Patents

Literature

130results about How to "Avoid Parasitic Capacitance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

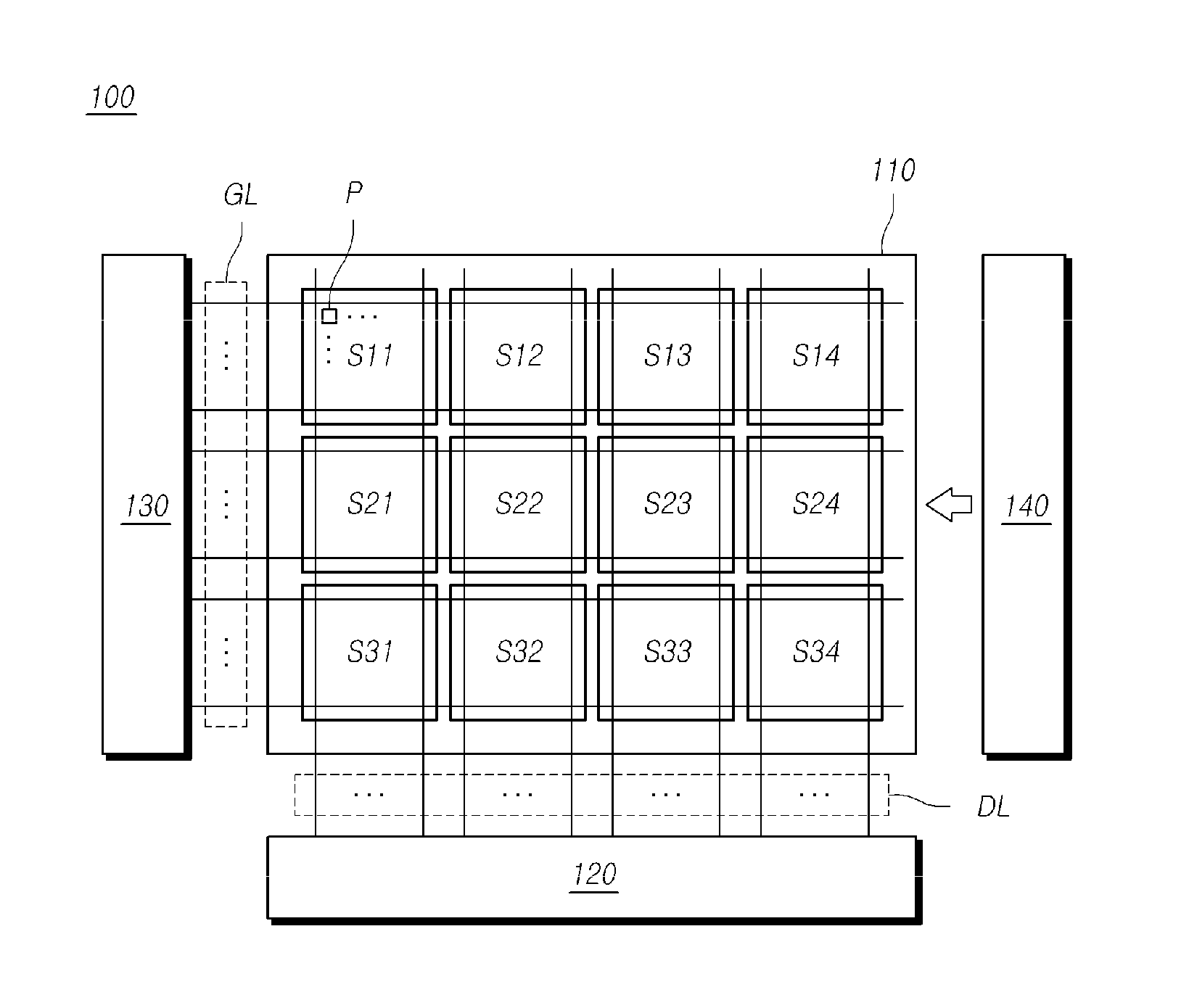

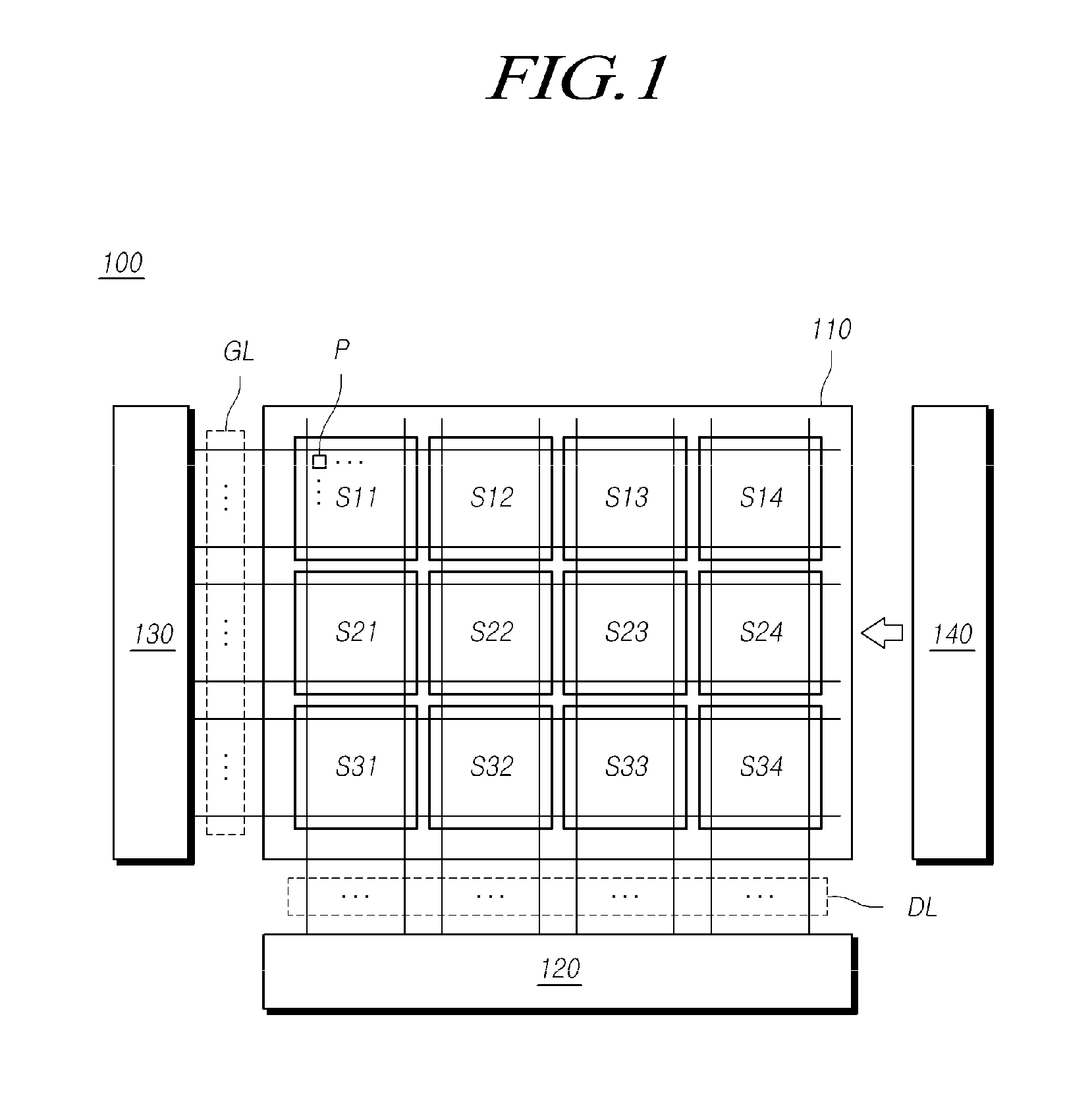

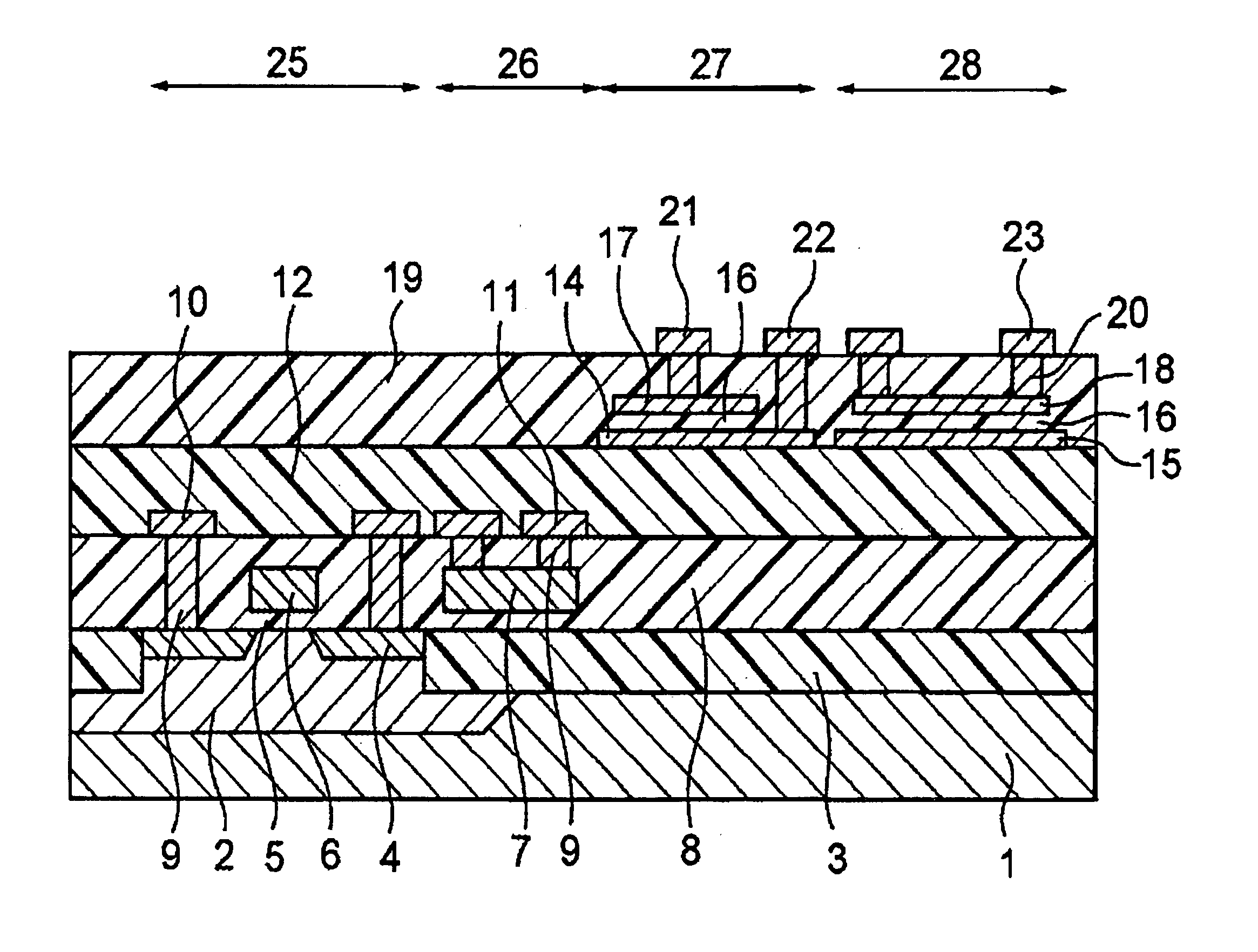

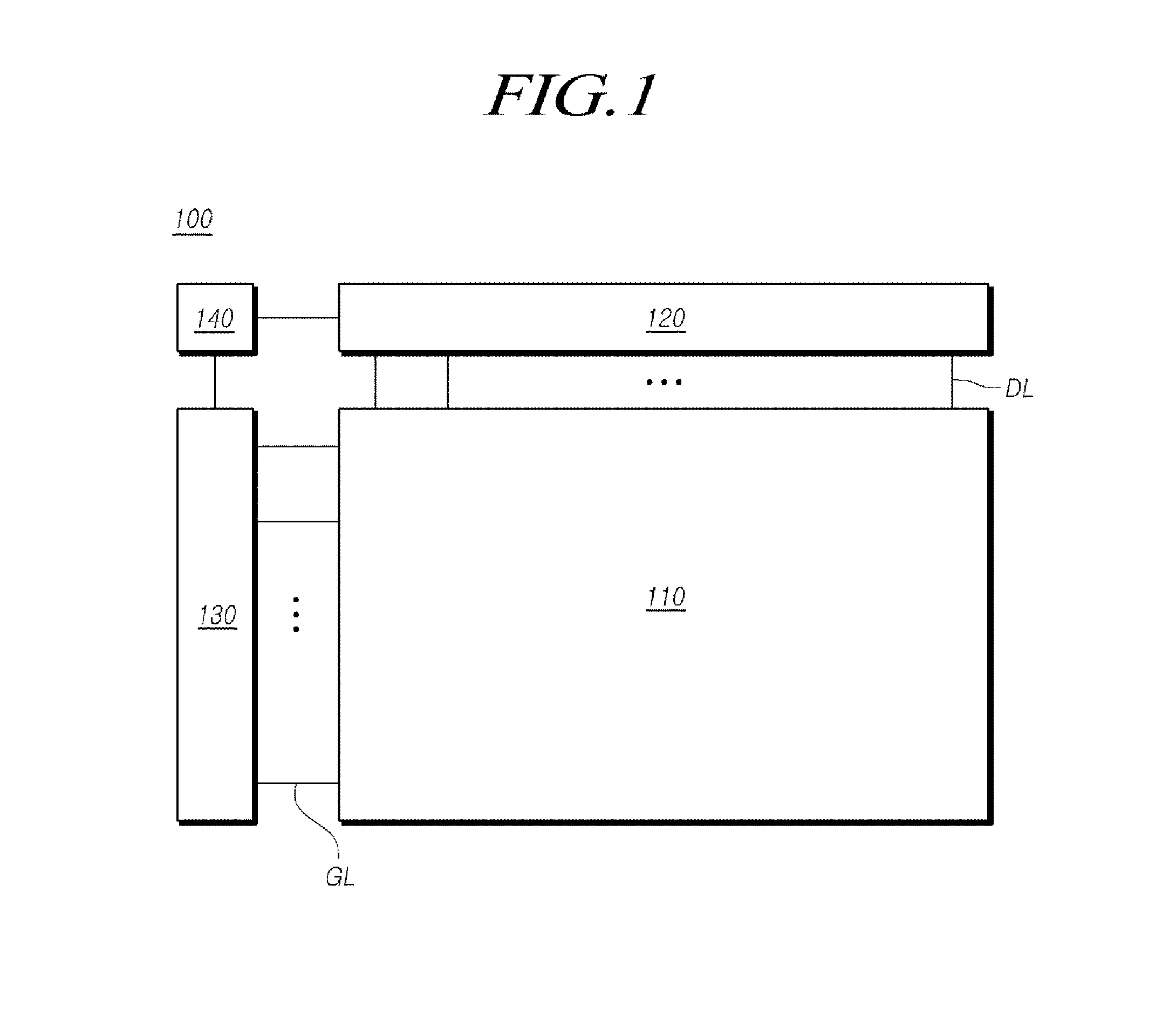

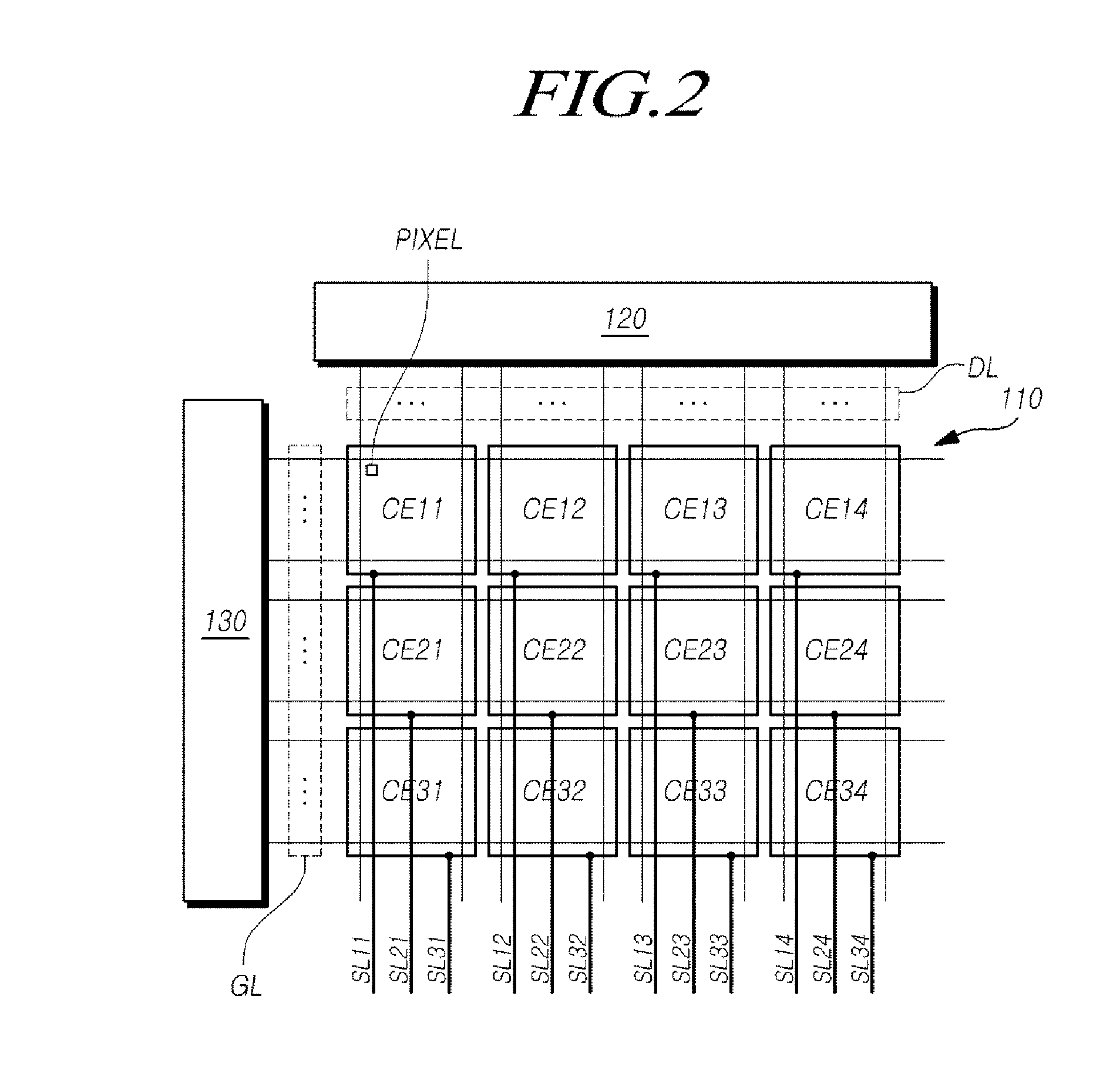

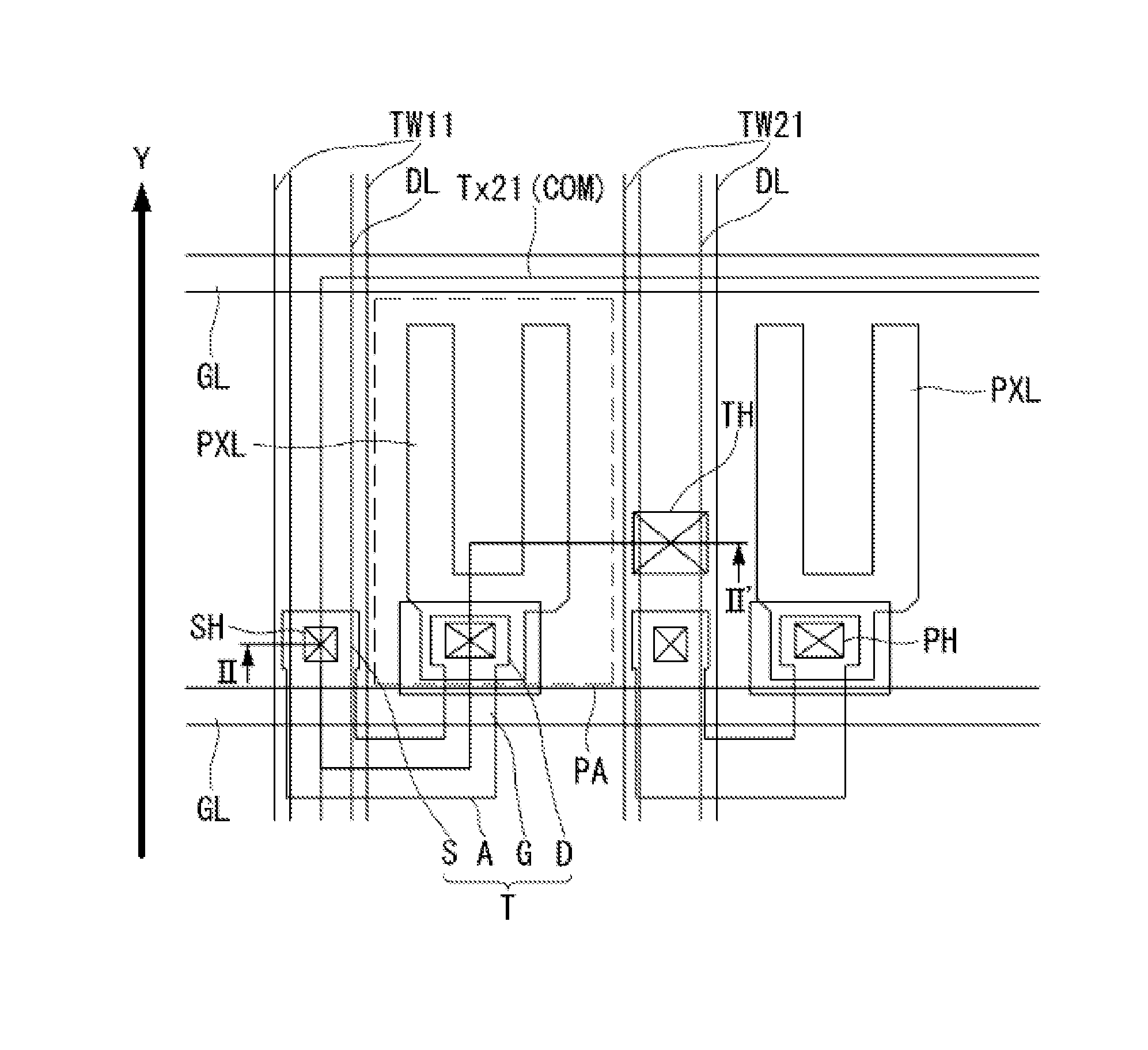

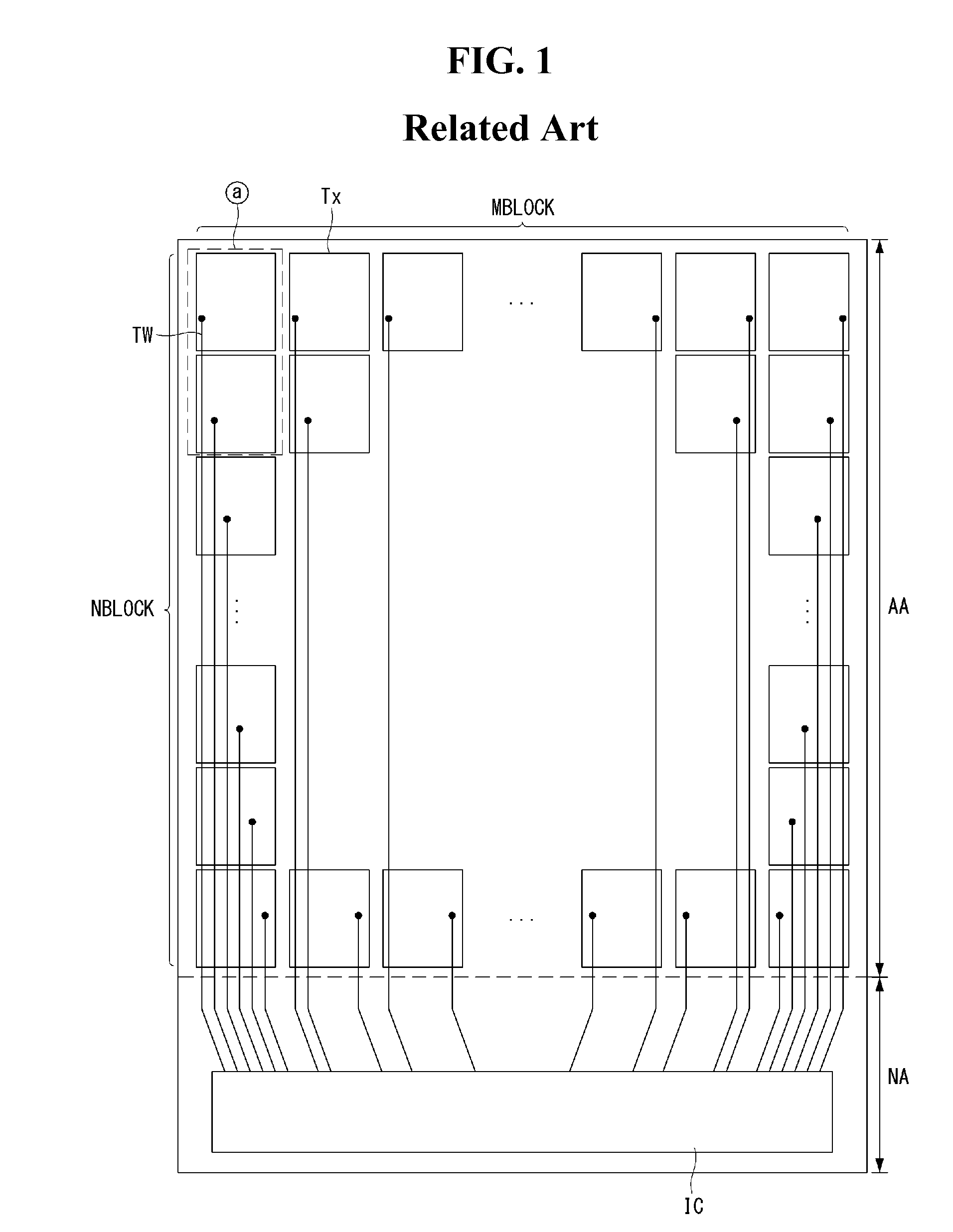

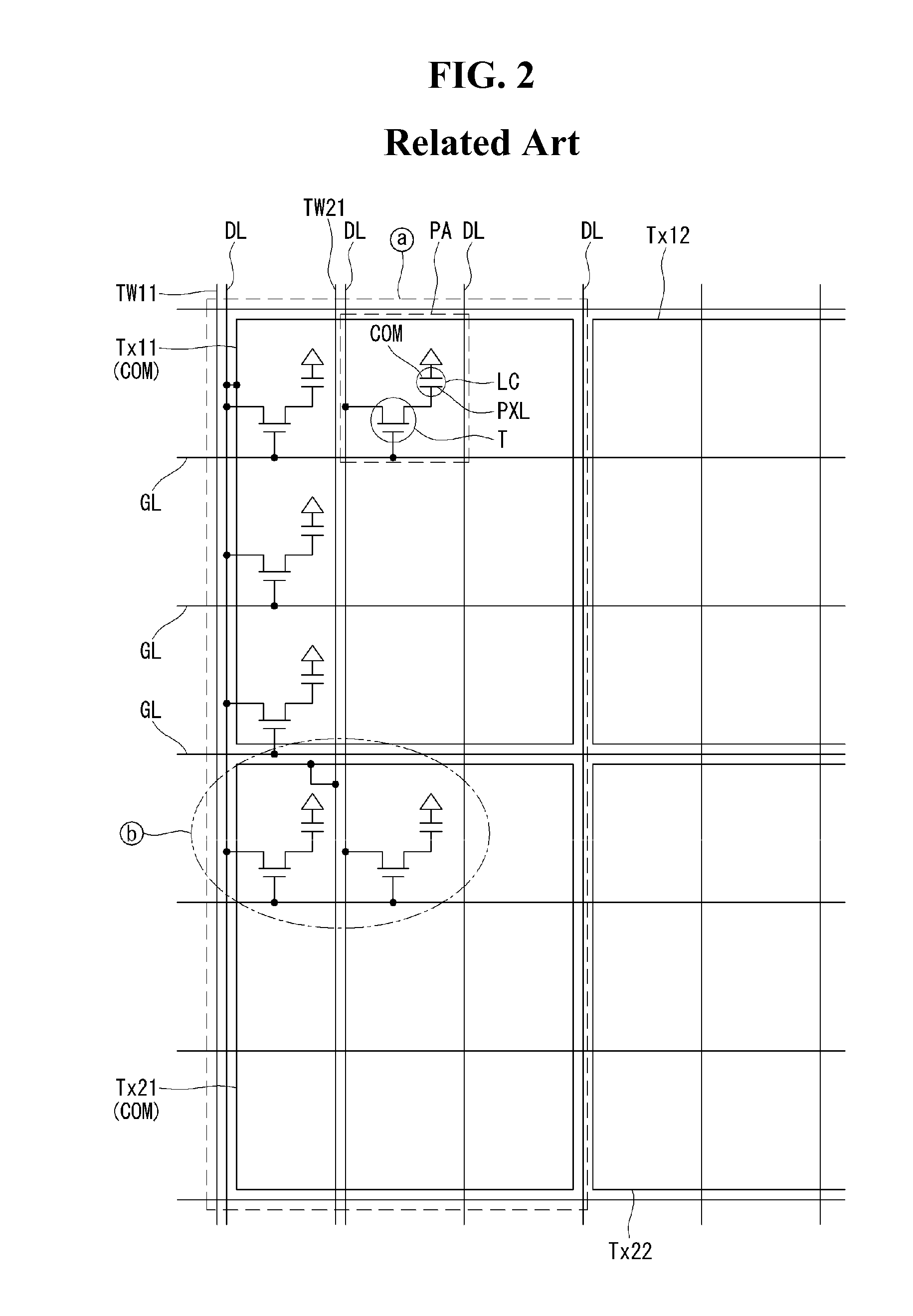

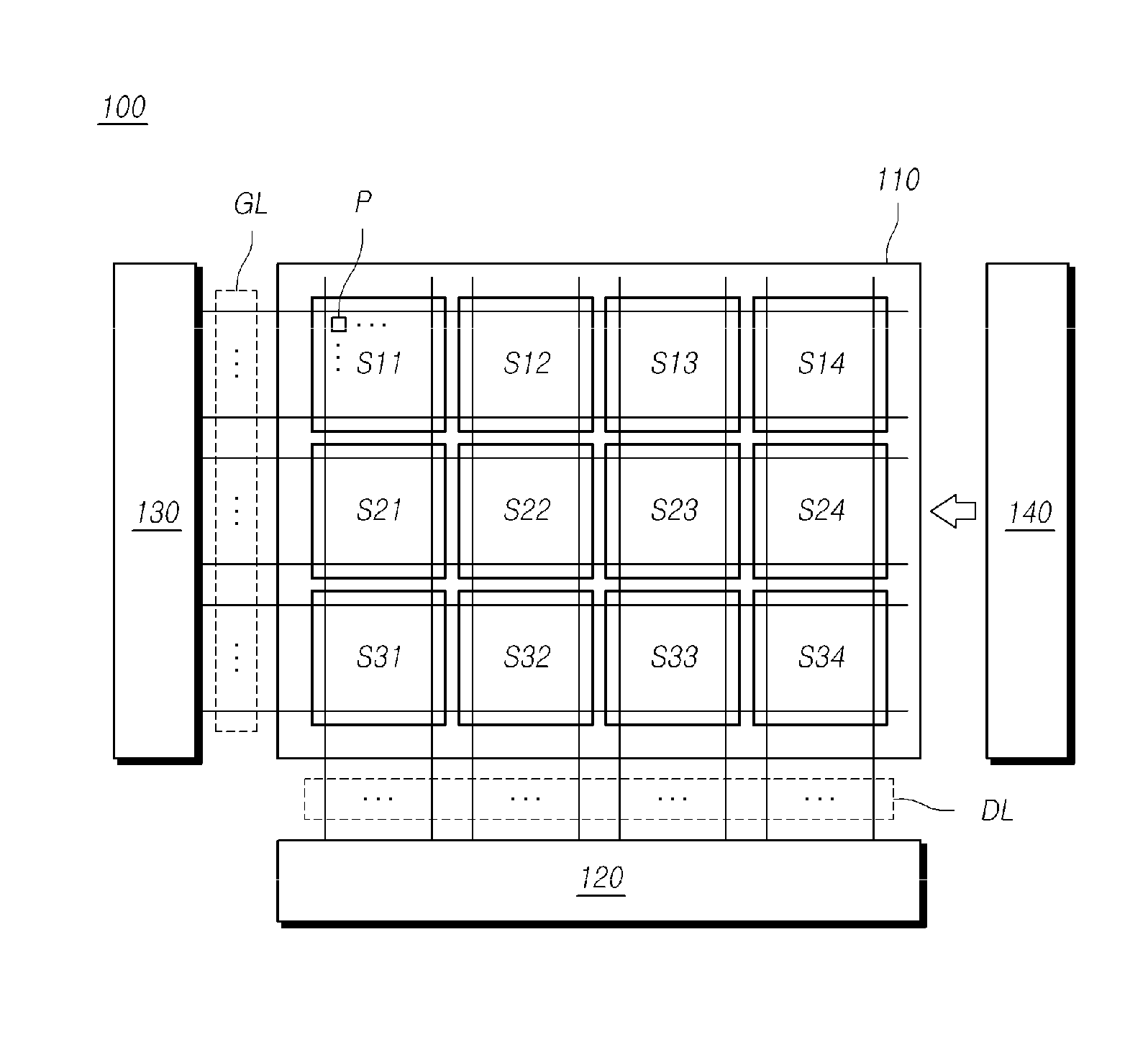

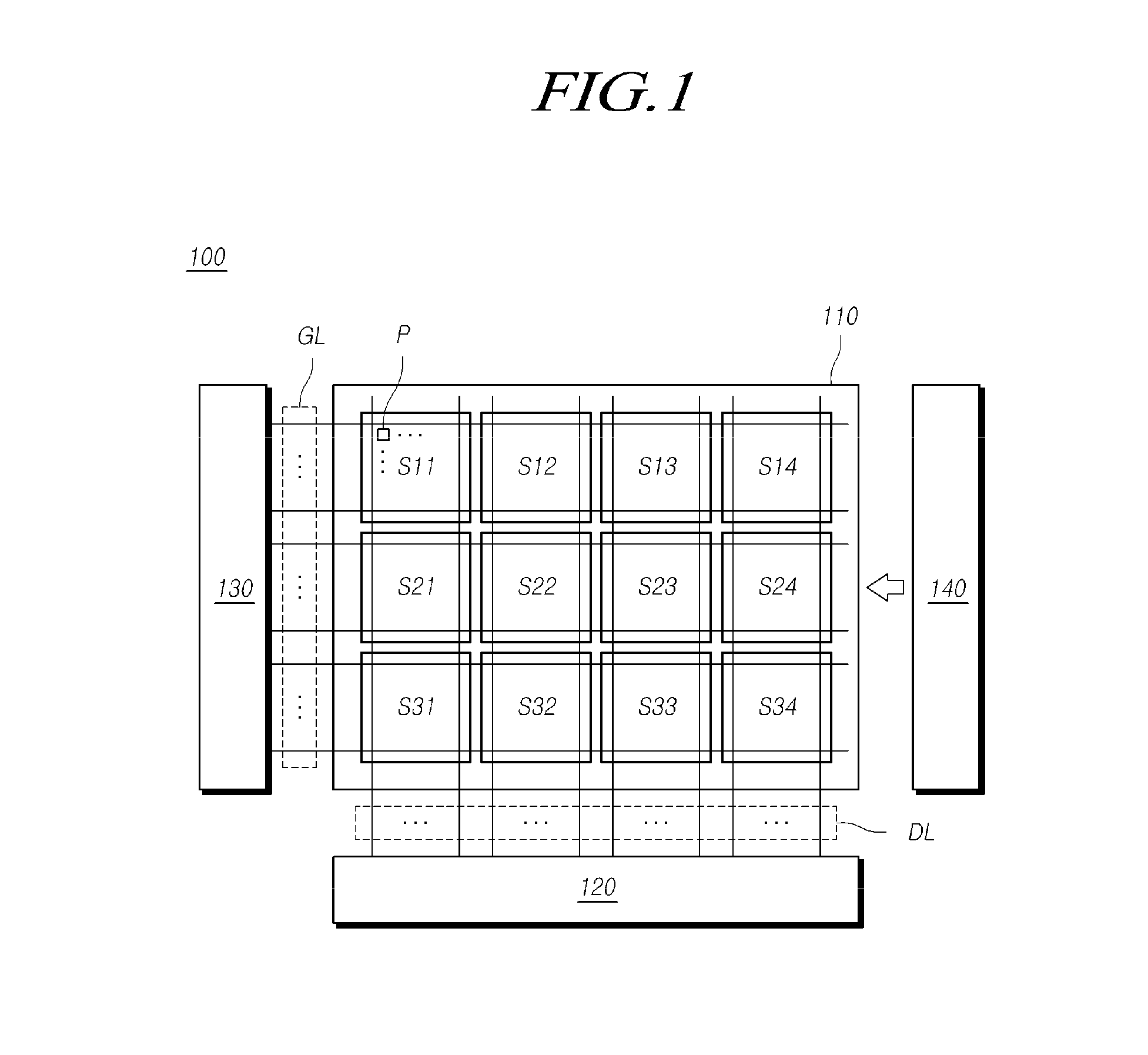

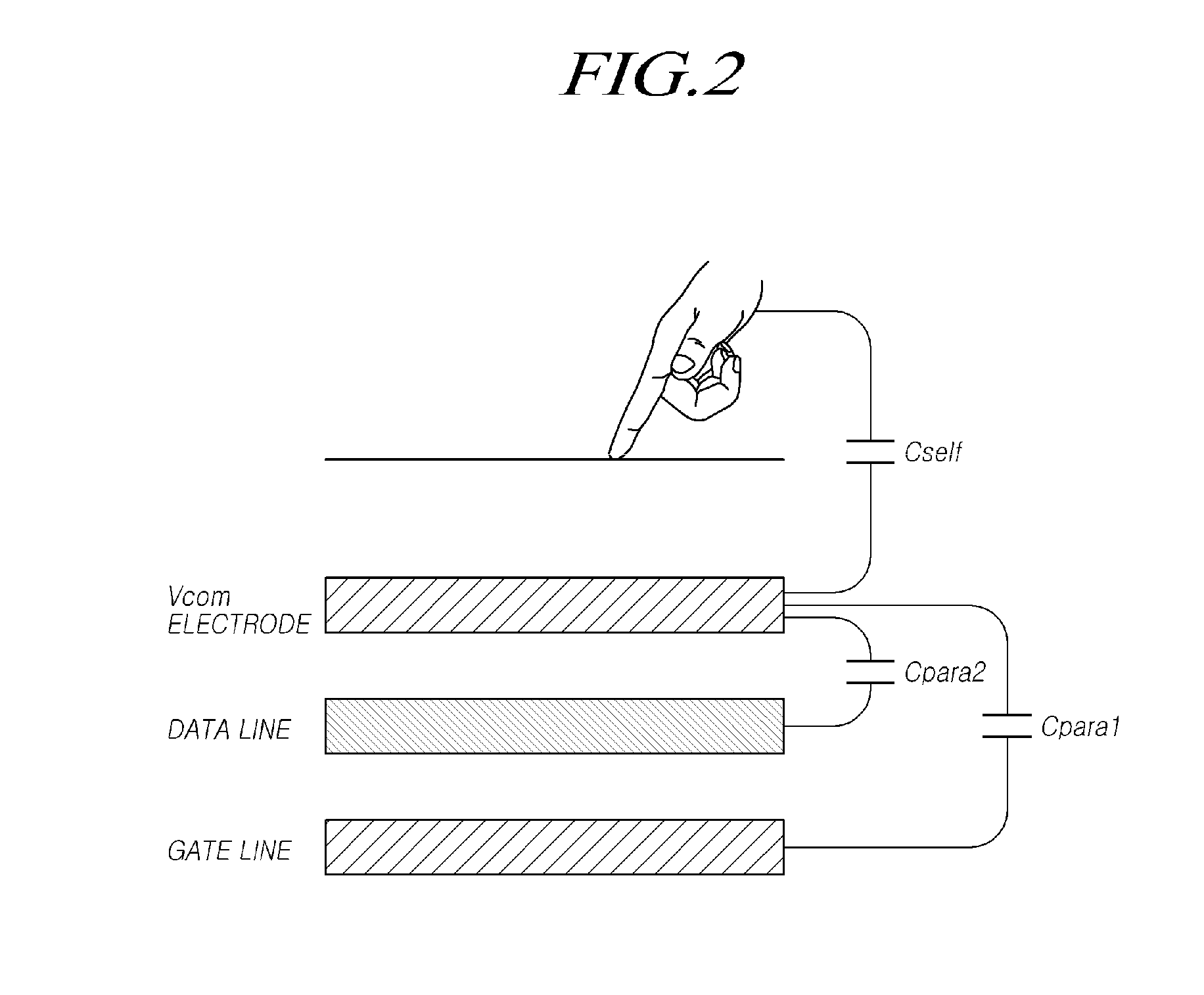

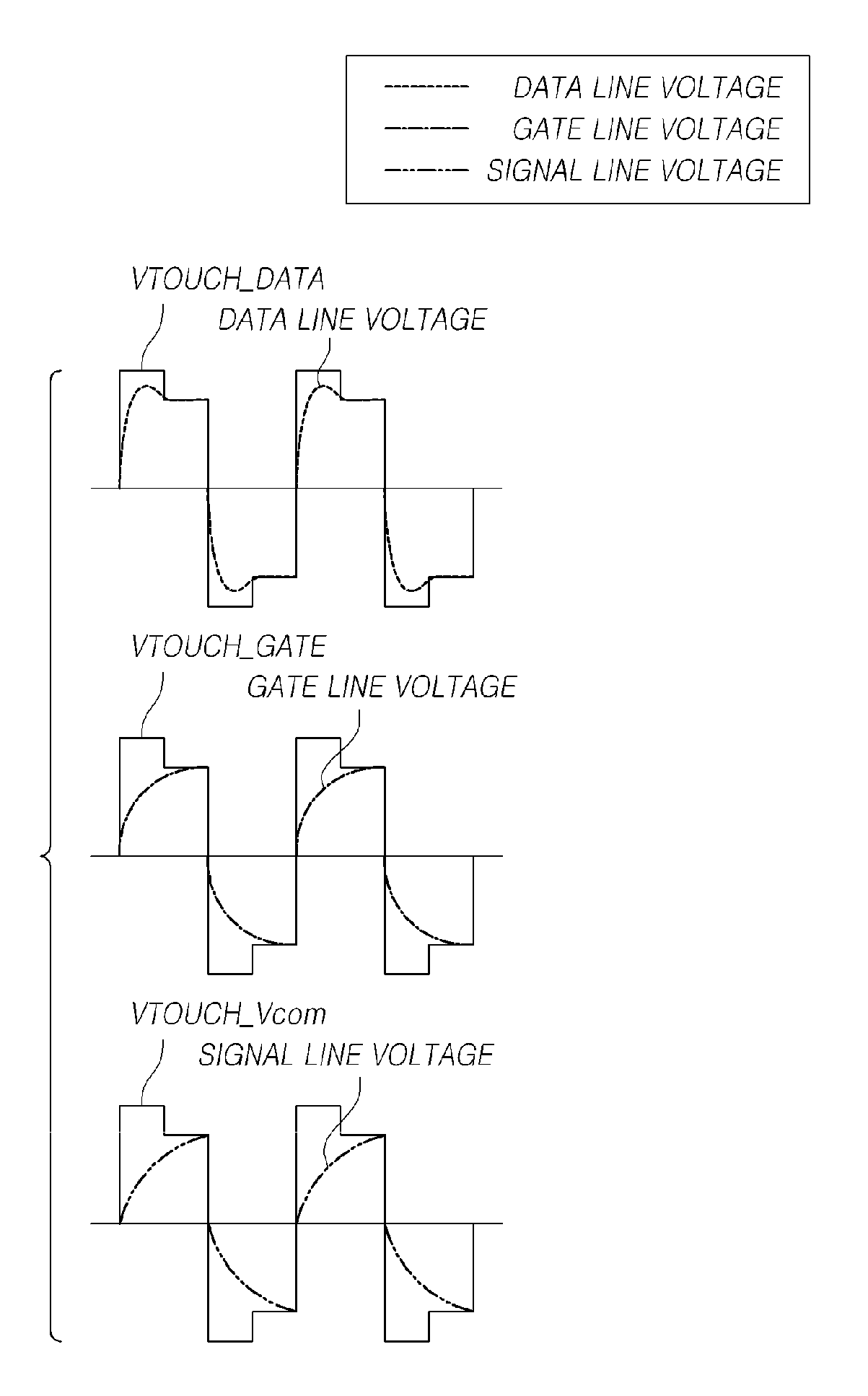

Display device integrated with touch screen panel and method of driving the same

ActiveUS20150177880A1Accuracy be lowerPrevent parasitic capacitanceStatic indicating devicesInput/output processes for data processingEngineeringData lines

