Patents

Literature

32results about How to "Convenient replacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

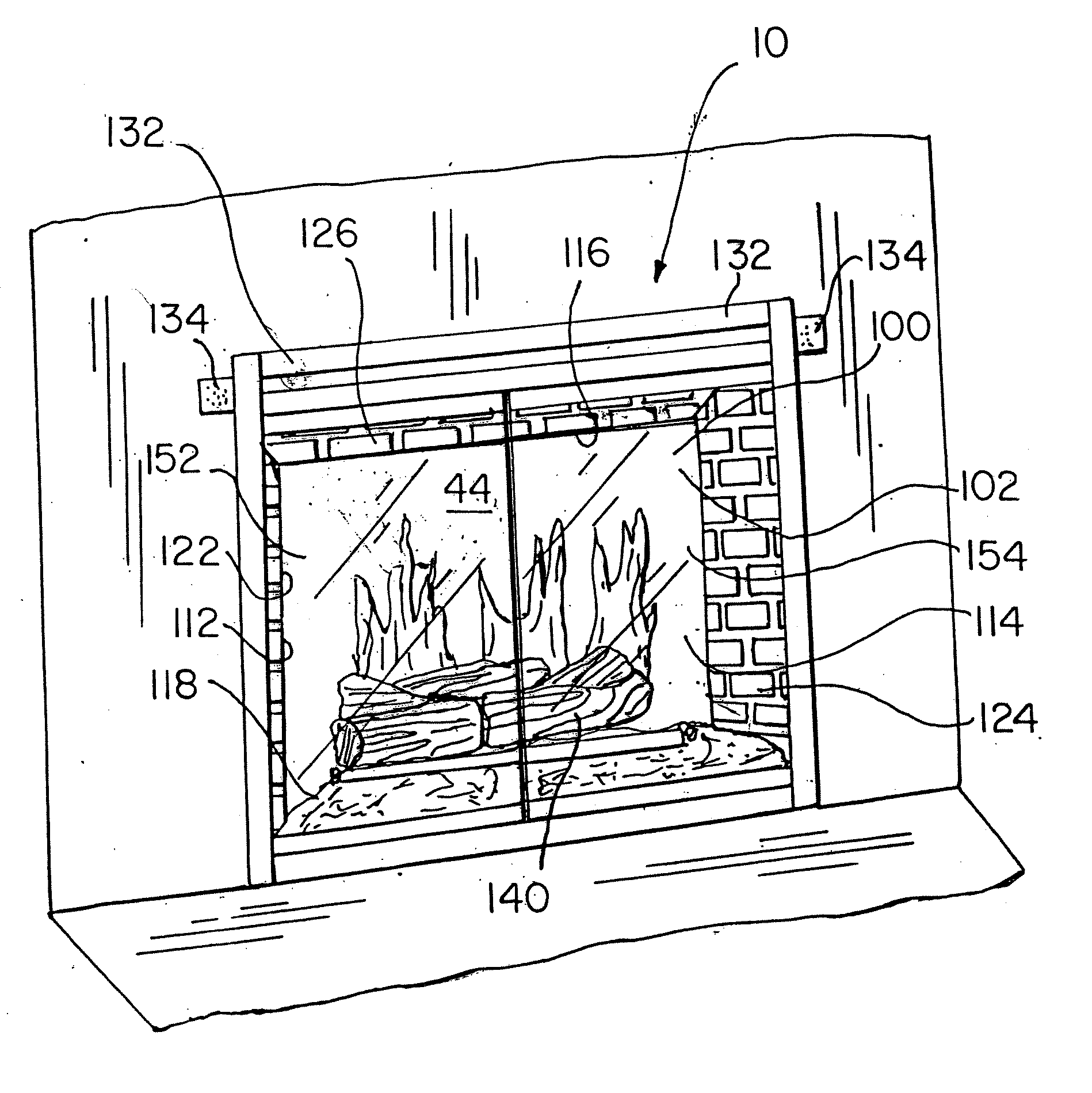

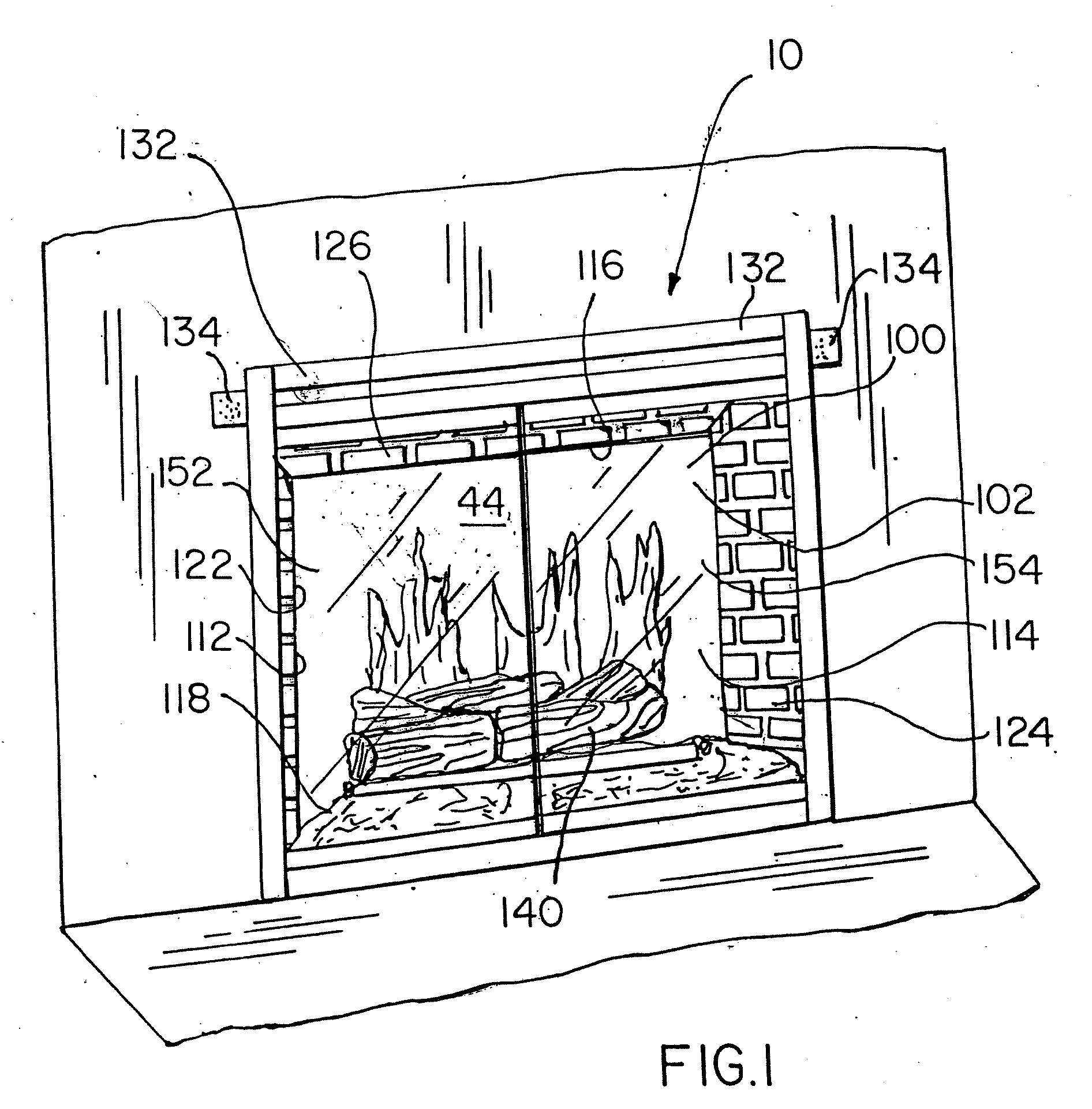

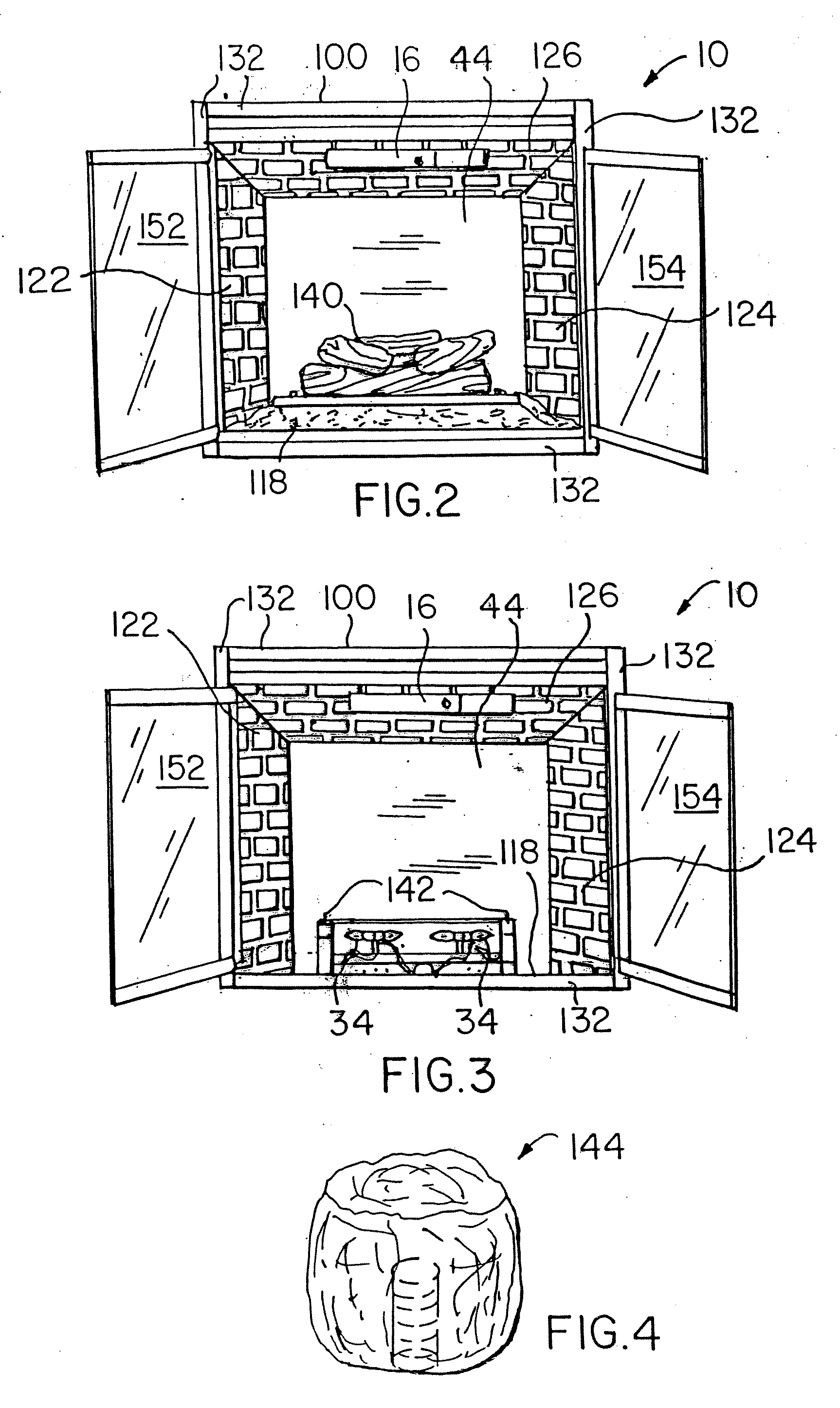

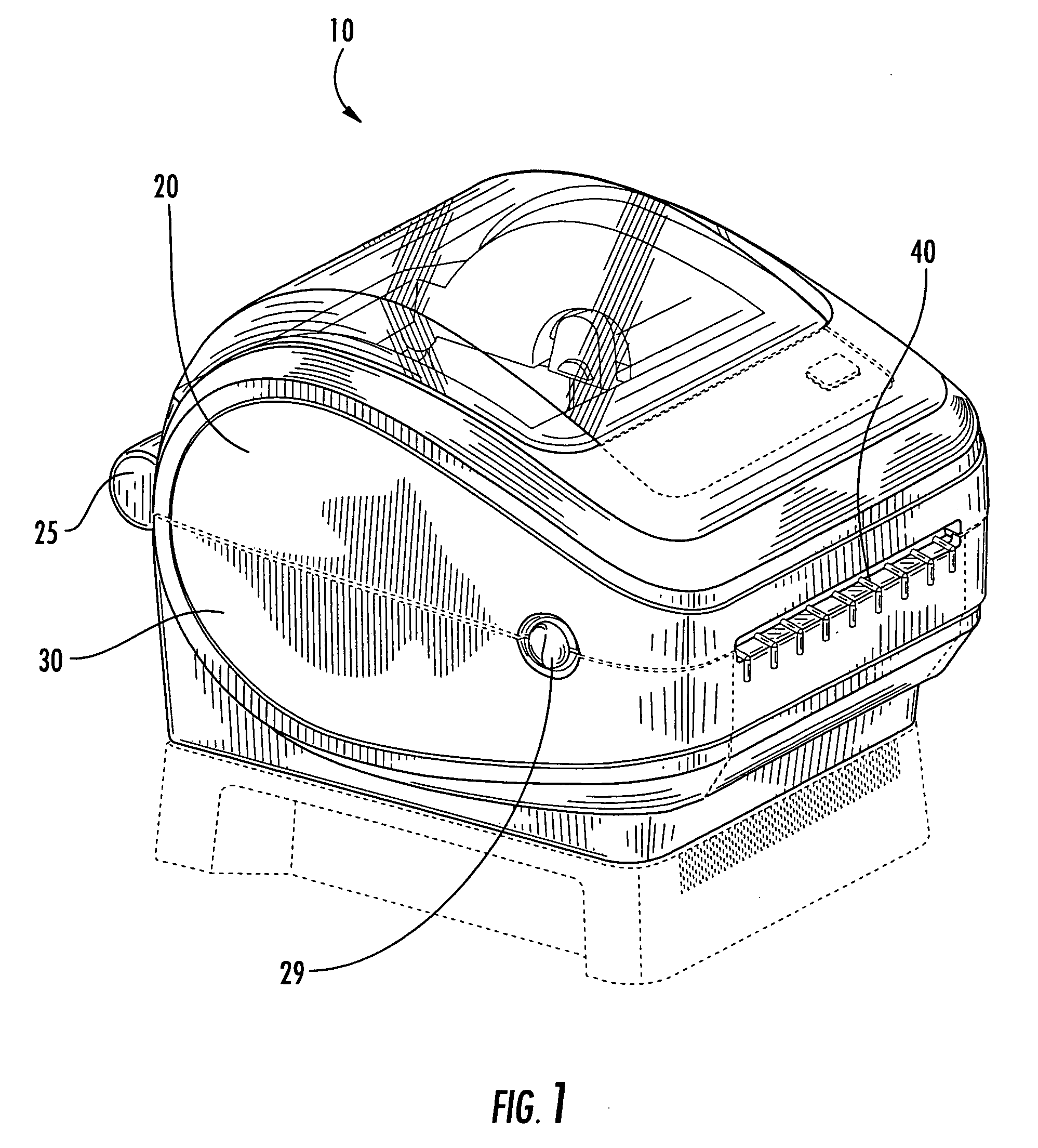

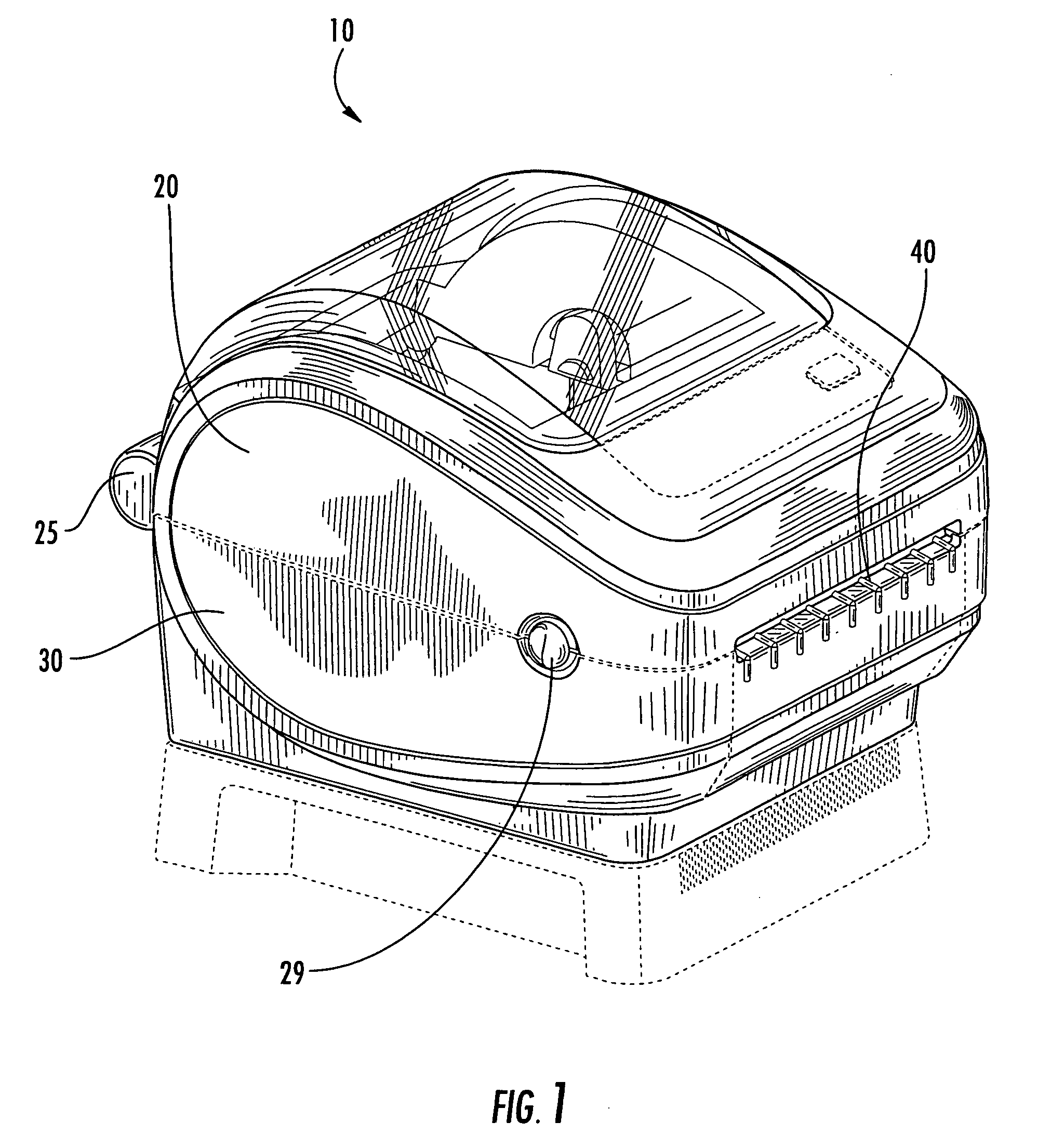

Electric fireplace

ActiveUS20080013931A1Easy to removeEasy to replaceDomestic stoves or rangesDrying solid materials with heatEmberElectricity

An electric fireplace includes a fireplace housing having a housing first and second side walls and a housing top wall, a housing floor, a housing back wall, and a housing open end opposite the housing back wall; a flame simulator mounted inside the housing; a diffusion screen removably mounted upright within the housing in front of the flame simulator; an ember bed simulating the appearance of fireplace fuel such as fire wood, embers or coal, and removably mounted inside the housing in front of the flame simulator, so that removal of the ember bed and the flame cutout panel provides access to the flame simulator from the housing open end; and a hot air generator removably mounted inside the housing to be accessible from the housing open end.

Owner:TWIN STAR INT

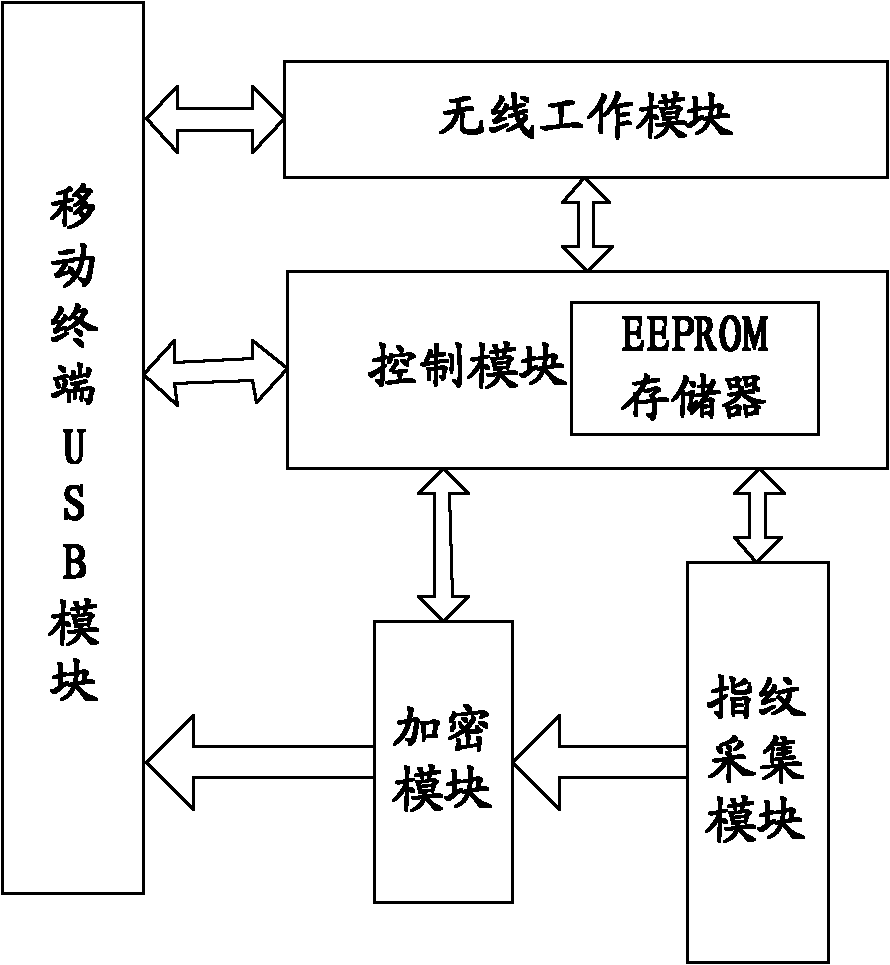

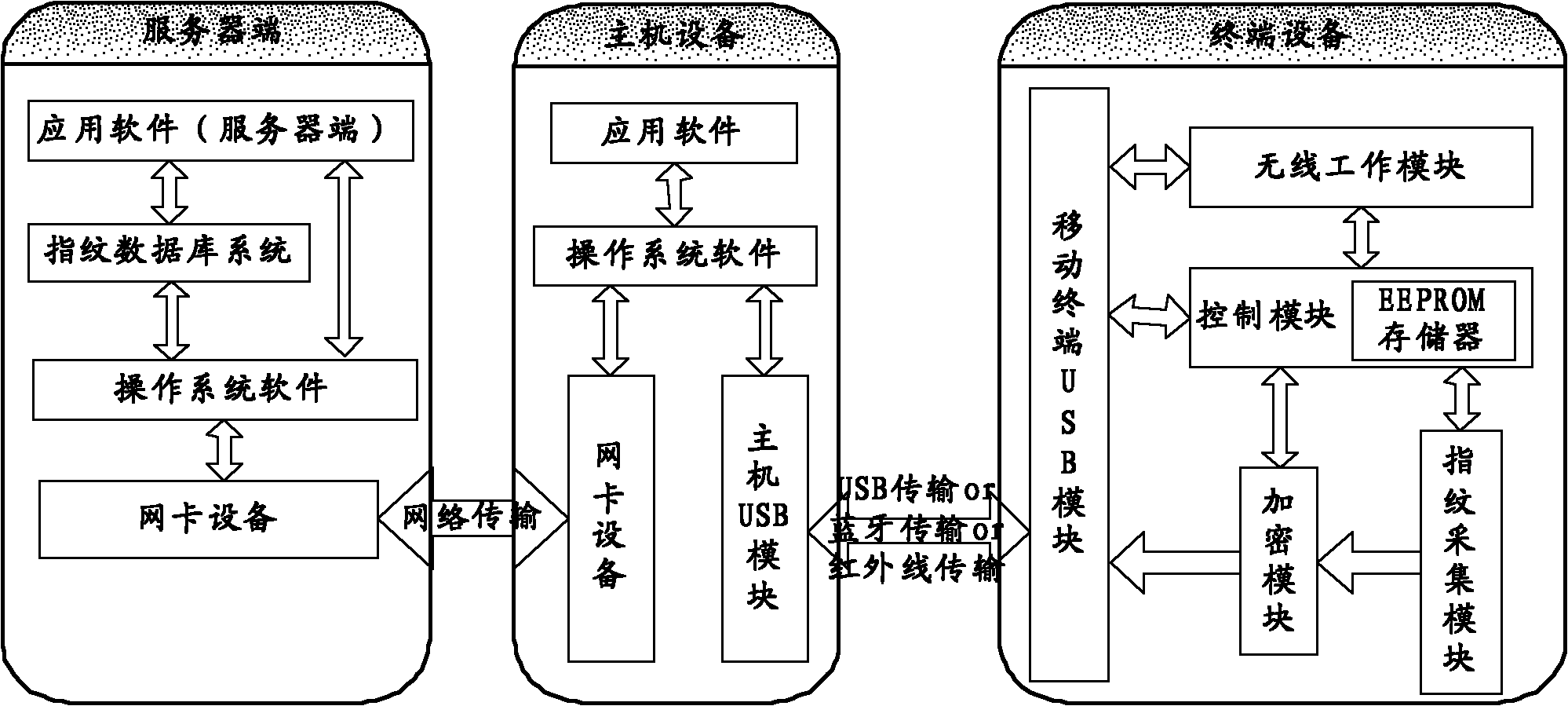

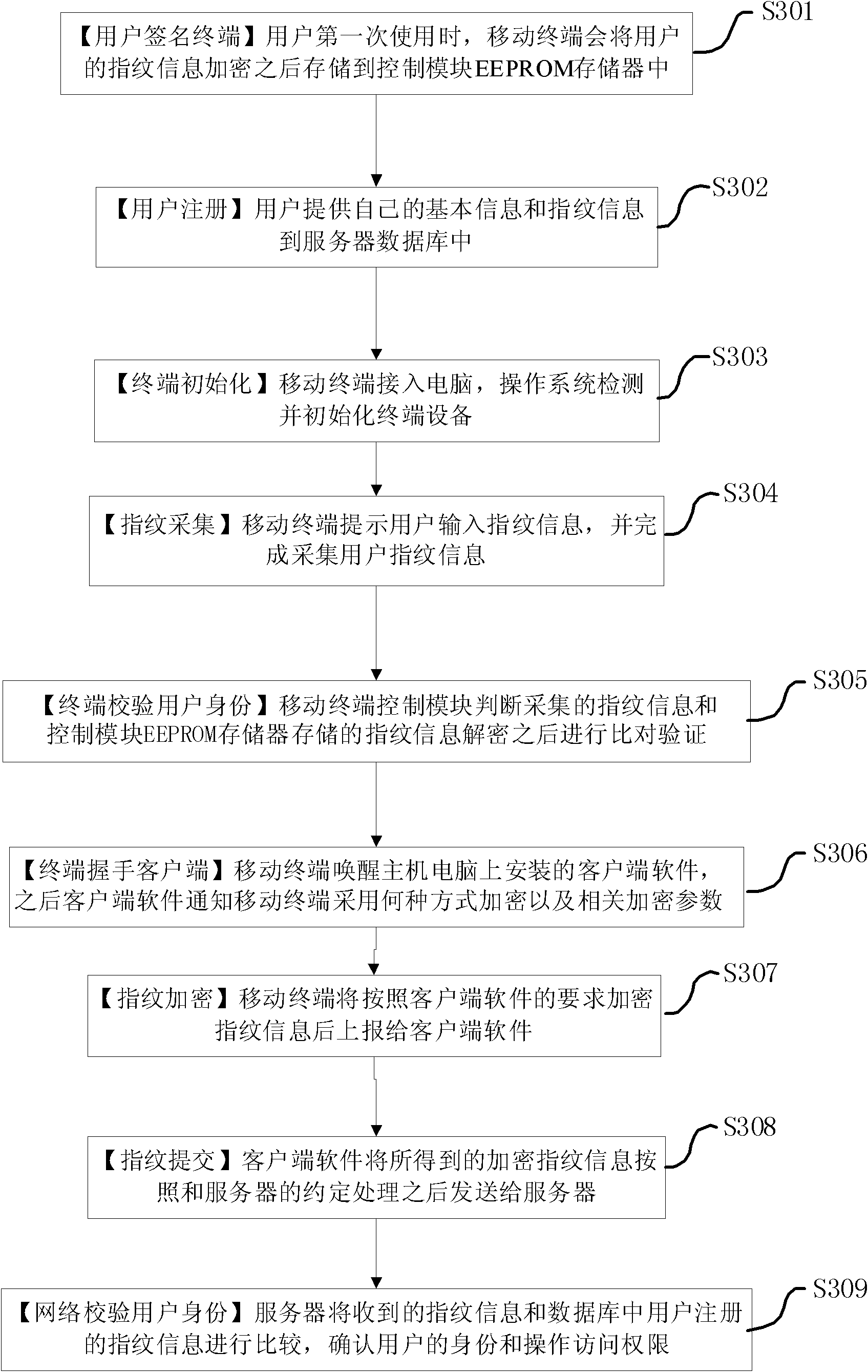

Fingerprint identification method, terminal and system

InactiveCN102004901AImprove compatibilityImprove acceleration performanceCharacter and pattern recognitionTransmissionTerminal equipmentComputer science

The invention relates to fingerprint identification method, terminal and system. The fingerprint identification method comprises the steps of: storing fingerprint information provided by a user per se into a server database; and when the user carries out operation requiring fingerprint identification through a mobile terminal, acquiring the user fingerprint information by the mobile terminal, sending the fingerprint information to the server database, comparing the sent fingerprint information with the stored fingerprint information by the server, if the two fingerprint information are identical, carrying out the operation requiring the fingerprint identification by the user through the mobile terminal. The invention fully utilizes the unique feature of a fingerprint to identify the identity of the user, provides simple and rapid identity identification and authentication for the user by additionally arranging a fingerprint identification unit on the common mobile terminal, can conveniently replace various traditional digital certificates, and increases the compatibility and the expansibility of the mobile terminal equipment for identity identification while greatly enhancing the security of identity identification.

