the gas discharge tube is regulated into an upper cover and an insulative base, and the internal side surface and the external side surface of the bottom surface of the insulative base are respectively subject to electrode integration, so that the discharge effect of the gas discharge tube is effectively increased and the preparation process and the preparation flow of a multi-terminal-to-ground gas discharge tube are greatly simplified so as to greatly simplify the preparation process and to realize batch production and high integration of the gas discharge tube. Also provided is a preparation method for an integrated gas discharge tube.

Owner:SHENZHEN BENCENT ELECTRONICS CO LTD

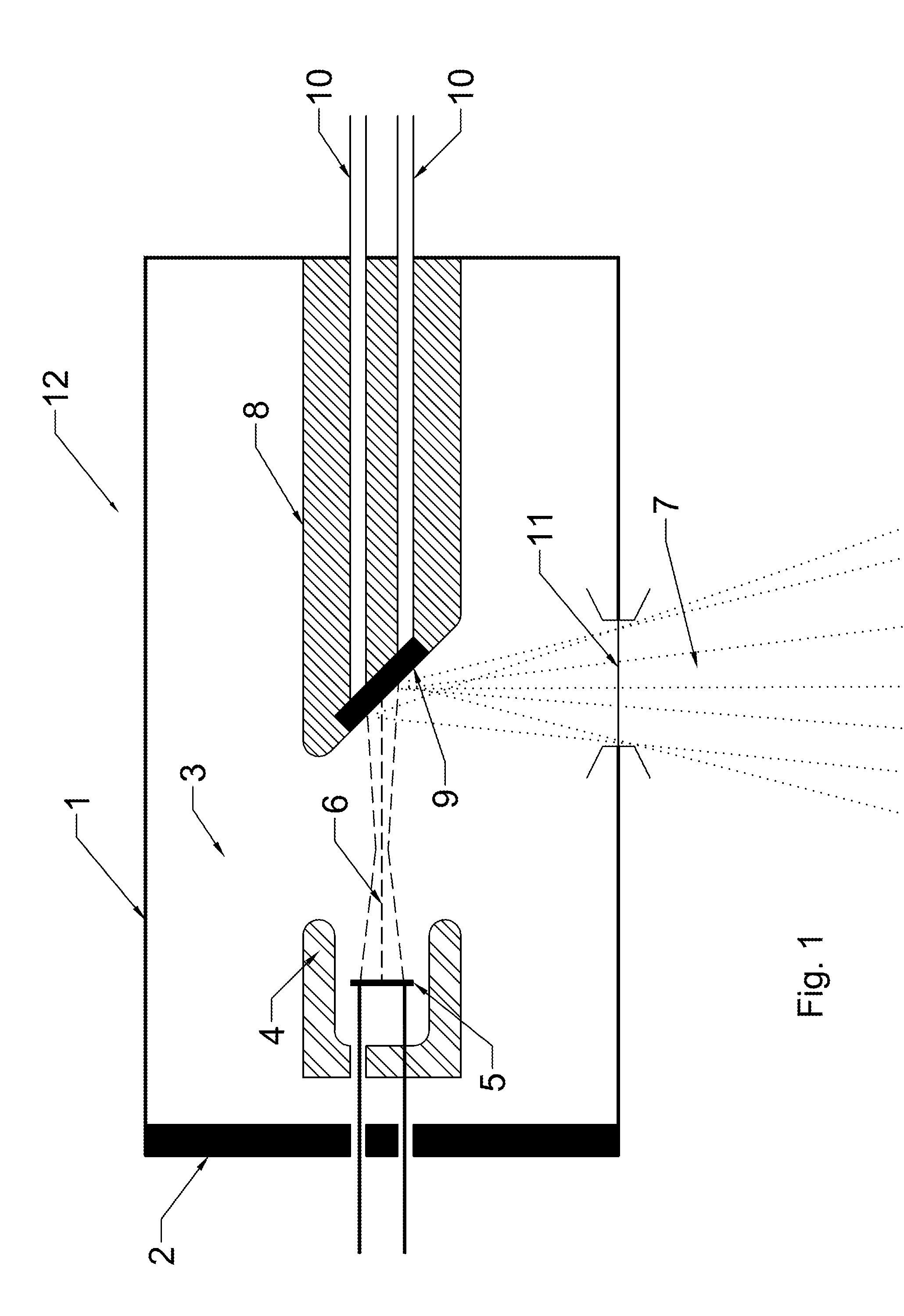

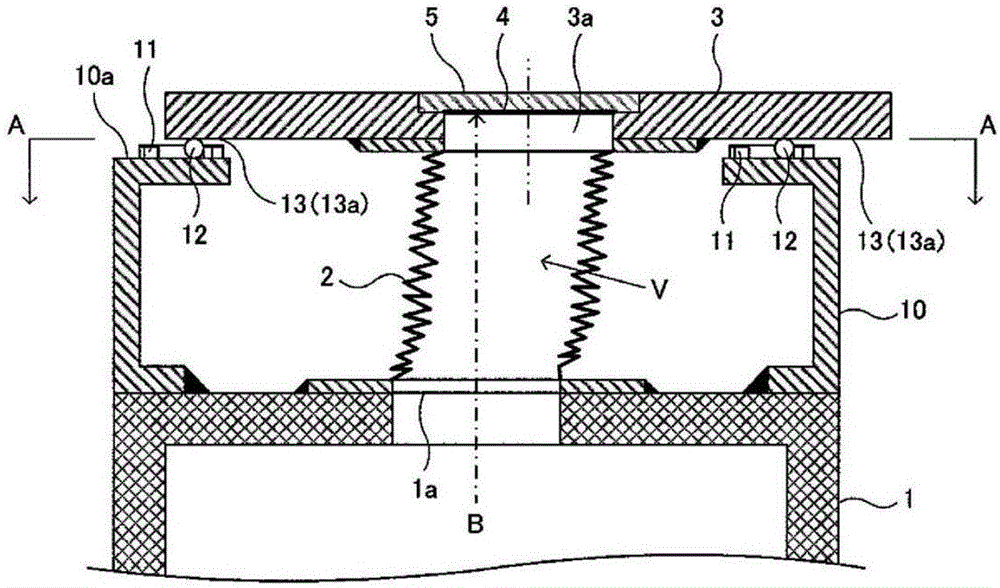

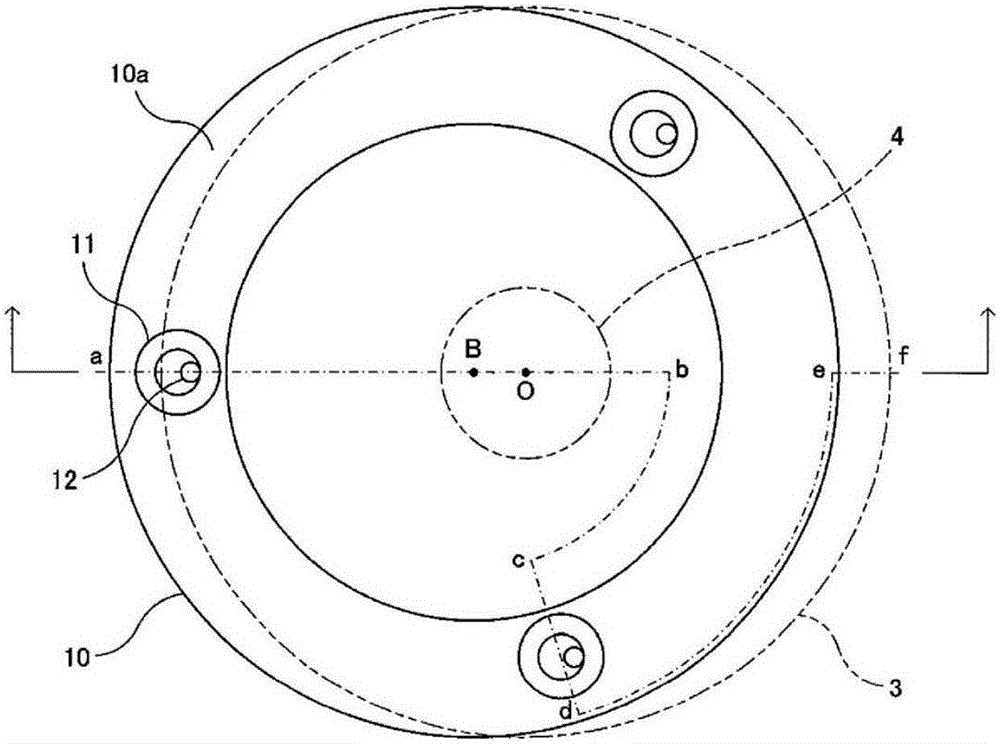

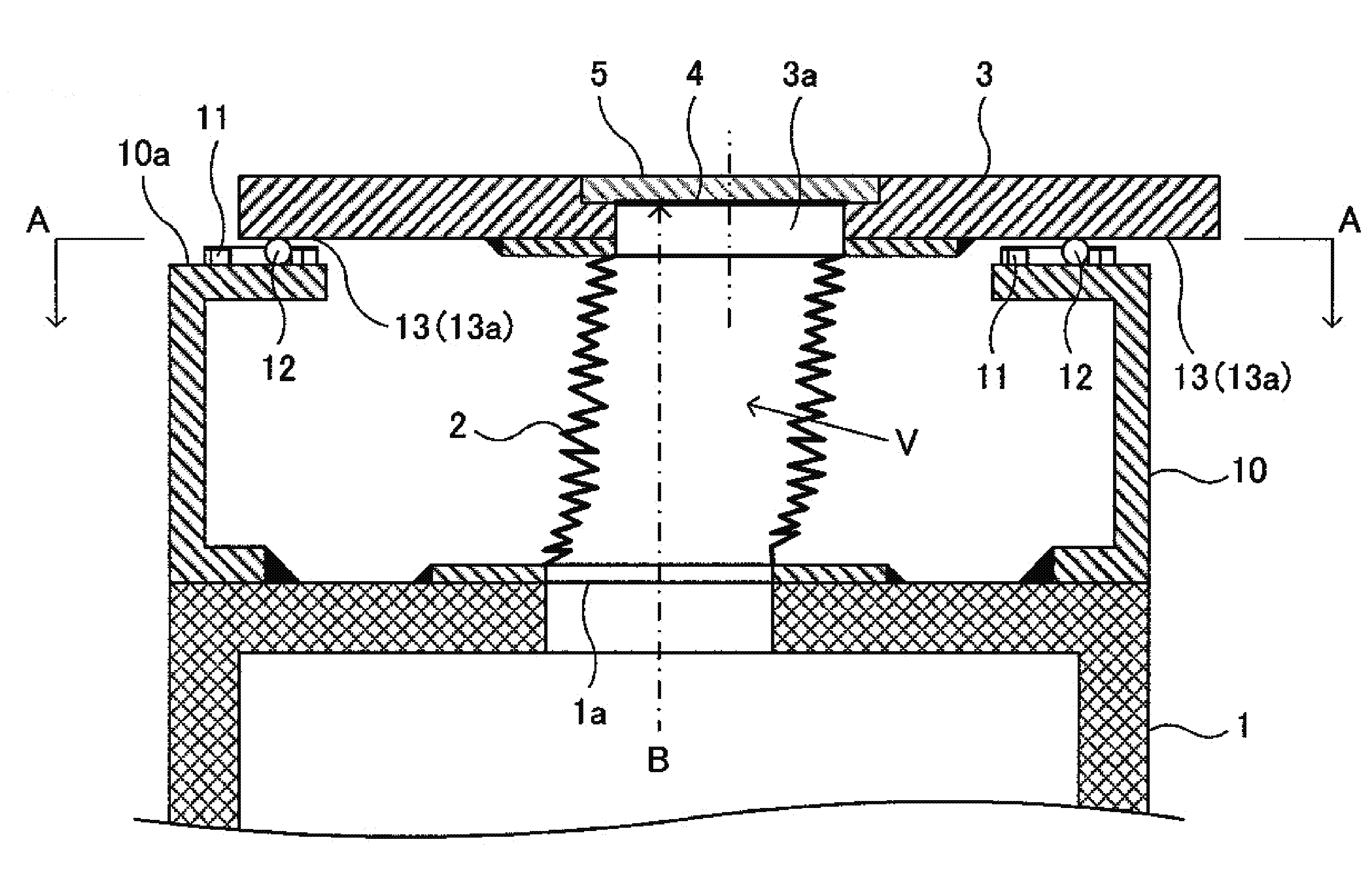

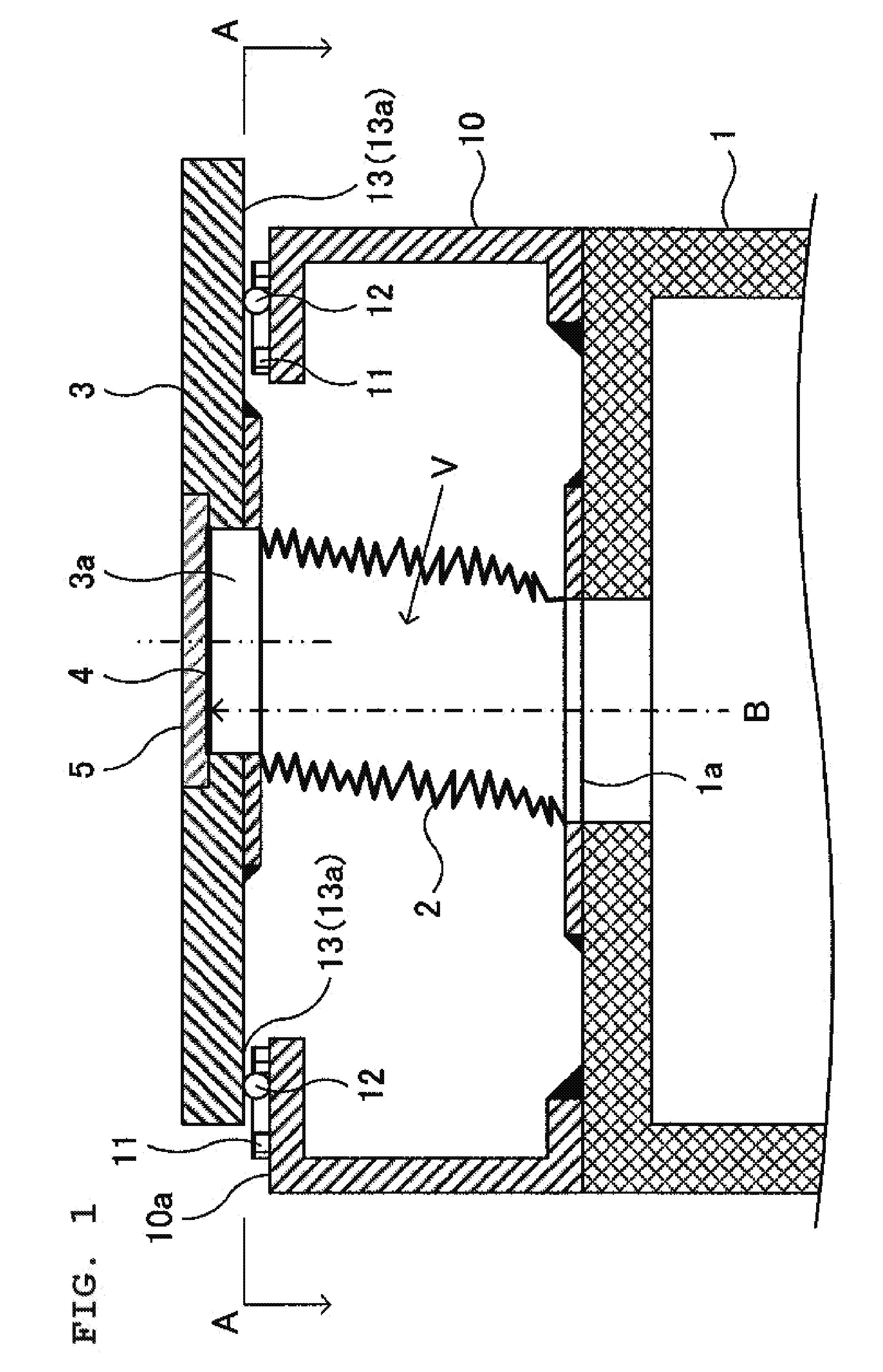

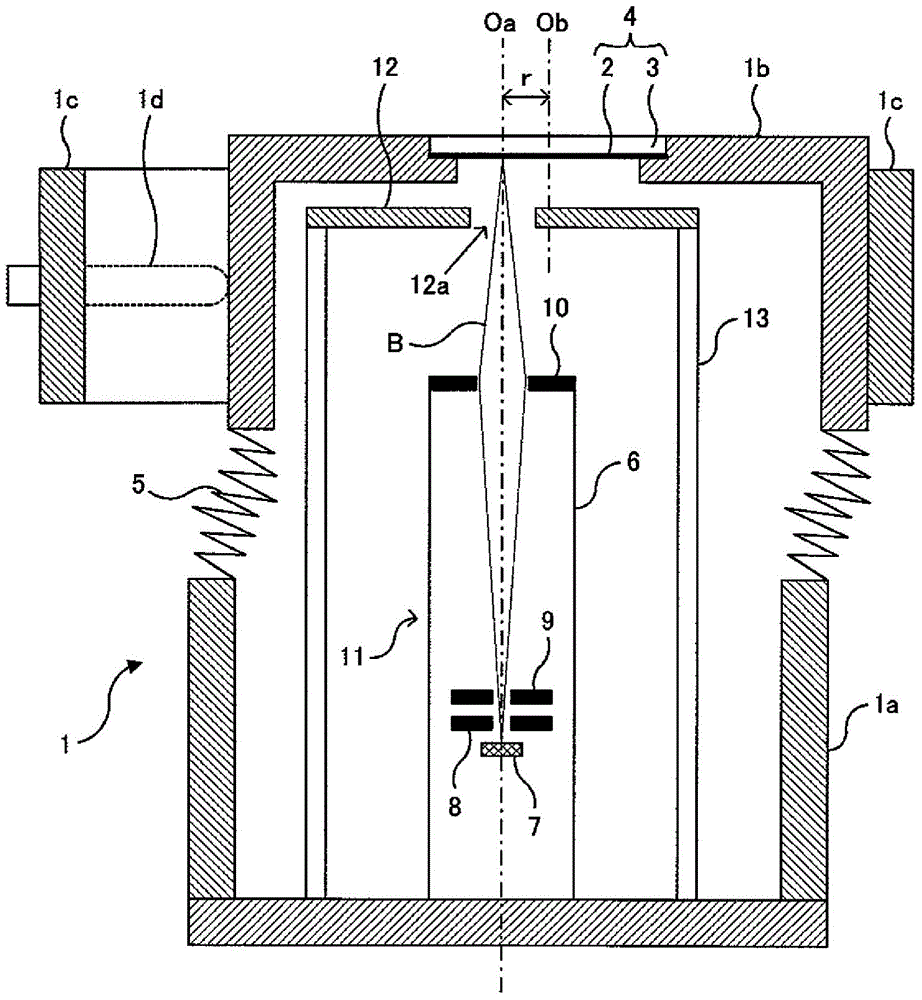

