Patents

Literature

90results about "X-ray tube laminated targets" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

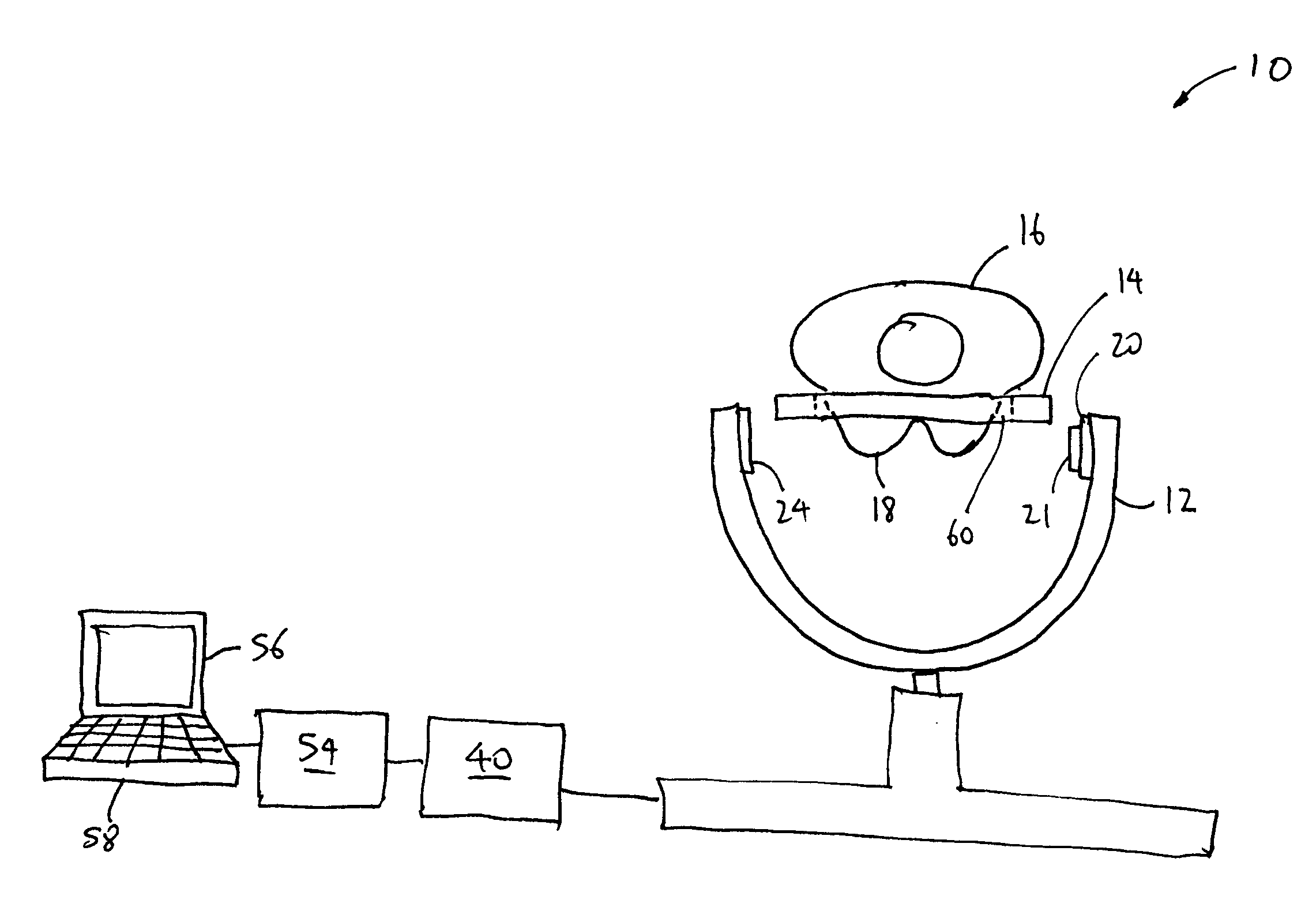

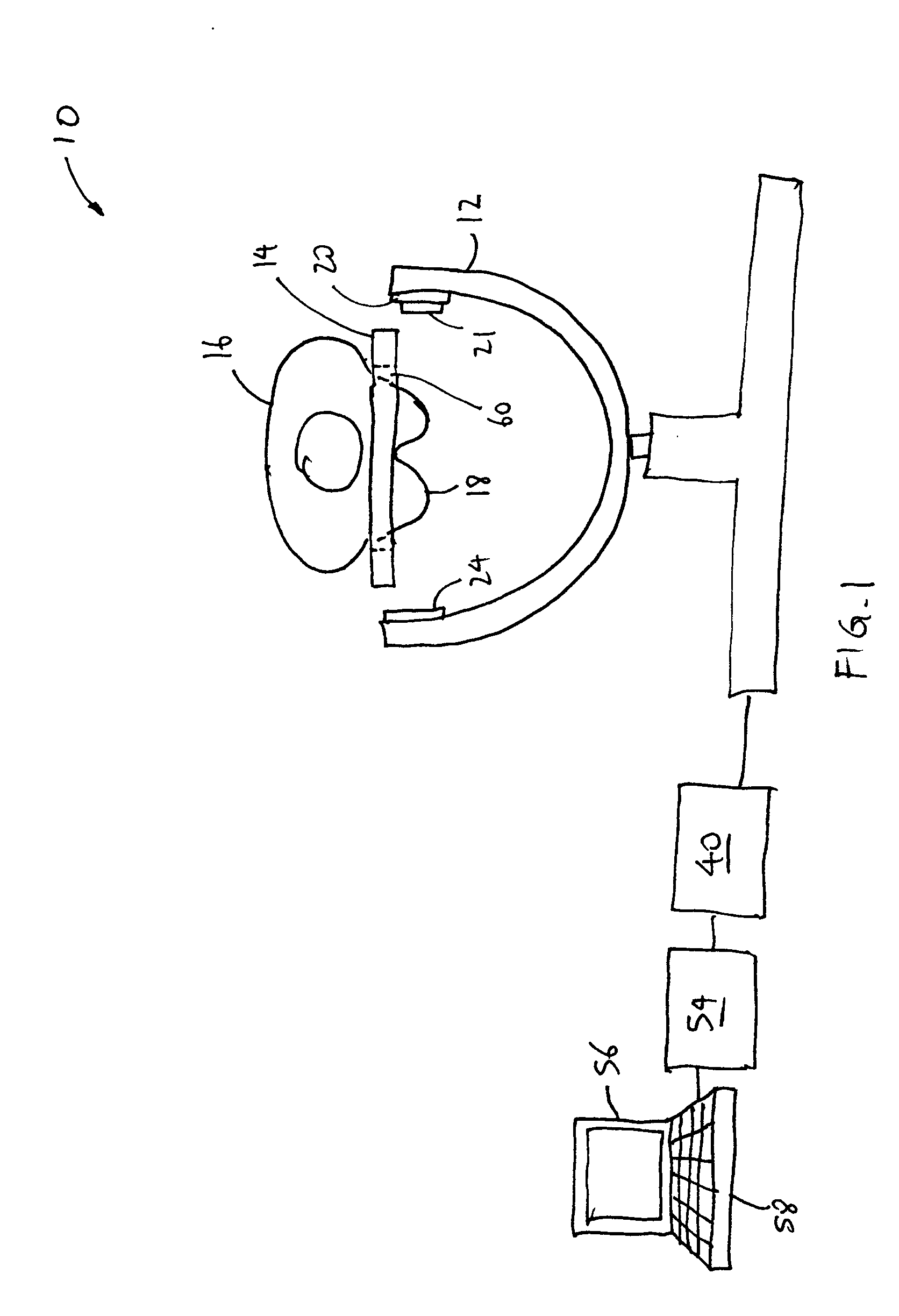

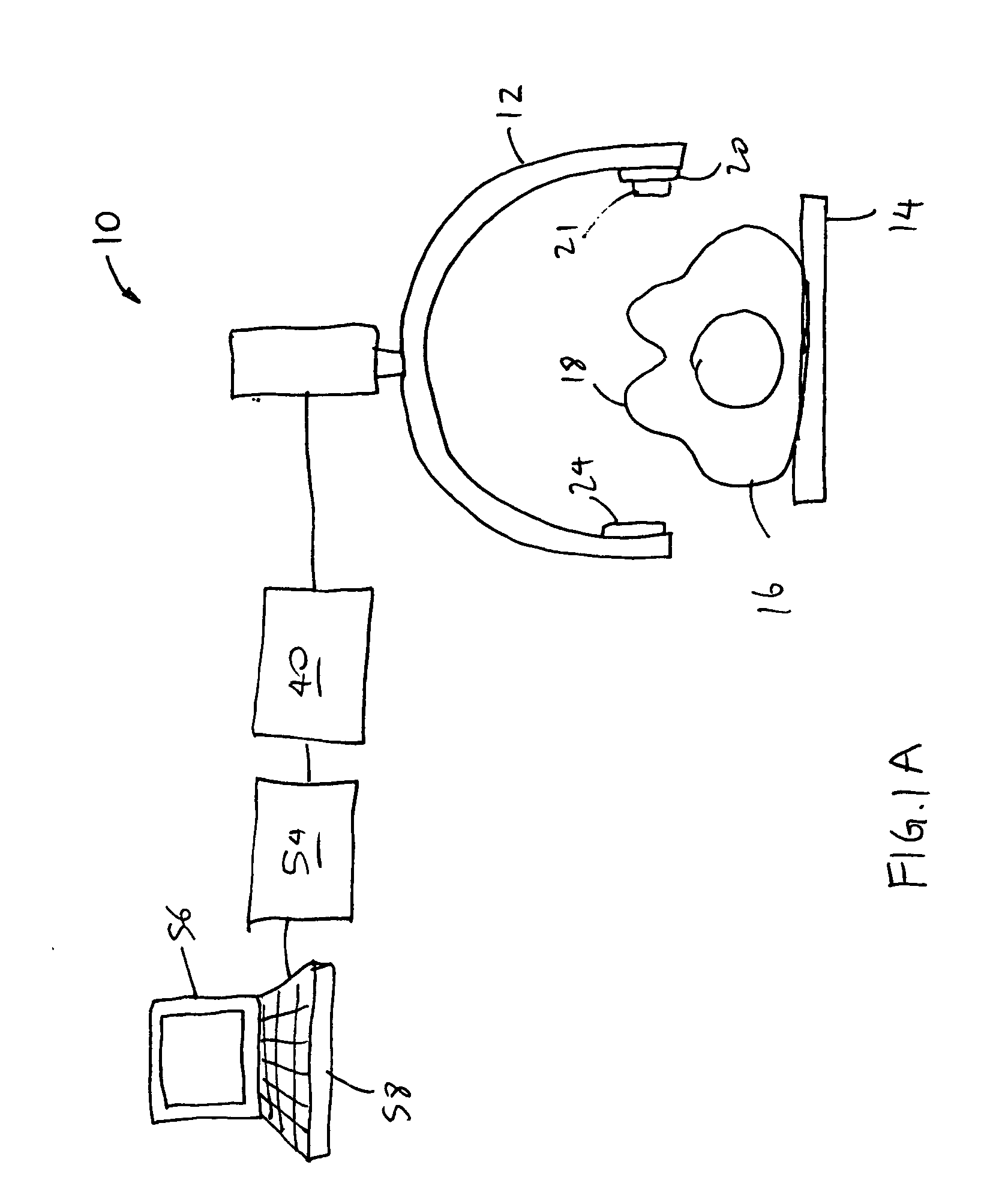

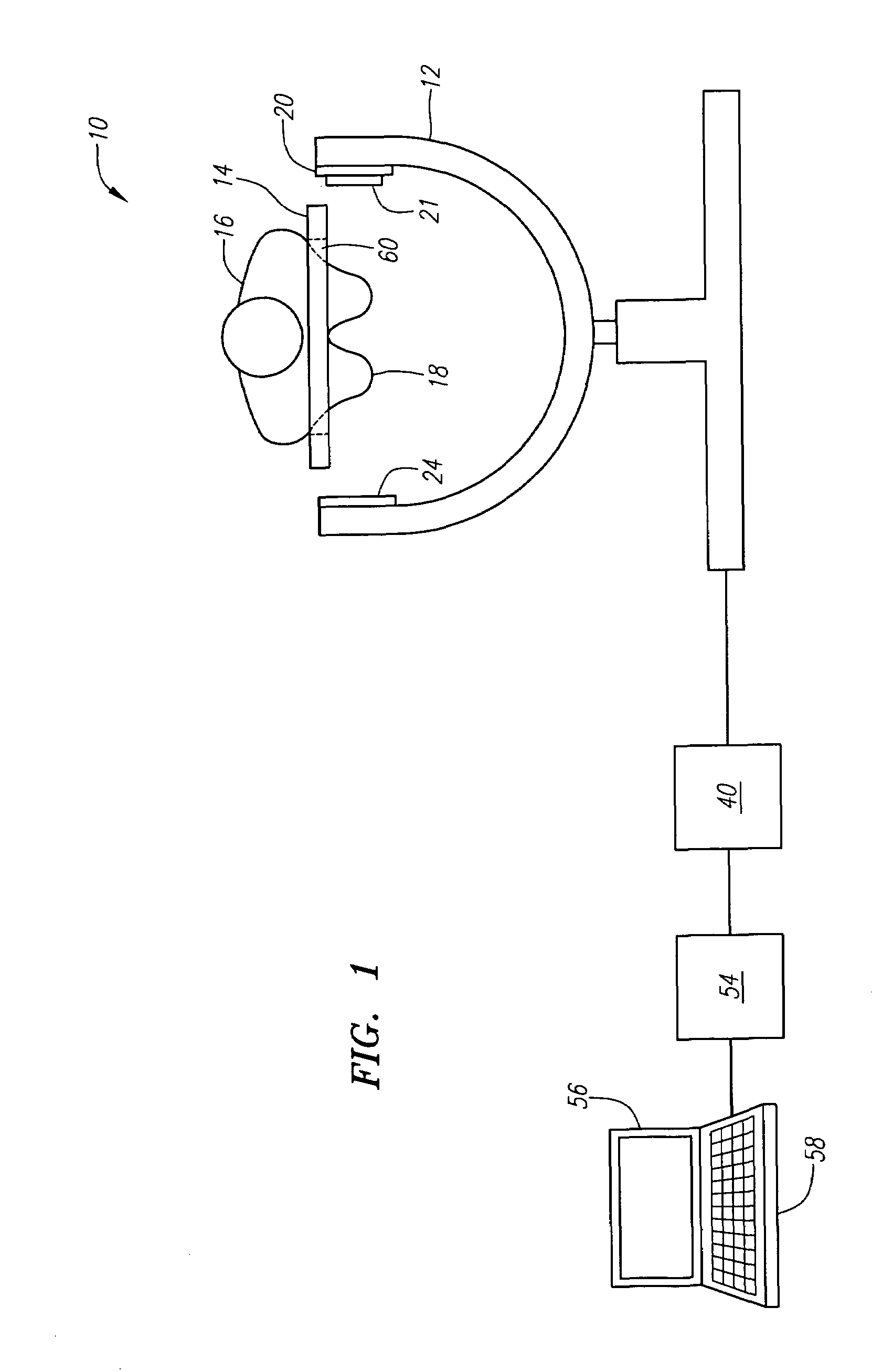