Owner:ZTE CORP

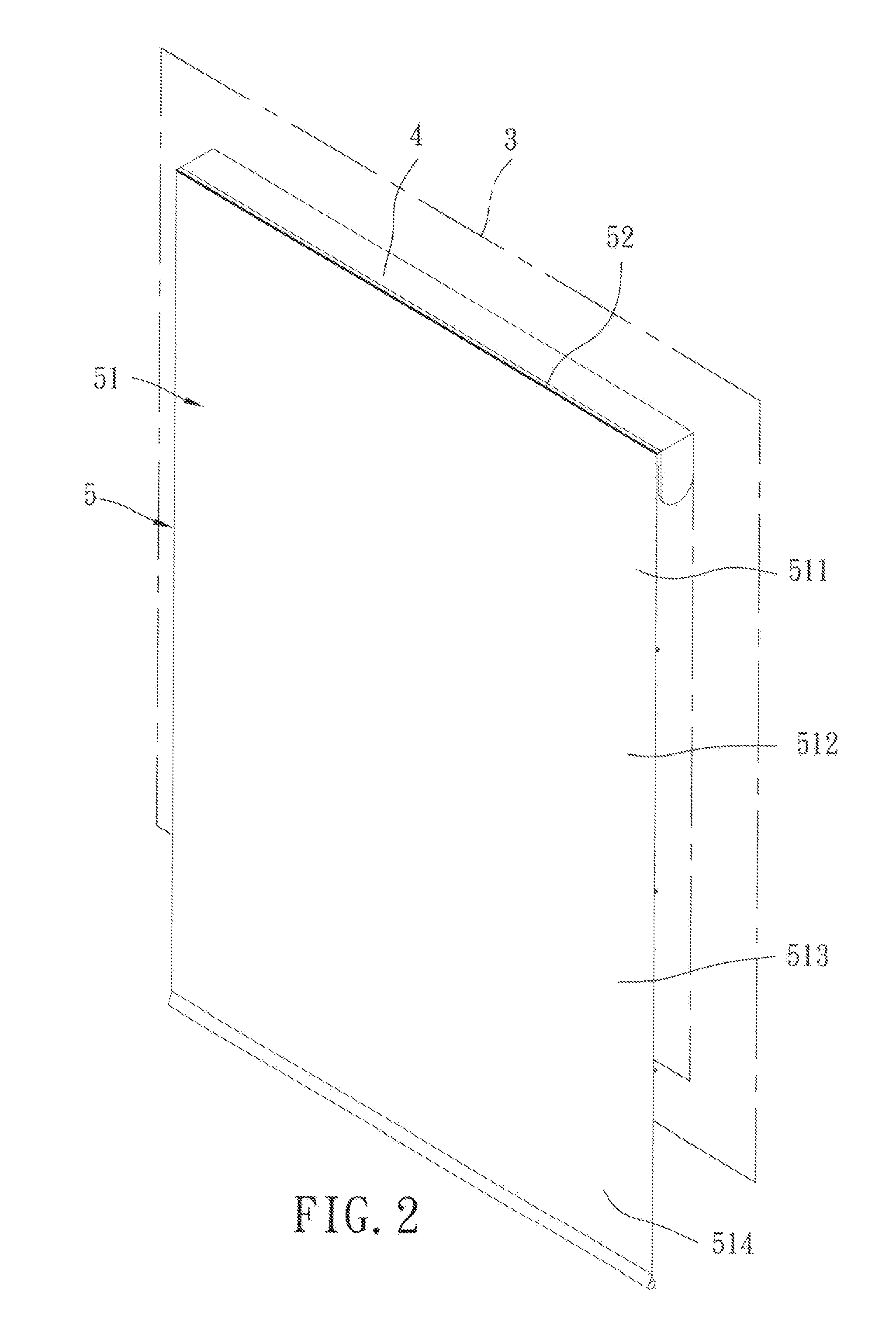

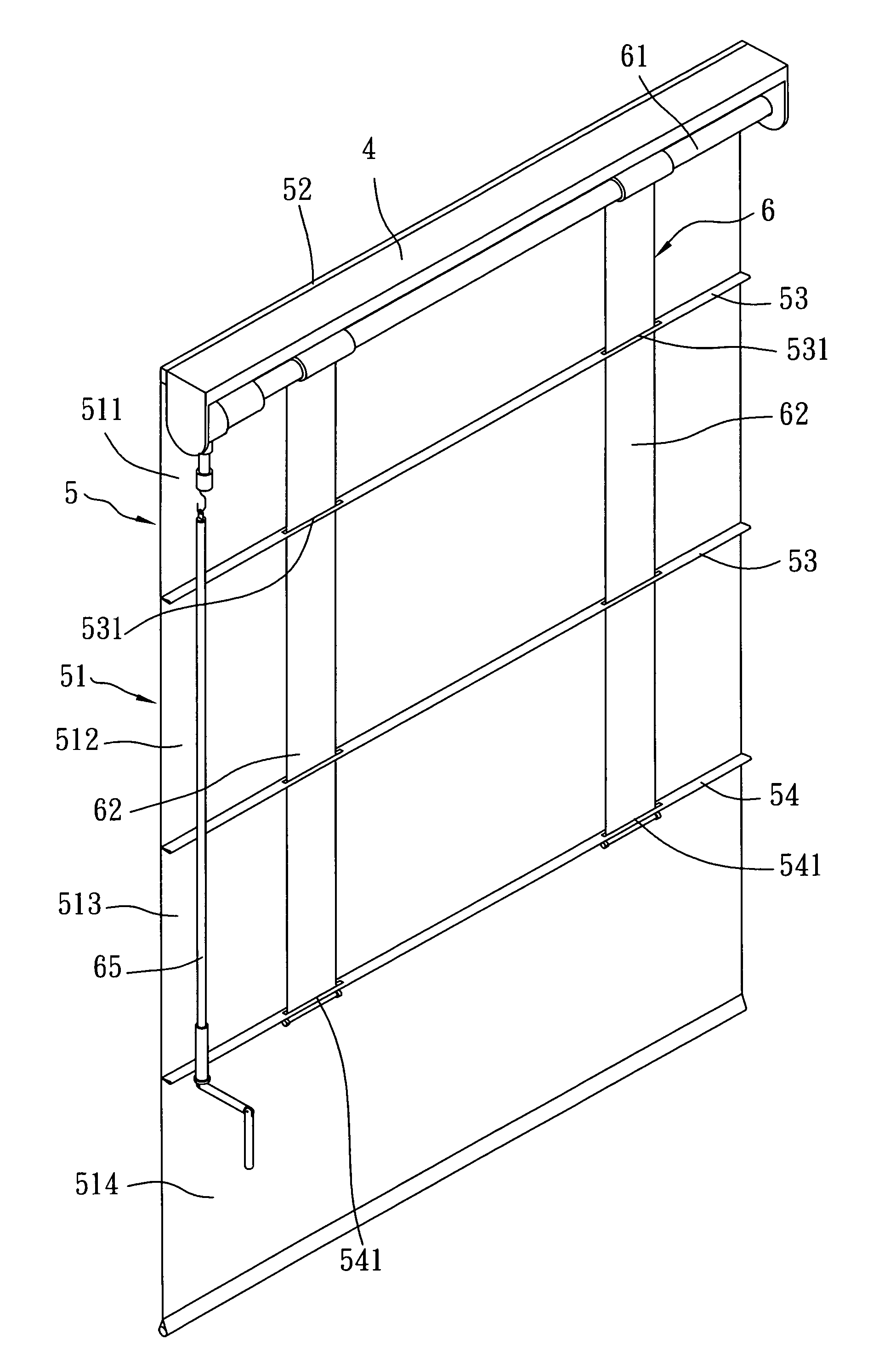

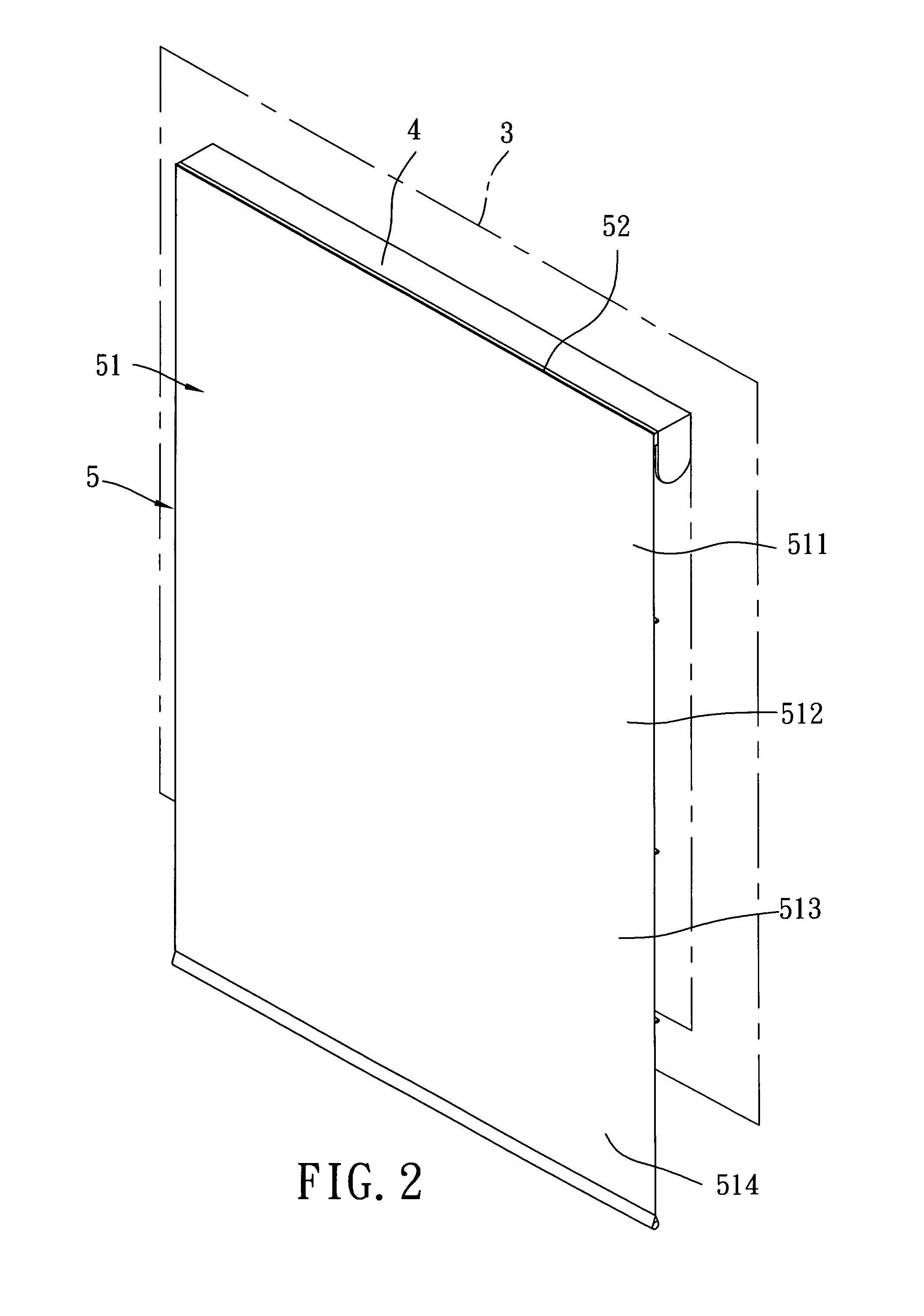

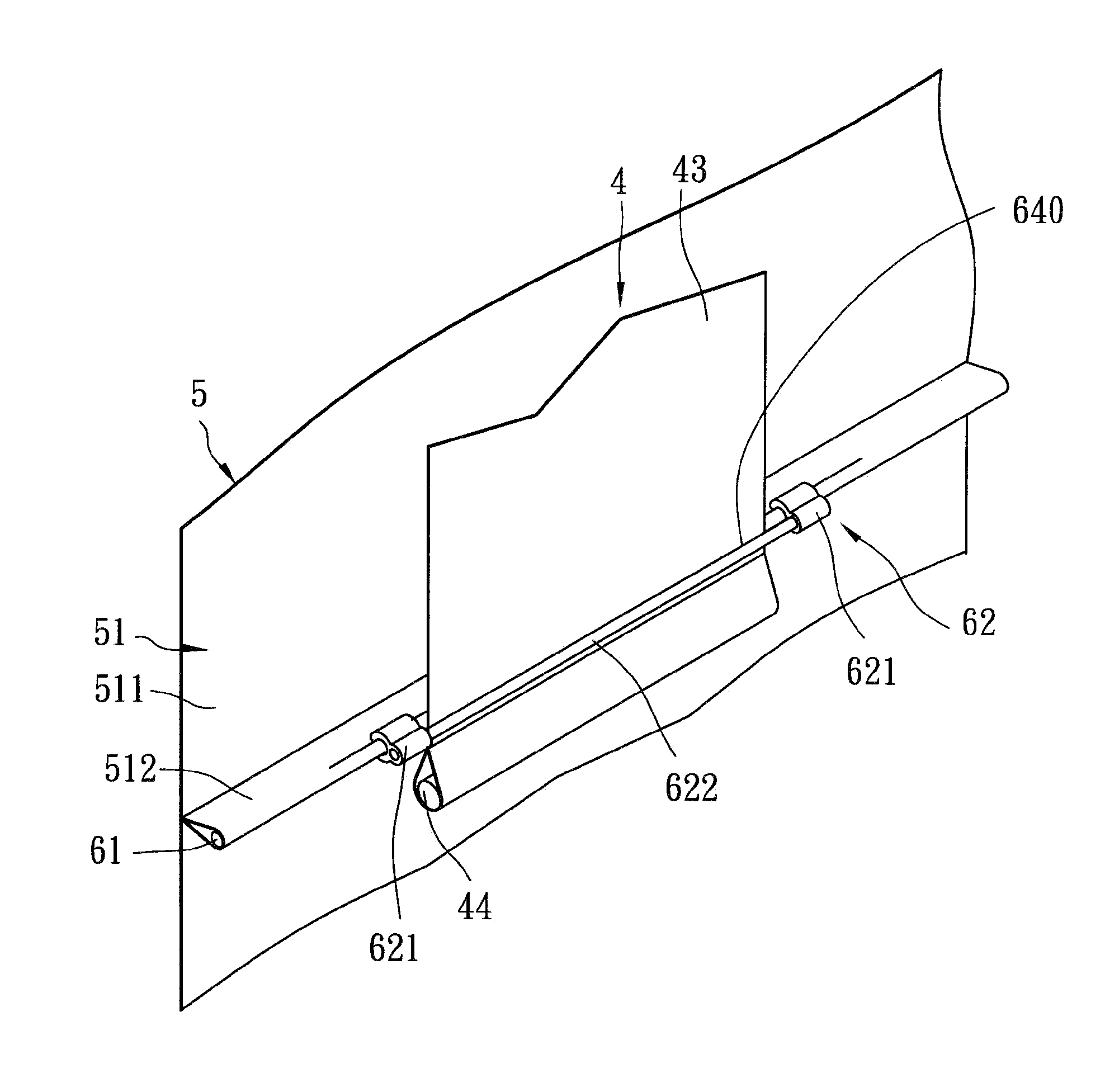

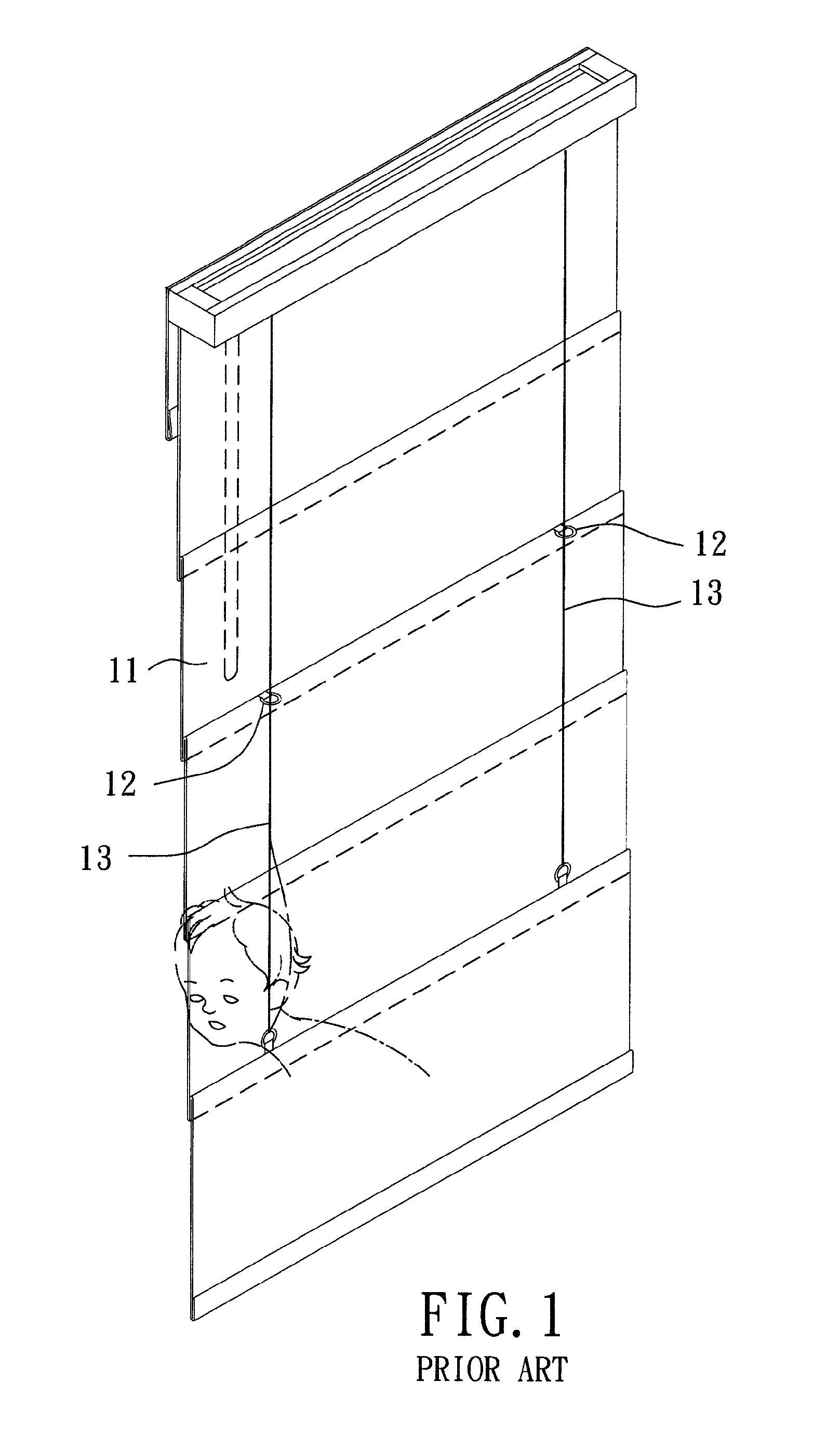

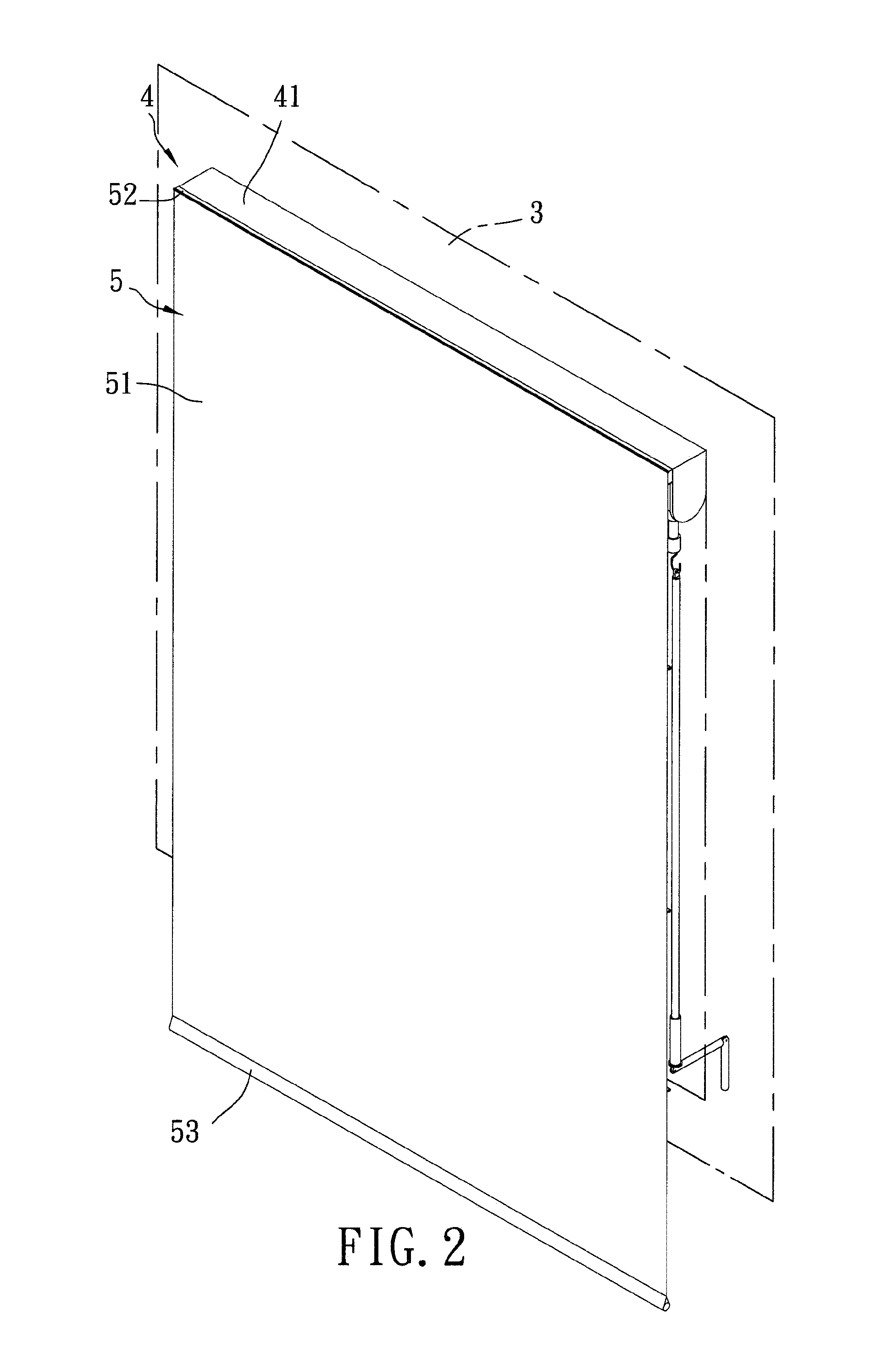

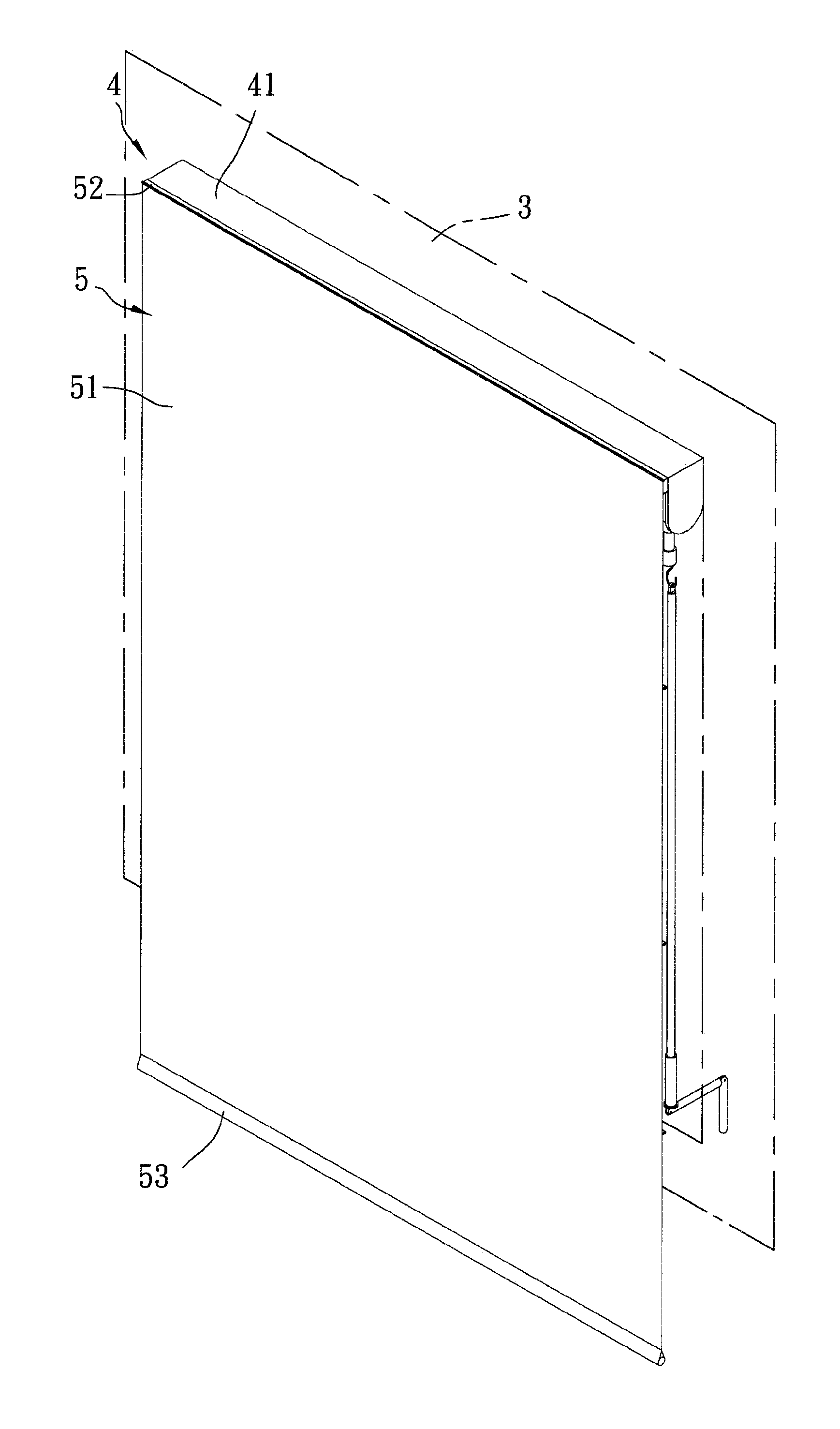

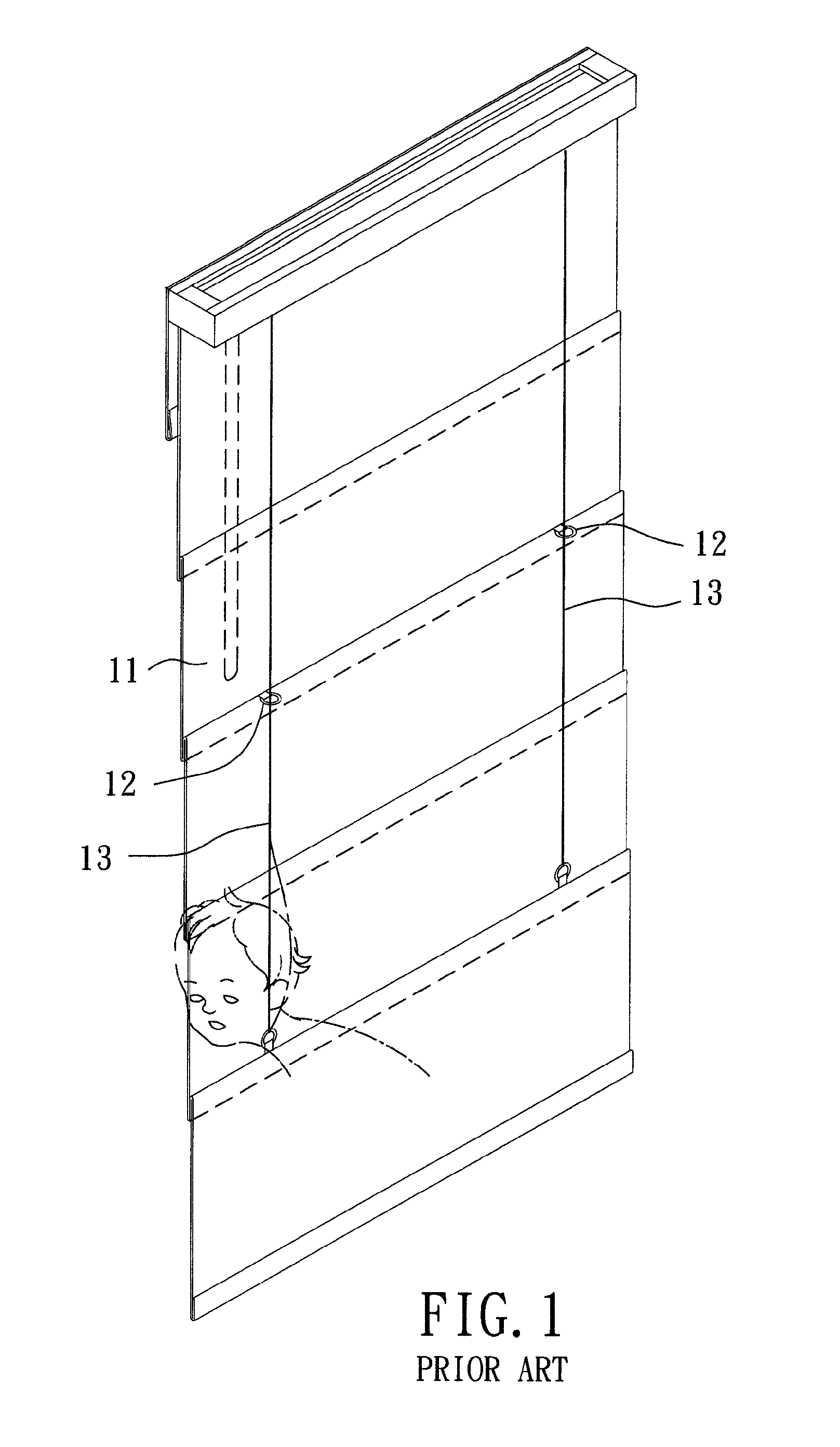

Roman curtain

ActiveUS20110186240A1Improve cleanlinessConvenient replacementExtensible doors/windowsCurtain accessoriesEngineeringMechanical engineering

Owner:LIN SHIH MING

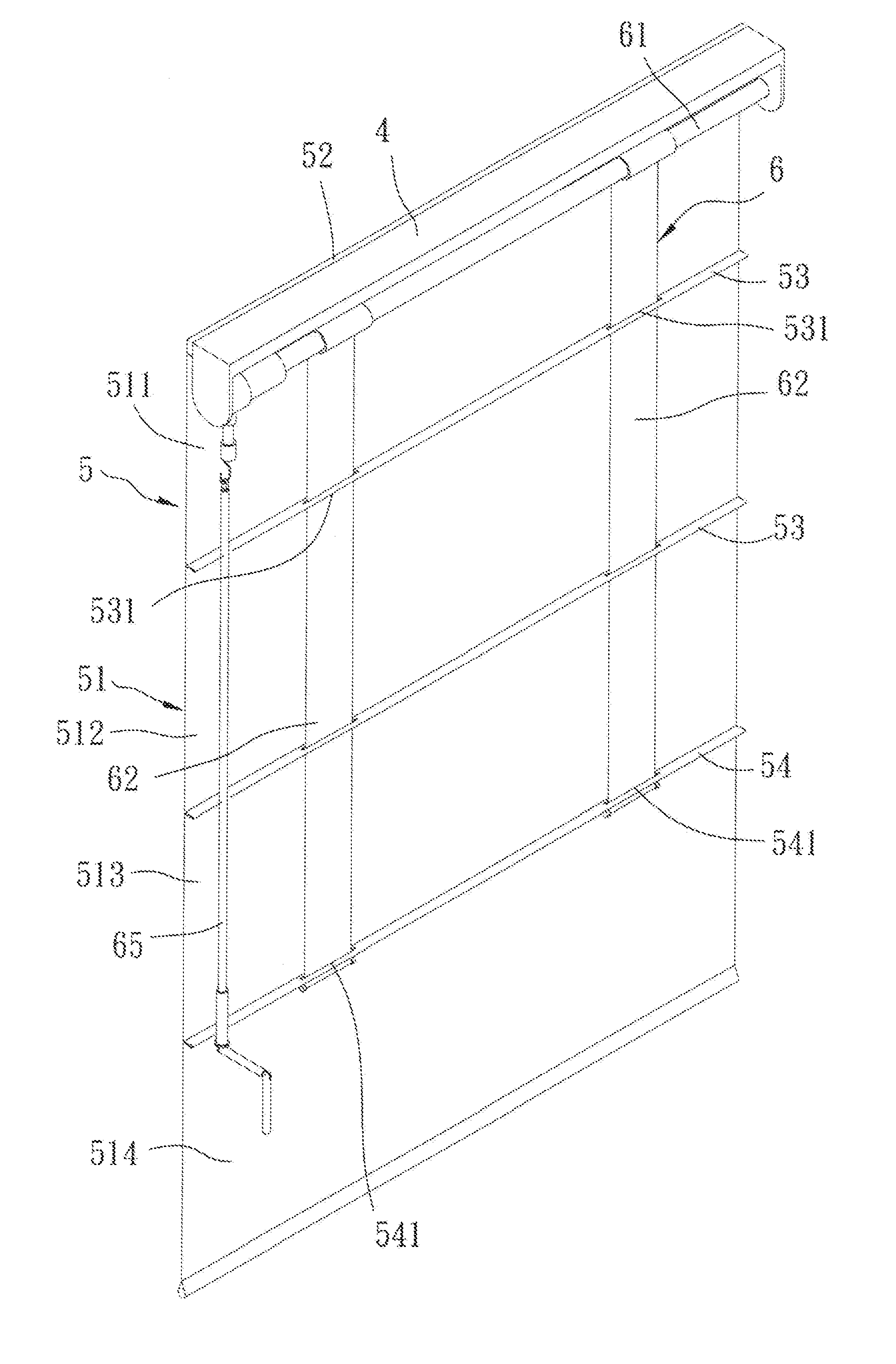

Roman curtain

ActiveUS8066050B2Improve cleanlinessConvenient replacementExtensible doors/windowsCurtain accessoriesEngineeringMechanical engineering

Owner:LIN SHIH MING

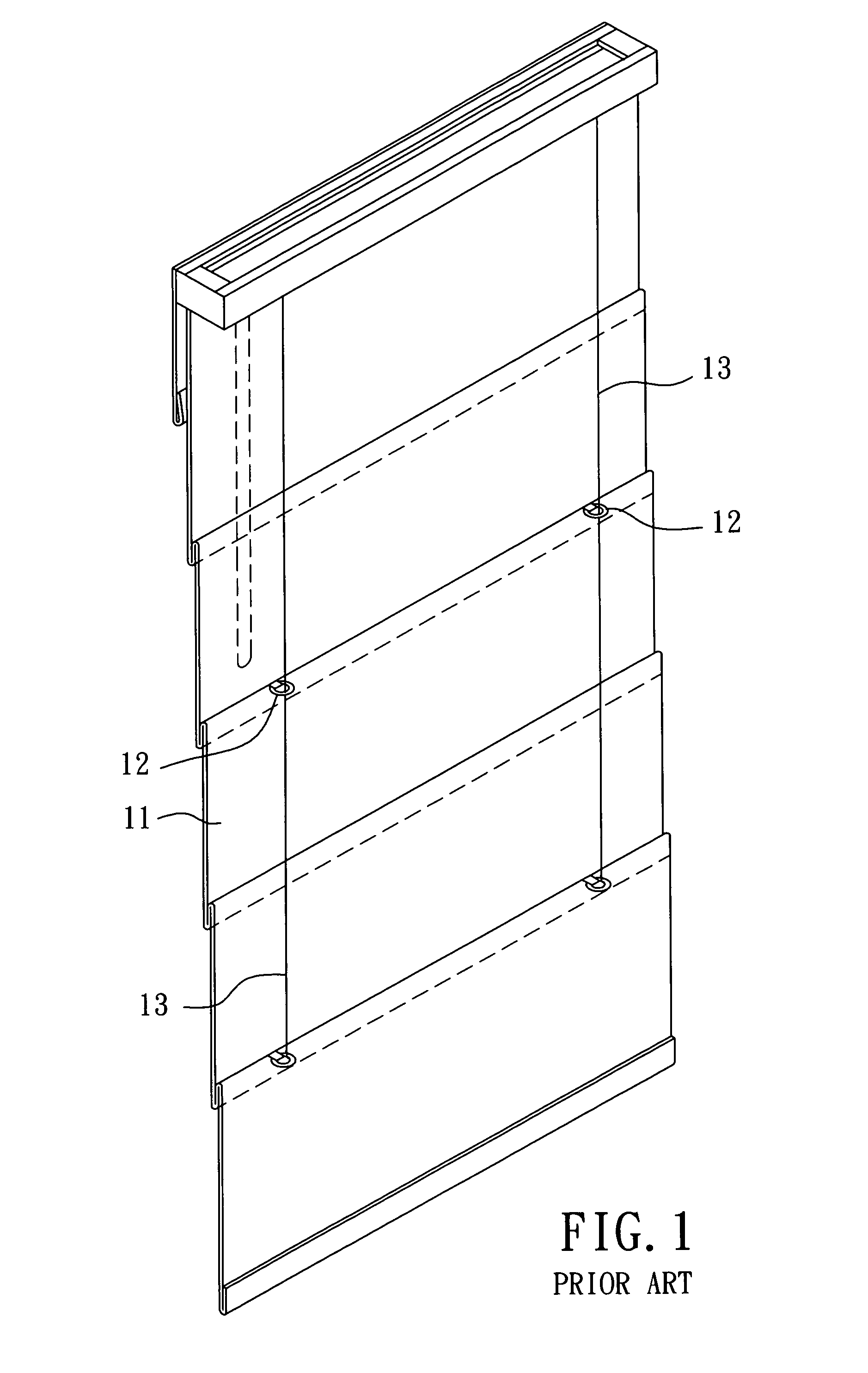

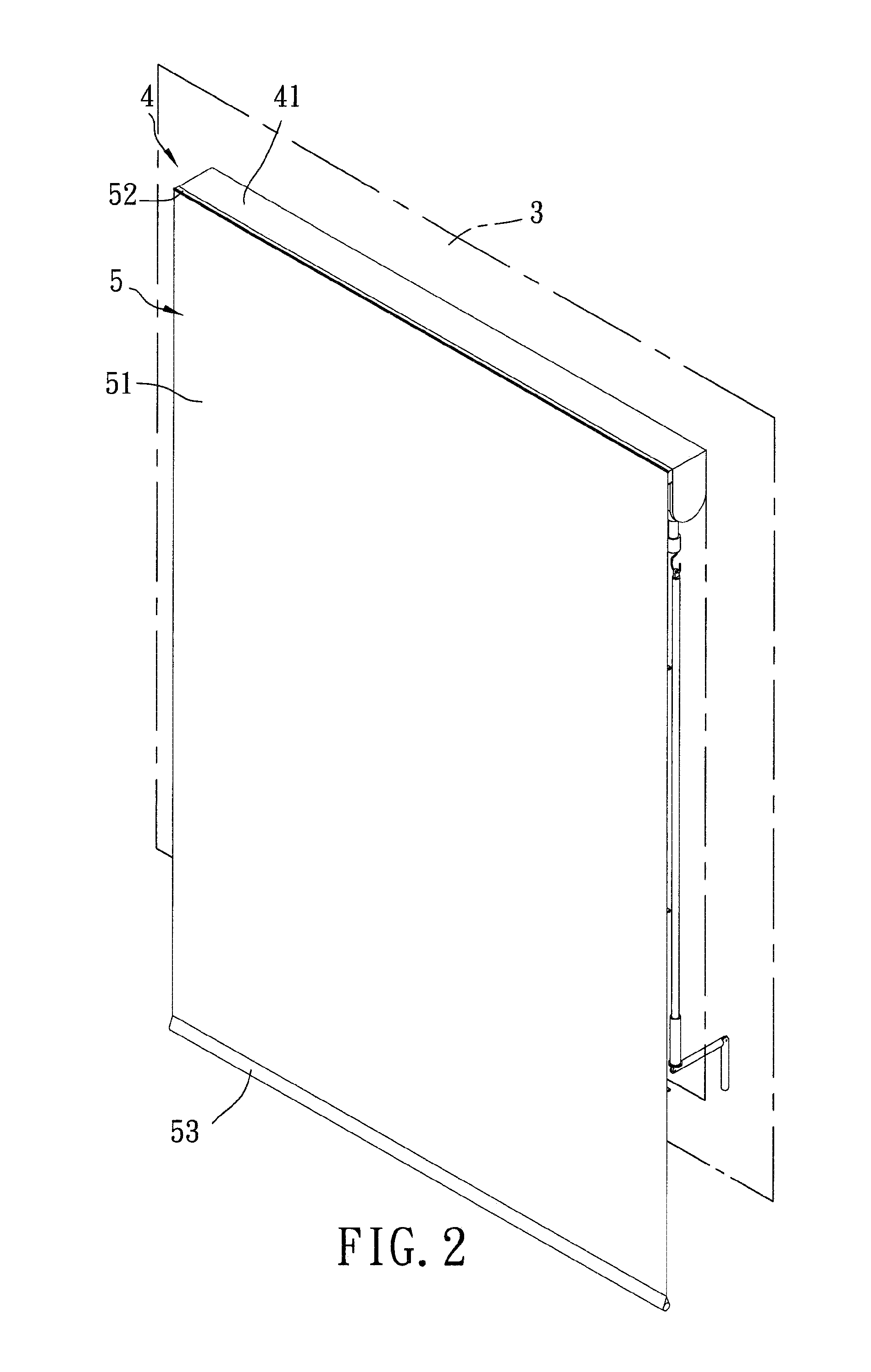

Window blind assembly

InactiveUS8281842B2Improve cleanlinessConvenient replacementScreensExtensible doors/windowsEngineeringMechanical engineering

Owner:LIN SHIH MING

Window blind assembly

InactiveUS20110203742A1Improve cleanlinessConvenient replacementScreensShutters/ movable grillesEngineeringMechanical engineering

A window blind assembly includes a roller blind unit, a curtain member unit, and a clamping unit. The roller blind unit includes a roller rod that extends horizontally and that is rotatably mounted at or in proximity to an upper edge portion of the window, and a roller blind piece a top edge of which is connected to the roller rod and which is able to be wound around and extended from the roller rod. The curtain member unit includes a curtain member having a sheltering portion and a plurality of partitioning portions. The clamping unit includes a plurality of connecting members associated respectively with the partitioning portions. Each of the connecting members has a confining portion, and two securing portions connected to opposite ends of the confining portion and that connect the confining portion to a respective one of the partitioning portions.