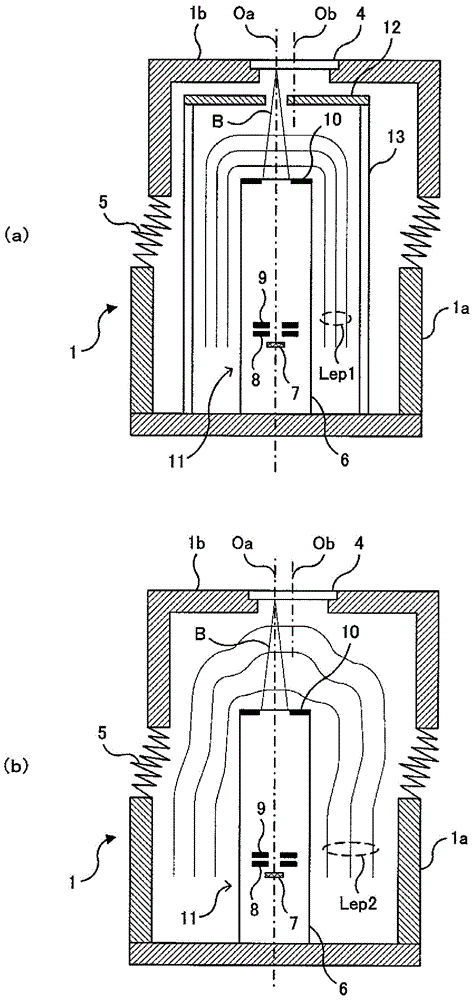

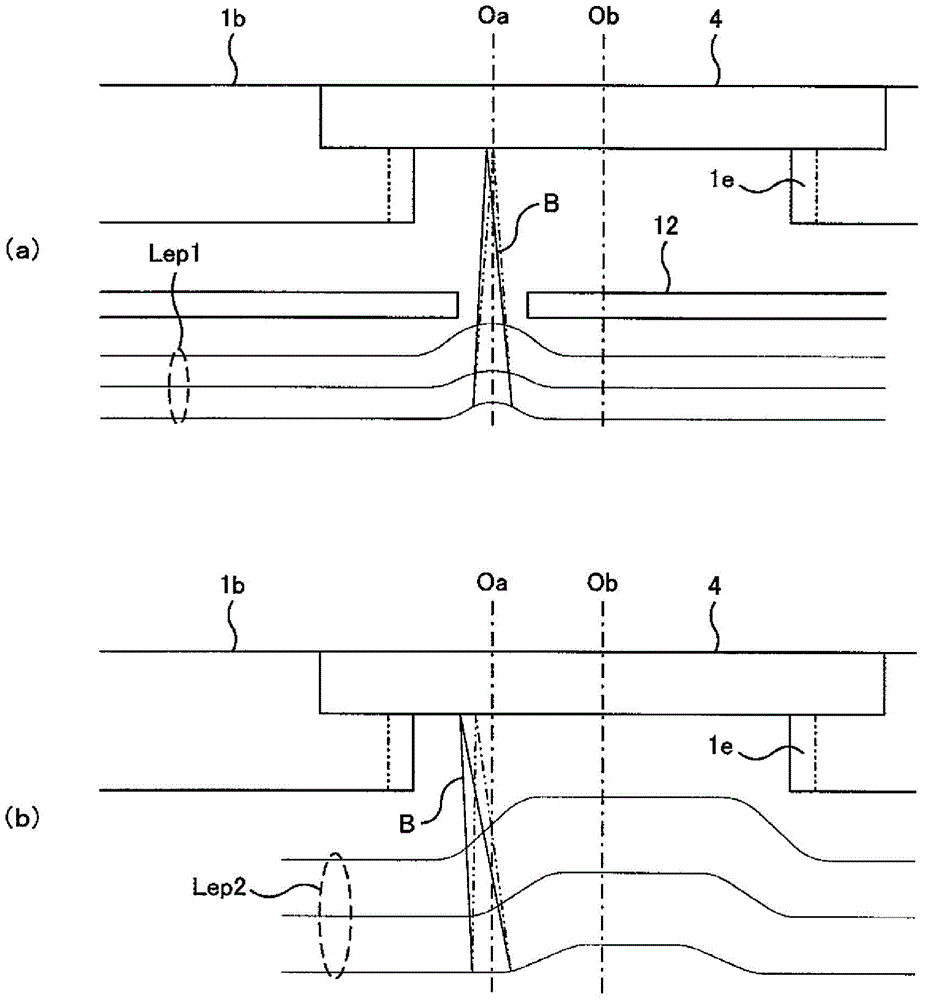

X-ray generating apparatus

InactiveCN106128925AEasy to moveWill not be affected by perspective magnificationX-ray tube electrodesVacuum tube vessels/containers/shieldsX-rayElectron

The present invention relates to an X-ray generating apparatus. A moving part(3) for holding an X-ray irradiation window (5) of a target (4) is connected to the body portion (1) of a vacuum container via the vacuum bellows (2), and a guiding mechanism for limiting the moving direction and the inclination of the moving part (3) is arranged outside the vacuum container. The guiding mechanism includes a guide flat surface (10a) formed on a side of the main body (1) along a plane orthogonal to the central axis of the electron beam (B), a flat surface (13a) for guiding the movable flat surface 13a, (3) is formed so as to face the guide flat surface (10a); and a plurality of rotating bodies (12) which are rotatable therebetween. As a result, the frictional force in the guiding mechanism can be reduced.