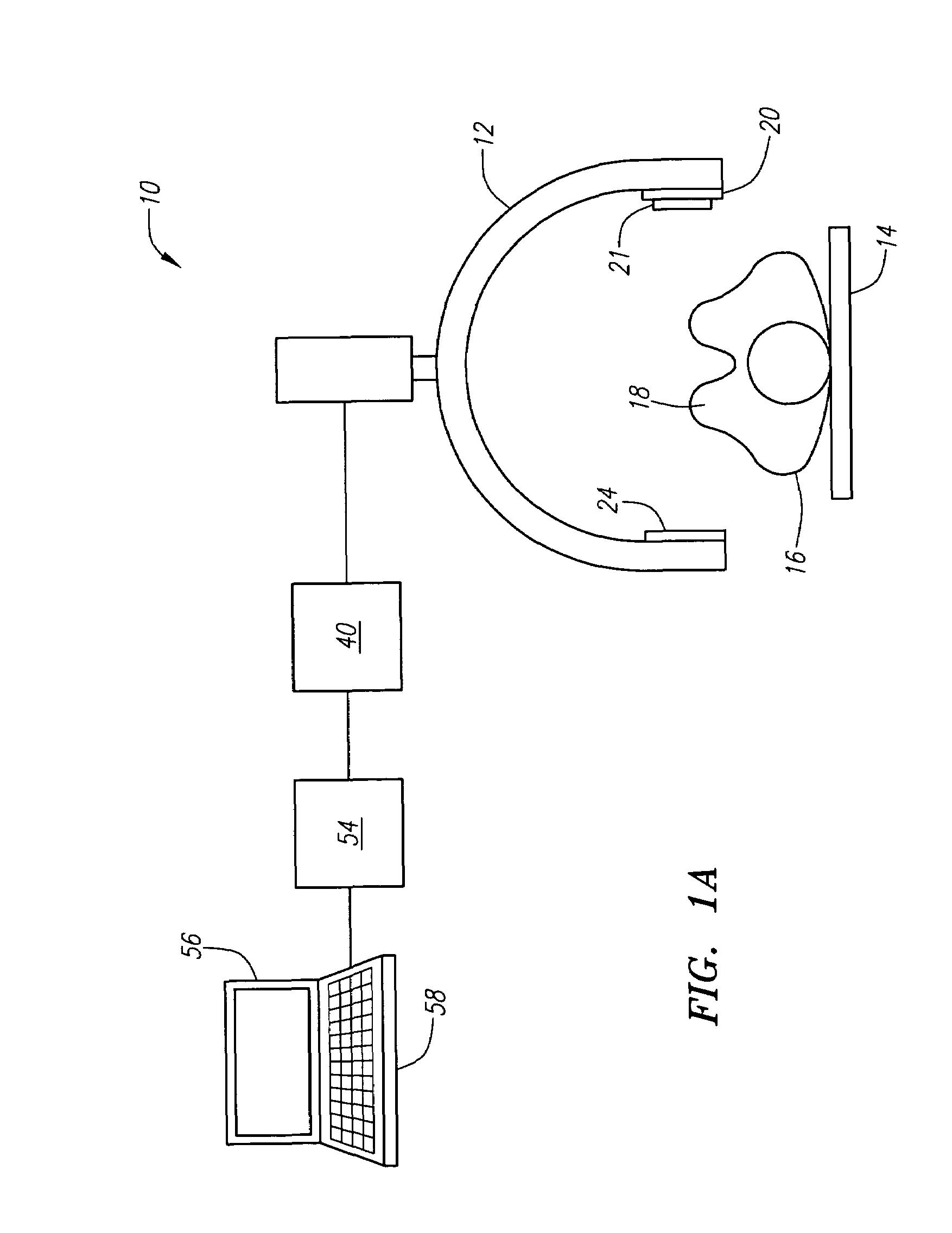

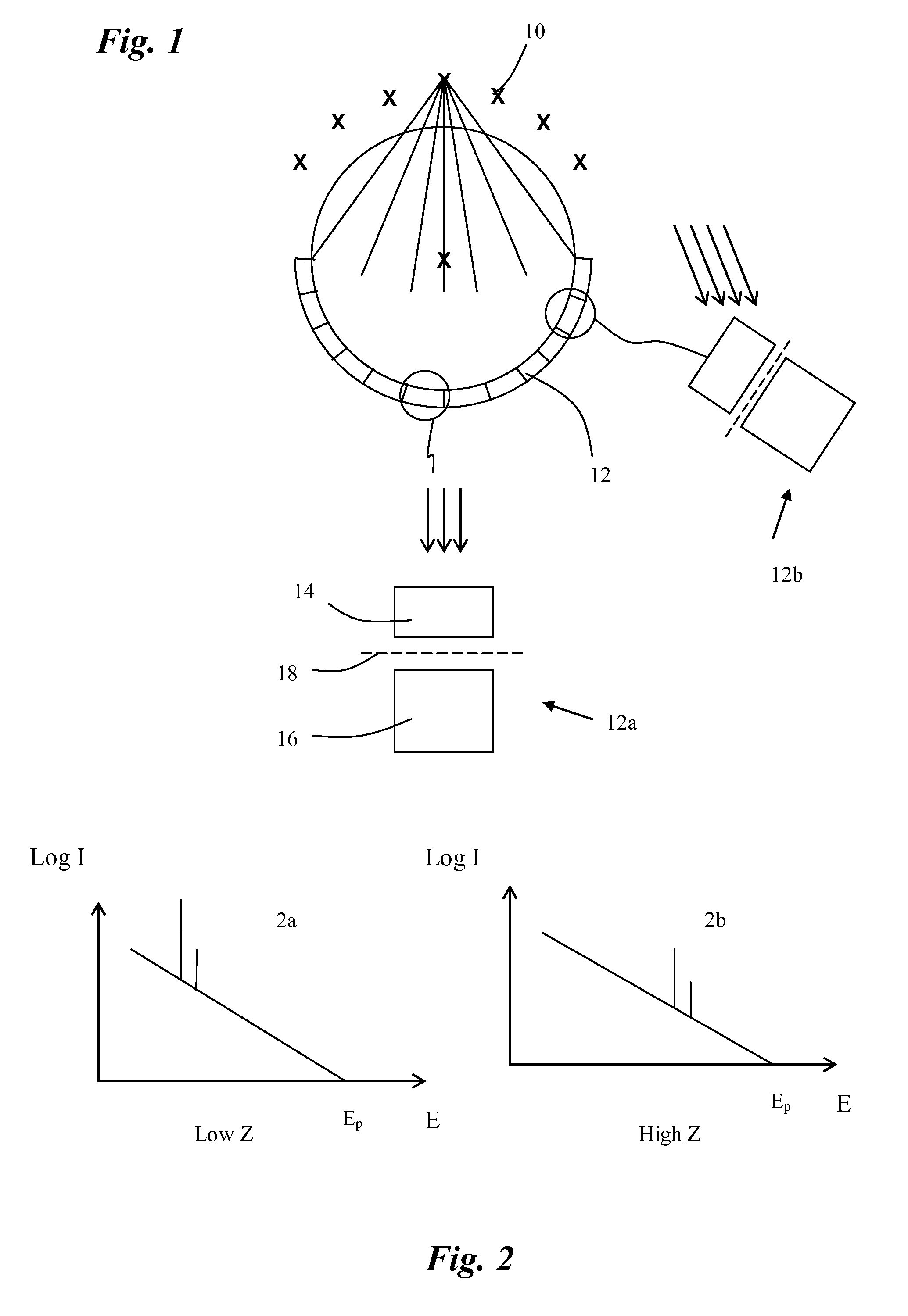

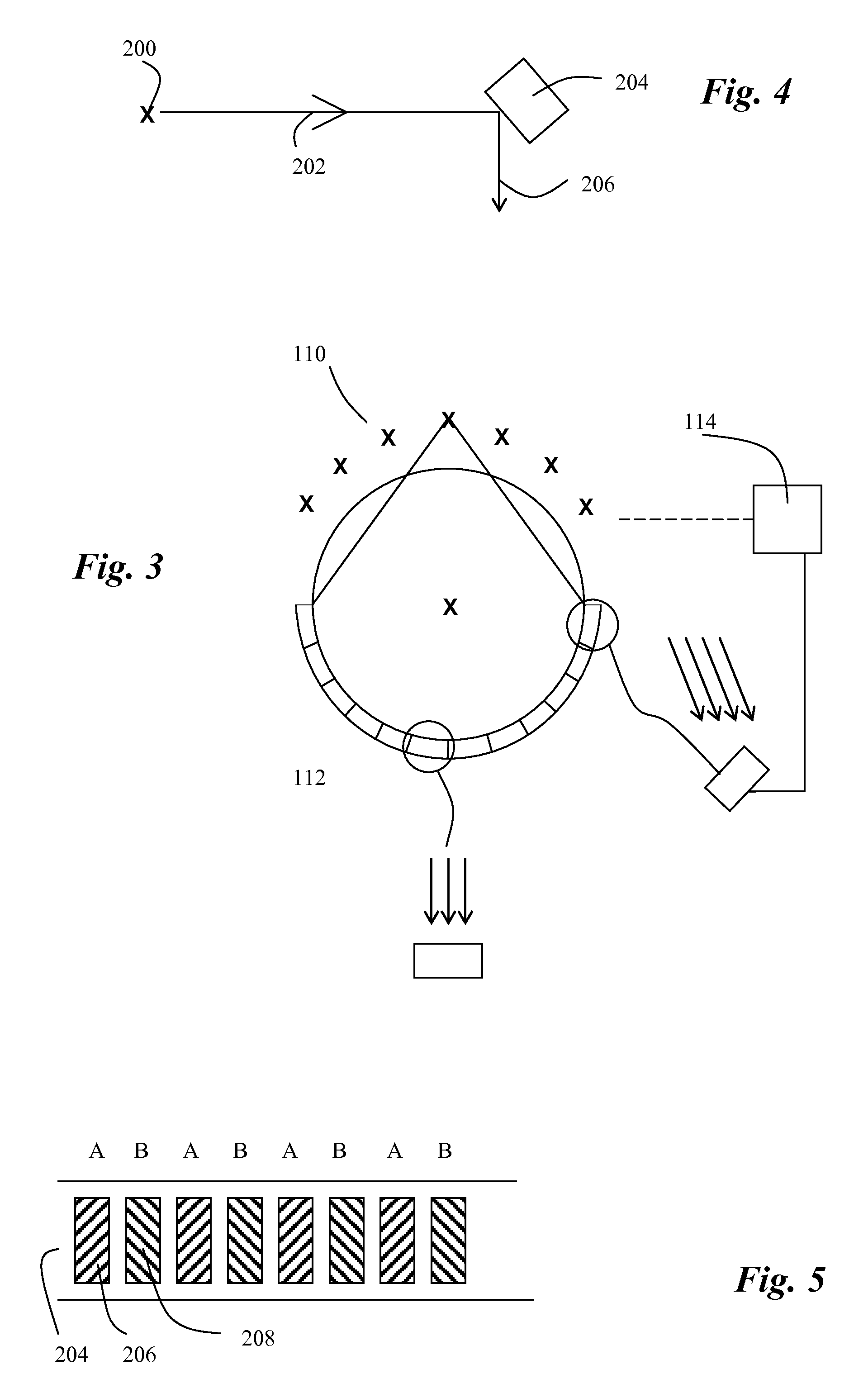

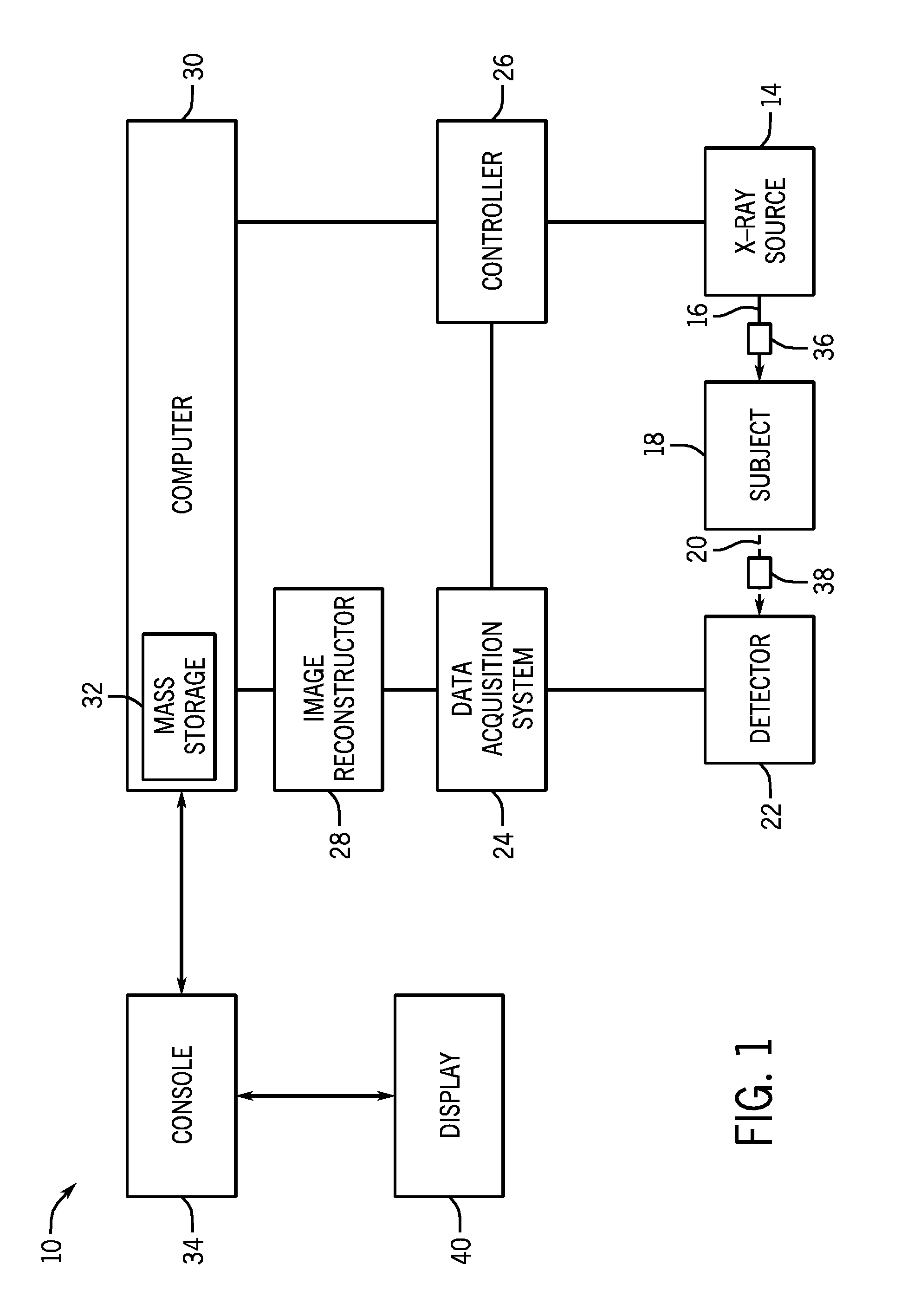

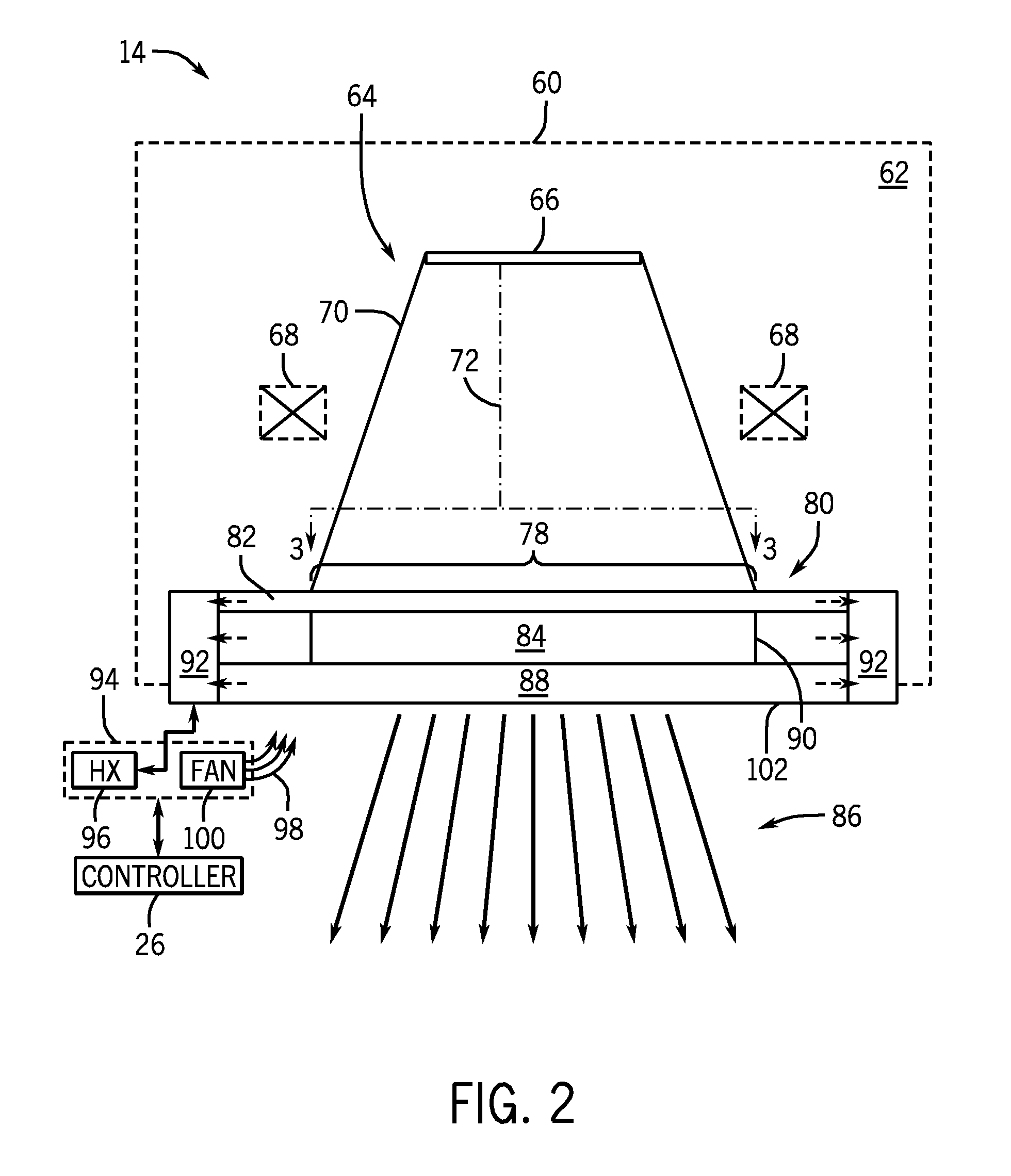

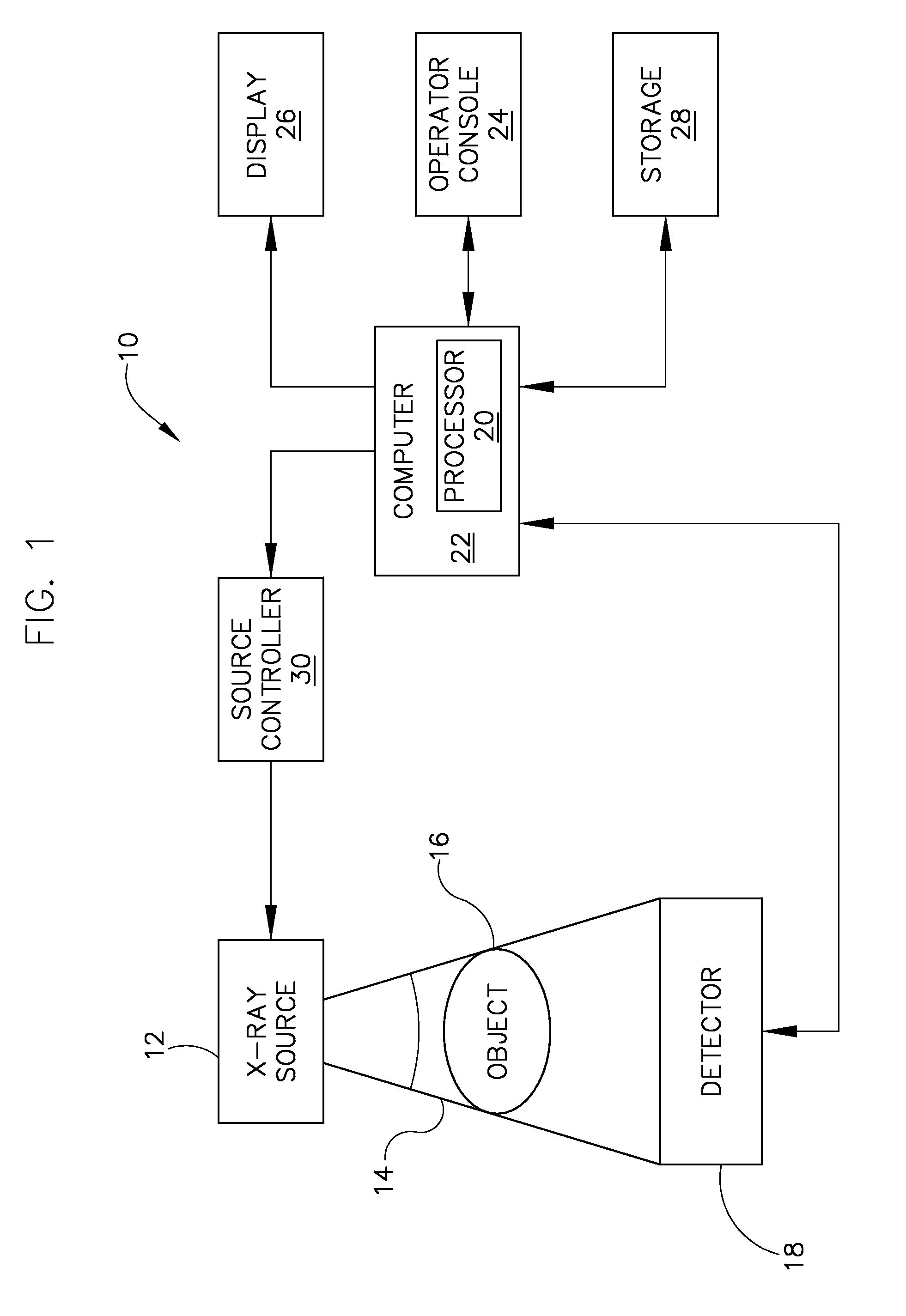

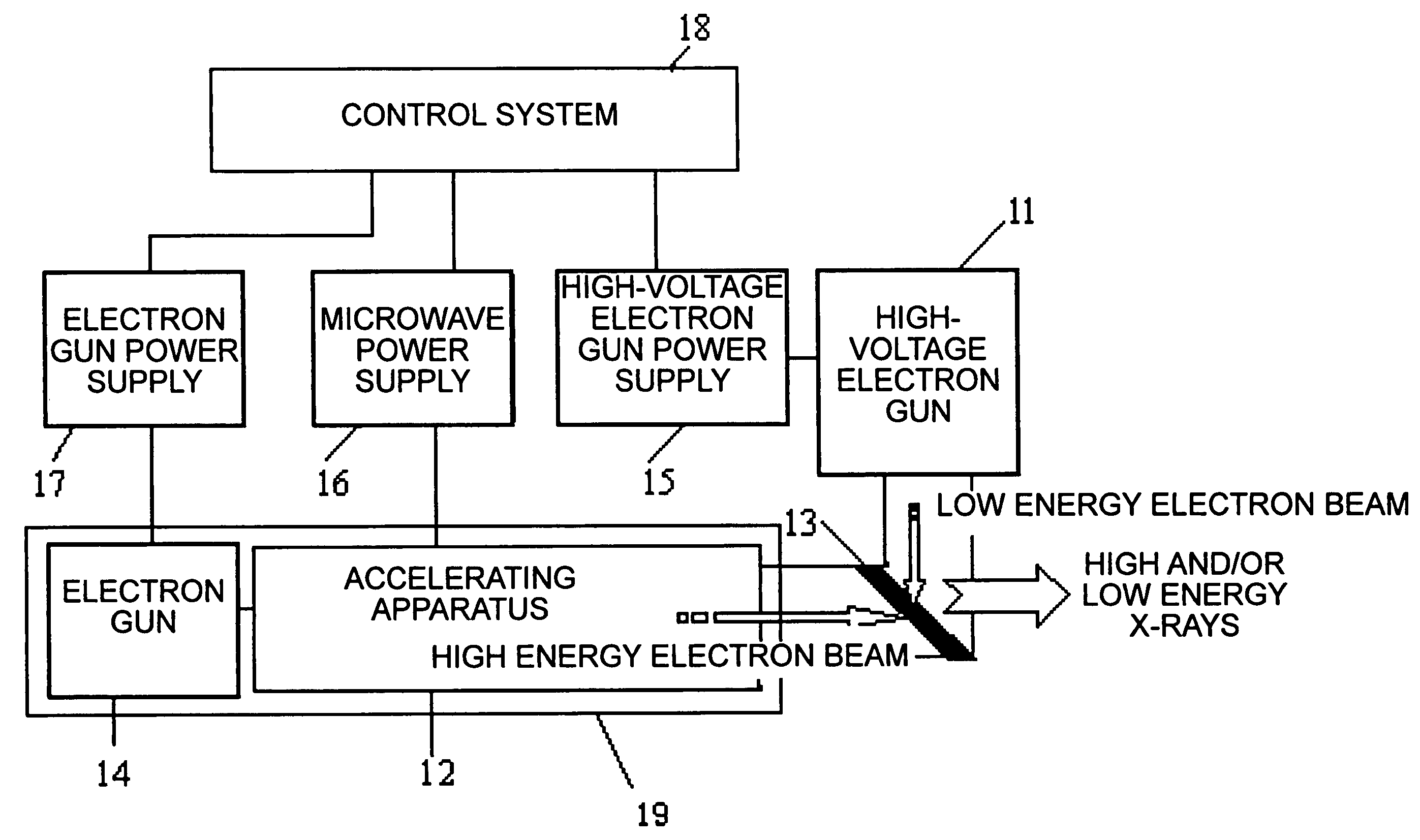

