Pixel structure and its production method

A pixel structure and conductive pattern technology, which is applied in semiconductor/solid-state device manufacturing, optics, instruments, etc., can solve the problems of increasing parasitic capacitance, affecting the pixel aperture ratio, and increasing the size, so as to achieve high aperture ratio and reduce crosstalk effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to enable examiners and those familiar with the art to further understand the present invention, the preferred embodiments of the present invention are listed below, together with the accompanying drawings, component symbols, etc., to describe in detail the composition of the present invention and the desired effects .

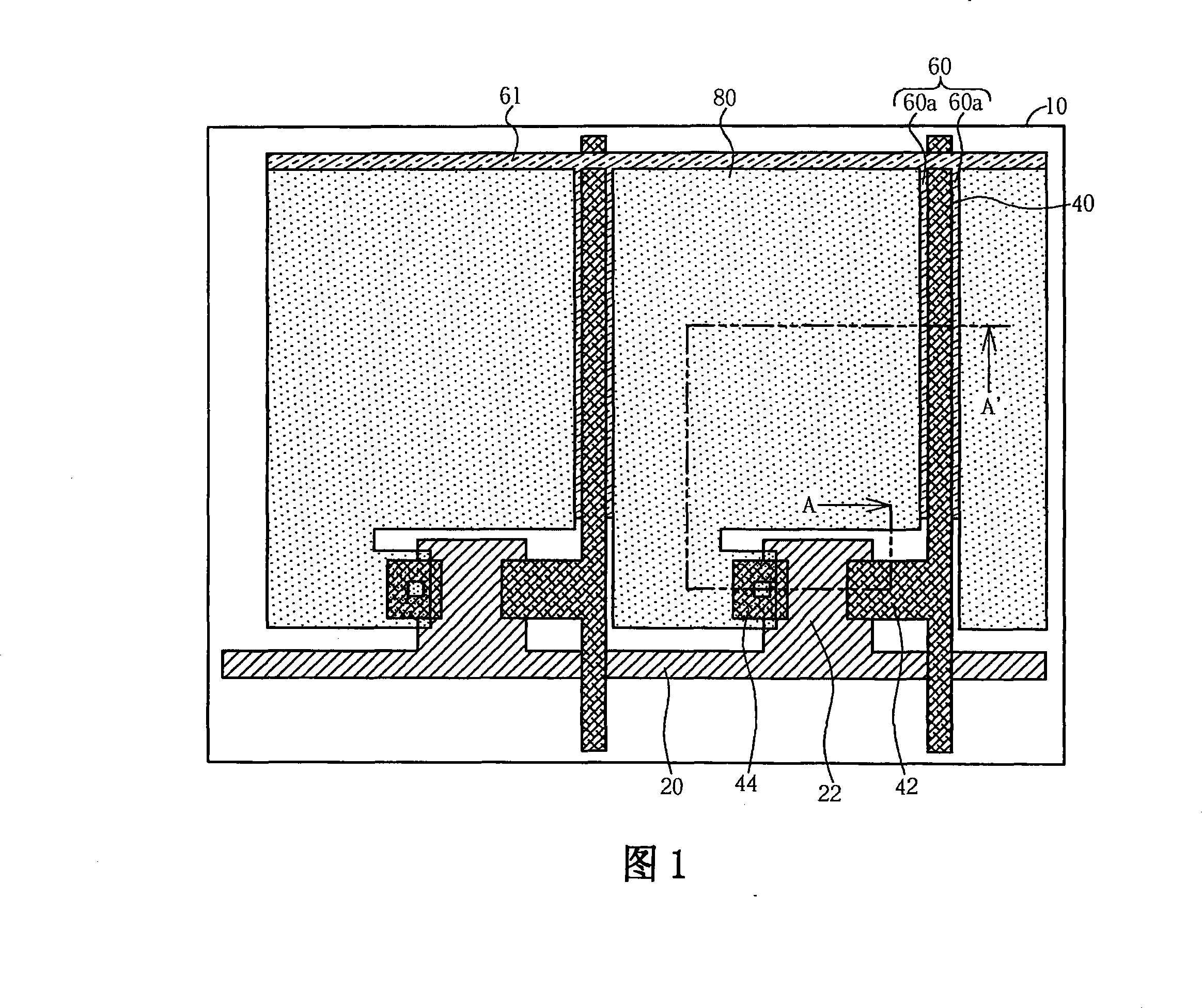

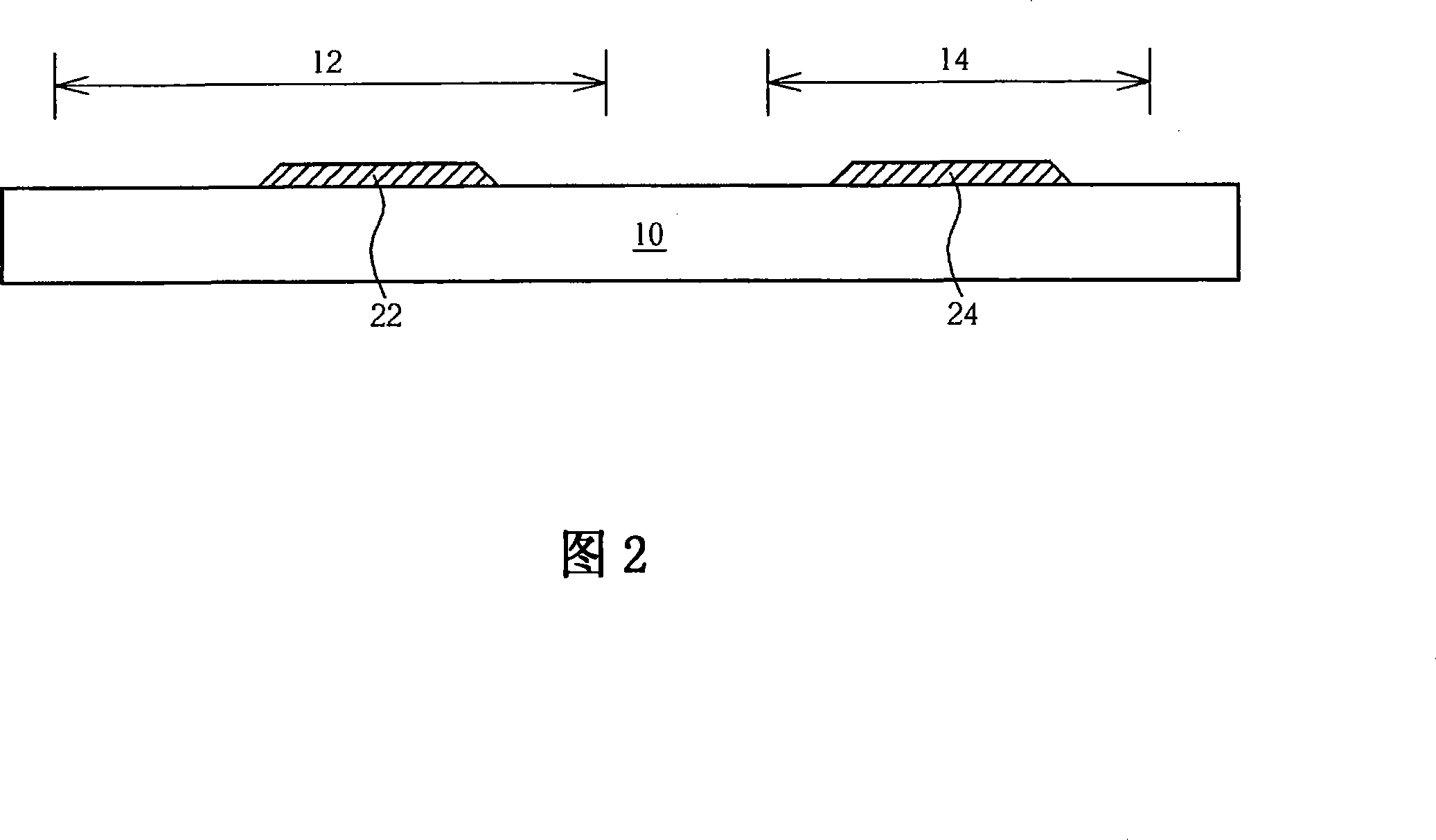

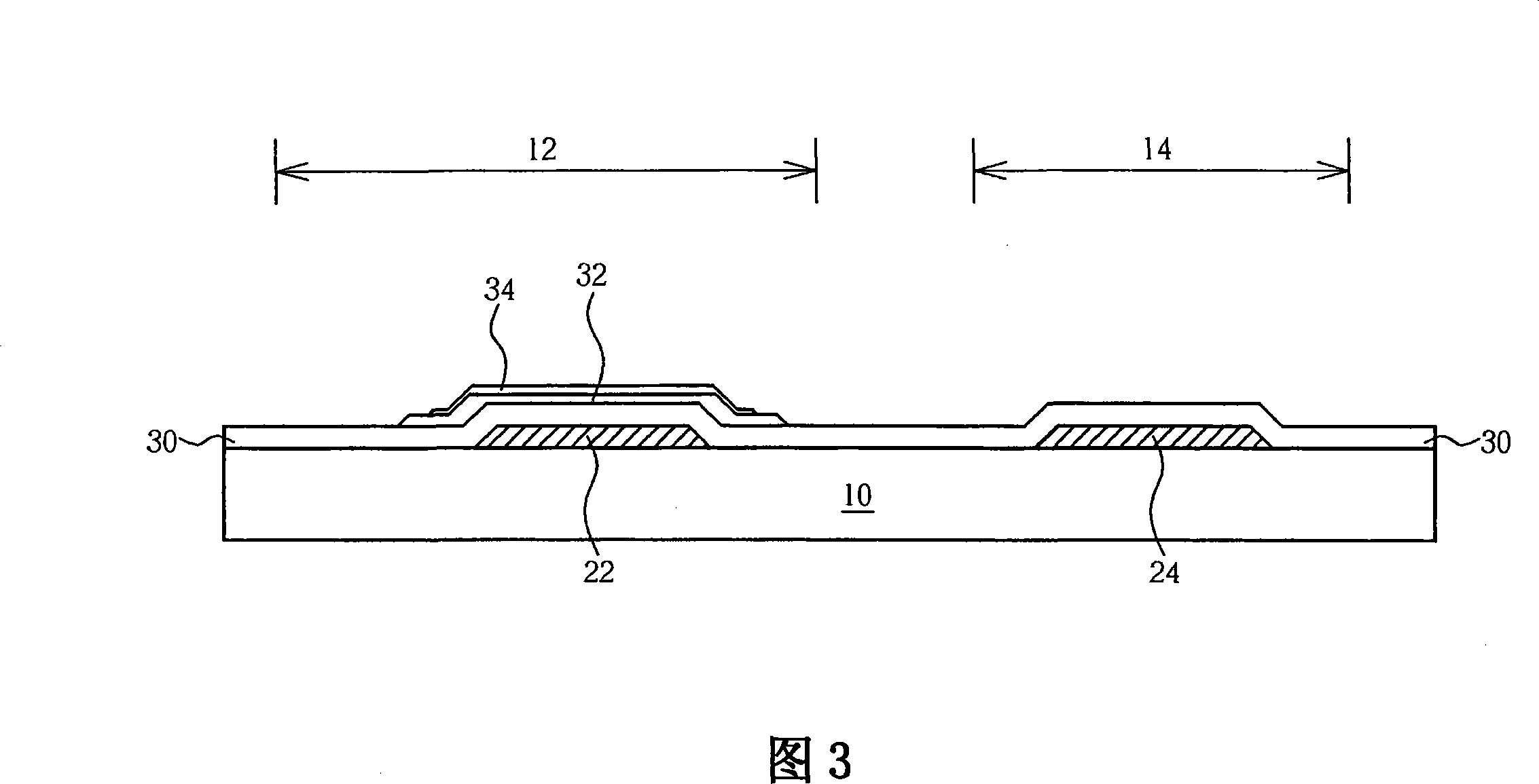

[0043] This embodiment illustrates the present invention by taking the pixel structure of an amorphous silicon thin film transistor liquid crystal display device as an example, but the application of the pixel structure of the present invention is not limited thereto, and can be applied to the pixel structure of other types of liquid crystal display devices. Please refer to Figures 1 to 7. Figure 1 is a schematic diagram of a pixel structure in a preferred embodiment of the present invention, and Figures 2 to 7 are schematic cross-sectional views of manufacturing the pixel structure in Figure 1, wherein Figure 1 shows a schematic top view of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com