Owner:SHIMADZU SEISAKUSHO LTD

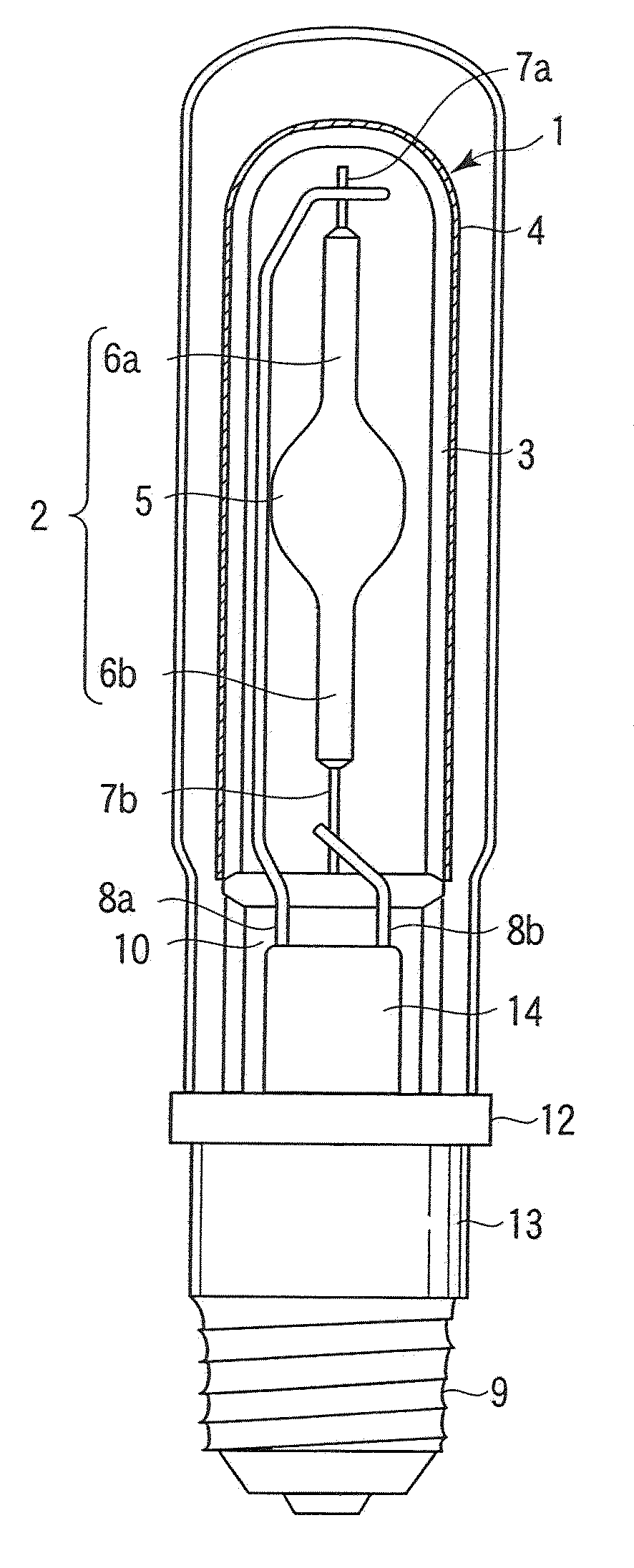

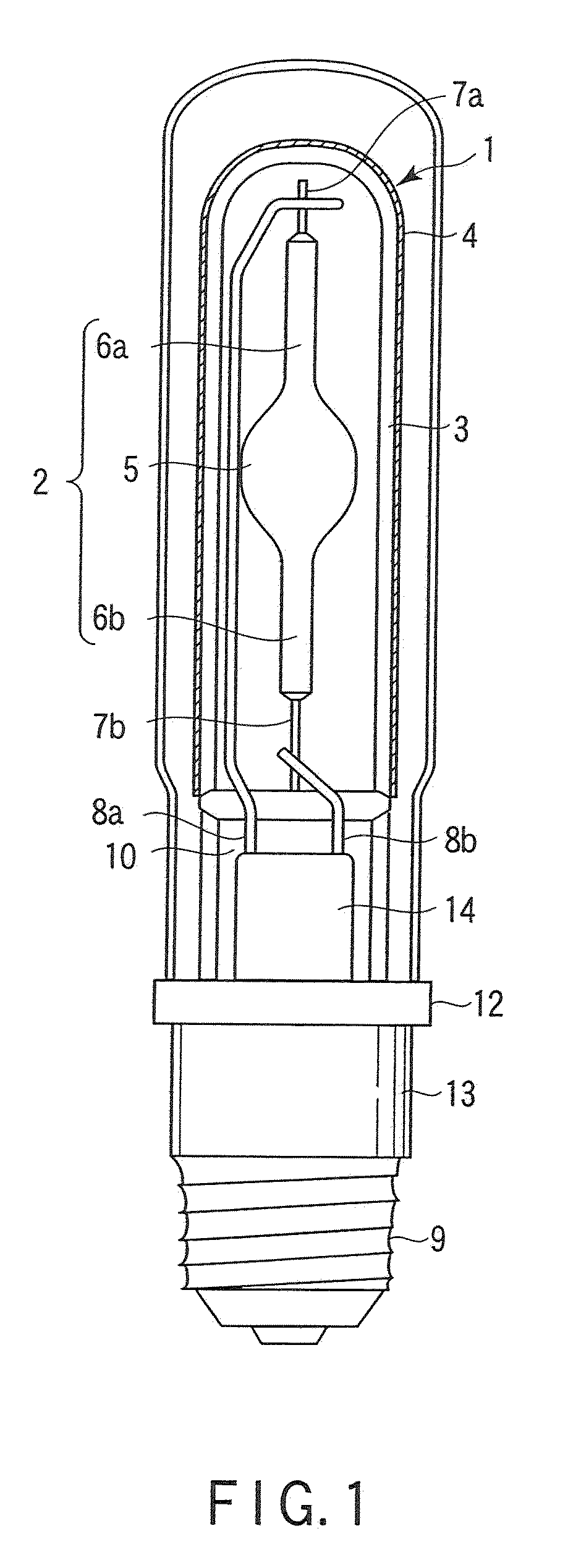

High-pressure discharge lamp and lighting equipment

InactiveUS20090267480A1Good colorImprove visibilityVacuum tube vessels/containers/shieldsGas discharge lamp detailsOptical propertyLight equipment

A high-pressure discharge lamp includes a luminous tube, a translucent protective tube disposed to cover the luminous tube, and a light-cutting layer formed on an outer or inner surface of the protective Lube and includes, as a main component, metal oxide particles which absorb light having a wavelength no greater than 600 nm and allow light having a wavelength of greater than 600 nm to permeate, the light-cutting layer having optical properties that a cut ratio of light having a wavelength of 450 nm is confined to 20-50%.