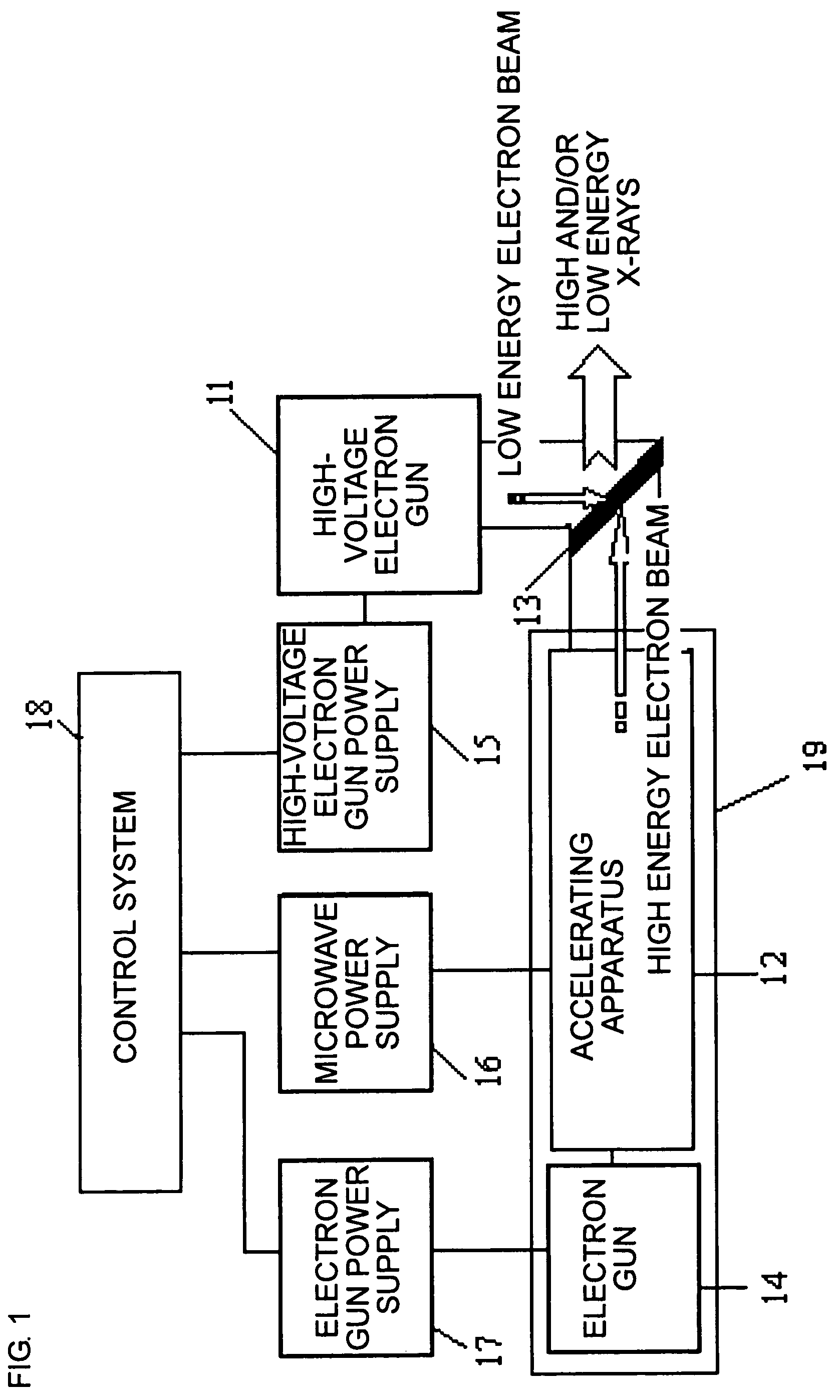

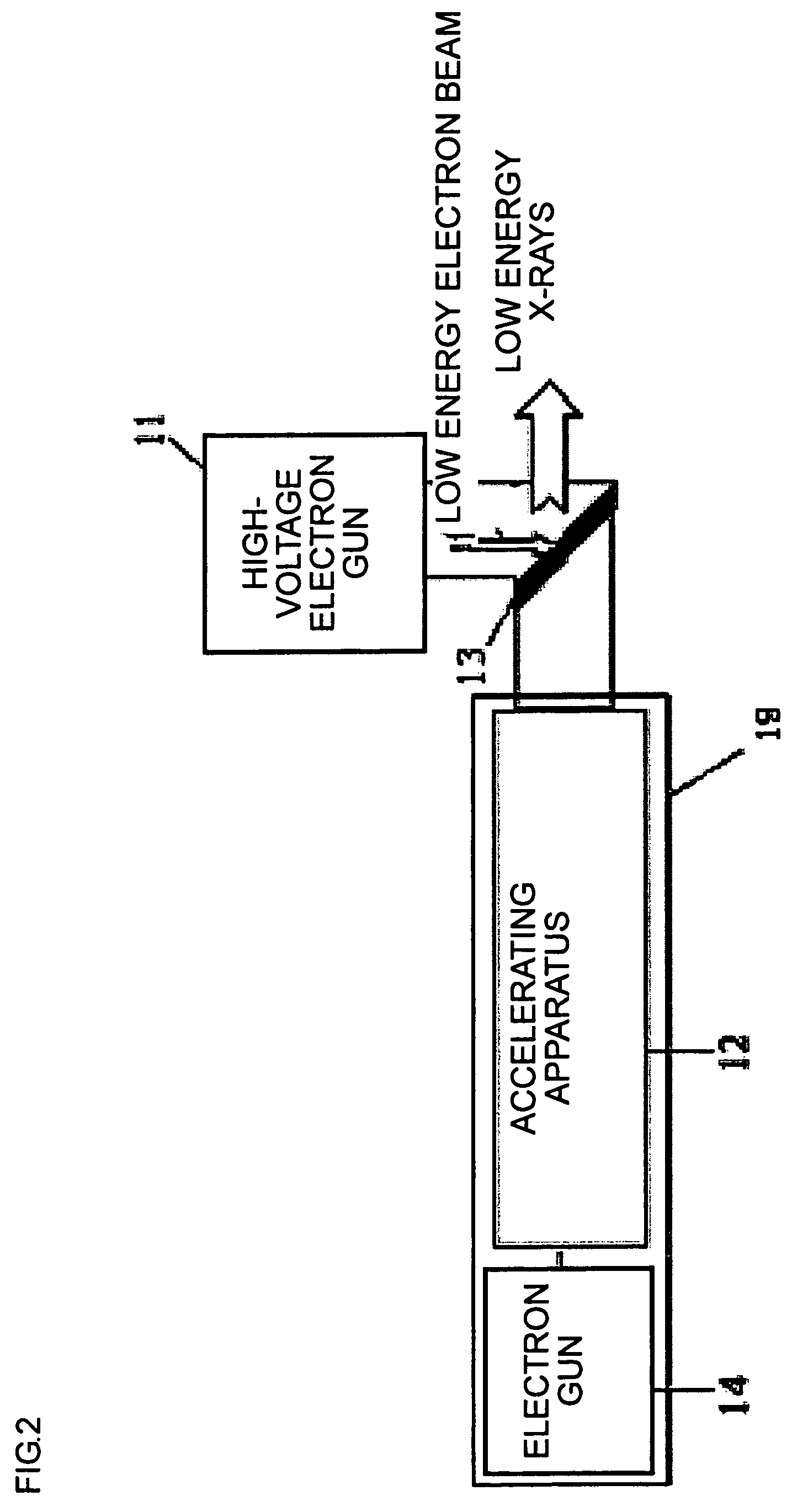

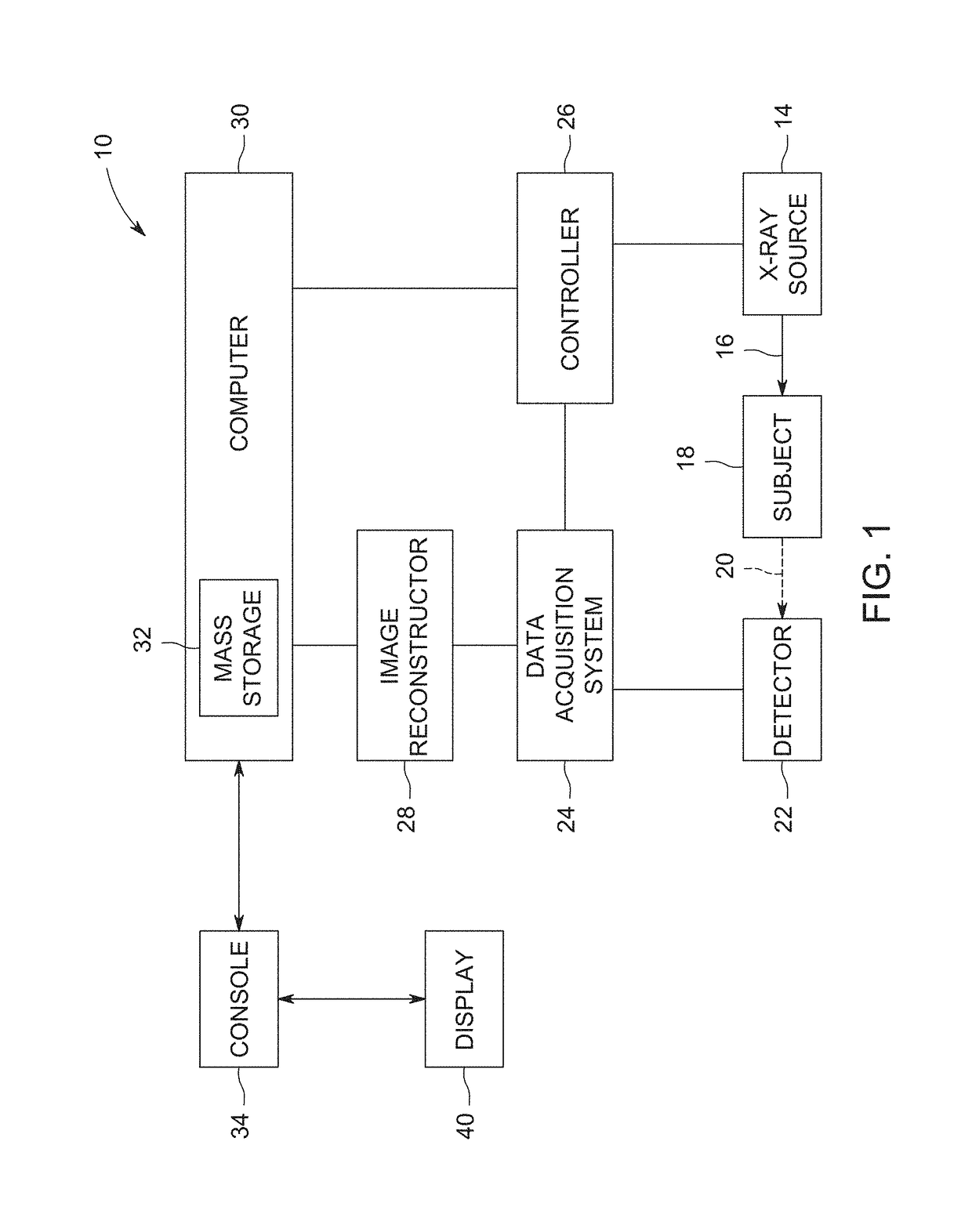

Multi-energy x-ray source

ActiveUS20050084073A1Characteristic is differentX-ray tube laminated targetsMaterial analysis using wave/particle radiationSoft x rayX-ray filter