Owner:LIN SHIH MING

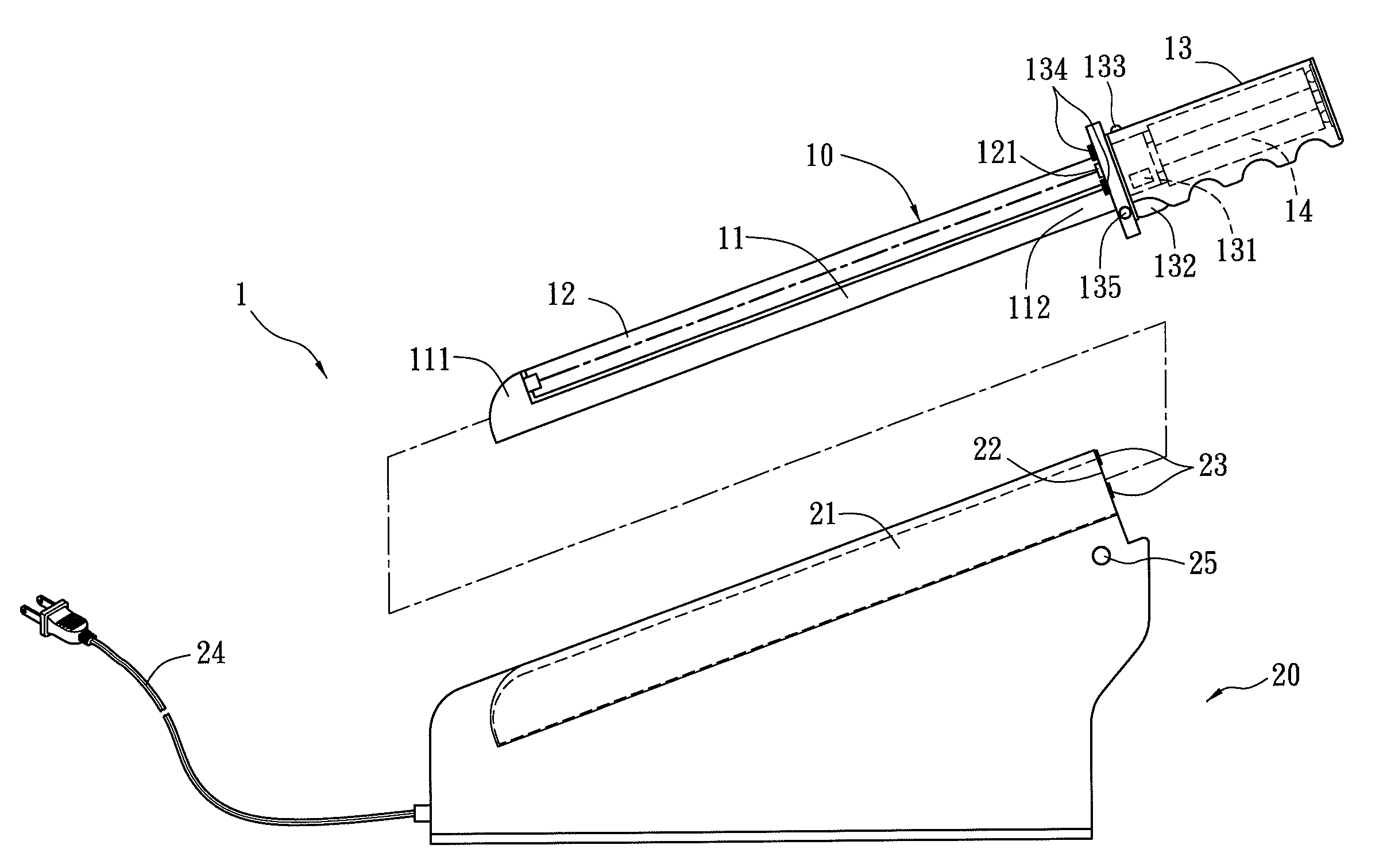

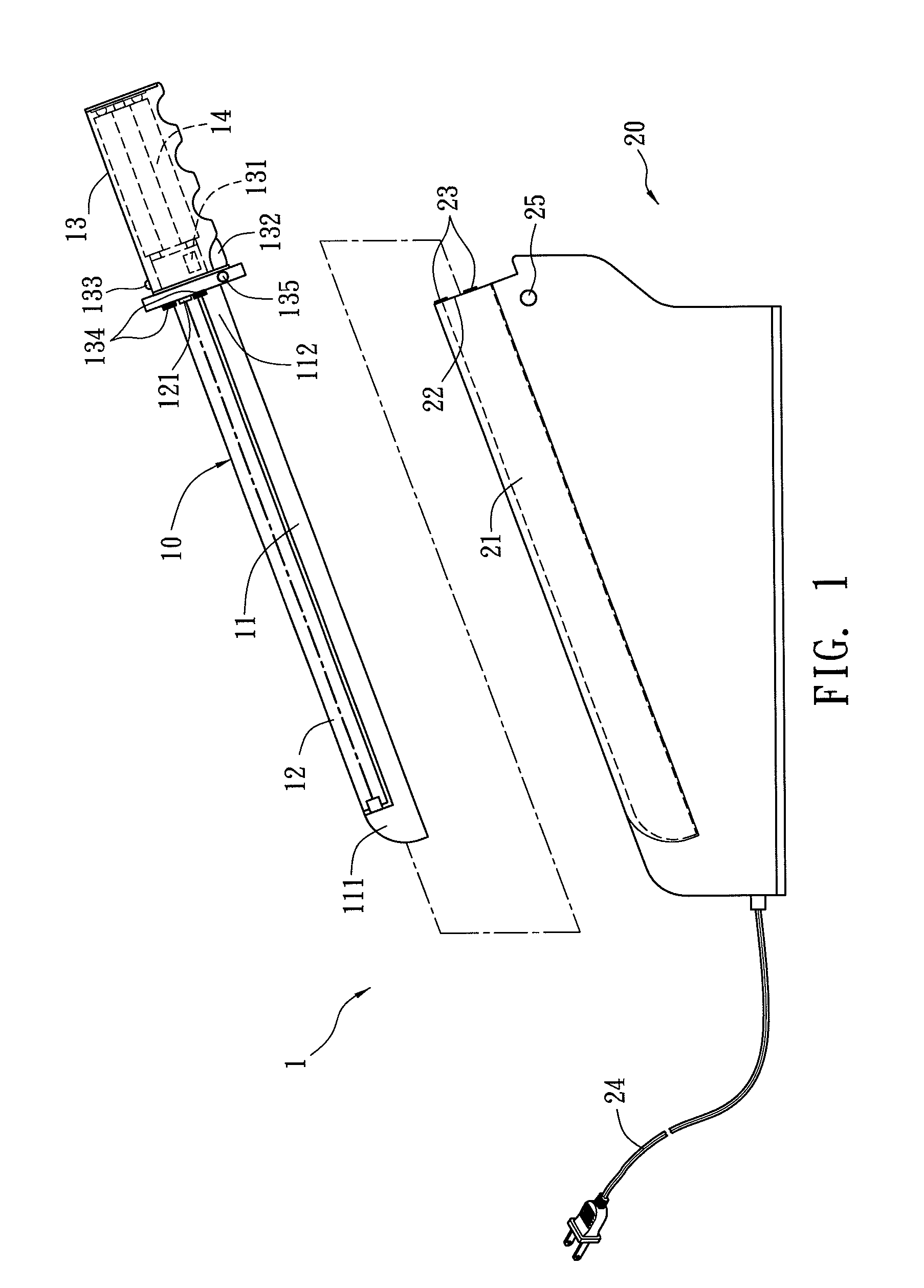

Electric heated knife assembly

InactiveUS20100186238A1Easy and flexible operationIncrease resistanceHeating element shapesPortable power-driven toolsUser needsHigh resistance

An electric heated knife assembly is disclosed. The electric heated knife assembly includes an electric heated knife and a corresponding stand while the electric heated knife consists of a metal blade with high resistance, a blade holding part, a handle and a rechargeable battery inside the handle. A switch and two contacting points for charging are arranged on front end of the handle. The stand is for setting and storage of the electric heated knife and is connected to an external power source by a wire with a plug. Two electrically conductive contacts corresponding to two contact points for charging on front end of the handle are set on surface with an insertion hole of the stand. Without being used, the electric heated knife is set on the stand and is charged according to users needs. When in use, press a switch on the handle so that the metal blade is heated by the power of the rechargeable battery. Thus the convenience of use of the electric heated knife is improved without restrictions of operation and cleaning of conventional electric heated knife.

Owner:SHIH MEN TZON

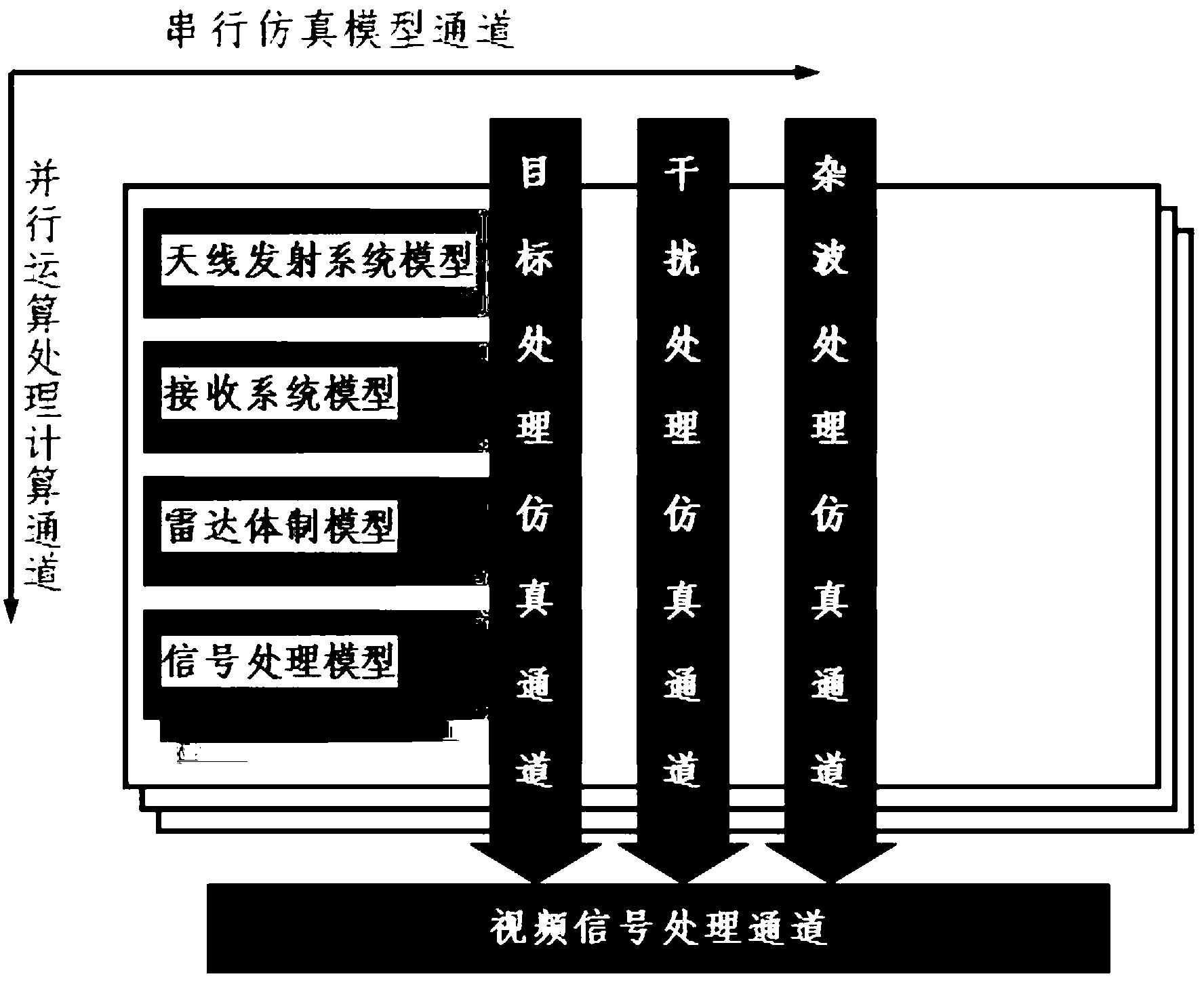

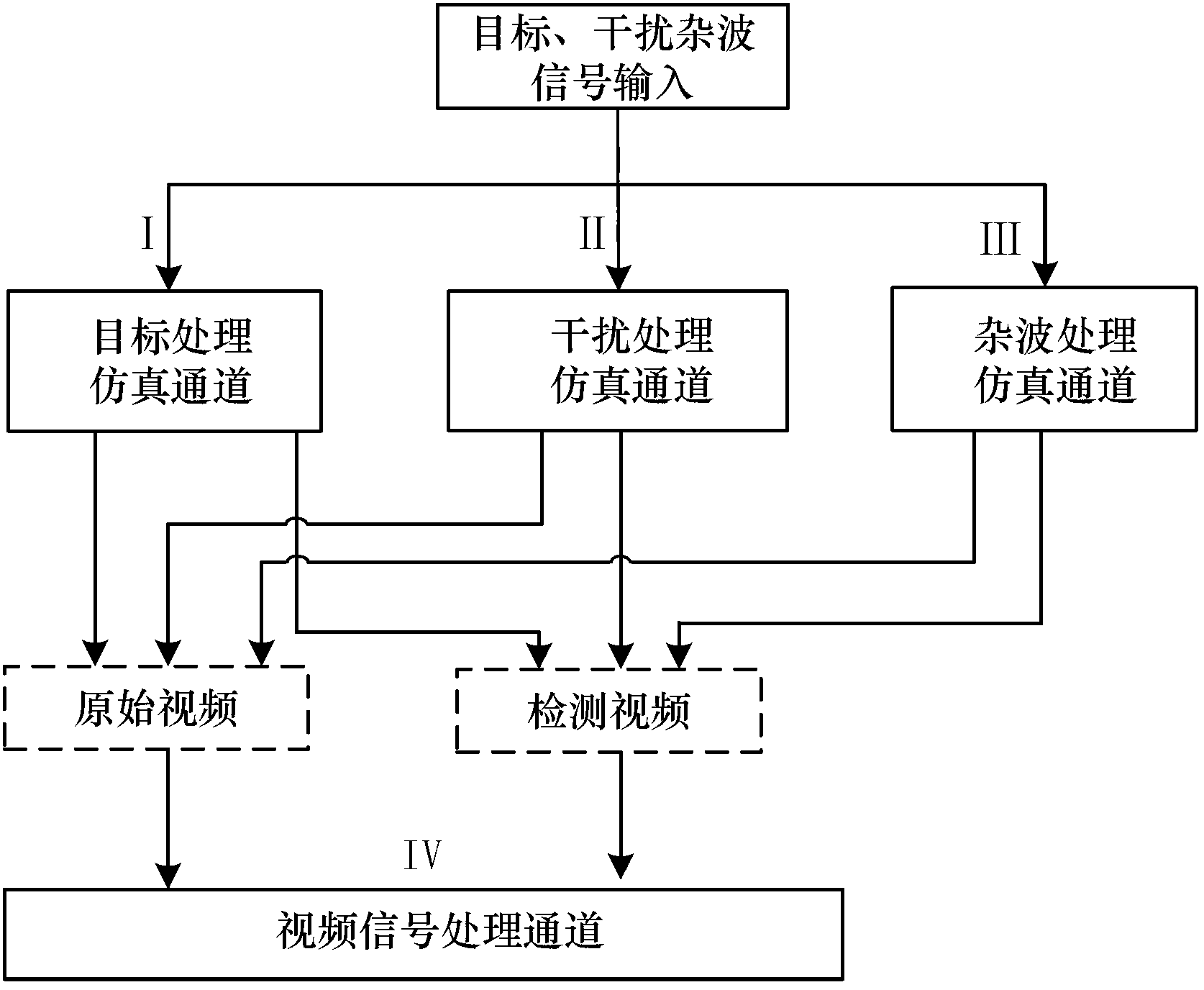

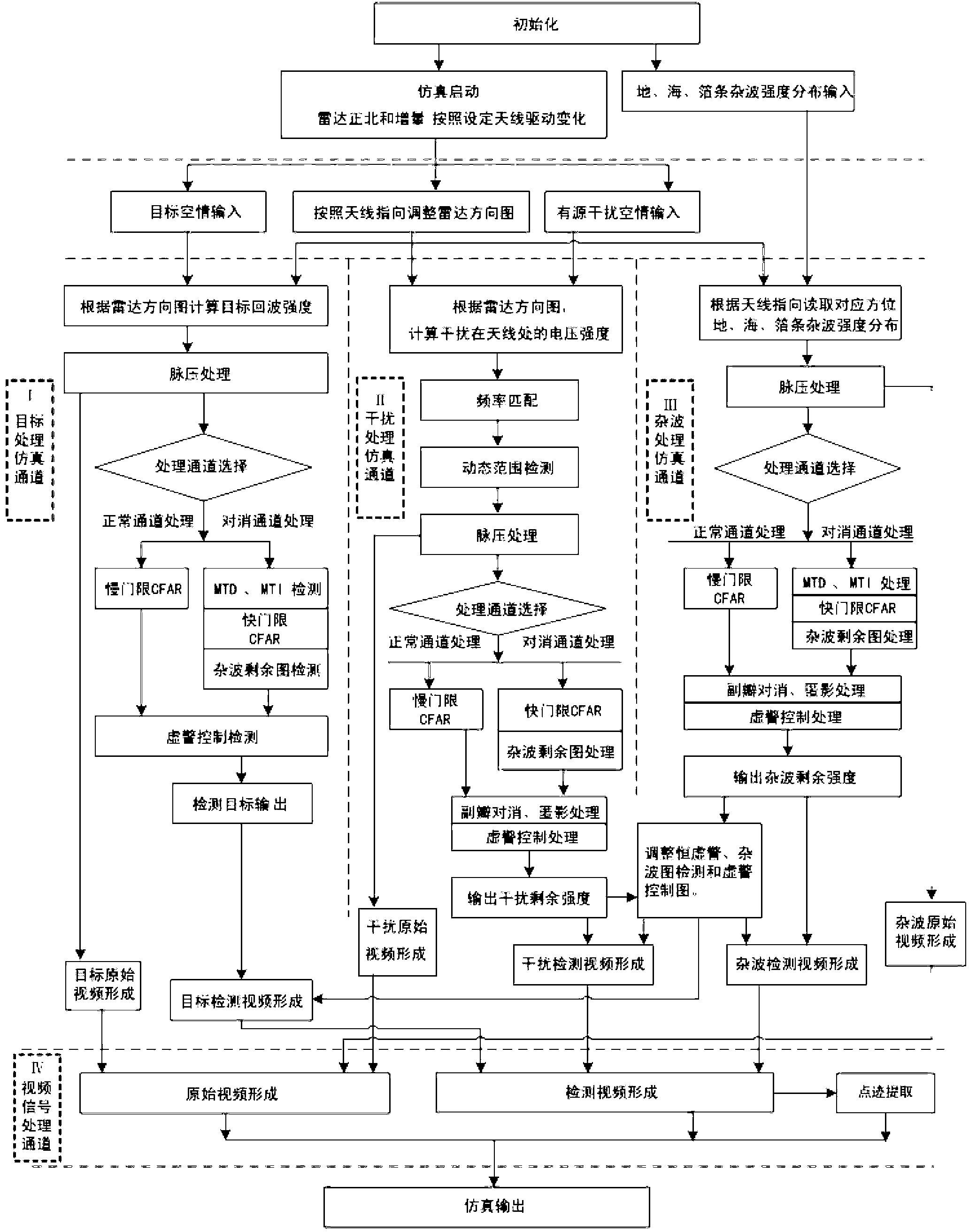

General performance simulation method and framework of air surveillance radar

ActiveCN103246556AImprove scalabilityConvenient replacementMultiprogramming arrangementsSpecial data processing applicationsSecondary surveillance radarReal-time simulation

The invention relates to a general performance simulation method and a framework of an air surveillance radar. General real-time simulation of detection performance of the air surveillance radar is achieved due to the utilization of a structure of a plurality of serial simulation module channels and parallel computation processing calculation channels. Processing modules related to the radar are serially connected through the serial simulation module channels according to treating processes of radar real installation signals to form into a simulation process of processing of at least a radar signal. Parallel simulation calculations of treating processes of a target signal, an interference signal and a clutter signal are respectively performed through a parallel calculation processing structure based on the serial simulation module channels and then various signals are performed composition and point trace cohesion to form and output a radar simulation result. The serial simulation module channels are reconfigurable; module composed structures and parameters can be changed; and an existing module or a new construct module can be utilized to achieve general performance simulation of the air surveillance radar.

Owner:中国人民解放军防空兵学院

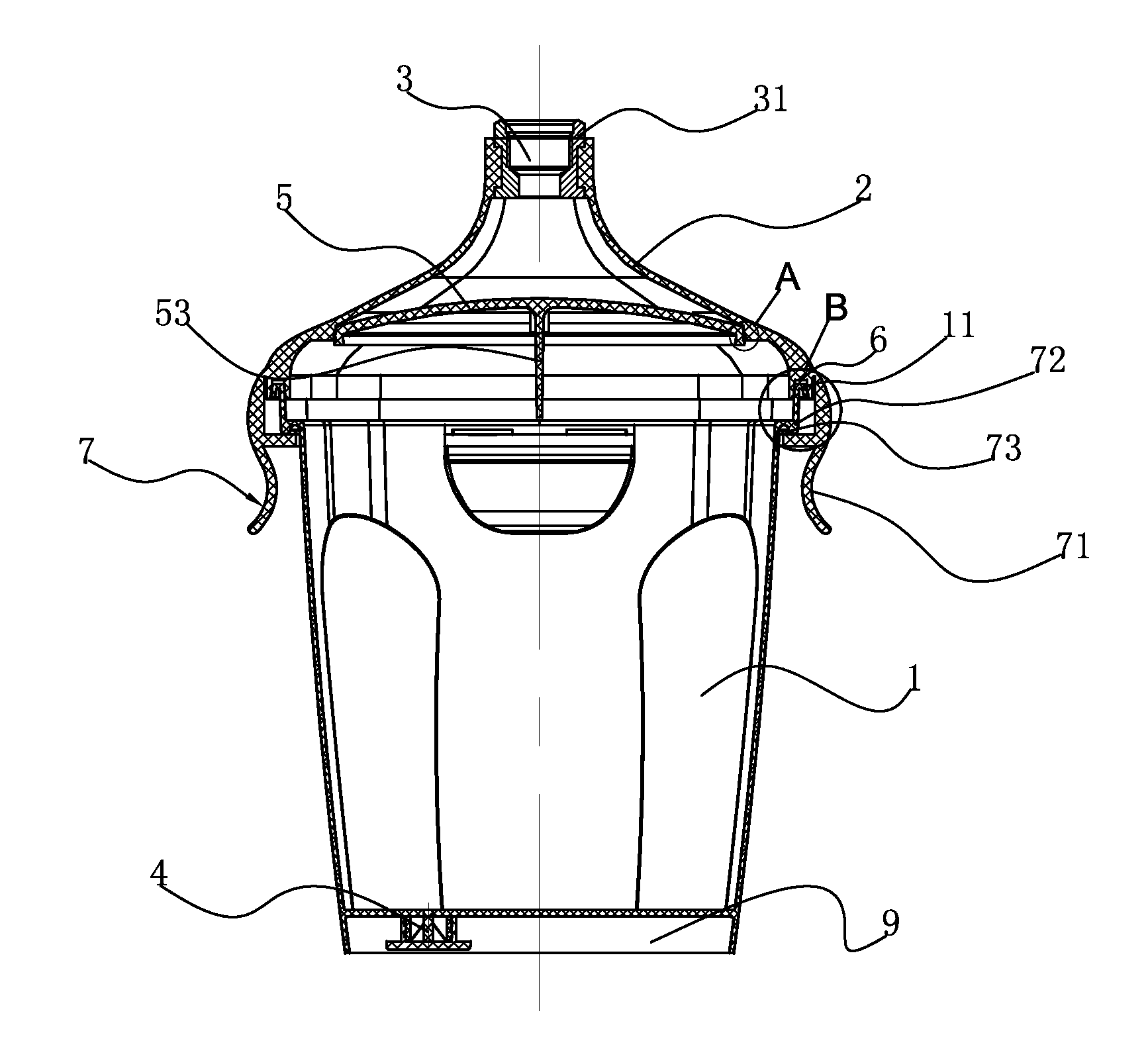

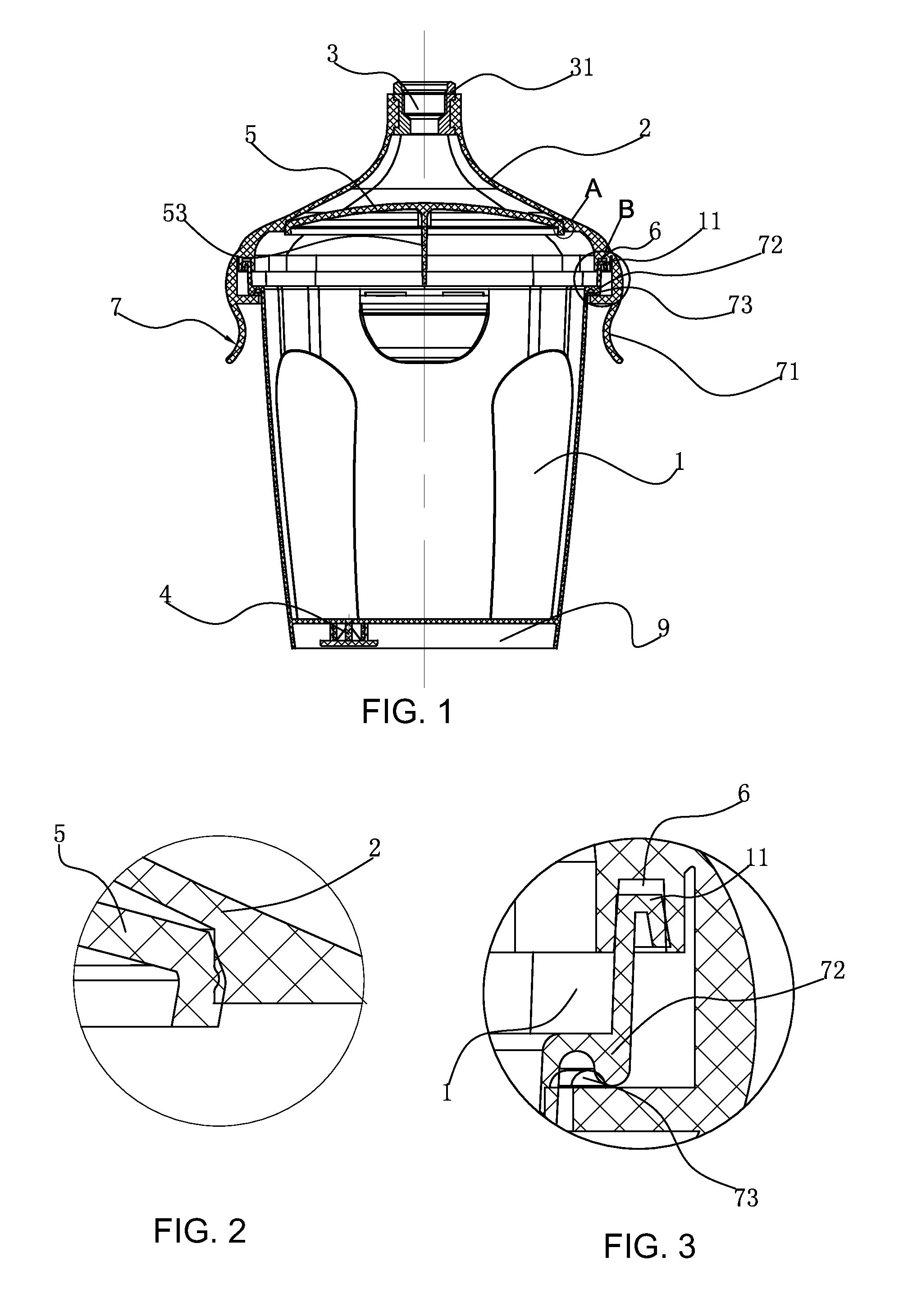

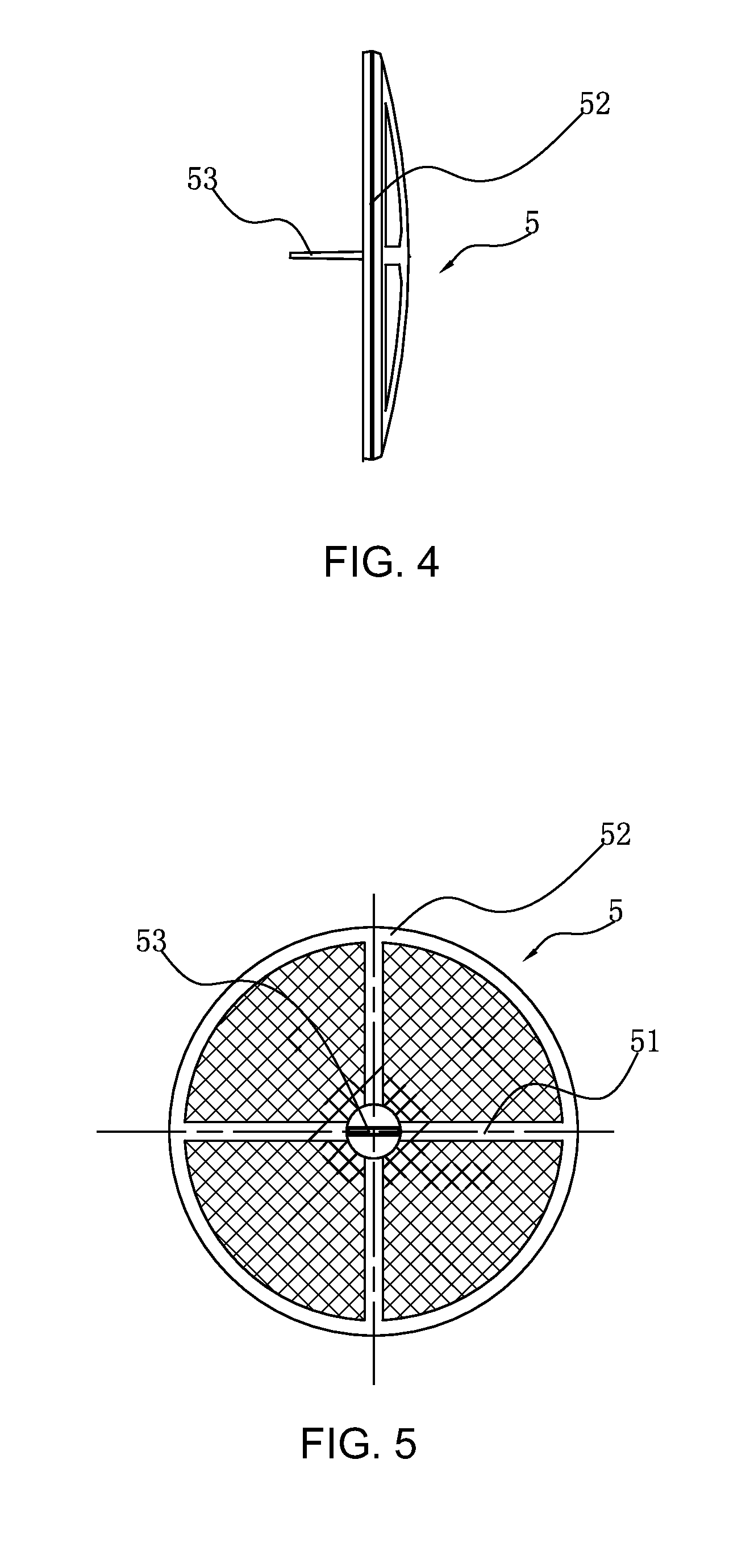

Fluid reservoir for paint spray gun

InactiveUS20120291890A1Simple structureImprove tightnessOperating means/releasing devices for valvesService pipe systemsFuel tankScrew thread

A fluid reservoir for a paint spray gun comprises a container having an opening and a cover body that sleeves on the opening; the cover body is provided with a connecting port that connects with the paint spray gun; a side of the container has scale and the container is provided with a ventilation device; a filtering device is installed in the fluid reservoir; the cover body is provided with a groove corresponding to the periphery of the container opening; the periphery of container opening is inserted into the groove; a buckle mechanism connects the cover body with the container. Compared with the structure of screw thread connection, such connection manner improves the tightness between the cover body and the container, and makes the cover body and the container easier to be assembled and disassembled.