Owner:TOSHIBA LIGHTING & TECH CORP

X-ray generating apparatus

InactiveUS20160329185A1Prevent deviationX-ray tube electrodesVacuum tube vessels/containers/shieldsX-rayEngineering

An x-ray generating apparatus comprises: a vacuum container having a main body, and a moving member coupled movably and airtightly to the main body via a vacuum bellows; and a guide mechanism, provided on an outer side of the vacuum container, for regulating the movement and inclination of the moving member in an approaching / separation direction with respect to an electron gun. The guide mechanism includes a guide portion where a guide flat surface along a plane orthogonal to a central axis of the electron beam is formed, the guide portion being provided on the main body side, a guided portion where a guided flat surface facing the guide flat surface is formed, the guided portion being provided on the moving member side, and at least three rolling elements placed between the guide flat surface and the guided flat surface.

Owner:SHIMADZU CORP

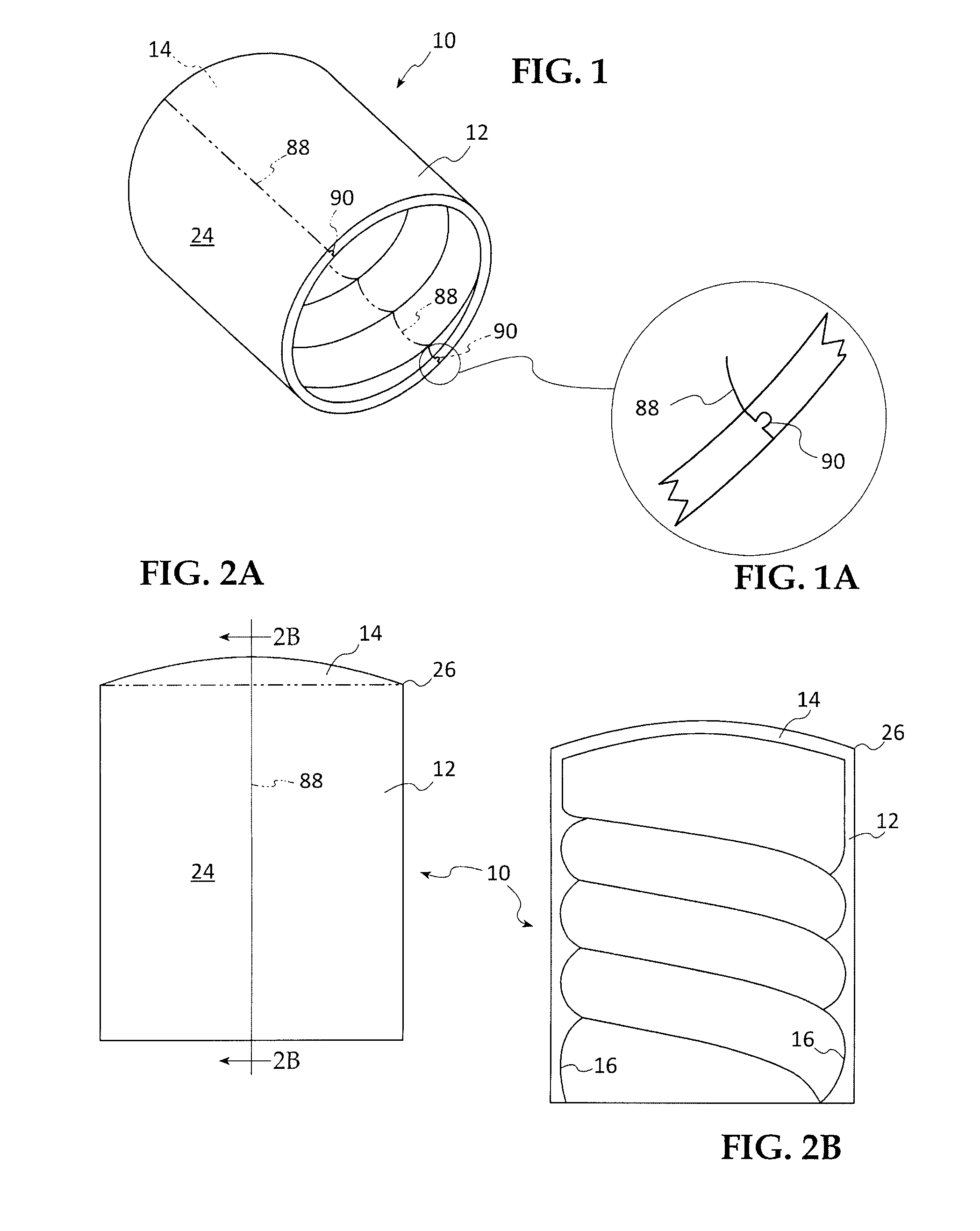

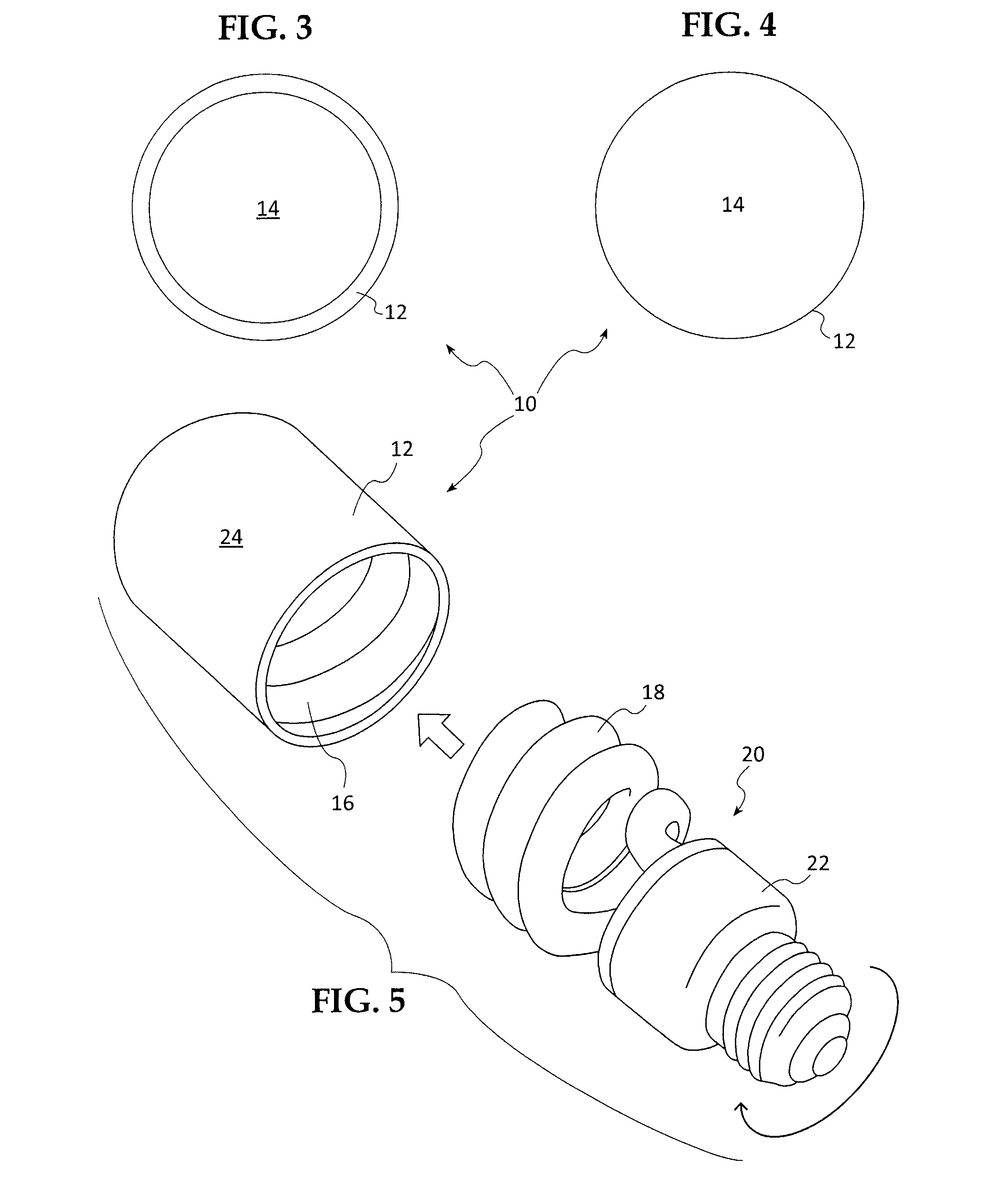

Folded and spiral CFL bulb safety cups, diffusion covers and shade assemblies

InactiveUS8242667B2Secure retentionPreventing cut and skin contactVacuum tube vessels/containers/shieldsDischarge tube main electrodesEngineeringMechanical engineering

Owner:DIVERSIFIED ELECTRONICS

Fluorescent lamp

InactiveUS20050067977A1Easy to installConvenient replacementLighting support devicesElongate light sourcesPower factorColor rendering index

A new fluorescent lamp comprises a lamp tube and an electronic ballast, it is characterized in that it is provided with an outer tube, there are respectively an outer plug at both ends of the outer tube, in which inserts a socket for the lamp tube. The electronic ballast is between the outer plug and the socket for the lamp tube at one end, said lamp tube is disposed between two sockets for the lamp tube. There are advantages as follows: an urgent lighting, the electronic ballast and the compact lamp tube are integrated as one whole; it is convenient for mounting and exchanging, a cost for mounting is greatly reduced; it is possible for repacking to maintain an original means, to reduce a contamination of waste; its weight is light; its power factor is high, more than 95%, it is economical in power, a cost for transporting is low; the color rendering index (CRI) is more than 80%; it is ignited immediately after it is turned on, it does not flash; it is applied to lamps having deferent power; the life of the lamp tube is prolonged by 50%; its output brightness is higher than existing lamps by twice or more; the lamp tube still steadily operates when a power supply is unexpected to be shut off, which reduces accident cases; the whole distortion of a resonant wave becomes smaller than 30%.