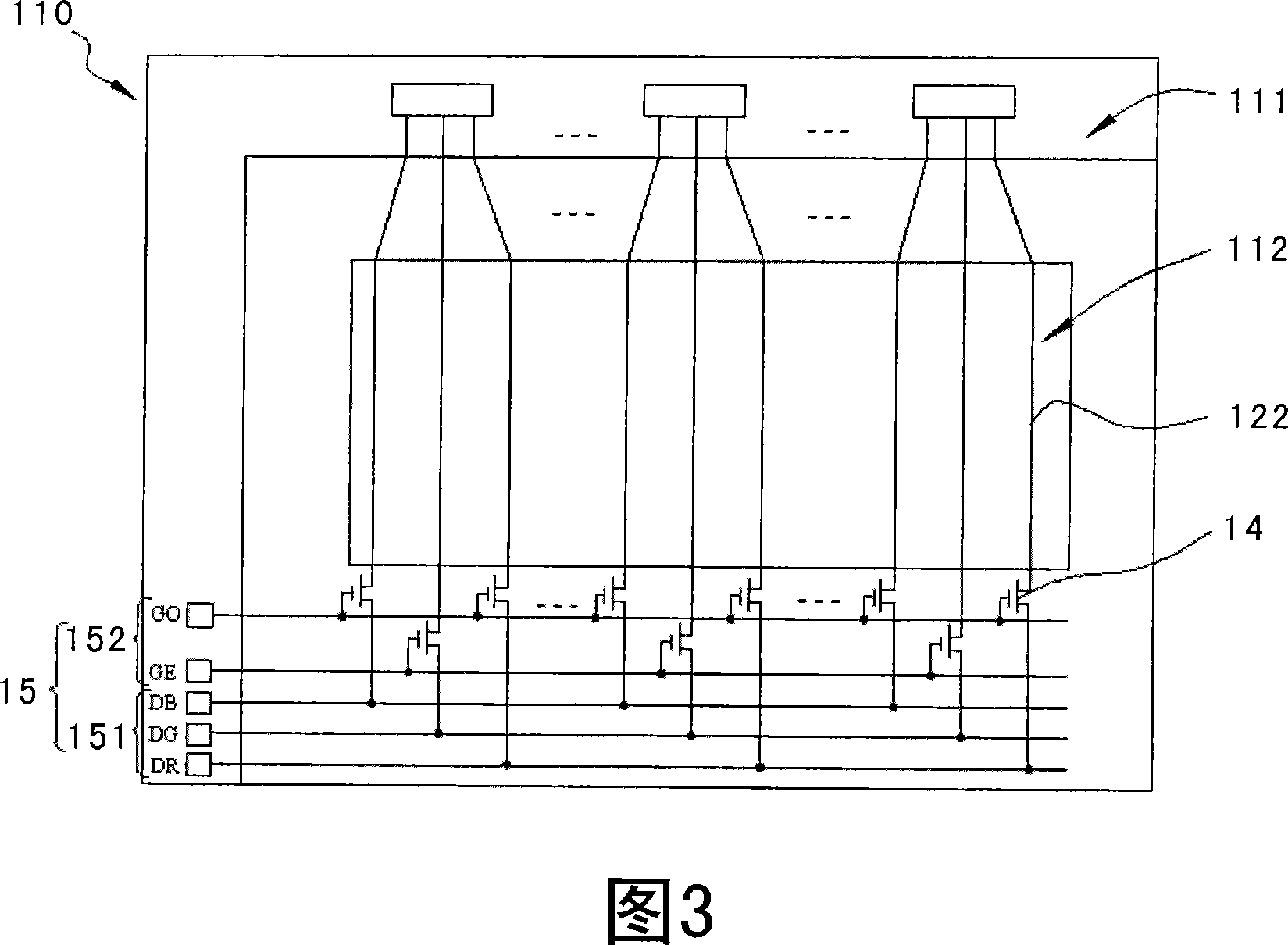

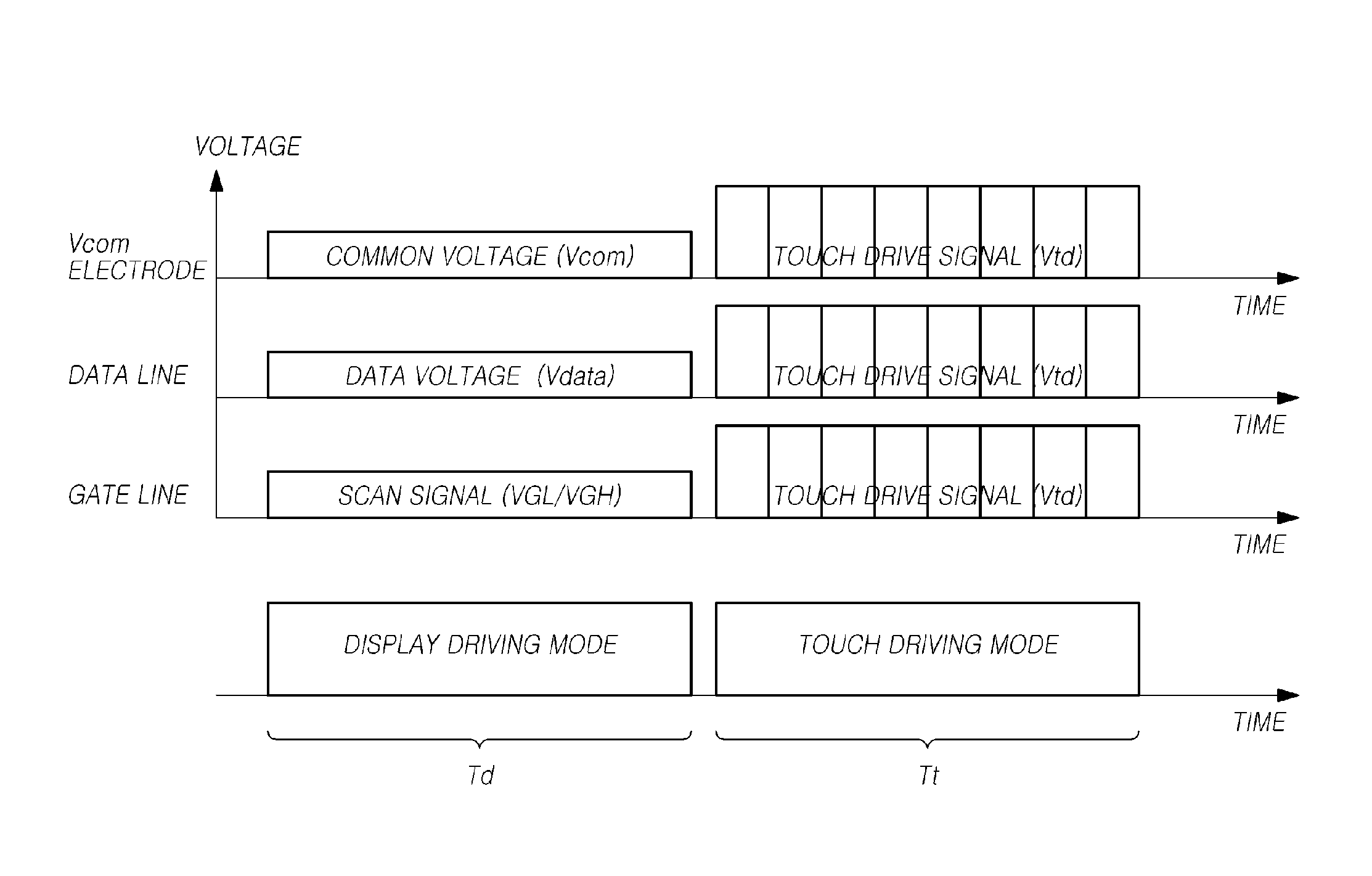

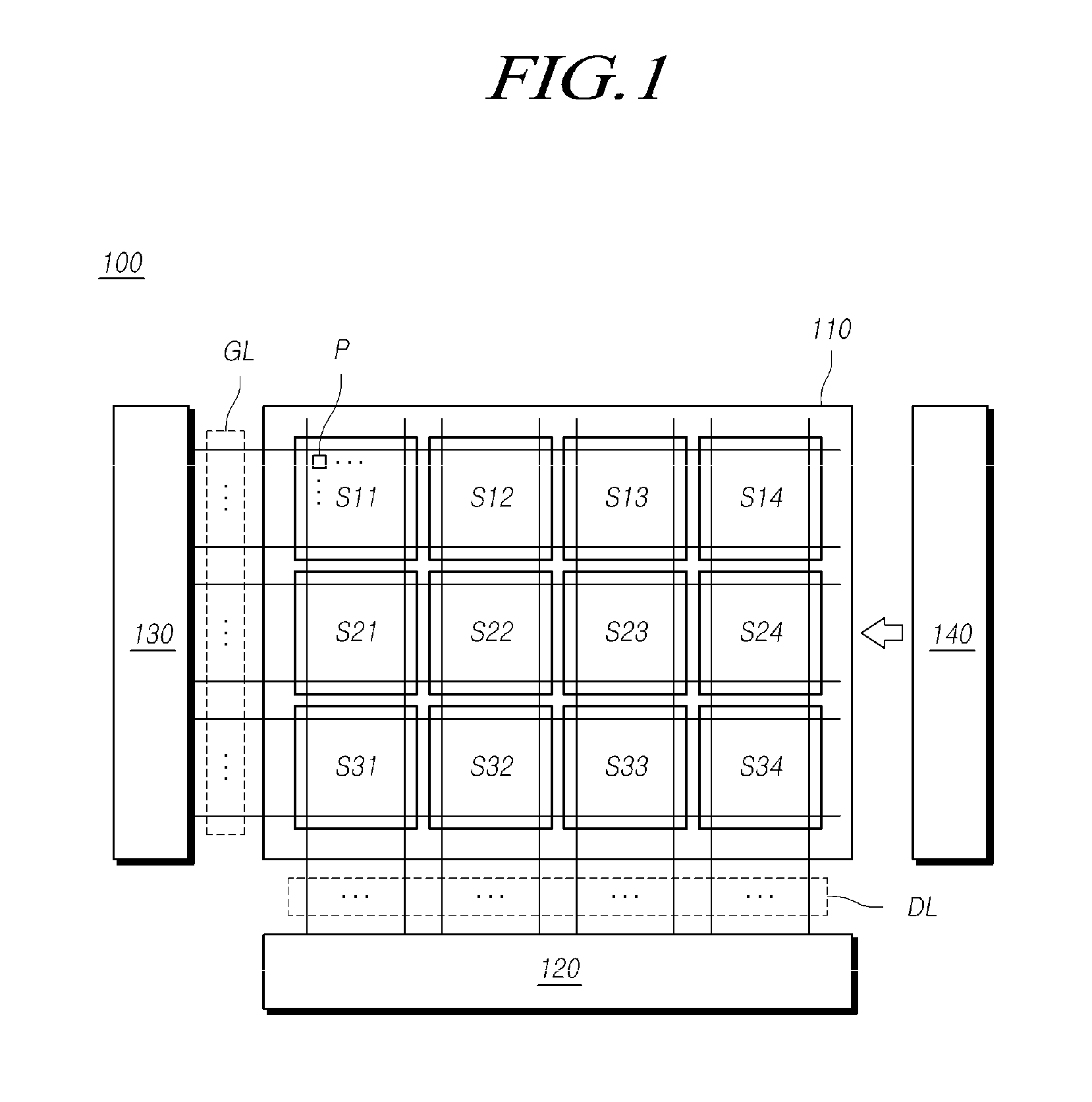

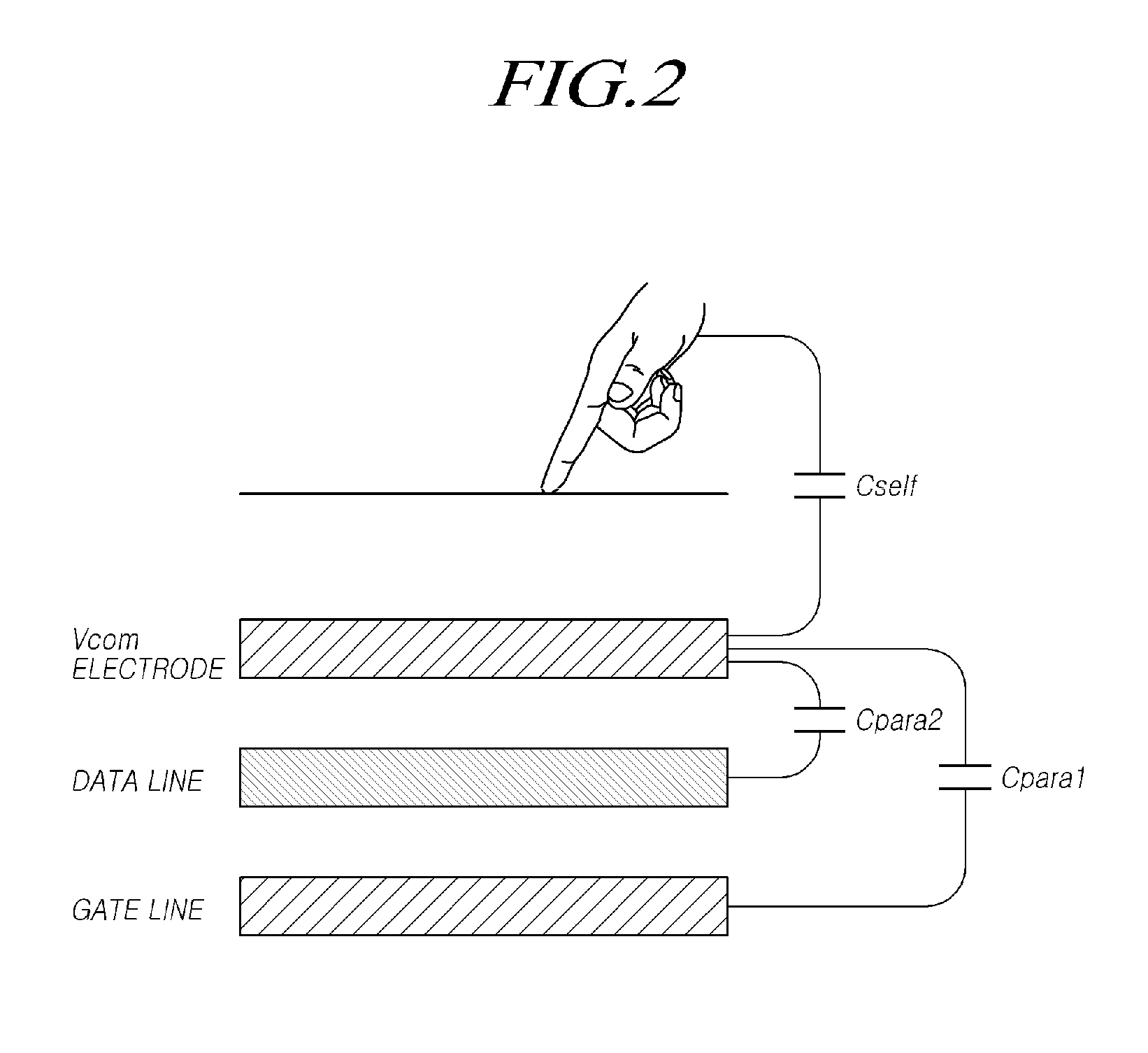

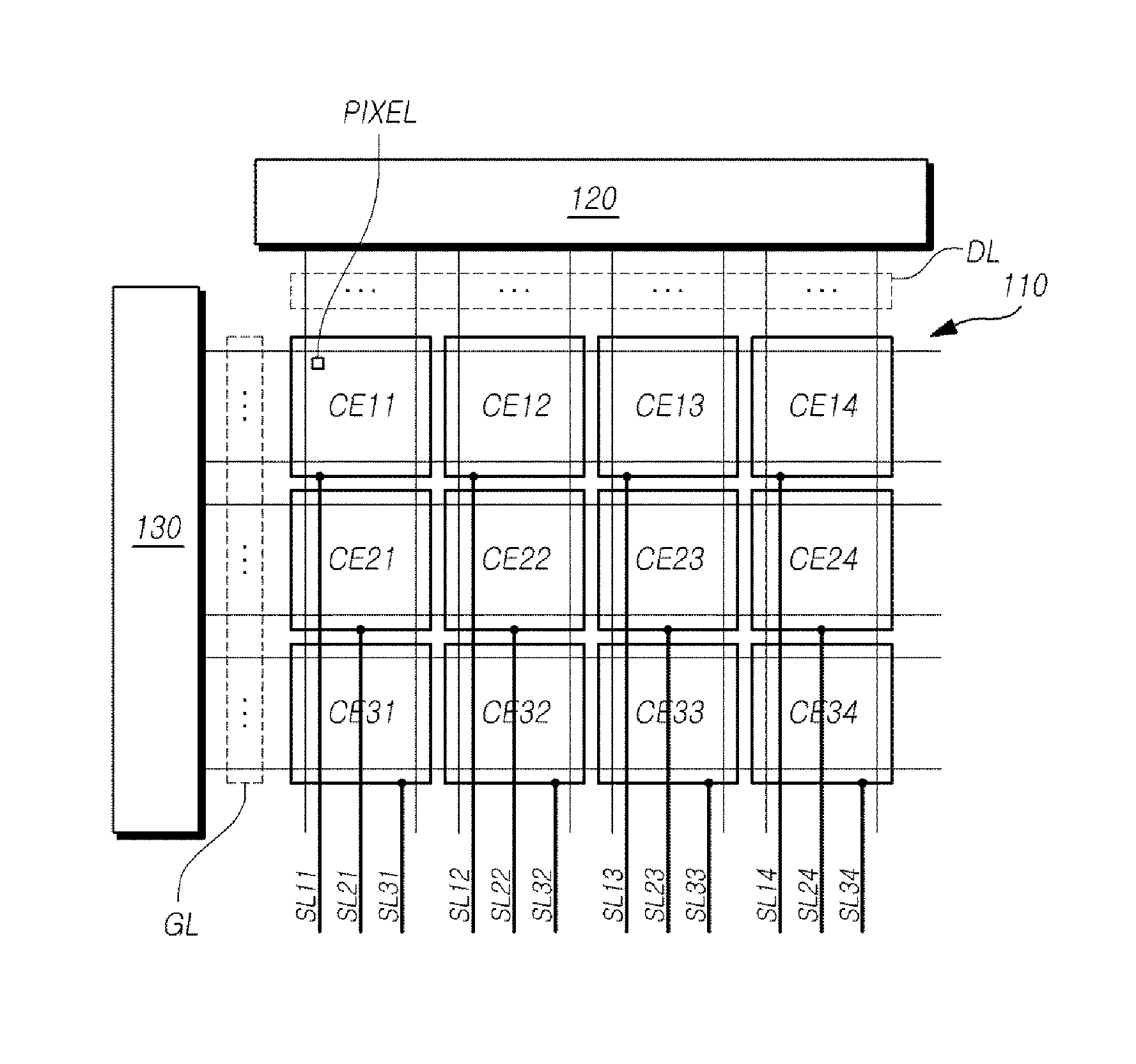

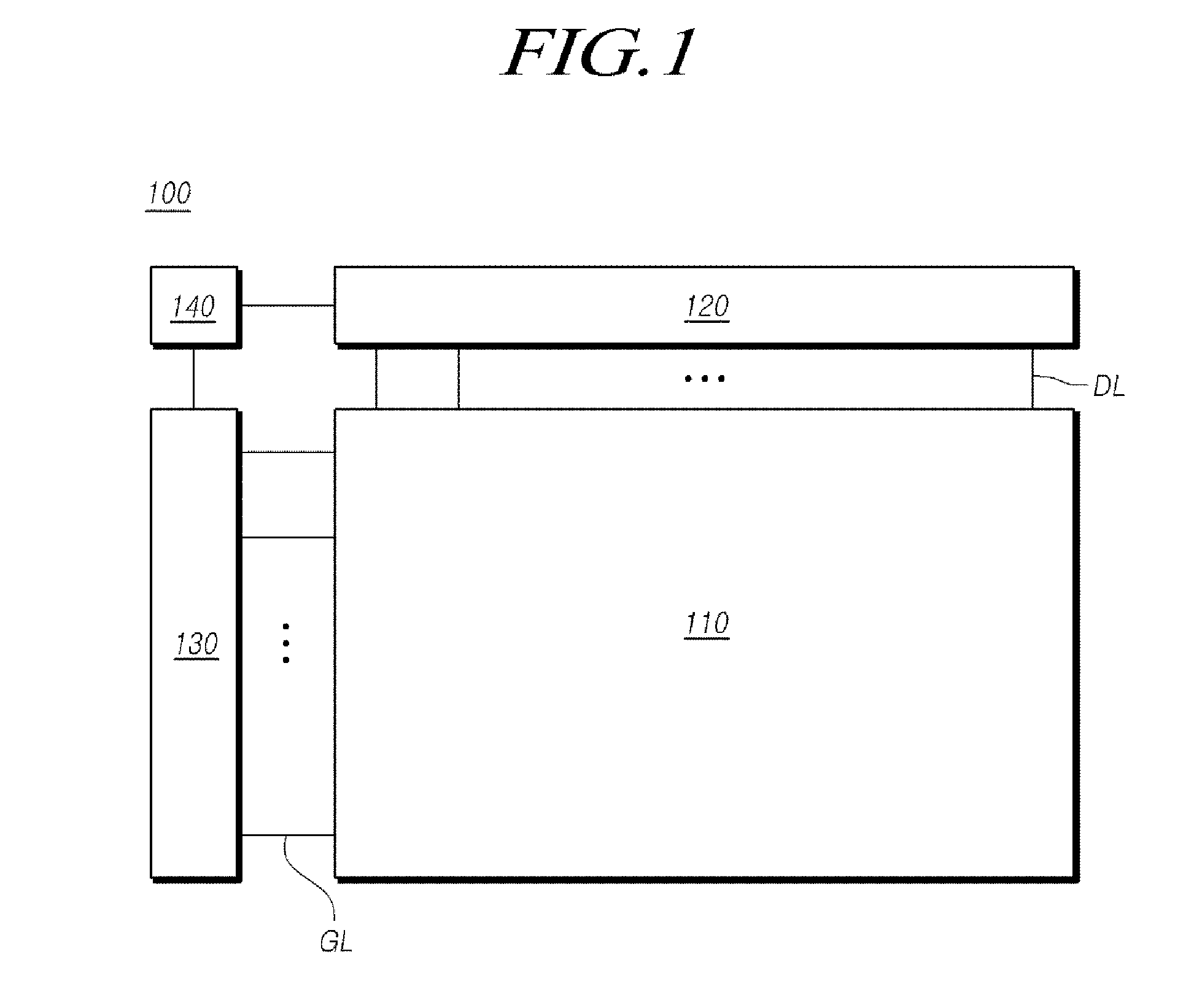

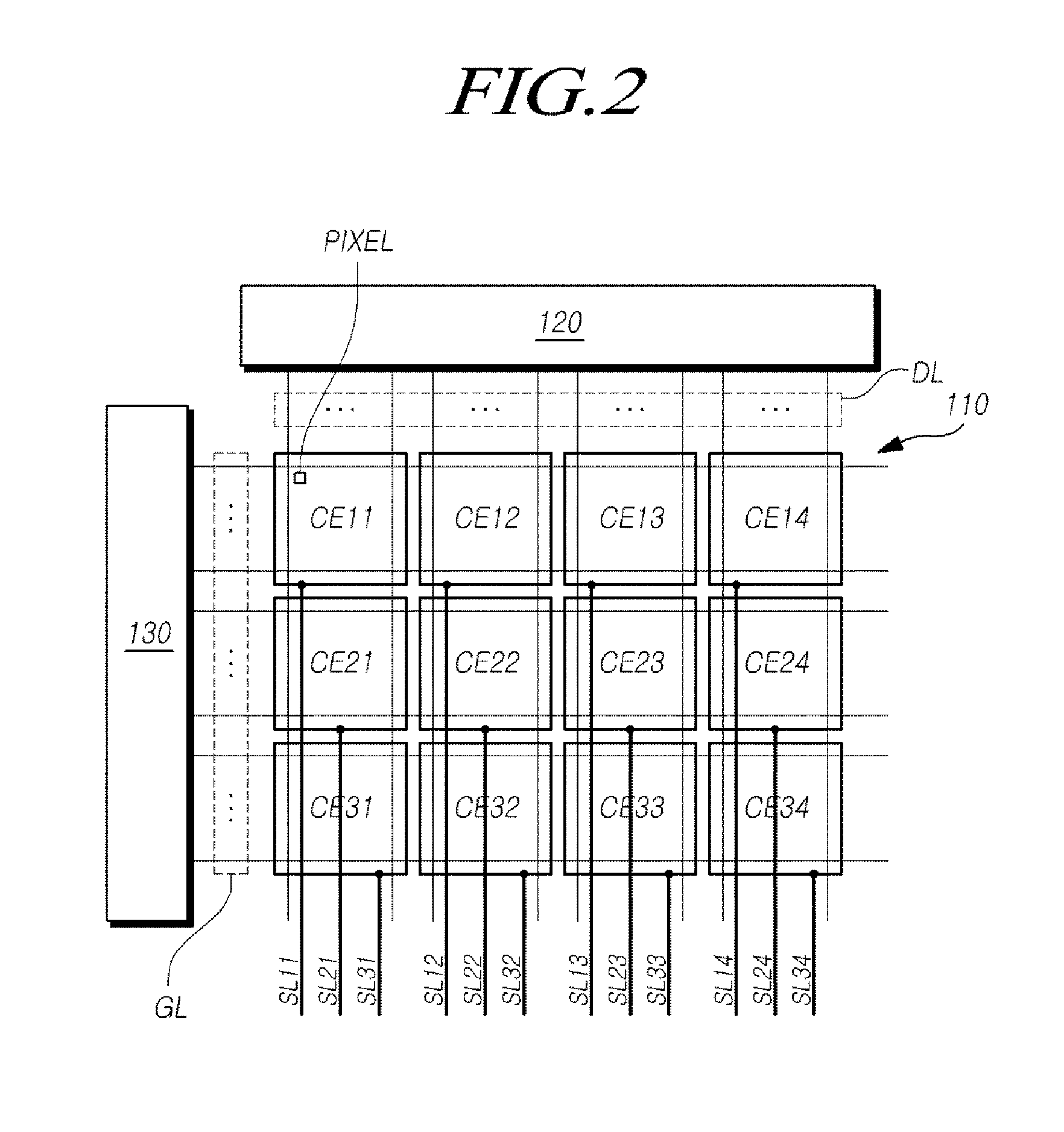

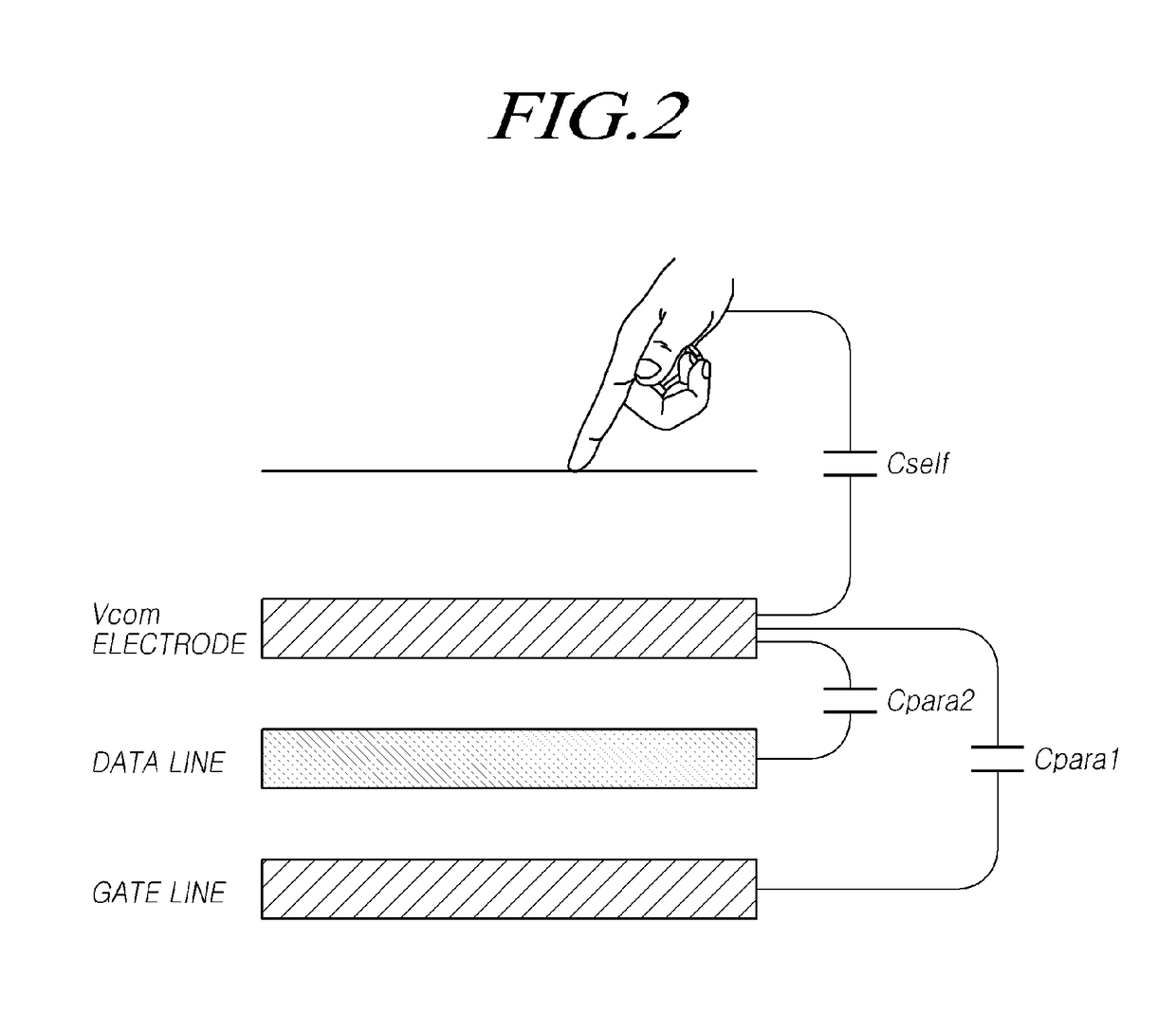

A display device integrated with a touch screen panel, and a method of driving the same, can prevent parasitic capacitance that would otherwise increase the load during a touch operation, lower the accuracy of touch sensing, or make touch sensing impossible. The display device includes data lines, gate lines, and a plurality of electrodes spaced apart from each other. A common voltage is applied to the electrodes in a display driving mode and a touch drive signal is applied to one or more of the electrodes in a touch driving mode. A data voltage is applied to the data lines in the display driving mode. A scan signal is supplied sequentially to the gate lines in the display driving mode and the touch drive signal or a signal corresponding to the touch drive signal is applied to one or more of the gate lines in the touch driving mode.

Owner:LG DISPLAY CO LTD

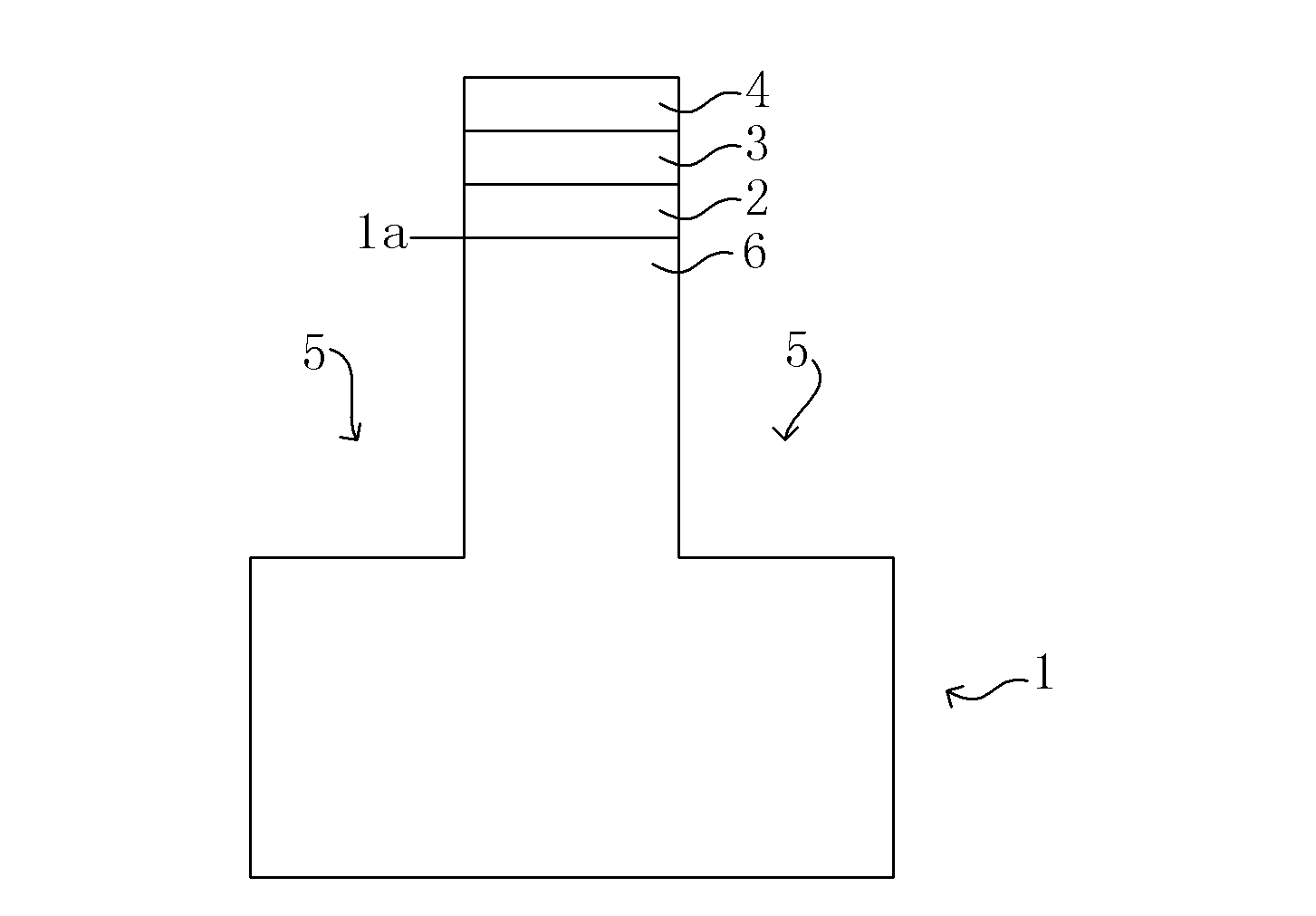

Semiconductor device having MIM structure resistor

ActiveUS20050082639A1Improved high-frequency characteristicImprove featuresTransistorSemiconductor/solid-state device detailsCapacitanceElectrical resistance and conductance

As for the resistor on the semiconductor substrate, it is required to achieve obtaining a metal resistor, which can be formed in the latter half of a preliminary process for manufacturing a semiconductor, in addition to forming a polysilicon resistor, which is formed in the first half of the preliminary process. A capacitor having MIM structure includes a lower electrode, a capacitive insulating film and an upper electrode, all of which are sequentially formed in this sequence. A resistor structure having MIM structure also includes a lower electrode, a capacitive insulating film and a resistor, all of which are sequentially formed in this sequence. In this case, the biasing conditions thereof should be selected so that the resistor structure lower electrode of the MIM structure resistor is not coupled to any electric potential, and is in a floating condition.