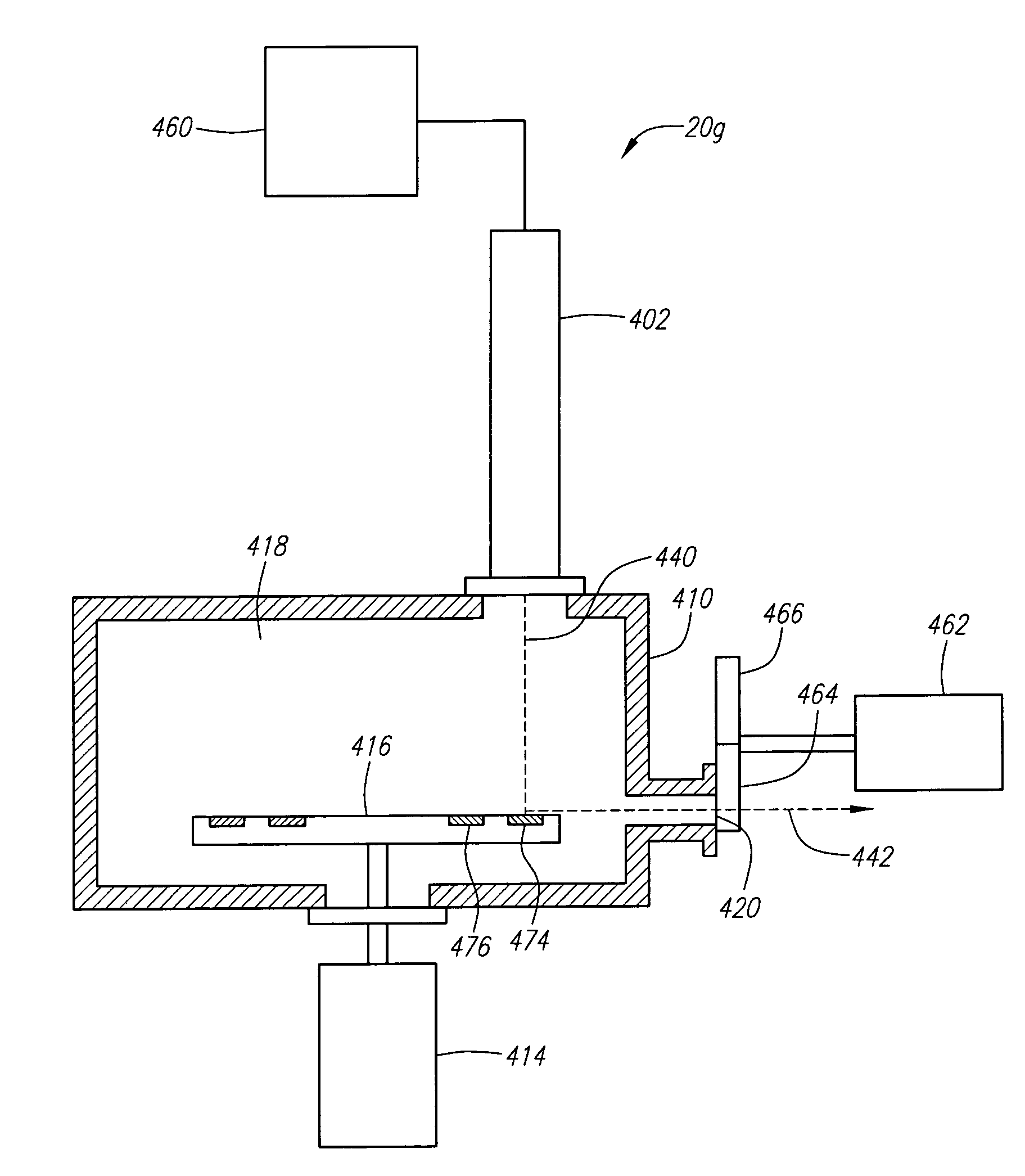

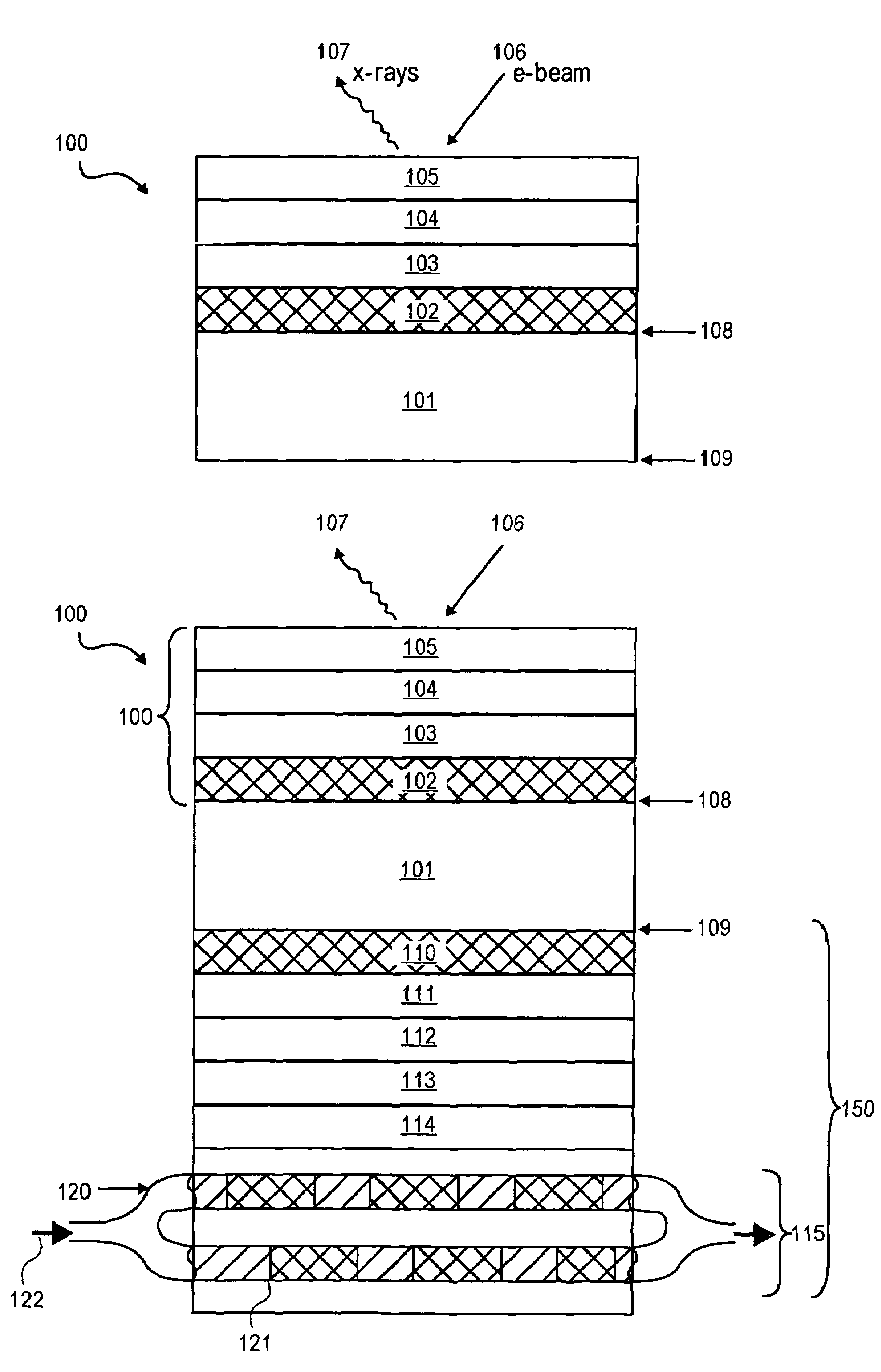

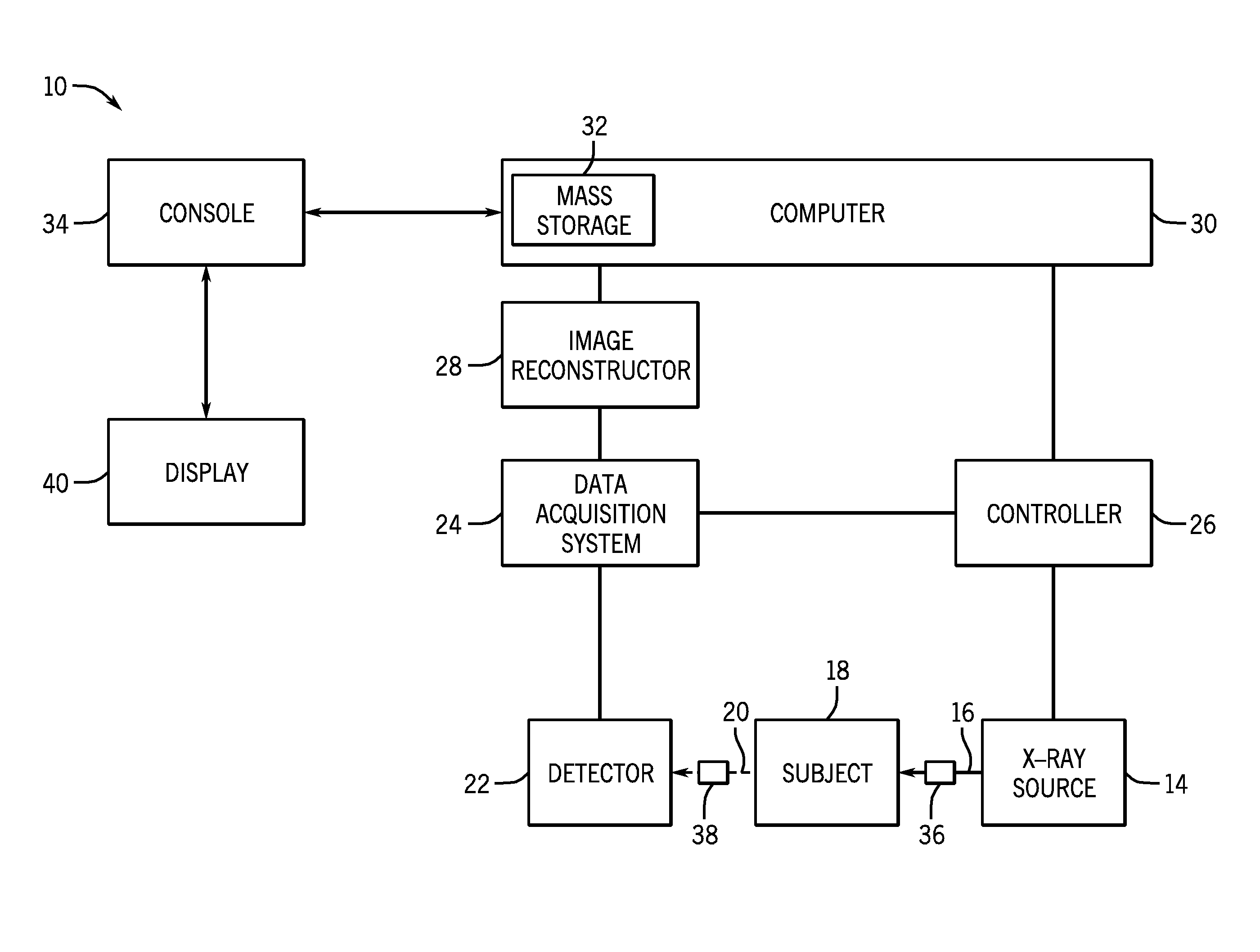

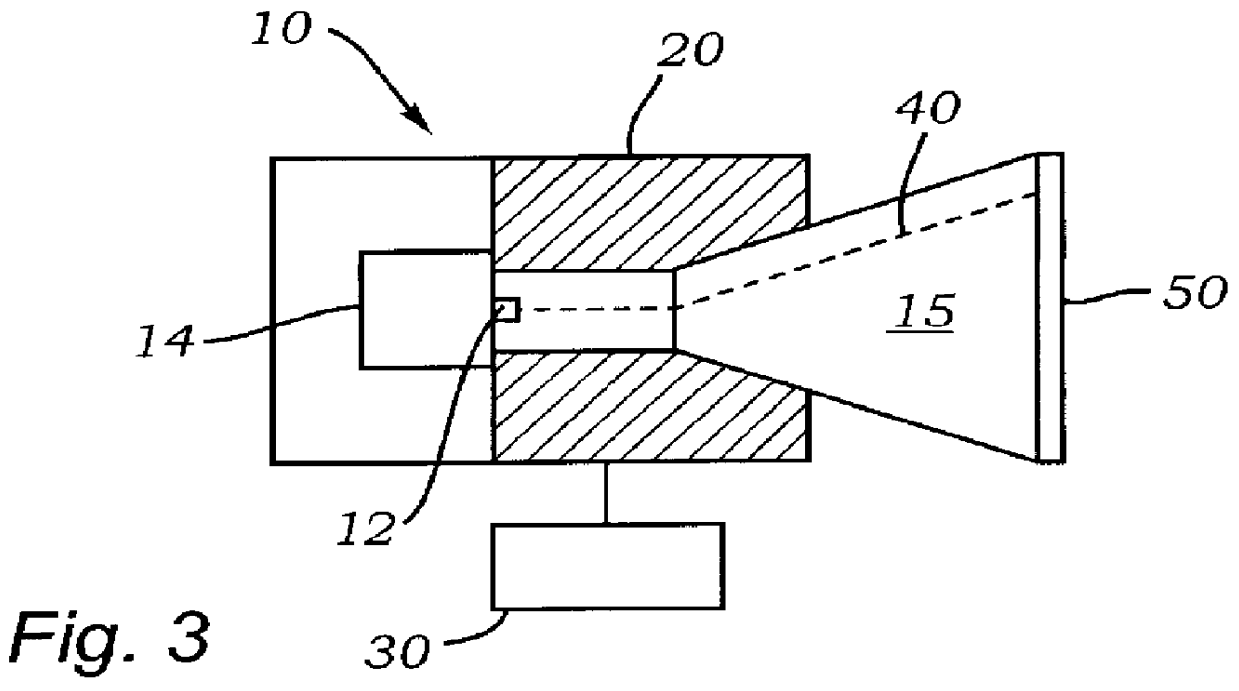

An apparatus for use in a radiation procedure includes a radiation filter having a first portion and a second portion, the first and the second portions forming a layer for filtering radiation impinging thereon, wherein the first portion is made from a first material having a first x-ray filtering characteristic, and the second portion is made from a second material having a second x-ray filtering characteristic. An apparatus for use in a radiation procedure includes a first target material, a second target material, and an accelerator for accelerating particles towards the first target material and the second target material to generate x-rays at a first energy level and a second energy level, respectively.

Owner:VARIAN MEDICAL SYSTEMS

Multi-energy x-ray source

InactiveUS7649981B2X-ray tube laminated targetsMaterial analysis using wave/particle radiationSoft x rayX-ray filter

An apparatus for use in a radiation procedure includes a radiation filter having a first portion and a second portion, the first and the second portions forming a layer for filtering radiation impinging thereon, wherein the first portion is made from a first material having a first x-ray filtering characteristic, and the second portion is made from a second material having a second x-ray filtering characteristic. An apparatus for use in a radiation procedure includes a first target material, a second target material, and an accelerator for accelerating particles towards the first target material and the second target material to generate x-rays at a first energy level and a second energy level, respectively.