Owner:PAN XINGGANG

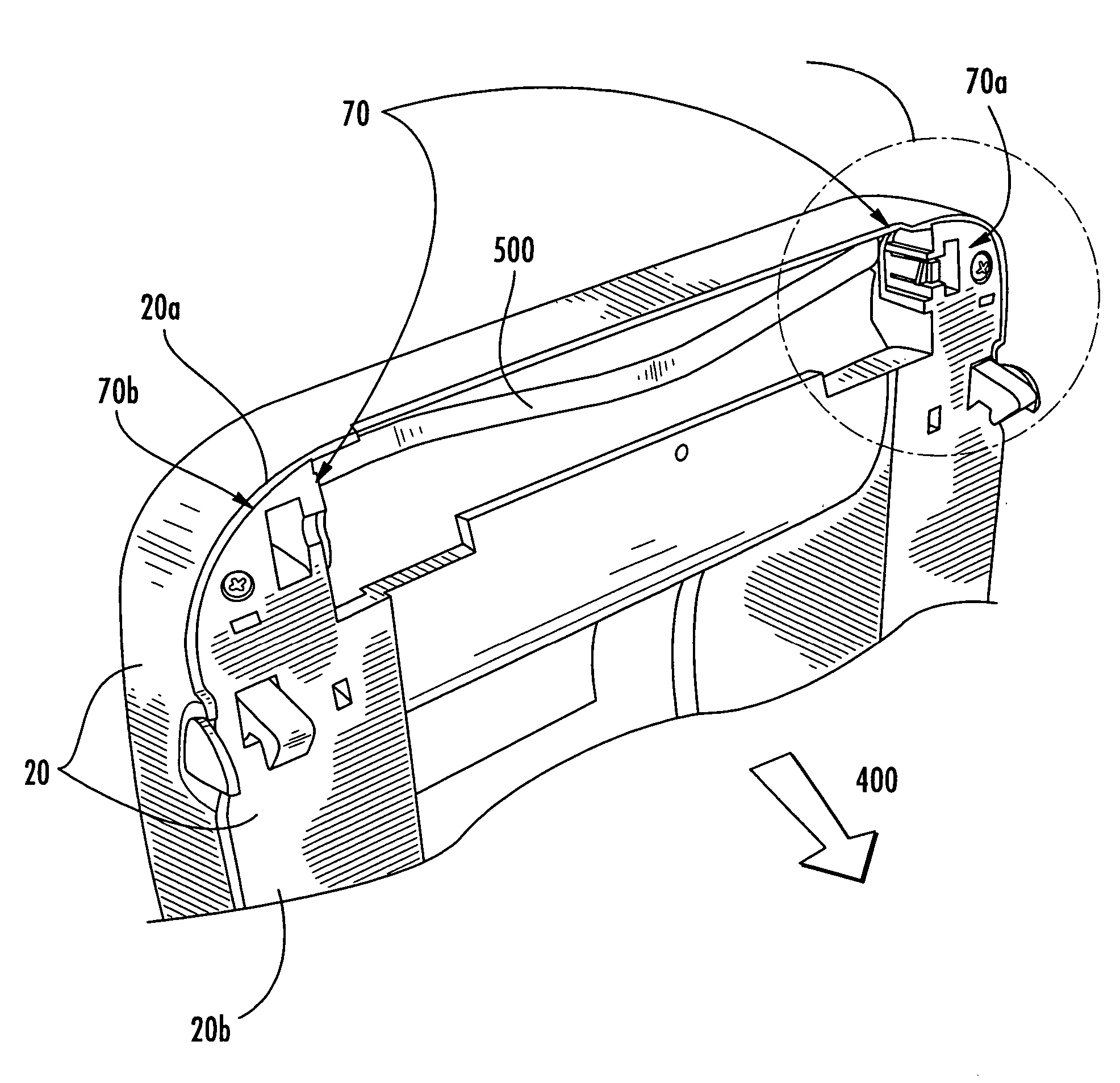

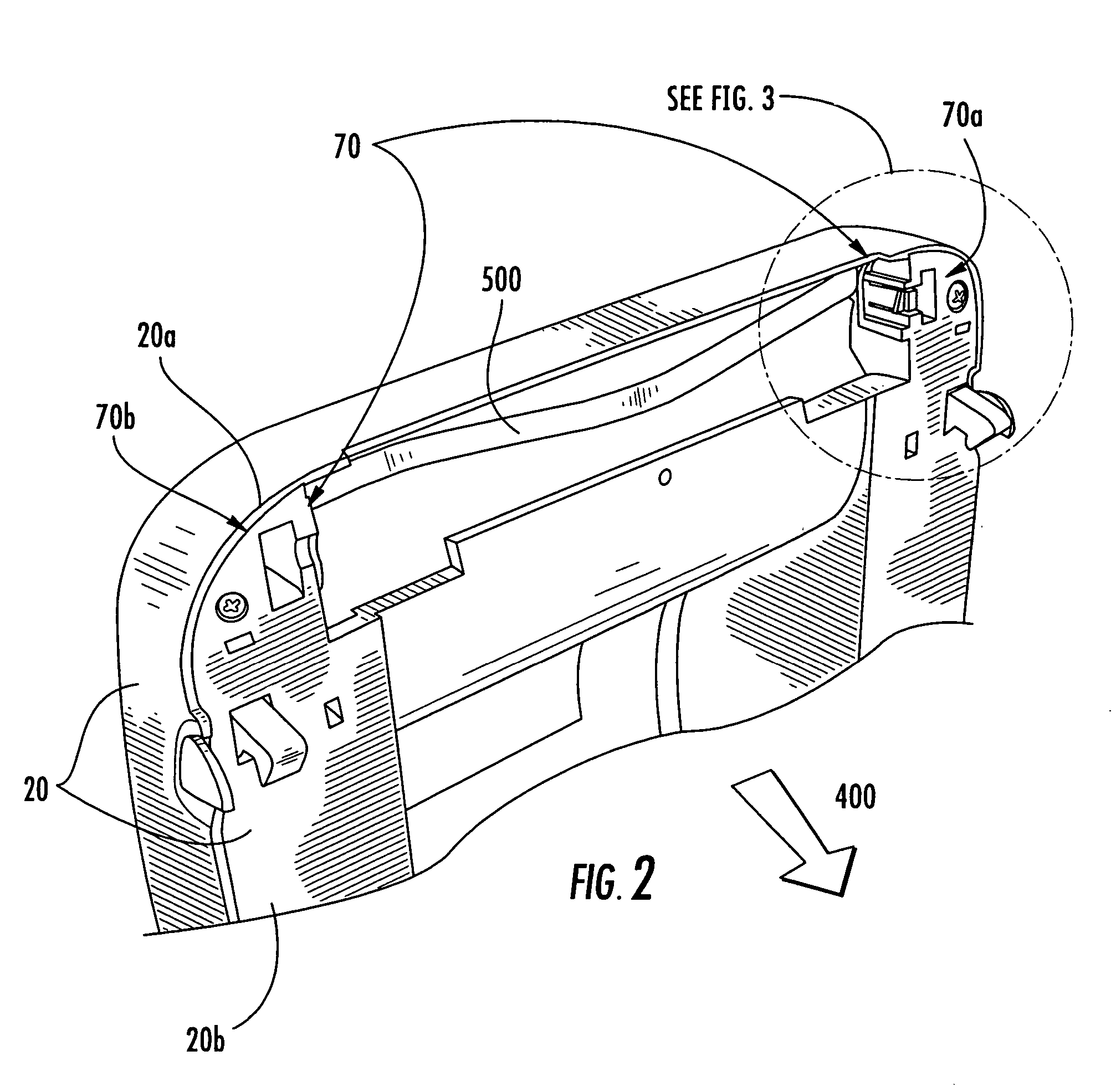

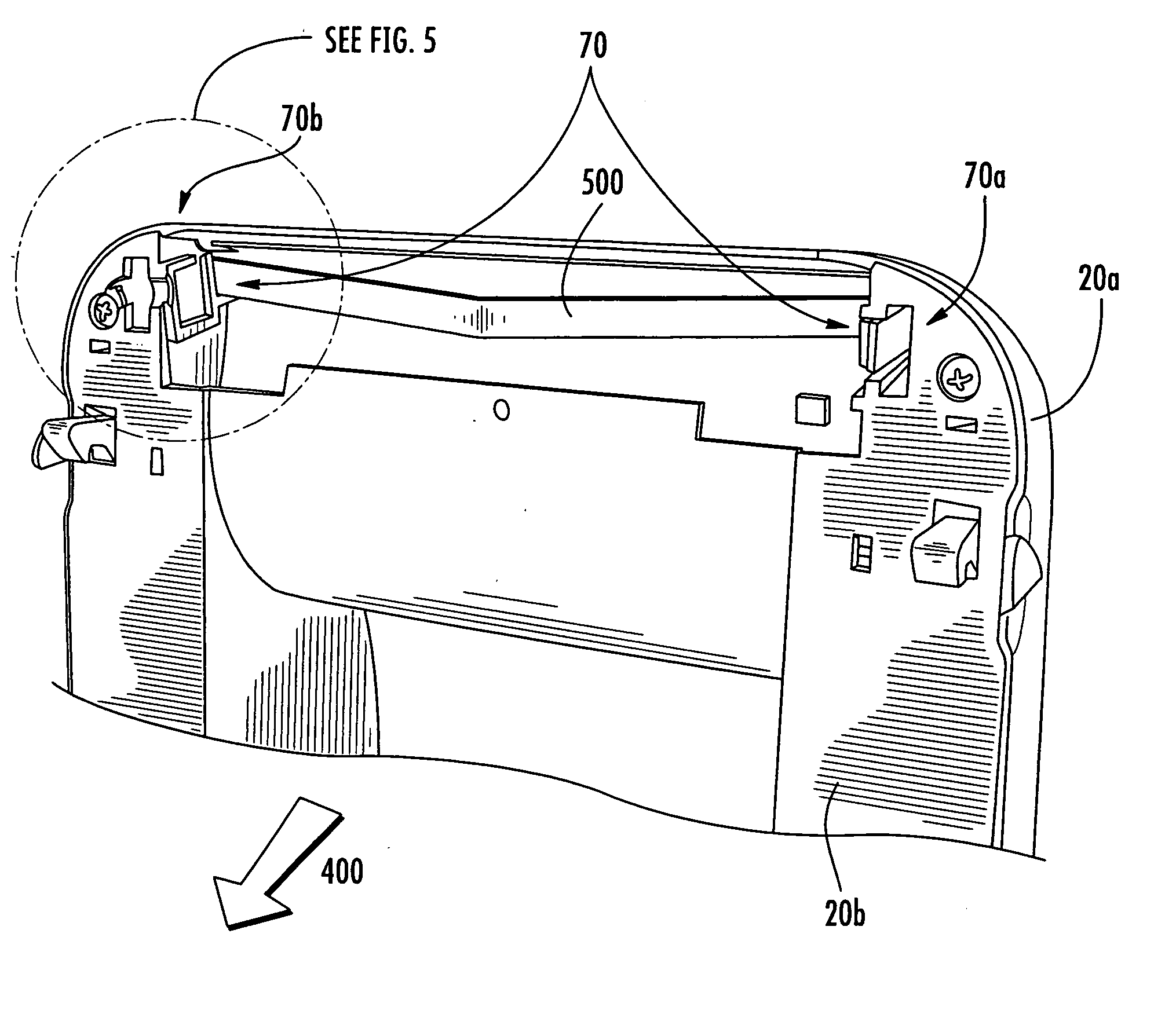

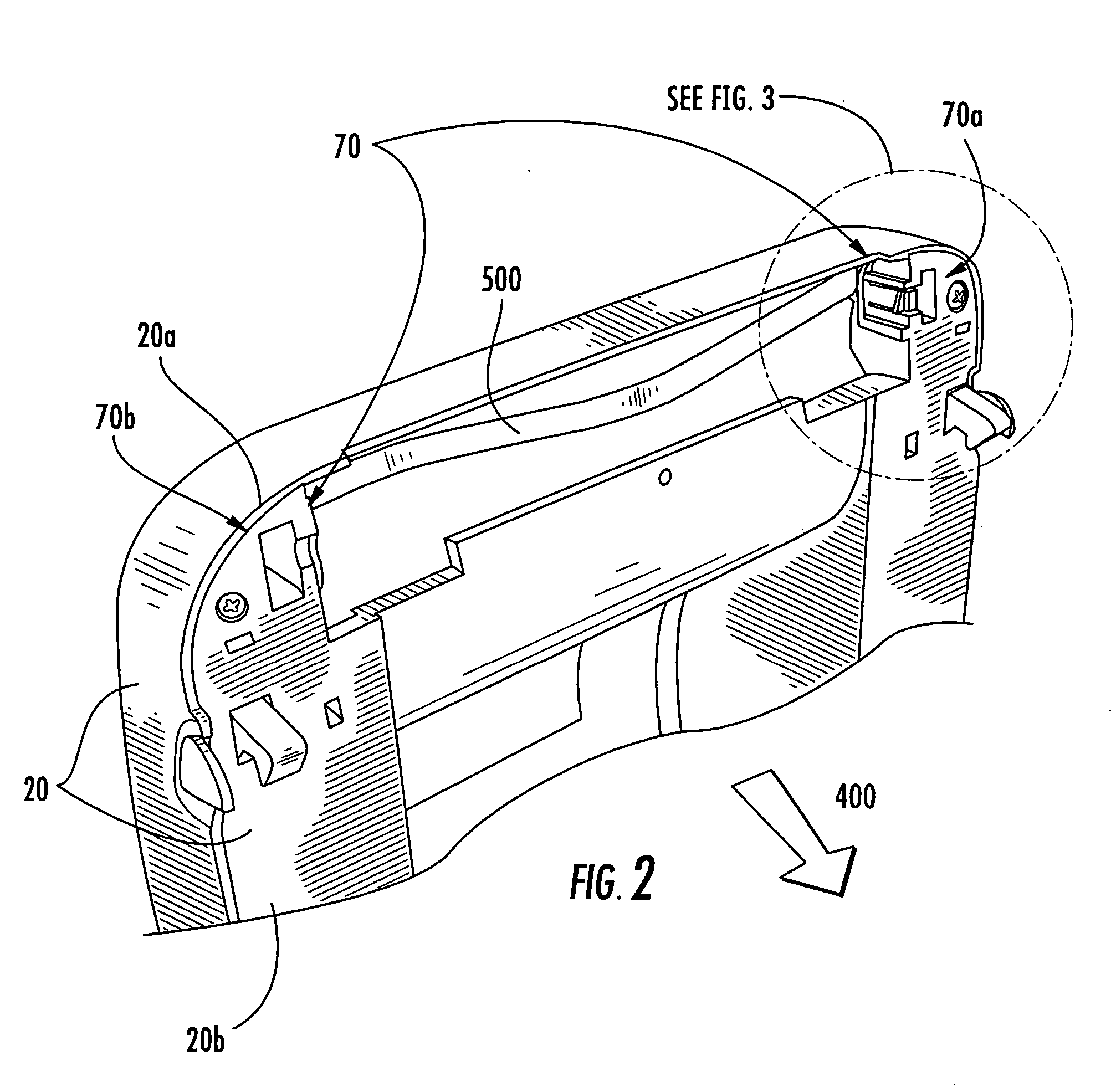

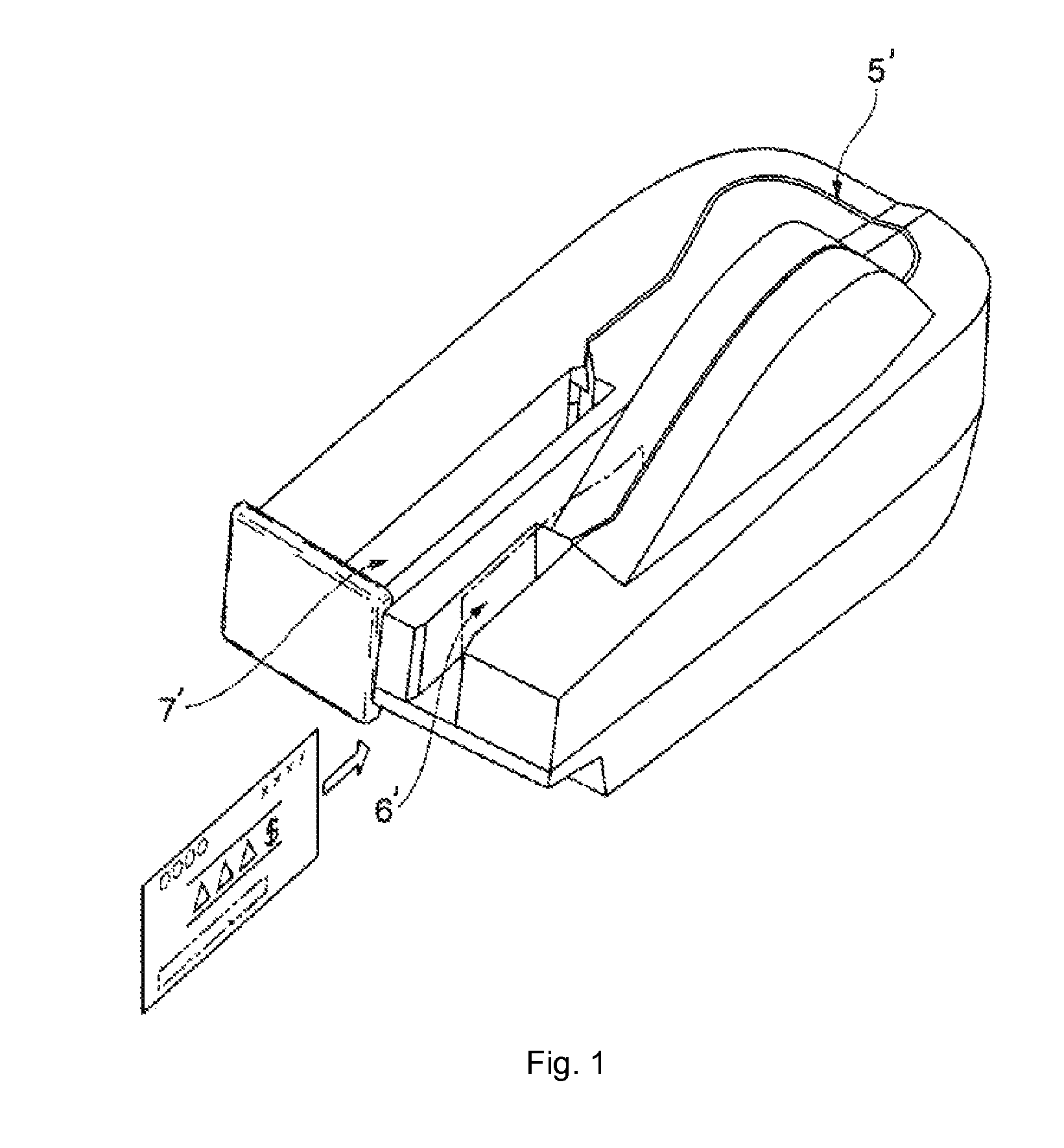

Thermal printer with quick-release printhead assembly

ActiveUS7245312B2Easy to installConvenient replacementRecording apparatusInking apparatusEngineeringFixed position

A quick-release printhead mounting assembly and thermal printer incorporating same, including a printing component, a printer housing, and, a component retention feature attached to or molded into the printer housing adapted for receiving and releasably fixing the printing component to the housing. The retention feature holds the printhead in a fixed position relative to the housing and, therefore, also relative to the platen of the printer. The printing component is advantageously a printhead, such as a thermal printhead, or the combination of a thermal printhead and a heat sink.

Owner:ZEBRA TECH CORP

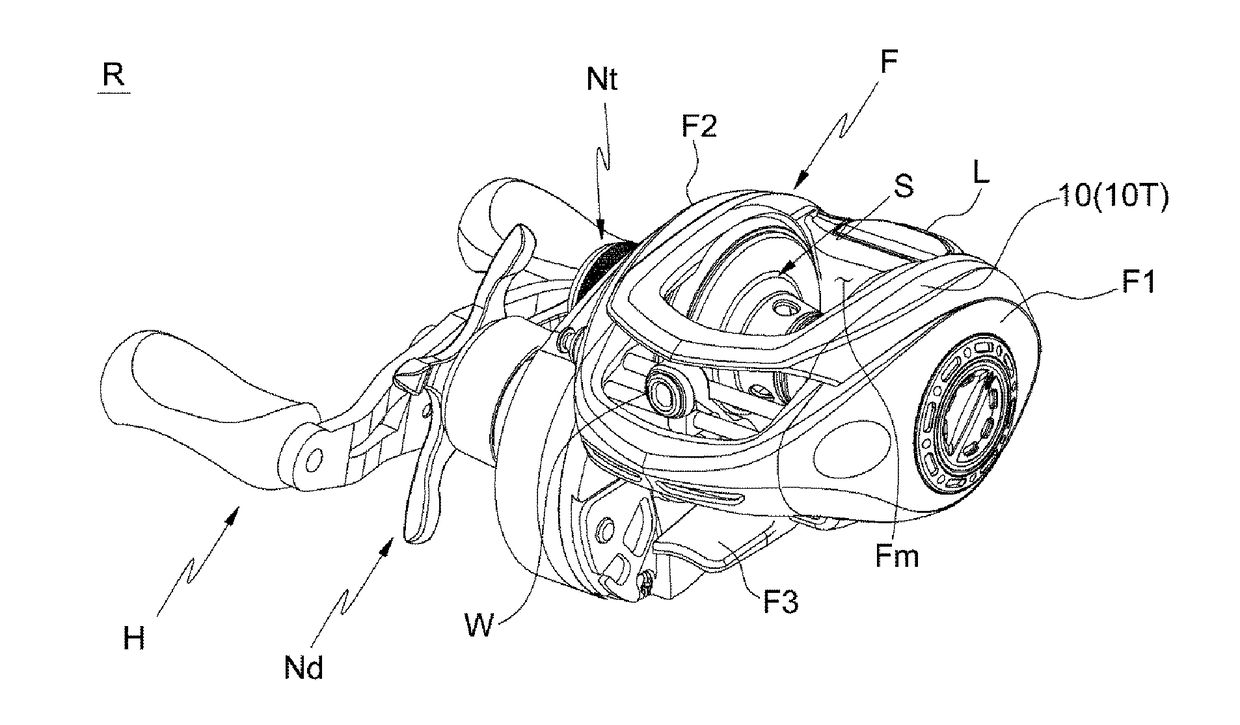

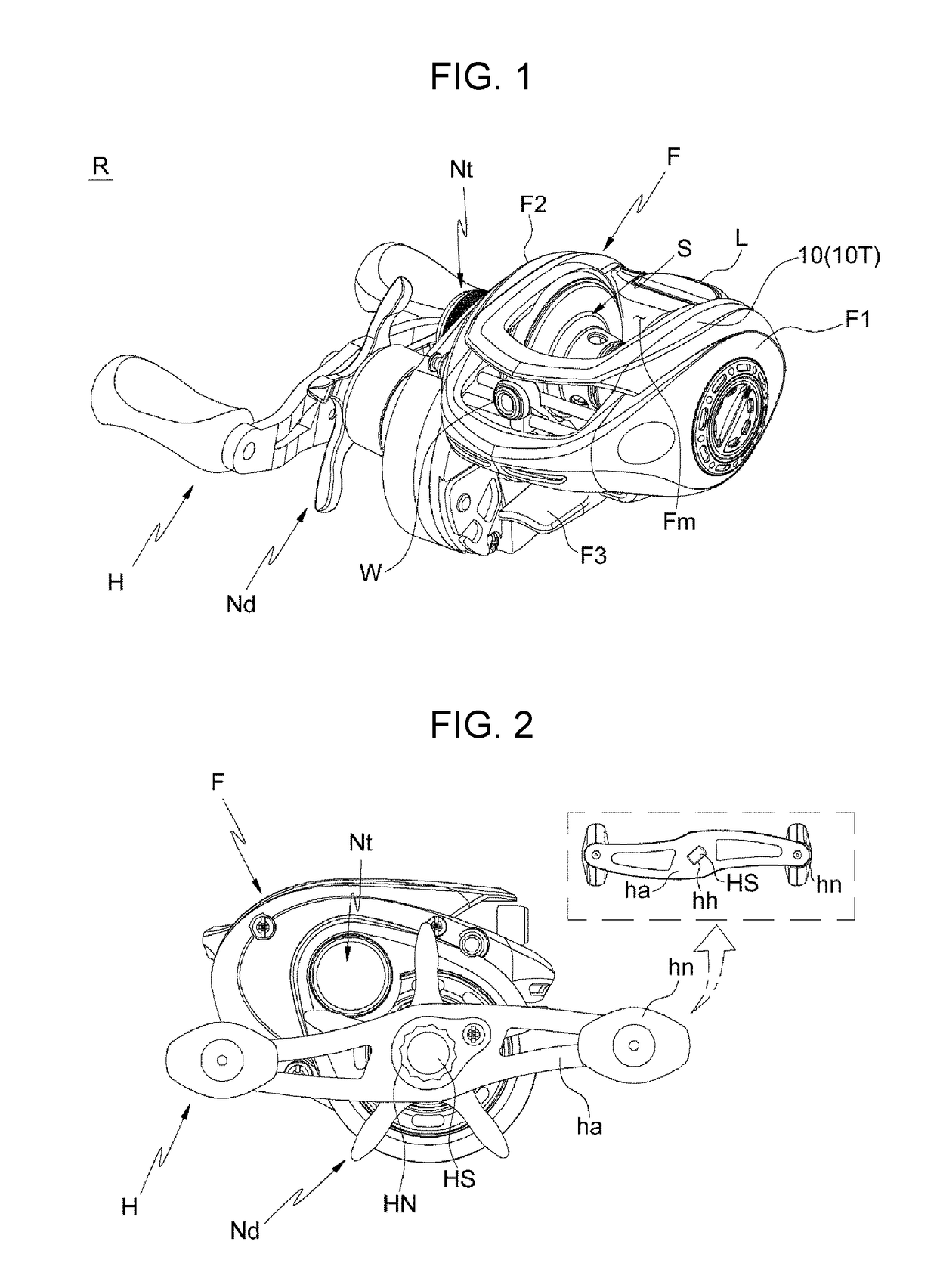

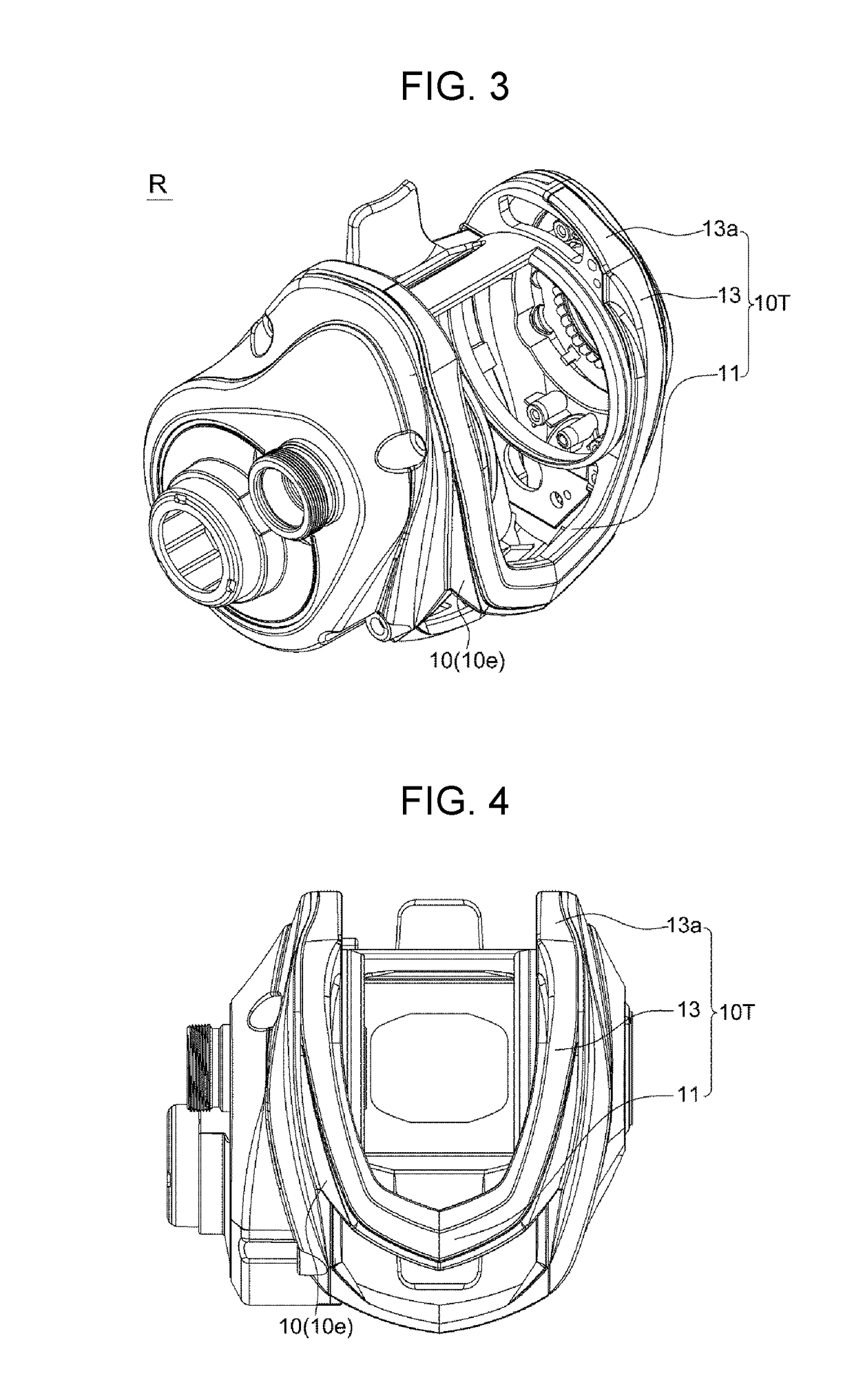

Fishing reel equipped with replaceable hood top

Provided is a fishing reel equipped with a replaceable hood top. The fishing reel includes: a frame having a mount; two side covers coupled to both sides of the frame; a spool disposed inside the mount of the frame and coupled to the side covers through a shaft; a reel foot coupled to a bottom of the frame to be mounted on a fishing rod; a hood coupled to a top of the frame; a handle coupled to a side of the frame through a shaft to rotate the spool; and a tension nut disposed on a side of the frame to adjust a casting distance by controlling a rotational speed of a spool shaft. The hood has coupling portions, and a replaceable hood top is coupled to the coupling portions.

Owner:DOYO ENG

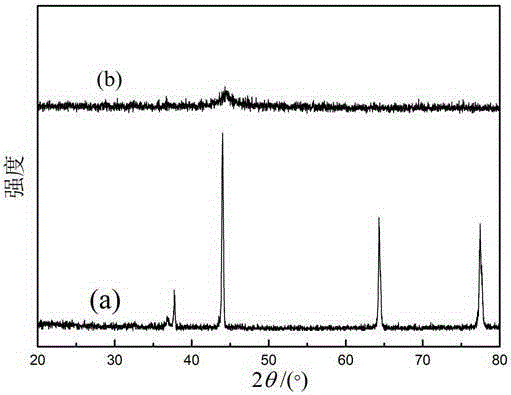

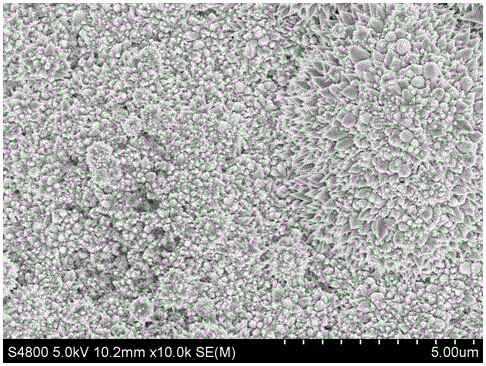

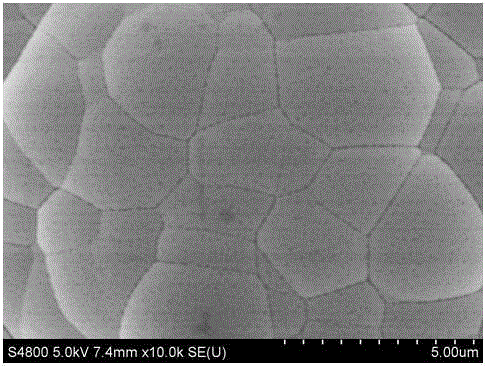

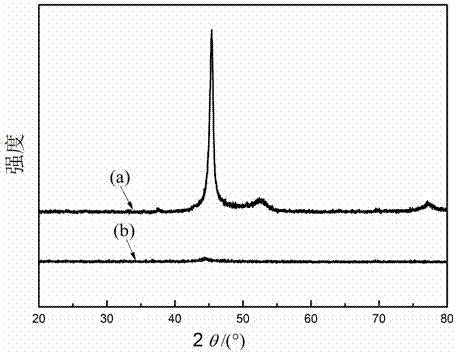

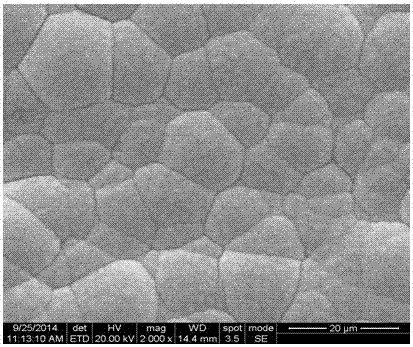

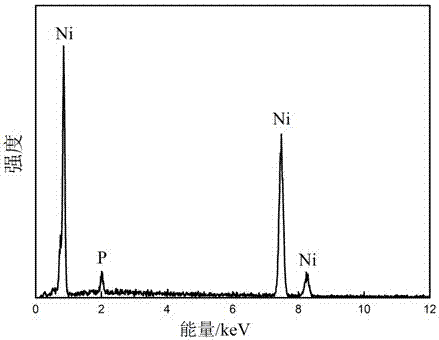

Magnesium alloy fluoride-free hydrazine chemical nickel plating solution and nickel plating process thereof

InactiveCN105331956AEasy handling and maintenanceReduce costs and risk of environmental pollutionLiquid/solution decomposition chemical coatingFluorine freeFluorous chemistry

The invention discloses a magnesium alloy fluoride-free hydrazine chemical nickel plating solution and a nickel plating process thereof. The nickel plating solution comprises an alkaline fluoride-free hydrazine chemical nickel plating solution and an acidic fluoride-free hydrazine chemical nickel plating solution; the pH value of the alkaline fluoride-free hydrazine chemical nickel plating solution is greater than or equal to 13, and the alkaline fluoride-free hydrazine chemical nickel plating solution consists of nickel chloride, hydrazine, a complexing agent, sodium hydroxide or potassium hydroxide, boric acid or thiourea; the pH value of the acid fluoride-free hydrazine chemical nickel plating solution is 4-6, and the acidic fluoride-free hydrazine chemical nickel plating solution consists of a nickel salt, sodium hypophosphite, citric acid and thiourea. The nickel plating process comprises the following steps: polishing, removing oil and grease, carrying out alkaline washing, pickling, activating, carrying out alkaline fluoride-free hydrazine chemical nickel plating, carrying out acidic fluoride-free hydrazine chemical nickel plating, and passivating. The plating solution is free of fluorine in component, safe in composition, and does not pollute the environment; the service life of the alkaline fluoride-free hydrazine chemical nickel plating solution is long; an outer layer of a composite coating obtained by nickel plating is an amorphous-state nickel phosphorus alloy; and the compact coating is high in compactness, relatively good in corrosion resistance and high in binding force, and has a good industrial application prospect.