Owner:SYNERGY LIGHTING GRP LTD

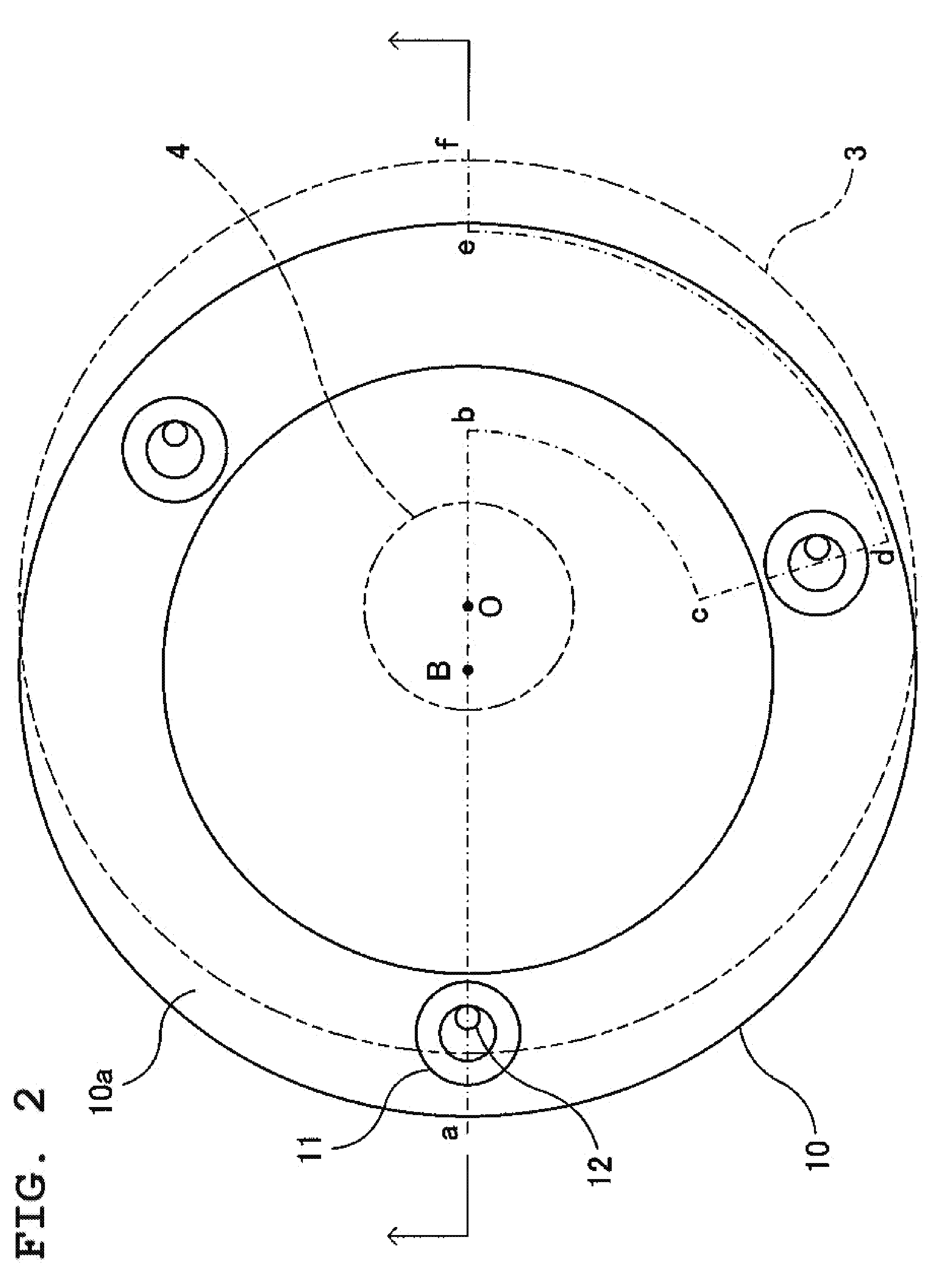

X-ray generator

InactiveCN104952677AAvoid changeSmall diameterX-ray tube electrodesVacuum tube vessels/containers/shieldsElectron sourceEngineering

An X-ray generator is provided using a transmission type target having a long life span, where it is possible to change the point for generating X-rays on the surface of the target while maintaining the vacuum chamber in a high vacuum state. A portion of a vacuum chamber 1 that includes a target 2 is linked to a main body portion 1a of the chamber through a linking member 5 as a movable chamber portion 1b. A fixed anode 12 is provided between the target 2 and the electrode 10 at the final stage from among a group of electrodes 8, 9 and 10 for electrostatically accelerating and converging electrons from an electron source 7 and is fixed to the main body portion 1a of the chamber in order to prevent the form of the electrical field from changing when the movable chamber portion 1b is shifted.