Owner:VARIAN MEDICAL SYSTEMS

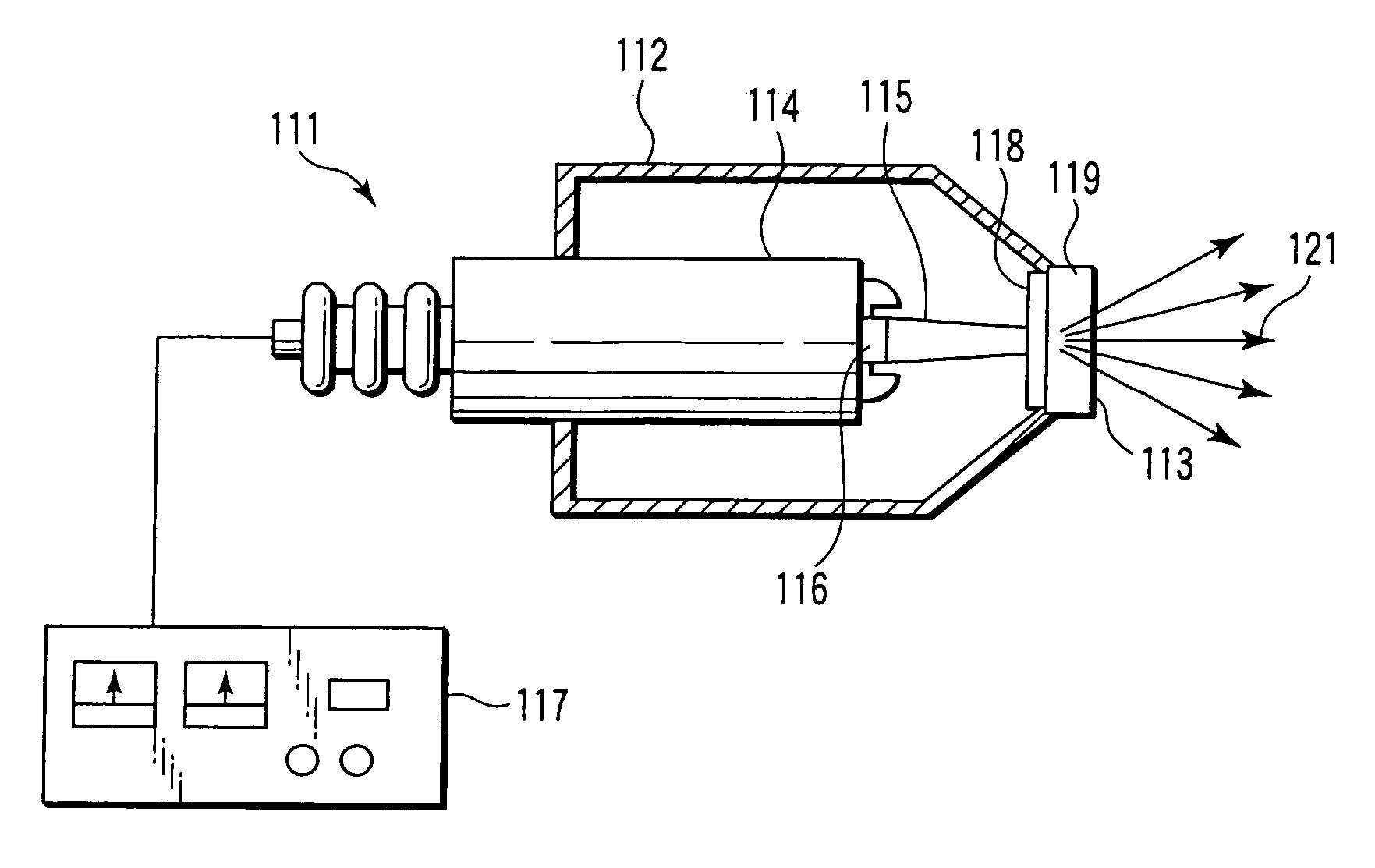

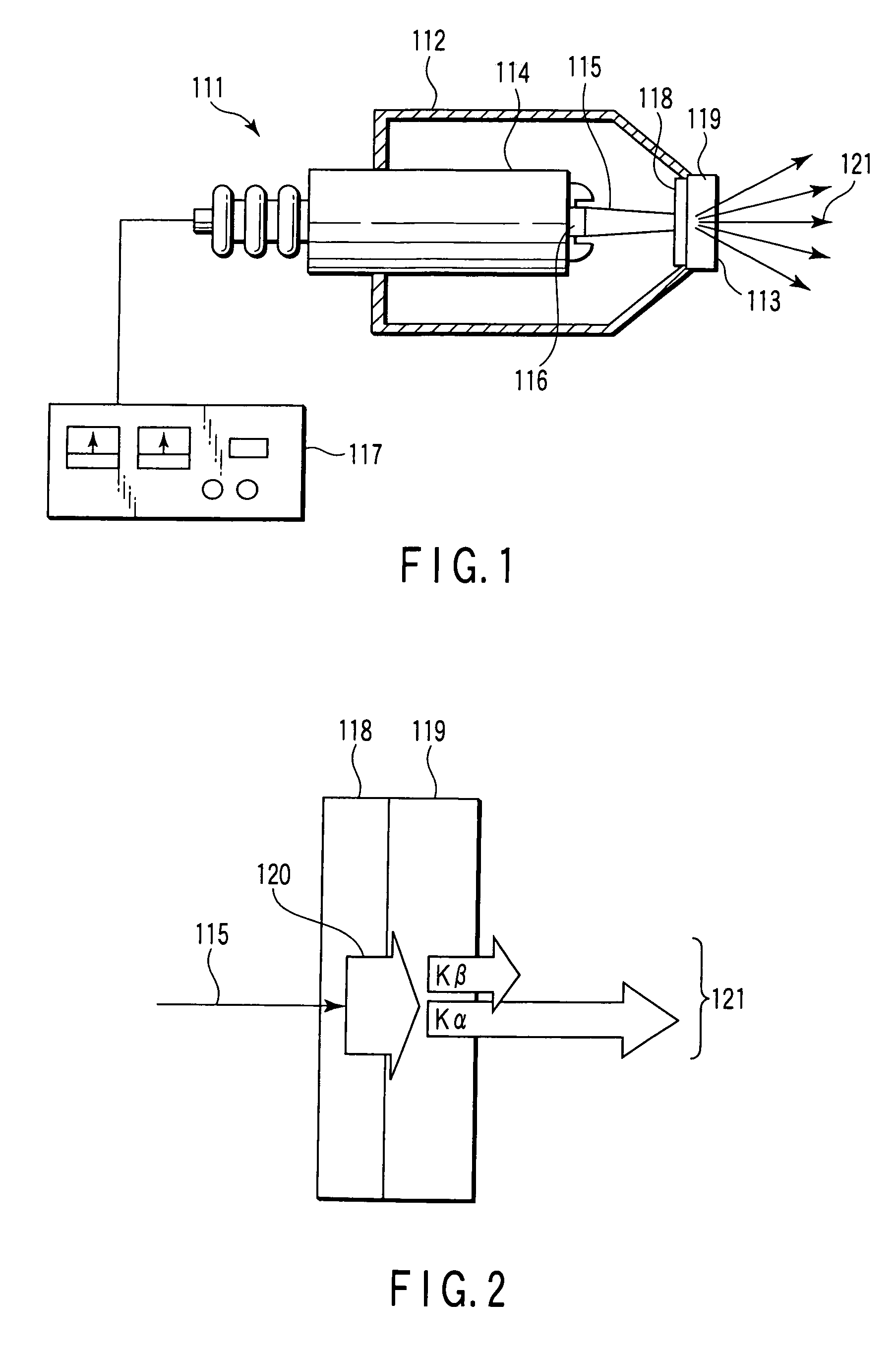

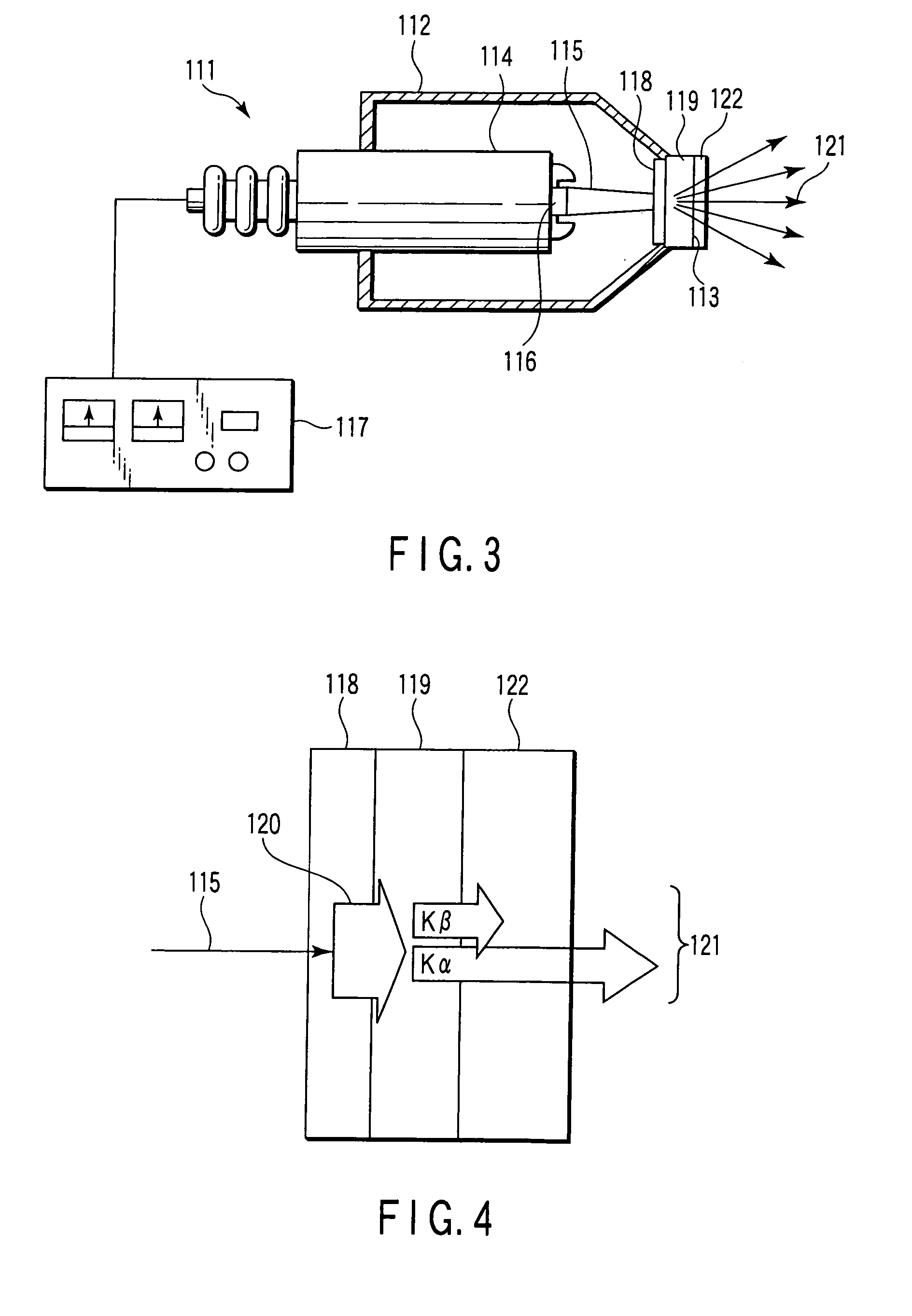

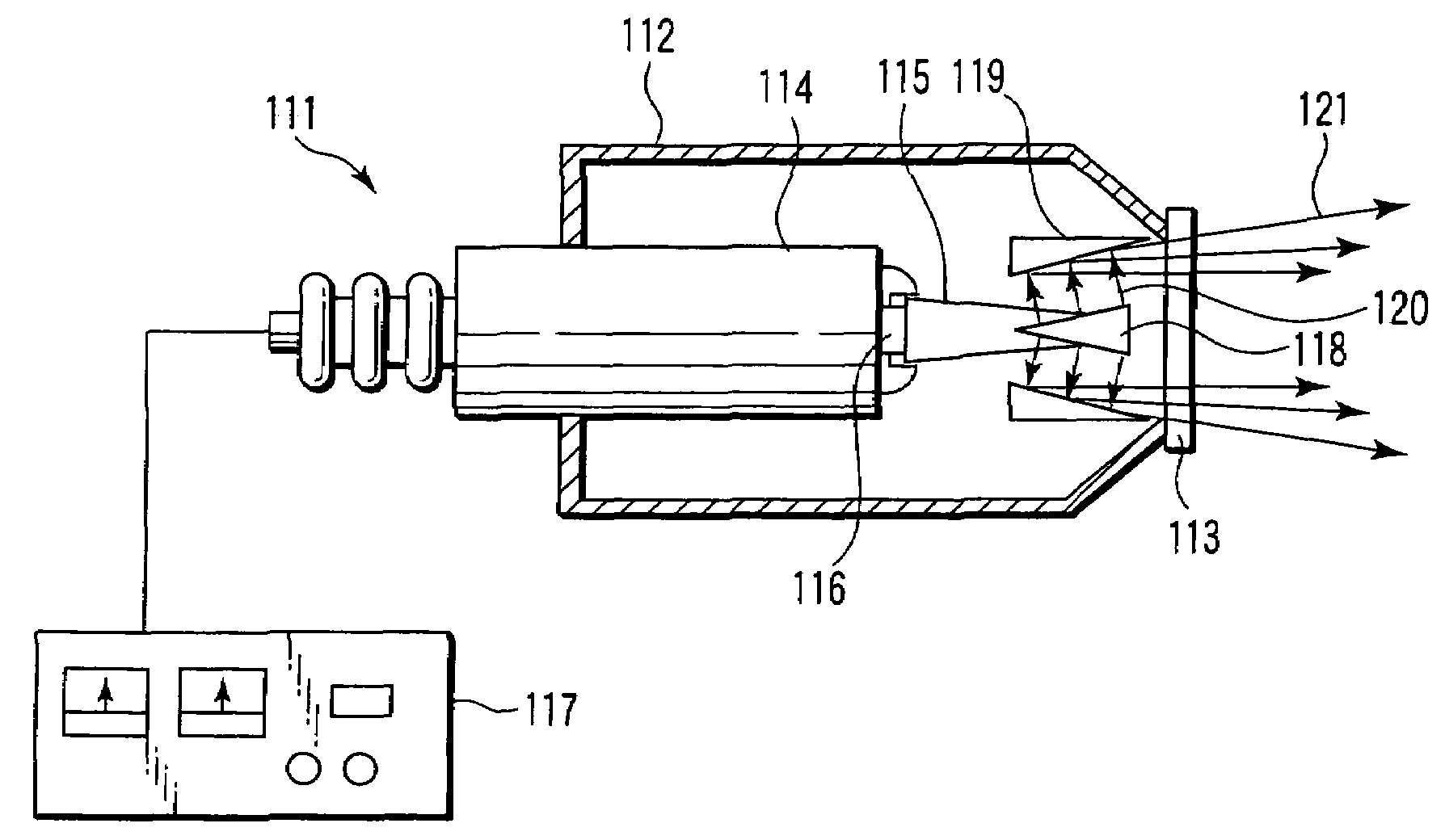

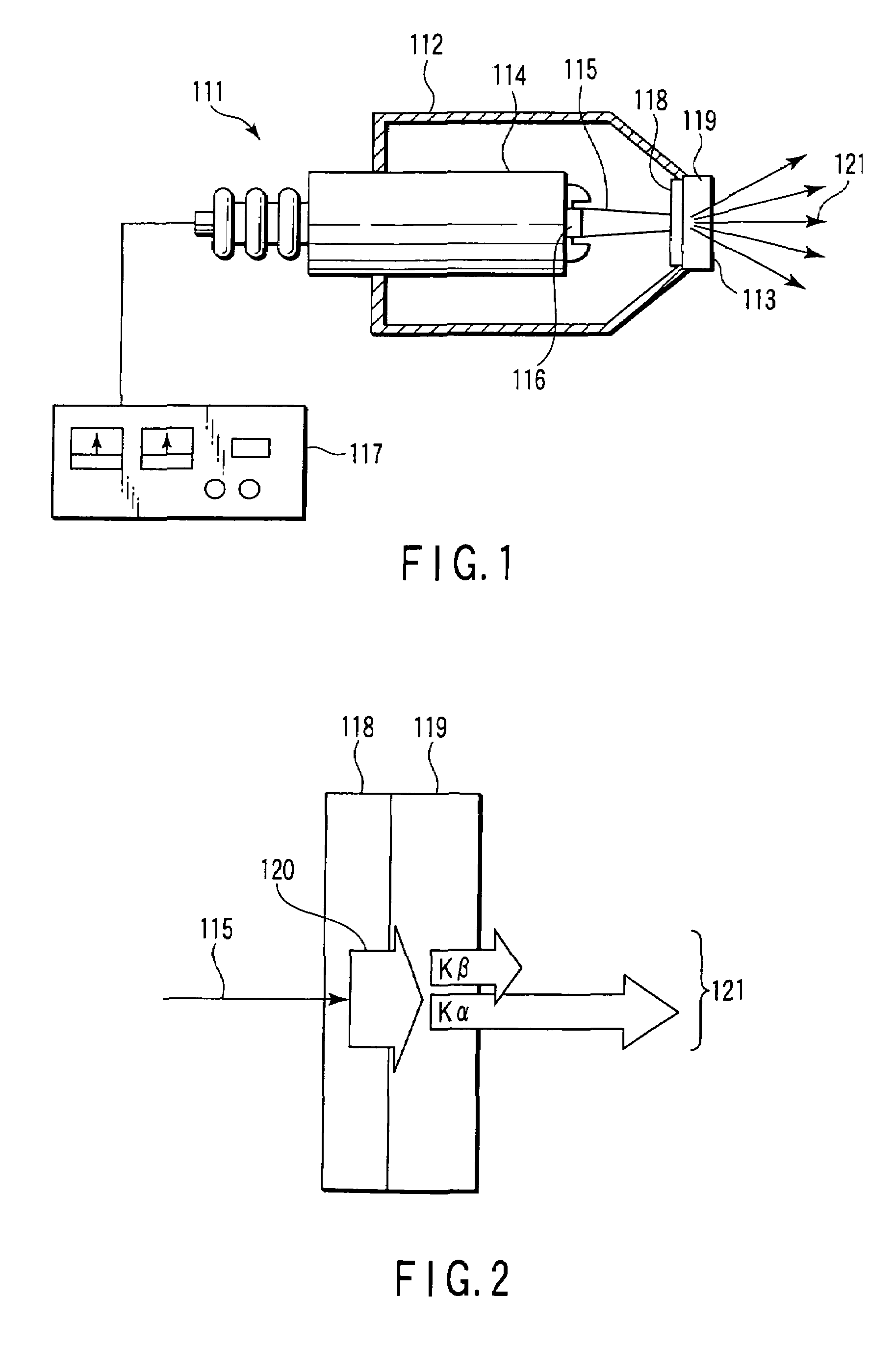

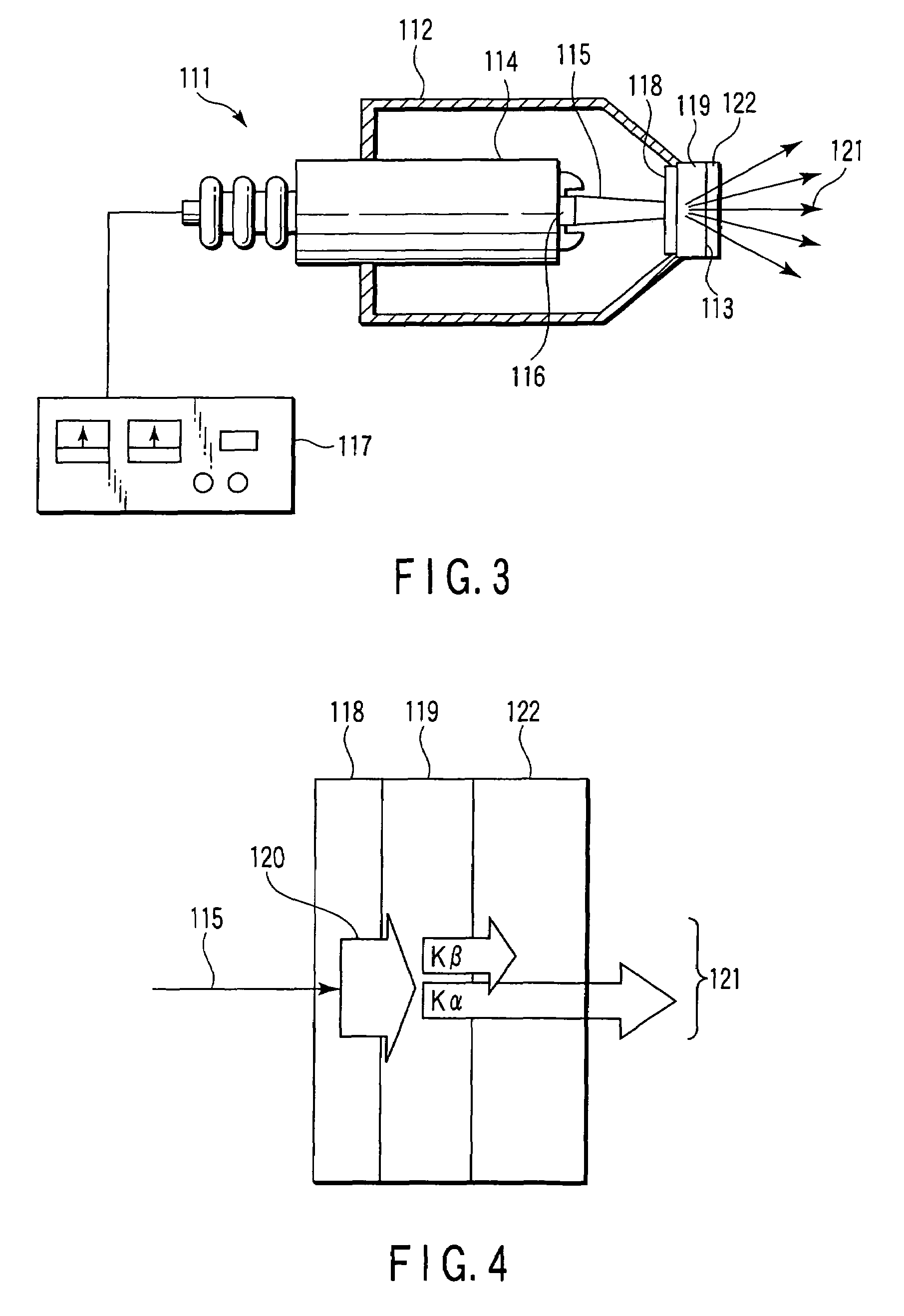

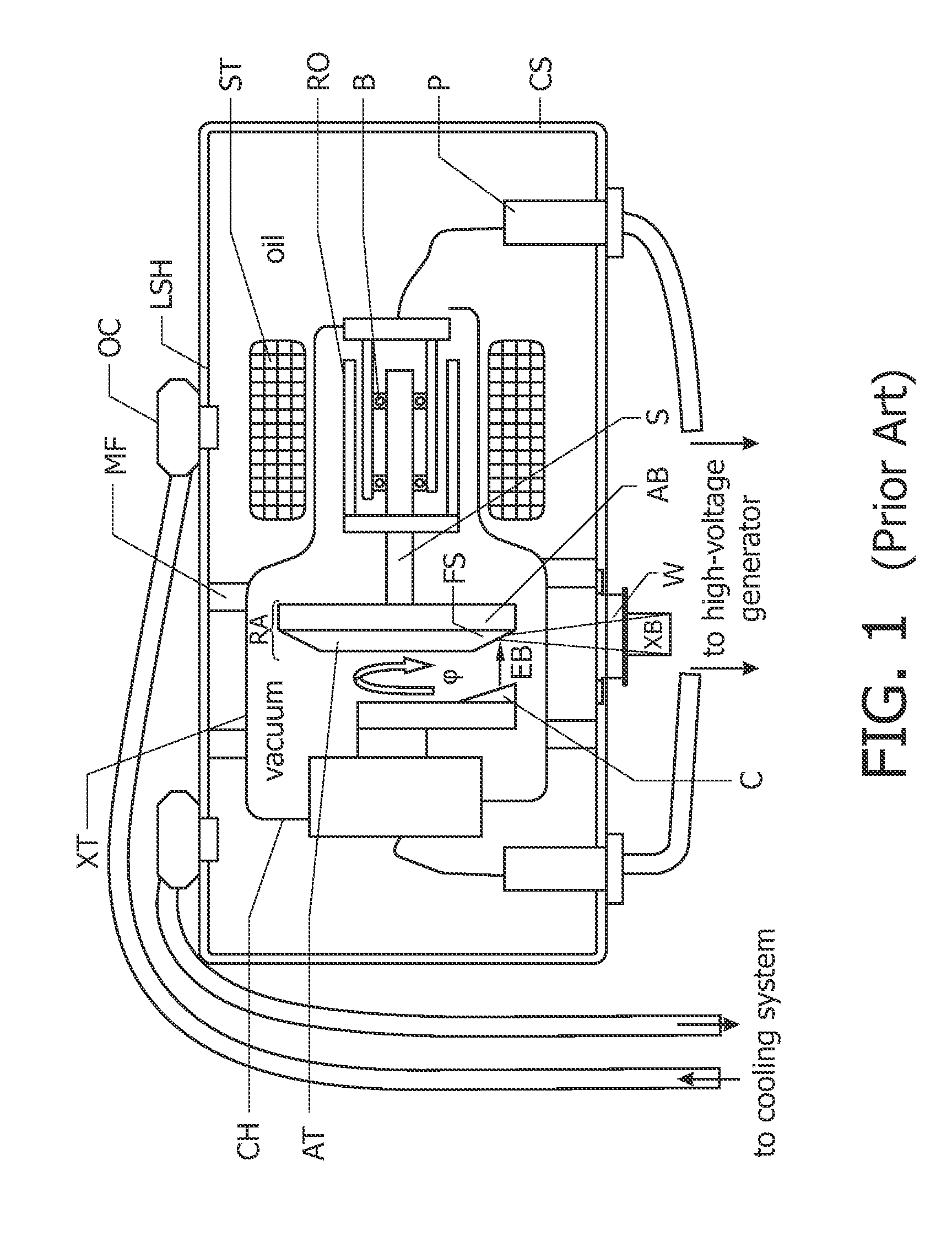

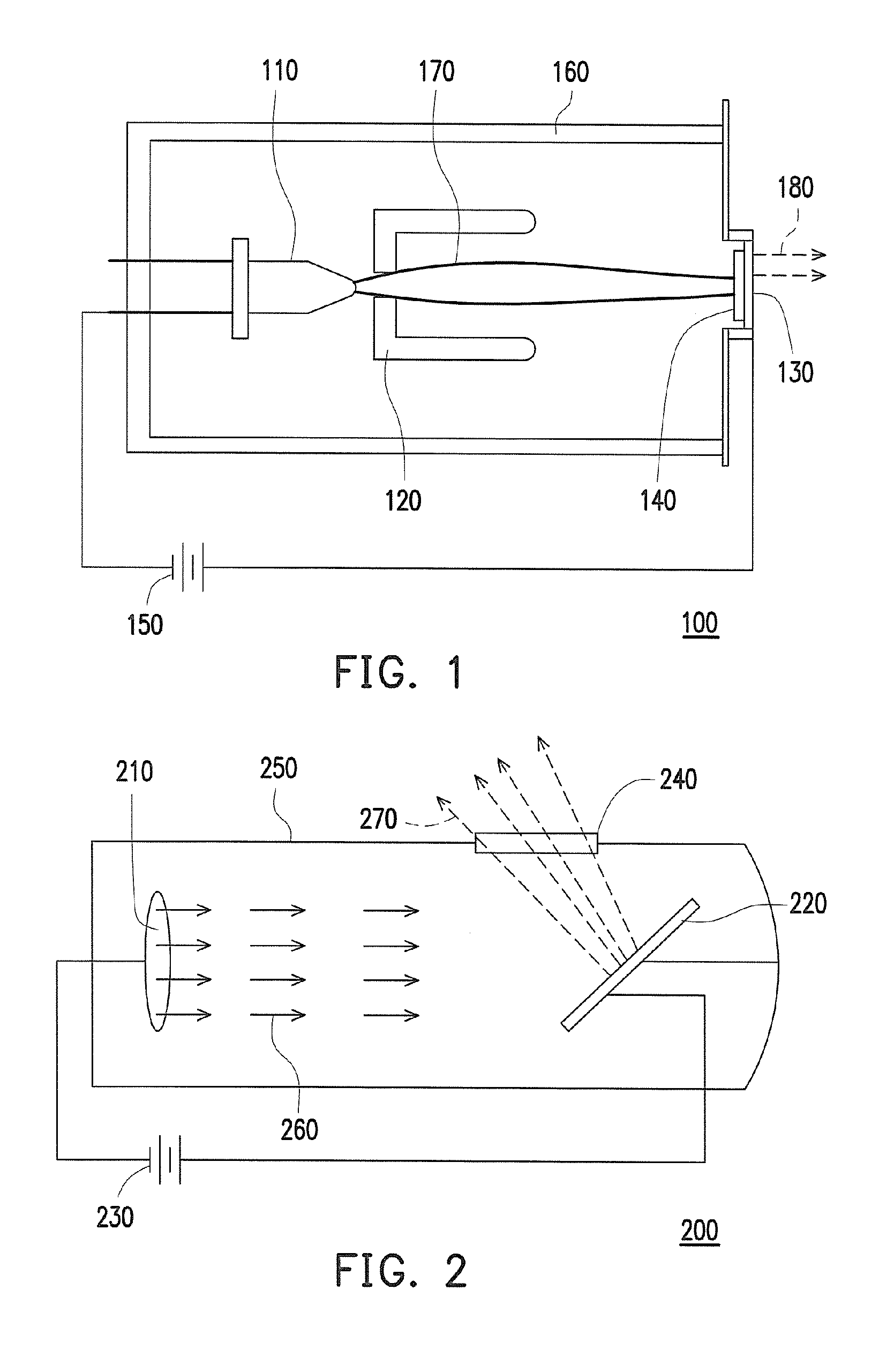

X-ray source and fluorescent X-ray analyzing apparatus

InactiveUS20080084966A1Eliminates unwanted noise componentGenerate efficientlyX-ray tube laminated targetsMaterial analysis using wave/particle radiationFluorescenceX-ray

The present invention relates to an X-ray source for emitting a characteristic X-ray and a fluorescent X-ray analyzing apparatus using the X-ray source. A secondary target is arranged in superposition on a primary target. An electron beam generated by an electron gun enters the primary target, which passes and emits a continuous X-ray. The secondary target transmits and emits a characteristic X-ray excited by the continuous X-ray emitted from the primary target. The primary target and the secondary target are superposed one on the other, so that the continuous X-ray emitted from the primary target efficiently excites the secondary target thereby to efficiently generate the characteristic X-ray.