Owner:RENESAS ELECTRONICS CORP

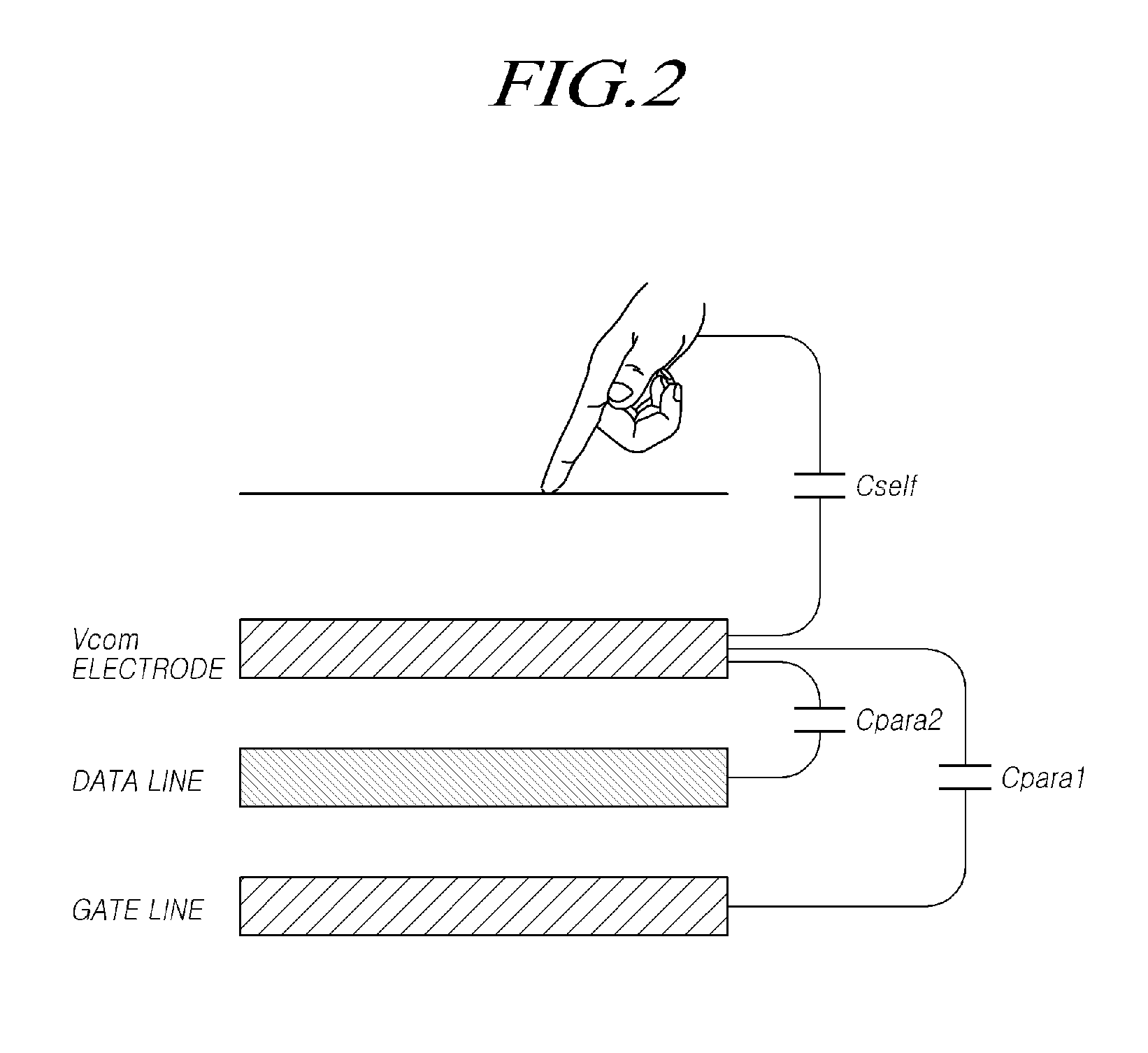

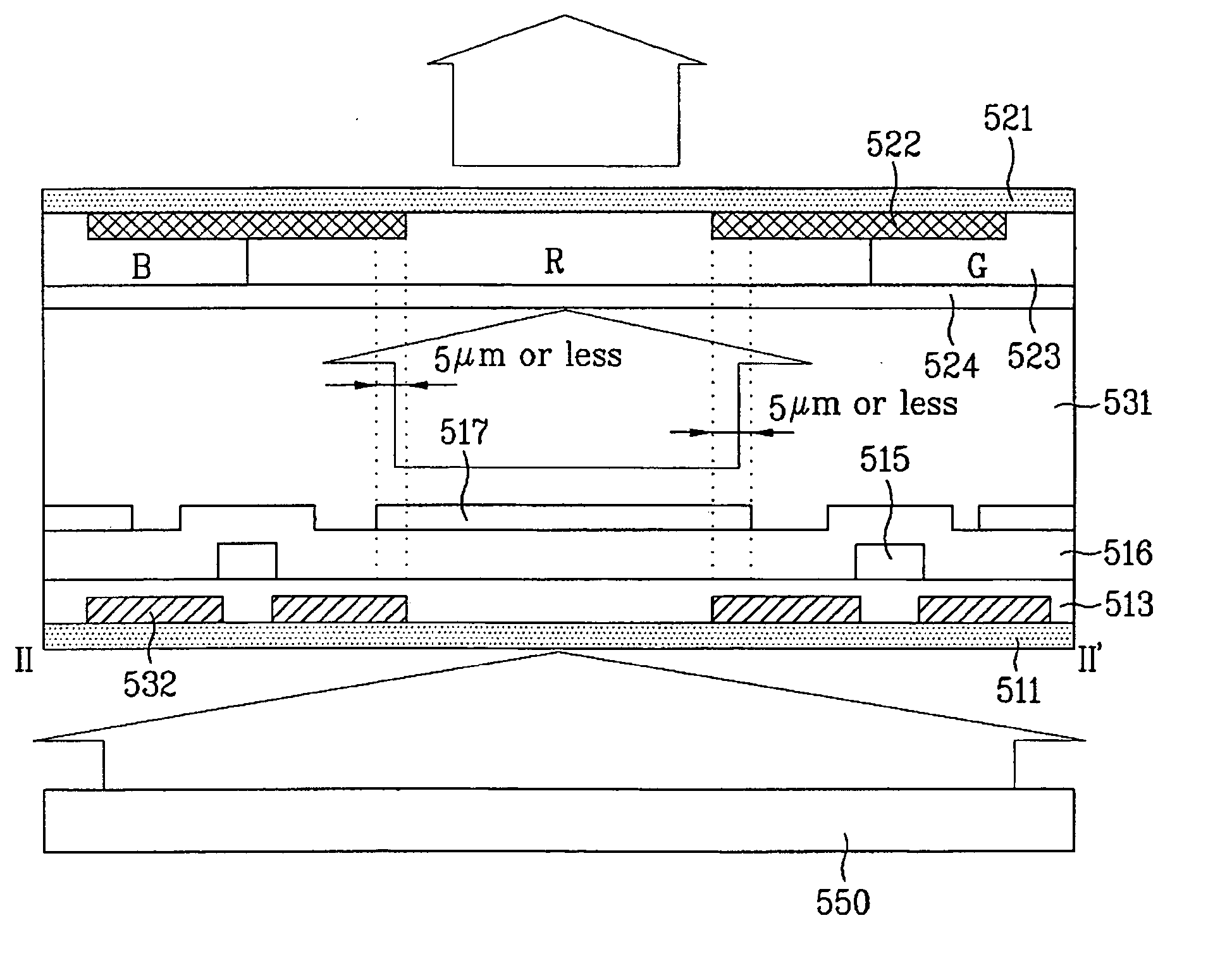

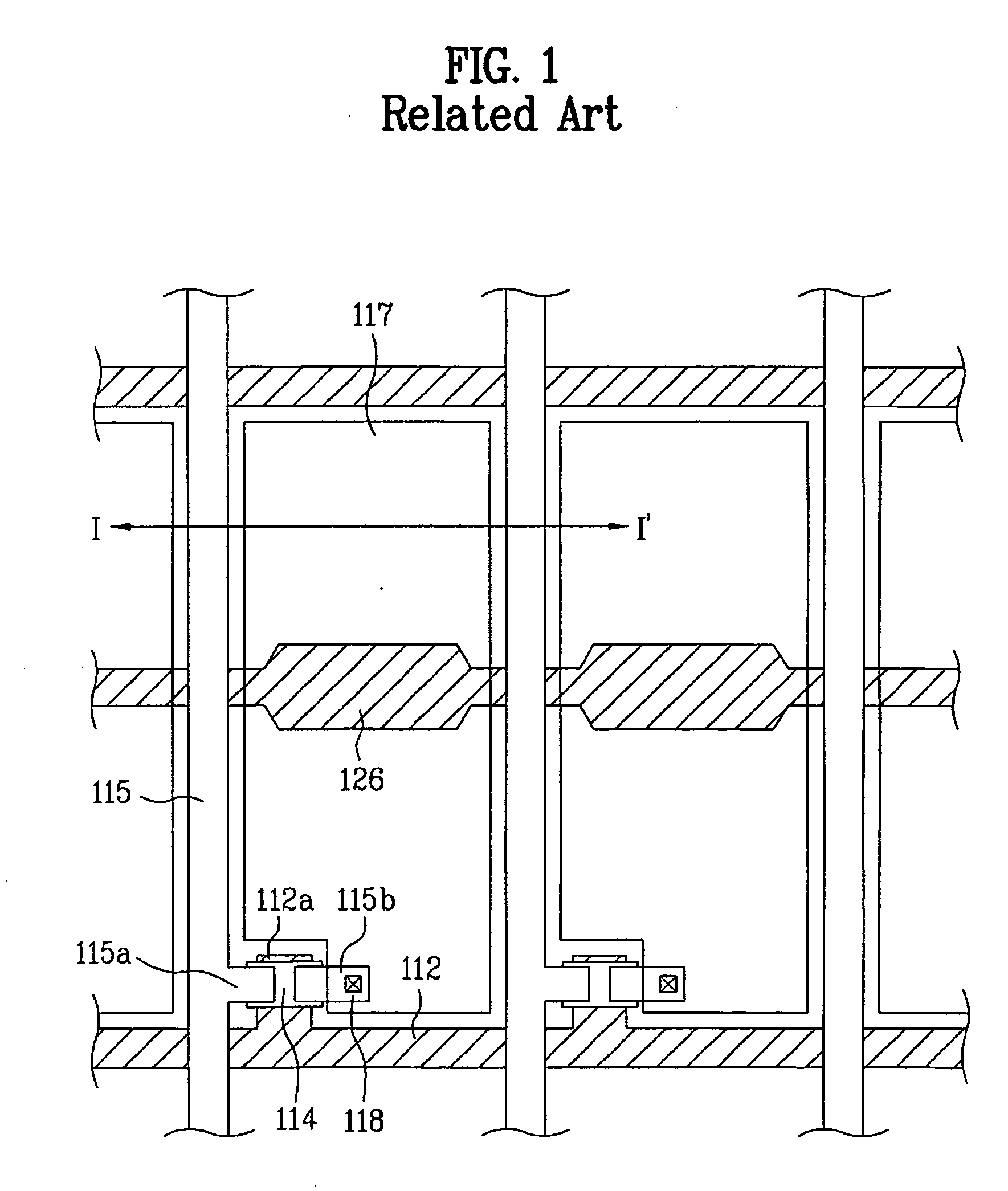

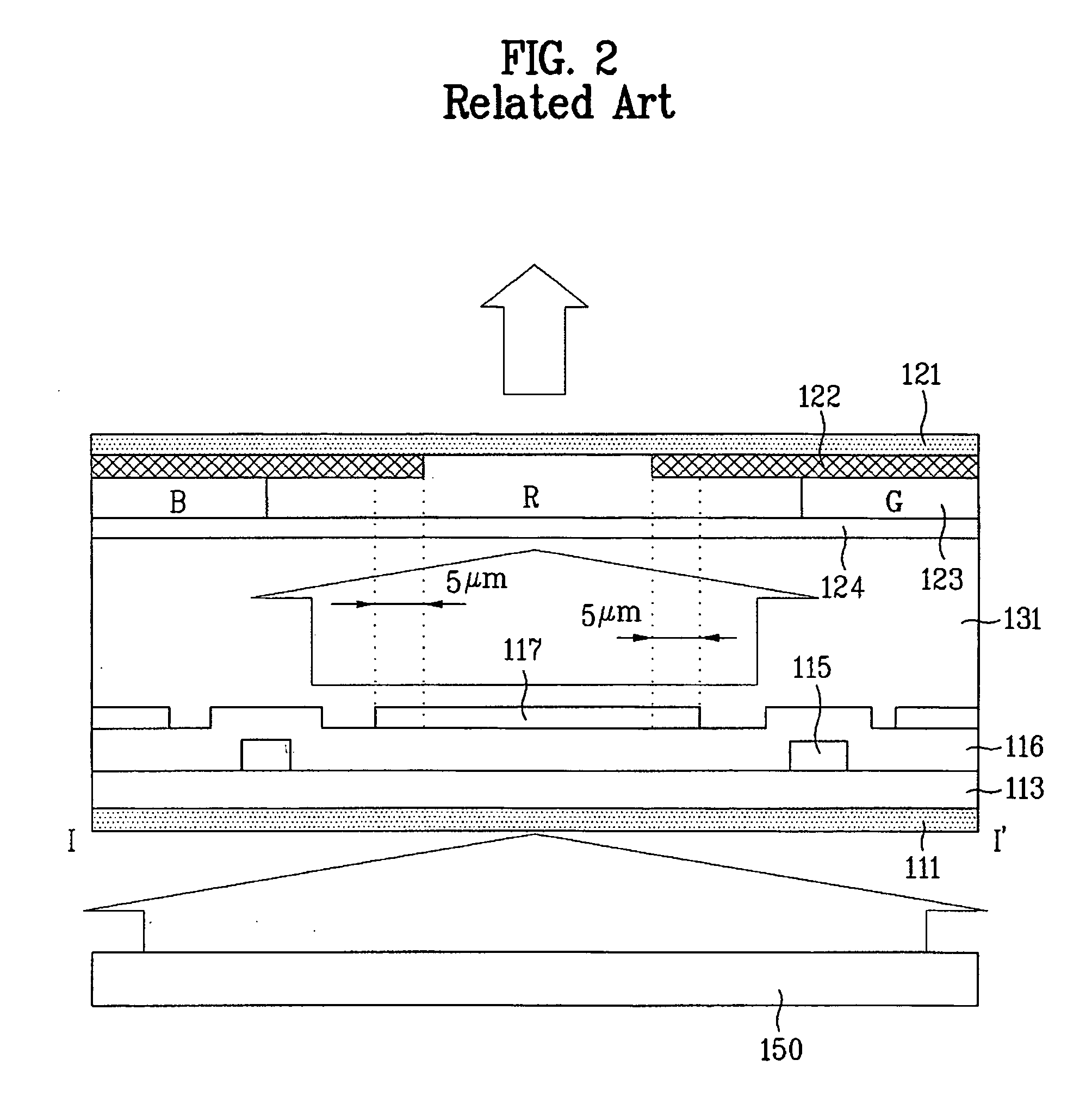

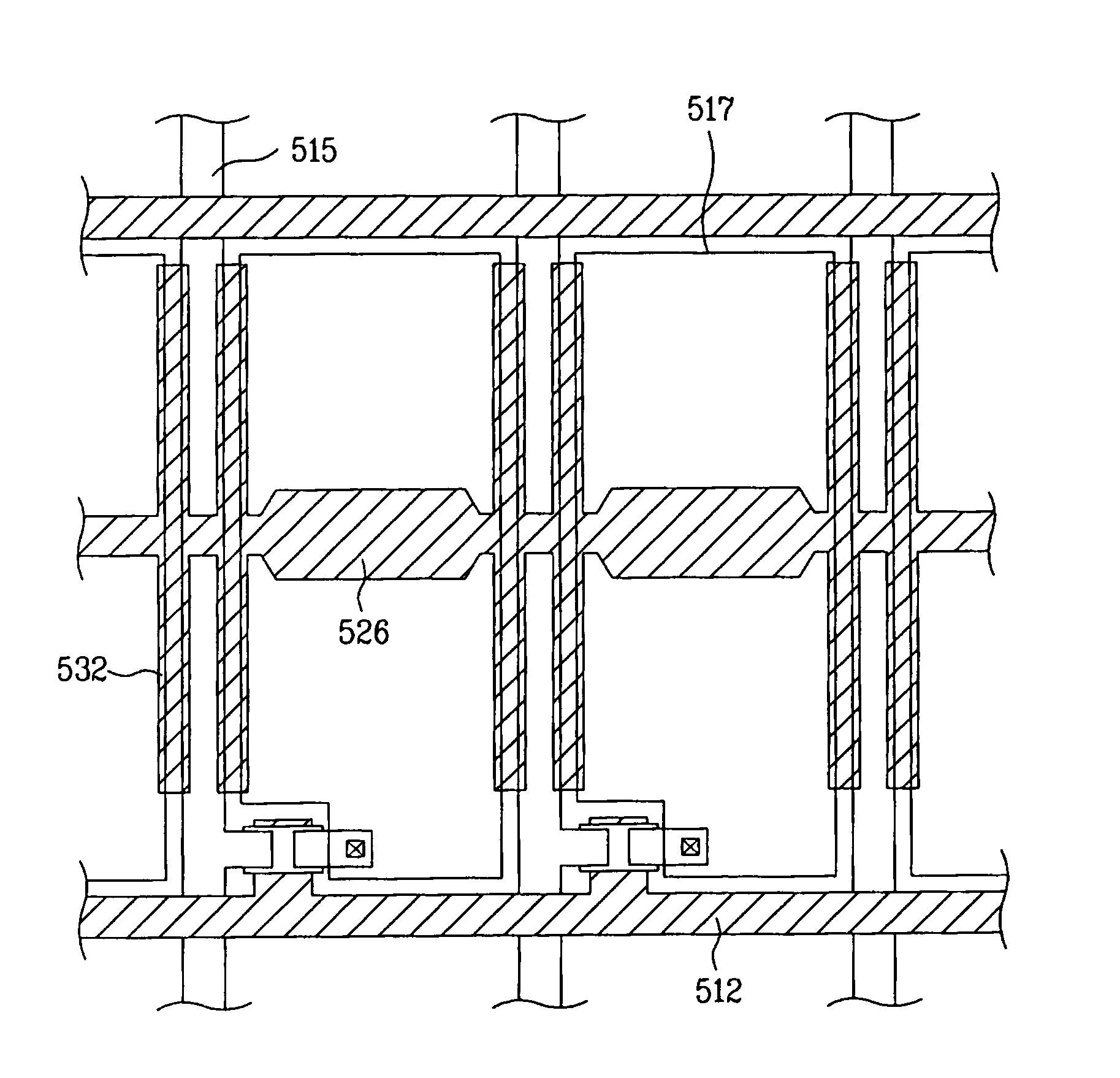

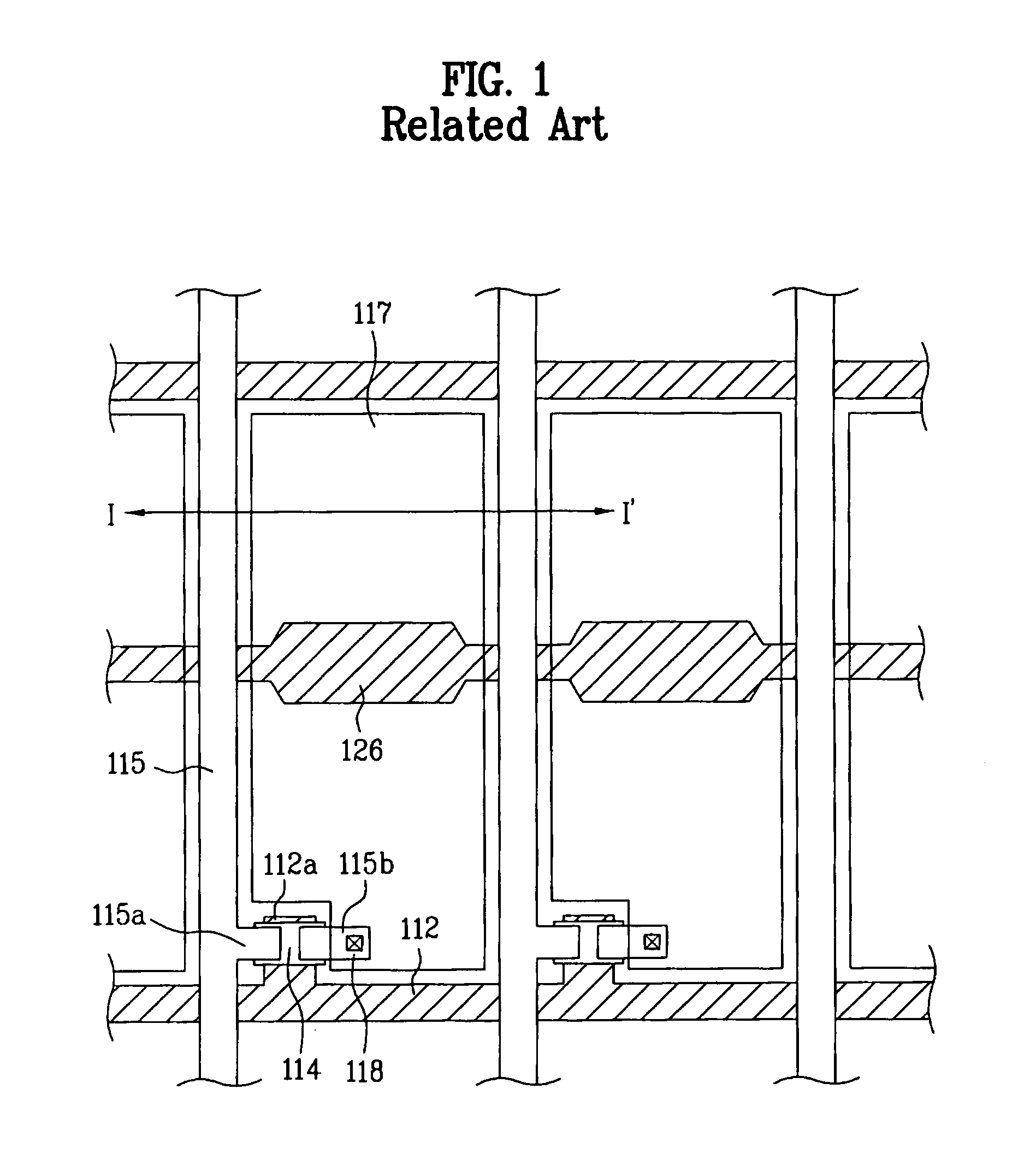

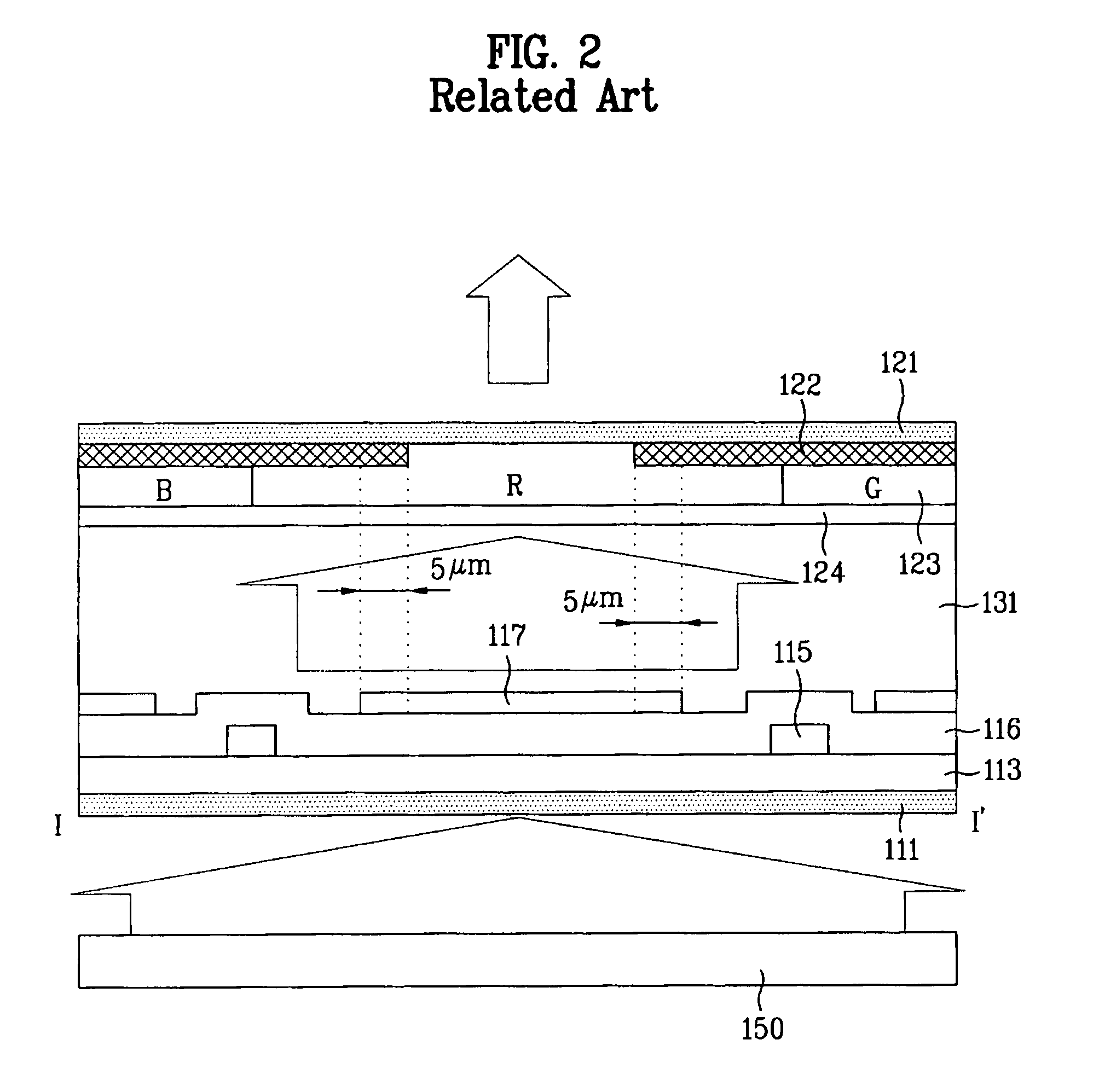

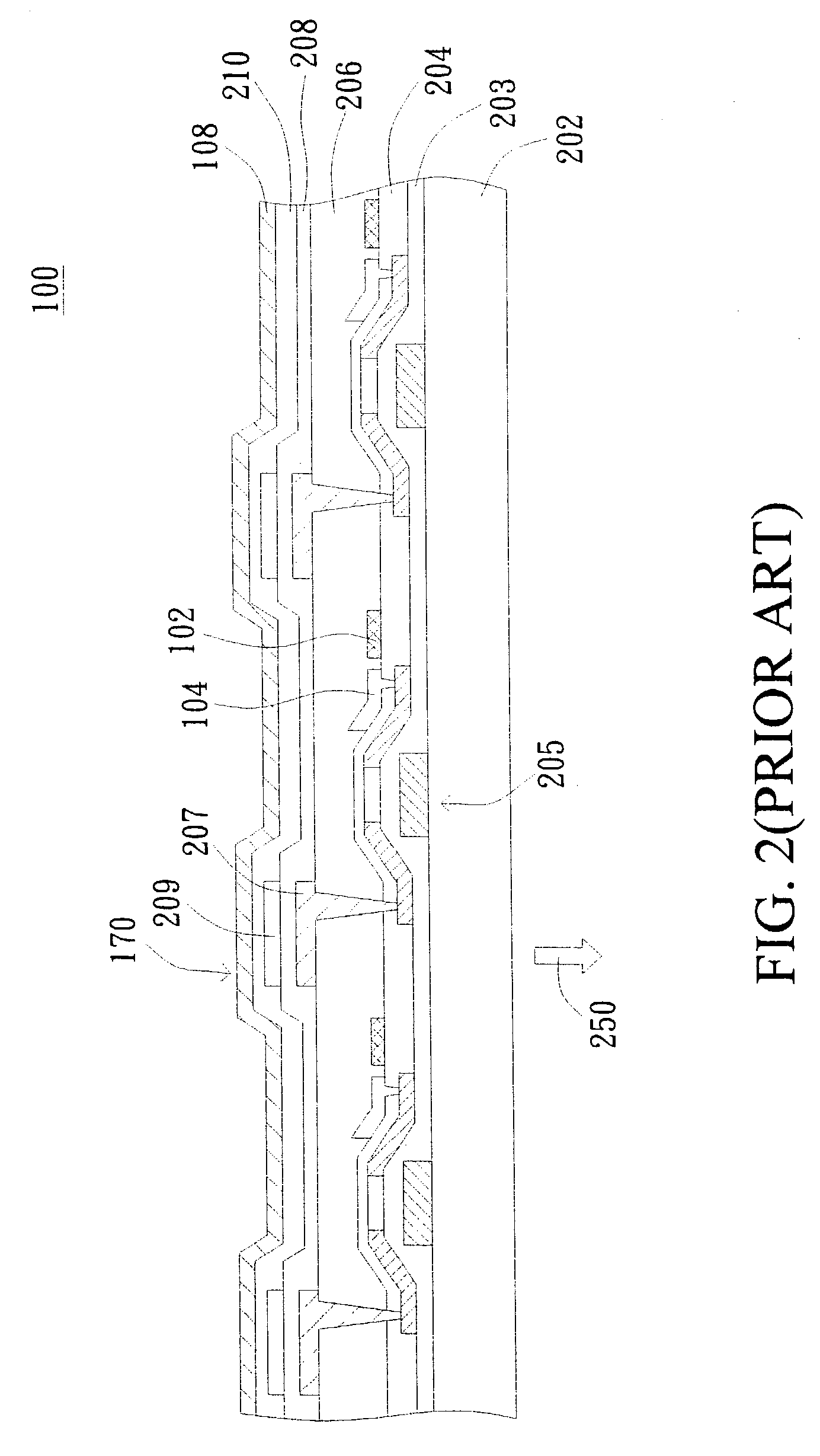

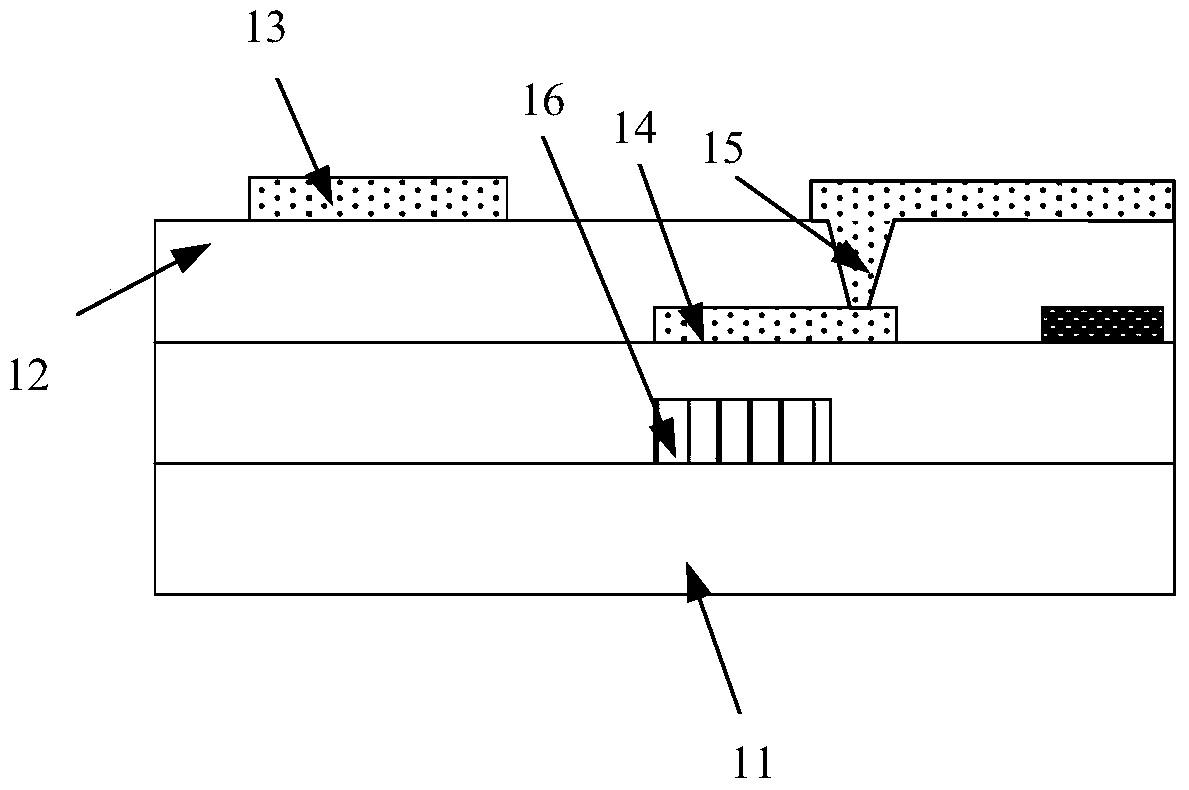

Liquid crystal display device

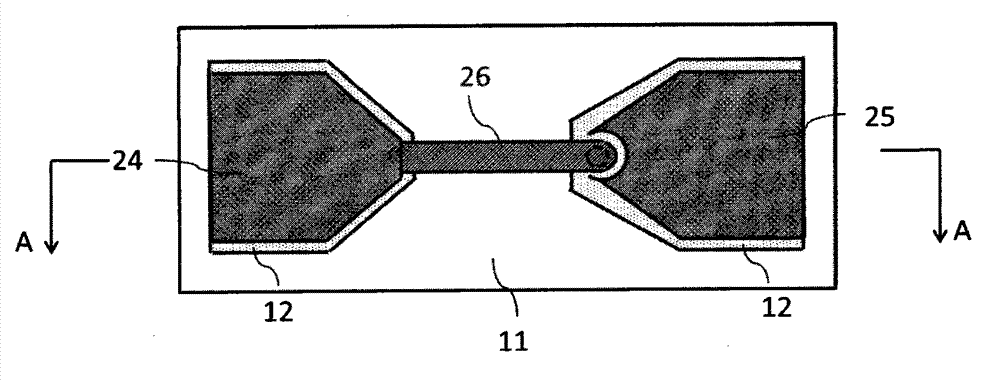

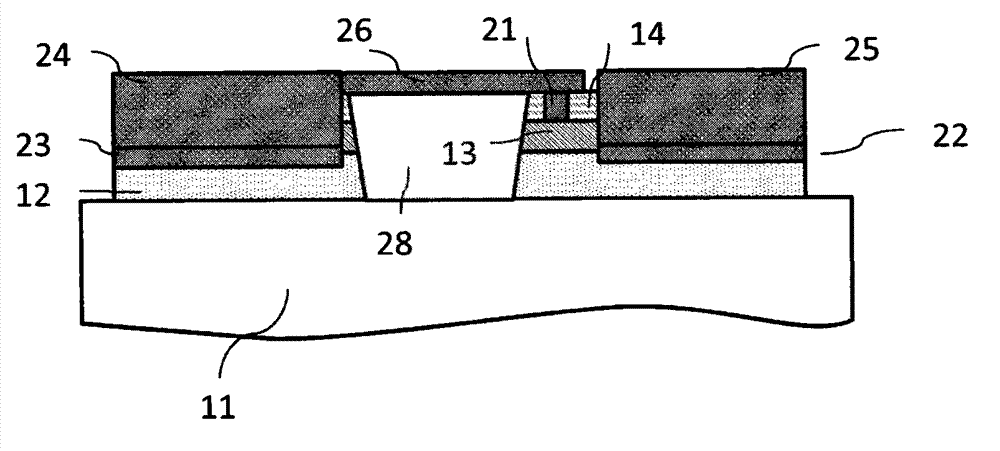

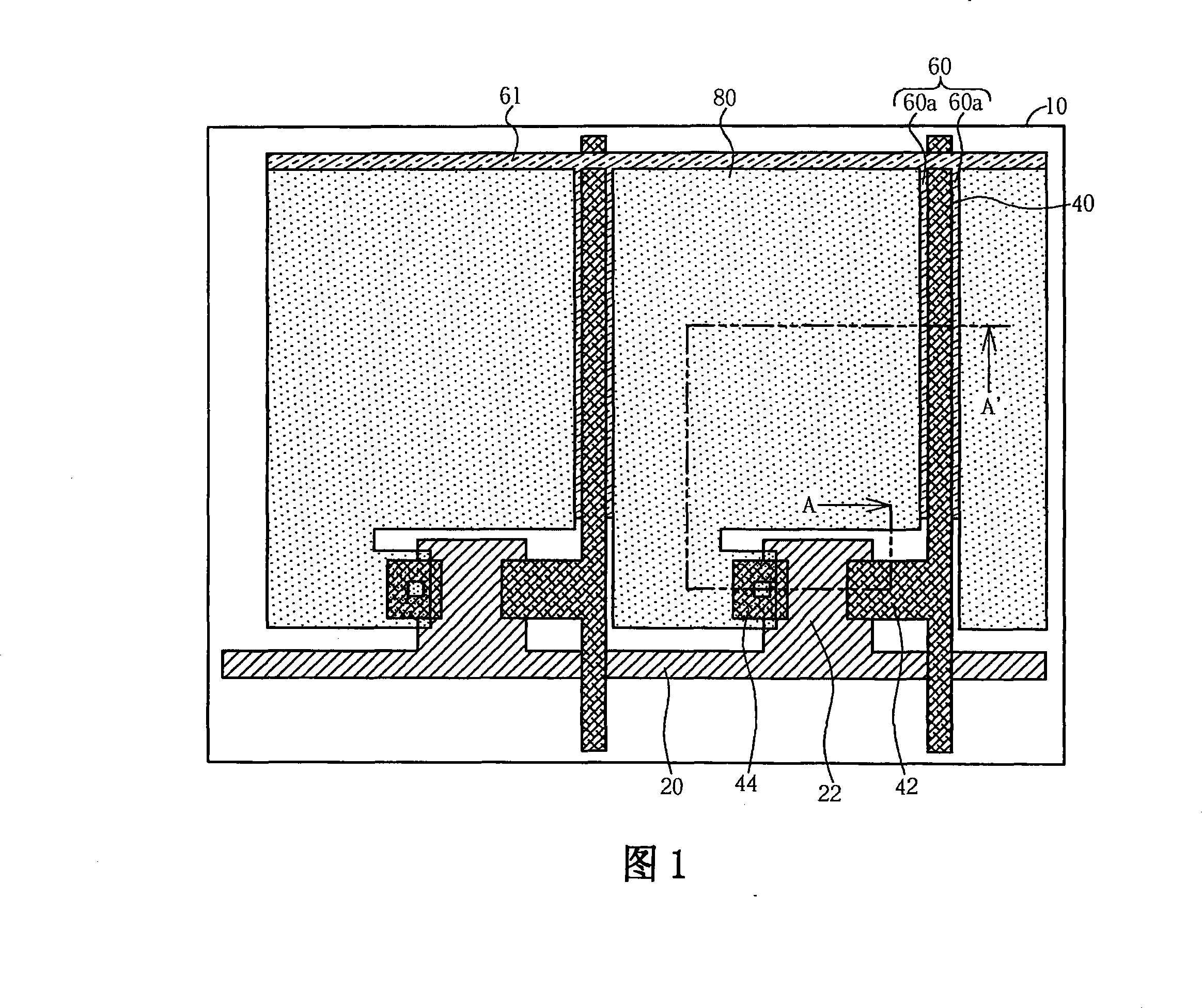

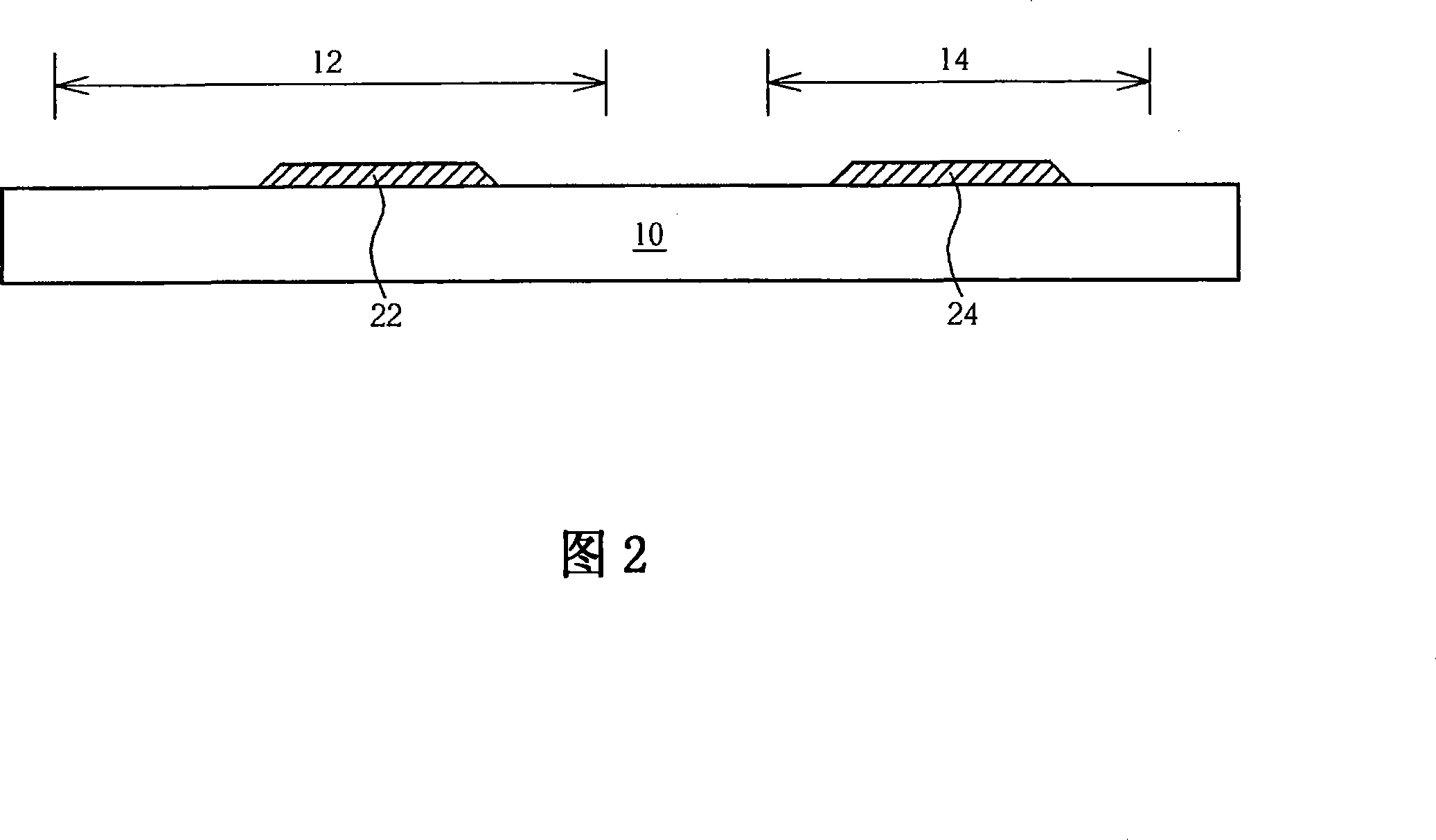

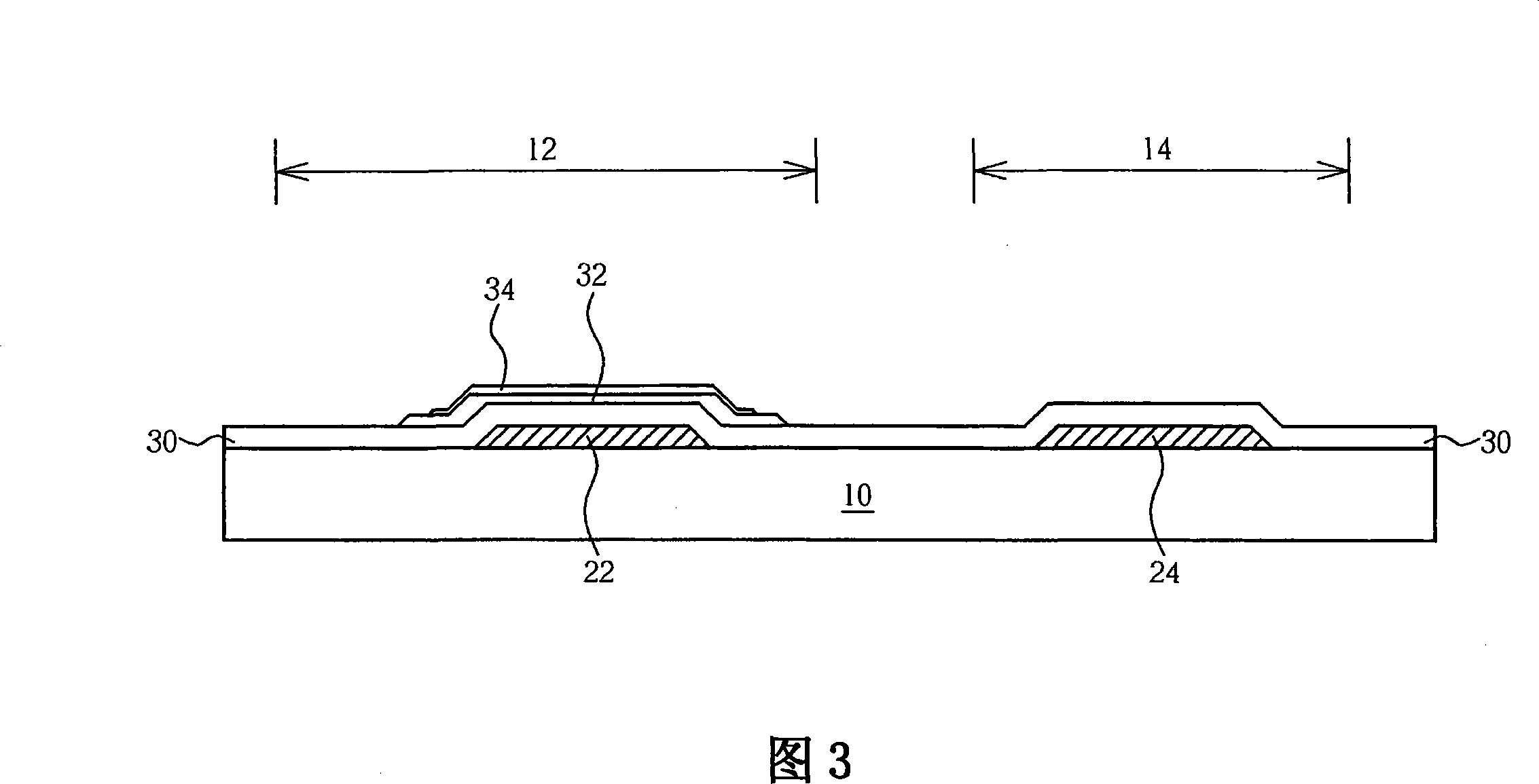

ActiveUS20050219436A1High resolutionHigh optical densityOther workshop equipmentNon-linear opticsLiquid-crystal displayParasitic capacitance

An LCD device with improved an aperture ratio and decreased parasitic capacitance has a passivation layer of an inorganic material and which includes a gate line on a first substrate; a gate insulating layer on an entire surface of the first substrate including the gate line; a data line on the gate insulating layer in perpendicular to the gate line, to define a pixel region; a thin film transistor at a crossing portion of the gate and data lines; a passivation layer on the entire surface of the first substrate including the thin film transistor; a pixel electrode on the passivation layer, for being connected with a drain electrode of the thin film transistor; and a light-shielding metal for receiving a voltage, formed between the data line and the pixel electrode, to prevent a parasitic capacitance between the data line and the pixel electrode.

