Magnesium alloy fluoride-free hydrazine chemical nickel plating solution and nickel plating process thereof

A technology of hydrazine chemistry and fluorine chemistry, applied in the field of electroless nickel plating solution and its nickel plating process, can solve the problems of reducing the deposition rate of electroless nickel plating, not being able to discharge in large quantities, and difficult to treat fluoride ion wastewater, so as to reduce costs and the environment. Risk of contamination, avoidance of accumulation of harmful substances, effect in favor of safe discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

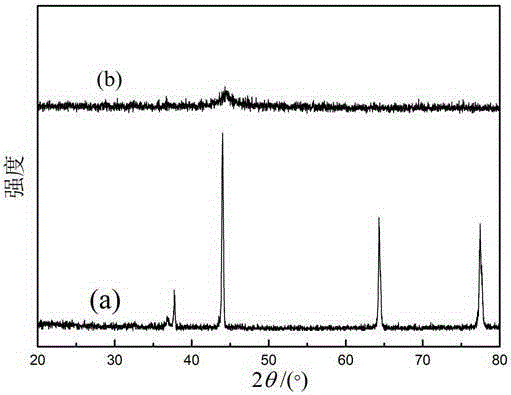

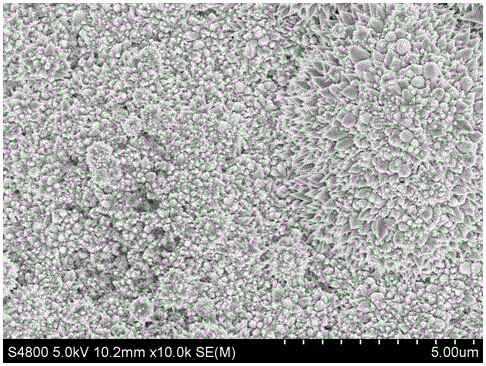

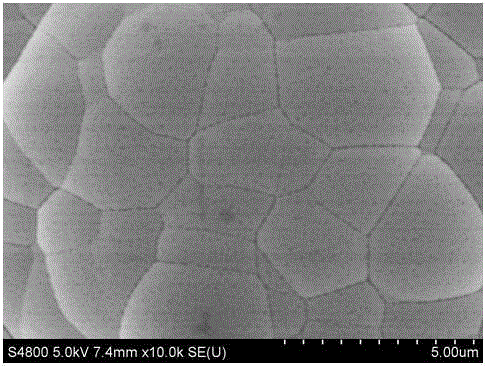

Image

Examples

Embodiment 1

[0058] The magnesium alloy fluorine-free hydrazine electroless nickel plating solution of the present embodiment includes an alkaline fluorine-free hydrazine electroless nickel plating solution and an acidic fluorine-free hydrazine electroless nickel plating solution;

[0059] The alkaline fluorine-free hydrazine electroless nickel plating solution has a pH value of 13 and consists of: nickel chloride 25g / L; hydrazine 16mL / L; ethylenediamine 50mL / L; sodium hydroxide 100g / L; boric acid 10g / L; Thiourea 1mg / L;

[0060] The acidic fluorine-free electroless nickel plating solution has a pH value of 5.5 and consists of: nickel sulfate 20g / L; sodium hypophosphite 20g / L; citric acid 5g / L; thiourea 1mg / L.

[0061] The magnesium alloy fluorine-free electroless nickel plating process of the present embodiment is:

[0062] (1) Polishing: Polish the AZ91D magnesium alloy sample with a polishing machine and wash it with water;

[0063] (2) Degreasing and degreasing: at room temperature, w...

Embodiment 2

[0081] The difference between this example and Example 1 is that in step (6) of the magnesium alloy fluorine-free electroless nickel plating process, the plating time of the alkaline fluorine-free hydrazine electroless nickel plating is changed to 90 minutes. The rest are the same as embodiment 1.

Embodiment 3

[0083] The difference between this example and Example 1 is that in step (6) of the magnesium alloy fluorine-free electroless nickel plating process, the plating time of the alkaline fluorine-free hydrazine electroless nickel plating is changed to 150 minutes. The rest are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com