Owner:TOSHIBA ELECTRON TUBE & DEVICES

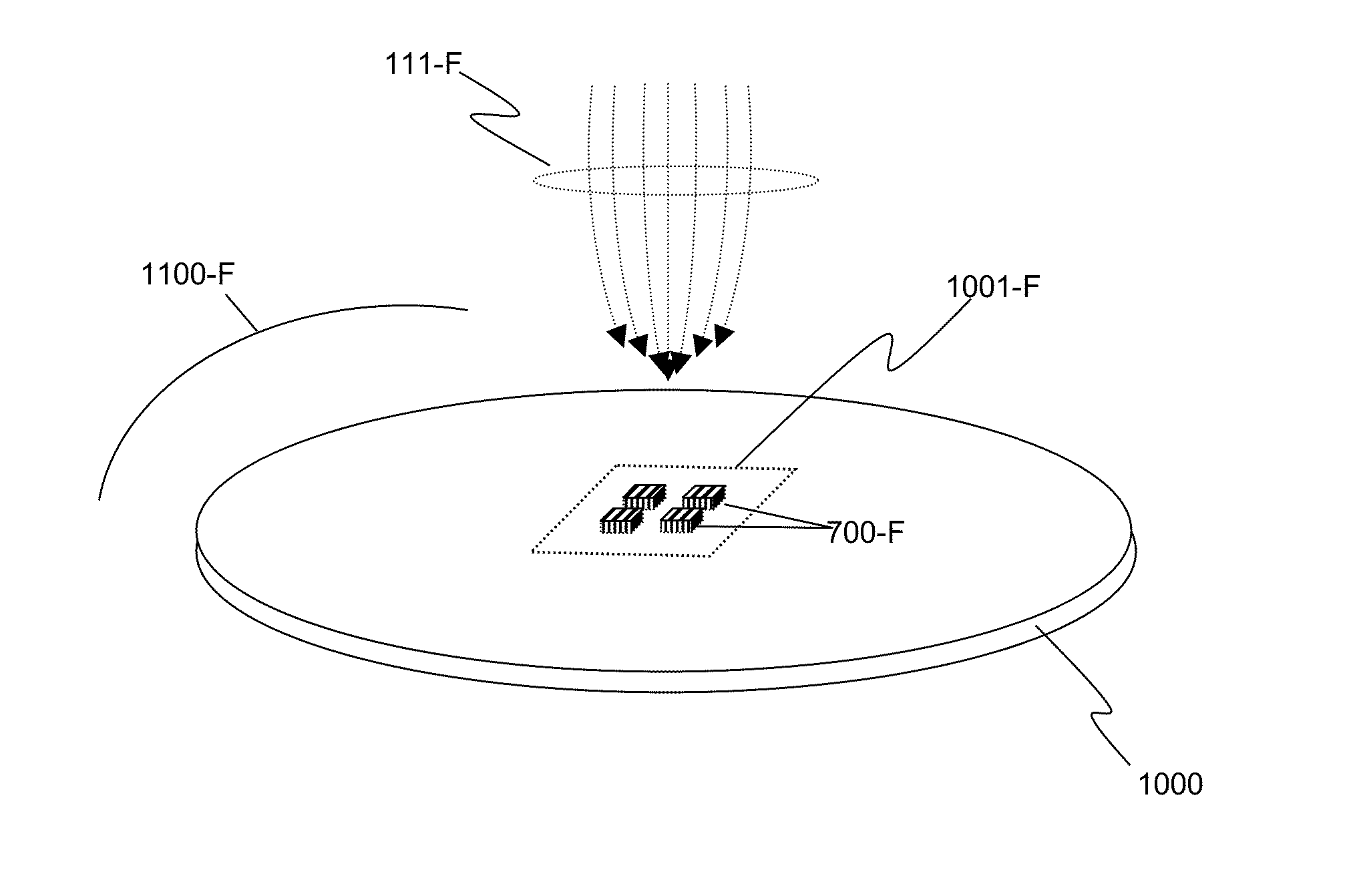

Structured targets for x-ray generation

InactiveUS20150092924A1Improve cooling effectHeat generationX-ray tube laminated targetsX-ray tube anode coolingMicron scaleHigh energy

We disclose targets for generating x-rays using electron beams, along with their method of fabrication. The targets comprise a number of microstructures fabricated from an x-ray target material arranged in close thermal contact with a substrate such that the heat is more efficiently drawn out of the x-ray target material. This in turn allows irradiation of the x-ray generating substance with higher electron density or higher energy electrons, which leads to greater x-ray brightness, without inducing damage or melting.The microstructures may comprise conventional x-ray target materials (such as tungsten) that are patterned at micron-scale dimensions on a thermally conducting substrate, such as diamond. The microstructures may have any number of geometric shapes to best generate x-rays of high brightness and efficiently disperse heat.In some embodiments, the target comprising microstructures may be incorporated into a rotating anode geometry, to enhance x-ray generation in such systems.

Owner:SIGRAY INC

Diamond anode

ActiveUS7359487B1Avoid damageImprove cooling effectX-ray tube laminated targetsX-ray tube anode coolingOptoelectronicsMaterials science

According to one aspect of the invention a robust anode structure and methods of making and using said structure to produce ionizing radiation are disclosed. An ionizing radiation producing layer is bonded to the target side of a highly conductive diamond substrate, by a metal carbide layer. The metal carbide layers improves the strength and durability of the bond, thus improving heat removal from the anode surface and reducing the risk of delaminating the ionizing radiation producing layer, thus reducing degradation and extending the anode's life. A smoothing dopant is alloyed into the radiation producing layer to facilitate keeping the layer surface smooth, thus improving the quality of the x-ray beam emitted from the anode. In an embodiment, the heat sink comprises a metal carbide skeleton cemented diamond material. In another embodiment, the heat sink is bonded to the diamond substrate structure in a high temperature reactive brazing process.

Owner:NOVA MEASURING INSTRUMENTS INC

Multilayer x-ray source target with high thermal conductivity

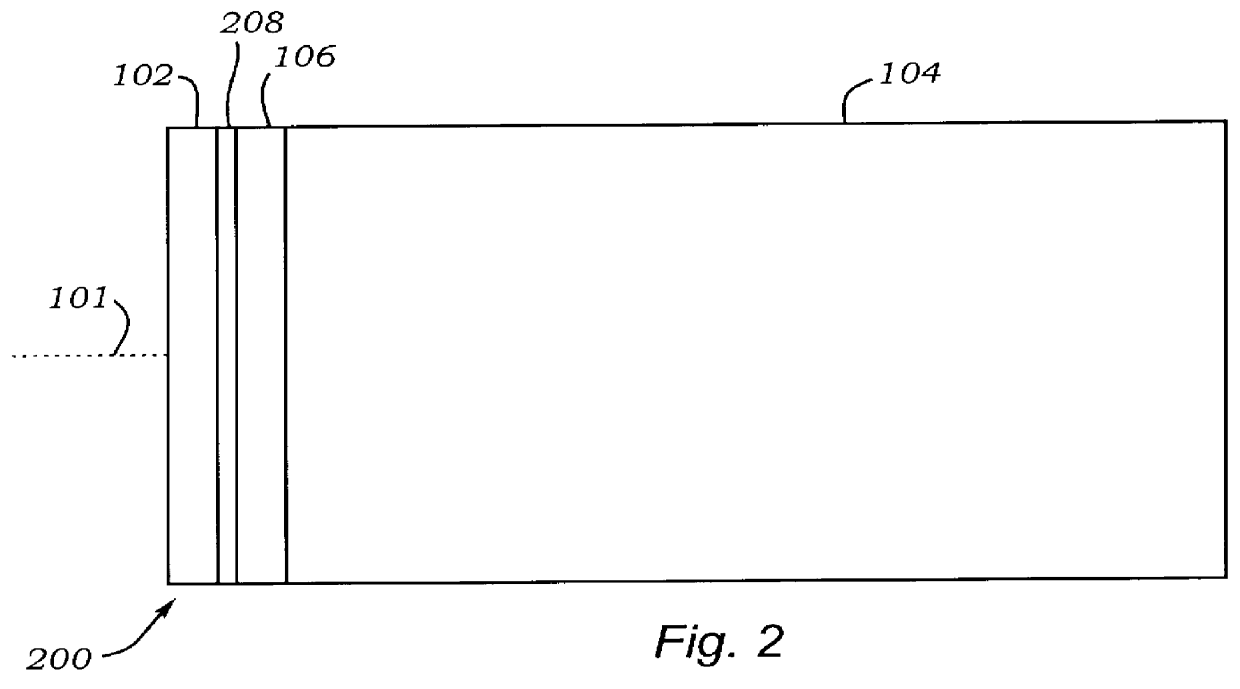

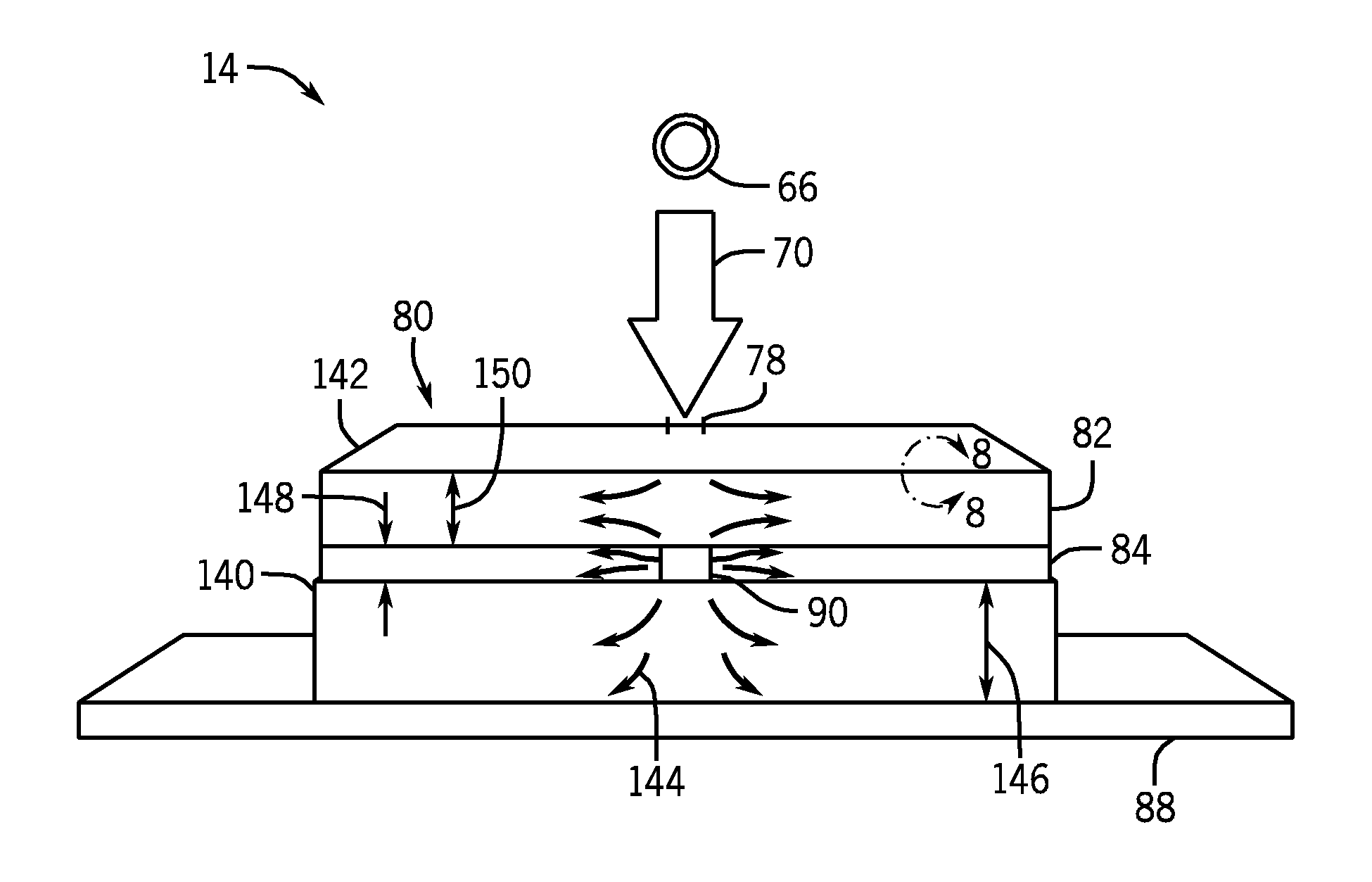

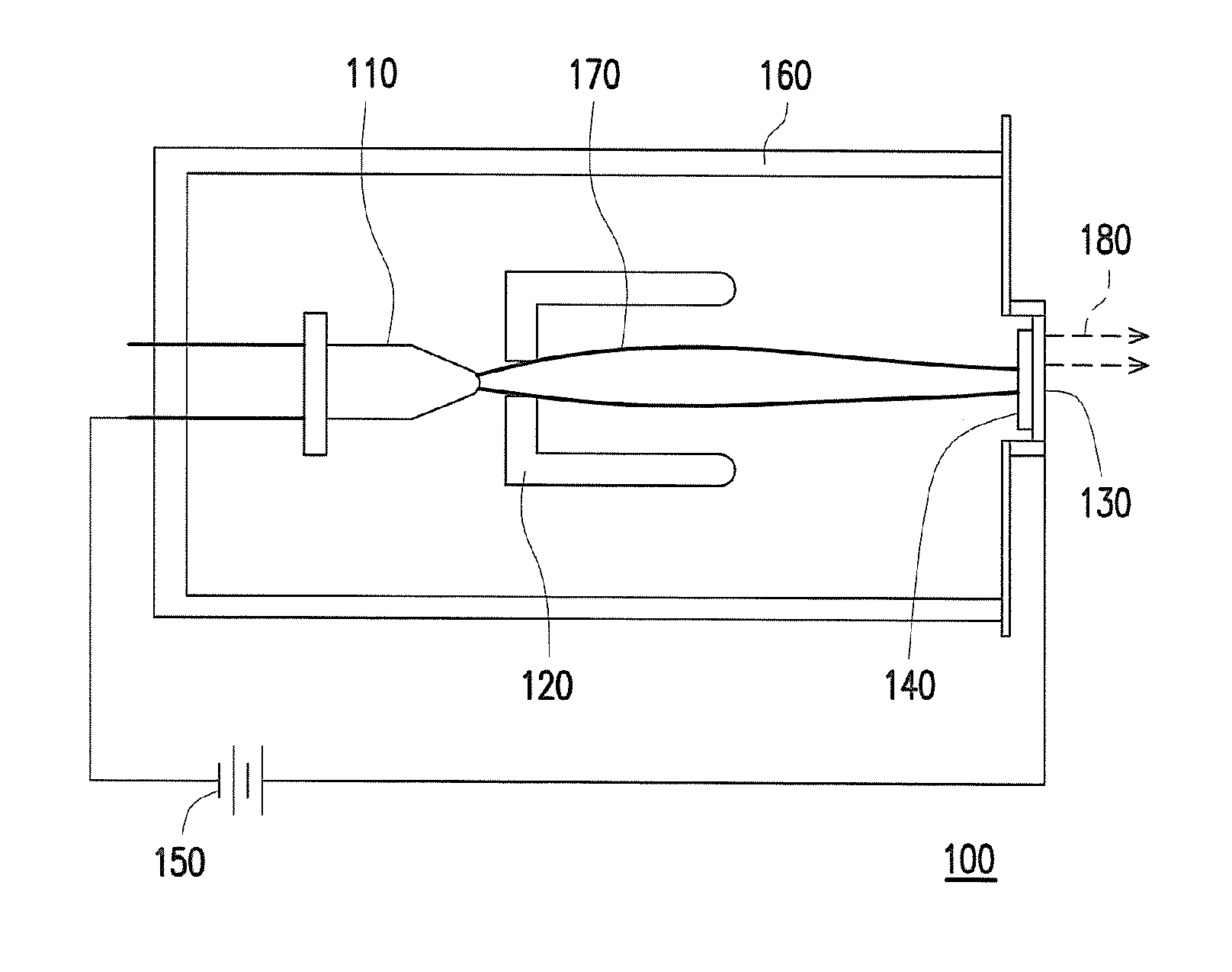

ActiveUS20140185778A1Improve thermal conductivityX-ray tube laminated targetsX-ray tube electrodesX-rayElectron