Owner:HUNAN UNIV

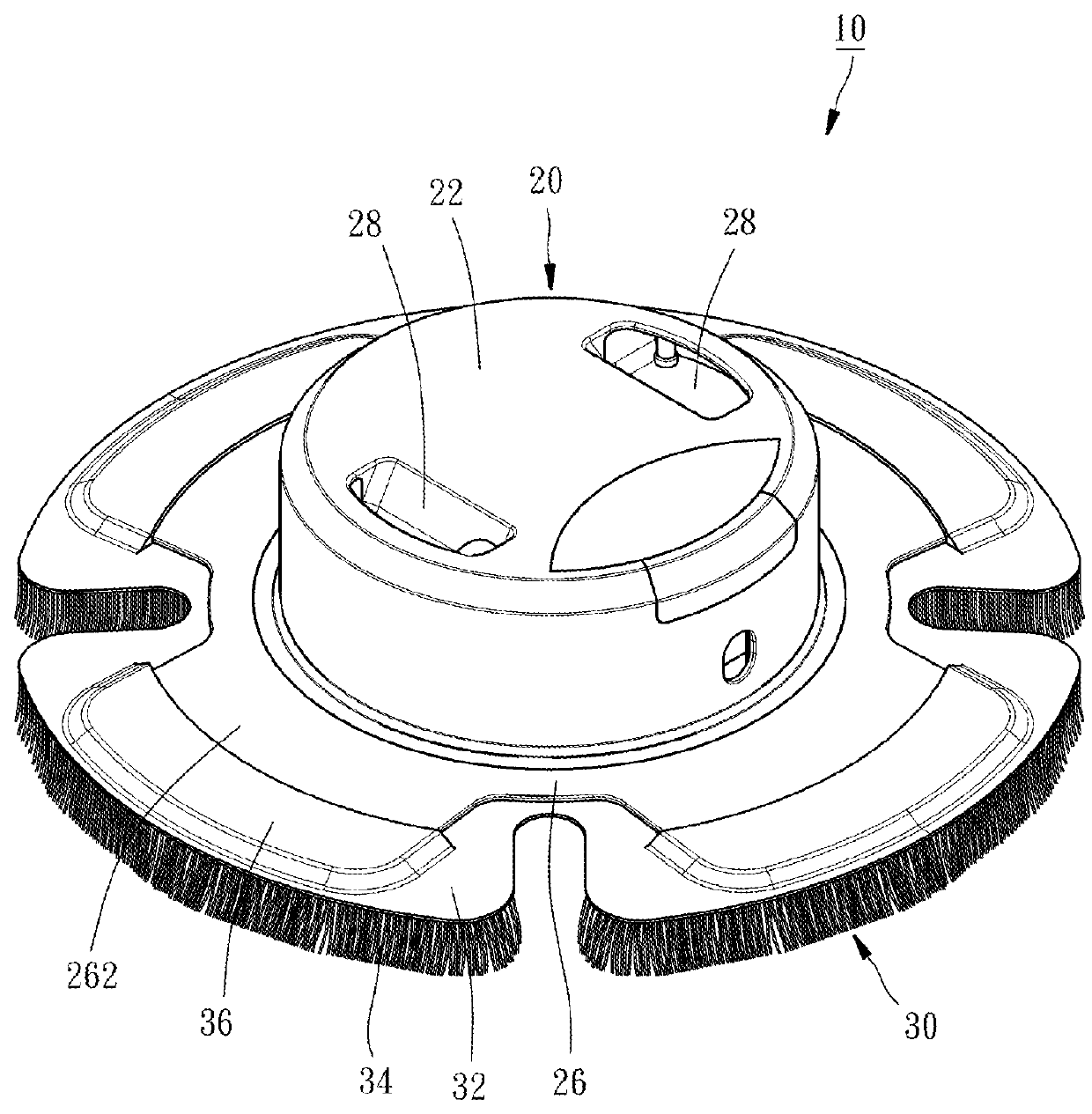

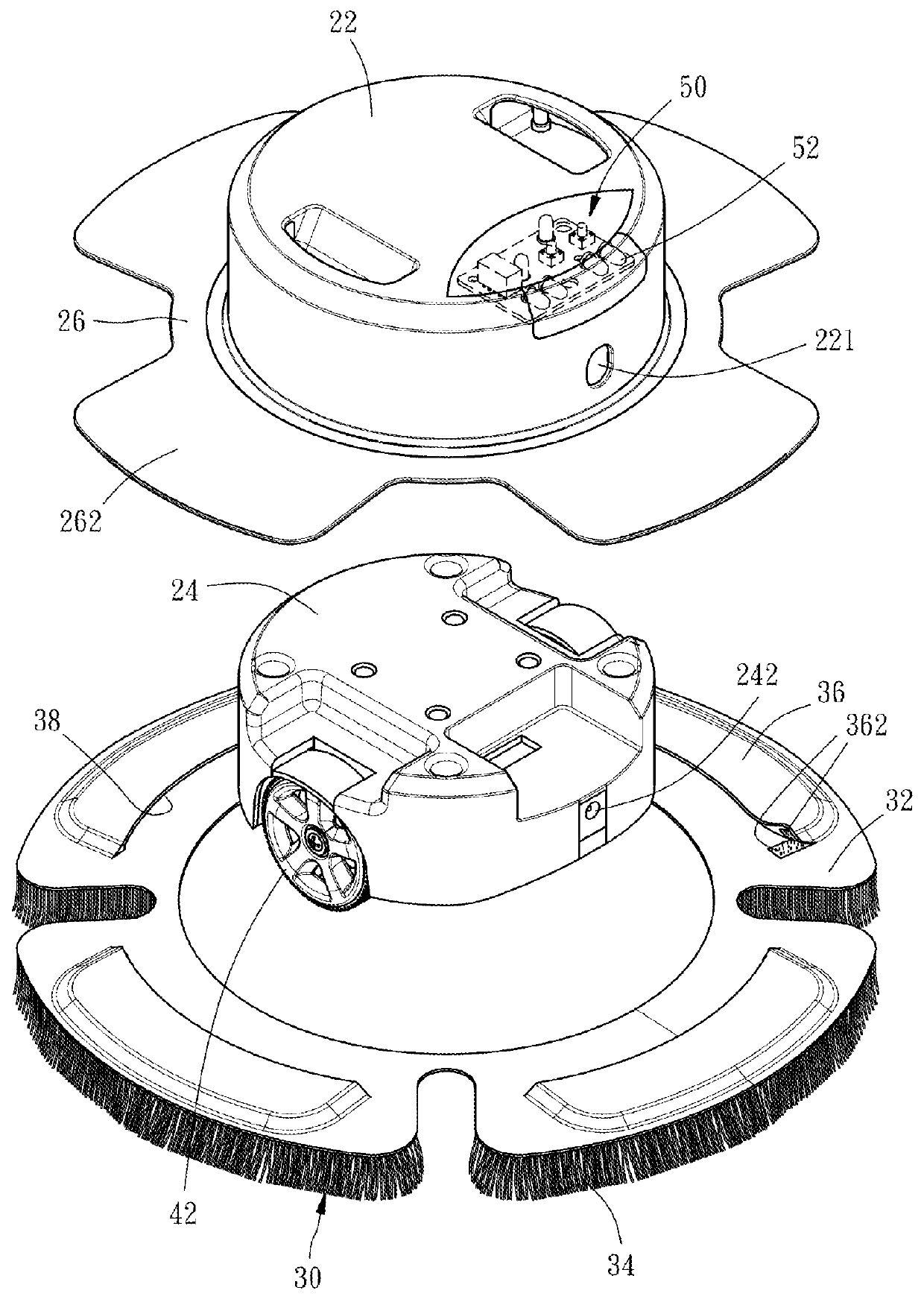

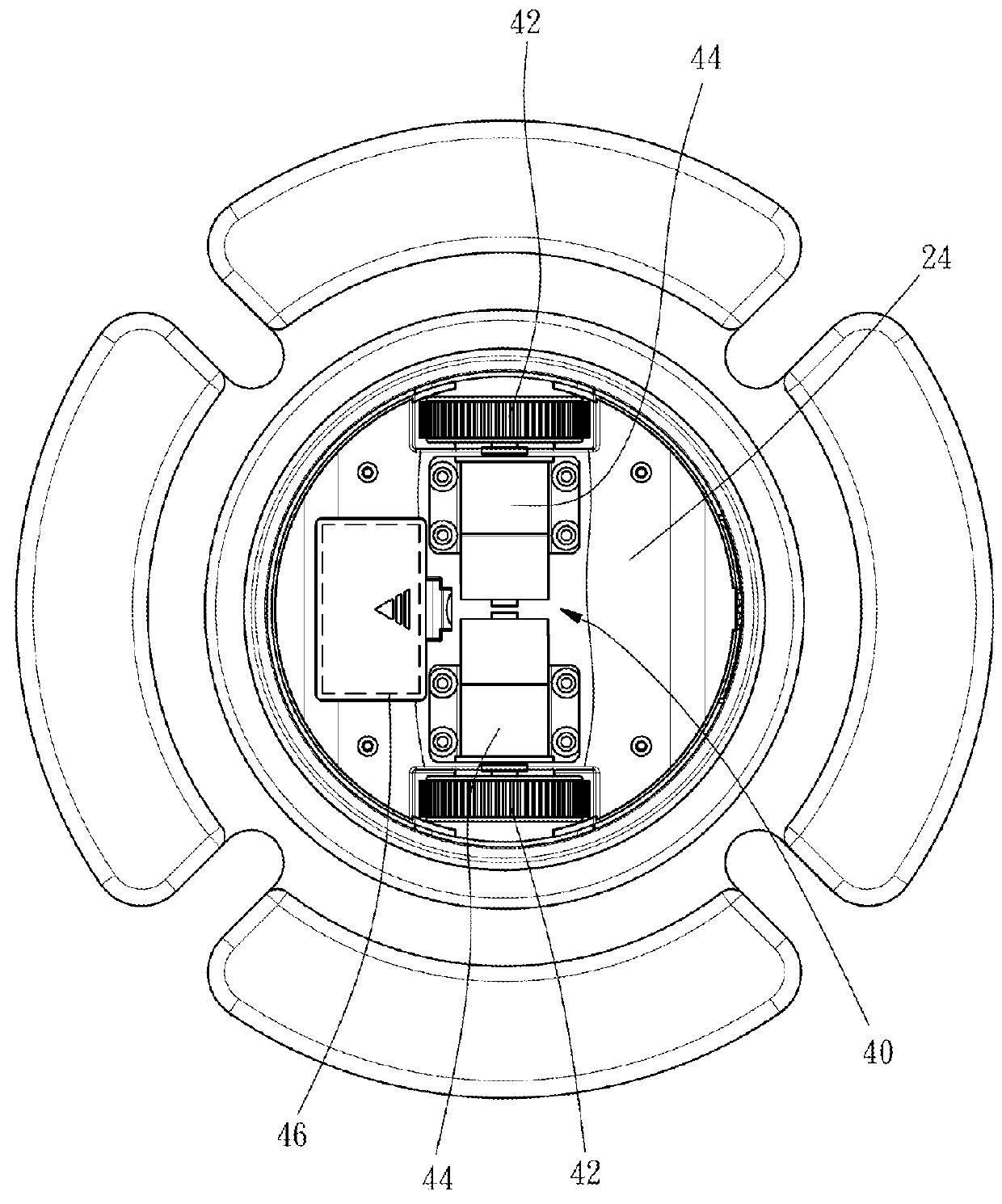

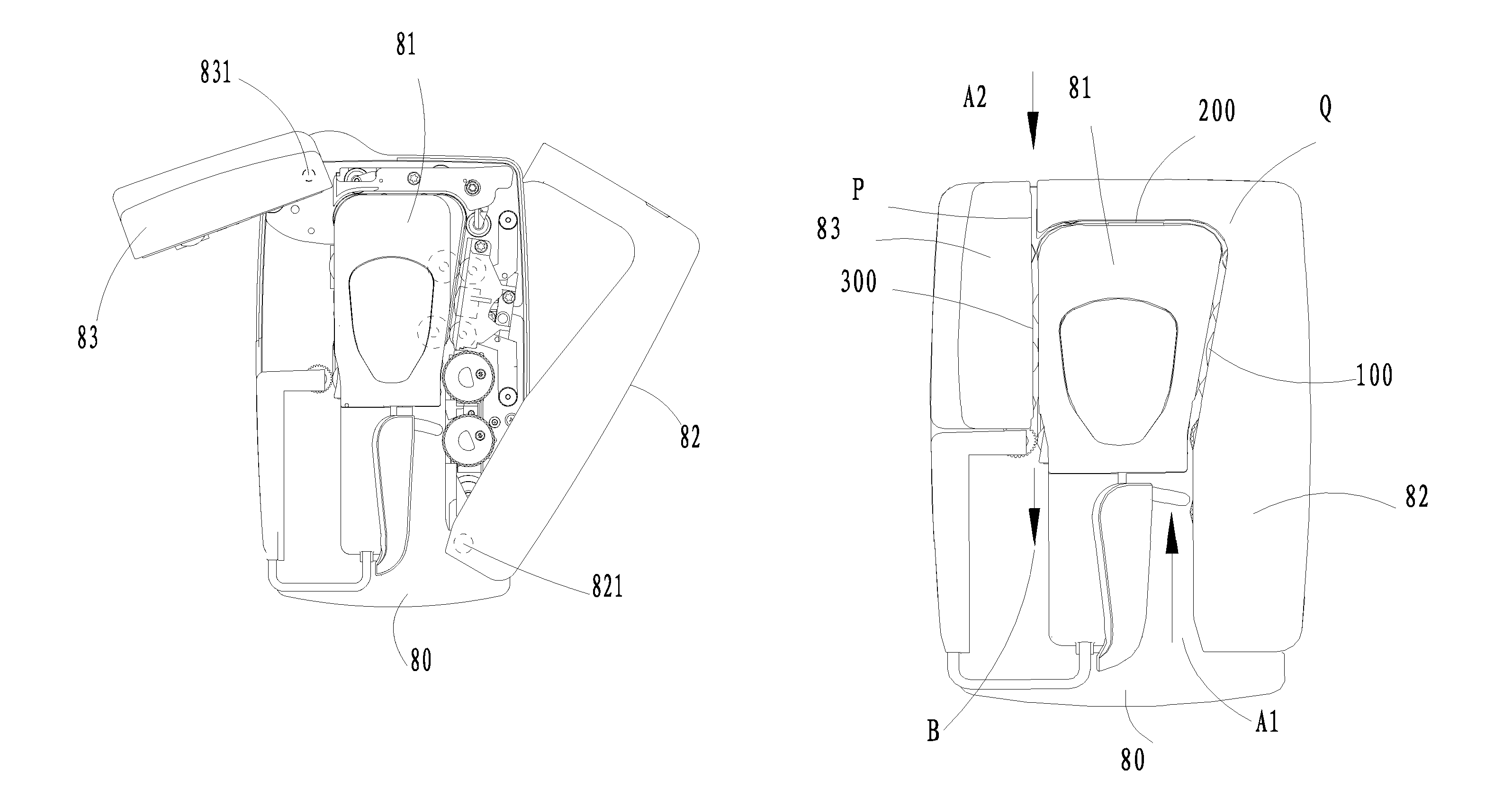

Mobile robotistic mopping machine

InactiveUS9357894B2Easy to cleanSimple structureAutomatic obstacle detectionTravelling automatic controlElectric machineryEngineering

A mobile robotistic mopping machine is formed of a body frame, a mop cloth, a power device, and a control device. The power device includes two opposite wheels and two opposite motors connected with the respective wheels for driving the wheels to rotate to further enable the body frame via the wheels to make the mop cloth move forward for cleaning the ground. The control device is electrically connected with the motors for controlling the motors. When the body frame makes the mop cloth move forward for a predetermined distance, the control device can control and make one of the motors reversely rotate and meanwhile make the other keep normal rotation to further enable the body frame to make the mop cloth turn for a predetermined angle and then keep moving forward.

Owner:EGENPOWER

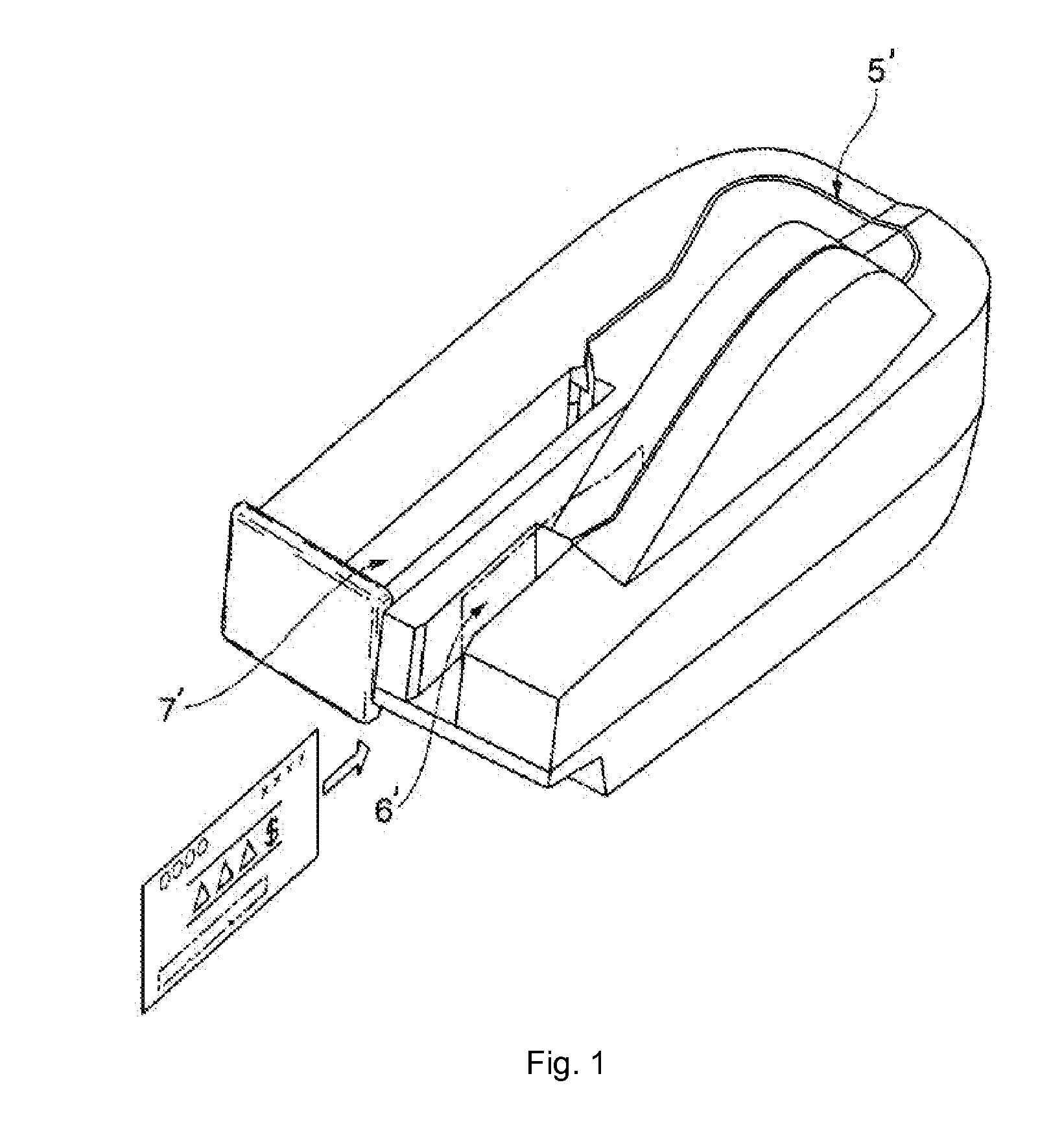

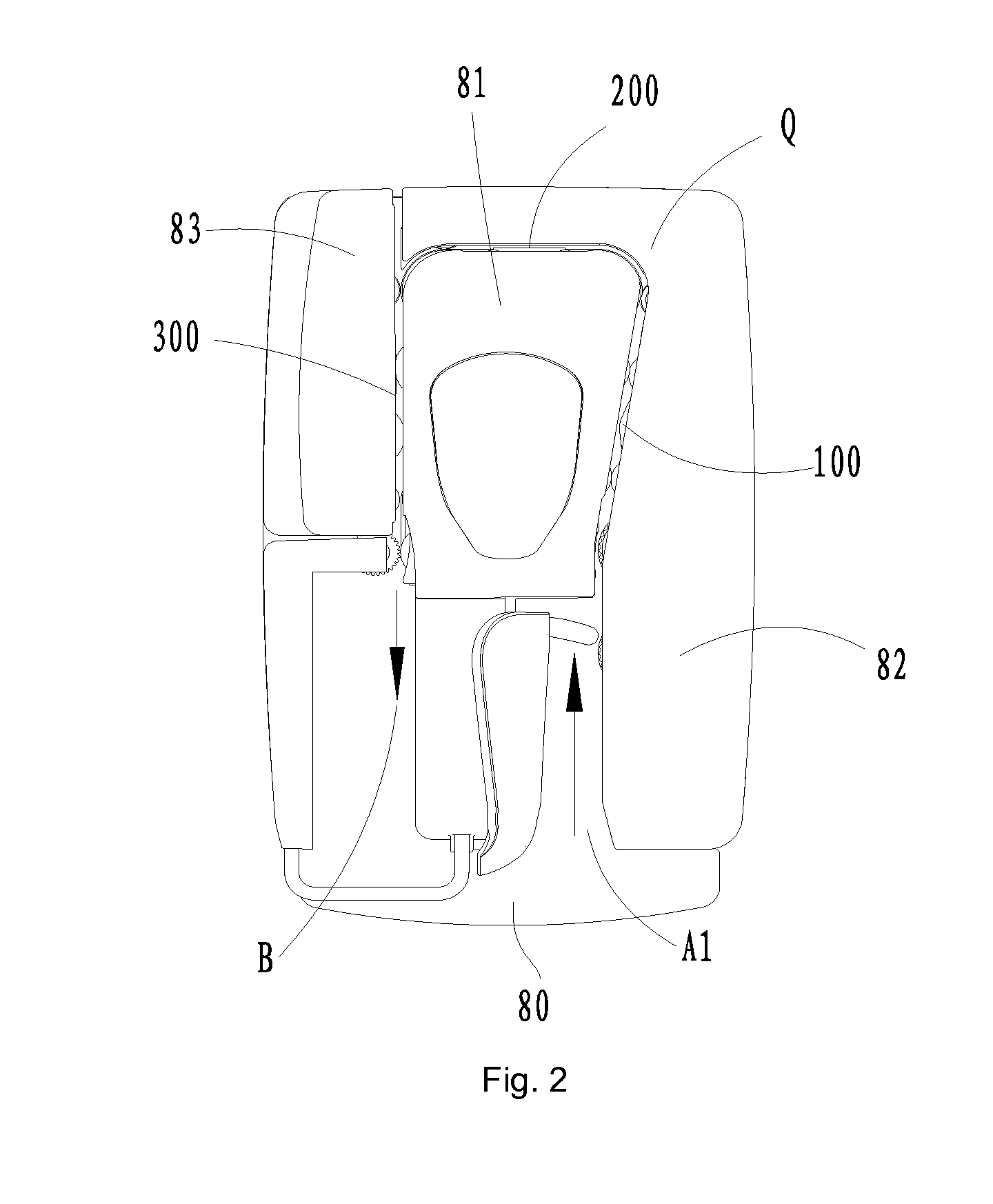

Cheque processing device

ActiveUS20150151936A1Easy maintenanceImprove maintainabilityPaper-money testing devicesCharacter and pattern recognitionFixed frameEngineering

Disclosed is a cheque processing device, including: a base, a frame located at the top face of the base and forming a U-shaped paper passage, and multiple sets of conveying roller assemblies (9) and multiple processing mechanisms provided along the U-shaped paper passage, wherein one end of the U-shaped paper passage is an inlet and the other end is an outlet. The frame comprises a fixed frame body, and a first movable frame body and a second movable frame body which form the U-shaped paper passage together with the fixed frame body, wherein the first movable frame body and the second movable frame body can both pivot on the base to open and close with respect to the fixed frame body.

Owner:DIGITAL CHECK CORP

Thermal printer with quick-release printhead assembly

ActiveUS20060279625A1Easy to installConvenient replacementRecording apparatusInking apparatusComputer printingEngineering

A quick-release printhead mounting assembly and thermal printer incorporating same, including a printing component, a printer housing, and, a component retention feature attached to or molded into the printer housing adapted for receiving and releasably fixing the printing component to the housing. The retention feature holds the printhead in a fixed position relative to the housing and, therefore, also relative to the platen of the printer. The printing component is advantageously a printhead, such as a thermal printhead, or the combination of a thermal printhead and a heat sink.

Owner:ZEBRA TECH CORP

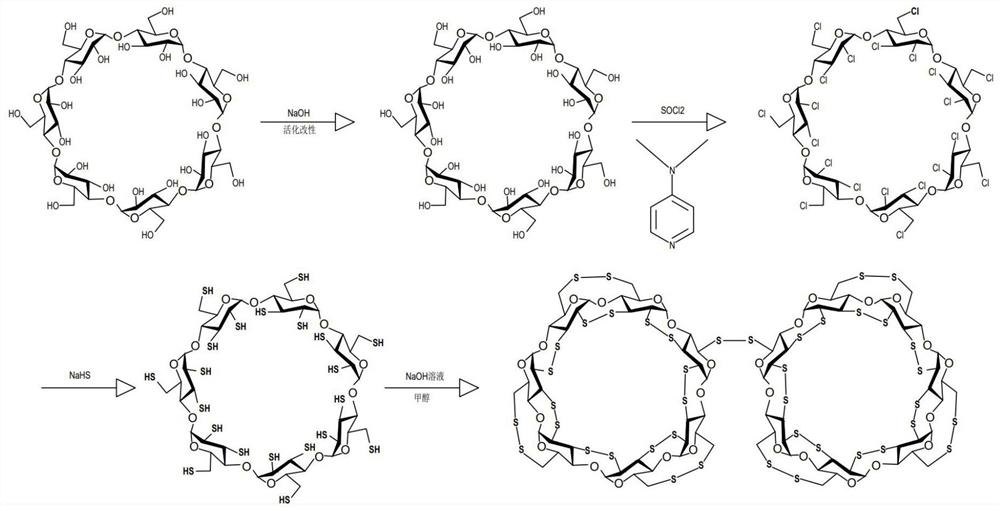

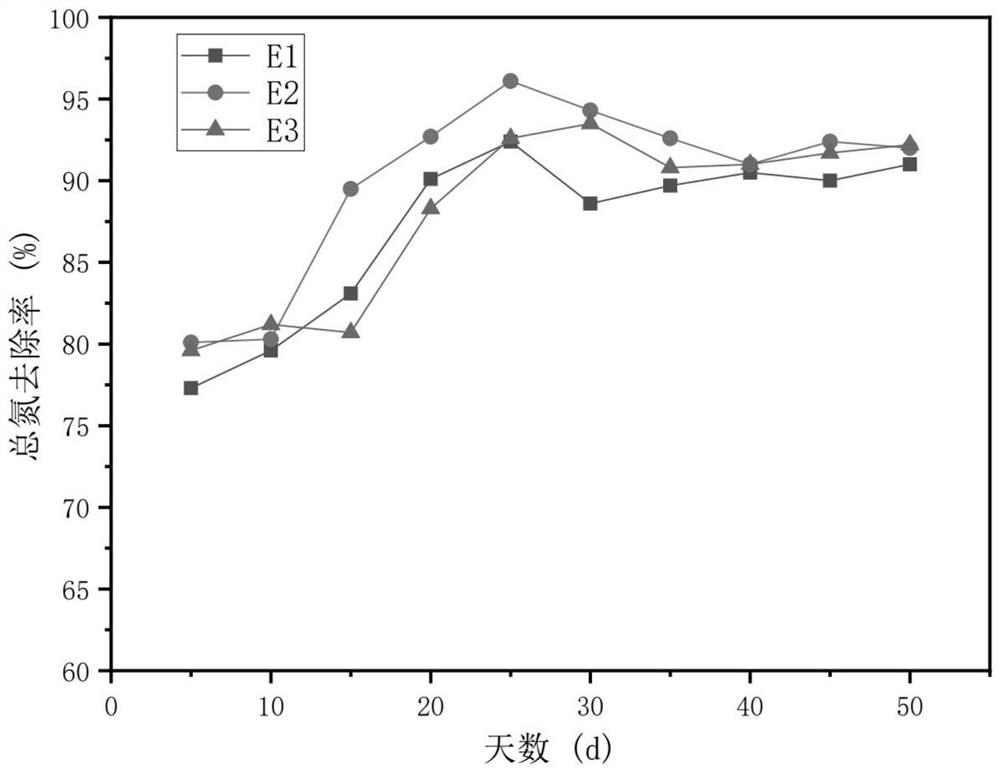

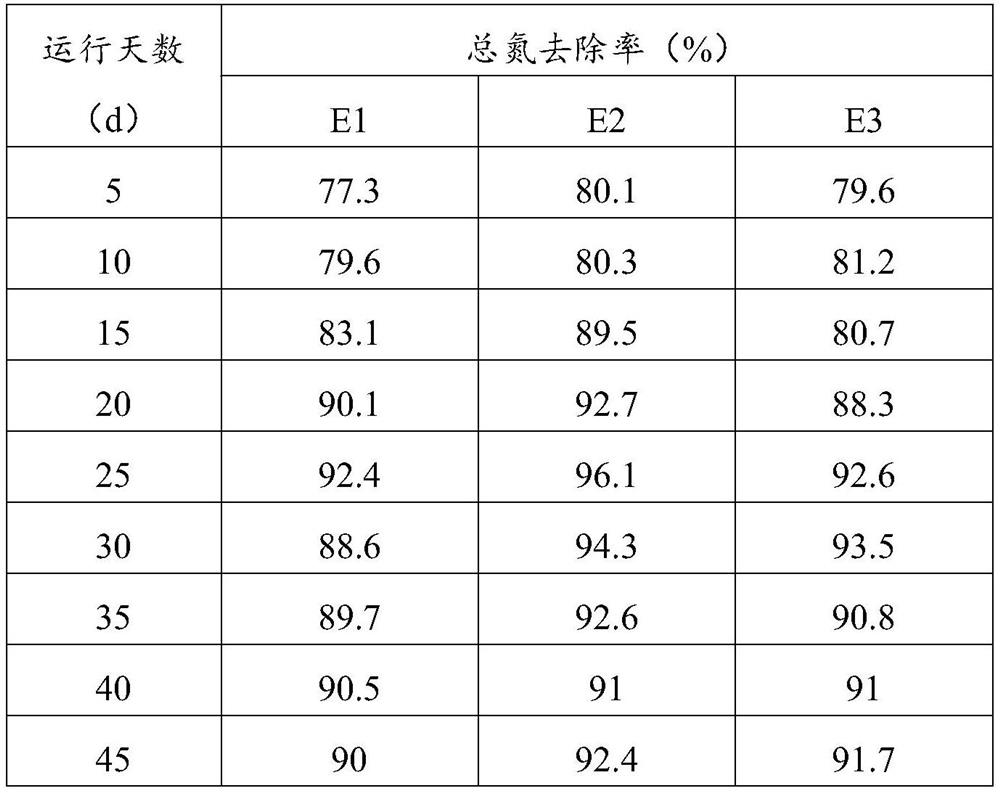

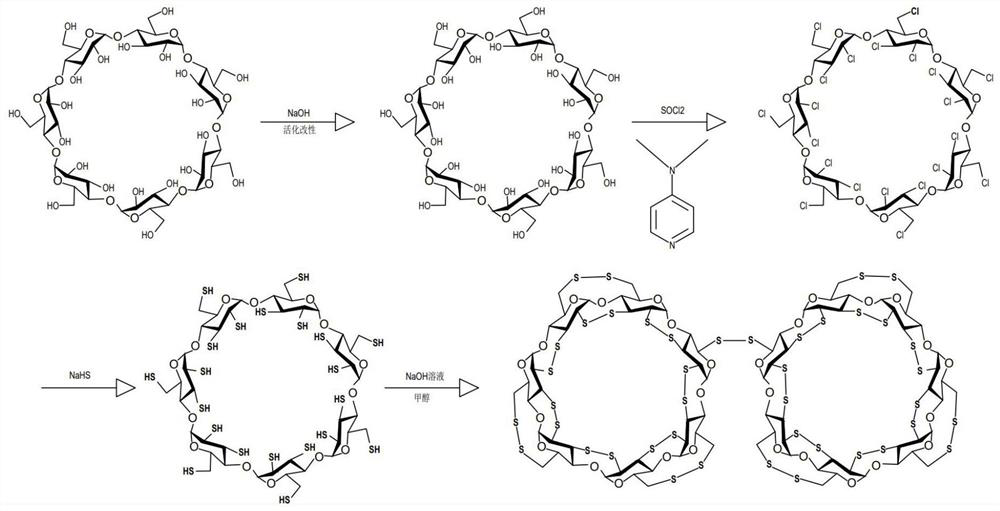

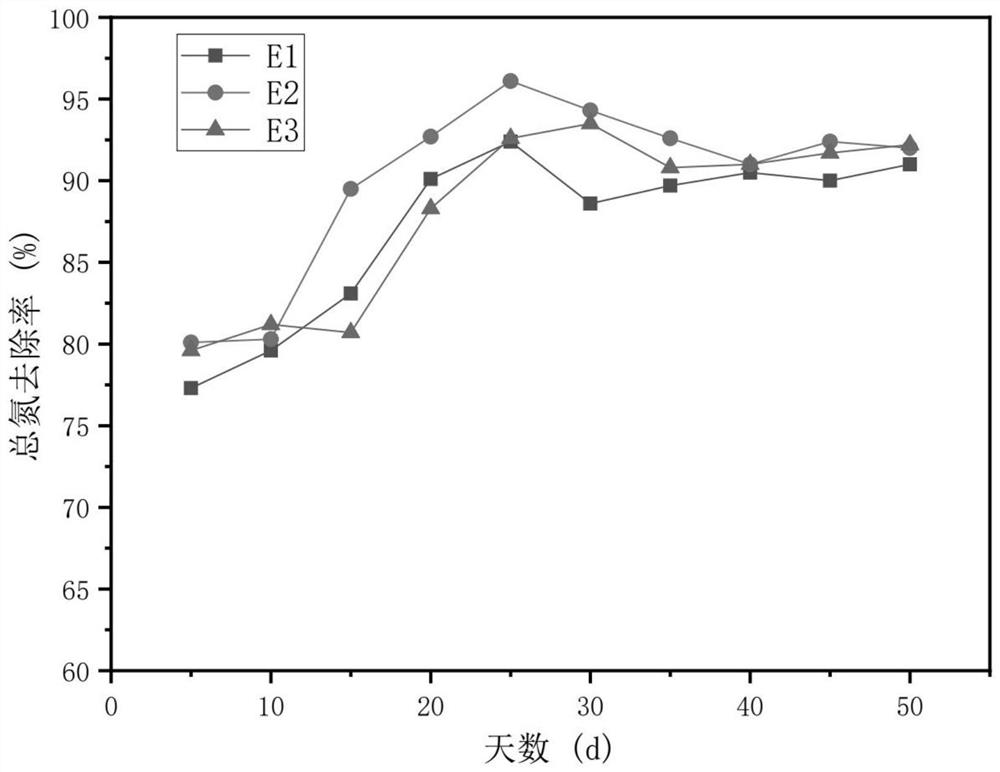

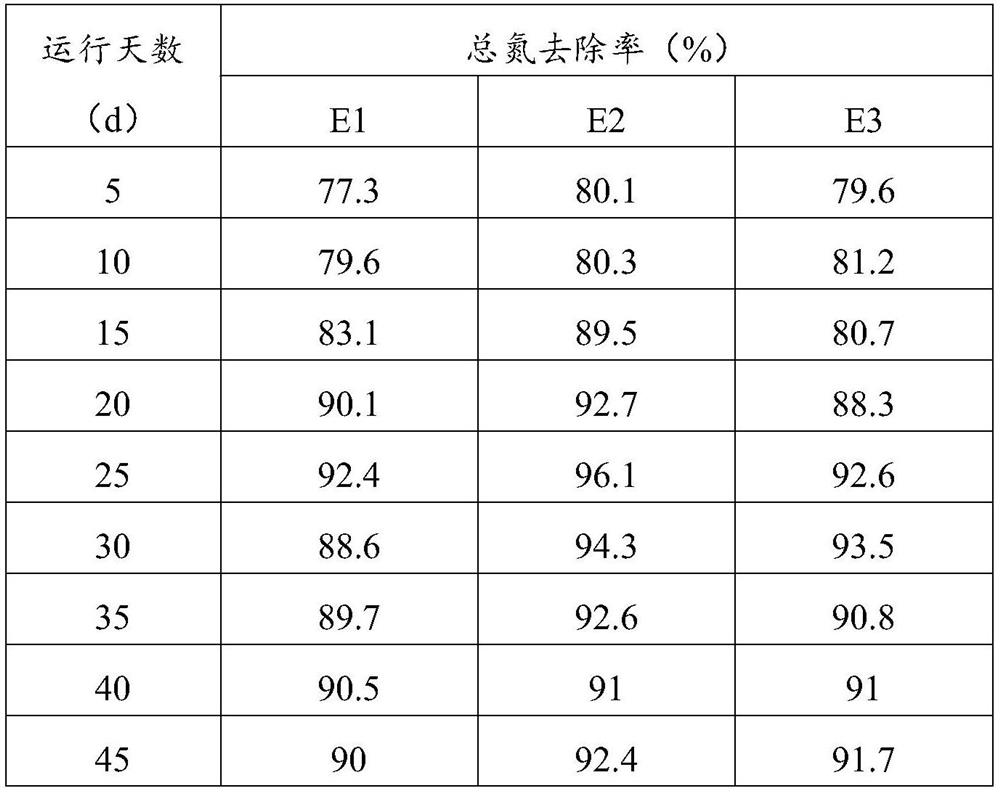

Biological filler for nitrogen removal by denitrification as well as preparation method and application thereof

ActiveCN113480002AConvenient replacementImprove denitrification effectWater contaminantsTreatment with anaerobic digestion processesNitrogen removalHalogen

The invention provides a biological filler for nitrogen removal by denitrification as well as a preparation method and application thereof, belonging to the technical field of sewage treatment. According to the invention, beta-cyclodextrin with a certain space net structure is adopted as a main body; firstly, hydroxyl functional groups on the periphery of the filler can be activated by soaking the beta-cyclodextrin in a sodium hydroxide ethanol solution, and replacement with halogen atoms is facilitated; the sodium hydrosulfide ethanol solution can further replace a halogen element with a sulfydryl functional group, so a sulfur element is loaded in the filler; the sulfydryl functional group can be further converted into a disulfide bond which is more stable and has a modified space net-shaped structure through dehydration condensation; and hot melting granulation molding is conducted to obtain the biological filler for nitrogen removal by denitrification. The prepared biological filler for nitrogen removal by denitrification can achieve sulfur autrophism-heterotrophism coupled denitrification effect for nitrogen removal, treatment efficiency is guaranteed and the problems that biofilm culturing time is long, treatment efficiency has bottleneck, secondary pollution is caused to effluenti and the like in existing autotrophic and heterotrophic denitrification treatment are solved.

Owner:NANJING UNIV

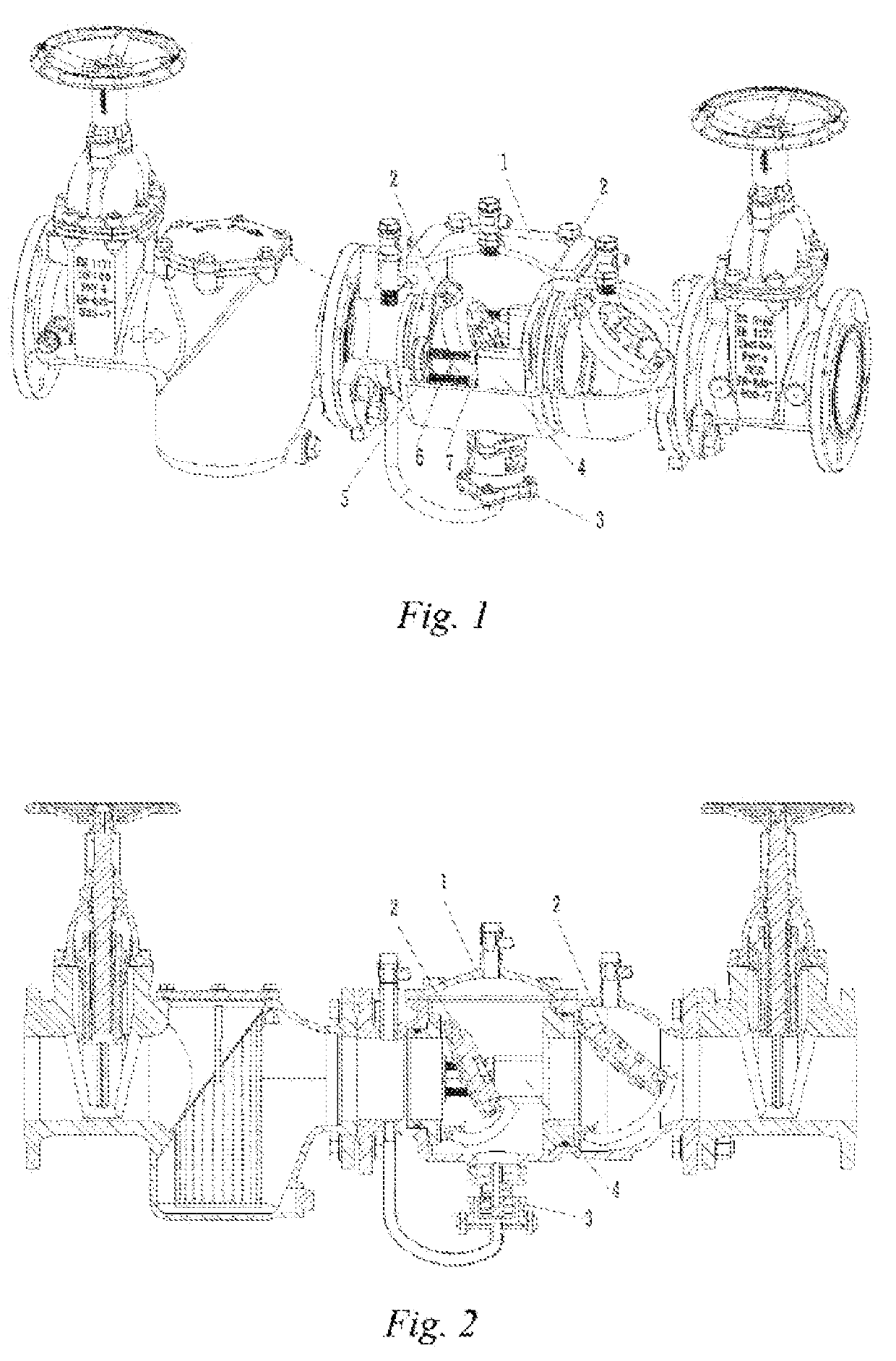

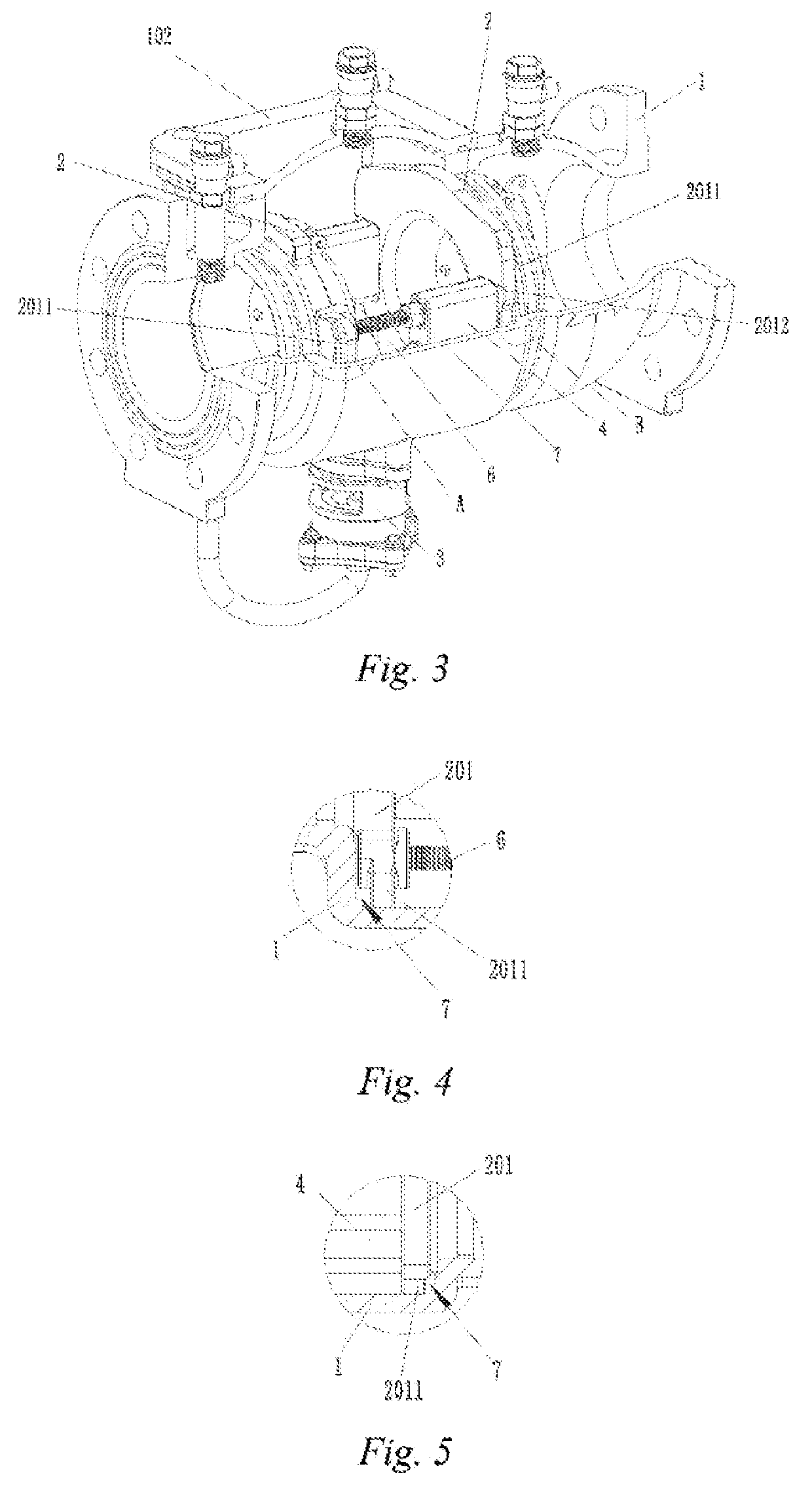

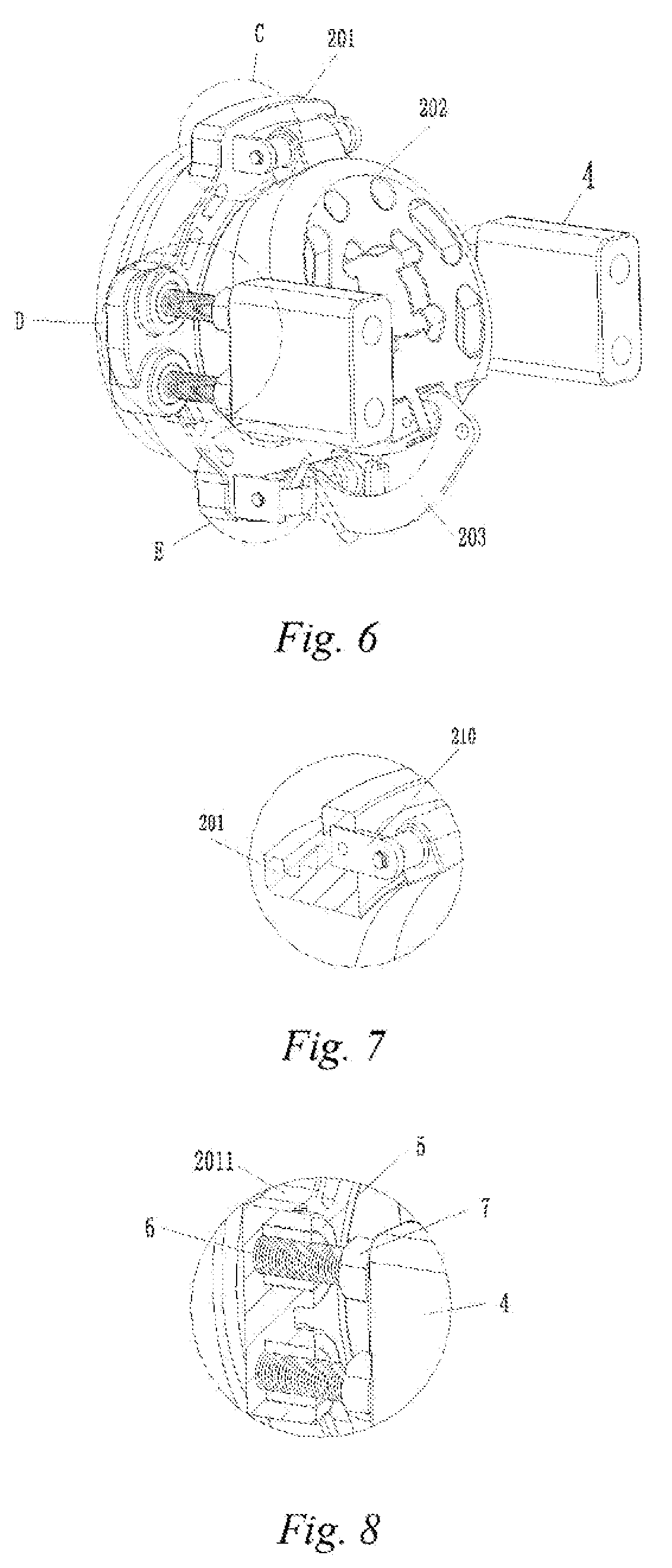

Reduced-Pressure Type Backflow Preventer

InactiveUS20190249778A1Easy to cleanEasy to replaceCheck valvesMultiple way valvesSpring forceEngineering

Disclosed is a reduced-pressure type backflow preventer comprising a valve body (1), two check valves (2) of the same structure and a drain valve:(3) wherein a cavity is formed body, and a valve wall of the valve body is provided With a water inlet, a water outlet, and a drain opening; the two check valves are both fixedly mounted inside the valve body supporting member (4), and are positioned at the water inlet and the water outlet, respectively; the drain valve is mounted outside the valve body, and is positioned at the drain opening; the check valve comprises a valve seat (201), a valve clack (202), a rocking bar (203), and a twin torsional spring (204); one side of the valve clack is hinged to an upper end of the valve seat, and the other side is provided with a roller (205); the rocking bar is connected to a lower end of the valve seat via a pin (206); the roller abuts against the rocking bar and slides on the rocking bar; the twin torsional spring is sheathed over the pin; and a spring force of the twin torsional spring acts on the rocking bar to maintain the valve clack in a normally closed state, and an external force is used to cause the roller on the valve clack to roll on the rocking bar so as to open the valve clack. The preventer provides a better flow preventing effect by virtue of the structure of the twin torsional spring and the rocking bar of the check valve.