Owner:LG DISPLAY CO LTD

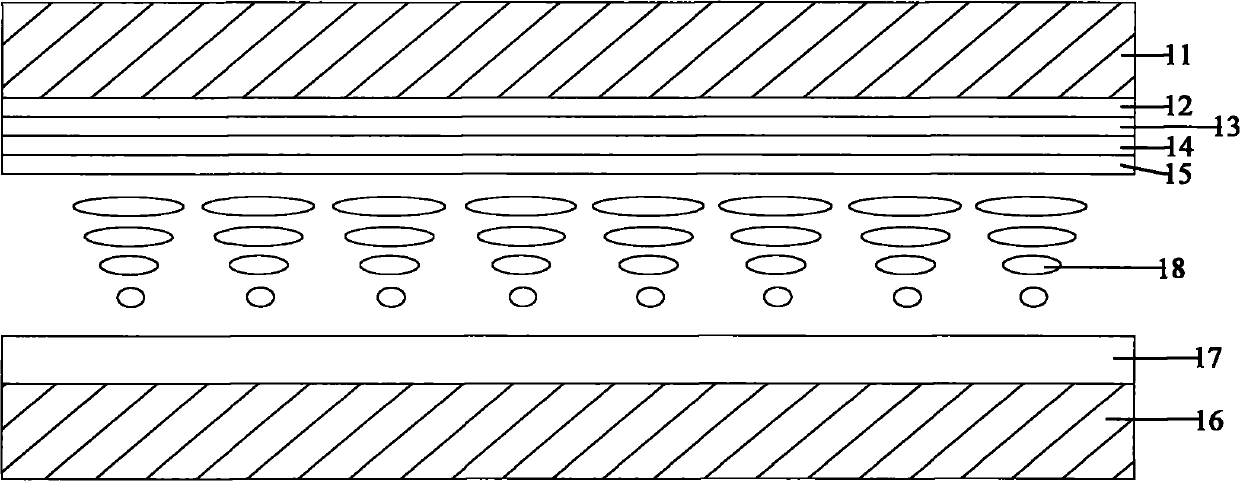

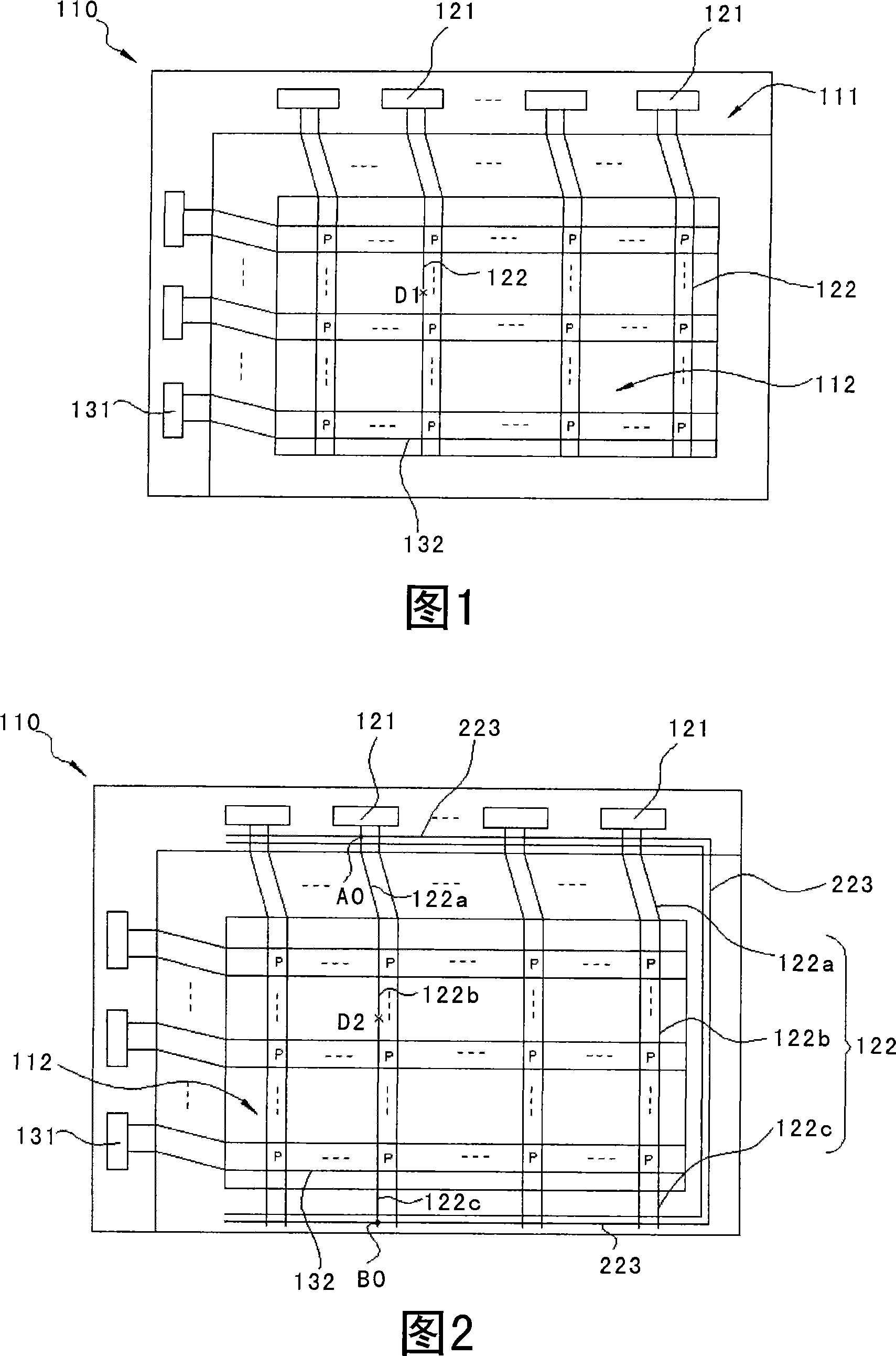

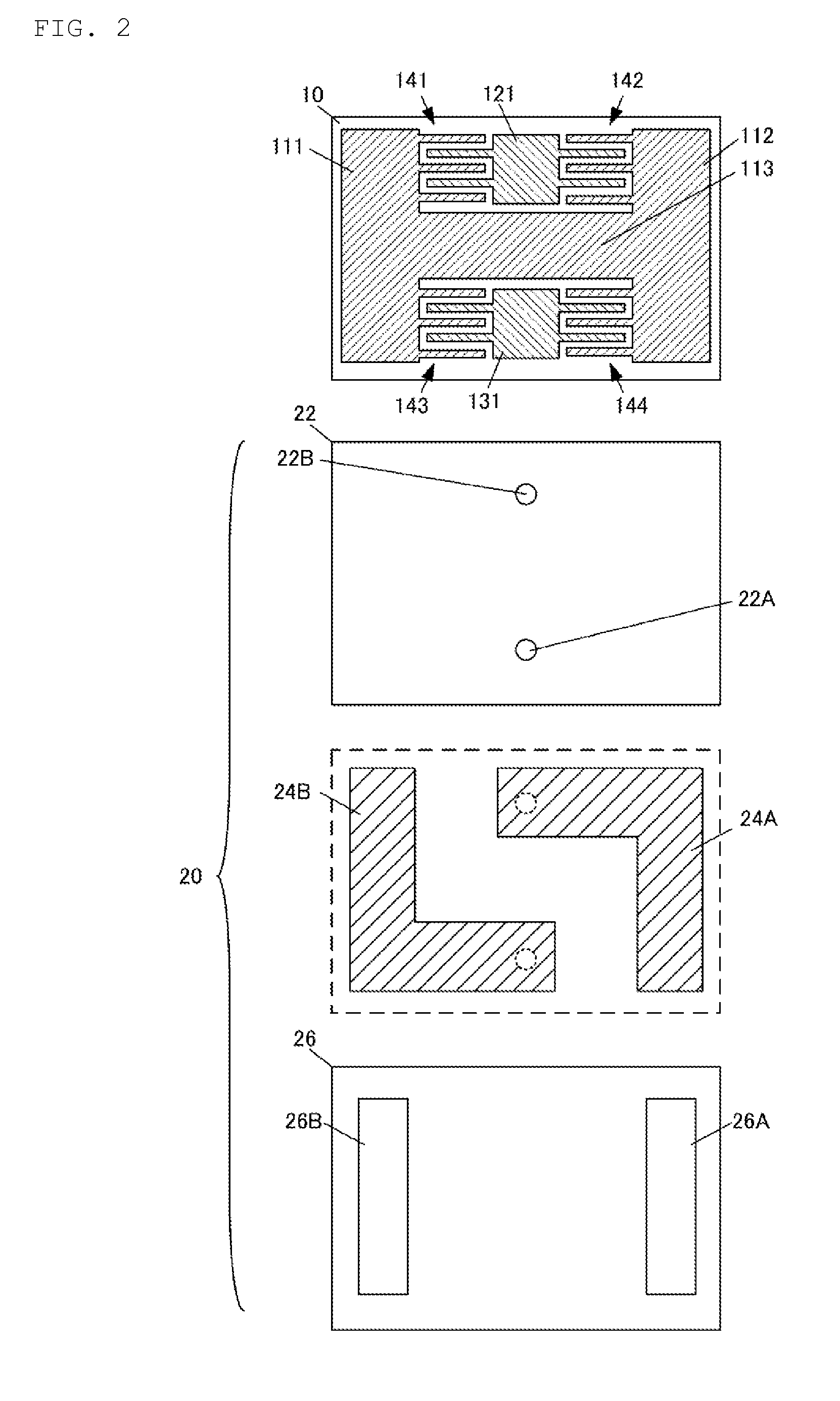

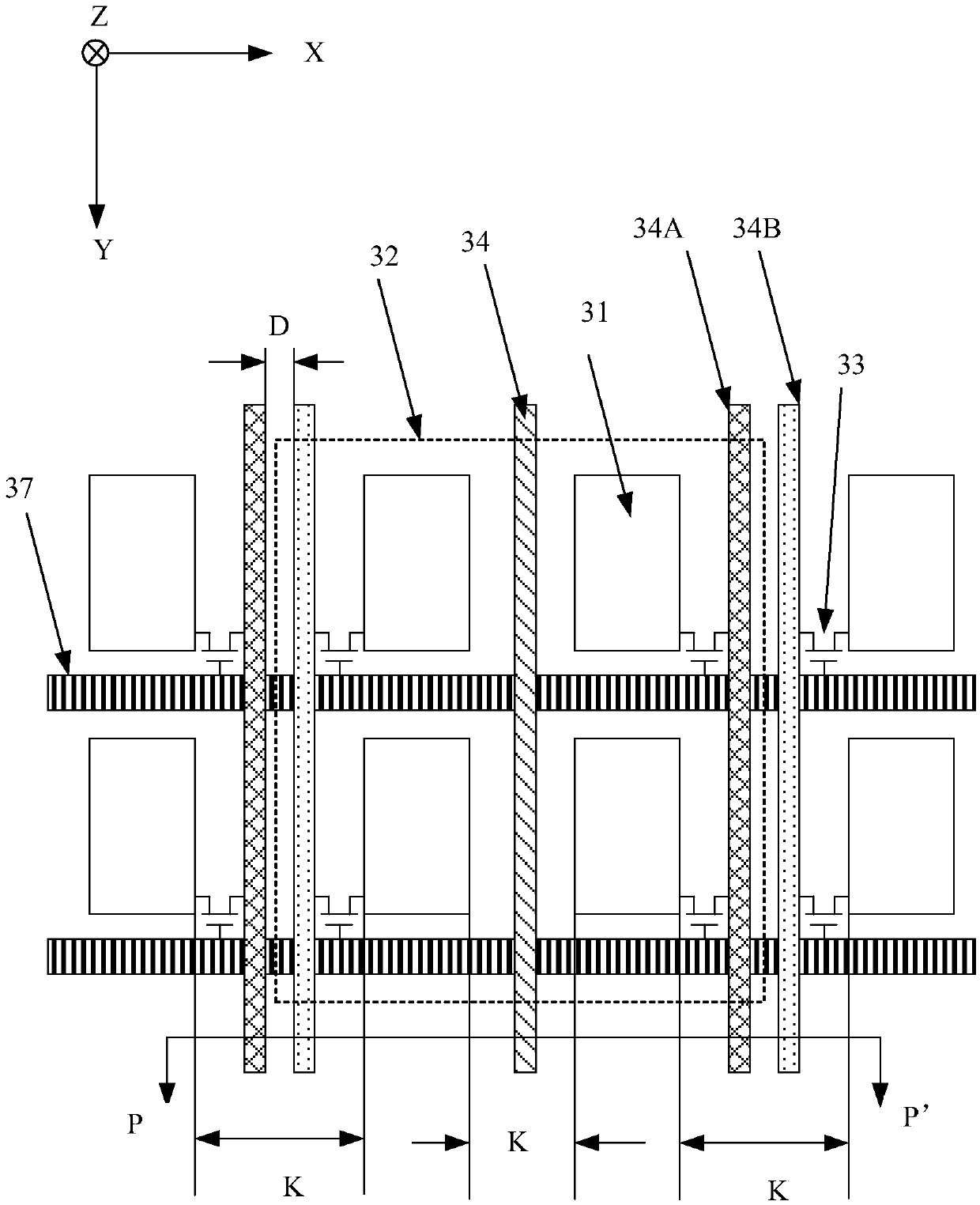

Mutual capacitance touch sensor , detection method thereof and touch display device

ActiveCN102200866AReduce parasitic capacitanceIncreasing the thicknessInput/output processes for data processingDisplay deviceParasitic capacitance

The invention provides a mutual capacitance touch sensor comprising a glass baseplate, a plurality of drive wires and a plurality of sensing wires, wherein the drive wires and the sensing wires are positioned on the glass baseplate. Mutual capacitance is formed between the driving wires and the sensing wires. The mutual capacitance touch sensor also comprises a printed circuit board positioned outside the glass baseplate, wherein extension parts of the driving wires and the sensing wires, and a plurality of metal bridges for connecting the extension parts of all the driving wires are formed on the printed circuit board. The invention also provides a detection method of the mutual capacitance touch sensor and a touch display device. According to the mutual capacitance touch sensor disclosed by invention, parasitic capacitance generated by the bridge joint of metal conductors can be reduced so as to further enhance the sensitivity of the touch sensor.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

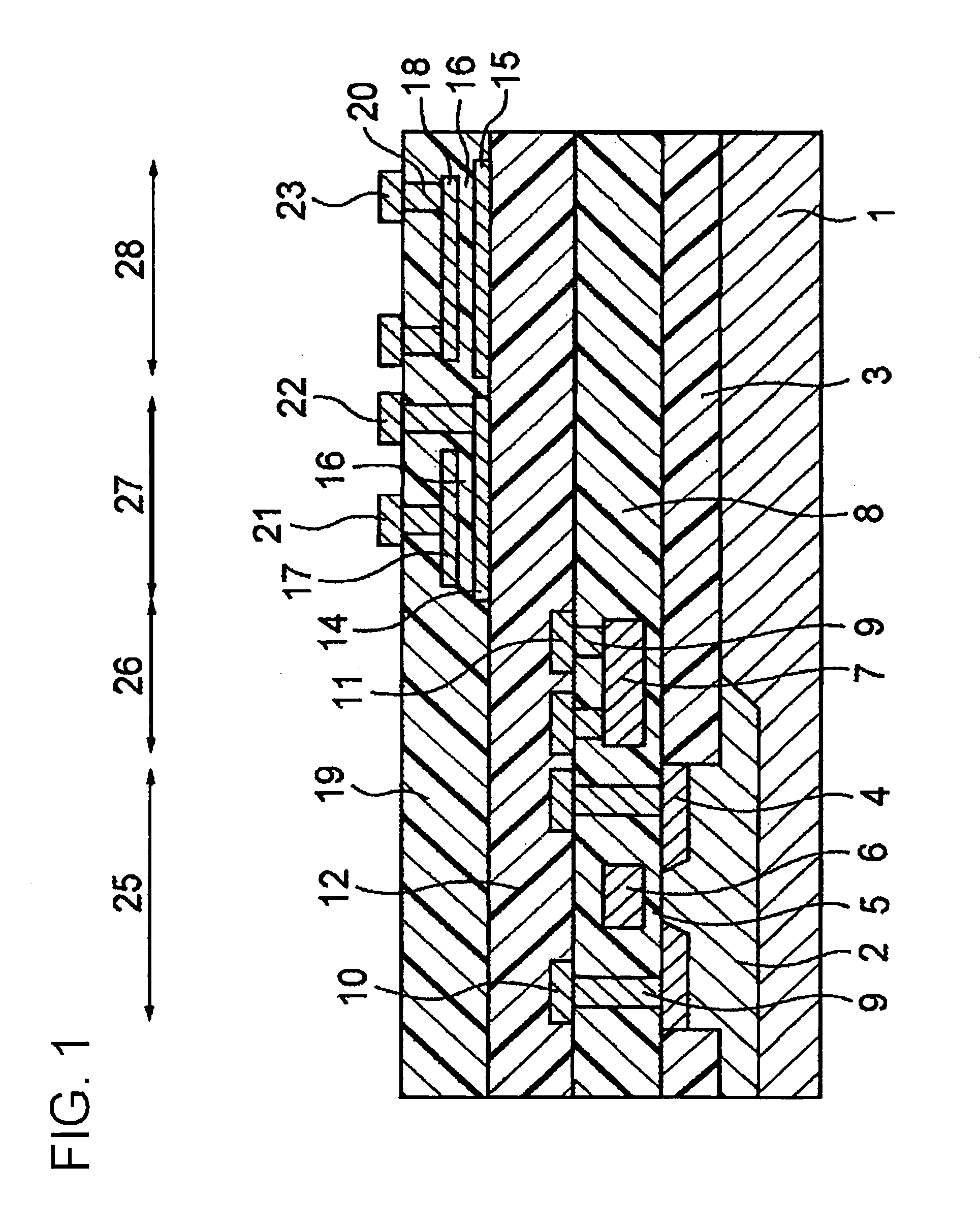

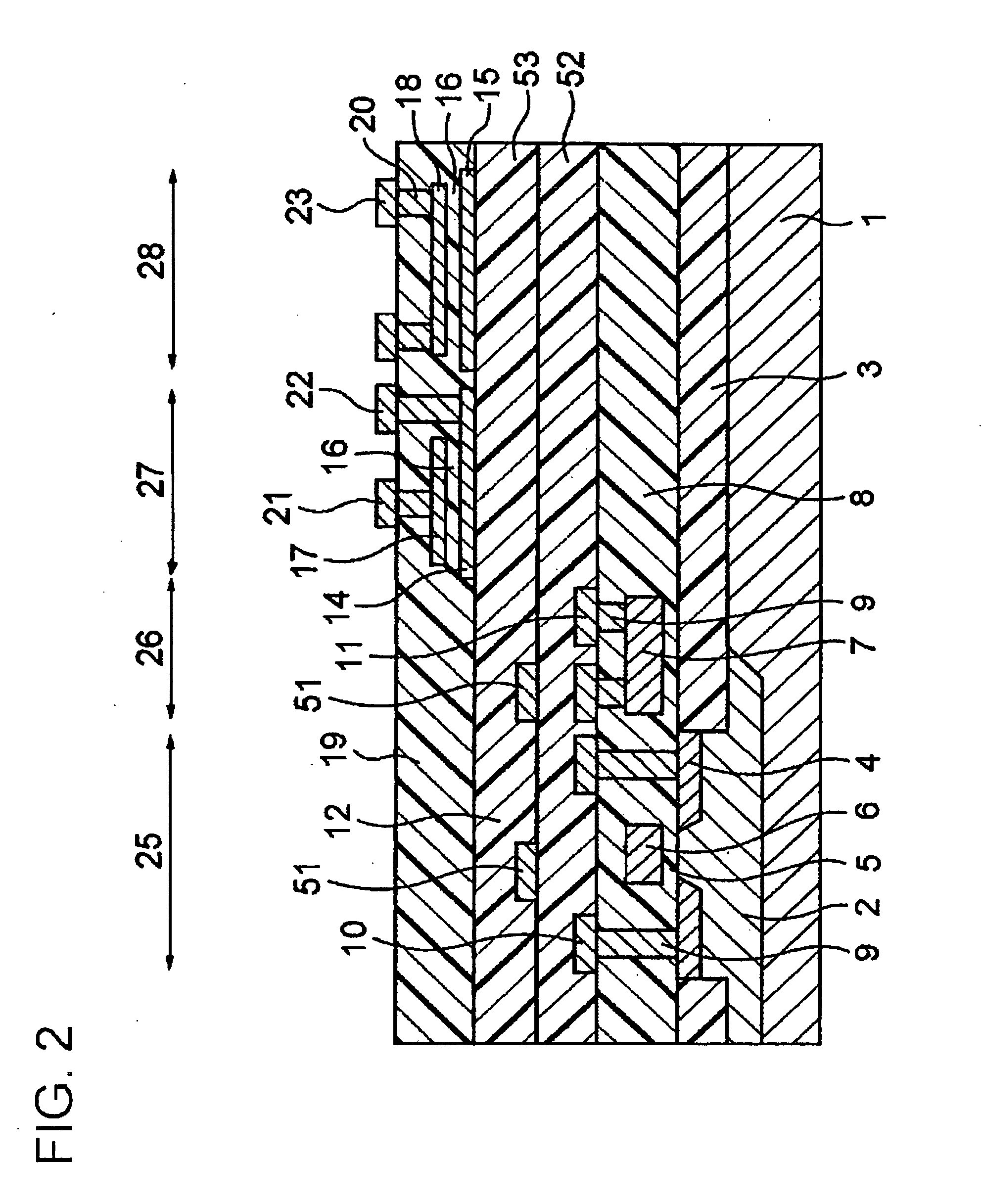

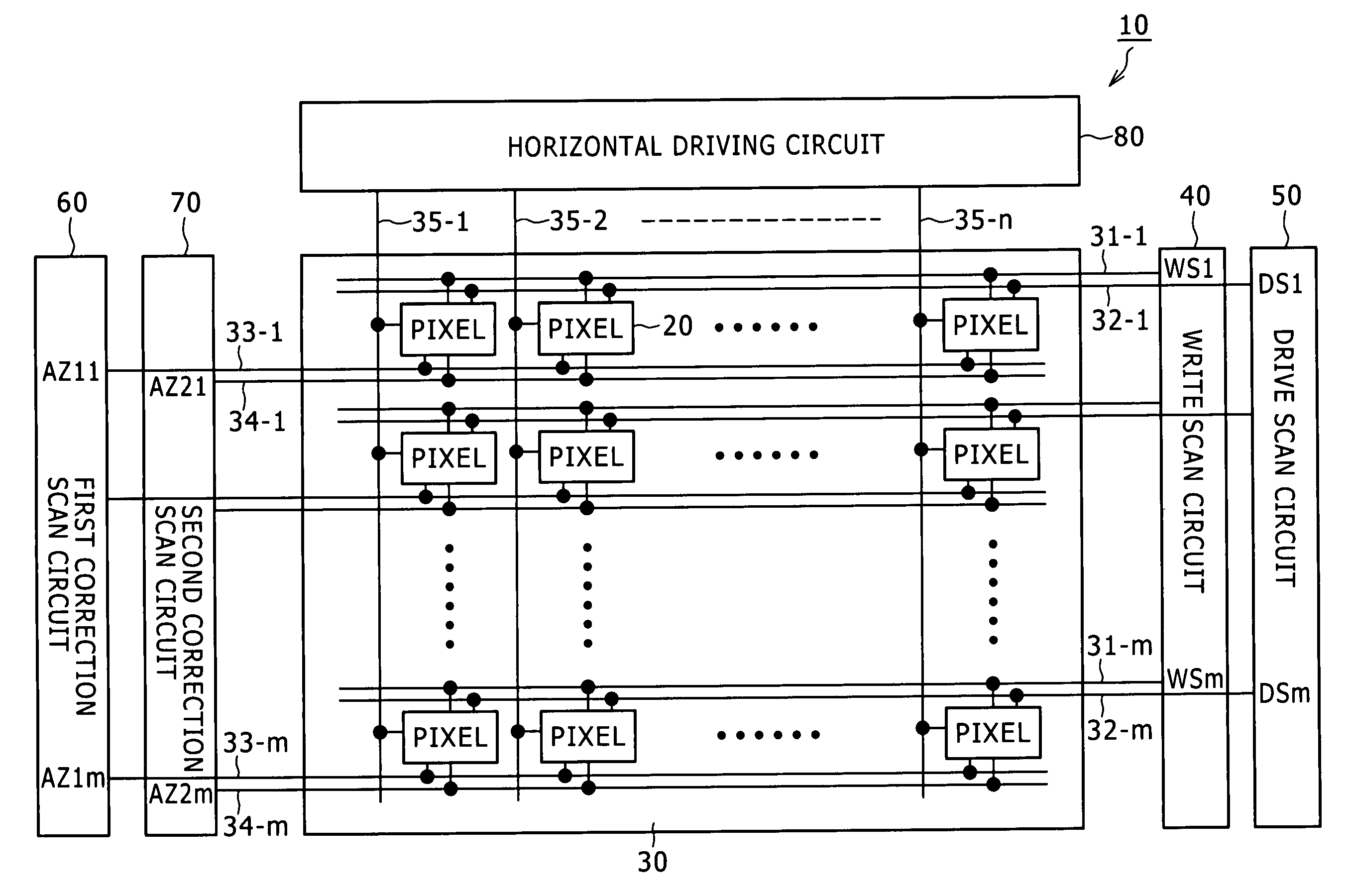

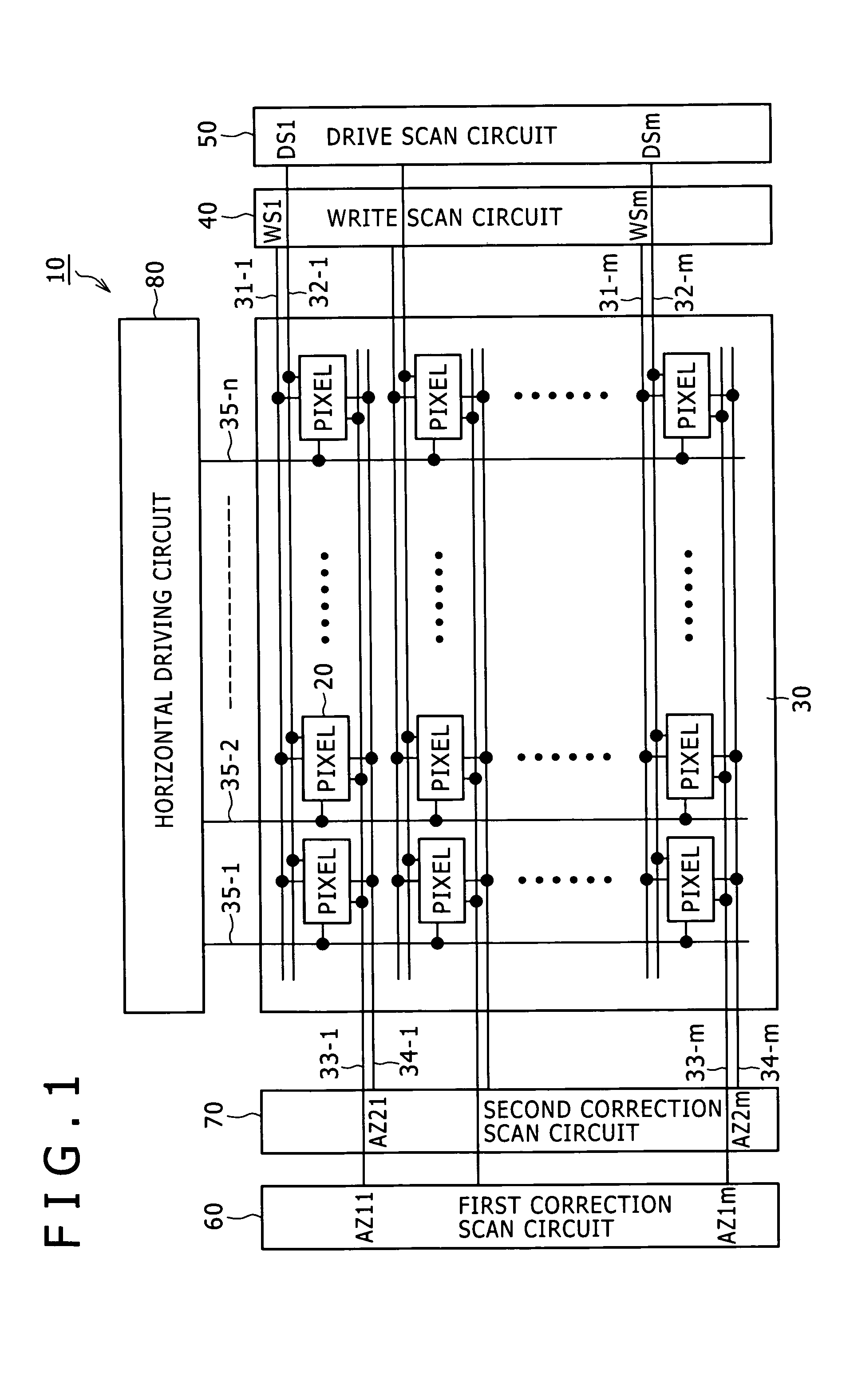

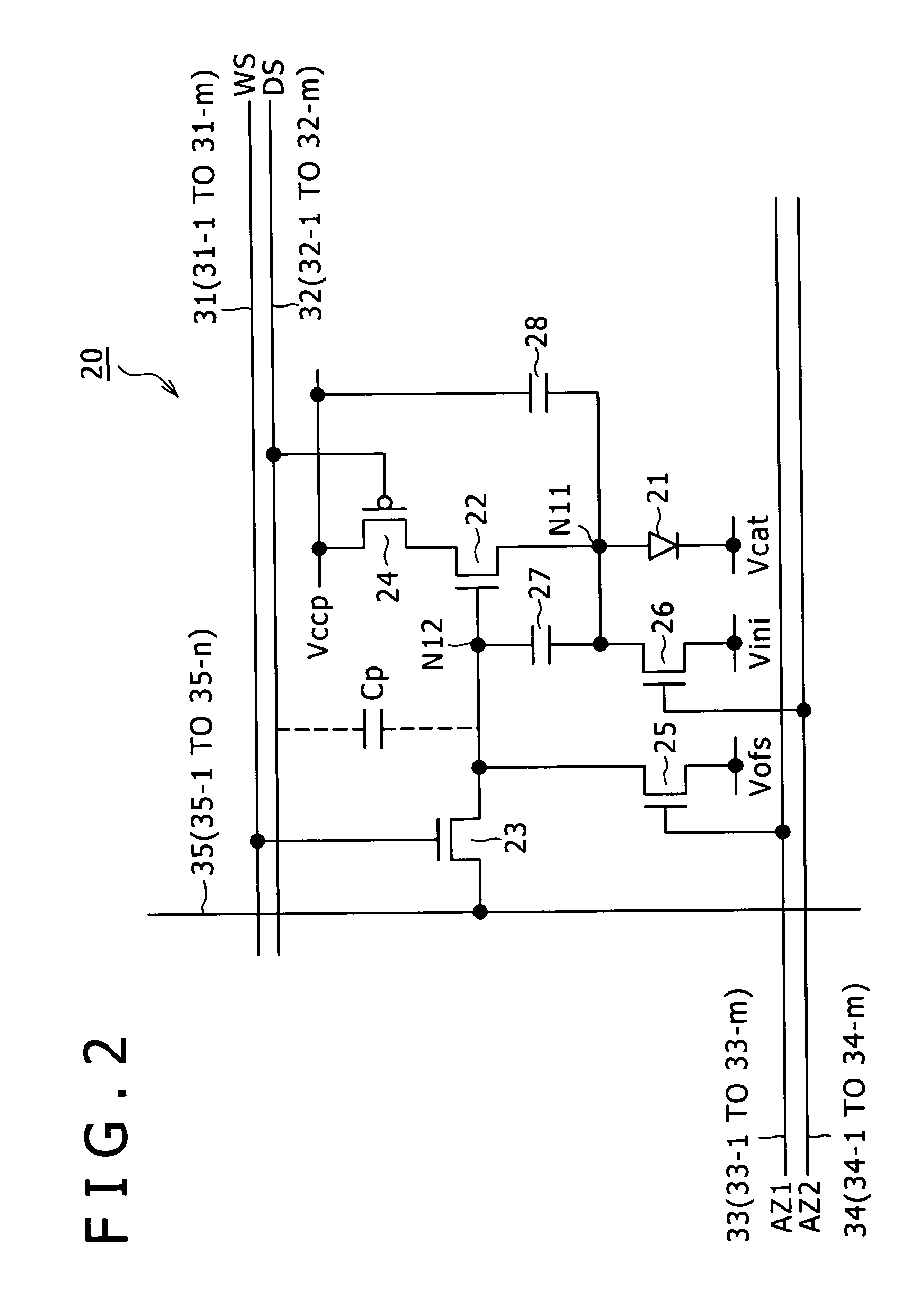

Display device and electronic equipment

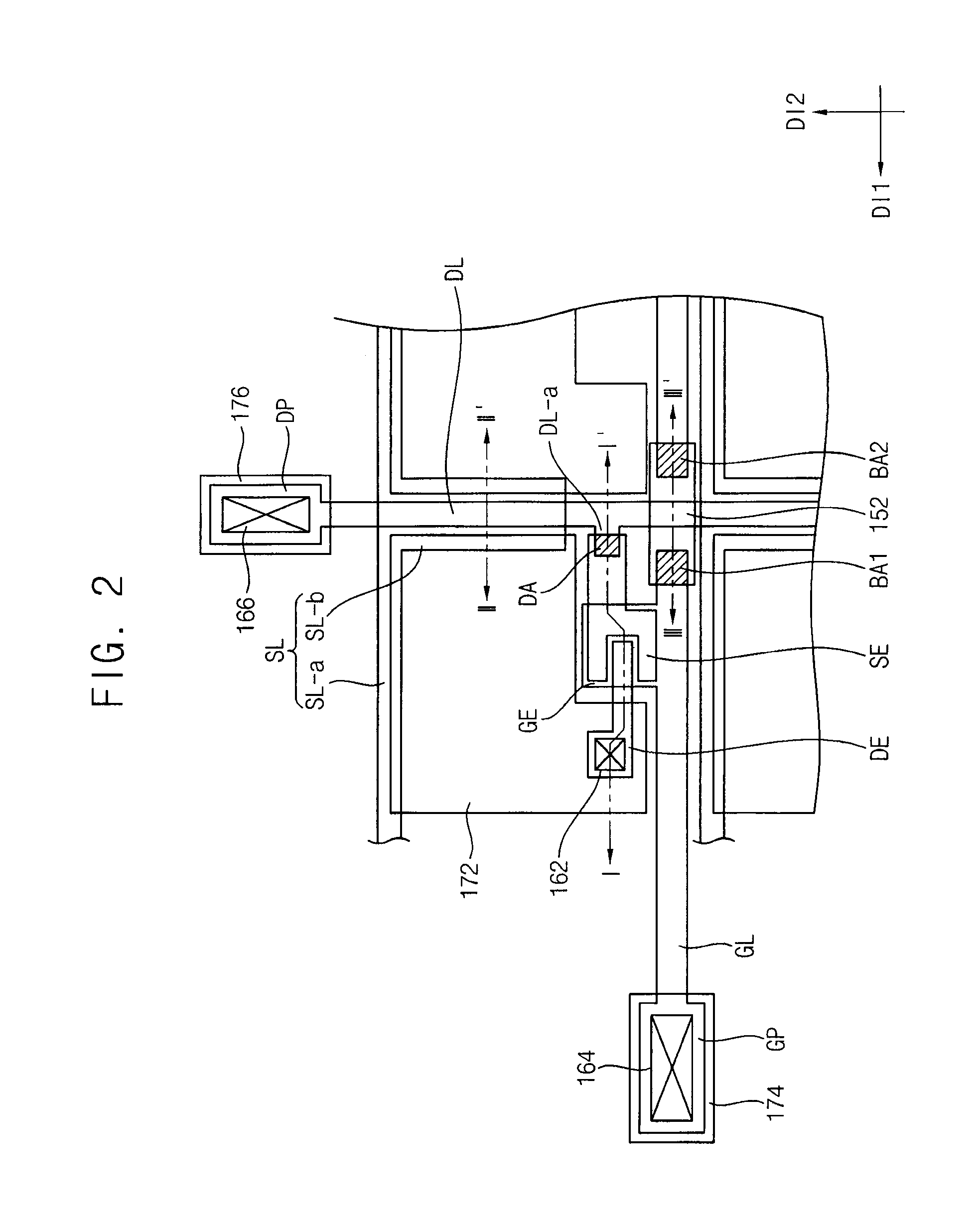

ActiveUS20090046041A1Avoid couplingMinimize parasitic capacitanceStatic indicating devicesSolid-state devicesCapacitanceScan line

The present invention provides a display device including a pixel array section, the pixel array section having pixels arranged in a matrix form, each of the pixels including: an electro-optical element; a write transistor; a holding capacitance; a drive transistor; and a switching transistor; a write scan line disposed for each of pixel rows of the pixel array section and adapted to convey a write signal to be applied to the gate electrode of the write transistor; and a correction scan line, wherein the wiring structure of the write scan line does not intersect with the wiring pattern connected to the gate electrode of the drive transistor.

