Biological filler for nitrogen removal by denitrification as well as preparation method and application thereof

A nitrification and denitrification biological and denitrification technology, which is applied in the field of denitrification and denitrification biological filler and its preparation, can solve the problems of long film hanging time, secondary pollution of effluent, bottleneck in treatment efficiency, etc. Good denitrification performance and water purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

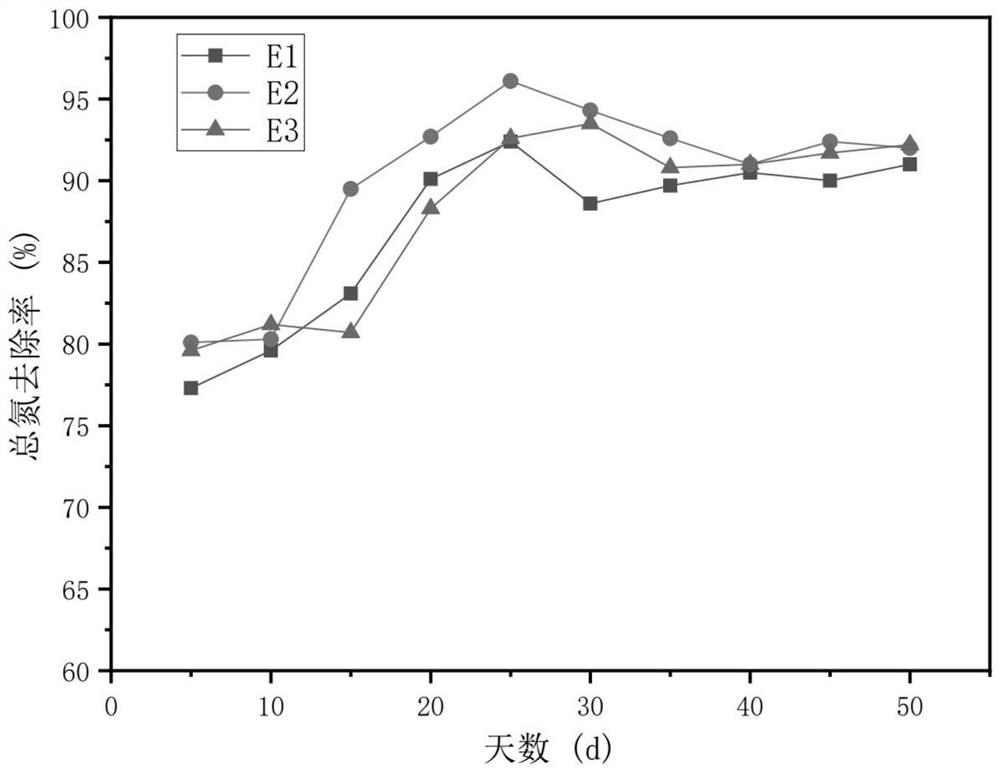

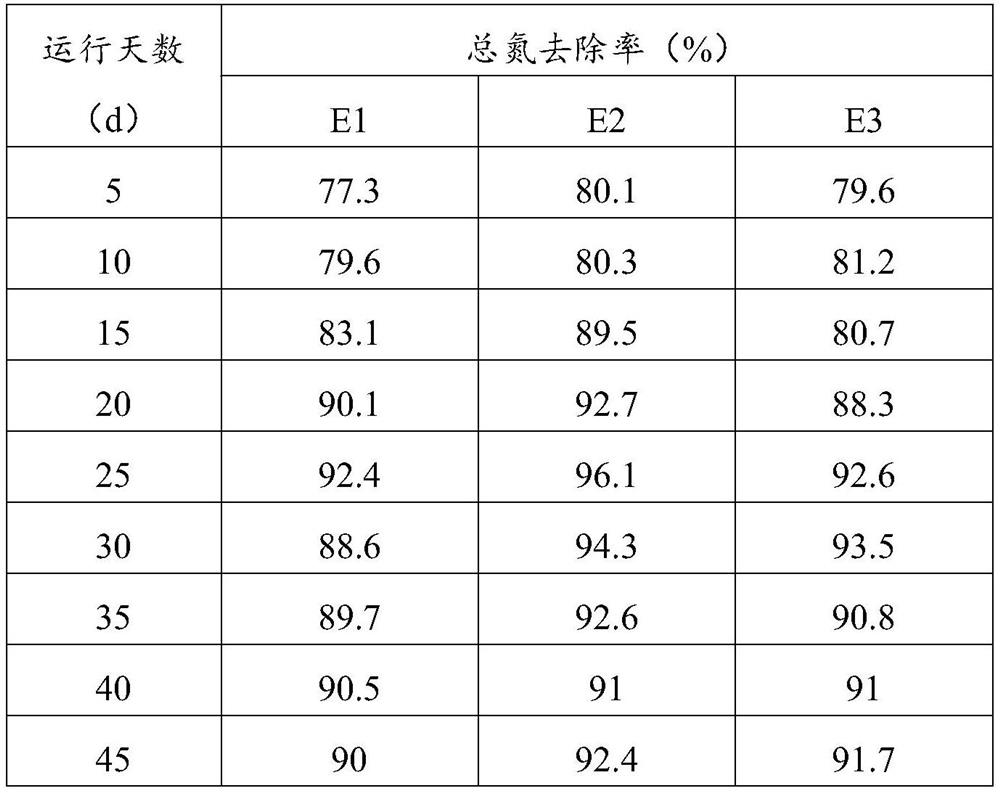

Examples

preparation example Construction

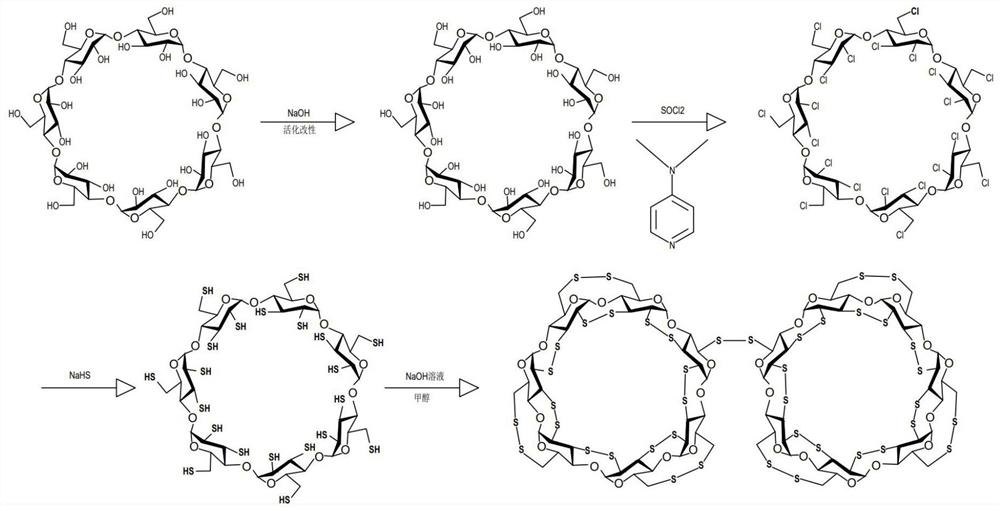

[0029] The present invention provides a method of preparing a denitrifying azide biomatic filler, comprising the steps of:

[0030] The β-cyclodextrin is refined in the sodium hydroxide solution, and activation modification is carried out to obtain an activated β-cyclodextrin;

[0031] The activated β-cyclodextrin and a halogenated product are mixed, and the halogenated reaction is carried out to obtain a halogenated beta-cyclodextrin;

[0032] The halide β-cyclodextrin is refined in a solution of sodium hydrogen sulfide ethanol, and the sulfhydryl-substituted reaction is obtained to give mercaptogenic β-cyclodextrin;

[0033] The mercaptogenated β-cyclodextrin and a dehydrating agent were mixed in an organic solvent to perform a dehydration condensation reaction to obtain a modified mesh structure β-cyclodextrin;

[0034] The modified mesh structure β-cyclodextrin and the binder were mixed to provide thermal measuring granules to obtain a denitrified nitrogen-filled biofill.

[0...

Embodiment 1

[0067] (1) Activation modification: Place the β-cyclorefine powder at a concentration of 3% sodium hydroxide solution, soaked for 24 h, then remove the filler, washed out of water, washed with anhydrous ethanol to 7.0, release Enter the vacuum drying box to dry to obtain an activated β-cyclodextrin;