Owner:GUANGDONG YONGQUAN VALVE TECH

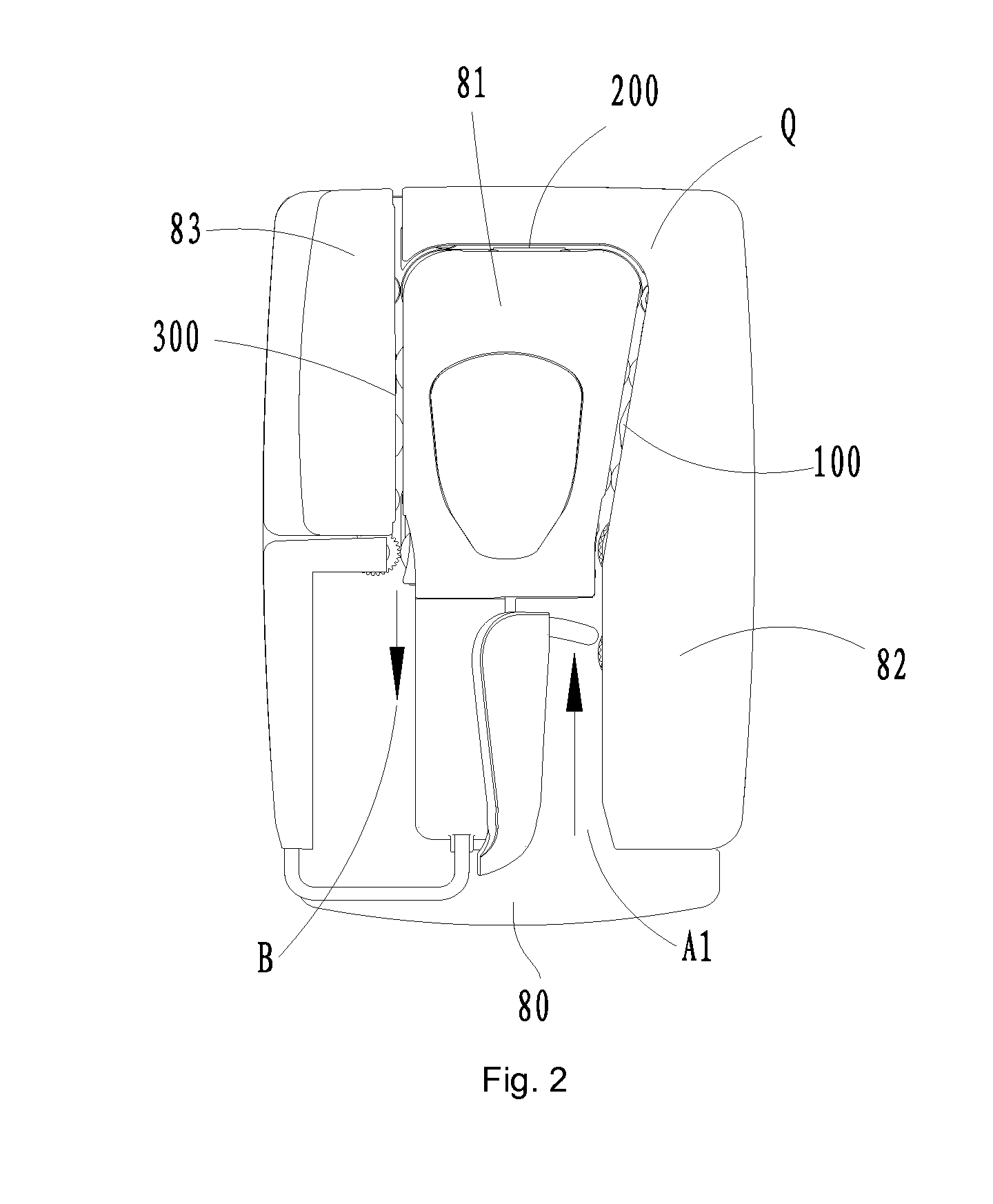

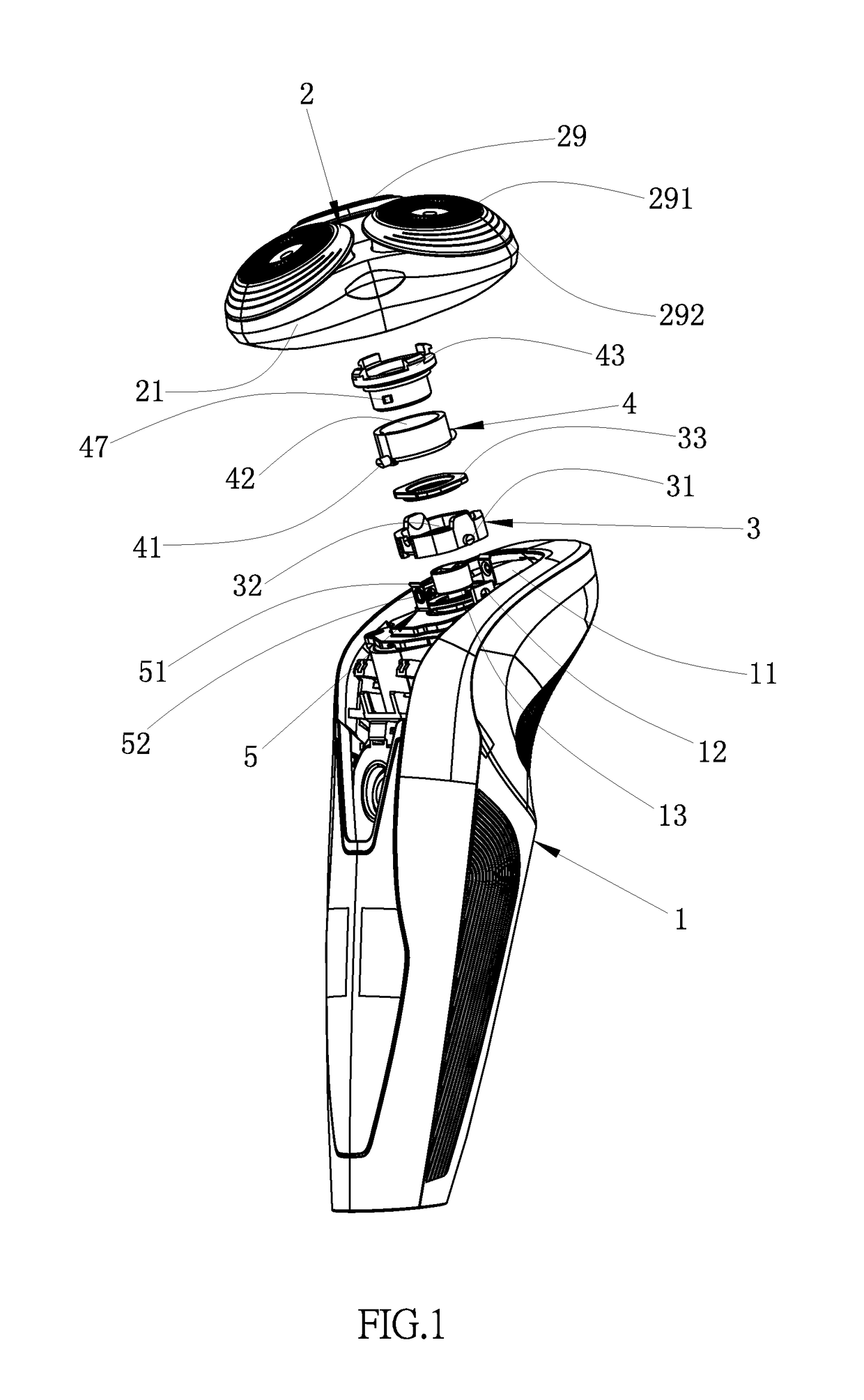

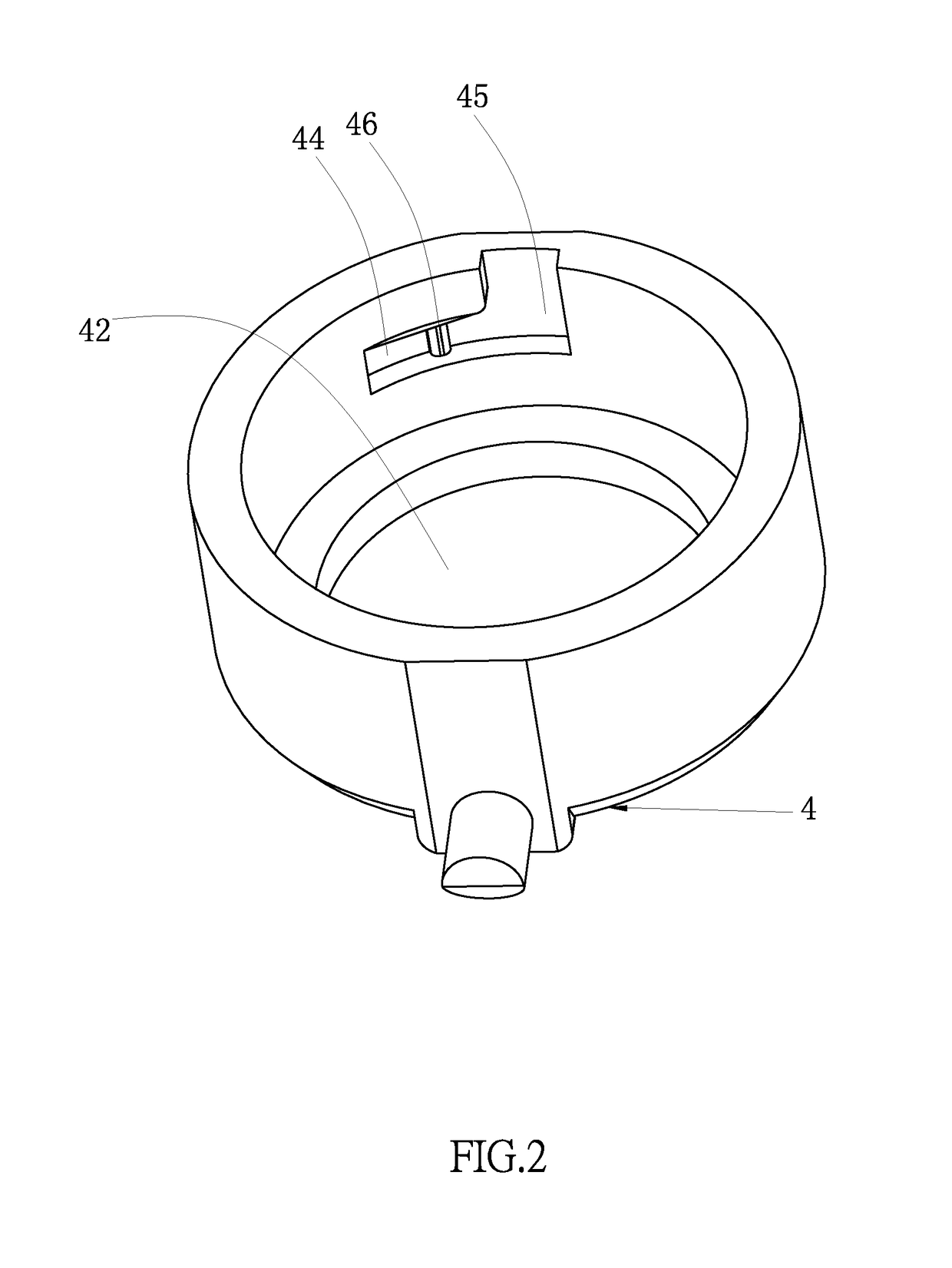

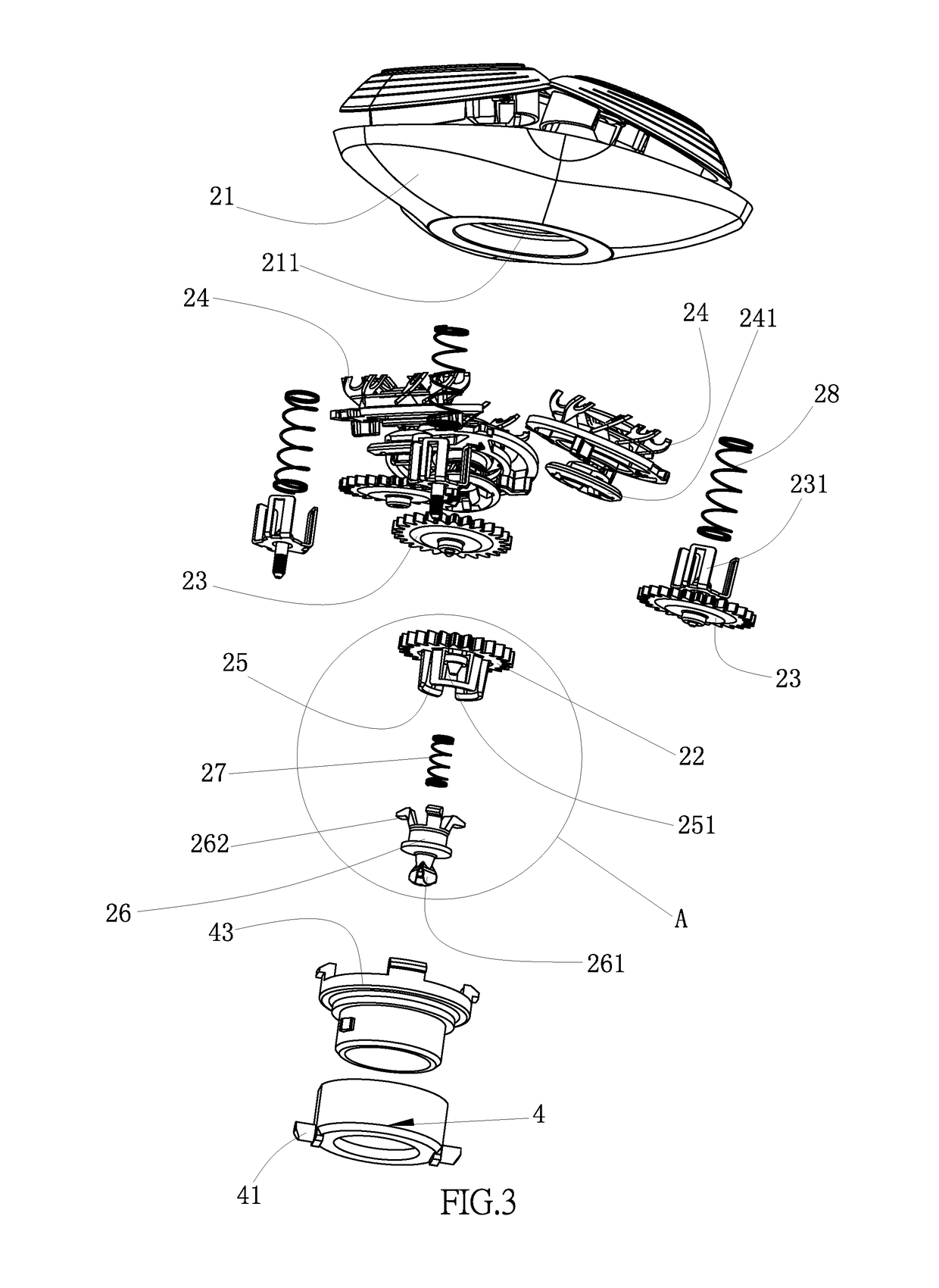

Detachable floating shaver

ActiveUS20190061182A1Convenient replacementImprove cleanlinessMetal working apparatusEngineeringRazor Blade

Owner:GUANGDONG ROMAN TECH CO LTD

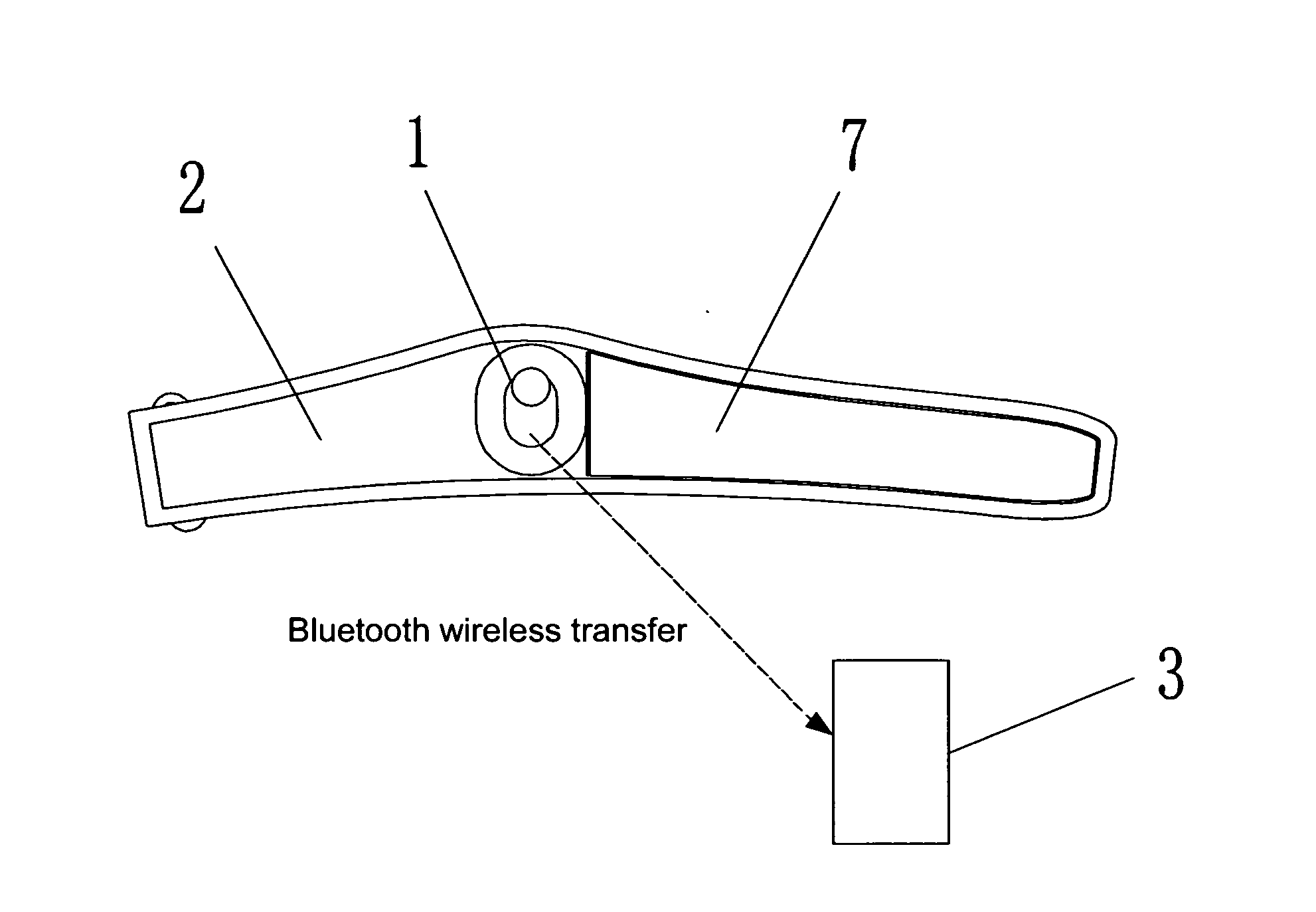

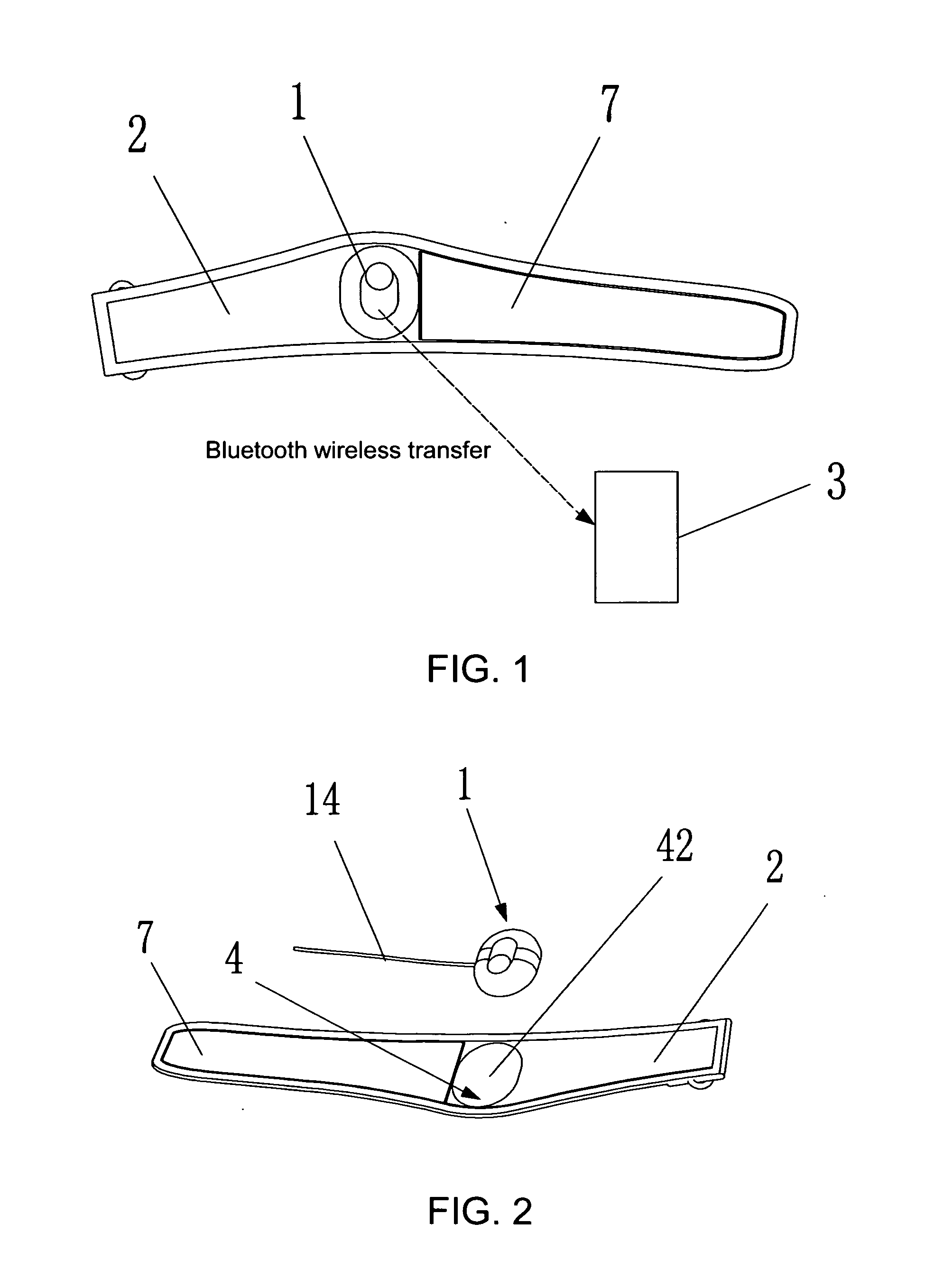

Infant body temperature and sleep monitoring system

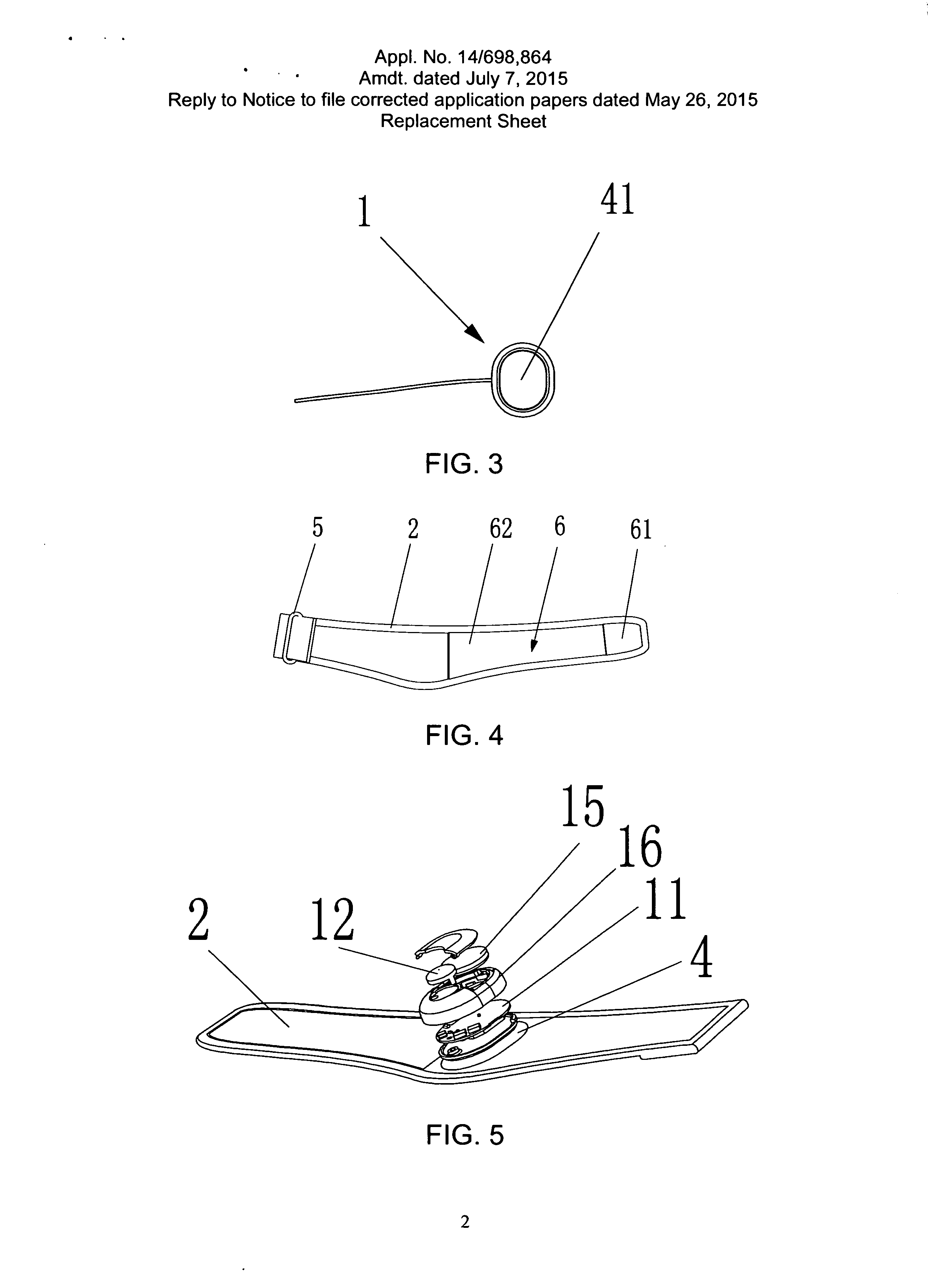

InactiveUS20160228004A1Improve permeabilitySimple structureInertial sensorsTelemetric patient monitoringEngineeringSleep monitoring

The present invention relates to an infant body temperature and sleep monitoring system including a Bluetooth body temperature thermometer main body, an arm belt and a Bluetooth receiving member; the Bluetooth body temperature thermometer main body is connected to a first side of the arm belt via a first adhesive strap; a second side of the arm belt is disposed with a fastening ring at a first end and a second adhesive strap at a second end; the second end of the arm belt which is disposed with the second adhesive strap passes through the fastening ring and engages with the second adhesive strap so that the arm belt forms a tightness-adjustable annular belt; the Bluetooth body temperature thermometer main body obtains body temperature data and transmits the body temperature data to the Bluetooth receiving member. The present invention is simple in structure, convenient and practical and easy to wear.

Owner:YU SHU +2

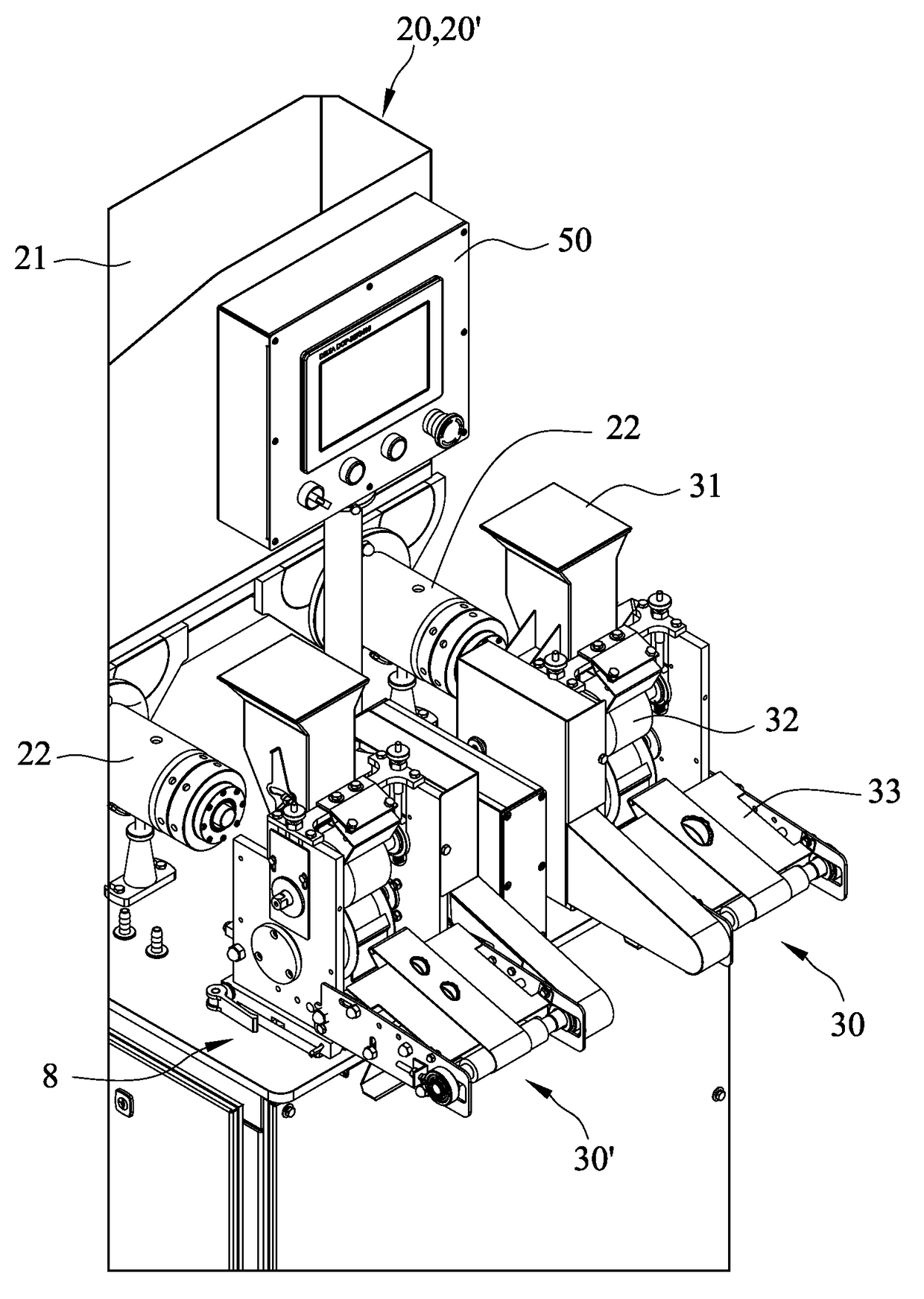

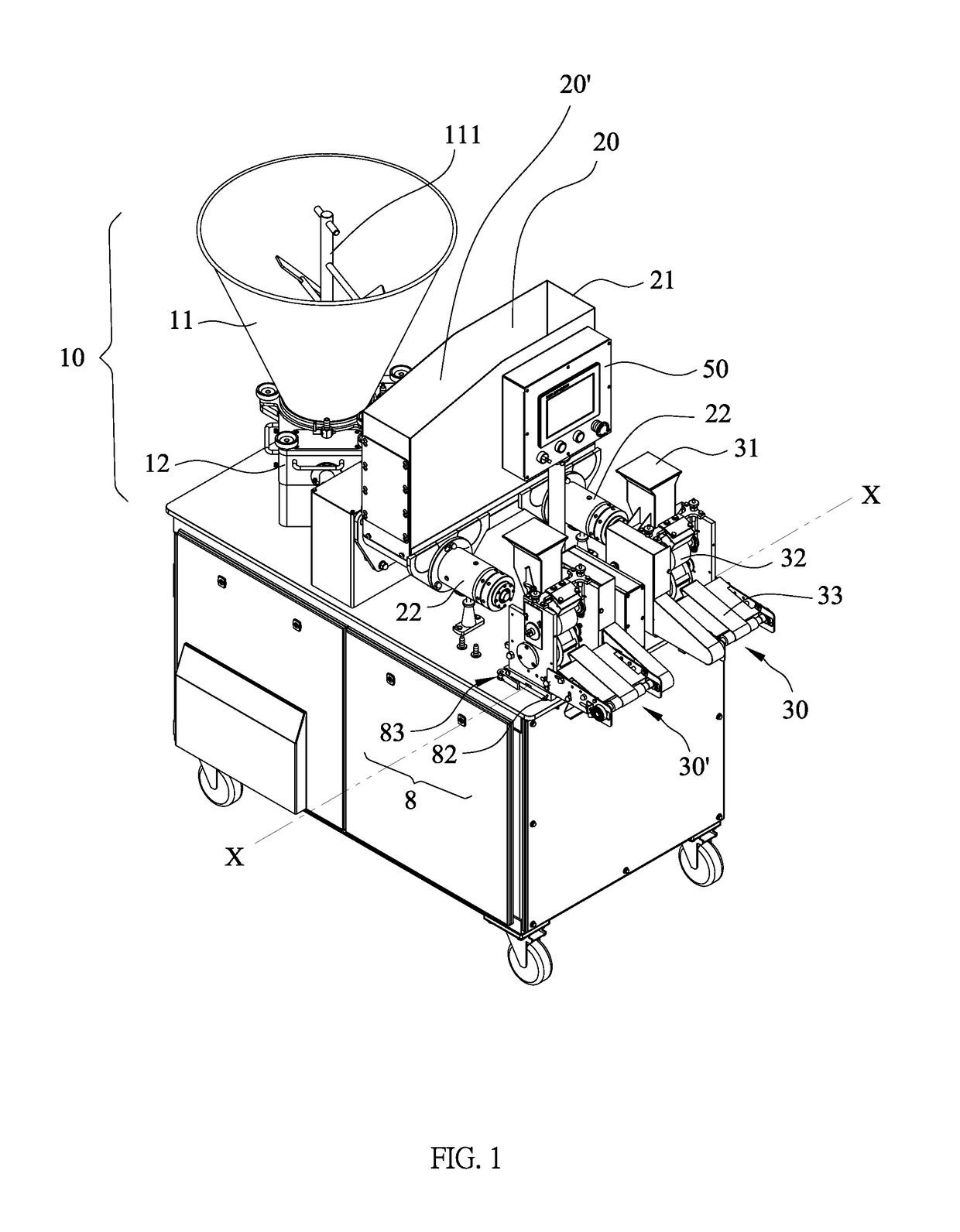

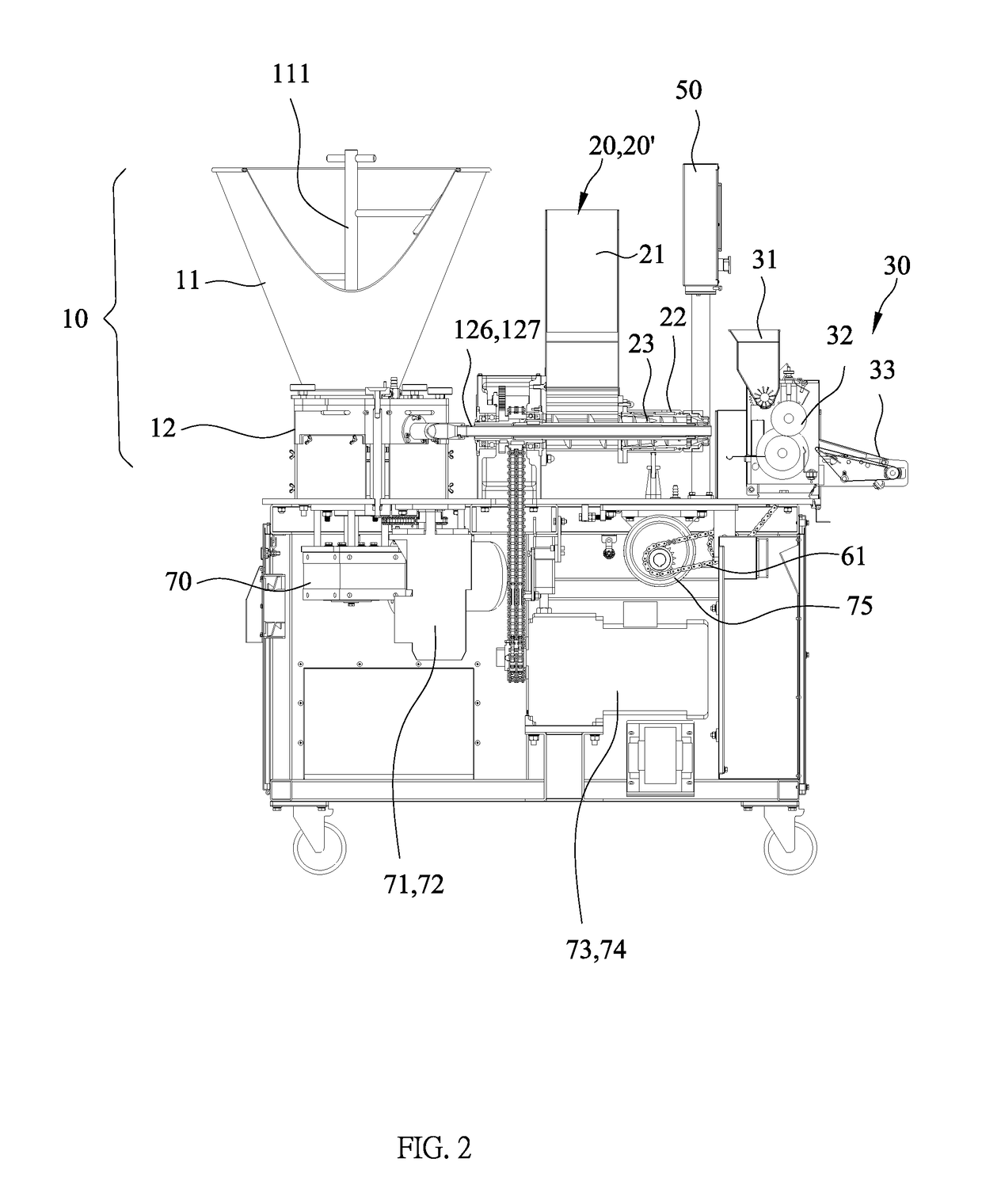

Dumpling wrapping device

ActiveUS9888693B2Improve cleanlinessConvenient replacementDough dividingDough processingProduction lineEngineering