Owner:SONY CORP

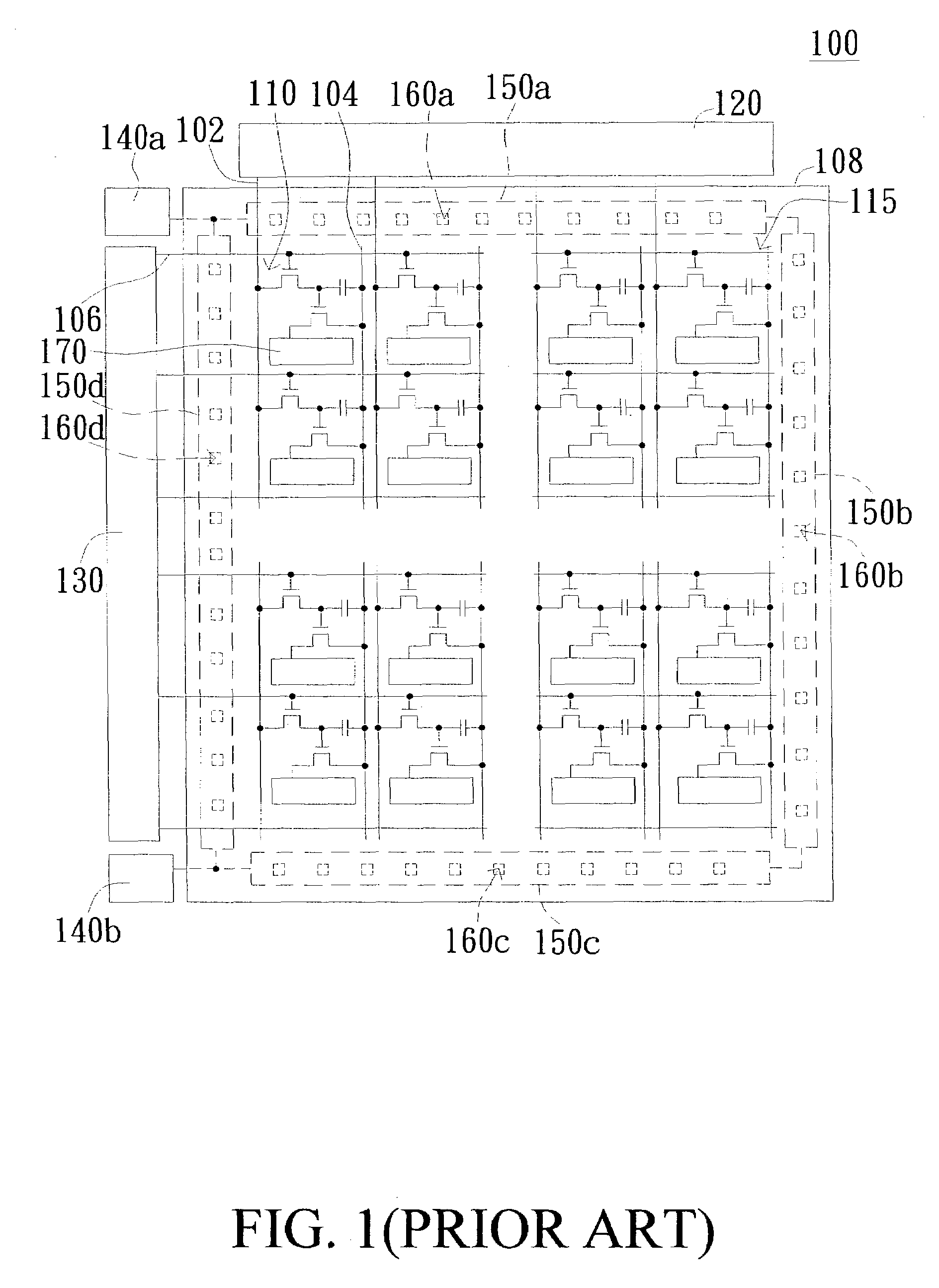

LCD device array substrate, its mending method and LCD device

ActiveCN101216643ALower resistanceReduce the effects of signal delaySolid-state devicesNon-linear opticsElectricityScan line

The invention discloses an LCD device array substrate, which comprises a data line; a scan line arranged to intersect the data line; a detection line assembly arranged at the periphery of a display region in the array substrate, at least a portion of the detection line assembly being used for detecting the array substrate; and a repair line assembly arranged at the periphery of the display region for repairing defects of defective data line of the data lines, wherein the detection line assembly is so arranged that the detection line assembly is electrically isolated from the repair line assembly when not carrying out repair operation and that the detection line assembly is electrically connected with the repair line assembly and the defective data line during repairing. The invention also discloses the repair method of the LCD device array substrate and an LCD device using the array substrate. According to the invention, the detection line assembly can be used as a portion of the repair circuit to repair the data line, thus significantly reducing the area of the non-display region.

Owner:KUSN INFOVISION OPTOELECTRONICS

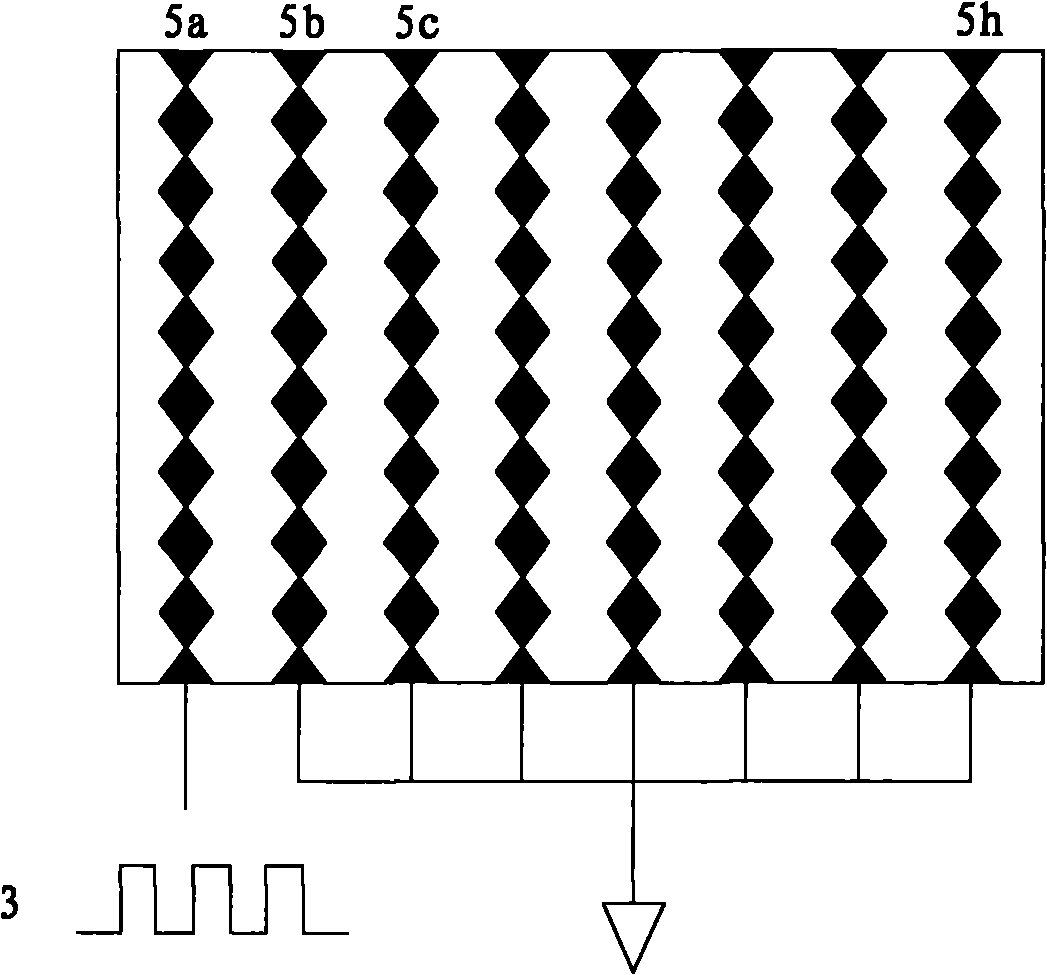

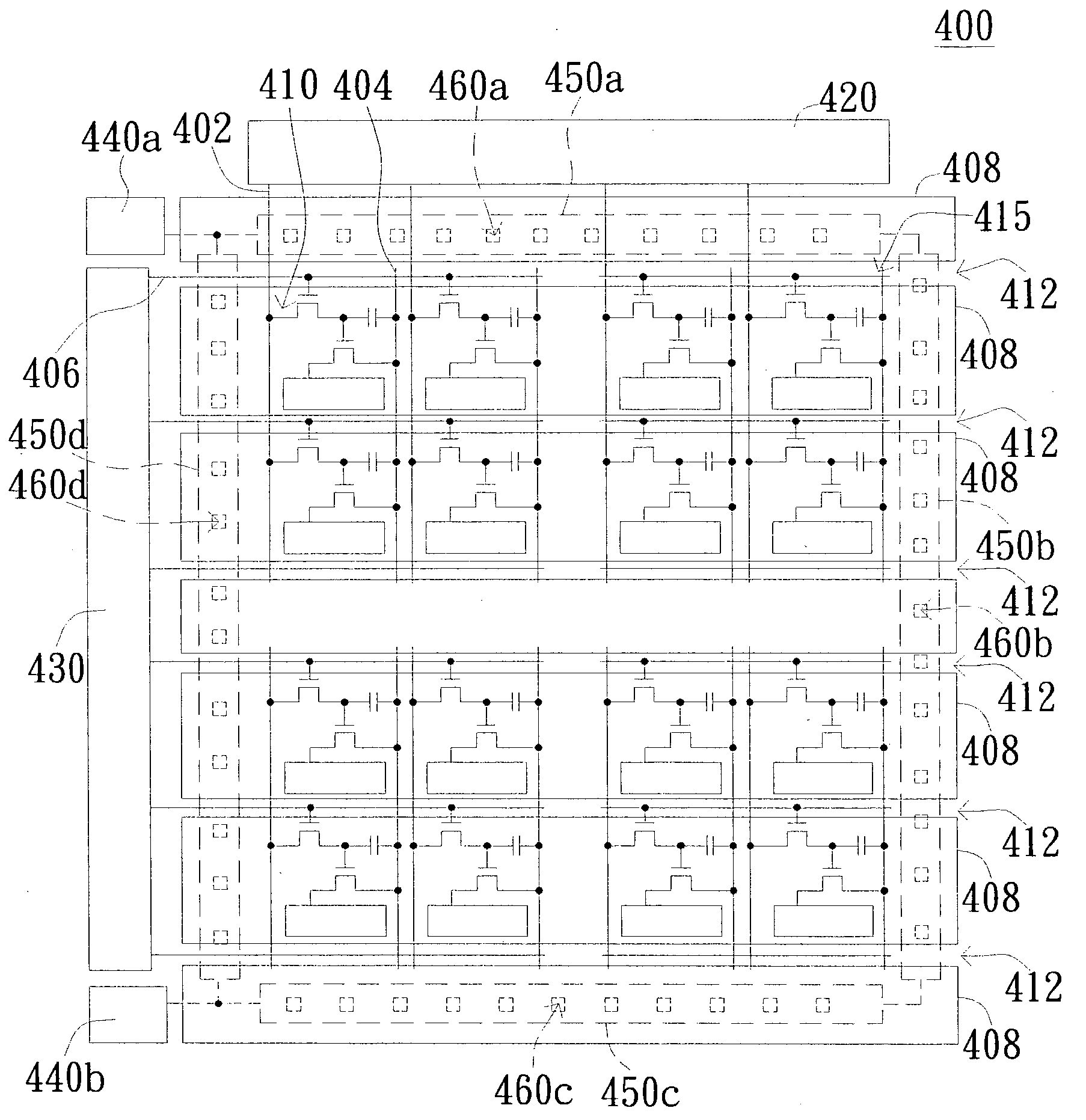

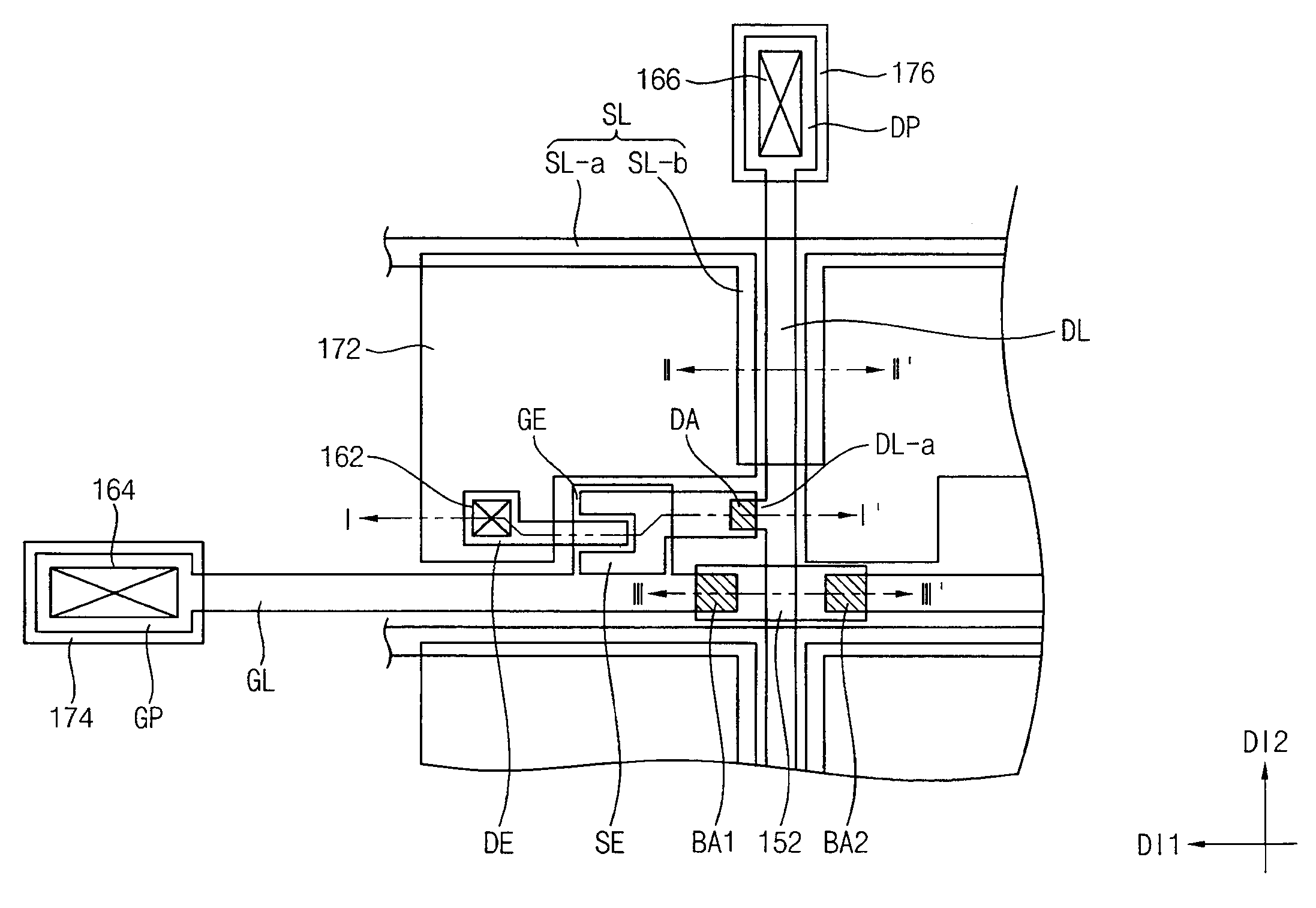

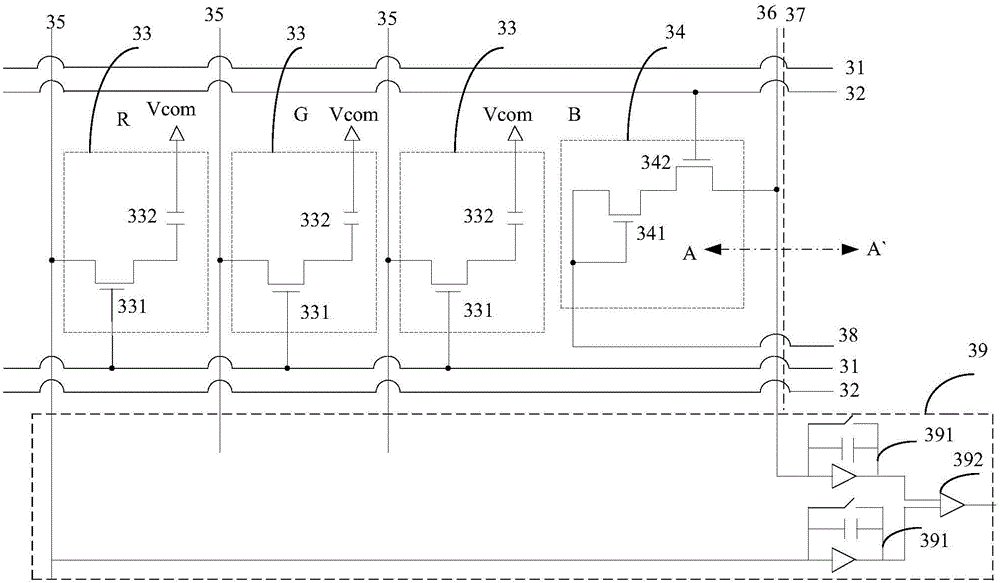

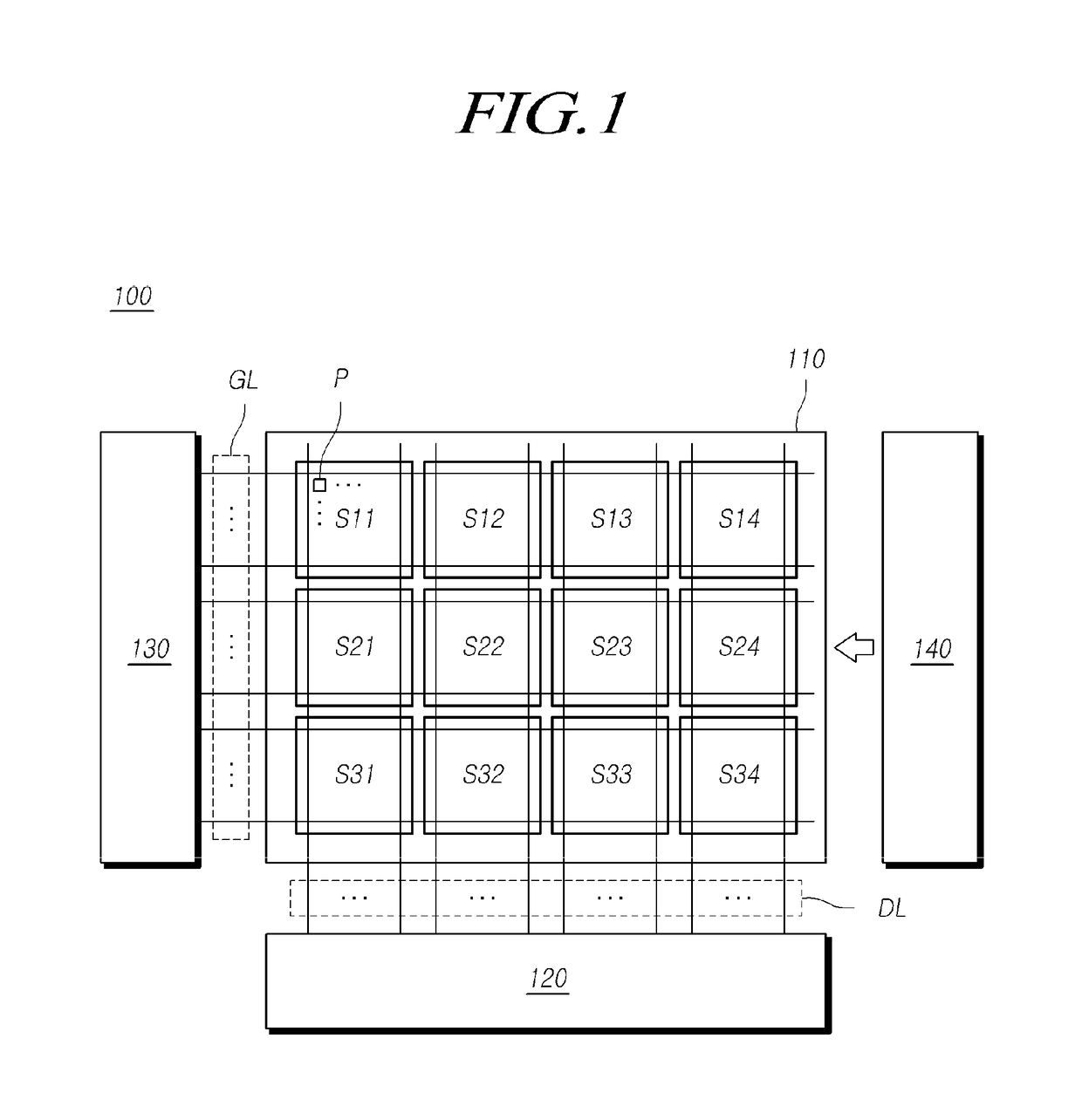

In-Cell Touch Display Device

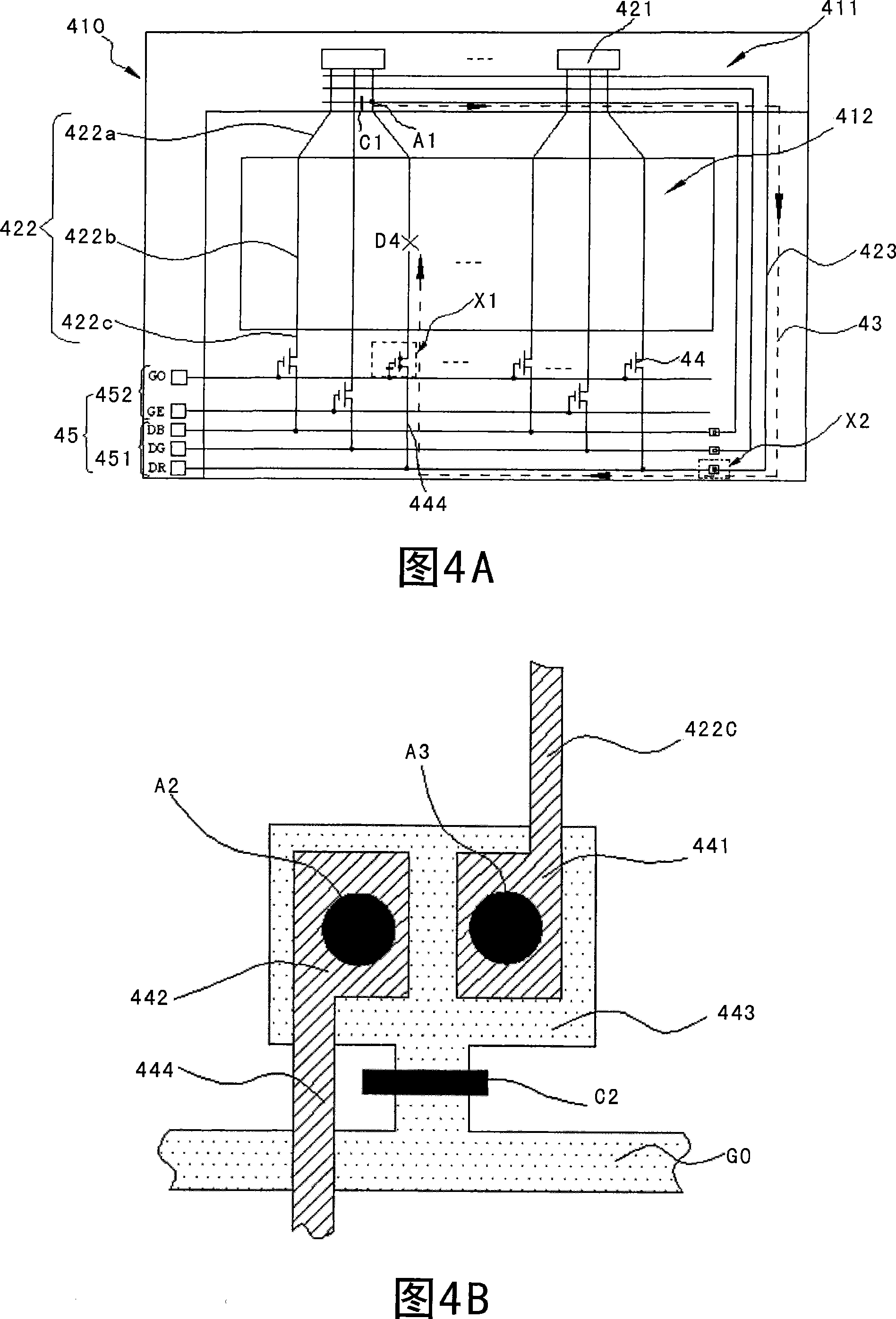

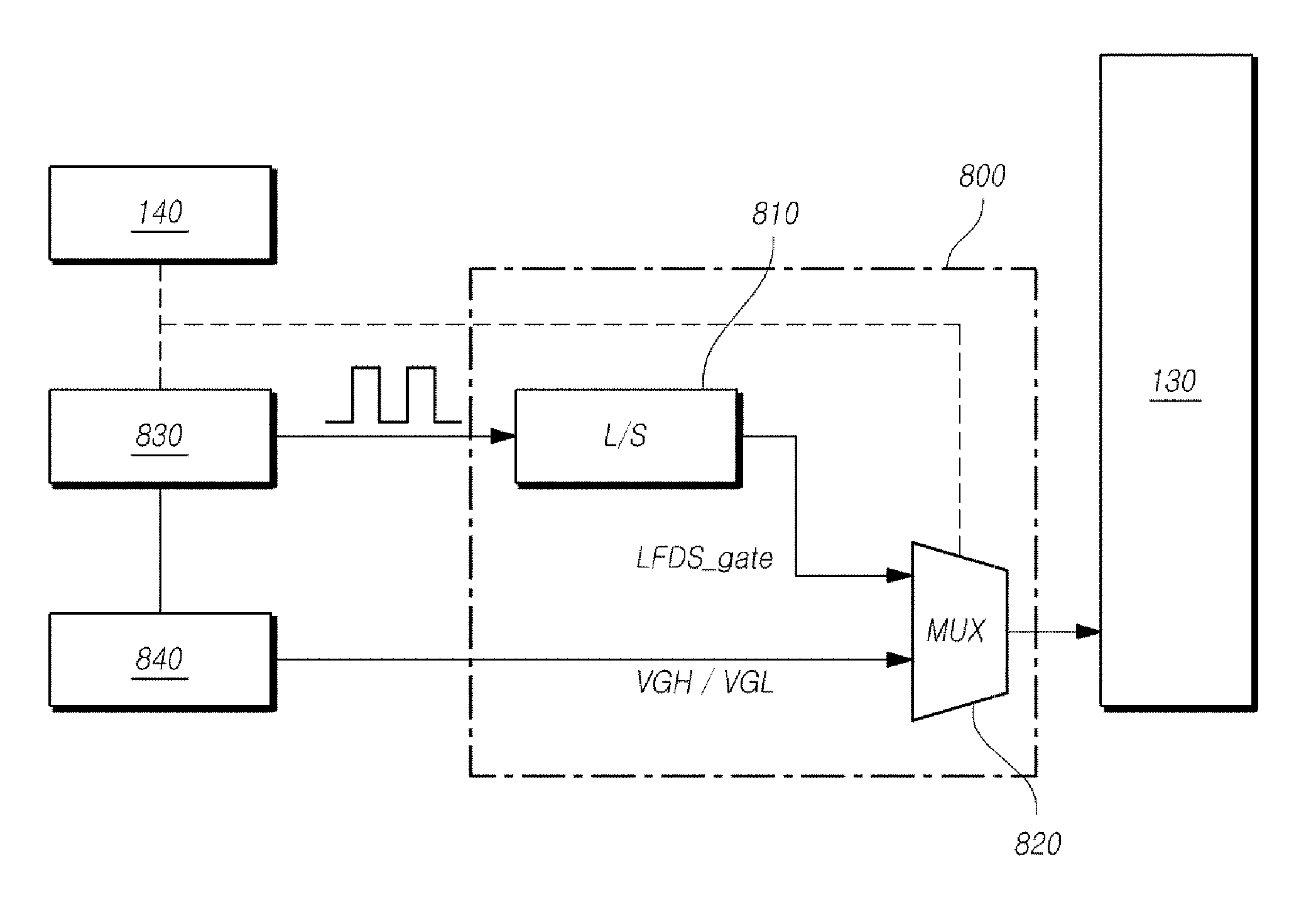

ActiveUS20160019827A1Avoid Parasitic CapacitanceIncreasing load of touchCathode-ray tube indicatorsNon-linear opticsMultiplexerDisplay device

An in-cell touch display device. A panel has a plurality of data lines, a plurality of gate lines and a plurality of touch electrodes disposed thereon. A touch driving signal is applied to the plurality of touch electrodes when a driving mode is a touch mode. A data driver drives the plurality of data lines. A gate driver drives the plurality of gate lines. The gate driver sequentially outputs a scanning signal for driving the plurality of gate lines to the plurality of gate lines when the driving mode is a display mode, and outputs a load-free driving signal corresponding to the touch driving signal to at least one gate line when the driving mode is the touch mode. A level shifter generates the load-free driving signal. A multiplexer inputs a scanning voltage or the load-free driving signal to the gate driver depending on the driving mode.

Owner:LG DISPLAY CO LTD

Liquid crystal display device having common line parallel to and between gate line and pixel electrode with light shield projecting from common line parallel to data line and overlapping area between data line and pixel electrode

ActiveUS7554630B2High resolutionHigh optical densityOther workshop equipmentNon-linear opticsLiquid-crystal displayParasitic capacitance

An LCD device with improved an aperture ratio and decreased parasitic capacitance has a passivation layer of an inorganic material and which includes a gate line on a first substrate; a gate insulating layer on an entire surface of the first substrate including the gate line; a data line on the gate insulating layer in perpendicular to the gate line, to define a pixel region; a thin film transistor at a crossing portion of the gate and data lines; a passivation layer on the entire surface of the first substrate including the thin film transistor; a pixel electrode on the passivation layer, for being connected with a drain electrode of the thin film transistor; and a light-shielding metal for receiving a voltage, formed between the data line and the pixel electrode, to prevent a parasitic capacitance between the data line and the pixel electrode.