[0068] (2) Chlorine: Put the activated β-cyclodextrin into a thionyl chloride solution of 1200 ml of mass concentration, and add 50 ml of mass concentration of 46% to DMAP solution, soak for 6 h, so After cleaning of the aqueous ethanol, it was dried in a vacuum drying overall to obtain a chlorinated beta-cyclodextrin;

[0069] (3) Sulfhydryl substituted: β-cyclodextrin is refined in a solution of 32% sulfide ethanol solution, and the water bath is placed in a water bath in a water bath of 60 ° C. At the same time, start the stirrer to continuously stir, stirring speed Take 120 rpm; after 8h, the filler is removed, and the surface of the filler is flushed with anhydrous ethanol, and ...

Embodiment 2

[0075] (1) Activation modification: Place the beta-cyclorefine powder in a hydroxide solution of 3% mass concentration, soaked for 18 h, after completion, remove the filler, washed with anhydrous ethanol to 7.0, release Enter the vacuum drying box to dry to obtain an activated β-cyclodextrin;

[0076] (2) Chlorine: Put the activated β-cyclodextrin into a thionyl chloride solution of 1200 ml of mass concentration, and add 50 ml of mass concentration of 46% to DMAP solution, soak for 6 h, so The aqueous ethanol was washed to the washing liquid pH of 7.0, and dried in a vacuum drying tank to give chlorinated β-cyclodextrin;

[0077] (3) Sulfhydryl substituted: β-cyclodextrin is refined in a solution of 32% sulfide ethanol solution, and the water bath is placed in a water bath in a water bath of 60 ° C. At the same time, start the stirrer to continuously stir, stirring speed For 100 rpm; after 8 h, the filler was removed, and the filler was washed with anhydrous ethanol and then dried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com