Owner:ANKO FOOD MACHINE

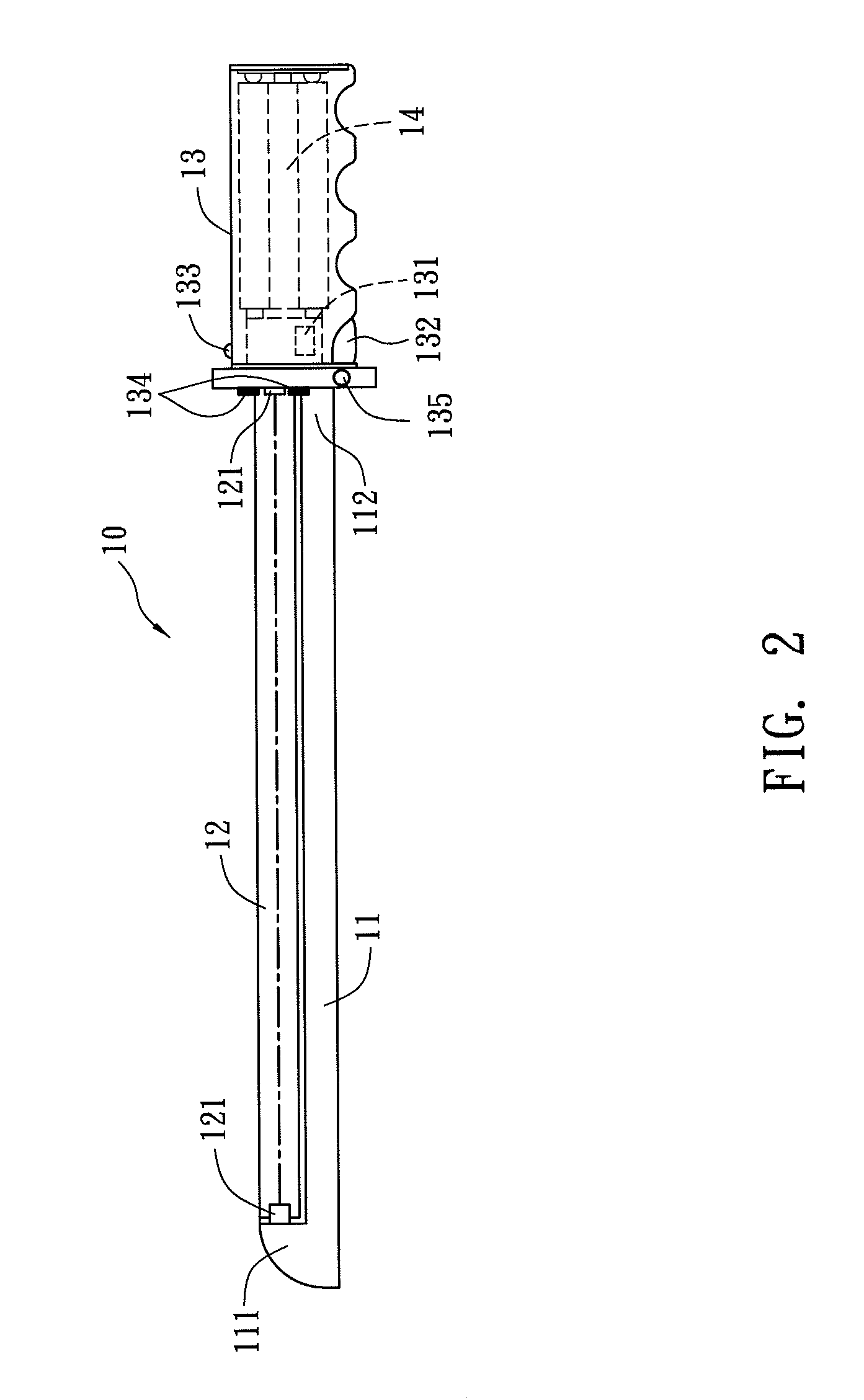

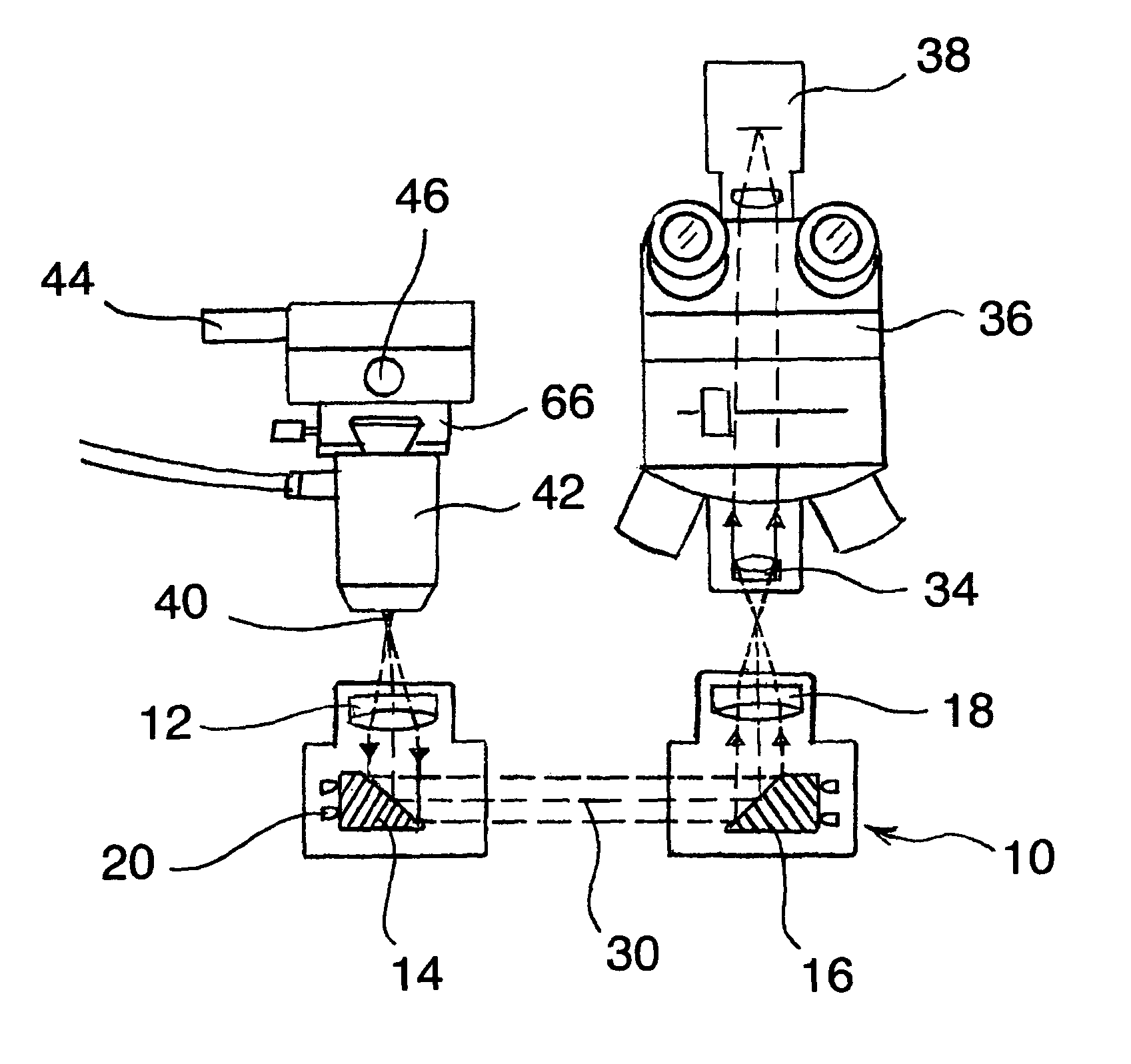

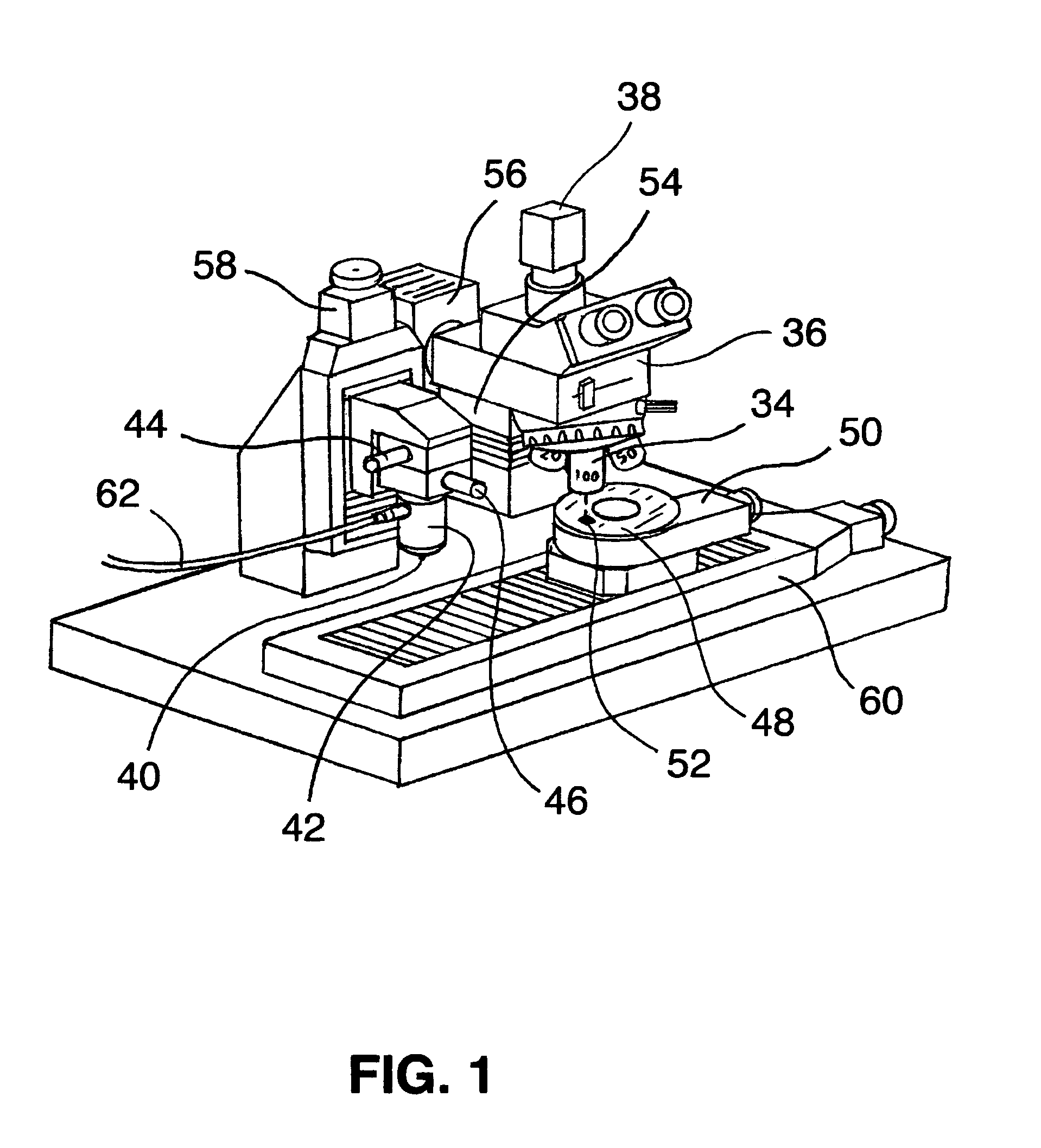

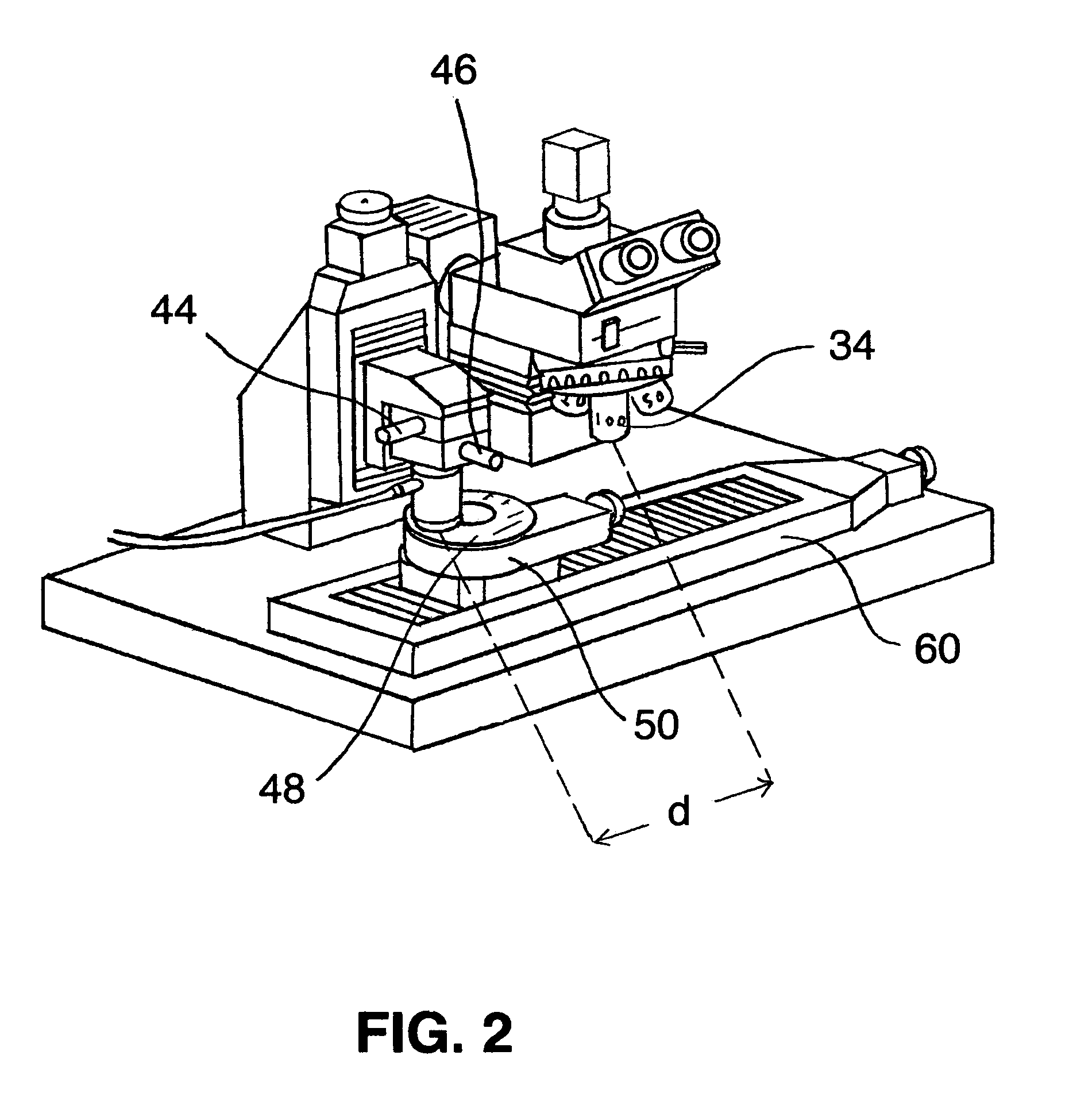

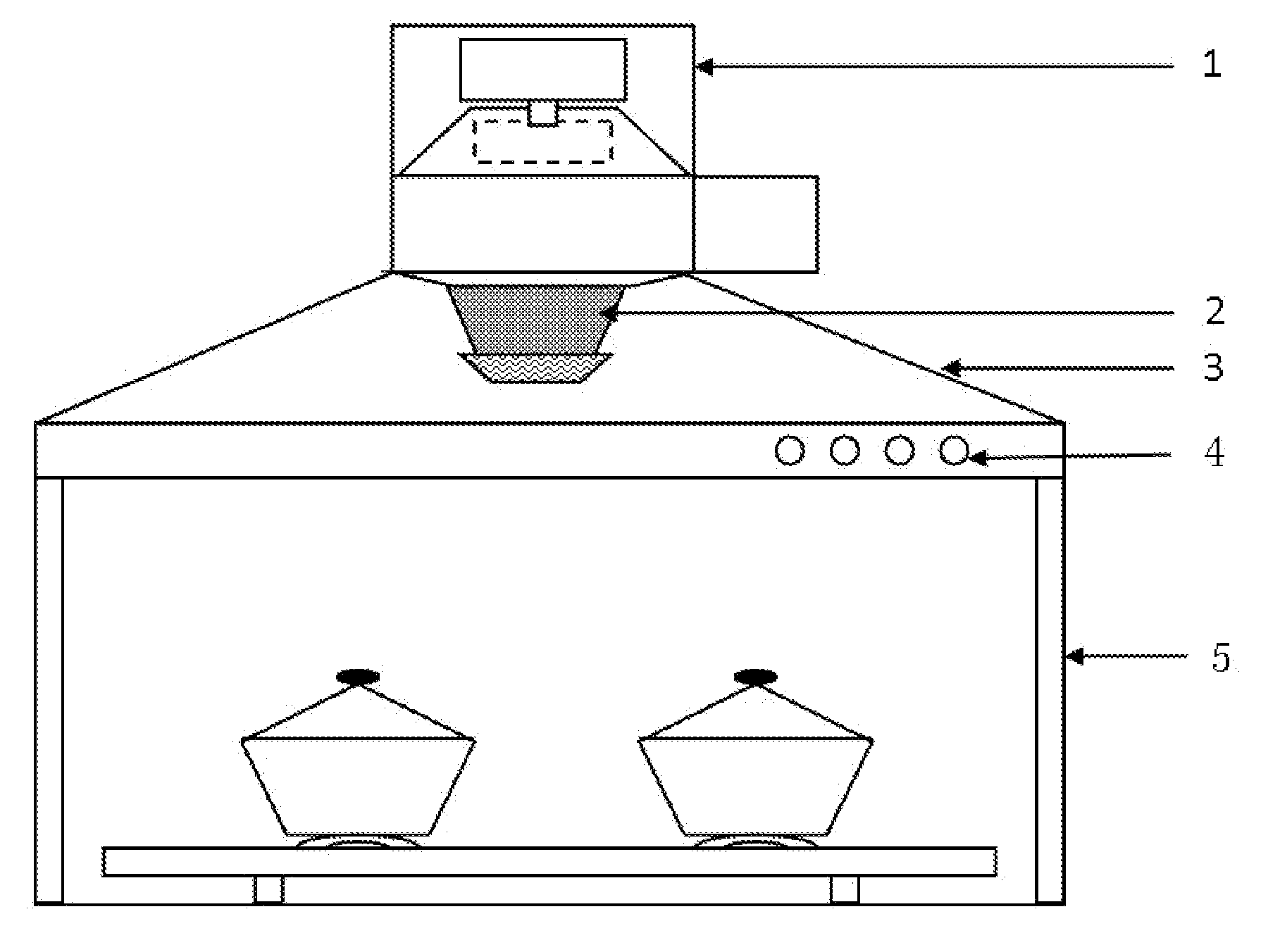

Probe alignment tool for the scanning probe microscope

InactiveUS8832859B2Convenient positioningConvenient replacementNanotechnologyScanning probe techniquesAtomic force microscopyScanning probe microscopy

A probe alignment tool (10) for scanning probe microscopes utilizes an attached relay optics to view the scanning probe microscope probe tip (40) and align its image in the center of the field of view of an optical microscope (36). Adjustments to optical microscope motorized stages (50) and (60) along with adjustments of scanning probe microscope stages (44), (46) and (58) allow determination of a path and distance from the center of the field of view to the probe tip (40). From such determination a target area to be examined by the scanning probe microscope may be positioned precisely and accurately under the probe tip (40). Replacement of a scanning probe microscope probe tip (40) in an atomic force microscope unit (42) may be accomplished without the loss of alignment measurements.

Owner:AFSHARI ALI R

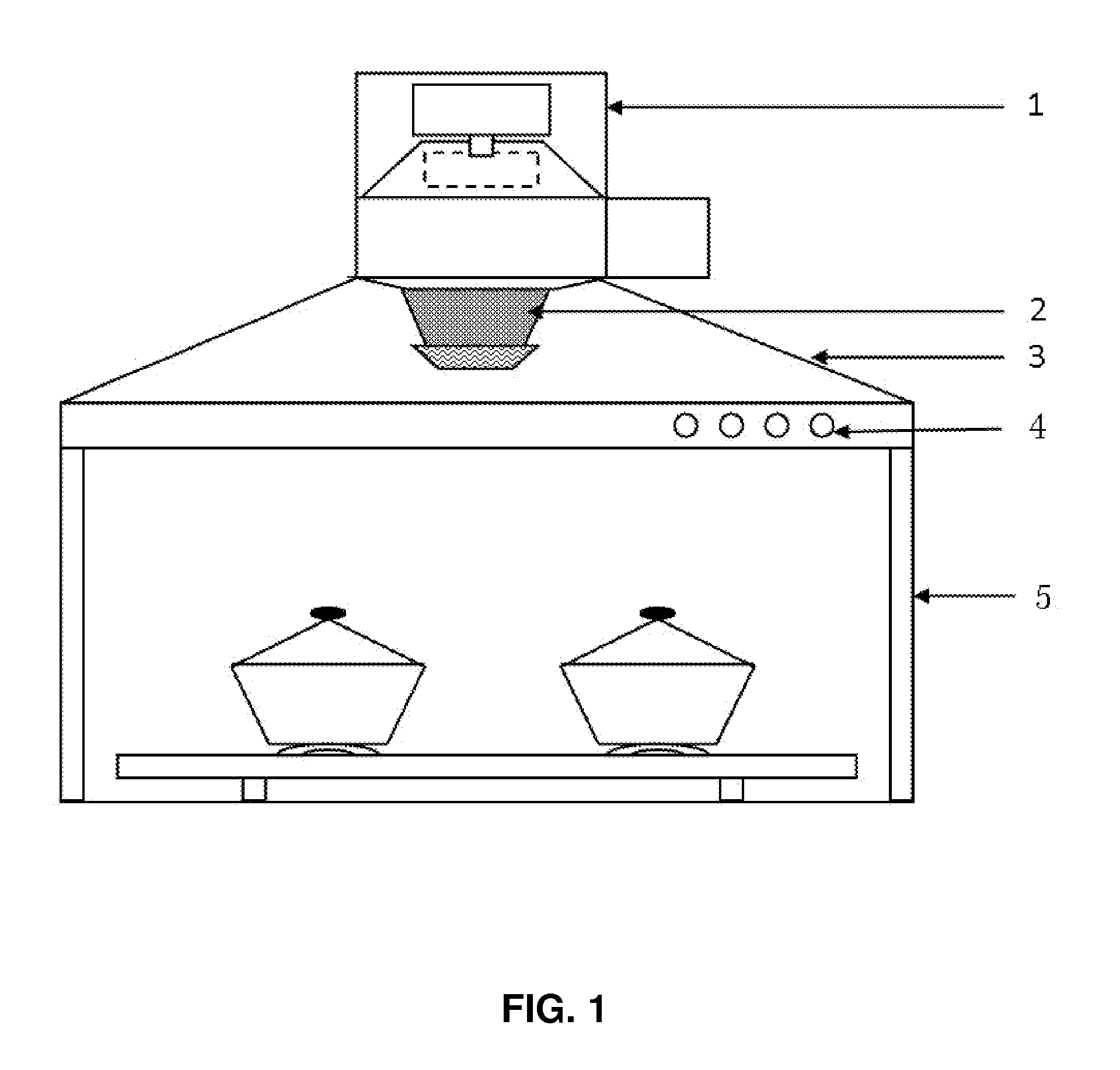

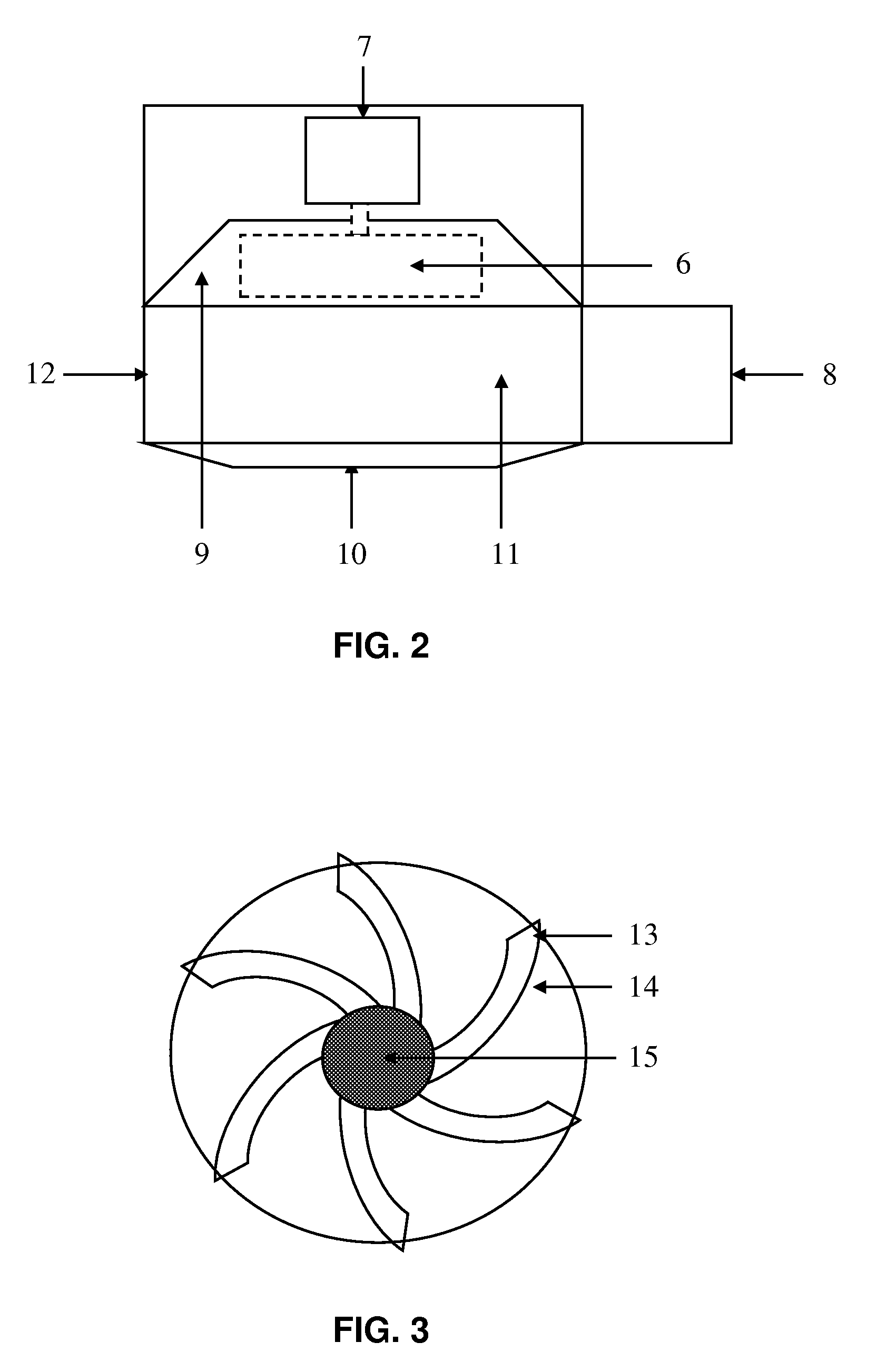

Range hood

InactiveUS20100326419A1Improve efficiencyReduce flow lossDomestic stoves or rangesLighting and heating apparatusImpellerEngineering

A range hood, containing at least a fan having a housing and an impeller, an oil filter, a cover, a fume exhaust cover, a light, and a switch. The housing of the fan is a circular double-chamber or multi-chamber structure with an air inlet and an air outlet, and the impeller of the fan contains at least one group of arc-shaped blades each having a closed side and being enlarged in an axial direction.