Owner:SHIMADZU SEISAKUSHO CO LTD

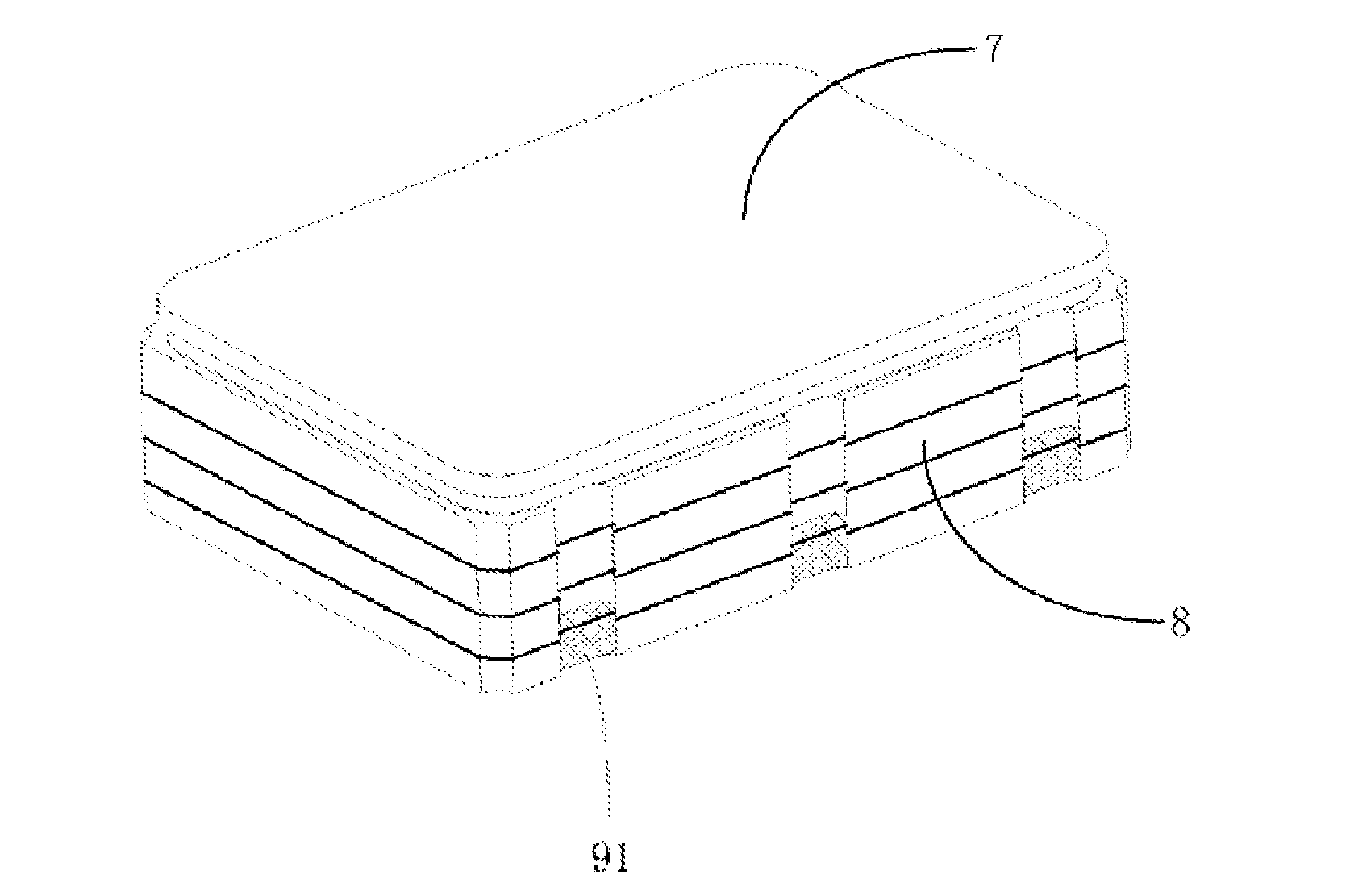

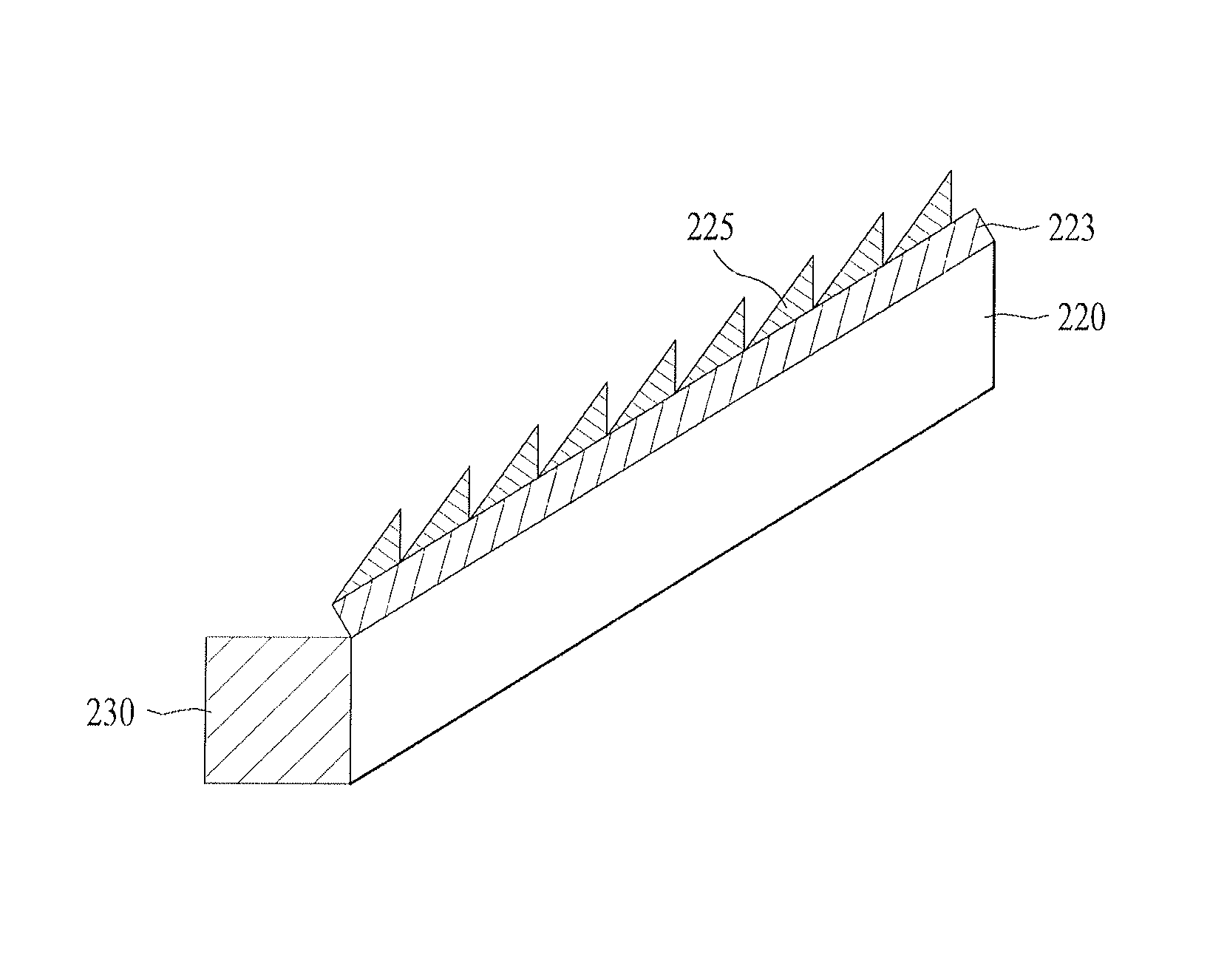

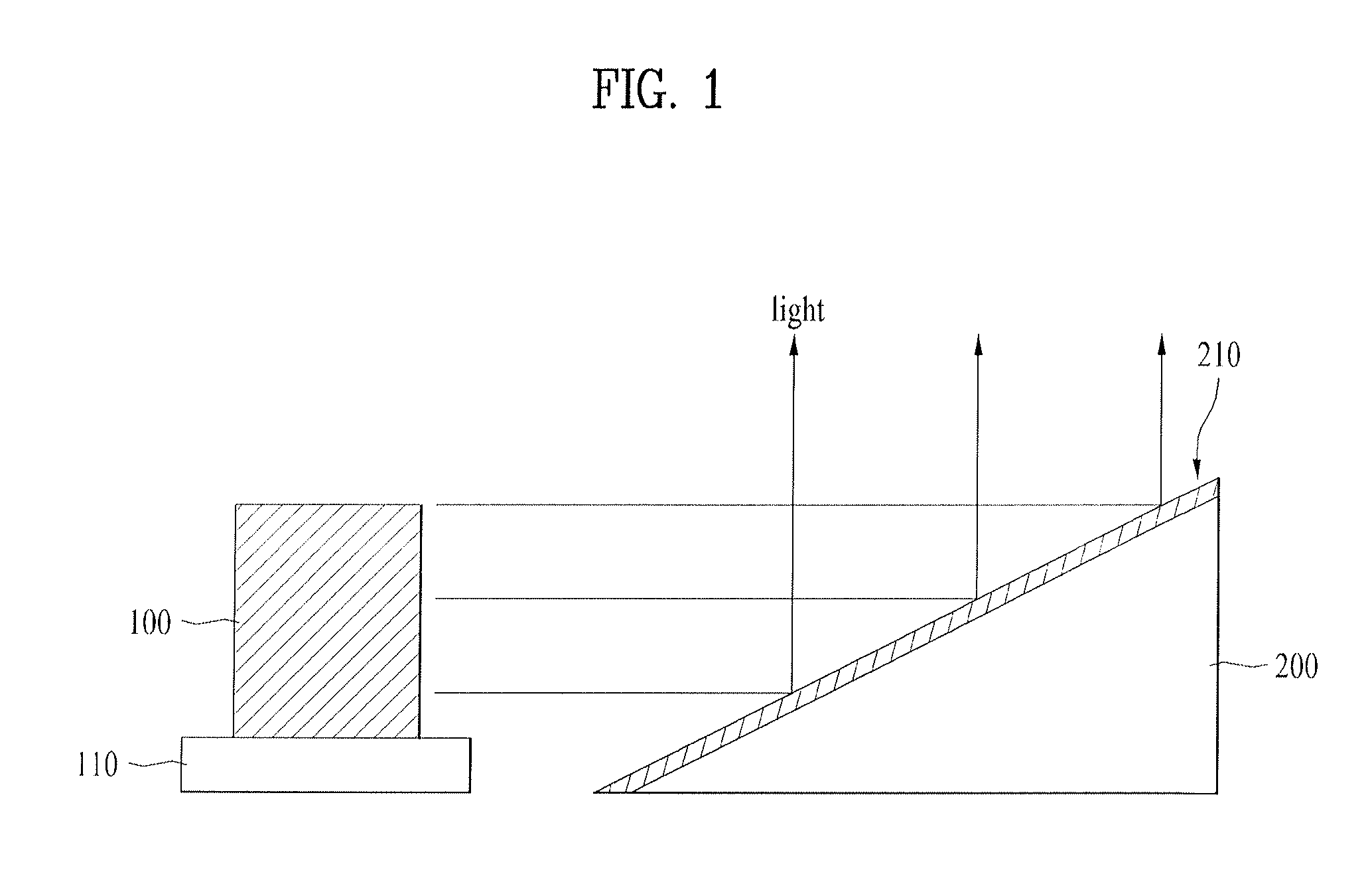

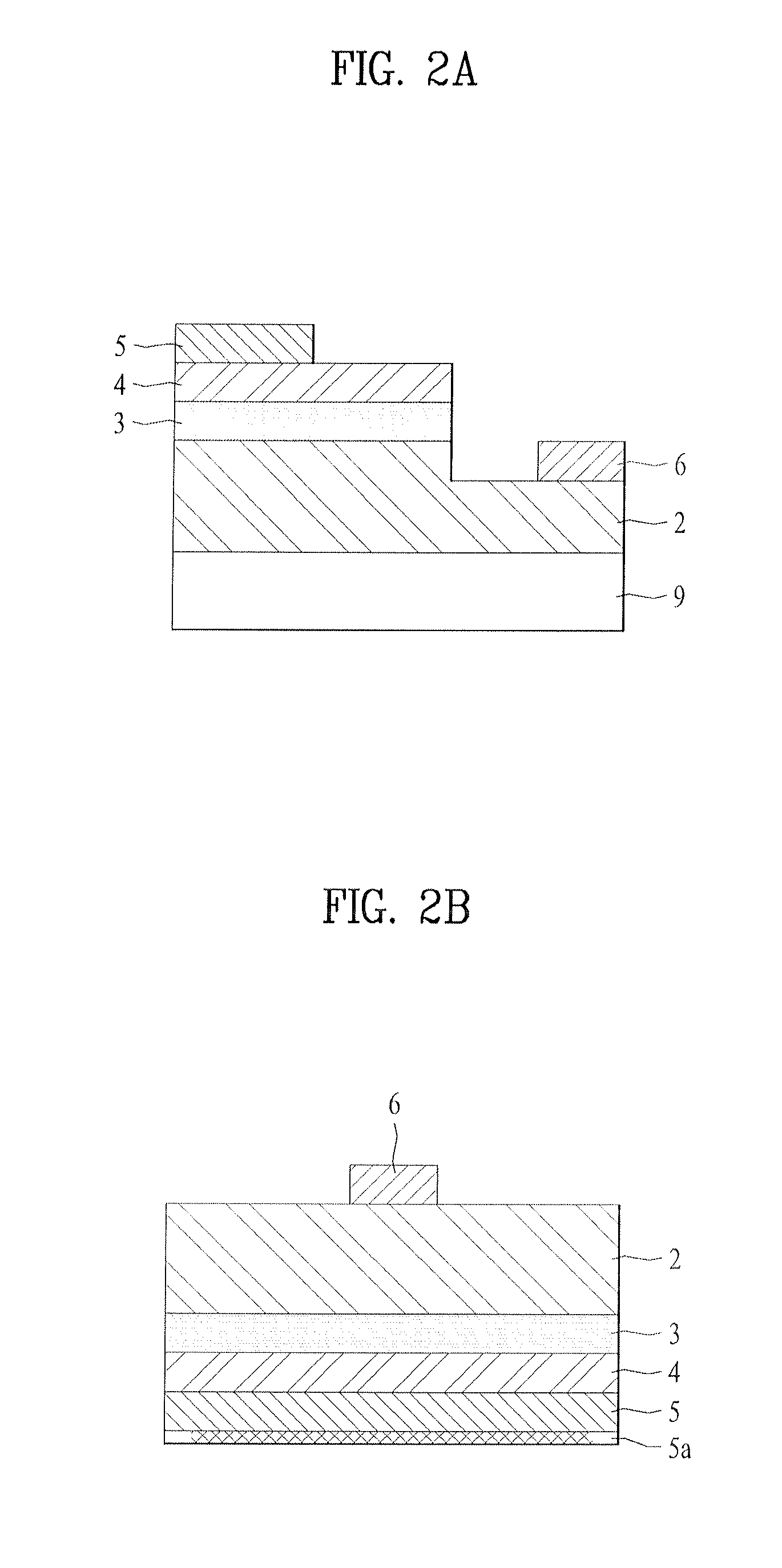

Backlight unit and display apparatus using the same

ActiveUS8684547B2Incadescent screens/filtersVacuum tube vessels/containers/shieldsEngineeringLight source

A backlight unit and a display apparatus using the same are disclosed. The backlight unit includes an optical sheet, a reflector having a reflective surface spaced apart from the optical sheet and having an inclined surface, a fixture connected to one side of the reflector, and a light source disposed to one side of the reflector.