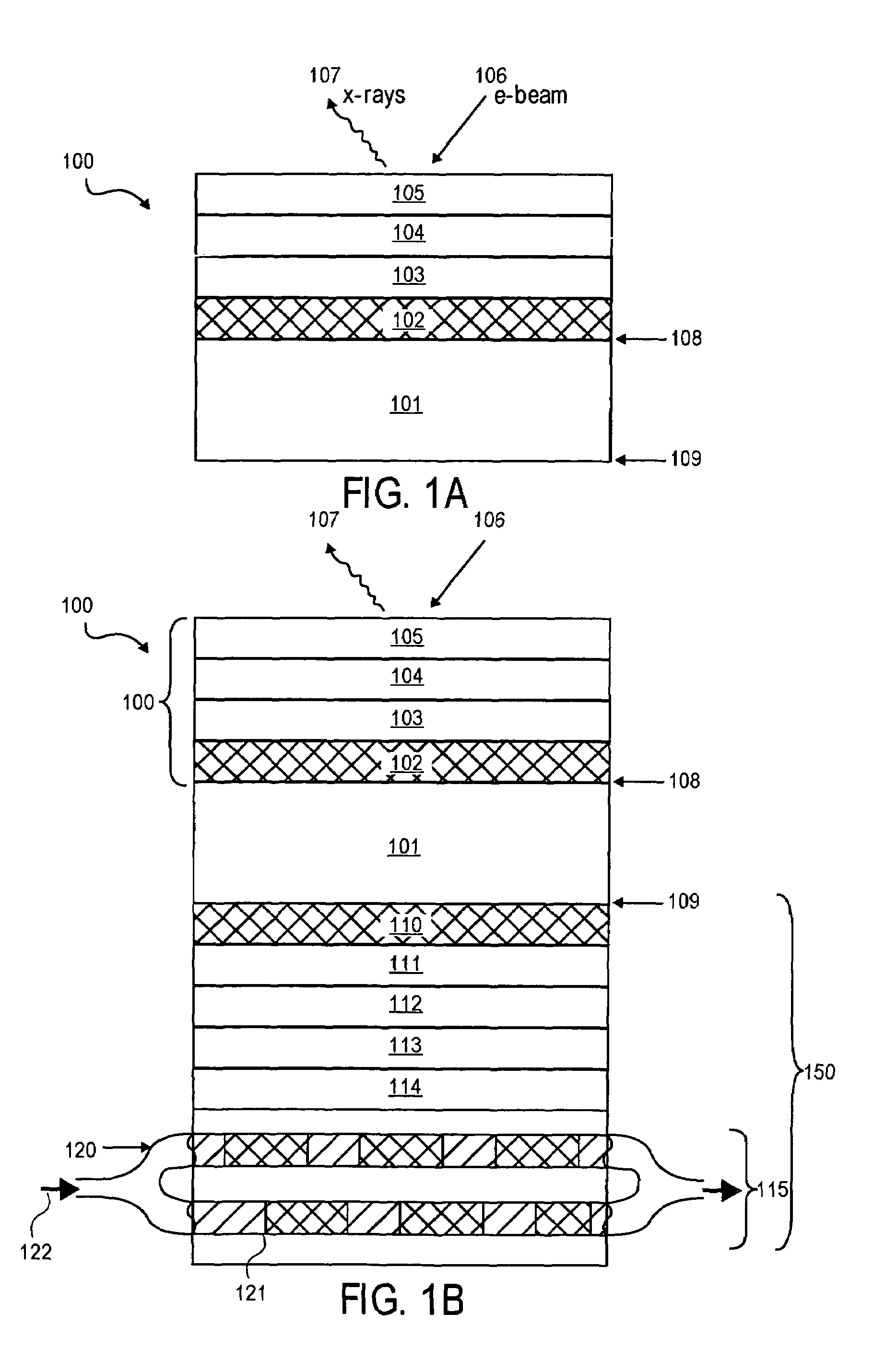

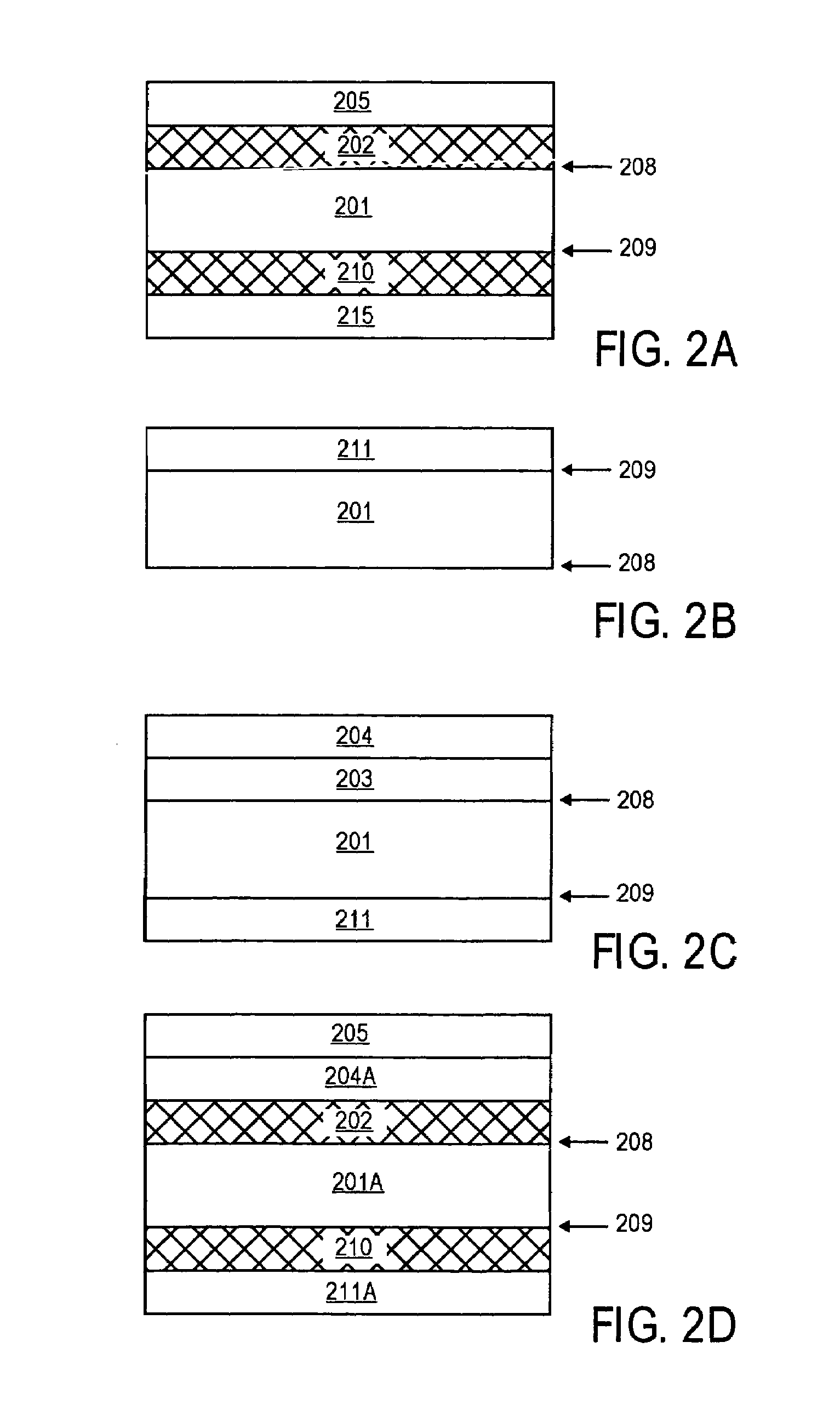

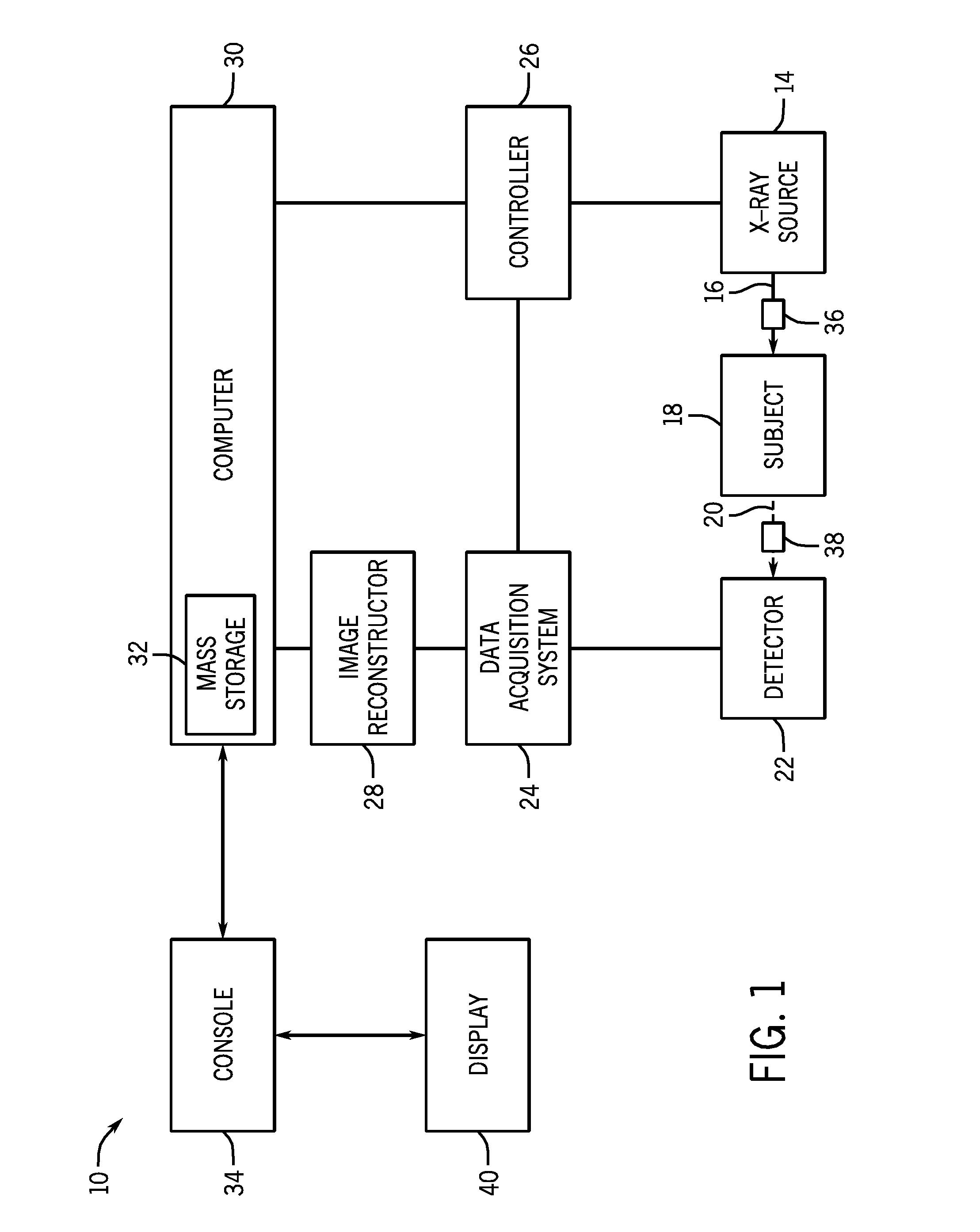

In one embodiment, an X-ray source is provided that includes one or more electron emitters configured to emit one or more electron beams and one or more source targets configured to receive the one or more electron beams emitted by the one or more electron emitters and, as a result of receiving the one or more electron beams, to emit X-rays. Each source target of the X-ray source includes a first layer having one or more first materials; and a second layer in thermal communication with the first layer and having one or more second materials. The first layer is positioned closer to the one or more emitters than the second layer, the first material has a higher overall thermal conductivity than the second layer, and the second layer produces the majority of the X-rays emitted by the source target.