Owner:SHANDONG UNIV

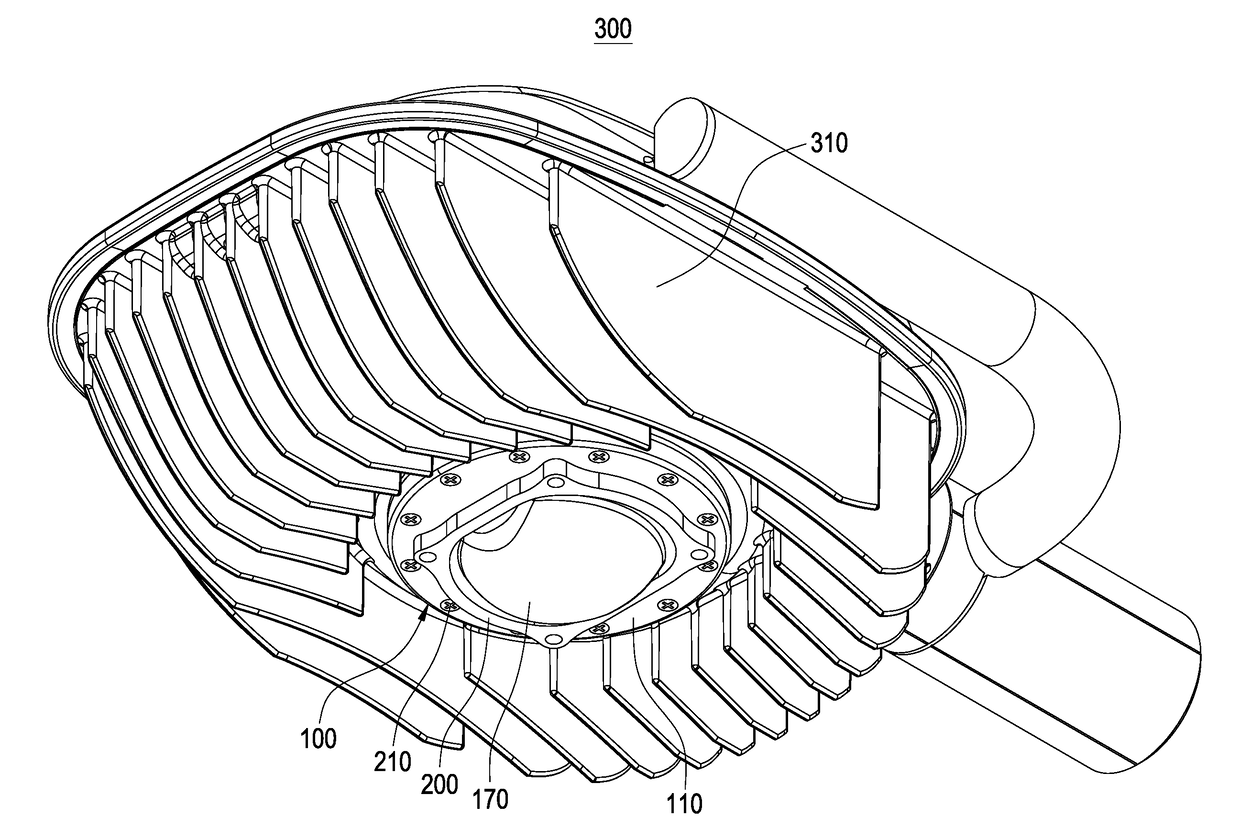

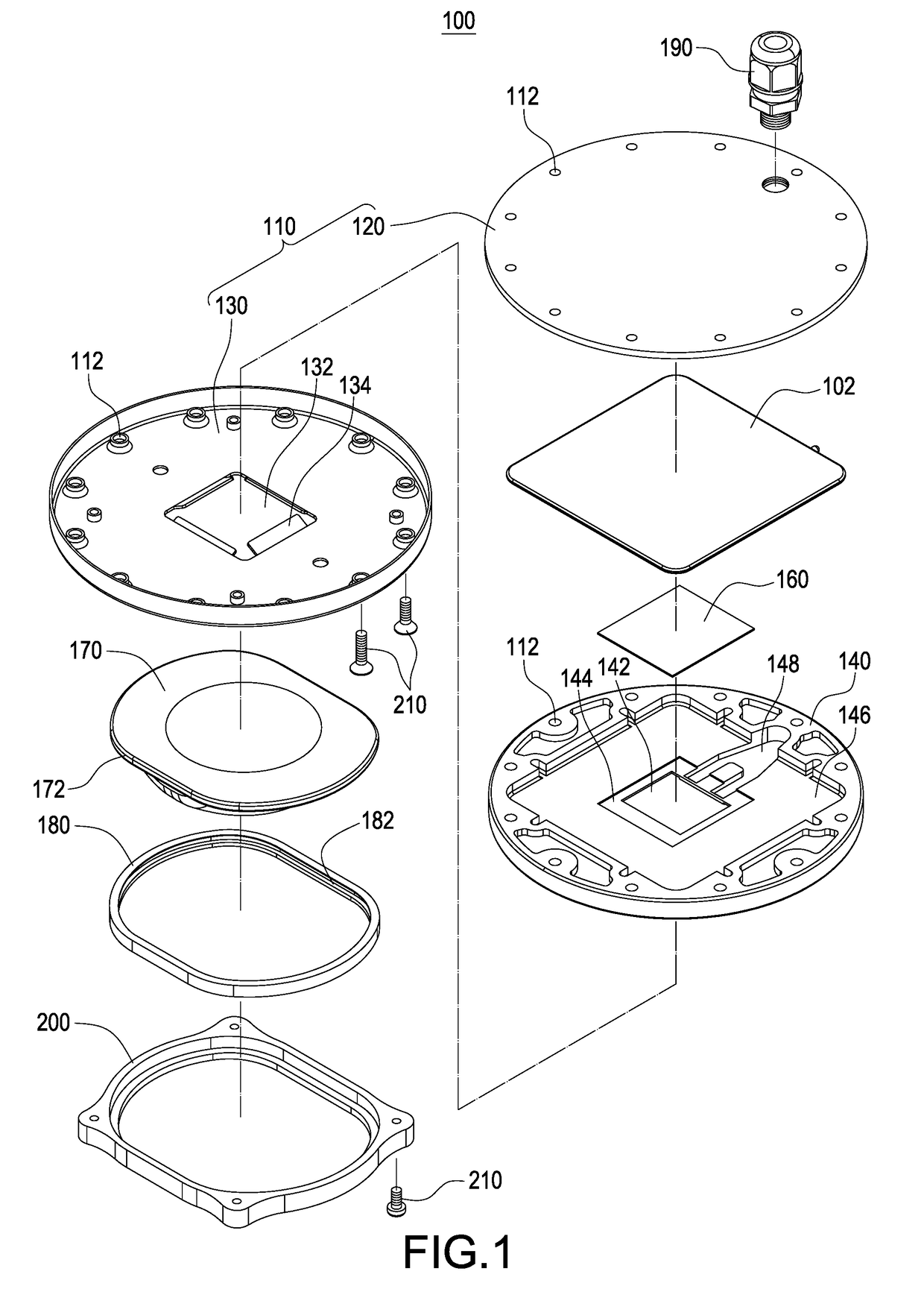

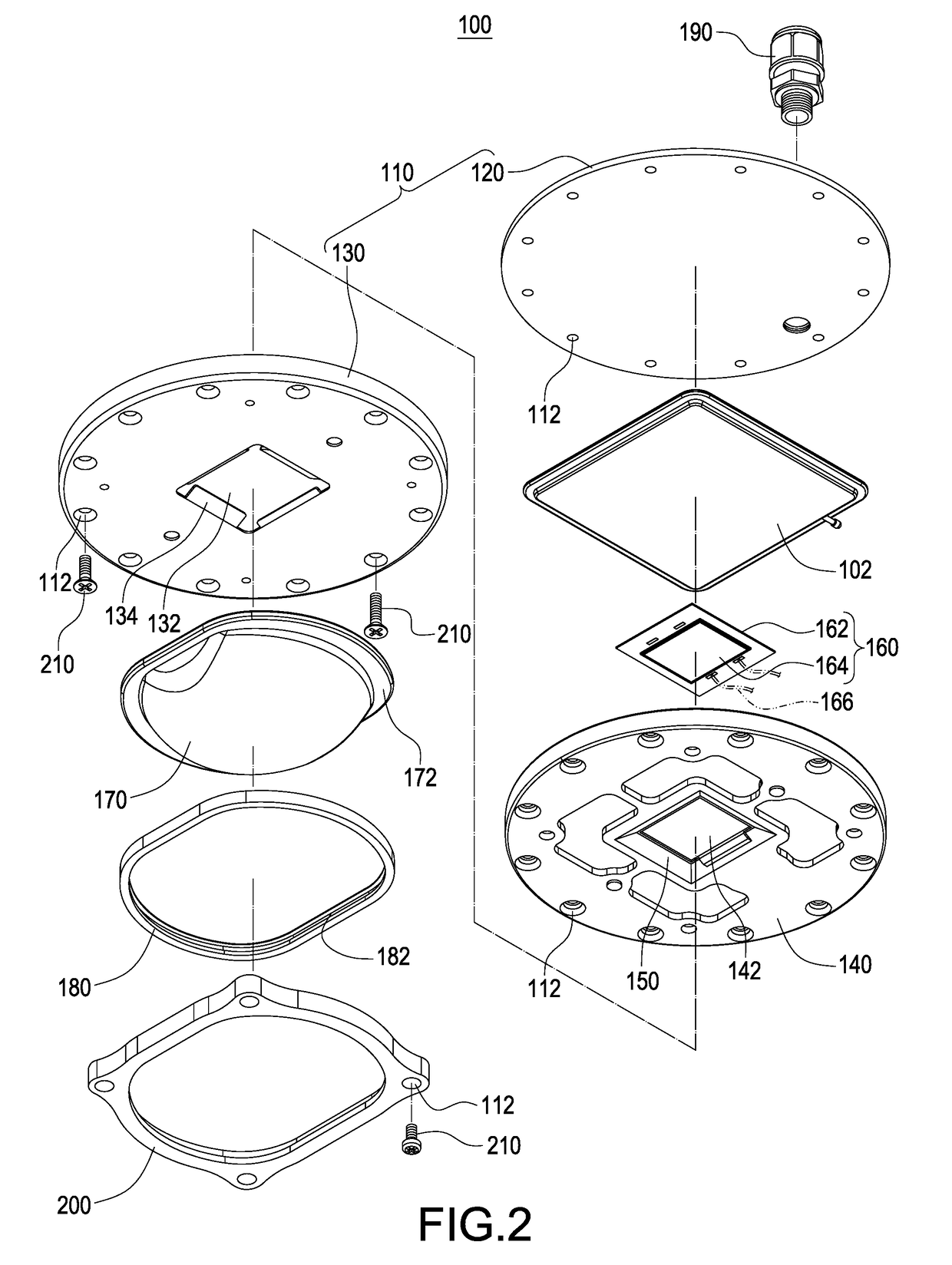

LED light source apparatus

InactiveUS20170328554A1Convenient replacementMeet convenient maintenanceMechanical apparatusPoint-like light sourceLight guideEffect light

An LED light source apparatus includes a lamp housing, a lighting module, and a lens. The lamp housing has a first shell body, a second shell body, and a waterproof pad disposed between the first and second shell bodies. The first shell body and the second shell body are covered to each other. The second shell body has an opening. The waterproof pad is provided with a throughhole corresponding to the opening. A light guide flap is disposed on the perimeter of the opening of the second shell body. The lighting module is disposed inside the lamp housing corresponding to the opening. The lens is installed on a side of the lamp housing corresponding to the lighting module. Therefore, the components or the lighting module with a different power can be conveniently replaced by modules and thus the present invention has the flexibility in replacement and maintenance.

Owner:HABEMIT INT

Cheque processing device

ActiveUS9533848B2Easy maintenanceImprove maintainabilityPaper-money testing devicesCharacter and pattern recognitionFixed framePulp and paper industry

Owner:DIGITAL CHECK CORP

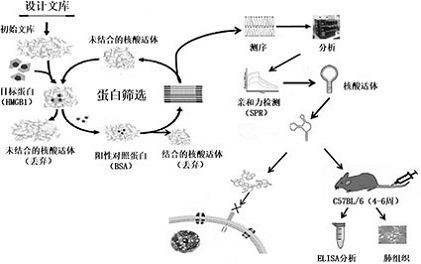

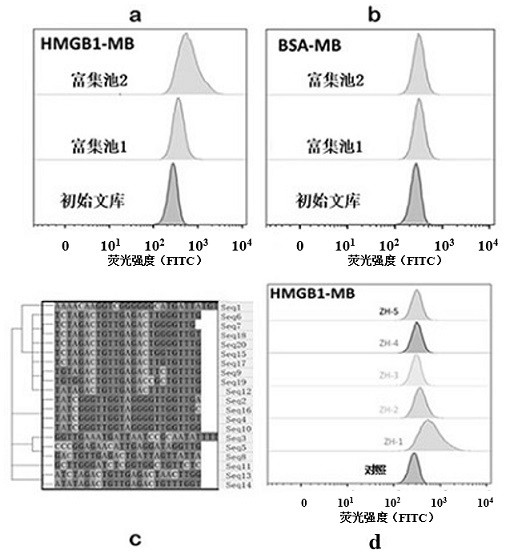

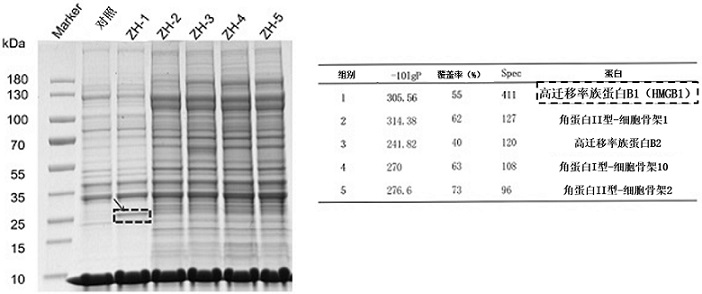

Nucleic acid aptamers targeting and antagonizing HMGB1 molecules

ActiveCN114807150AHigh affinityLow immunogenicityOrganic active ingredientsAntipyreticAptamerDisease

The invention discloses a nucleic acid aptamer for targeting and antagonizing HMGB1 molecules, and belongs to the technical field of biology. The aptamer can be efficiently combined with HMGB1, has the advantages of good affinity, low immunogenicity, small molecular weight, low synthesis cost, easiness in storage, convenience in modification and substitution and the like, and has important application value in the fields of nucleic acid antagonists of HMGB1, detection and the like. Besides, the aptamer can be used for preparing medicines for treating inflammations such as acute pneumonia and the like, and experiments find that the aptamer can effectively reduce significant down-regulation of IL-6 and TNF-alpha in blood of mice with acute inflammations, which indicates that the aptamer ZH-1a can inhibit release of inflammation-related factors in inflammatory diseases.

Owner:中国科学院基础医学与肿瘤研究所(筹)

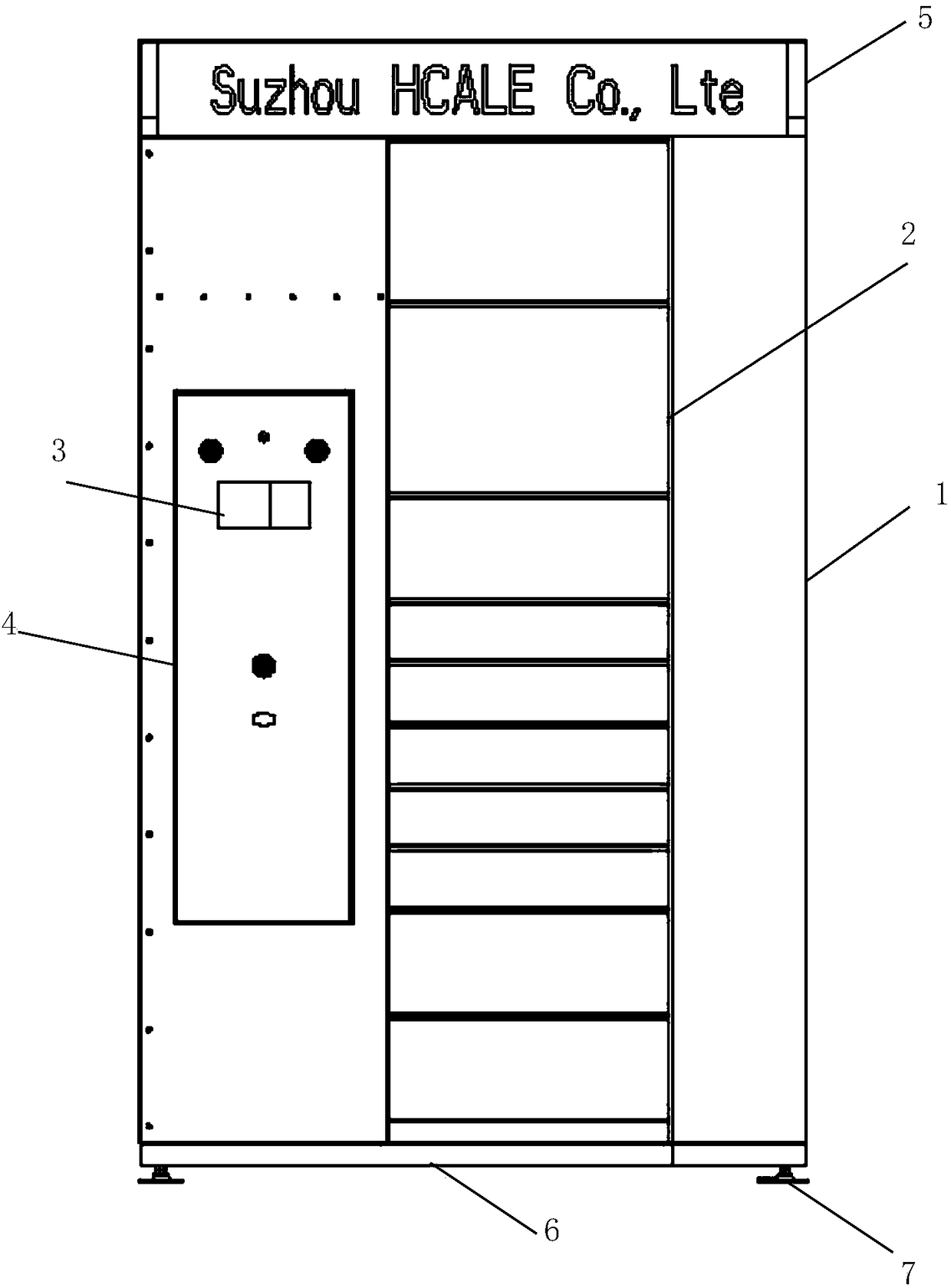

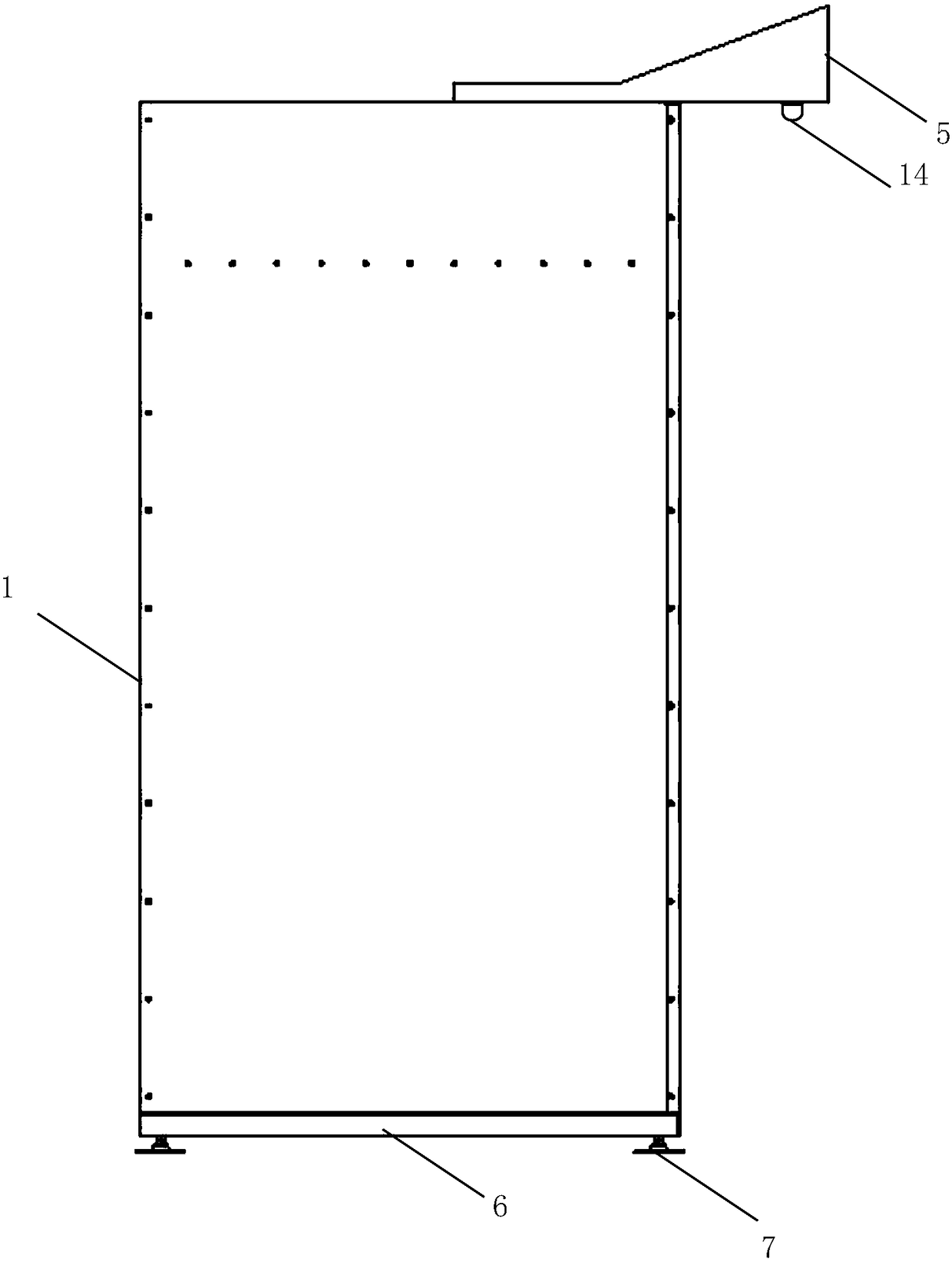

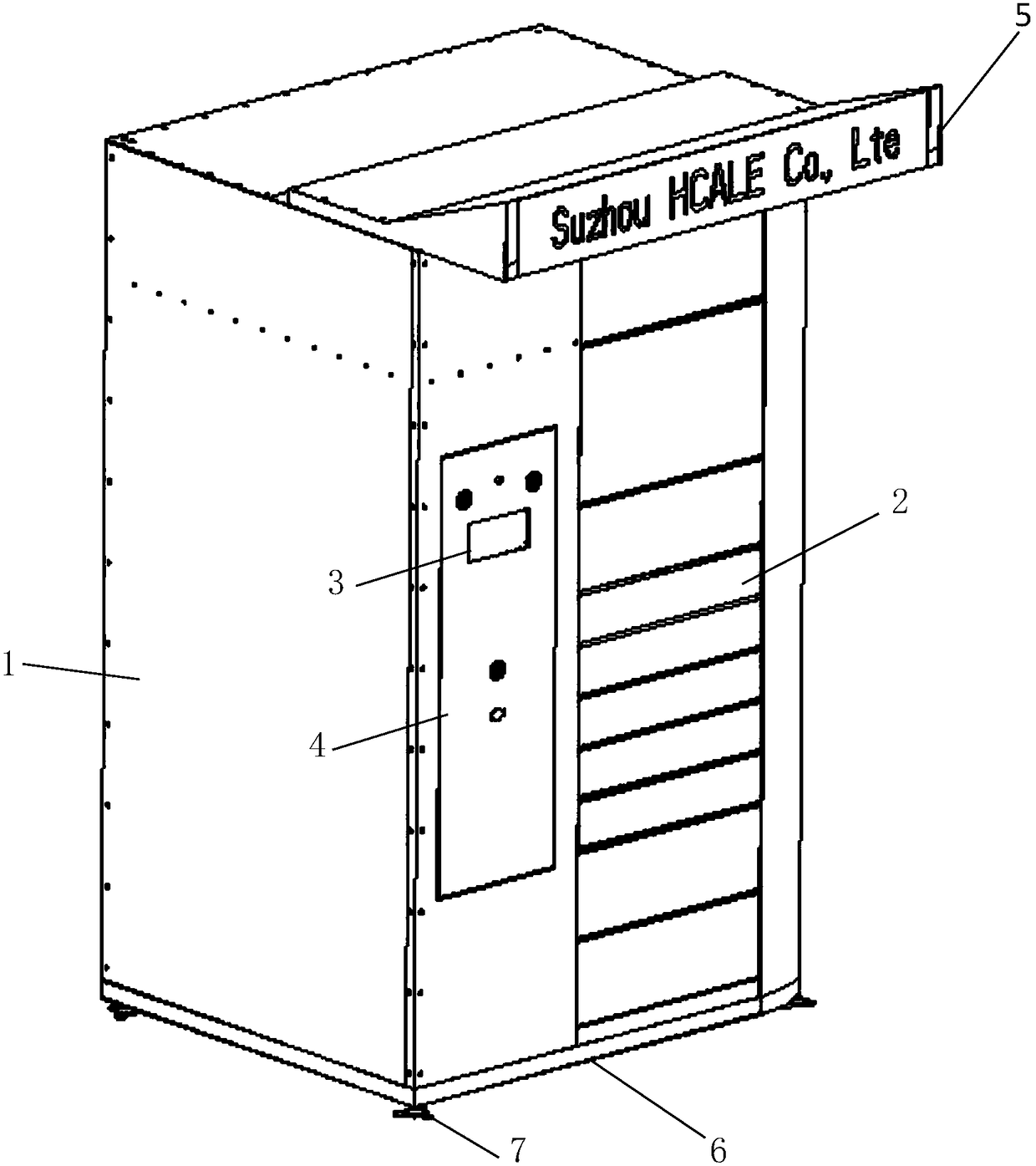

Public storage cabinet and manufacturing method thereof

InactiveCN108492477AConvenient replacementApparatus for meter-controlled dispensingIndividual entry/exit registersEmbedded systemEngineering

The invention relates to a public storage cabinet, in particular to a public storage cabinet used for storing letters or expresses and a manufacturing method thereof. The storage cabinet comprises a cabinet body, a centre shaft and a motor connected with the centre shaft, the cabinet body is rectangular or rounded, and a storage box is arranged inside the cabinet body; panels are respectively arranged on the upper, left, right and back faces of the cabinet body, a base is arranged at the lower portion of the cabinet body, and a cabinet door and a control panel are arranged on the front portionof the cabinet body; a control center module is arranged inside the cabinet body, the centre shaft vertically penetrates through the storage box, the storage box is a vertical cylinder and is dividedinto multiple layers by partitions, and the multiple layers are fixed to the centre shaft; each layer of the storage box takes the centre shaft as the center and is partitioned into a plurality of fan-shaped storage cases, the motor is started by the control center to rotate a corresponding storage case to face a corresponding cabinet door, and the control center orders the cabinet door to be opened, thereby achieving storing and taking expresses.

Owner:SUQIAN FENGCHI SECURITY & PROTECTION

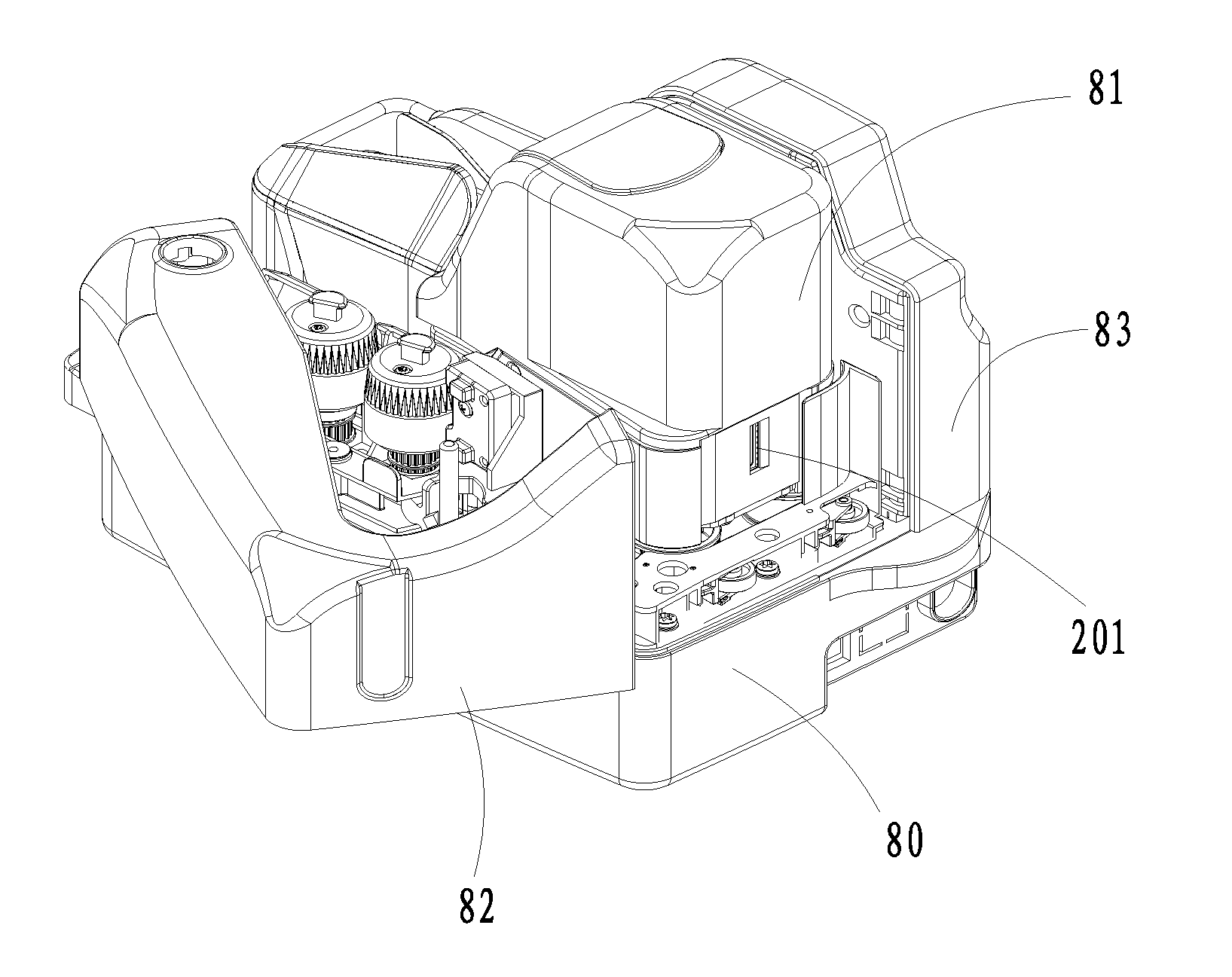

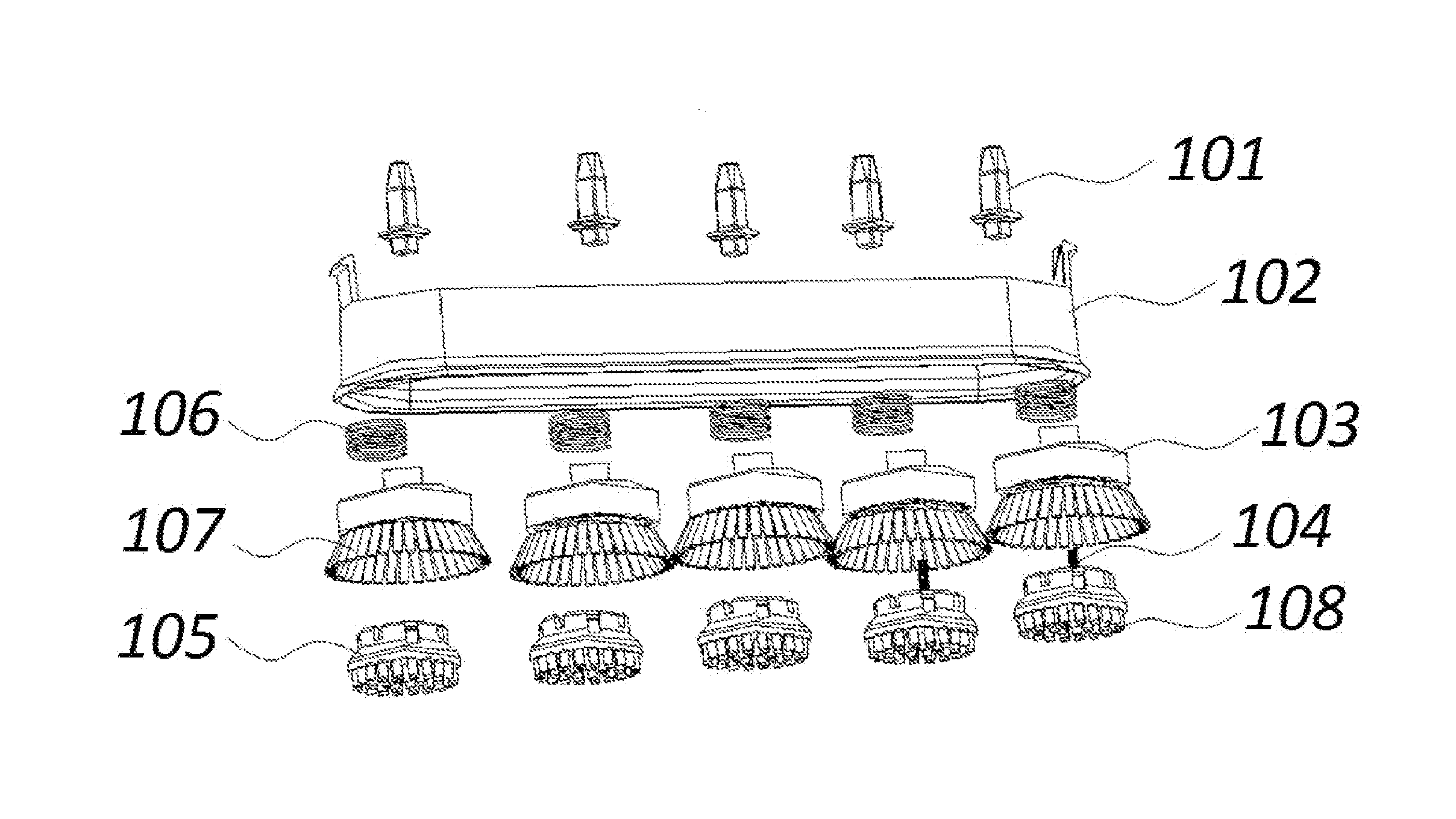

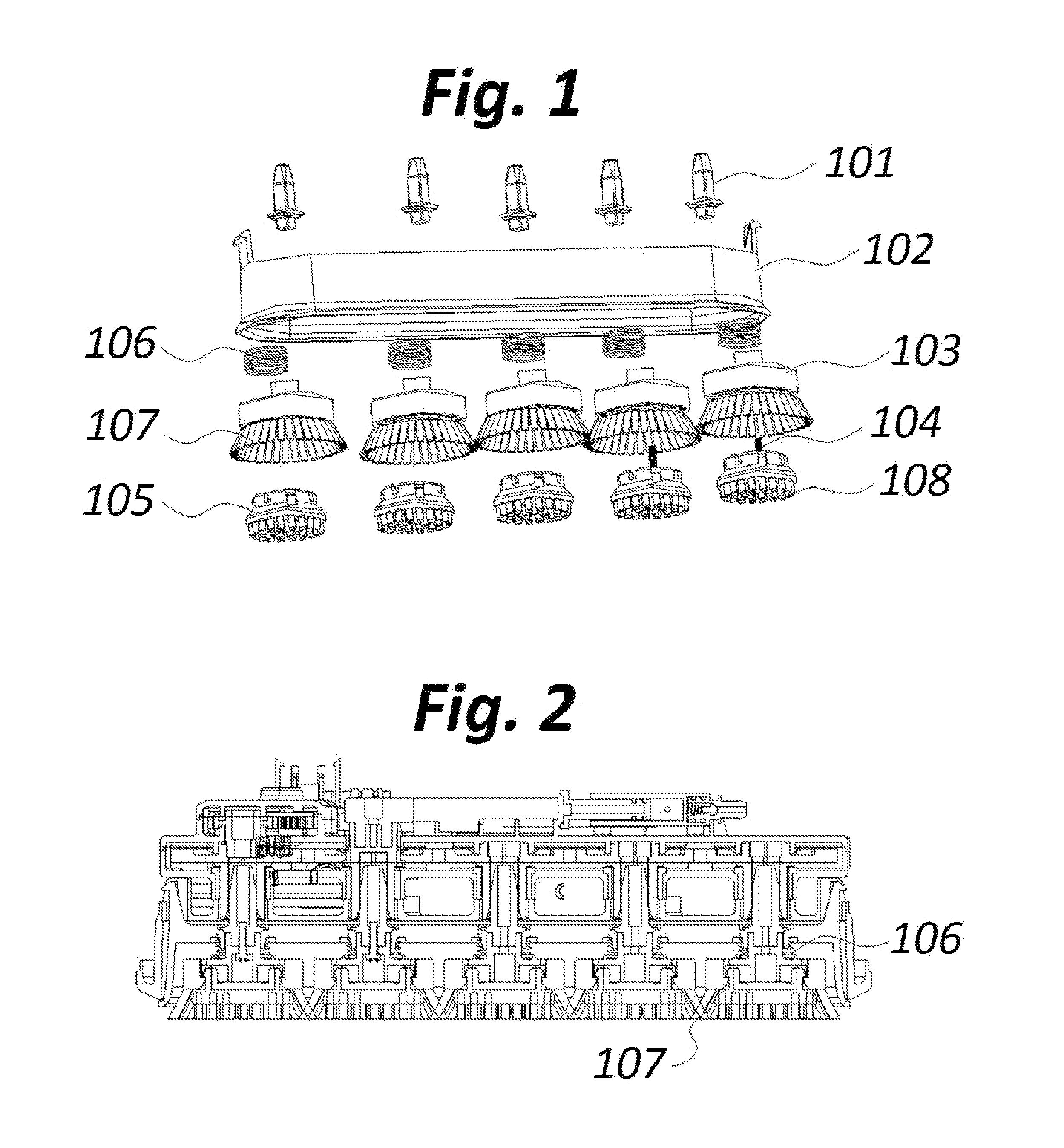

Brush for use in steam cleaning devices

InactiveUS20140047657A1Effectively clean a surface with no blind spots or damage to the surfaceImprove economyCarpet cleanersFloor cleanersBristleMechanical engineering

A floor cleaner brush arrangement includes a housing having mounted thereto a plurality of adjacent rotating brush assemblies. The rotating brush assemblies each include bristles extending there-from downwardly to the floor and outwardly into an overlapping and intermeshing relationship with the bristles of the brush assembly or assemblies adjacent thereto. The bristles of adjacent brush assemblies cooperate when rotating to contact the floor in overlapping fashion to eliminate cleaning blind spots.

Owner:ROBERTSON TERRY WILLIAM +1

A kind of denitrification and denitrification biological filler and its preparation method and application

ActiveCN113480002BConvenient replacementImprove denitrification effectWater contaminantsTreatment with anaerobic digestion processesCyclodextrinSodium hydrosulfide

The invention provides a denitrification and denitrification biological filler, a preparation method and application thereof, and relates to the technical field of sewage treatment. The present invention adopts β-cyclodextrin with a certain spatial network structure as the main body, first soaking in sodium hydroxide ethanol solution can activate the hydroxyl functional group on the periphery of the filler, and replace it with halogen atoms conveniently; It is further replaced with mercapto functional groups to load sulfur in the filler; then dehydration condensation can further convert mercapto functional groups into more stable disulfide bonds with modified spatial network structure; denitrification can be obtained after hot melt granulation Nitrogen removal biological filler. The denitrification and denitrification biological filler prepared by the invention can realize the denitrification effect of sulfur autotrophic and heterotrophic coupled denitrification, while ensuring the treatment efficiency, it solves the problem of long film-hanging time in the existing autotrophic and heterotrophic denitrification treatment , There are bottlenecks in processing efficiency, secondary pollution of effluent and other problems.

Owner:NANJING UNIV

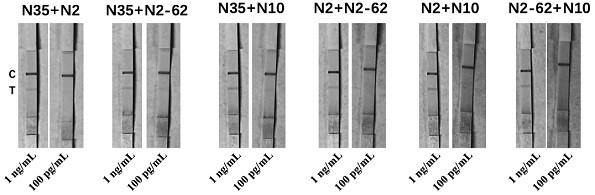

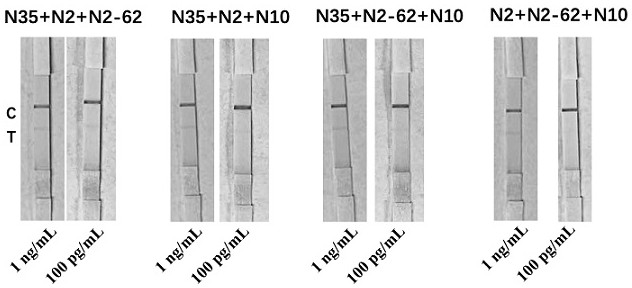

Multi-nucleic acid aptamers for detecting pathogenic microorganisms and combinations thereof

ActiveCN114807151AHigh affinityLow immunogenicityBiological material analysisAgainst vector-borne diseasesPathogenic microorganismAptamer

The invention discloses a multi-nucleic acid aptamer for detecting pathogenic microorganisms and a combination of the multi-nucleic acid aptamer, and belongs to the technical field of biological detection. The nucleic acid aptamer and the combination thereof disclosed by the invention can be specifically combined with pathogenic microorganisms, so that the nucleic acid aptamer and the combination thereof can be used for identifying and identifying the pathogenic microorganisms. The aptamer is screened by using an index enrichment ligand systematic evolution technology, and when the screened aptamer is used for detecting pathogenic microorganisms, the specificity is high, and the sensitivity is high. In addition, the aptamer has the characteristics of small molecular weight, better stability, easiness in modification, no immunogenicity, short preparation period and the like, and is more suitable for detecting pathogenic microorganisms compared with an antibody.

Owner:中国科学院基础医学与肿瘤研究所(筹)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com