Owner:LG DISPLAY CO LTD

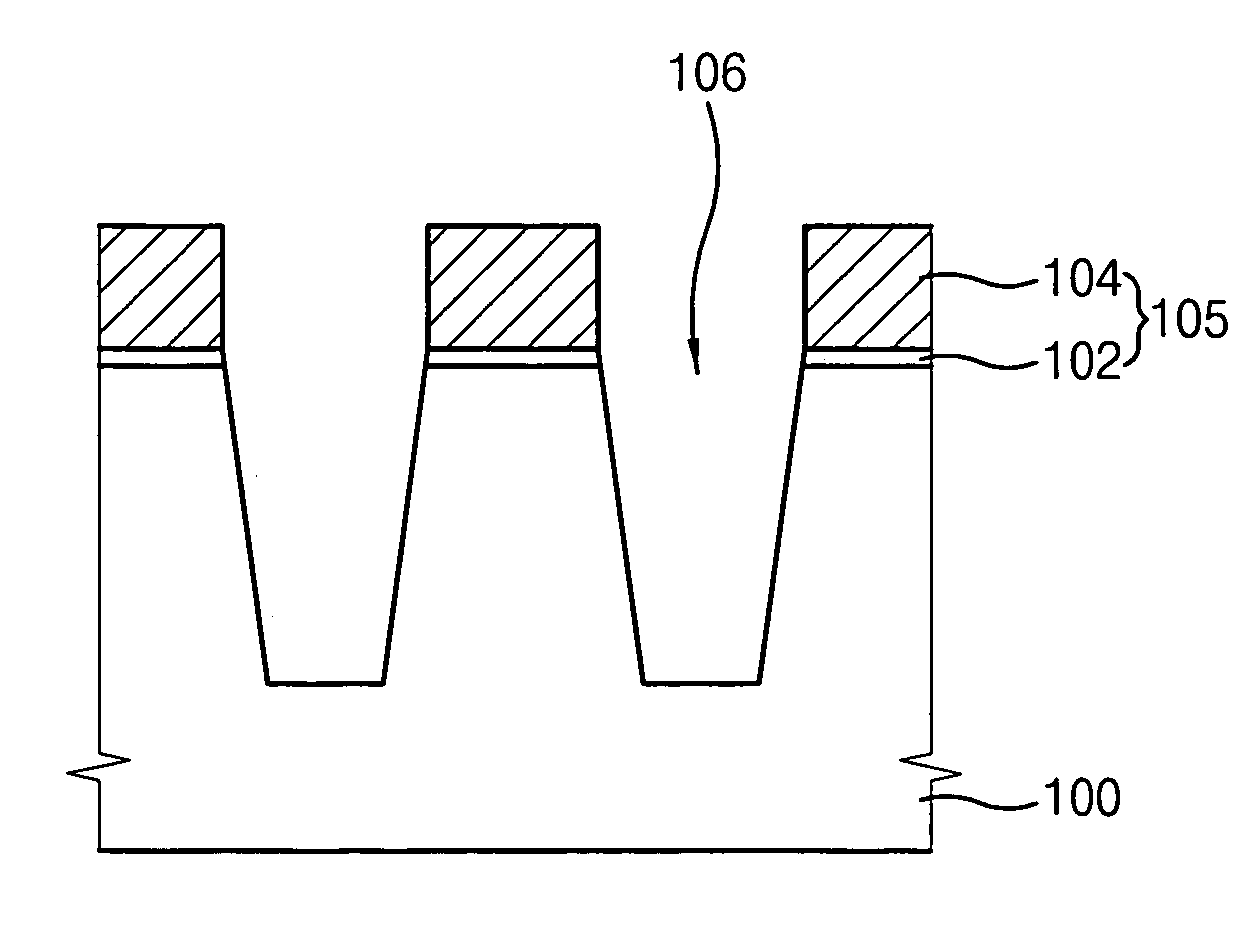

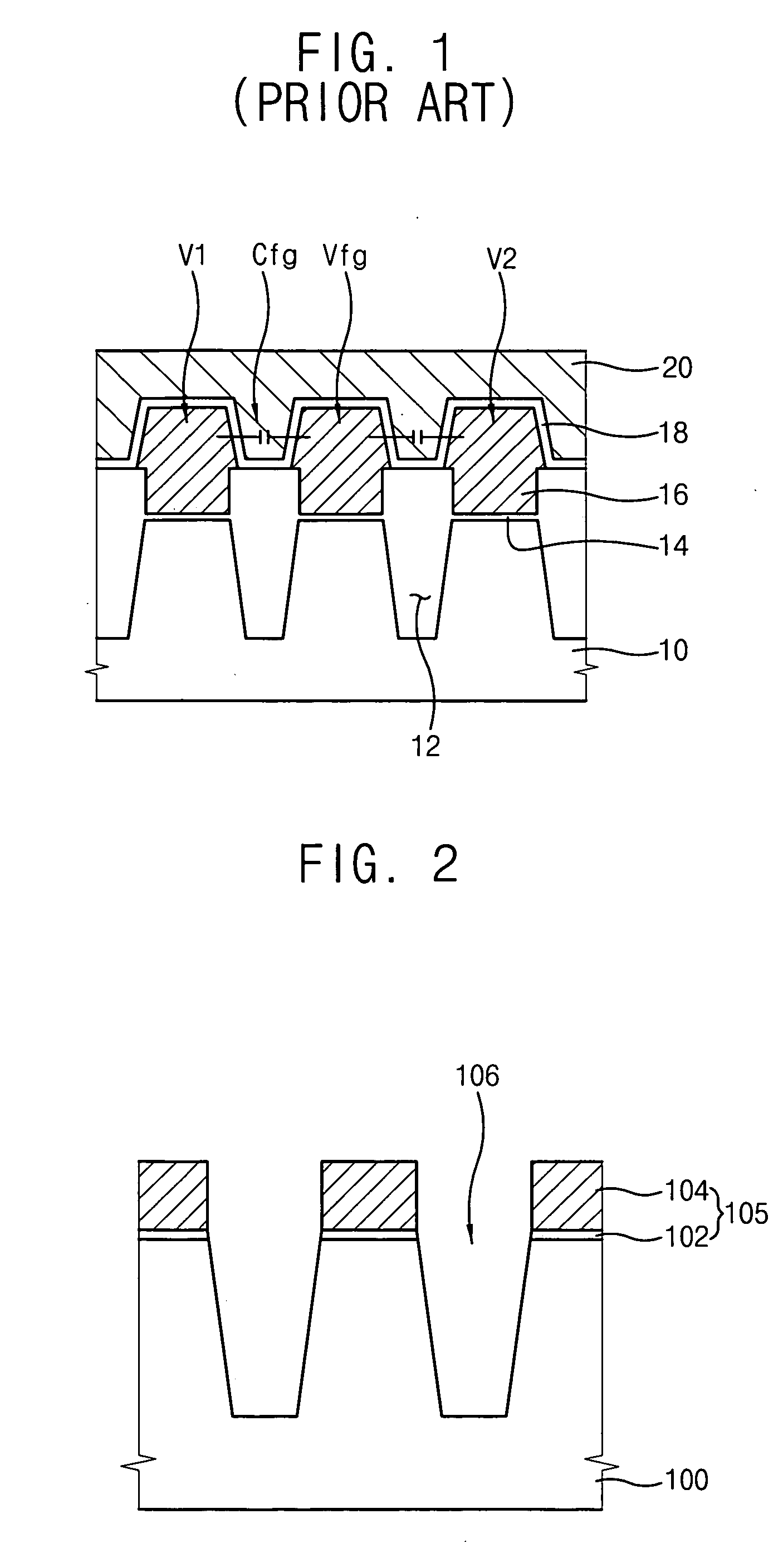

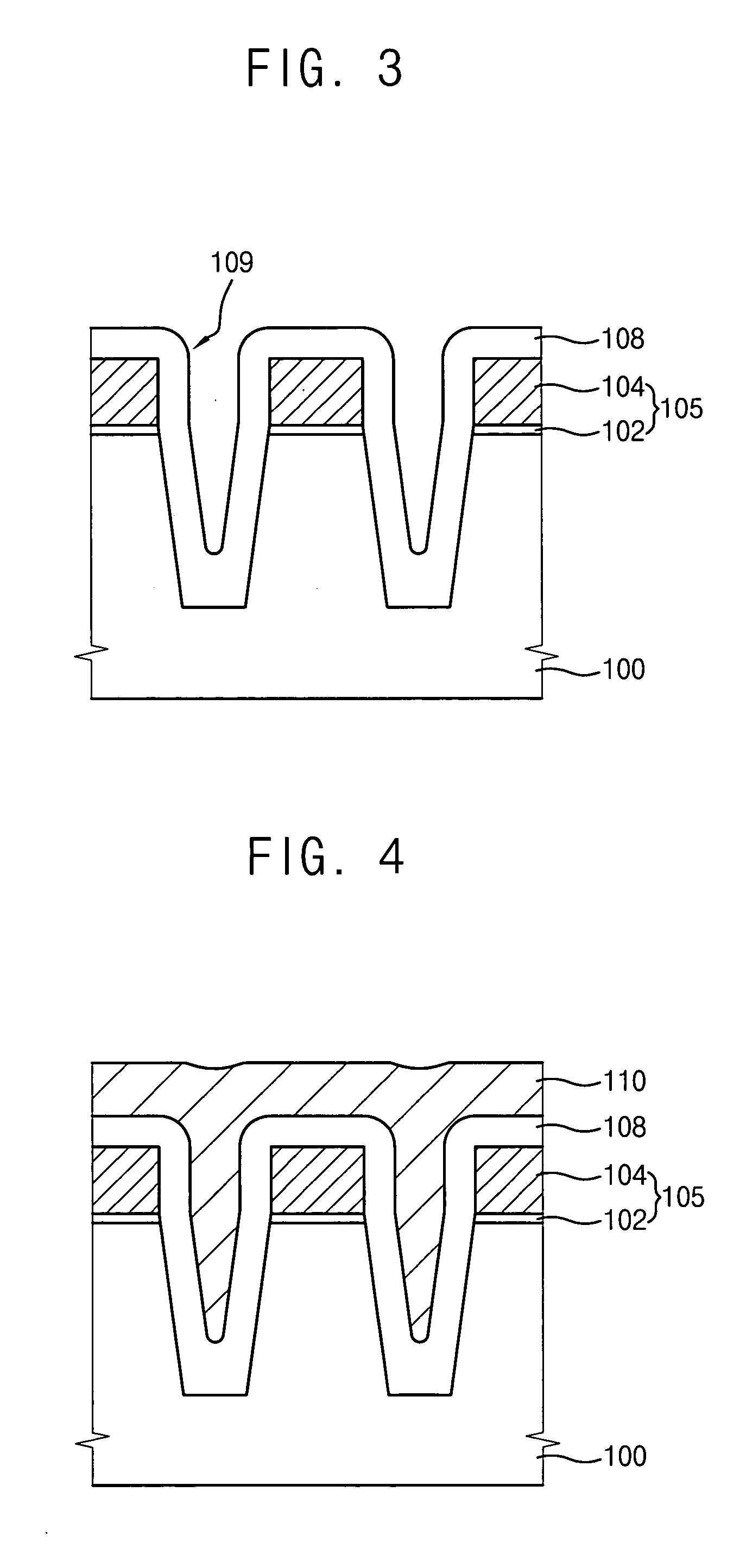

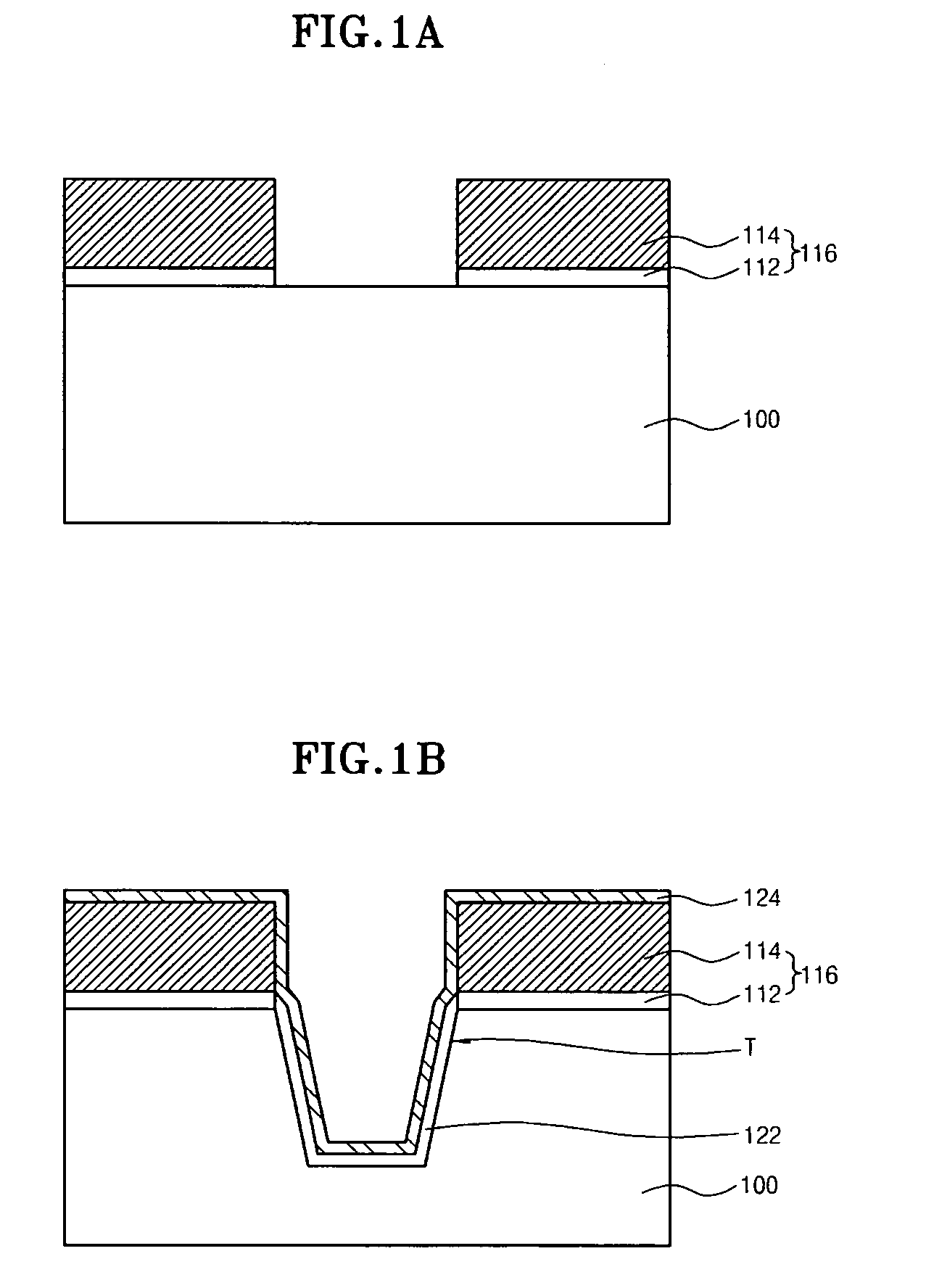

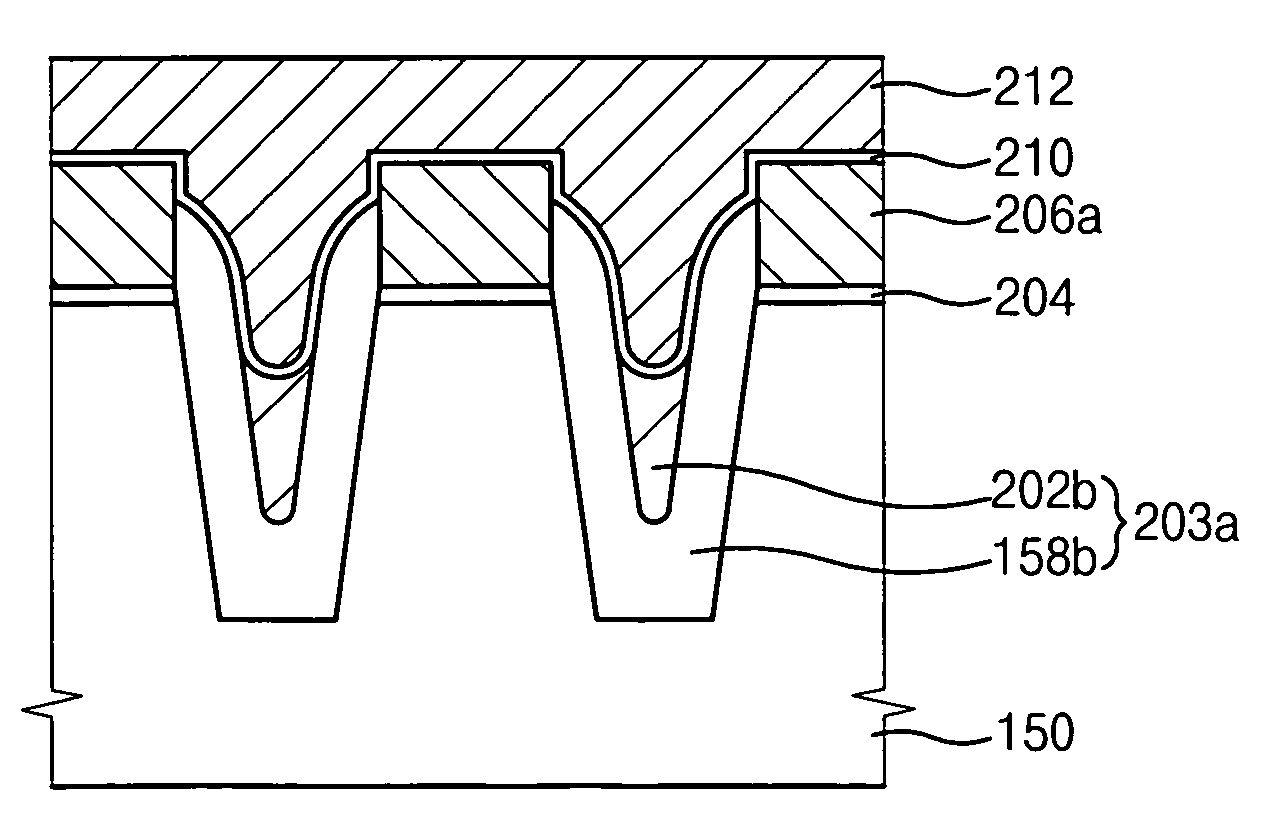

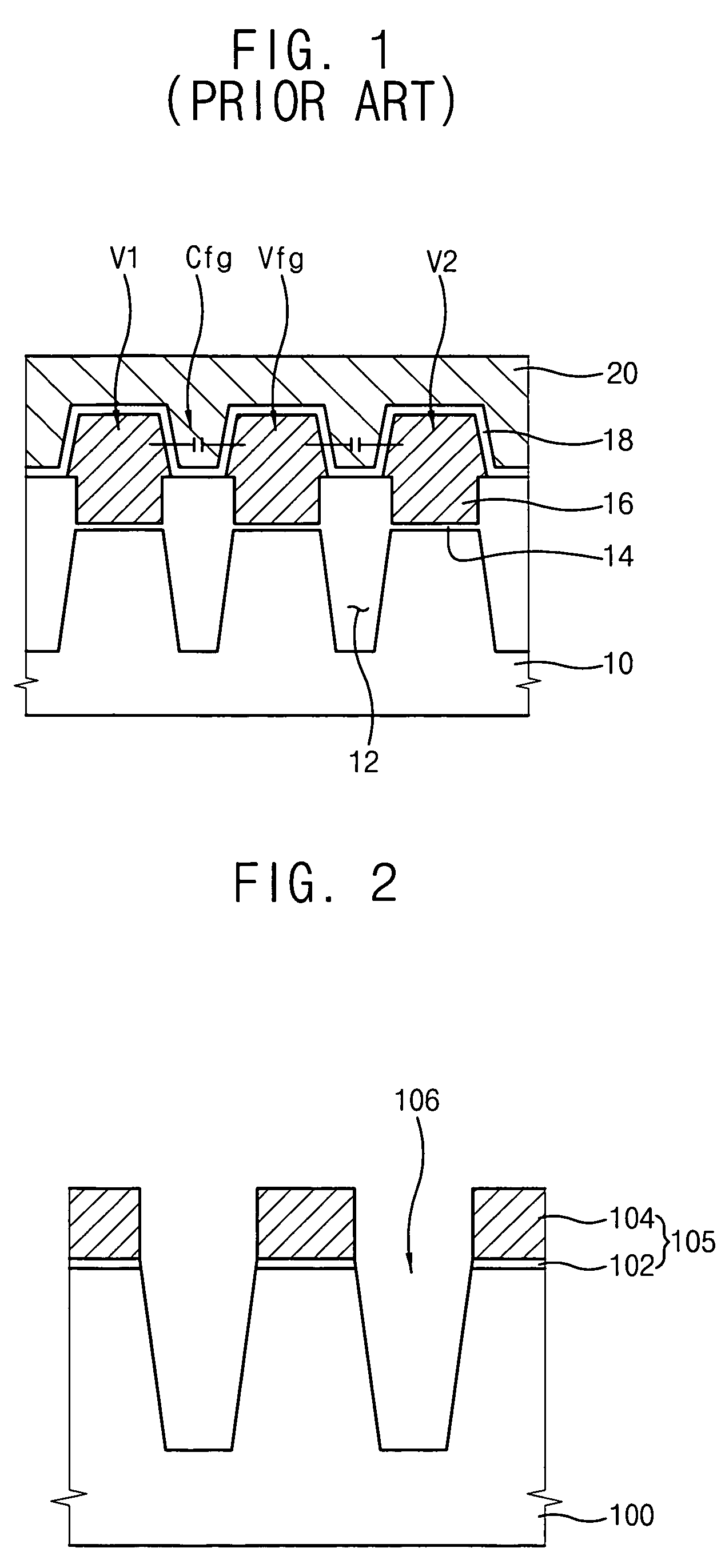

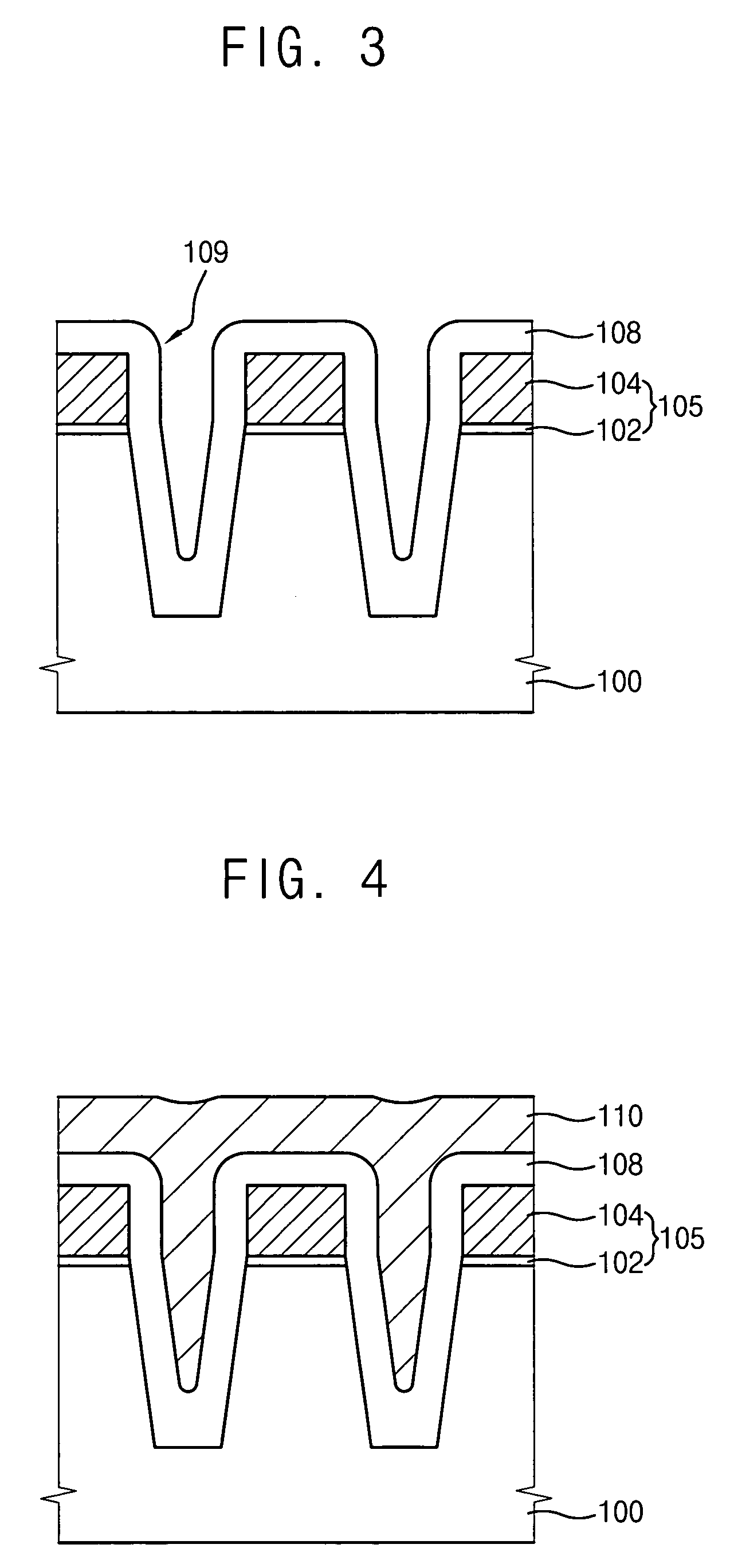

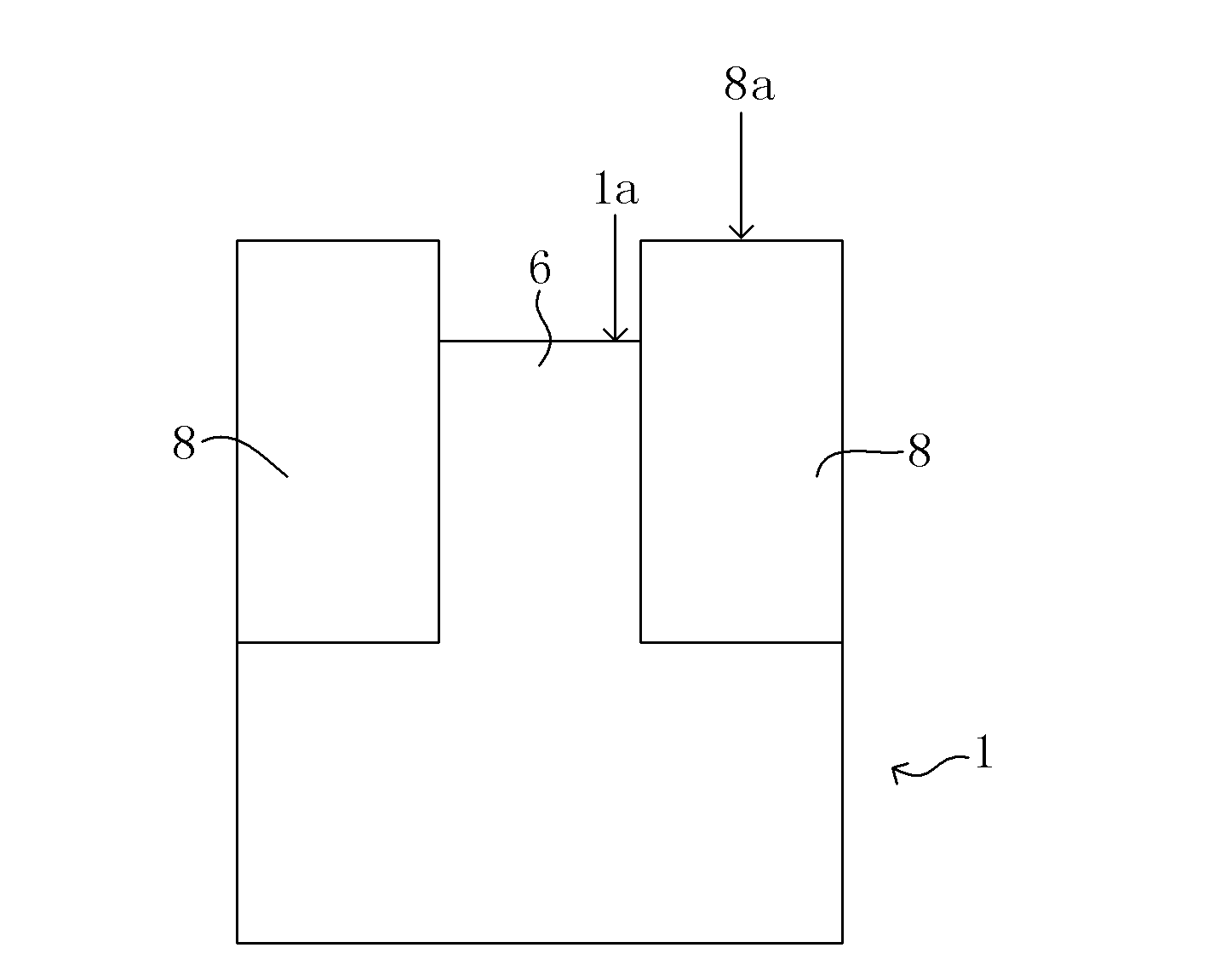

Method of forming a trench isolation layer and method of manufacturing a non-volatile memory device using the same

InactiveUS20060094203A1Reduce parasitic capacitanceMinimizes parasitic capacitanceSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerParasitic capacitance

In a method of forming a device isolation layer for minimizing a parasitic capacitor and a non-volatile memory device using the same, a trench is formed on a substrate. A first insulation layer is formed on a top surface of the substrate and on inner surfaces of the trench, so that the trench is partially filled with the first insulation layer. A second insulation layer is formed on the first insulation layer to a thickness to fill up the trench, thereby forming a preliminary isolation layer. An etching rate of the second insulation layer is different from that of the first insulation layer. A recess is formed at a central portion of the preliminary isolation layer by partially removing the first and second insulation layers, thereby forming the device isolation layer including the recess. The recess in the device isolation layer reduces a parasitic capacitance in a non-volatile memory device.

Owner:SAMSUNG ELECTRONICS CO LTD

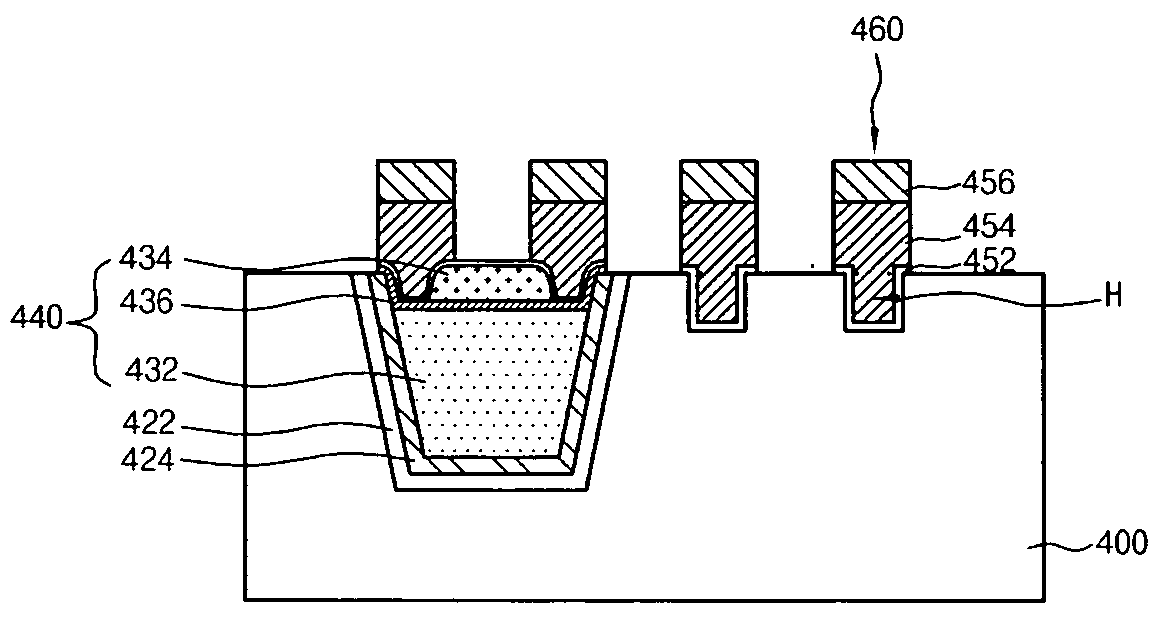

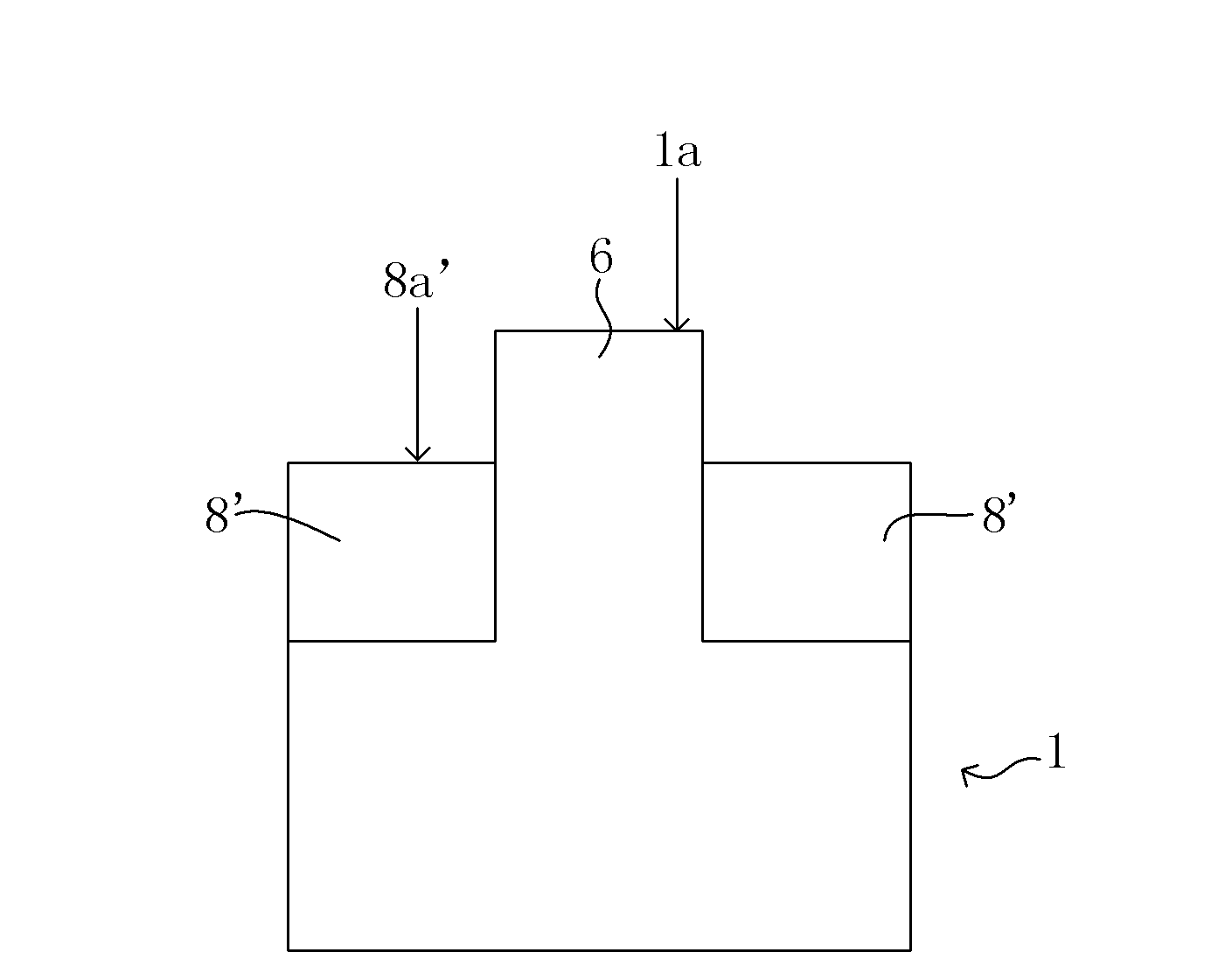

Method of forming isolation structure of semiconductor device for preventing excessive loss during recess gate formation

InactiveUS20080001249A1Less lossPrevent excessive lossTransistorSolid-state devicesSemiconductorHard mask

An isolation structure of a semiconductor device is formed by forming a hard mask layer on a semiconductor substrate having active and field regions to expose the field region. A trench is defined by etching the exposed field region of the semiconductor substrate using the hard mask as an etch mask. An SOG layer is formed in the trench partially filling the trench. An amorphous aluminum oxide layer is formed on the resultant substrate including the SOG layer. An HDP layer is formed on the amorphous aluminum oxide layer to completely fill the trench. The HDP layer and the amorphous aluminum oxide layer are subjected to CMP to expose the hard mask. The hard mask and portions of the amorphous aluminum oxide layer that are formed on the HDP layer are removed. The amorphous aluminum oxide layer is crystallized.

Owner:SK HYNIX INC

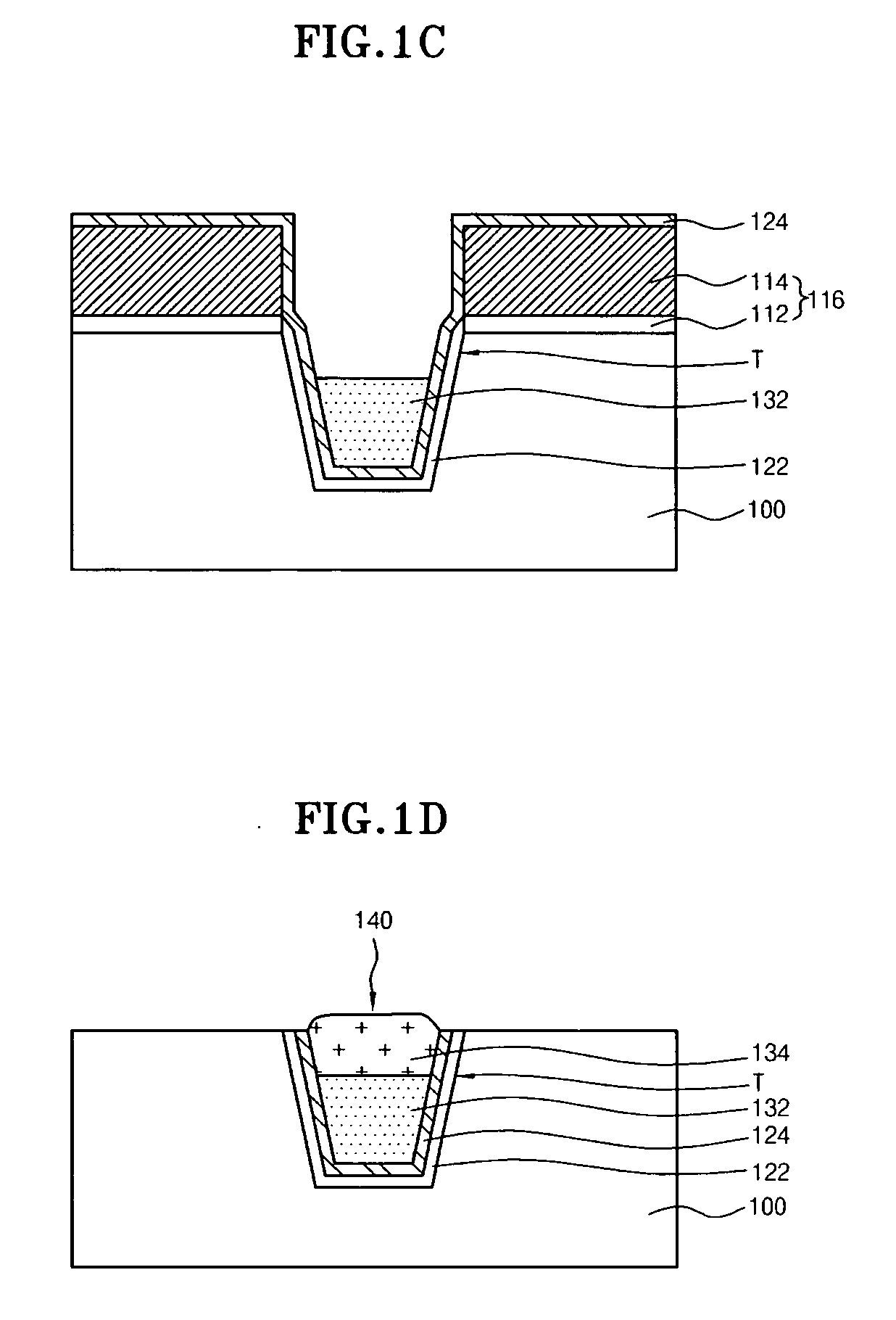

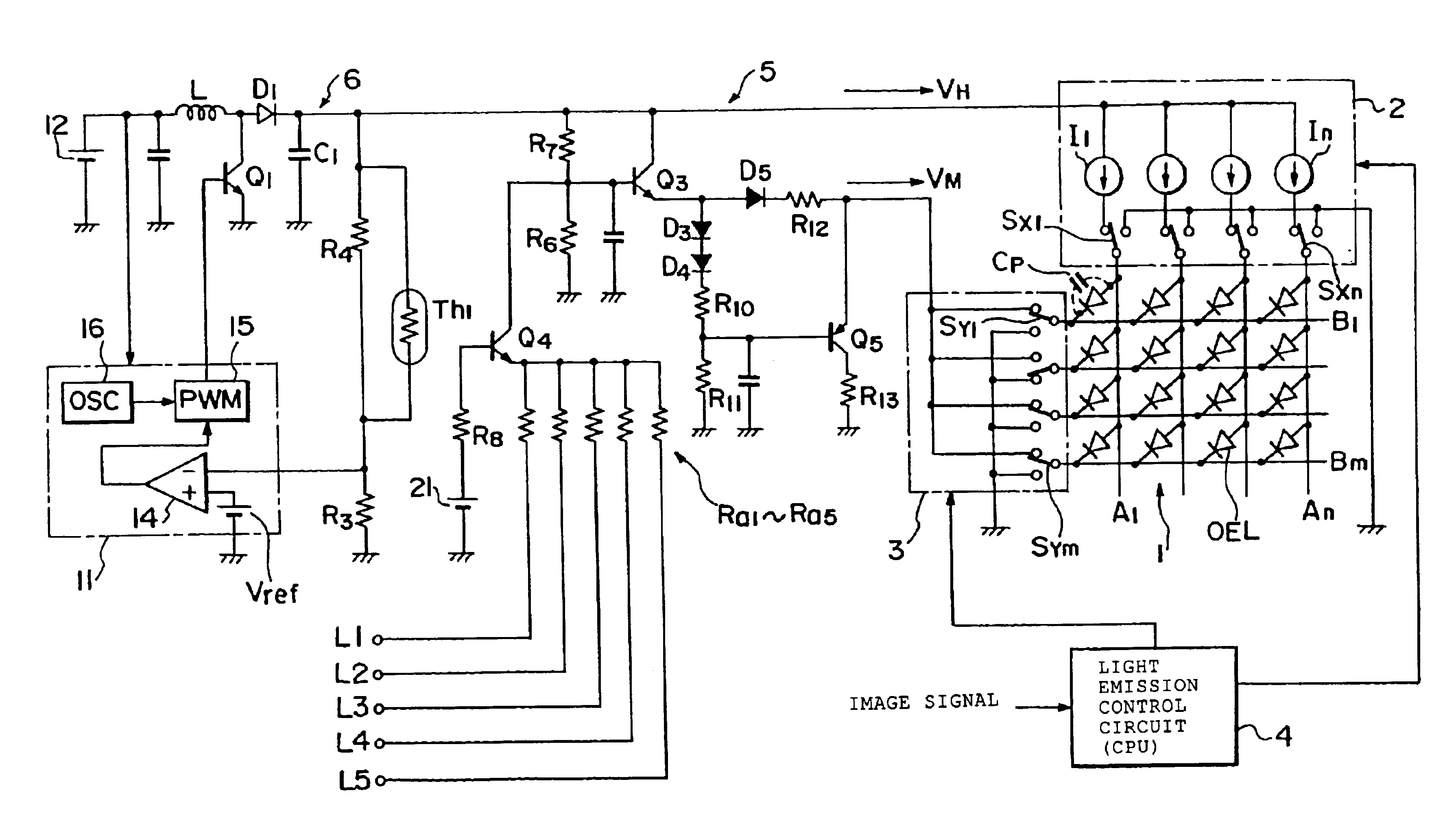

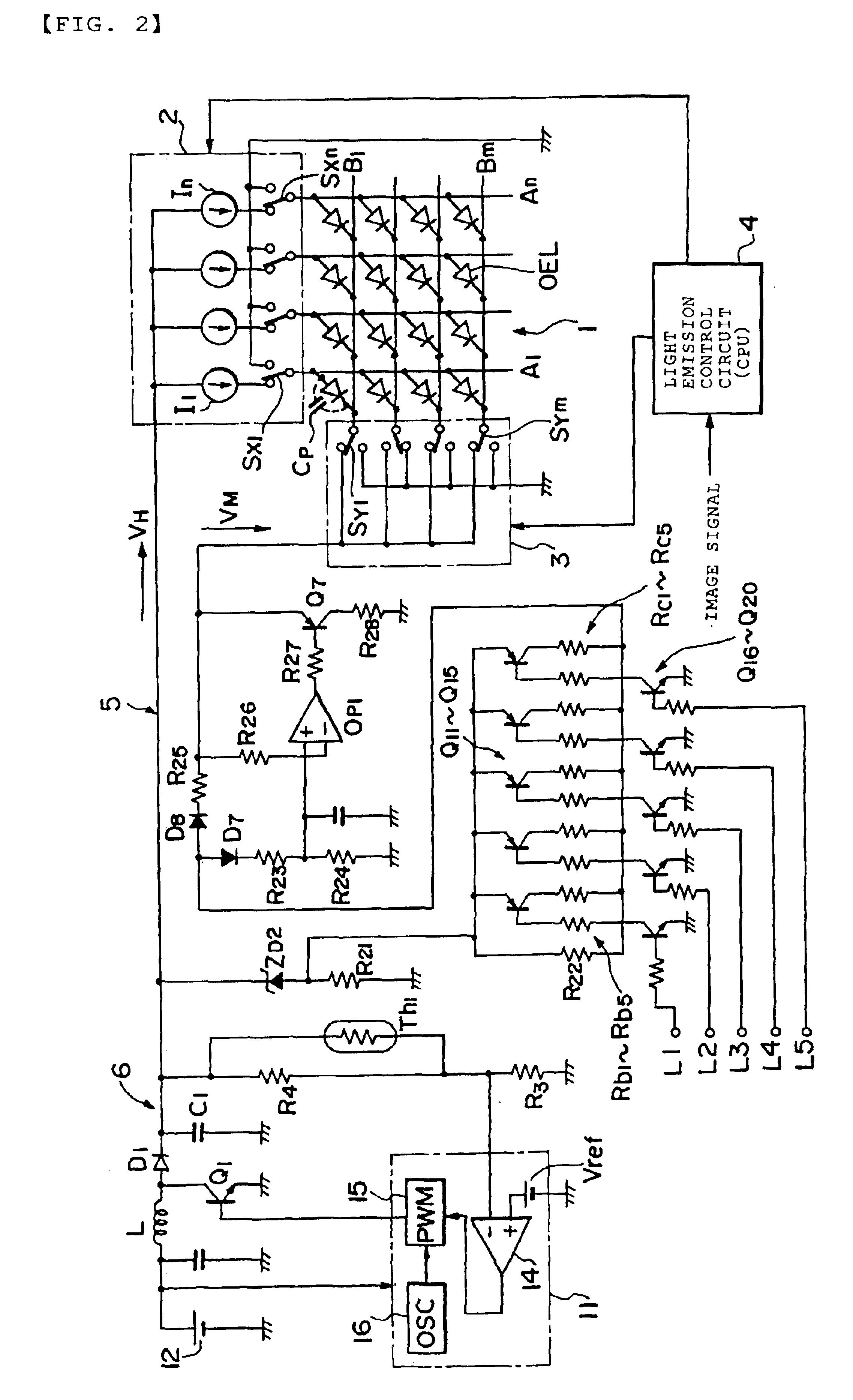

Drive method of light-emitting display panel and organic EL display device

InactiveUS6894436B2Easy to getExtend the scope of controlSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceParasitic capacitance

In a drive method of a light-emitting display panel capable of emitting light in low luminance, the parasitic capacitances of the light-emitting elements disposed in the light-emitting display panel are precharged making use of a reverse bias voltage before they are lit. In this case, a reverse bias voltage created by a reverse bias voltage creation circuit or a peak current being precharged is controlled by selectively grounding control terminals based on dimmer control. In particular, when the light-emitting elements are emitted in low luminance, the reverse bias voltage is output in a low level, thereby the light-emitting elements are prevented from being precharged with an excessive voltage. The above arrangement can realize light emission control in low luminance.