Owner:SUZHOU LEKIN SEMICON CO LTD

Lamps with replaceable covers

InactiveUS8138672B2Point-like light sourceVacuum tube vessels/containers/shieldsEngineeringPrinted circuit board

Owner:FOXSEMICON INTEGRATED TECH INC

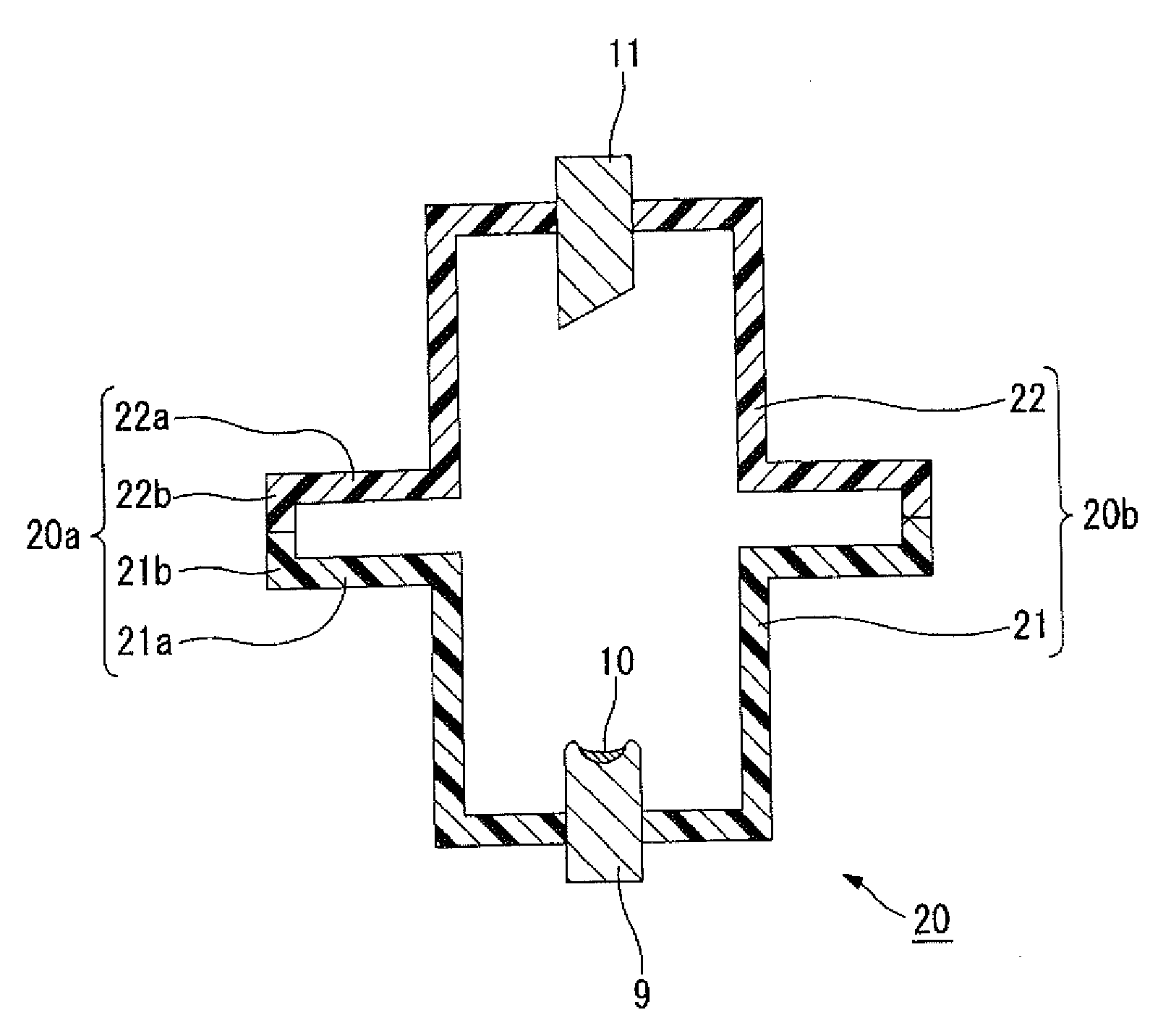

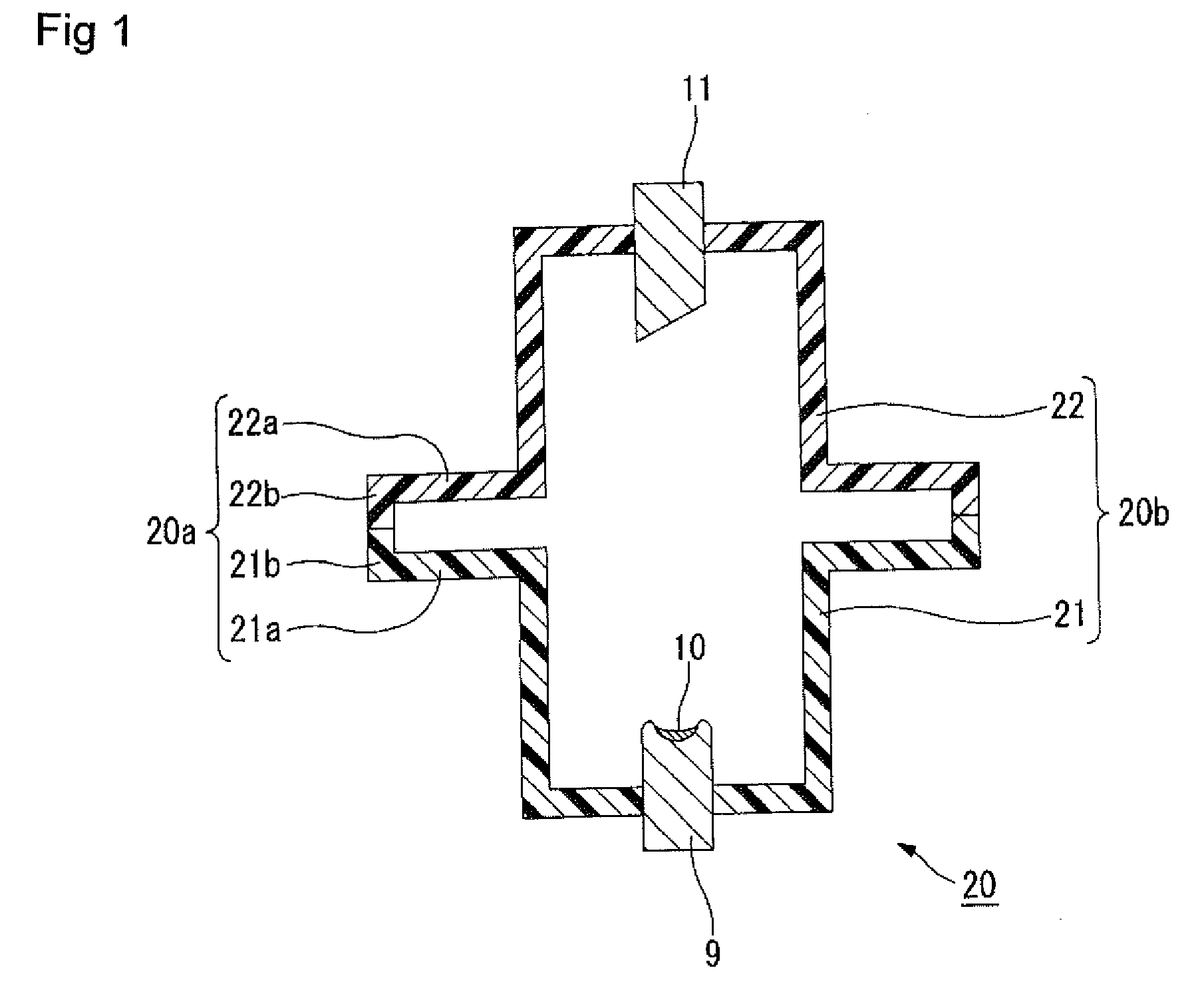

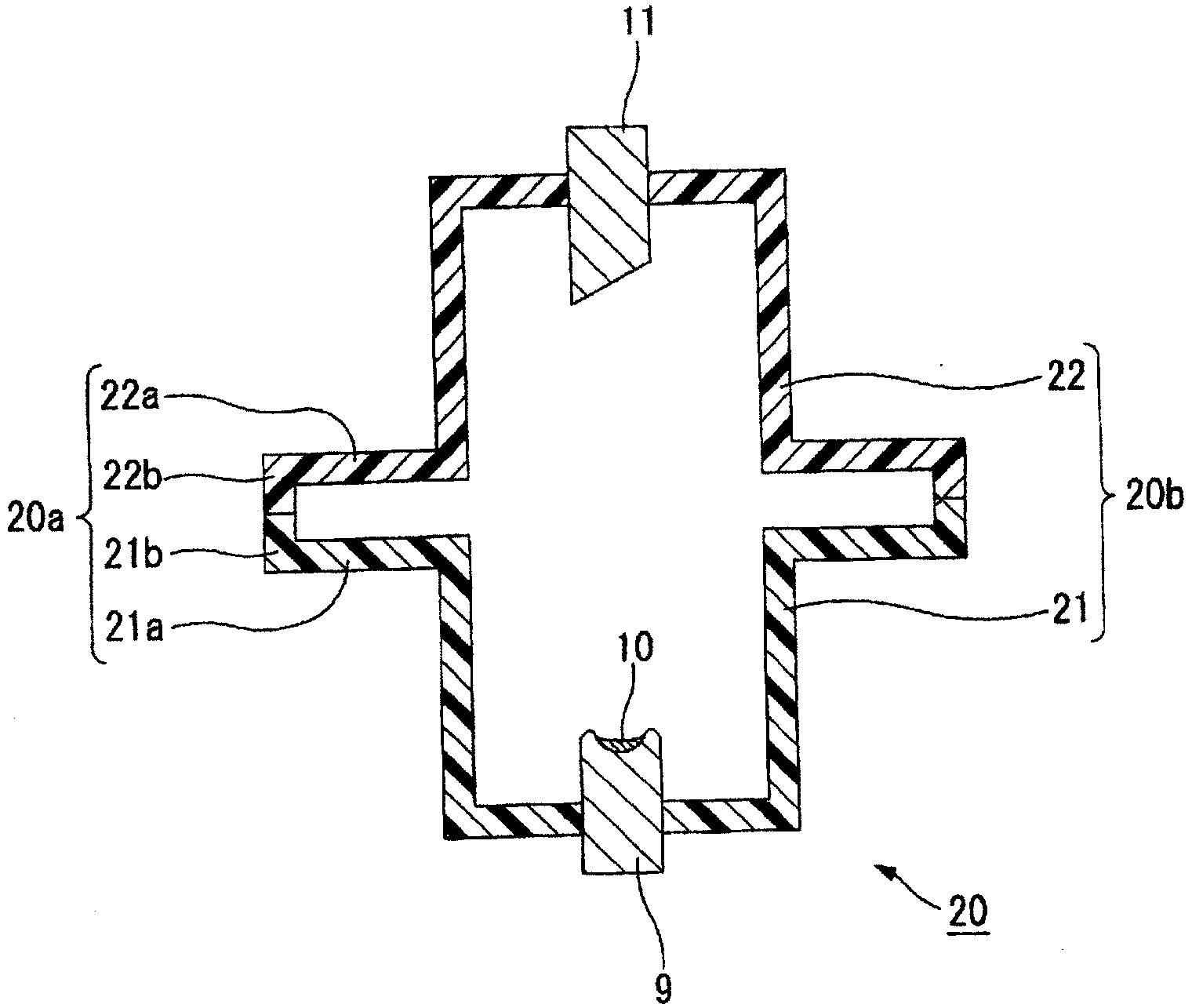

Field emission apparatus and hand-held nondestructive inspection apparatus

InactiveUS20130234582A1Improve heat release efficiencyIncrease creepage distanceElectrode assembly support/mounting/spacing/insulationControl electrodesField emission deviceCarbon film

In the present invention, heat dissipation is improved by extending the creepage distance in a vacuum vessel according to the size of a flange portion, without lengthening the vacuum vessel in the direction in which an electron beam is emitted.A vacuum vessel (20) in which a flange portion (20a) having a hollow portion between a cold cathode (9) and an anode (11) is formed is used.One example is a vacuum vessel (20) in which a cold cathode vessel (21) and an anode vessel (22), both cylindrically shaped, are communicated with each other and a hollow flange portion (20a) is formed between the vessels (21, 22).A focusing electrode (14) and a getter material (15), for example, are disposed in the hollow portion of the flange portion (20a).A cold cathode (9) which has a guard electrode on the outer side of the periphery of a carbon film structure (10) formed on a substrate (7) may be used. The carbon film structure (10) may be formed in the middle of an electrode surface of the substrate (7).

Owner:MICRO X JAPAN

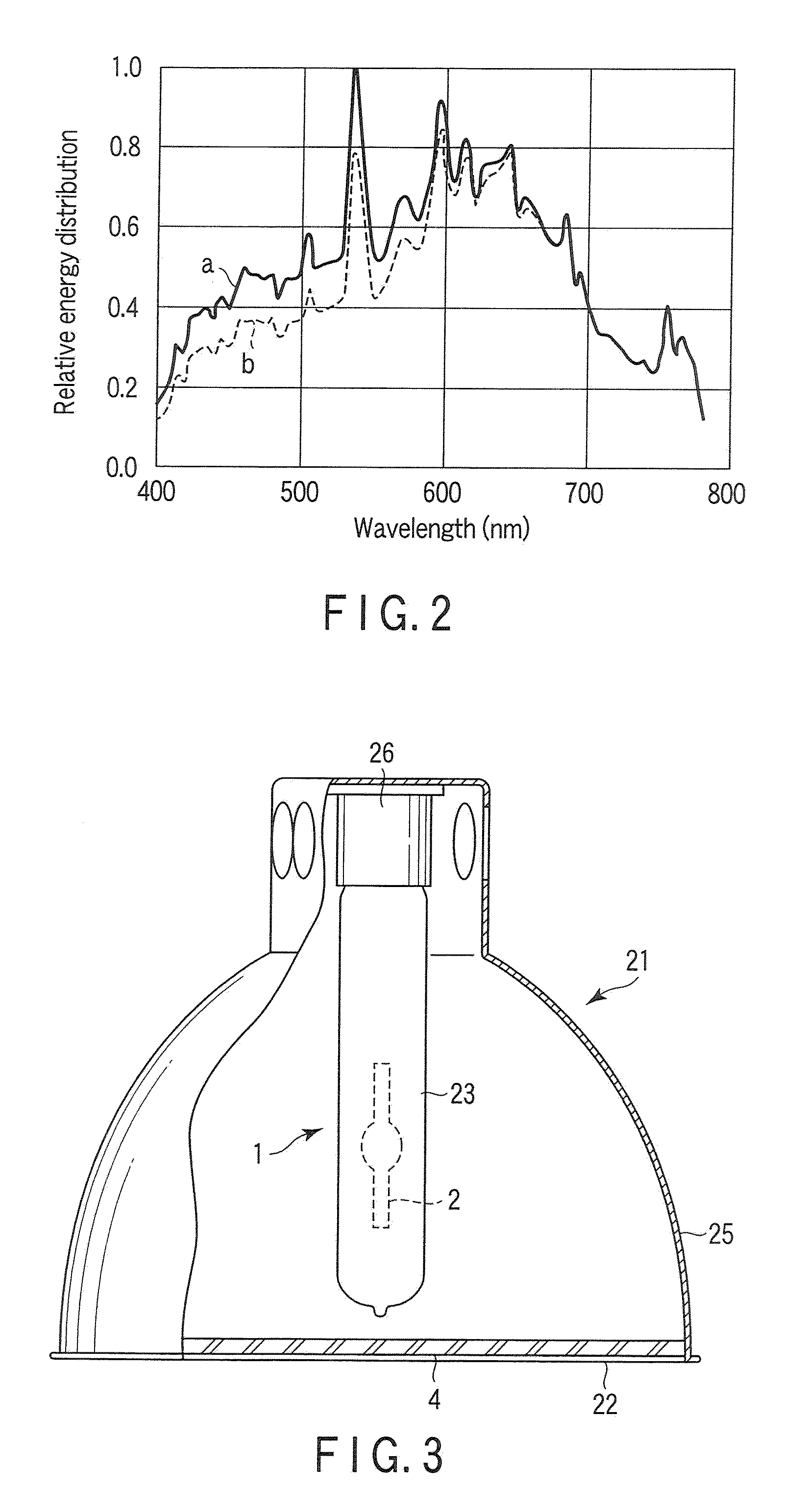

Light source module

InactiveUS20070182302A1Improved projected beam performanceReduce system costVehicle headlampsIncadescent screens/filtersWave shapeLight beam

There is disclosed a light source module comprising a high intensity discharge light source; optical elements including at least a reflector for redirecting and focusing the light emanating from said light source; and electronic elements for supplying said light source with voltage and current of a predetermined waveform and magnitude. The light source may have optical and / or electric parameters at least partially different from optical and / or electrical standard parameters of a light source of identical type. In order to provide a predetermined illuminating beam pattern compatible with the standard, the optical and / or electronic elements are adjusted to the optical and / or electrical parameters of said light source.

Owner:GENERAL ELECTRIC CO

