Brush for use in steam cleaning devices

a technology for steam cleaning and brushes, applied in the direction of brushes, carpet cleaners, domestic applications, etc., can solve the problems of requiring laborious back and forth scrubbing, brushing is inadequate for removing stubborn stains and grime, and the entire device is required for back and forth passing over the surface, etc., to achieve the effect of cleaning a surface without blind spots or damage to the surfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

:

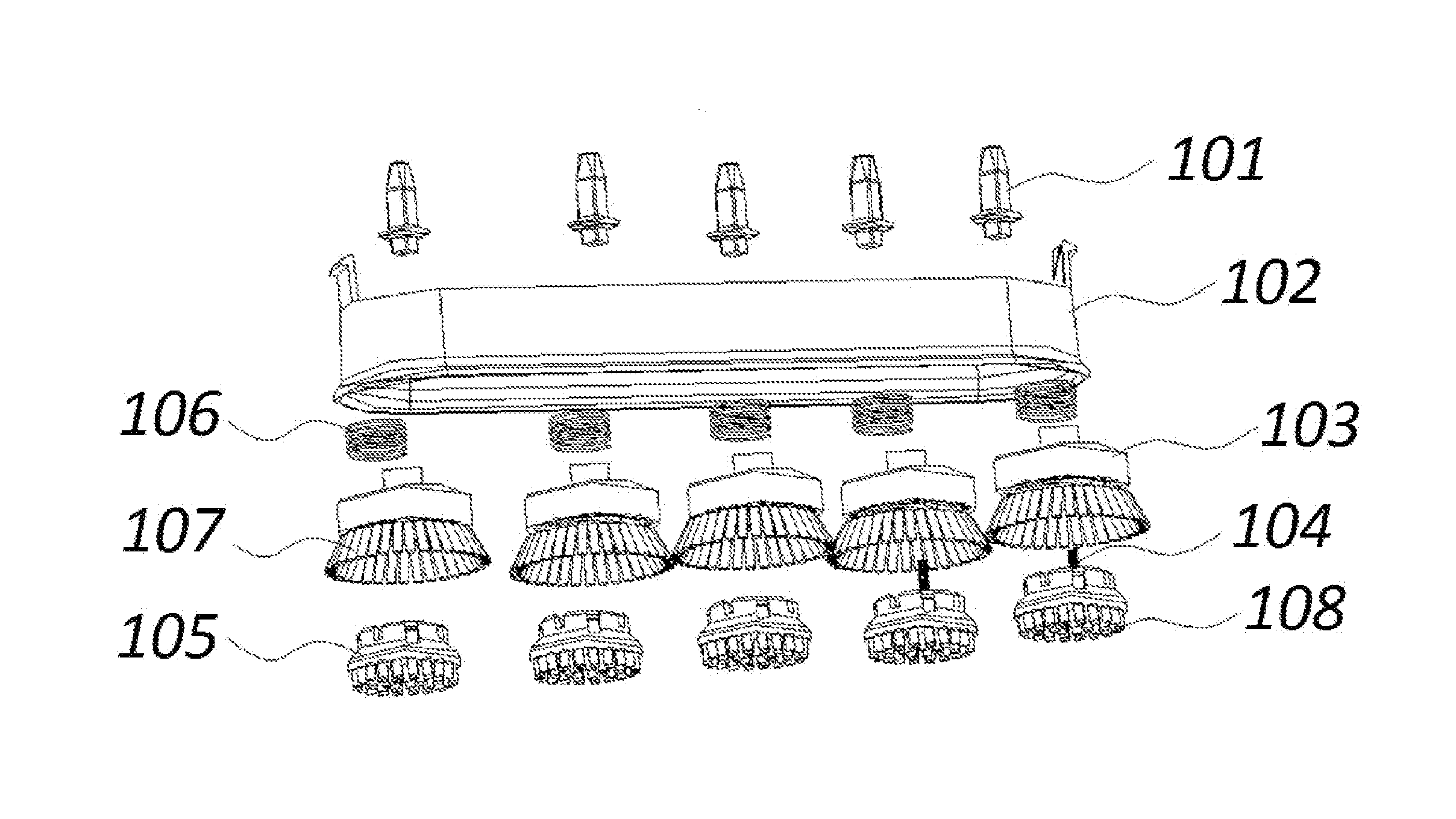

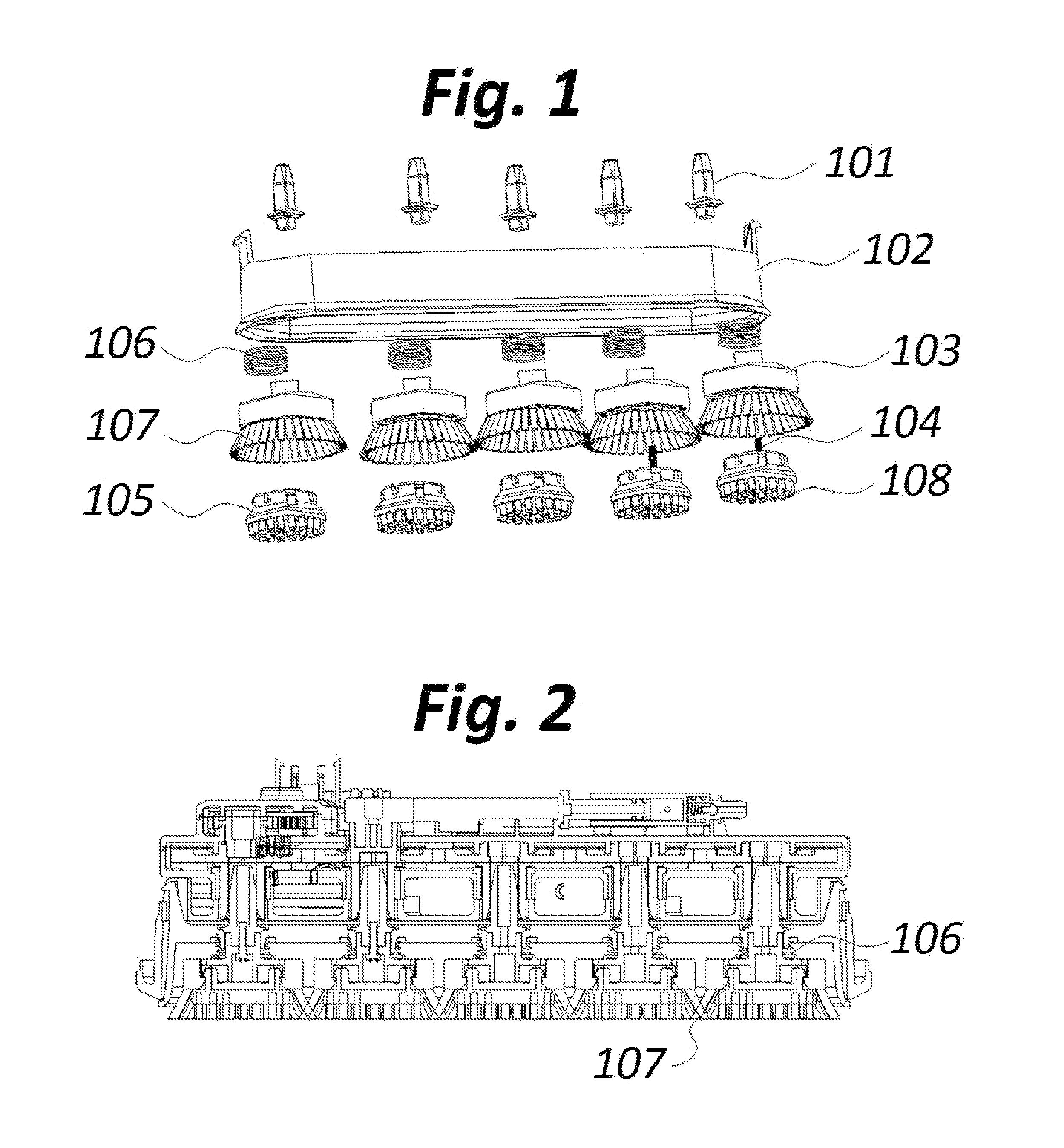

[0016]Referring to FIG. 1 and FIG. 2, brush mechanism 100 consists of brush cover 102 and five similar brush assemblies; each consisting of a transmission shaft 101, a peripheral brush body 103, a central brush body 105, a mounting screw 104, and a pressure spring 106. Each peripheral brush body includes peripheral bristles 107 and each central brush body includes central bristles 108.

[0017]Each brush assembly is assembled around and including the brush cover by passing the transmission shaft down through a receiving hole in the cover, surrounding the passed-through bottom end of the transmission shaft with a pressure spring, trapping the pressure spring between the underside of the brush cover and the peripheral brush body by affixing the peripheral brush body to the transmission shaft with a mounting screw, and receiving the central brush body within the peripheral brush body so that the peripheral brush body surrounds the central brush body. The central brush body snap-fits with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com