Owner:TOHOKU PIONEER CORP

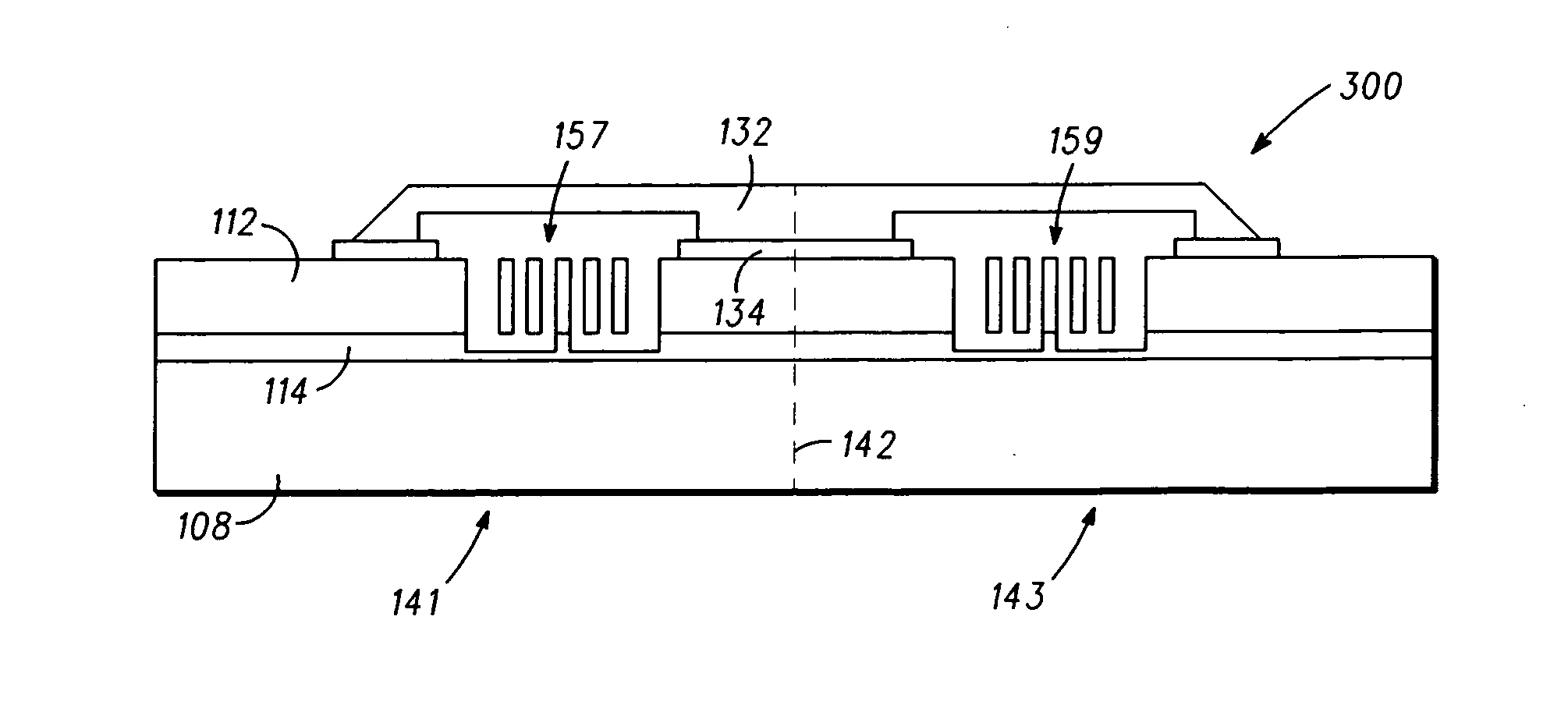

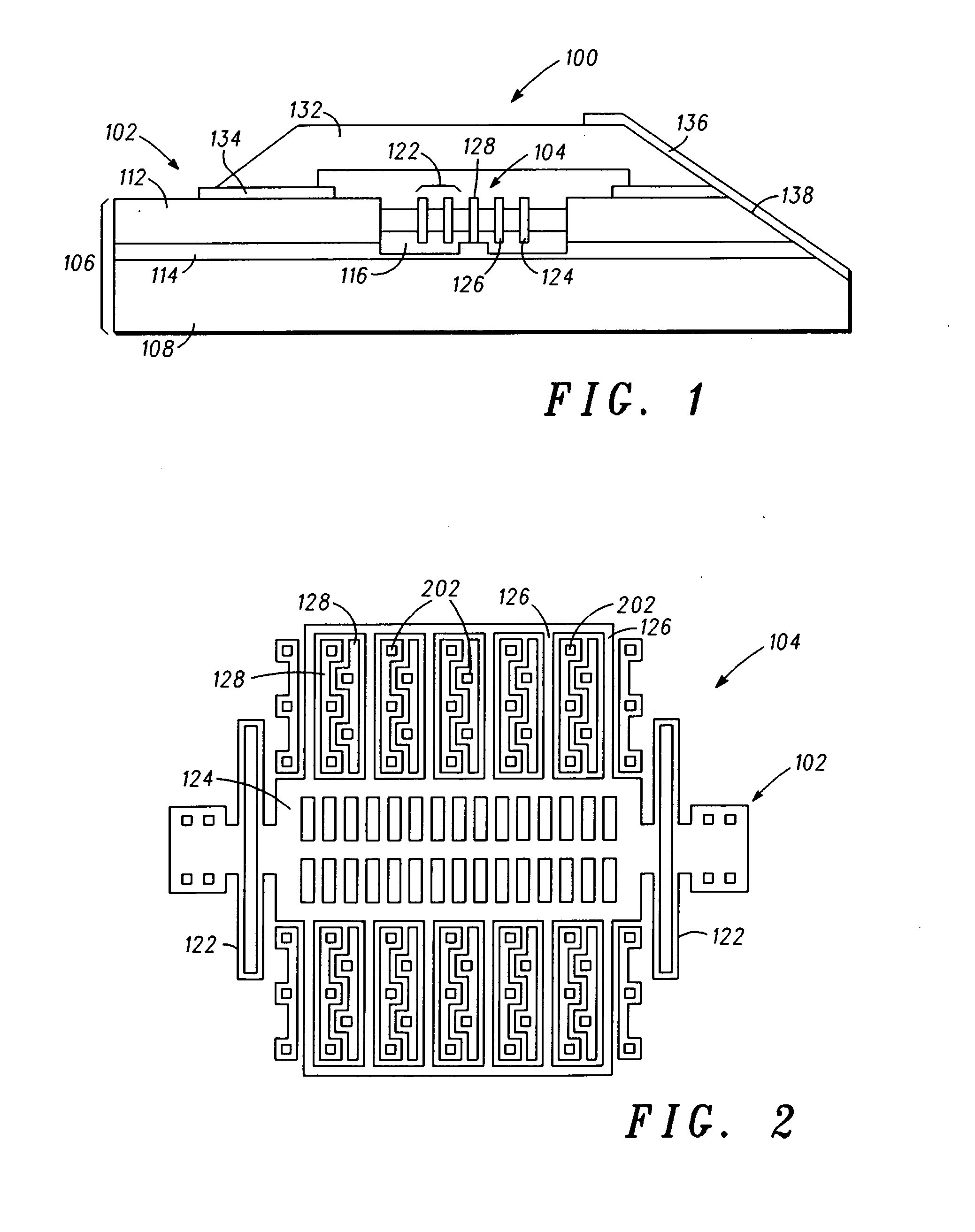

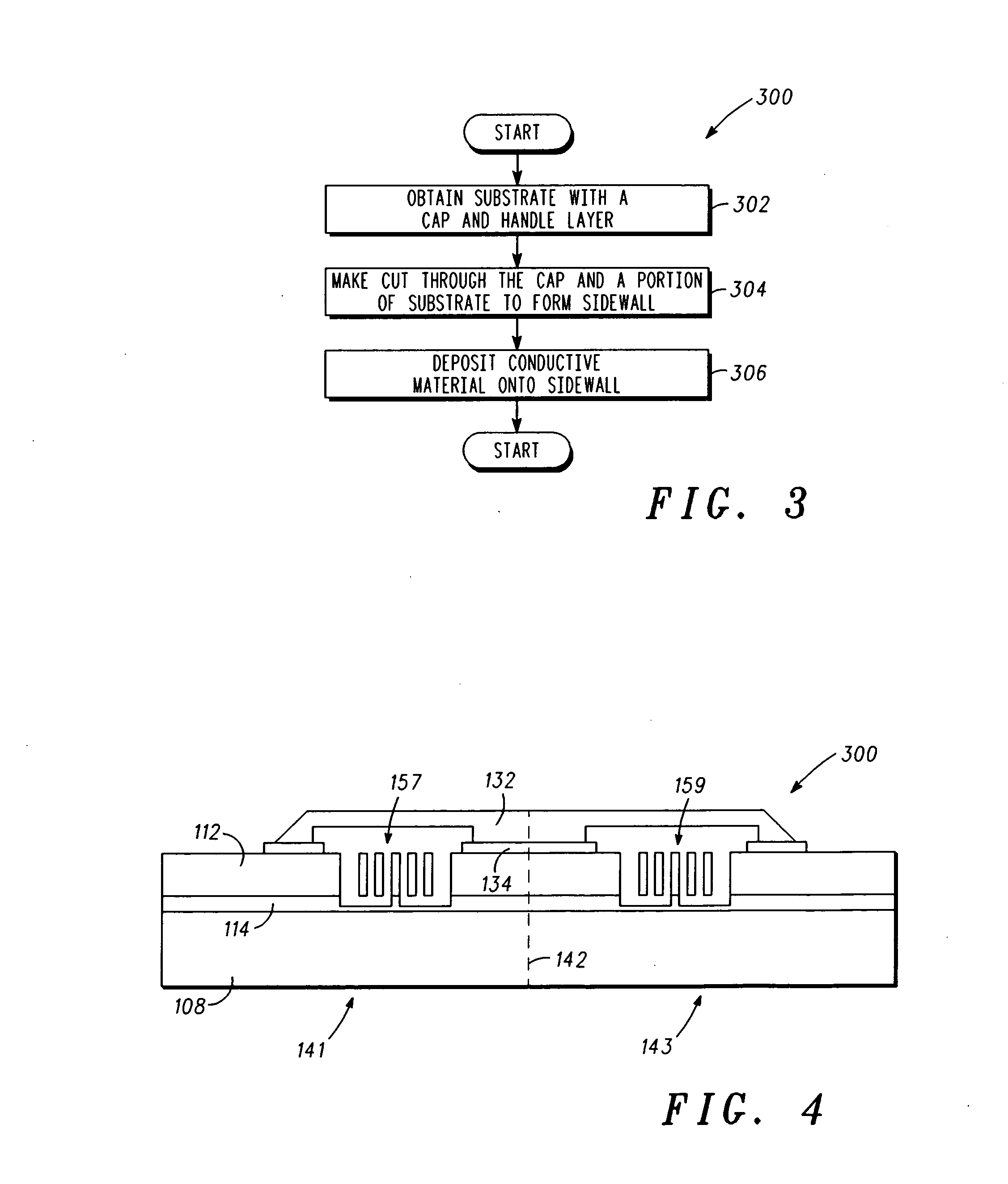

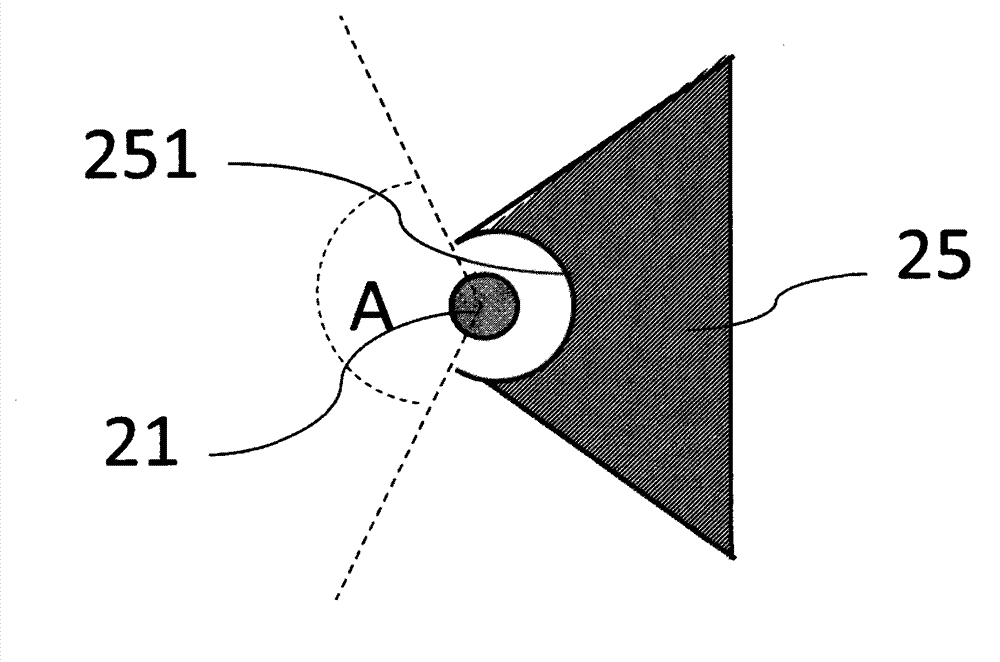

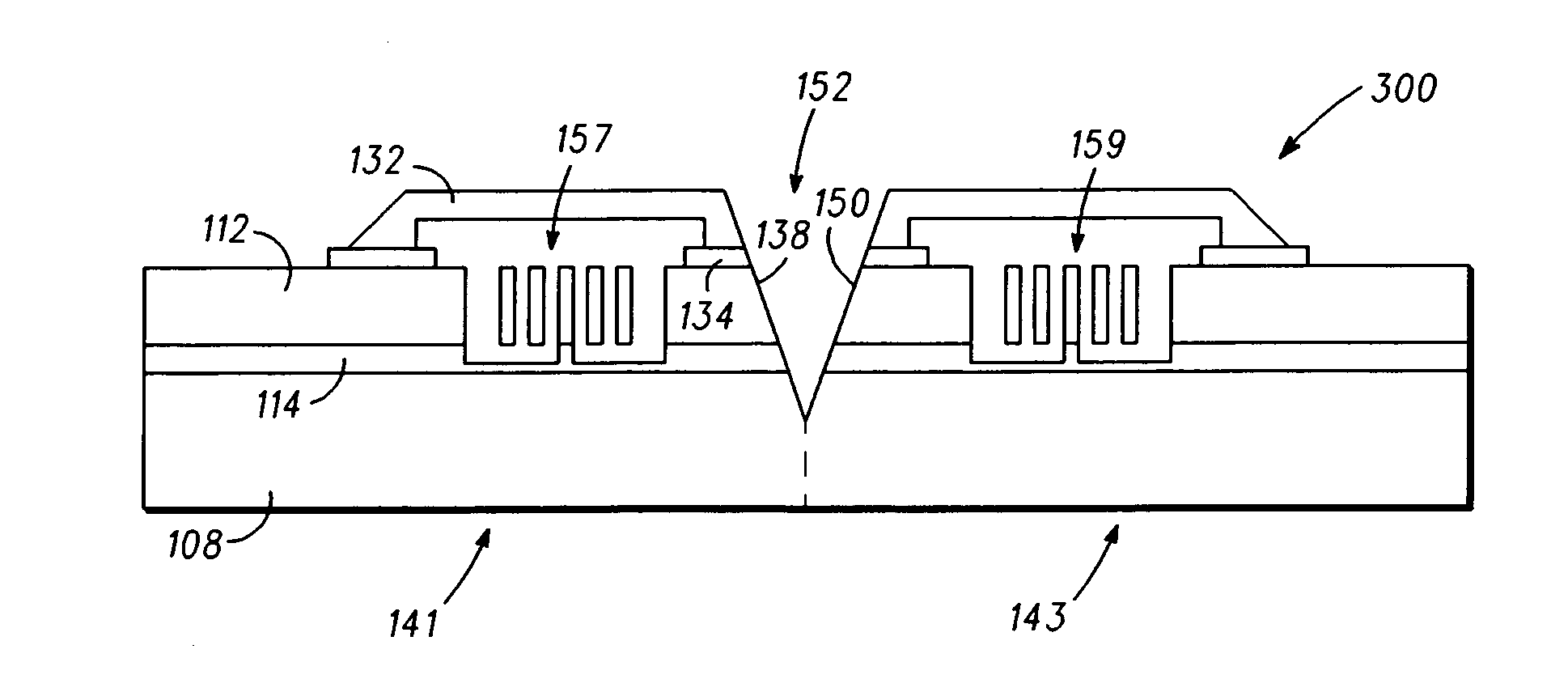

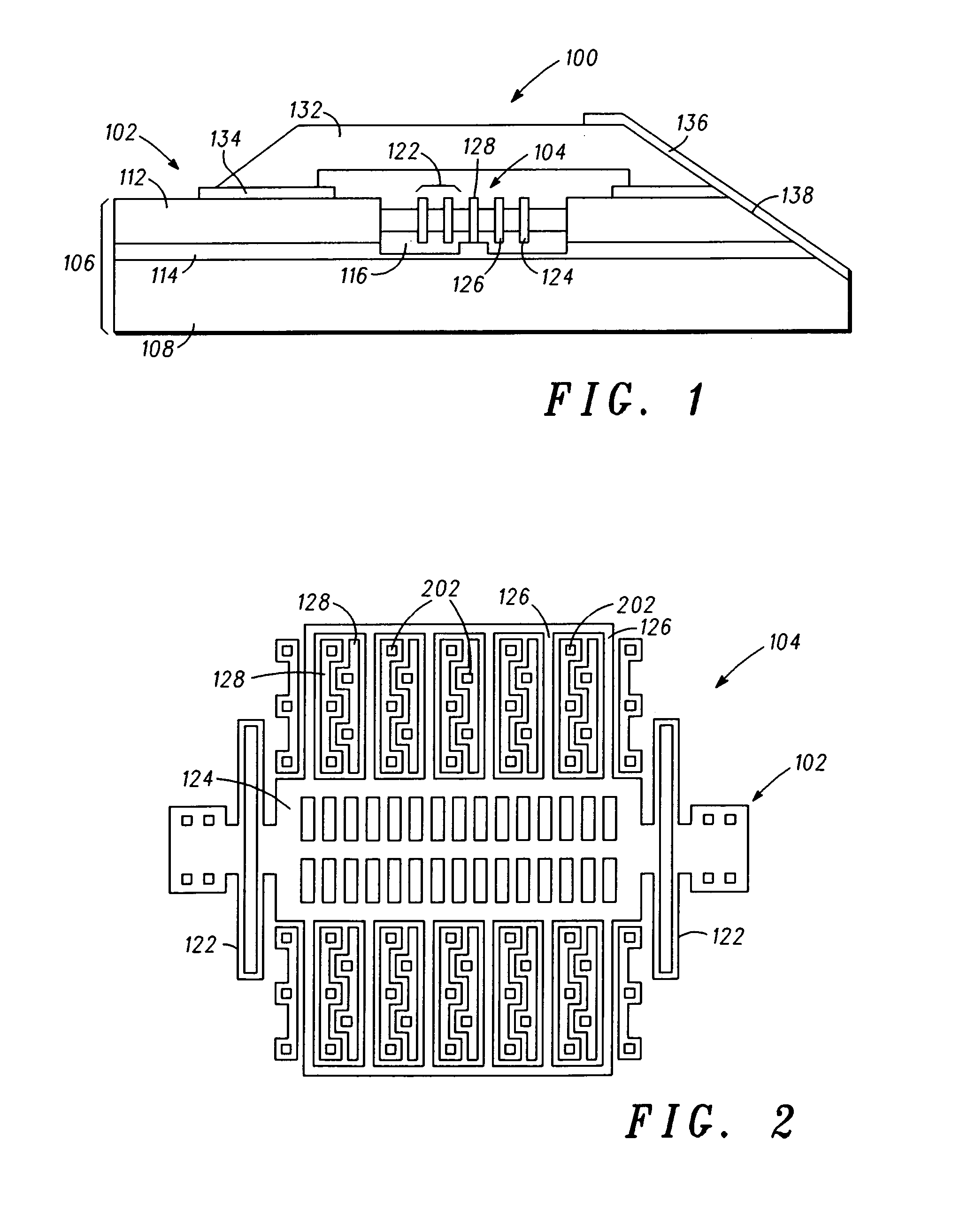

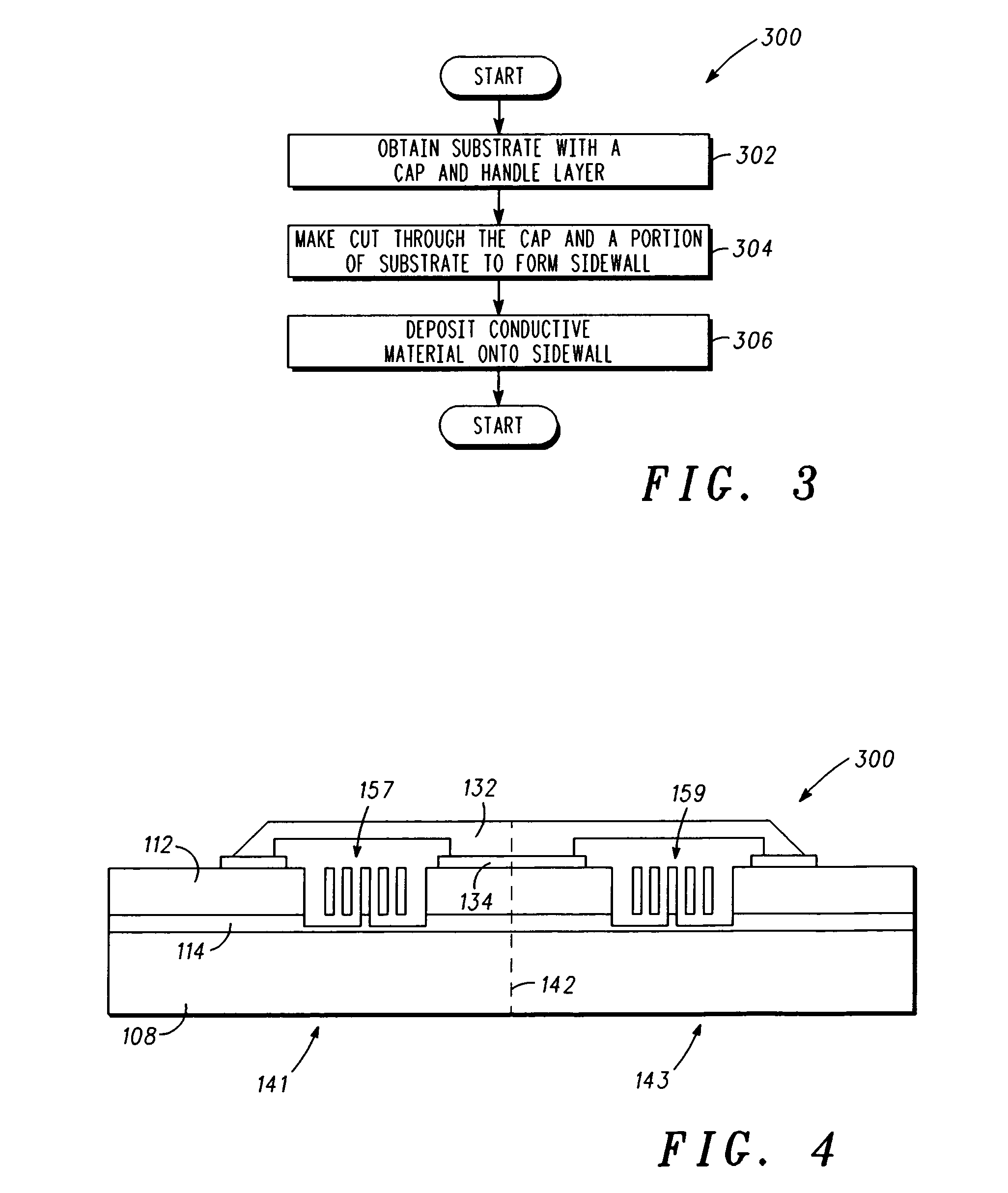

Substrate contact for a capped MEMS and method of making the substrate contact at the wafer level

InactiveUS20060286707A1Avoid Parasitic CapacitanceSemiconductor/solid-state device manufacturingAcceleration measurementEngineeringConductive materials

A MEMS device (100) is provided that includes a handle layer (108) having a sidewall (138), a cap (132) overlying said handle layer (108), said cap (132) having a sidewall (138), and a conductive material (136) disposed on at least a portion of said sidewall of said cap (138) and said sidewall of said handle layer (138) to thereby electrically couple said handle layer (108) to said cap (132). A wafer-level method for manufacturing the MEMS device from a substrate (300) comprising a handle layer (108) and a cap (132) overlying the handle layer (108) is also provided. The method includes making a first cut through the cap (132) and at least a portion of the substrate (300) to form a first sidewall (138), and depositing a conductive material (136) onto the first sidewall (138) to electrically couple the cap (132) to the substrate (300).

Owner:NORTH STAR INNOVATIONS

Manufacturing method of Terahertz Schottky diode

ActiveCN102891081AReduce noiseReduce parasitic effectsSemiconductor/solid-state device manufacturingSemiconductor devicesHigh concentrationOhmic contact

The invention provides a manufacturing method of a Terahertz Schottky diode. The manufacturing method comprises: a high-concentration gallium arsenide-doped layer and a low-concentration gallium arsenide-doped layer are sequentially formed on a substrate of a gallium arsenide semiconductor; an Ohmic contact cathode and Ohmic contact metals are formed on the high-concentration gallium arsenide-doped layer; a silicon dioxide layer with small bores is formed on the low-concentration gallium arsenide-doped layer; a Schottky contact anode is formed; an Ohmic contact cathode pressure point, a Schottky contact anode extension pressure point and a suspending plating bridge are formed; and the Schottky contact anode extension pressure point is connected with the Schottky contact anode through the impending plating bridge. According to the Schottky diode manufactured by the manufacturing method provided by the invention, parasitic effects are reduced, thermionic noises existing in n+GaAs, the discontinuity of the anode pressure point to the impending plating bridge and the series resistance of the diode can be lowered, and the integration with peripheral circuits is easily realized by using flip chip bonding.

Owner:孙琦

Ultra high resolution flat panel display having in-cell type touch sensor

ActiveUS20160188061A1Parasitic capacitanceImprove Sensing PerformanceStatic indicating devicesNon-linear opticsImage resolutionDisplay device

A display having a touch sensor comprises: a plurality of pixel areas disposed in a matrix manner on a substrate; a routing line running along a first direction on the substrate; a first passivation layer covering the routing line; a touch electrode covering the routing line and corresponding to a grouped pixel areas on the first passivation layer; a touch contact hole exposing some portions of the routing line by penetrating the touch electrode and the first passivation layer; a second passivation layer covering the touch electrode; a passivation contact hole exposing the touch contact hole and some portions of the touch electrode around the touch contact hole by penetrating the second passivation layer; and a touch terminal connecting the touch electrode and the routing line on the second passivation layer.

Owner:LG DISPLAY CO LTD

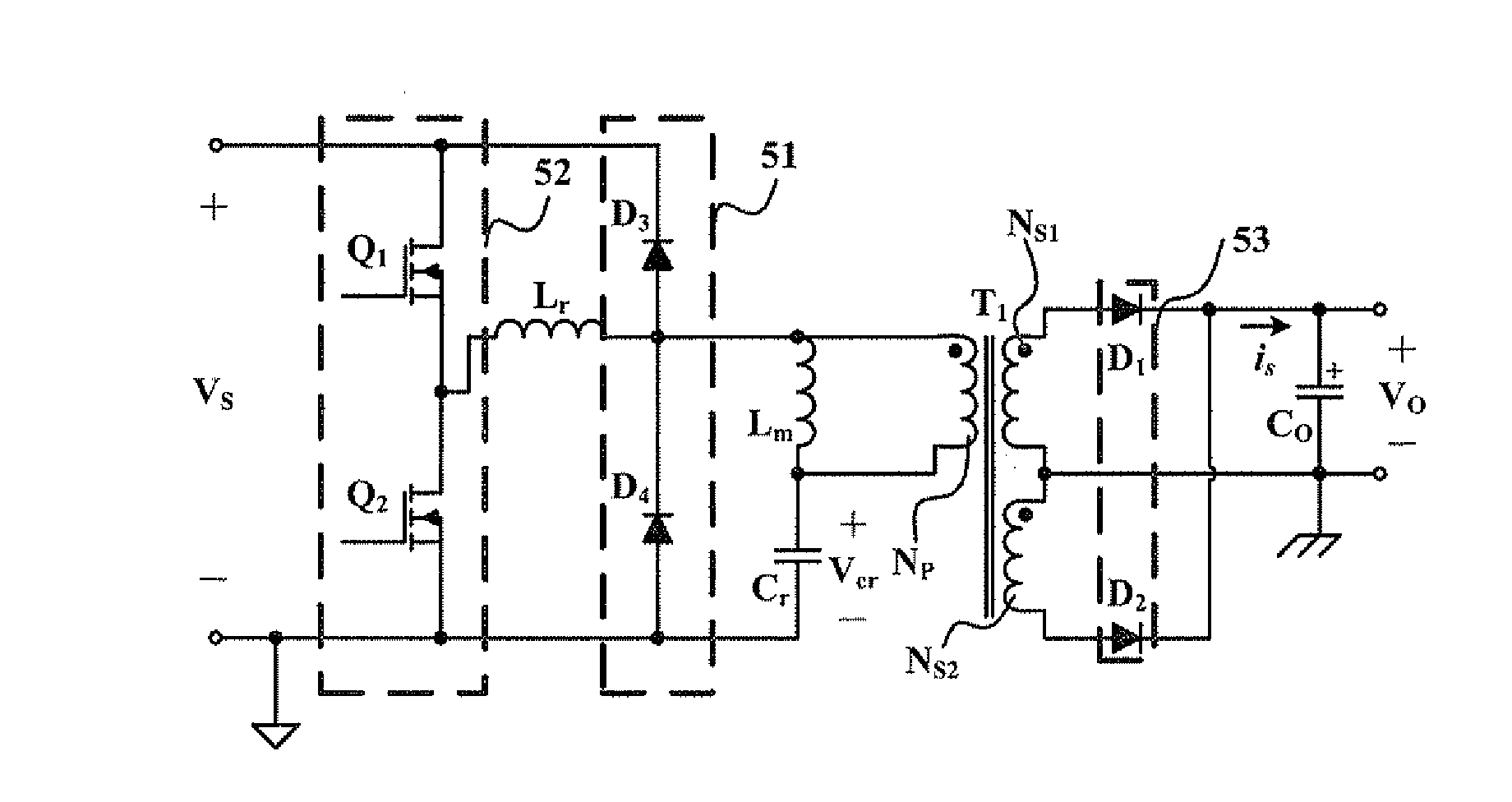

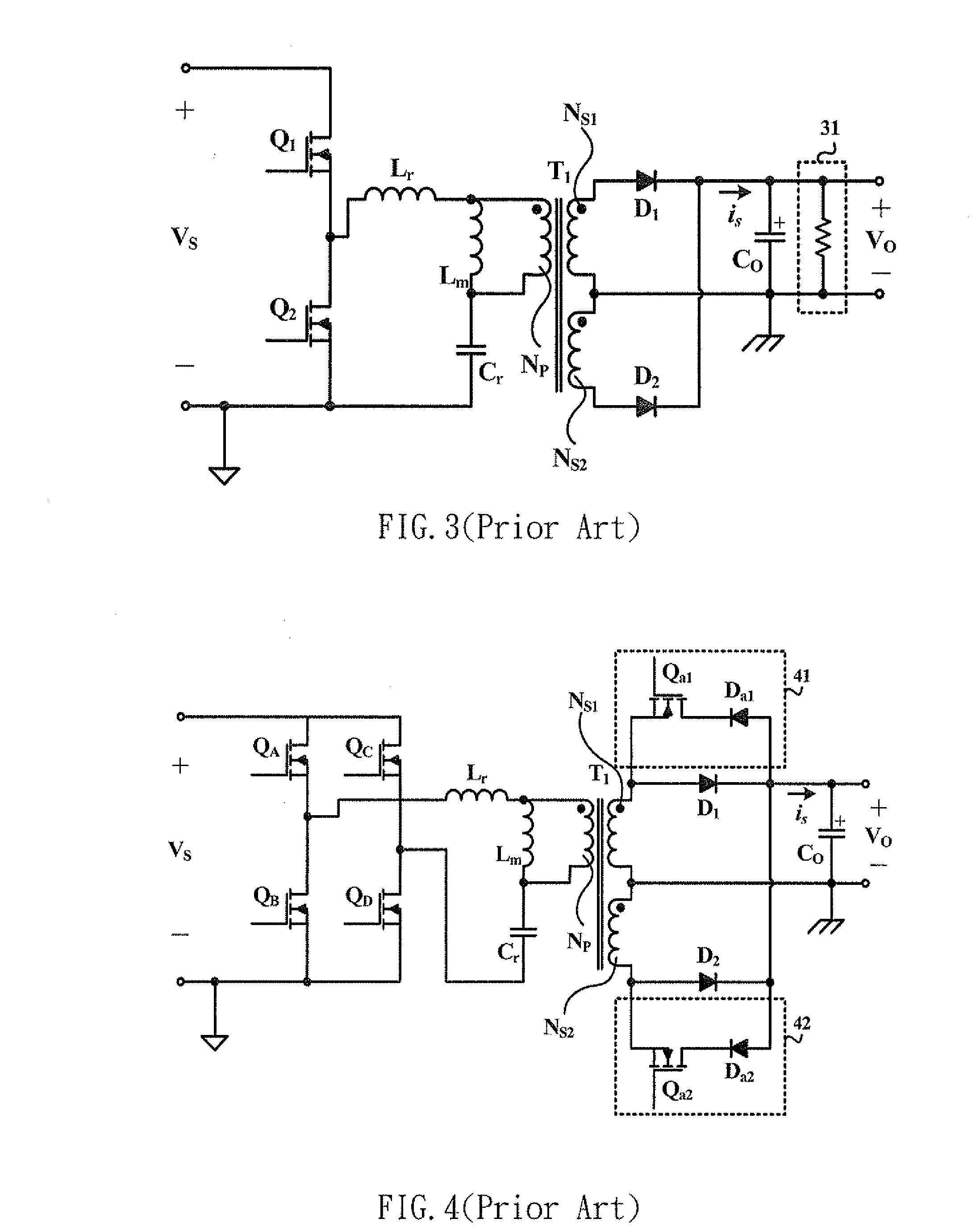

Llc resonant power converter with current-circulating circuit for enabling light-load regulation

InactiveUS20130294113A1Enabling light-load regulationSmoothly receive energy transferredEfficient power electronics conversionDc-dc conversionFull waveResonant power converters

The present invention is to provide a power converter, which includes a half-bridge circuit parallel-connected to an input voltage and having two series-connected power switches, an LLC resonant circuit formed by a resonant inductor, magnetic inductance of a primary winding and a resonant capacitor, a current-circulating circuit parallel-connected to the half-bridge circuit and having two series-connected rectifiers, and a full-wave rectification circuit connected to a secondary winding for generating an output voltage across an output capacitor. The LLC resonant circuit is parallel-connected to one of the power switches, and the line between the two rectifiers is cross-connected to the line between the resonant inductor and the primary winding. Thus, since the current-circulating circuit is able to guide current through the resonant inductor into circulation in switching moment of the power switches, parasitic capacitance of the primary winding is prevented from being overcharged by the current through the resonant inductor accordingly.

Owner:SKYNET ELECTRONICS

Display device integrated with touch screen panel and method of driving the same

ActiveUS9098161B2Easy loadingConvenient and accurateStatic indicating devicesInput/output processes for data processingTouch SensesDisplay device

Owner:LG DISPLAY CO LTD

Substrate contact for a capped MEMS and method of making the substrate contact at the wafer level

InactiveUS7316965B2Avoid Parasitic CapacitanceSemiconductor/solid-state device manufacturingAcceleration measurementEngineeringConductive materials

A MEMS device (100) is provided that includes a handle layer (108) having a sidewall (138), a cap (132) overlying said handle layer (108), said cap (132) having a sidewall (138), and a conductive material (136) disposed on at least a portion of said sidewall of said cap (138) and said sidewall of said handle layer (138) to thereby electrically couple said handle layer (108) to said cap (132). A wafer-level method for manufacturing the MEMS device from a substrate (300) comprising a handle layer (108) and a cap (132) overlying the handle layer (108) is also provided. The method includes making a first cut through the cap (132) and at least a portion of the substrate (300) to form a first sidewall (138), and depositing a conductive material (136) onto the first sidewall (138) to electrically couple the cap (132) to the substrate (300).

Owner:NORTH STAR INNOVATIONS

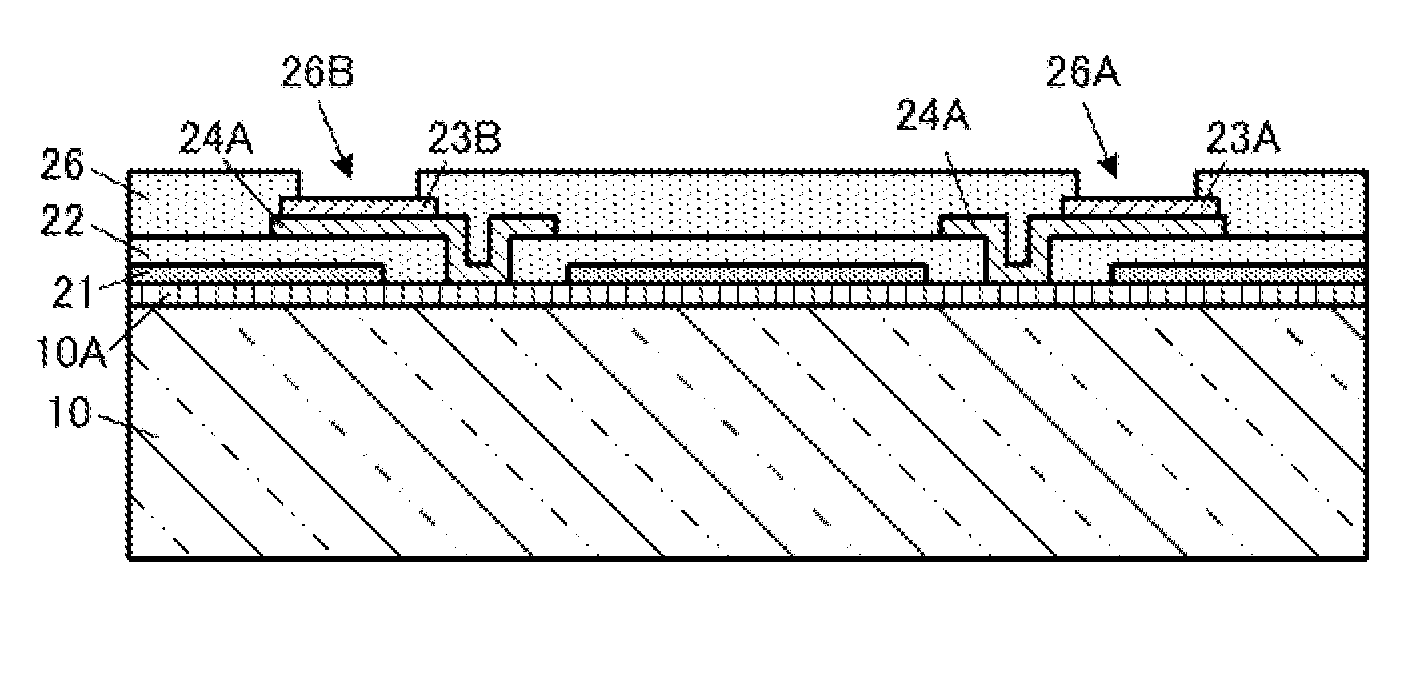

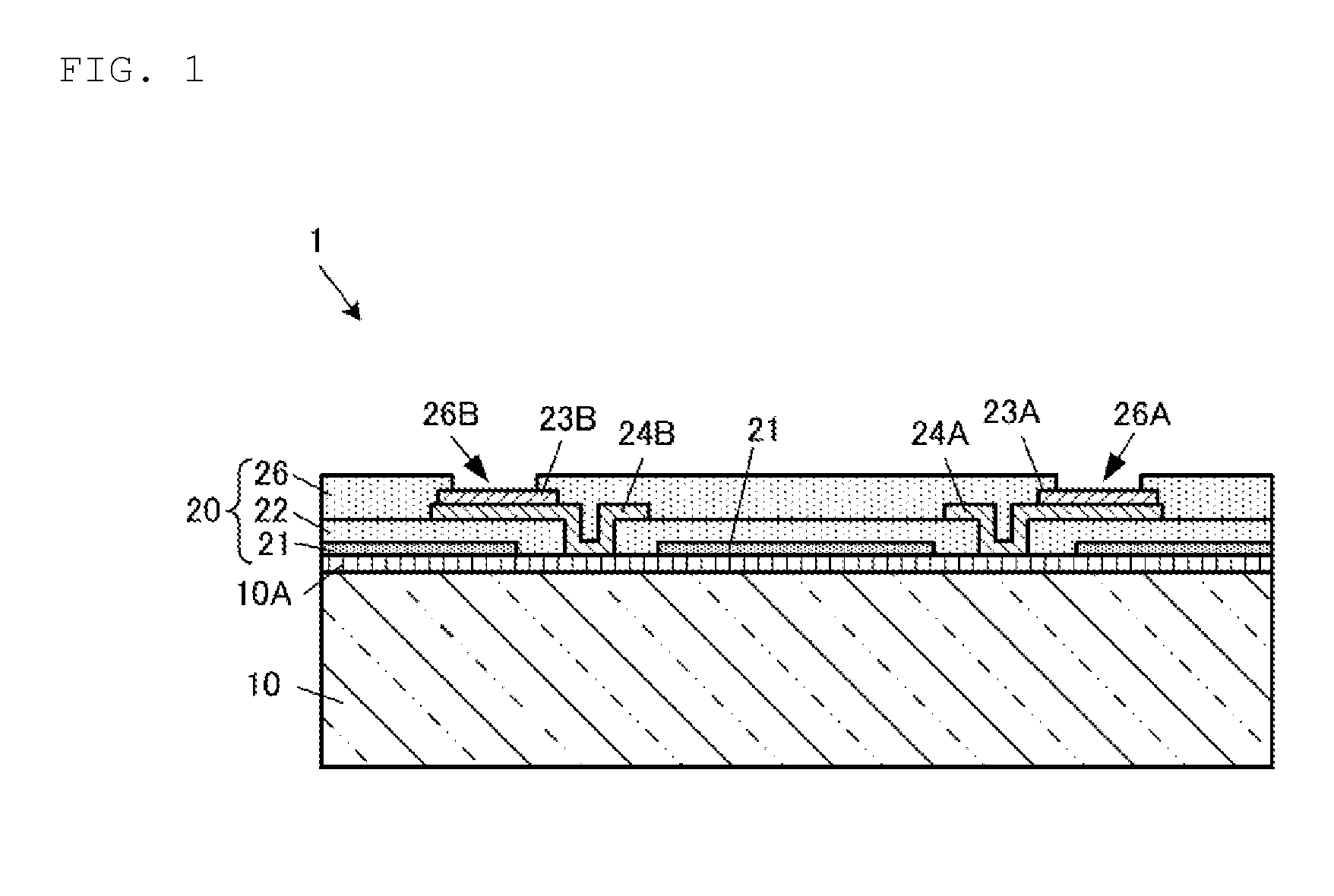

Semiconductor device

ActiveUS20150371941A1Unnecessary parasitic capacitance can be preventedReduce parasitic capacitanceSemiconductor/solid-state device detailsSolid-state devicesFrequency bandPower semiconductor device

An ESD protection device includes a Si substrate and a rewiring layer. The rewiring layer includes Ti / Cu / Ti electrodes are electrically connected through contact holes to an ESD protection circuit with Al electrodes films, which is formed at the surface of the Si substrate. The Al electrode film is electrically connected to the Ti / Cu / Ti electrode, whereas the Al electrode film is electrically connected to the Ti / Cu / Ti electrode. A diode forming region is formed between Al electrode films, whereas a diode forming region is formed between Al electrode films. The Ti / Cu / Ti electrode has no overlap with the diode forming region, whereas the Ti / Cu / Ti electrode has no overlap with the diode forming region. Thus, a semiconductor device is provided which is able to reduce the generation of parasitic capacitance, and able to be applied up to a higher frequency band.

Owner:MURATA MFG CO LTD

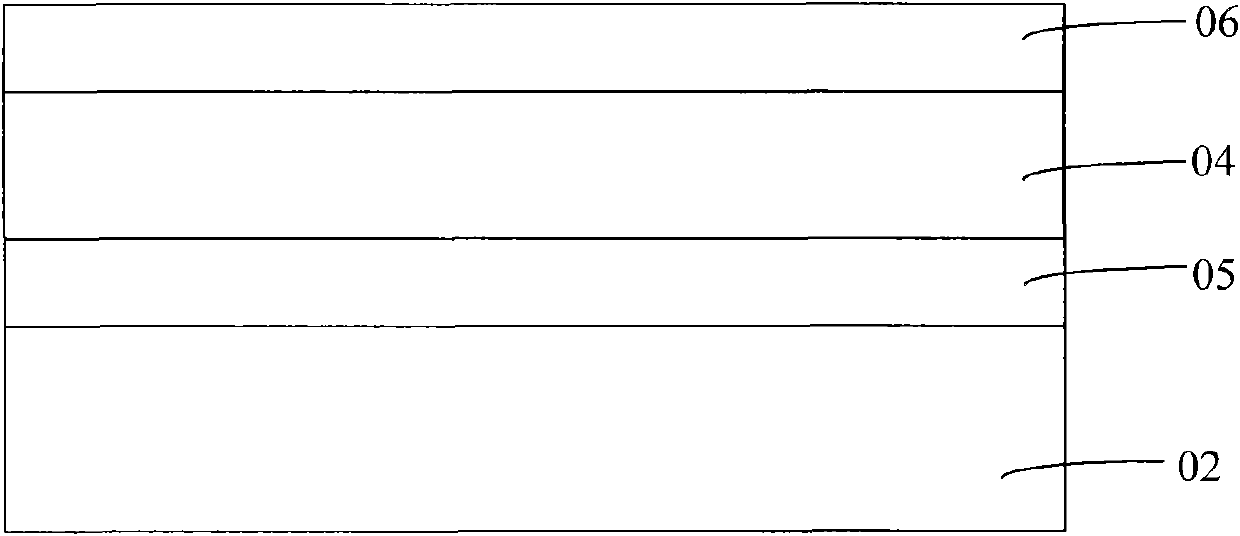

Liquid crystal picture element and producing method thereof and liquid crystal display device

ActiveCN101021659ANo burdenAvoid Parasitic CapacitanceStatic indicating devicesSemiconductor/solid-state device detailsVertical projectionLiquid-crystal display

The invention provides a liquid crystal pixel and the making method and LCD thereof. And the liquid crystal pixel comprises a data line, a doped polycrystalline layer and a shielding metal layer, where the doped polycrystalline silicon layer is located under the data line and the vertical projection of the polycrystalline silicon layer does not overlap the data line; the shielding metal layer is located between the data line and the doped polycrystalline silicon layer and form a storage capacitor together with the polycrystalline silicon layer. In addition, the invention also provides a liquid crystal pixel making method, which stores video data by the store capacitor and can not cause burden to the data line but can avoid possible parasitical capacitor between the pixel electrode and the data line.