Field emission apparatus and hand-held nondestructive inspection apparatus

InactiveCN103262202AImprove cooling effectElectrode assembly support/mounting/spacing/insulationControl electrodesCarbon filmField electron emission

In the present invention, heat dissipation is improved by extending the creeping distance in a vacuum vessel according to the size of a flange part, without lengthening the vacuum vessel in the direction in which an electron beam is emitted. A vacuum vessel (20) in which a flange portion (20a) having a hollow portion between a cold cathode (9) and an anode (11) is formed is used. One example is a vacuum vessel (20) in which a cold cathode vessel (21) and an anode vessel (22), both cylindrically shaped, are communicated with each other and a hollow flange portion (20a) is formed between the vessels (21, 22). A focusing electrode (14) and a getter material (15), for example, are disposed in the hollow portion of the flange portion (20a). A cold cathode (9) which has a guard electrode on the outer side of the periphery of a carbon film structure (10) formed on a substrate (7) may be used. The carbon film structure (10) may be formed in the middle of an electrode surface of the substrate (7).

Owner:MICRO X JAPAN

High voltage high current regulator

ActiveUS9025353B2Minimized size requirementPreventing internal electrical short circuitsVacuum tube vessels/containers/shieldsConversion without intermediate conversion to dcControl signalCold cathode

High voltage high current regulator circuit for regulating current is interposed between first and second terminals connected to an external circuit and comprises at least one main-current carrying cold-cathode field emission electron tube conducting current between the first and second terminals. First and second grid-control cold-cathode field emission electron tubes provide control signals for first and second grids of the at least one main-current carrying cold-cathode field emission electron tube for positive and negative excursions of voltage on the first and second terminals, respectively. The current regulator circuit may be accompanied by a voltage-clamping circuit that includes at least one cold-cathode field emission electron tube. At least two cold-cathode field emission electron tubes, configured to operate at high voltage and high current, are preferably contained within a single vacuum enclosure and are interconnected to provide a circuit function, so as to form a high voltage high current vacuum integrated circuit.

Owner:ADVANCED FUSION SYST LLC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com