Owner:AU OPTRONICS CORP

Method of forming a trench isolation layer and method of manufacturing a non-volatile memory device using the same

InactiveUS7601588B2Reduce parasitic capacitanceMinimizes parasitic capacitanceSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerParasitic capacitance

In a method of forming a device isolation layer for minimizing a parasitic capacitor and a non-volatile memory device using the same, a trench is formed on a substrate. A first insulation layer is formed on a top surface of the substrate and on inner surfaces of the trench, so that the trench is partially filled with the first insulation layer. A second insulation layer is formed on the first insulation layer to a thickness to fill up the trench, thereby forming a preliminary isolation layer. An etching rate of the second insulation layer is different from that of the first insulation layer. A recess is formed at a central portion of the preliminary isolation layer by partially removing the first and second insulation layers, thereby forming the device isolation layer including the recess. The recess in the device isolation layer reduces a parasitic capacitance in a non-volatile memory device.

Owner:SAMSUNG ELECTRONICS CO LTD

Organic light emitting diodes display

ActiveUS7079093B2Resistance time delayAvoid signal delayControl electrodesDischarge tube luminescnet screensResistance capacitanceTime delays

An organic light emitting diodes display device includes a number of data lines, scan lines, and cathode electrodes. These scan lines are perpendicular to the data lines to form a number of pixels, each of which possess a pixel area respectively. All the pixels areas form a pixel area array. These cathode electrodes are parallel to the scan lines or data lines and partially cover the pixel area array. Spaces between each two cathode electrodes are above the scan lines or data lines to avoid the parasitic capacitance between the cathode electrodes and scan lines or data lines. And thus the resistance capacitance time delay is prevented.

Owner:AU OPTRONICS CORP

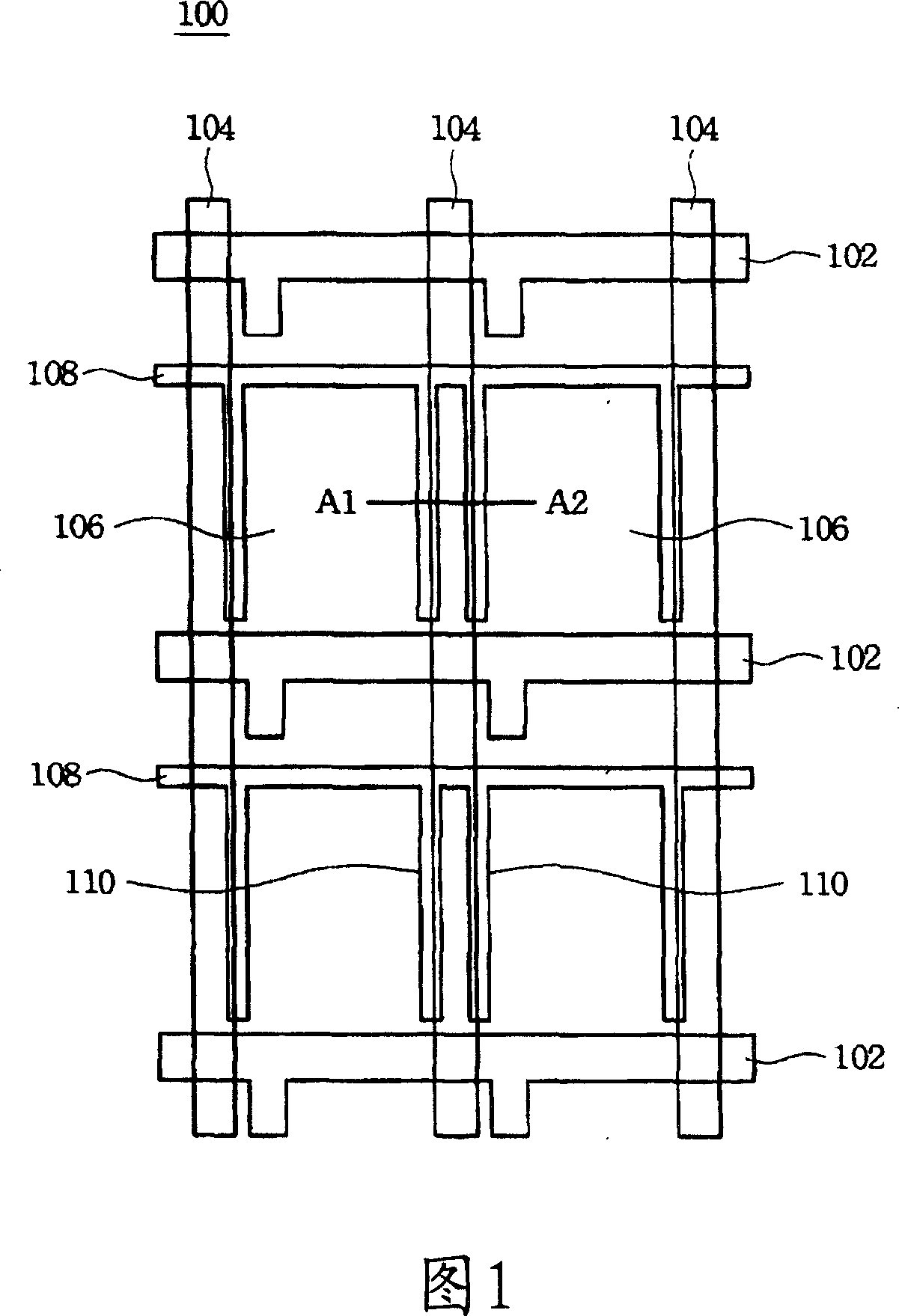

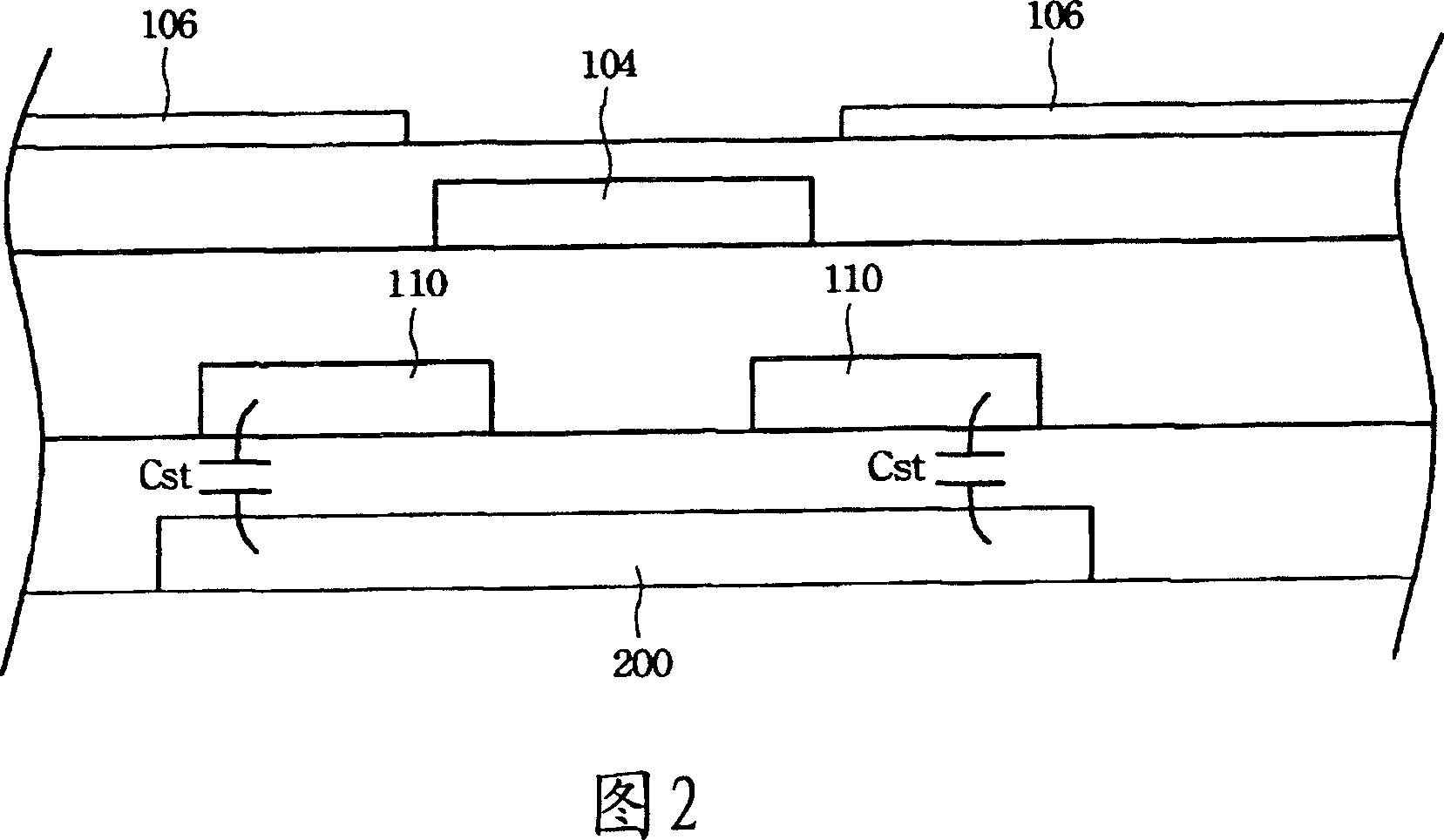

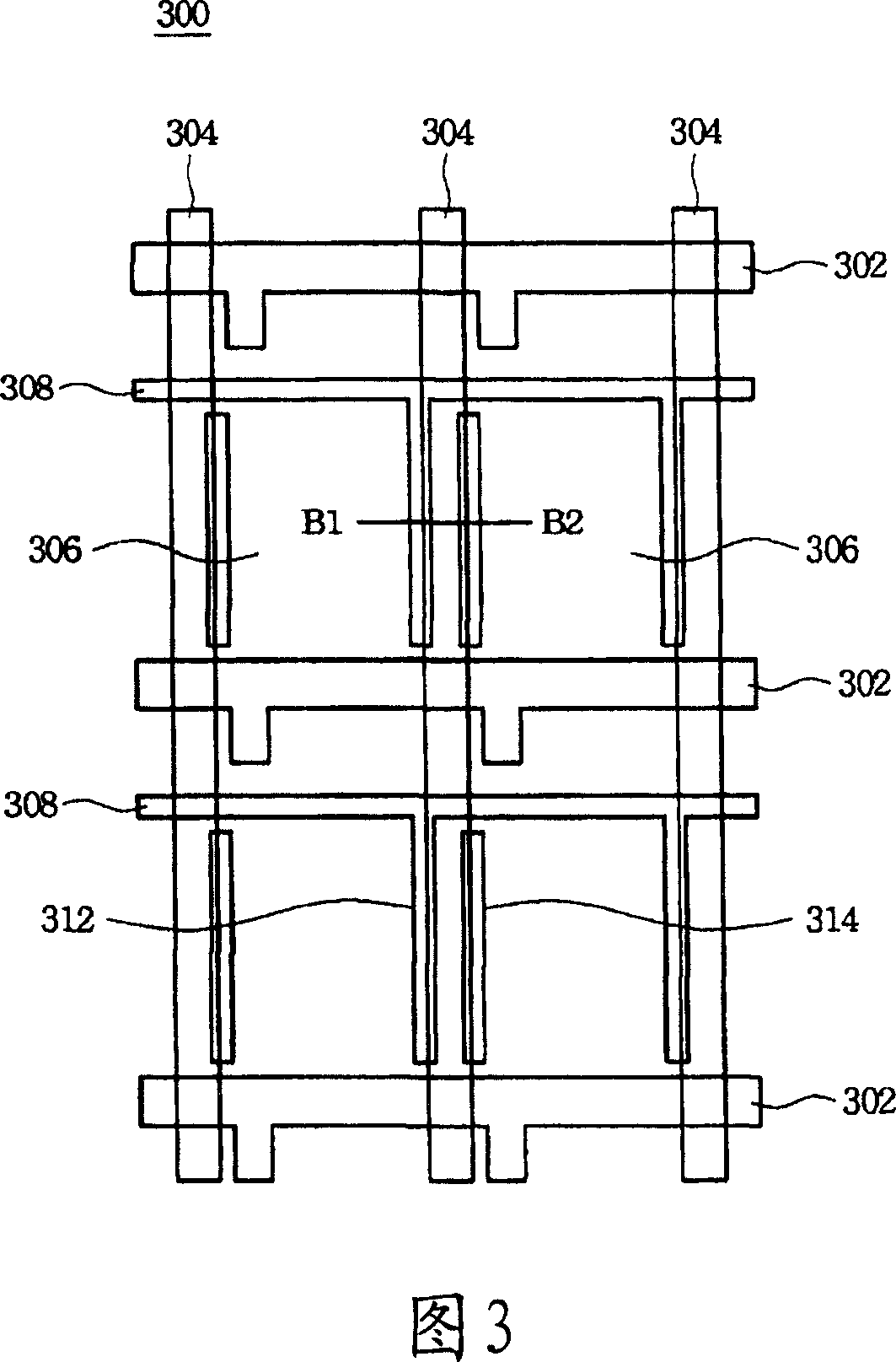

Display substrate, method of manufacturing the display substrate and display apparatus having the display substrate

ActiveUS20090167733A1Reduce distanceIncrease aperture ratioSolid-state devicesCathode-ray tube indicatorsEngineeringData lines

A display substrate includes a base substrate, a first line, a second line, a bridge line, a thin-film transistor (TFT), a storage line, and a pixel electrode. The first line extends in a first direction on the base substrate. The second line extends in a second direction on the base substrate and is divided into two portions with respect to the first line. The bridge line makes contact with the two portions of the second line in first and second bridge contact regions. The TFT includes a source electrode making contact with one of the first and second lines in a data contact region. The storage line is formed on the one of the first and second lines. The pixel electrode is formed on the storage line and is electrically connected to the TFT. The display substrate reduces formation of parasitic capacitance between pixel electrode and data line.

Owner:SAMSUNG DISPLAY CO LTD

Pixel structure and its production method

ActiveCN101221961AIncrease opening ratioAvoid Parasitic CapacitanceSemiconductor/solid-state device detailsSolid-state devicesInsulation layerParasitic capacitance

The invention provides a pixel structure and the production method thereof. The pixel structure comprises a substrate, a shading pattern floatingly arranged on the substrate, an insulation layer arranged on the substrate and the shading pattern, a data line arranged above the shading pattern and corresponding to the shading pattern, a dielectric layer arranged on the data line and the insulation layer, and a third-layer conductive pattern arranged on the dielectric layer. The third-layer conductive pattern comprises a common wire and a common pattern, wherein, the common pattern has two branch lines, a gap exists between the two branch lines, and further more the gap is positioned above the data line. The pixel structure of the invention takes advantage of the shading pattern of a first-layer conductive pattern to shield the light leakage which is easy to be produced on both sides of the data line of a second-layer conductive pattern, and takes advantage of the common pattern of the third-layer conductive pattern to shield the pixel electrode and the data line to avoid the parasitic capacitance produced between the pixel electrode and the data line.

Owner:AU OPTRONICS CORP

In-cell touch display device

ActiveUS20160018916A1Avoid Parasitic CapacitanceIncreasing load of touchCathode-ray tube indicatorsNon-linear opticsGate driverEngineering

An in-cell touch display device. A panel has a plurality of data lines, a plurality of gate lines and a plurality of touch electrodes disposed thereon. A touch driving signal is applied to the plurality of touch electrodes when a driving mode is a touch mode. A data driver drives the plurality of data lines. A gate driver drives the plurality of gate lines. The gate driver sequentially outputs a scanning signal for driving the plurality of gate lines to the plurality of gate lines when the driving mode is a display mode, and outputs a load-free driving signal corresponding to the touch driving signal to at least one gate line when the driving mode is the touch mode. A level shifter generates the load-free driving signal. A multiplexer inputs a scanning voltage or the load-free driving signal to the gate driver depending on the driving mode.

Owner:LG DISPLAY CO LTD

Array substrate, display and electronic equipment

ActiveCN105511688AAvoid parasitic capacitance of theHigh precisionStatic indicating devicesNon-linear opticsElectricityOptoelectronics

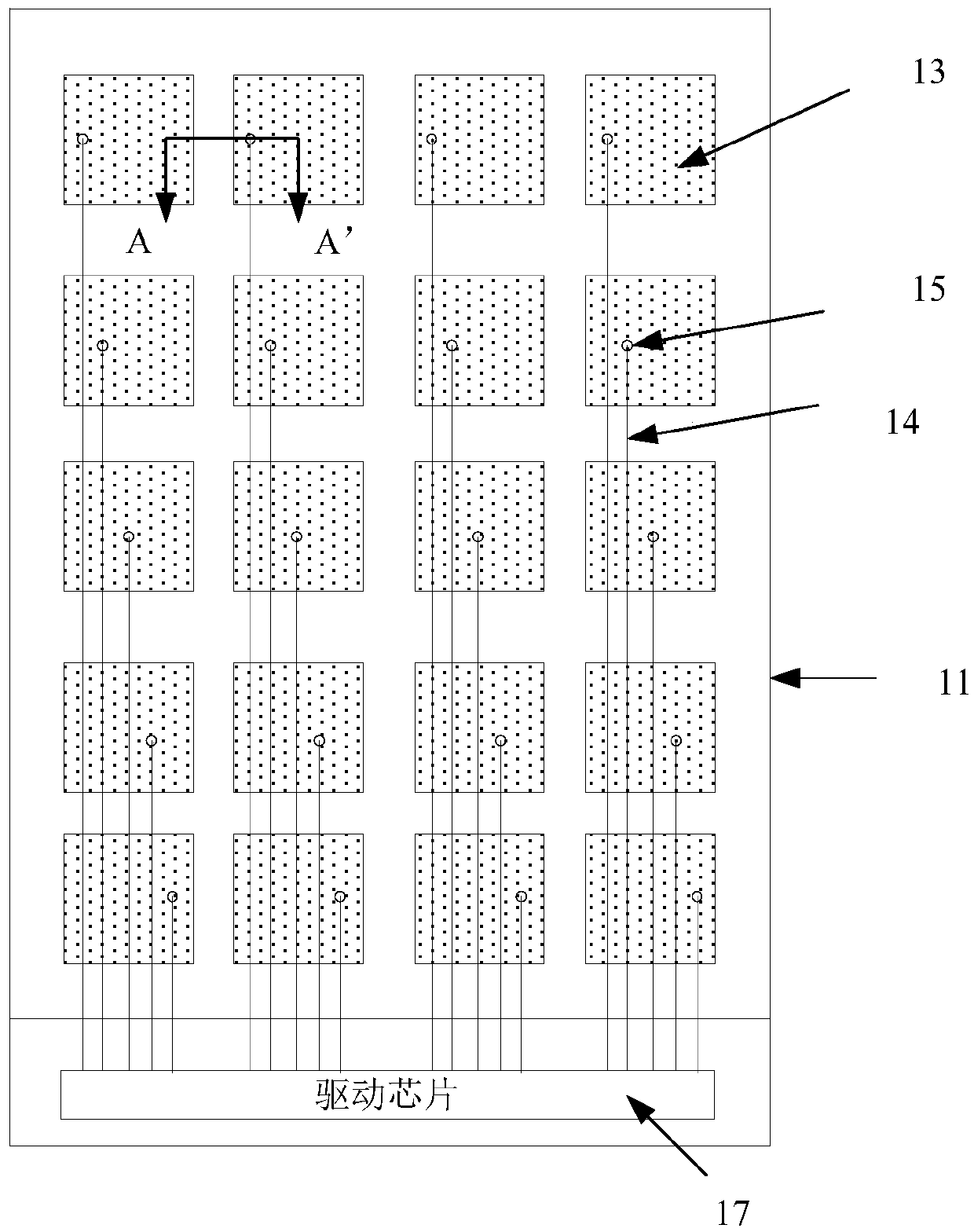

The invention discloses an array substrate, a display and electronic equipment. The array substrate comprises a public electrode layer and a pixel electrode layer which are opposite to each other, wherein the pixel electrode layer comprises a plurality of arrayed pixel electrodes, and the public electrode layer comprises a plurality of public electrode blocks; the array substrate further comprises a plurality of switch devices, a plurality of data lines extending along the column direction of the array, and a plurality of public routings electrically connected with the public electrode blocks in a one-to-one correspondence manner; projections of the public routings in the pixel electrode layer are not superposed with the pixel electrodes in the direction vertical to the pixel electrode layer; a pixel clearance is reserved between every two adjacent pixel electrodes; projections of the public routings in the pixel electrode layer and projections of the data lines in the pixel electrode layer are positioned in different pixel clearances in the direction vertical to the pixel electrode layer; two data lines of which the projections are positioned in the same pixel clearance are positioned on different layers. The array substrate is higher in touch detection precision.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

Display Device Integrated with Touch Screen Panel and Method of Driving the Same

ActiveUS20150301639A1Easy loadingConvenient and accurateStatic indicating devicesInput/output processes for data processingTouch SensesDisplay device

A display device integrated with a touch screen panel, and a method of driving the same, can prevent parasitic capacitance that would otherwise increase the load during a touch operation, lower the accuracy of touch sensing, or make touch sensing impossible. The display device includes data lines, gate lines, and a plurality of electrodes spaced apart from each other. A common voltage is applied to the electrodes in a display driving mode and a touch drive signal is applied to one or more of the electrodes in a touch driving mode. A data voltage is applied to the data lines in the display driving mode. A scan signal is supplied sequentially to the gate lines in the display driving mode and the touch drive signal or a signal corresponding to the touch drive signal is applied to one or more of the gate lines in the touch driving mode.

Owner:LG DISPLAY CO LTD

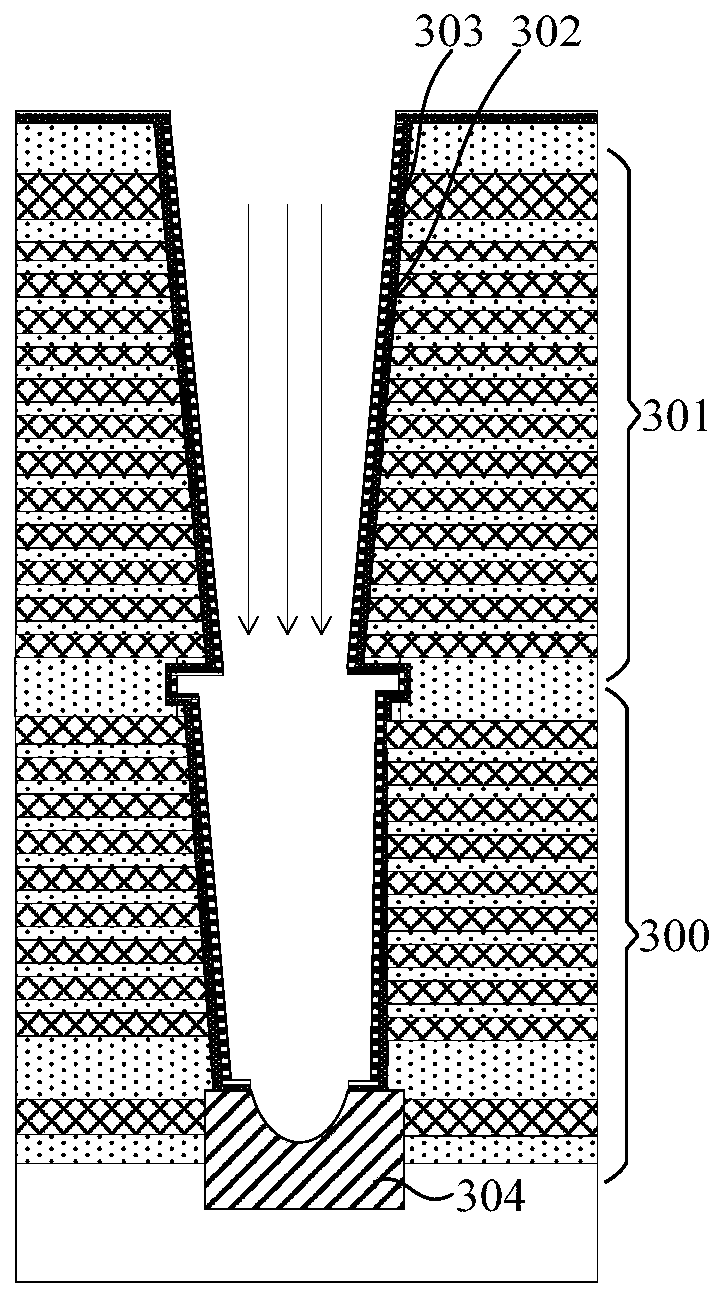

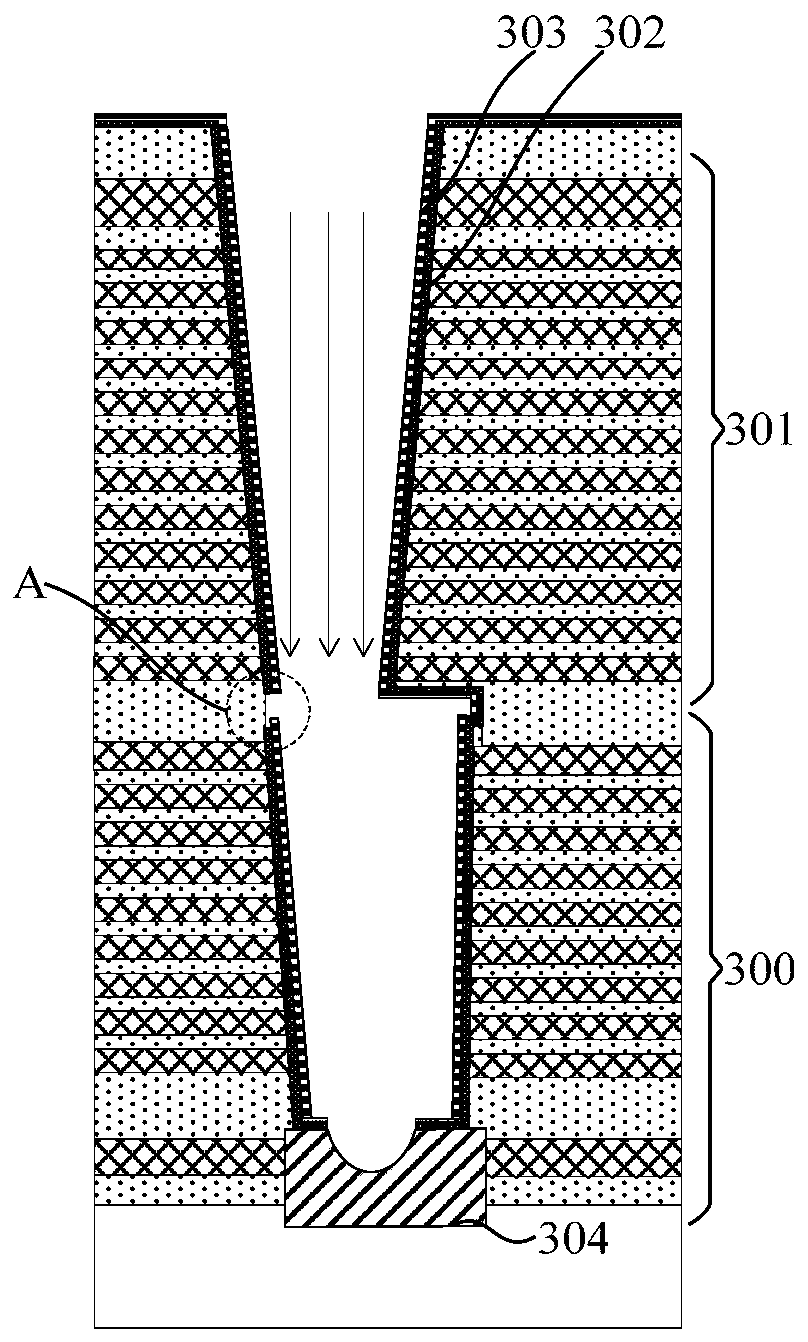

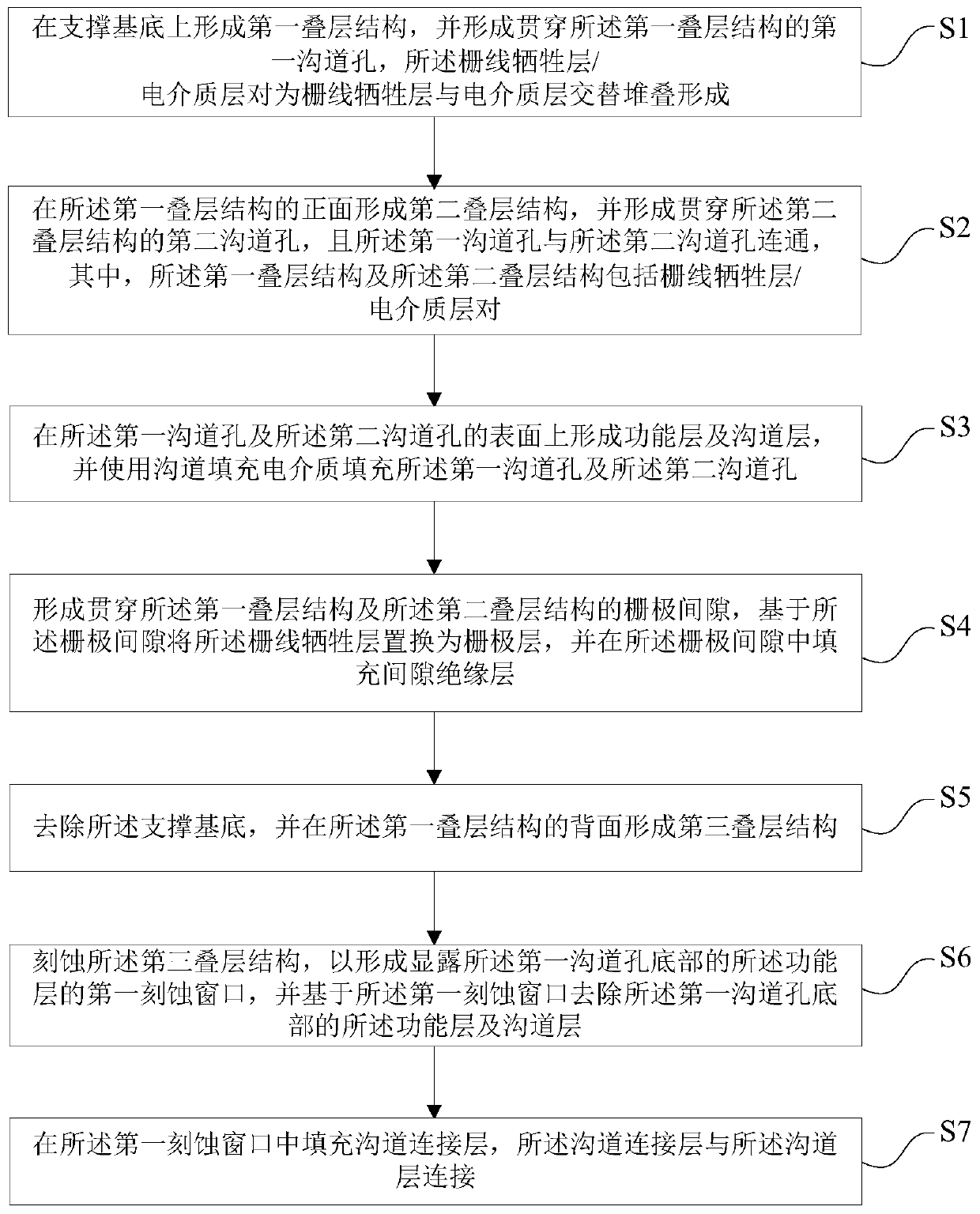

Three-dimensional NAND memory device structure and preparation method thereof

ActiveCN111403409AAchieve connectionAvoid risk of damageSolid-state devicesEnergy efficient computingDielectricPhysics

The invention provides a three-dimensional NAND memory device structure and a preparation method thereof. The method comprises the following steps: forming a first laminated structure and a second laminated structure with communicated channel holes on a support substrate; forming a functional layer, a channel layer and a filling dielectric on the surface of the channel hole; forming a gate gap; filling a gap insulating layer in the gate gap; removing the support substrate, and forming a third laminated structure on the back surface of the first laminated structure; etching the third laminatedstructure to form a first etching window, and removing the functional layer at the bottom of the first channel hole based on the first etching window; and filling a channel connection layer in the first etching window. The channel connection layer is formed at the corresponding position of the back surface of the channel hole, so that the risk that the functional layer at the connecting part of the upper channel hole and the lower channel hole is damaged when the channel connection layer and the channel layer are connected through a process of punching from the front surface of the channel hole is avoided; and in addition, the process for forming the channel connection layer is low in complexity, easy to control and high in yield.

Owner:YANGTZE MEMORY TECH CO LTD

Fin type field effect transistor and manufacture method thereof

ActiveCN103165447AGood electrical propertiesAvoid Parasitic CapacitanceSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureParasitic capacitance

The invention provides a fin type field effect transistor and a manufacture method of the fin type field effect transistor. The method comprises the steps that a fin is formed on a semiconductor substrate, a virtual grid electrode is formed on the semiconductor substrate with the formed fin and stretches across the fin, first side walls are formed on two sides of the virtual grid electrode, ions are implanted in the fin so as to form a source electrode and a drain electrode of the fin type field effect transistor, the virtual grid electrode is eliminated, an opening is formed in the position of the virtual grid electrode, a high-K-grid medium layer and a metal grid electrode material layer are sequentially deposited so as to fill the opening, and a metal grid electrode is formed, and the first side walls and the high-K-grid medium layer on the side wall of the metal grid electrode are eliminated. According to the fin type field effect transistor, the high-K-grid medium layer on two sides of the metal grid electrode are effectively eliminated in sequence, stray capacitance is prevented from generating between the metal grid electrode and the source electrode or the drain electrode, other semiconductor structures are prevented from being damaged during the eliminating process, and the fin type field effect transistor is enabled to be good in electrical properties.

Owner:SEMICON MFG INT (SHANGHAI) CORP

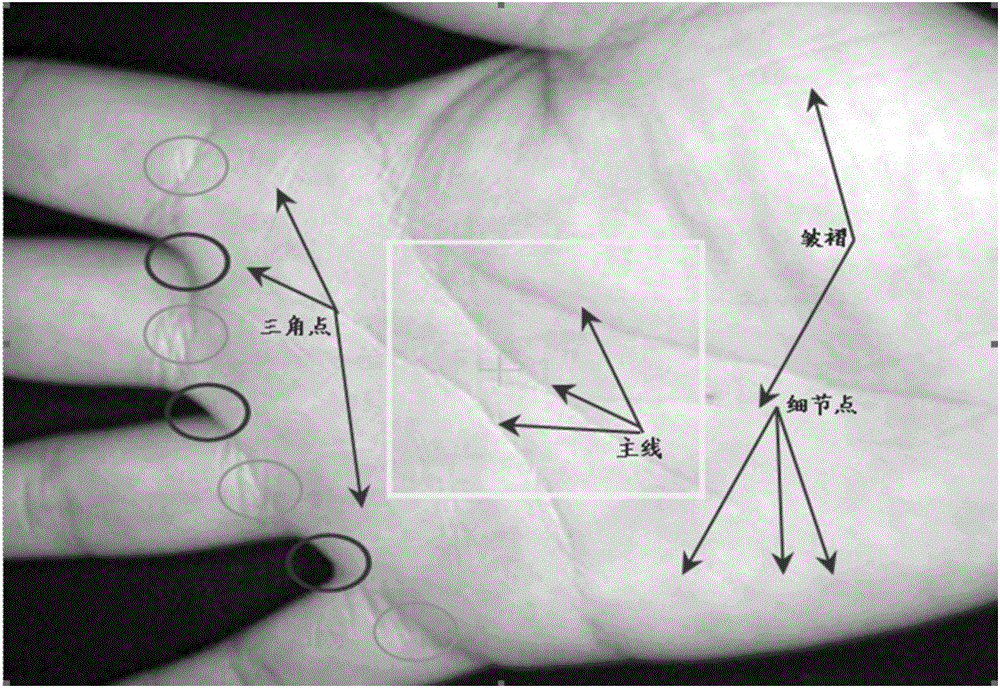

Array substrate and preparation method therefor, display panel and display apparatus

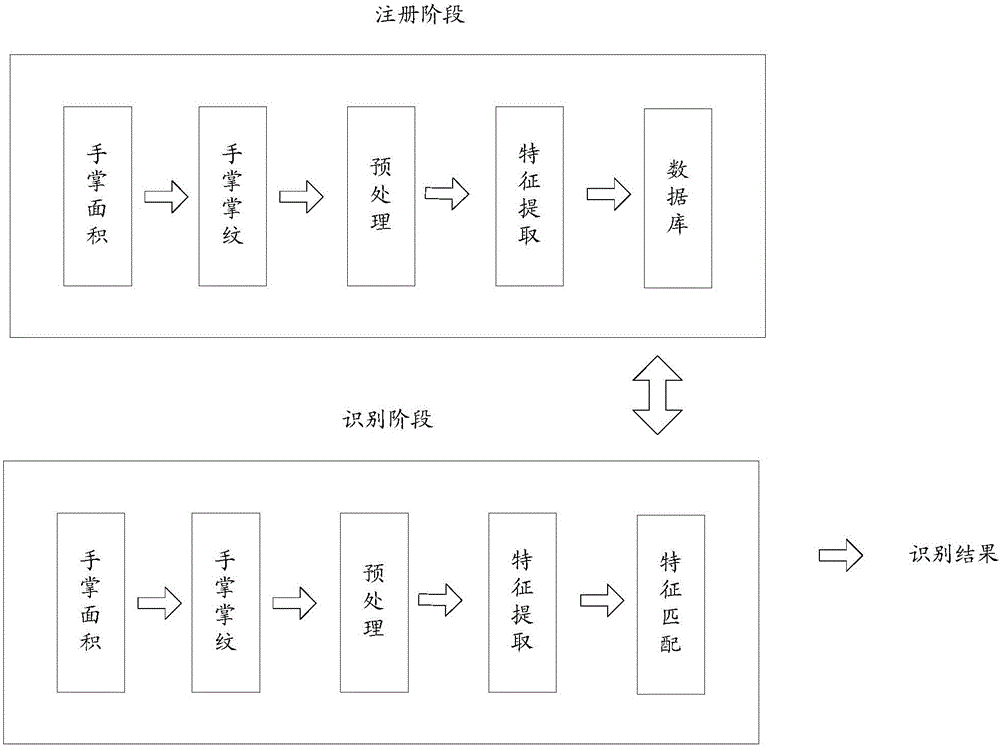

ActiveCN105870105AReduce distractionsEasy to identifySemiconductor/solid-state device detailsSolid-state devicesParasitic capacitanceSignal lines

The invention discloses an array substrate and a preparation method therefor, a display panel and a display apparatus, and belongs to the display field. The array substrate comprises multiple pixel units, a reading signal line, a first gate electrode signal line, a second gate electrode signal line, a data line and a shielding signal line, wherein each pixel unit comprises three sub pixel units; each sub pixel unit comprises a display sub unit; at least one pixel unit also comprises a palmprint recognition sub unit; the shielding signal line is parallel to the reading signal line; one end of the shielding signal line is grounded while the other end of the shielding signal line is connected with the input end of the first gate electrode signal line; the corresponding display sub units are connected with the first gate electrode signal line and the data line; and the palmprint recognition unit is connected with the second gate electrode signal line and the reading signal line. According to the array substrate, due to the addition of the shielding signal line, the interference on the reading signal line from the grid electrode signal lines can be reduced, stray capacitance can be prevented from being generated on the reading signal line, and the palmprint recognition effect is improved.

Owner:BOE TECH GRP CO LTD +1

Display device having in-cell touch structure and method of driving the same

ActiveUS9690437B2Avoid Parasitic CapacitanceIncrease loadCathode-ray tube indicatorsInput/output processes for data processingData signalReference wave

A display driver circuit comprises first circuitry to generate a touch drive signal, and second circuitry to provide the touch drive signal to touch sense electrodes of the display device and a touch data signal to data lines of the display device during a touch period and to provide display data signals to data lines of the display device during a display period. A touch gate signal is provided to gate lines of the display device during the touch period. The touch drive signal, the touch data signal, and the touch gate signal mimic a reference waveform, but amplitudes of one or more of the touch drive signal, the touch data signal, and the touch gate signal are overdriven by their respective overdrive amplitude with respect to the reference waveform during their respective overdrive duration.

Owner:LG DISPLAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com