Owner:GENERAL ELECTRIC CO

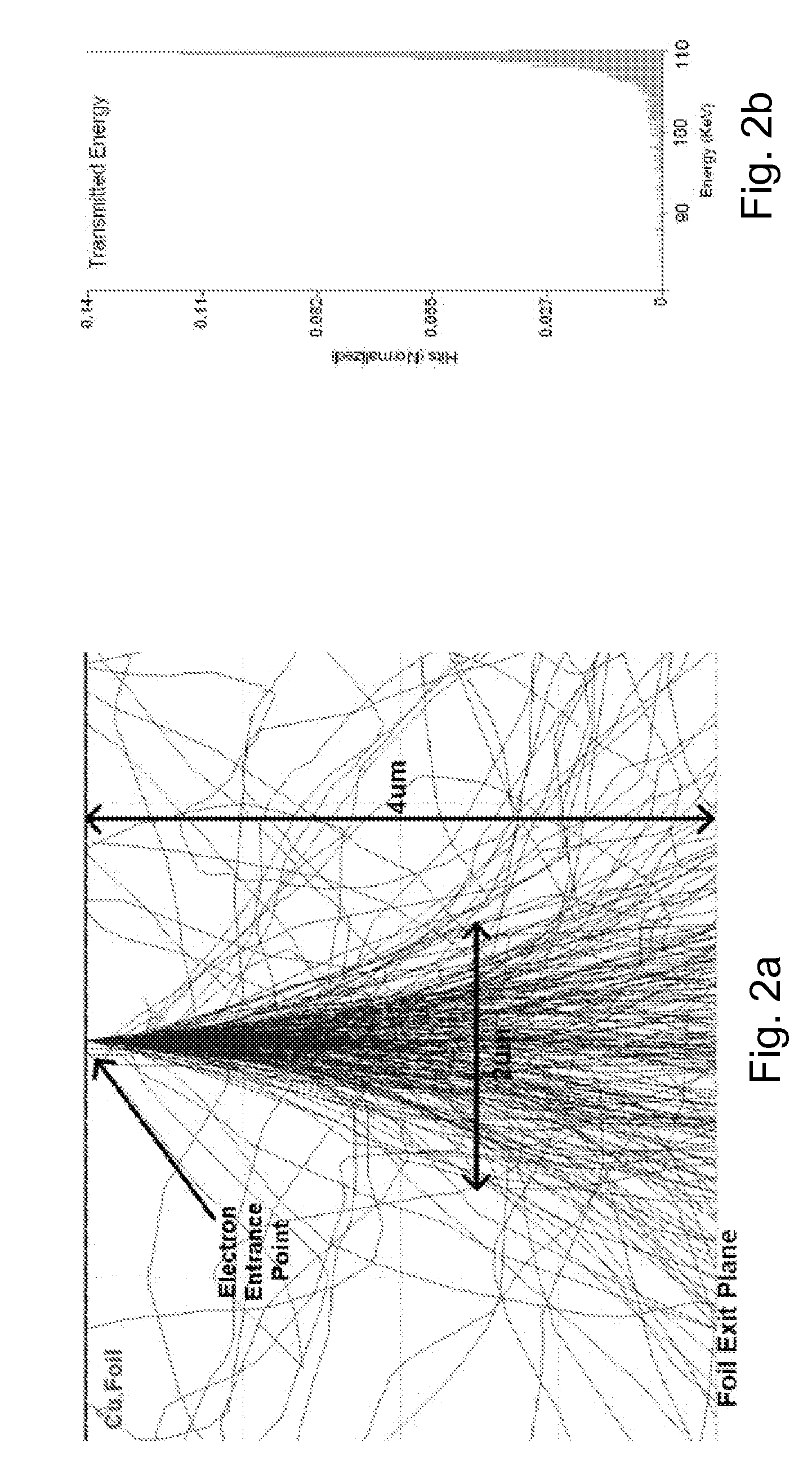

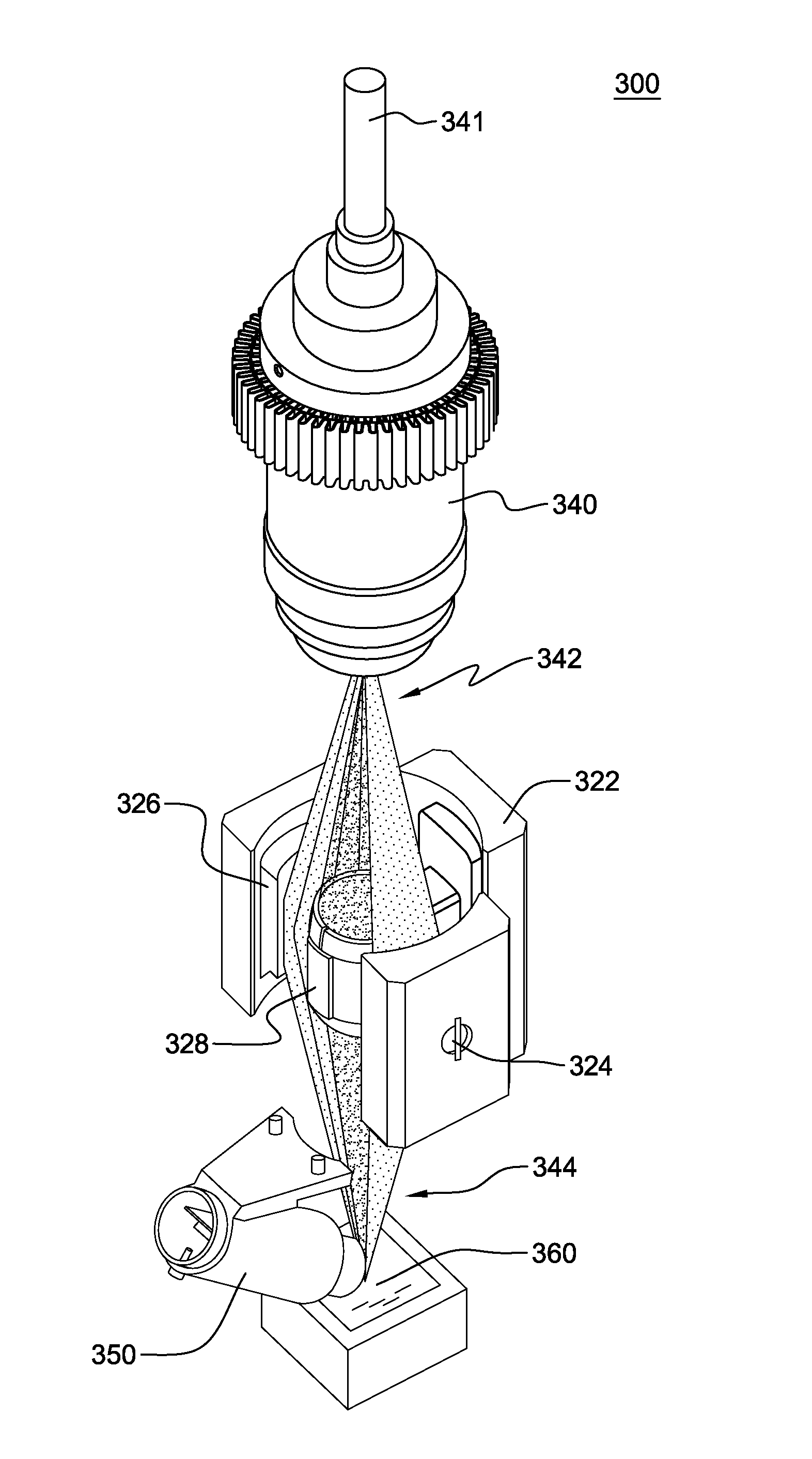

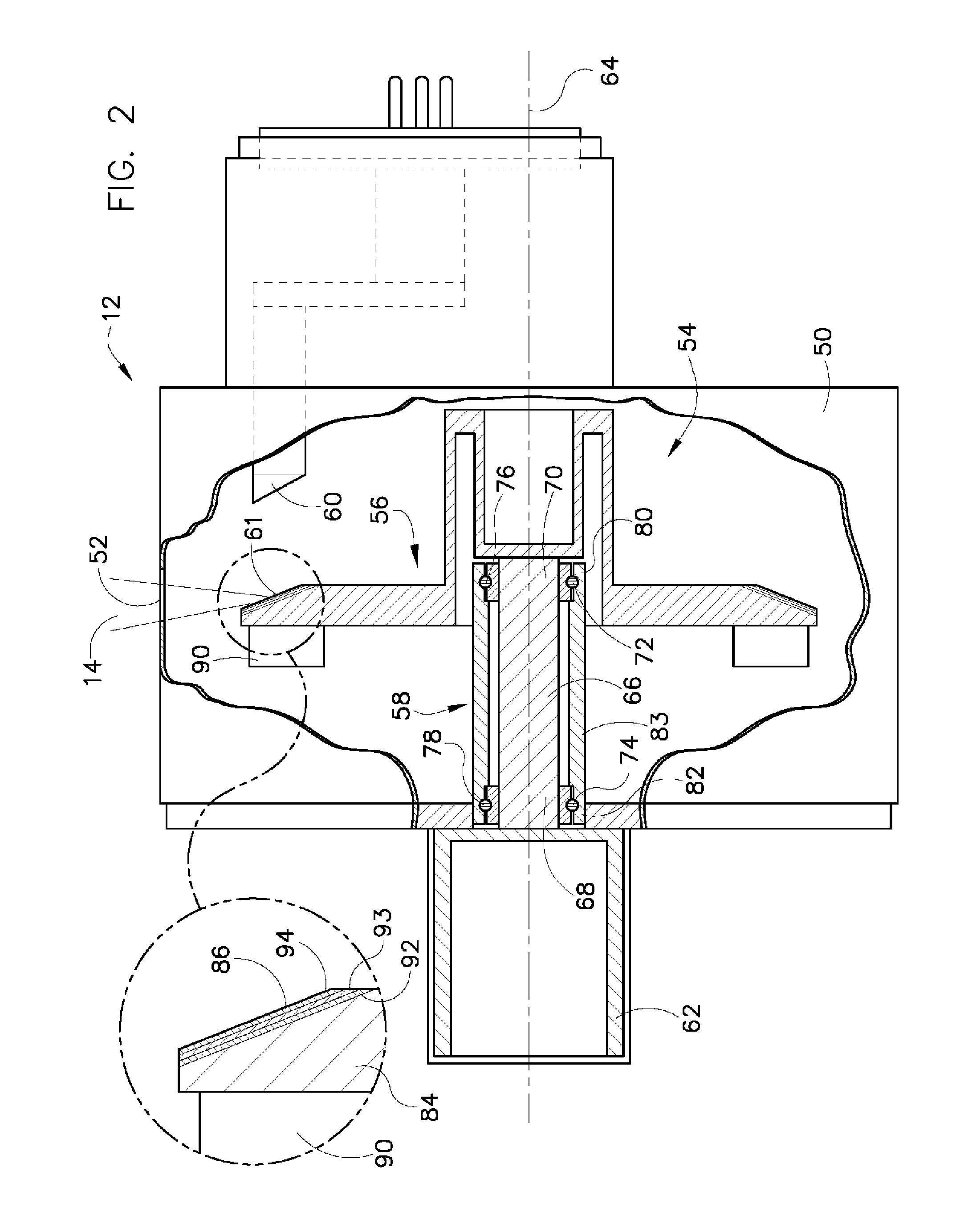

Structured anode X-ray source for X-ray microscopy

ActiveUS7443953B1Improve performanceImprove thermal performanceX-ray tube laminated targetsX-ray tube electrodesHigh energyX-ray

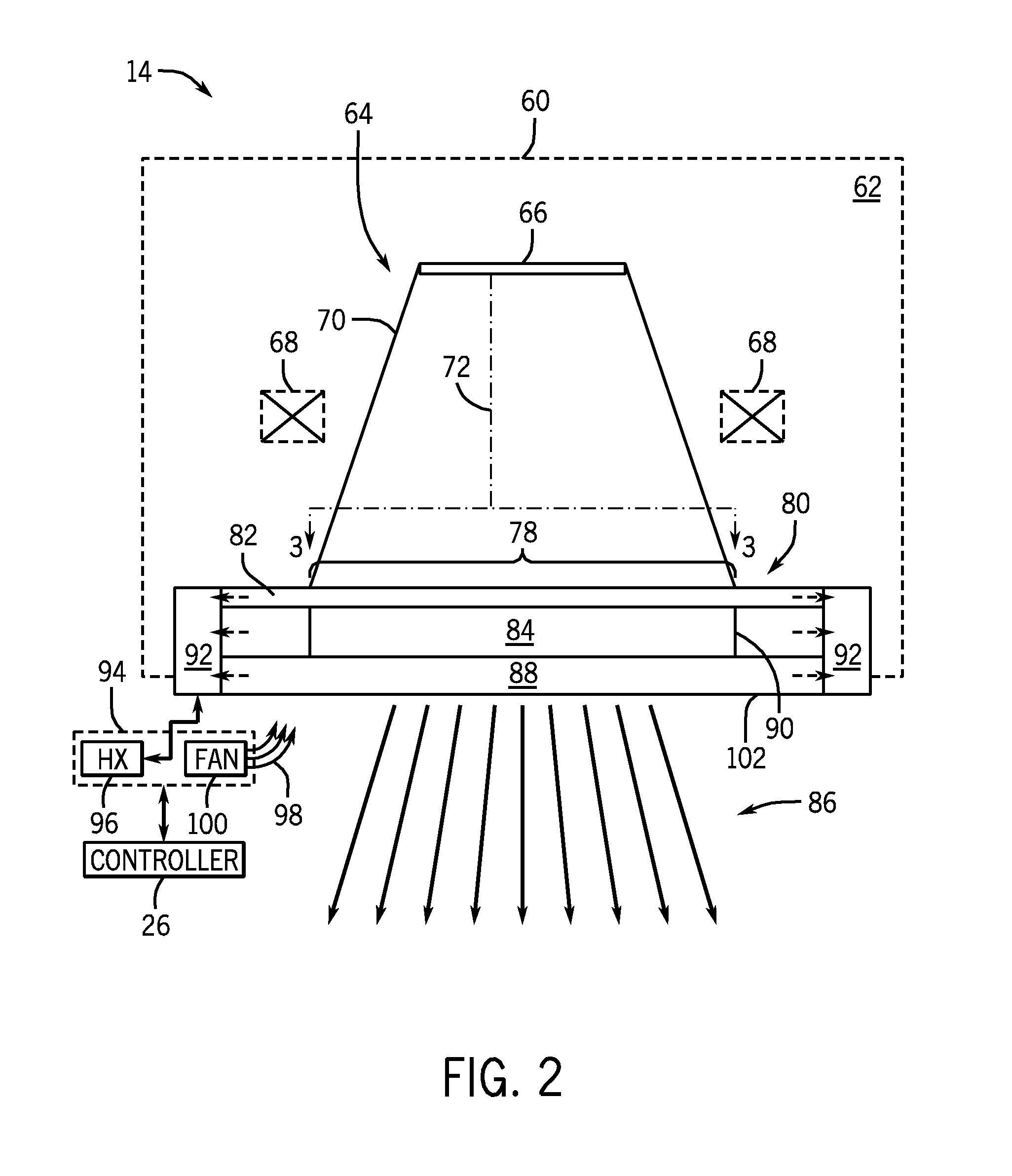

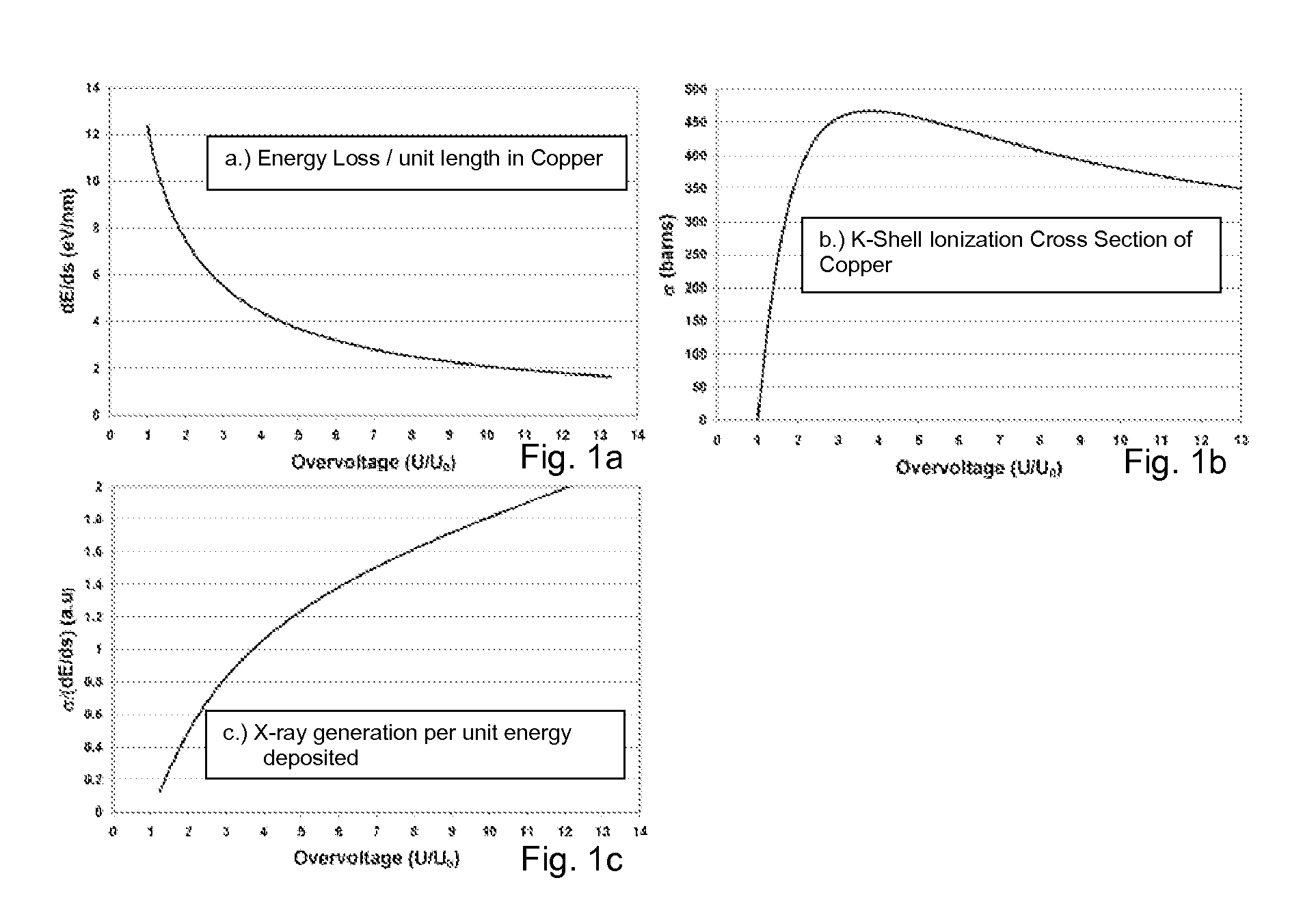

An x-ray source comprises a structured anode that has a thin top layer made of the desired target material and a thick bottom layer made of low atomic number and low density materials with good thermal properties. In one example, the anode comprises a layer of copper with an optimal thickness deposited on a layer of beryllium or diamond substrate. This structured target design allows for the use of efficient high energy electrons for generation of characteristic x-rays per unit energy deposited in the top layer and the use of the bottom layer as a thermal sink. This anode design can be applied to substantially increase the brightness of stationary, rotating anode or other electron bombardment-based sources where brightness is defined as number of x-rays per unit area and unit solid angle emitted by a source and is a key figure of merit parameter for a source.

Owner:CARL ZEISS X RAY MICROSCOPY

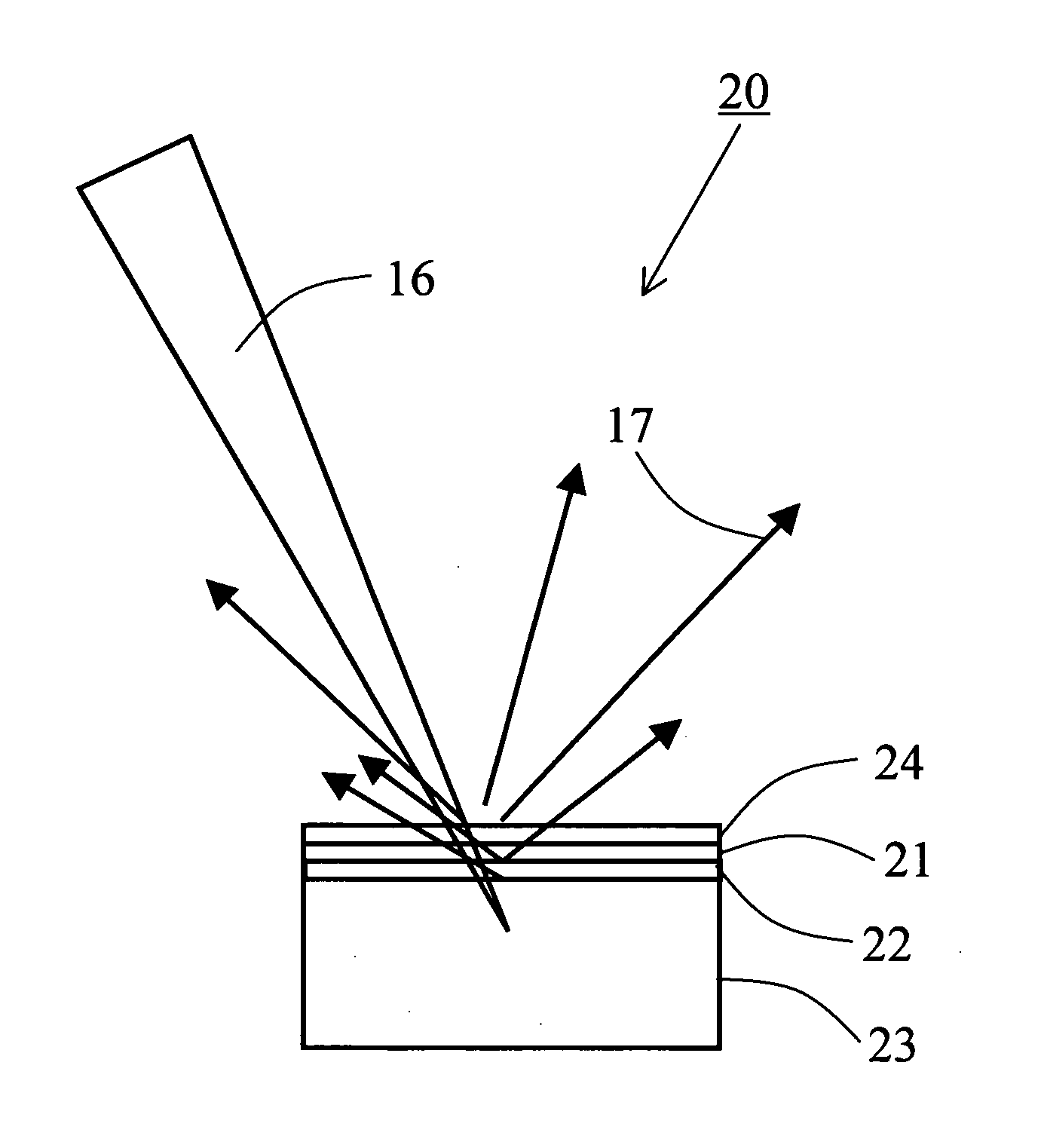

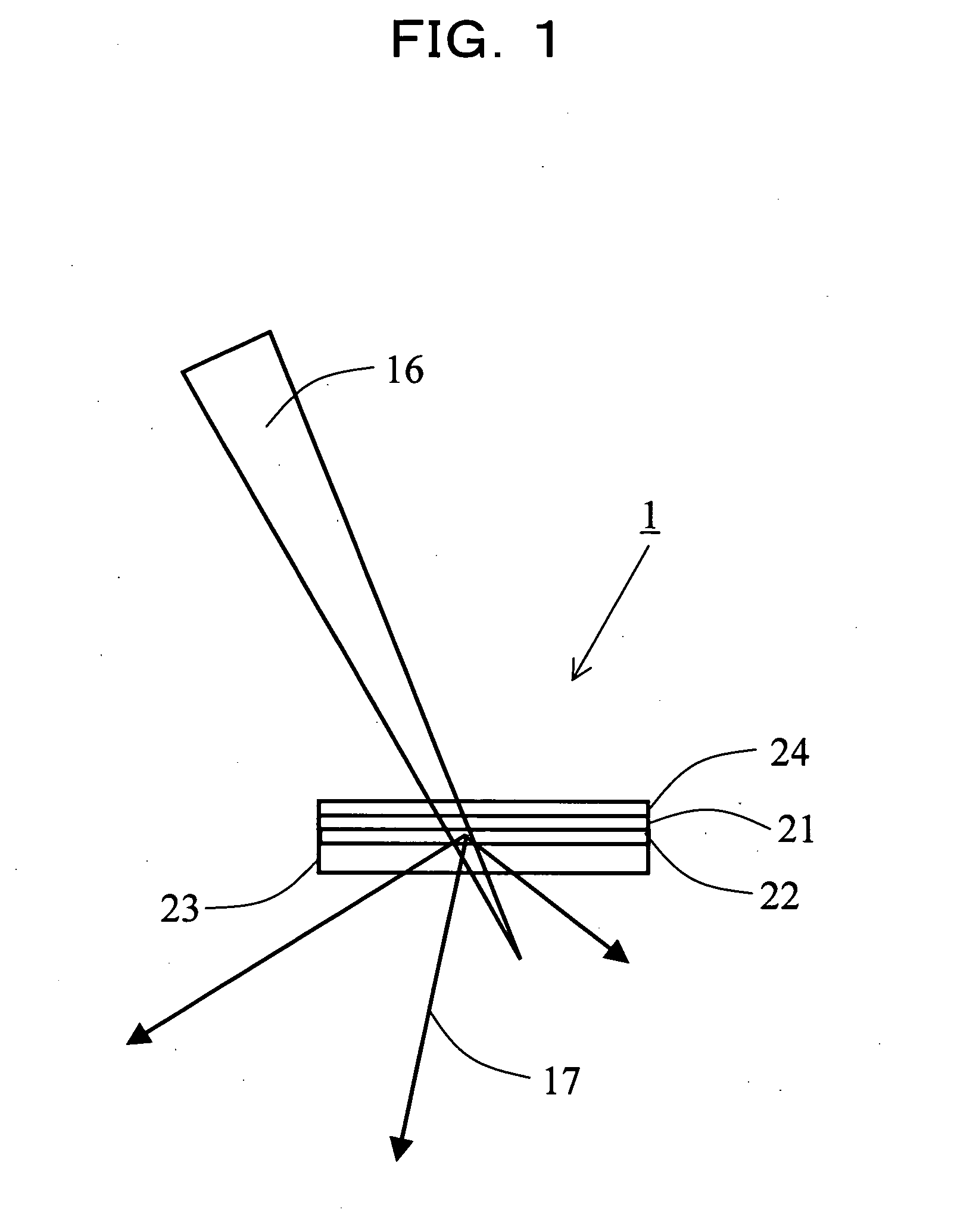

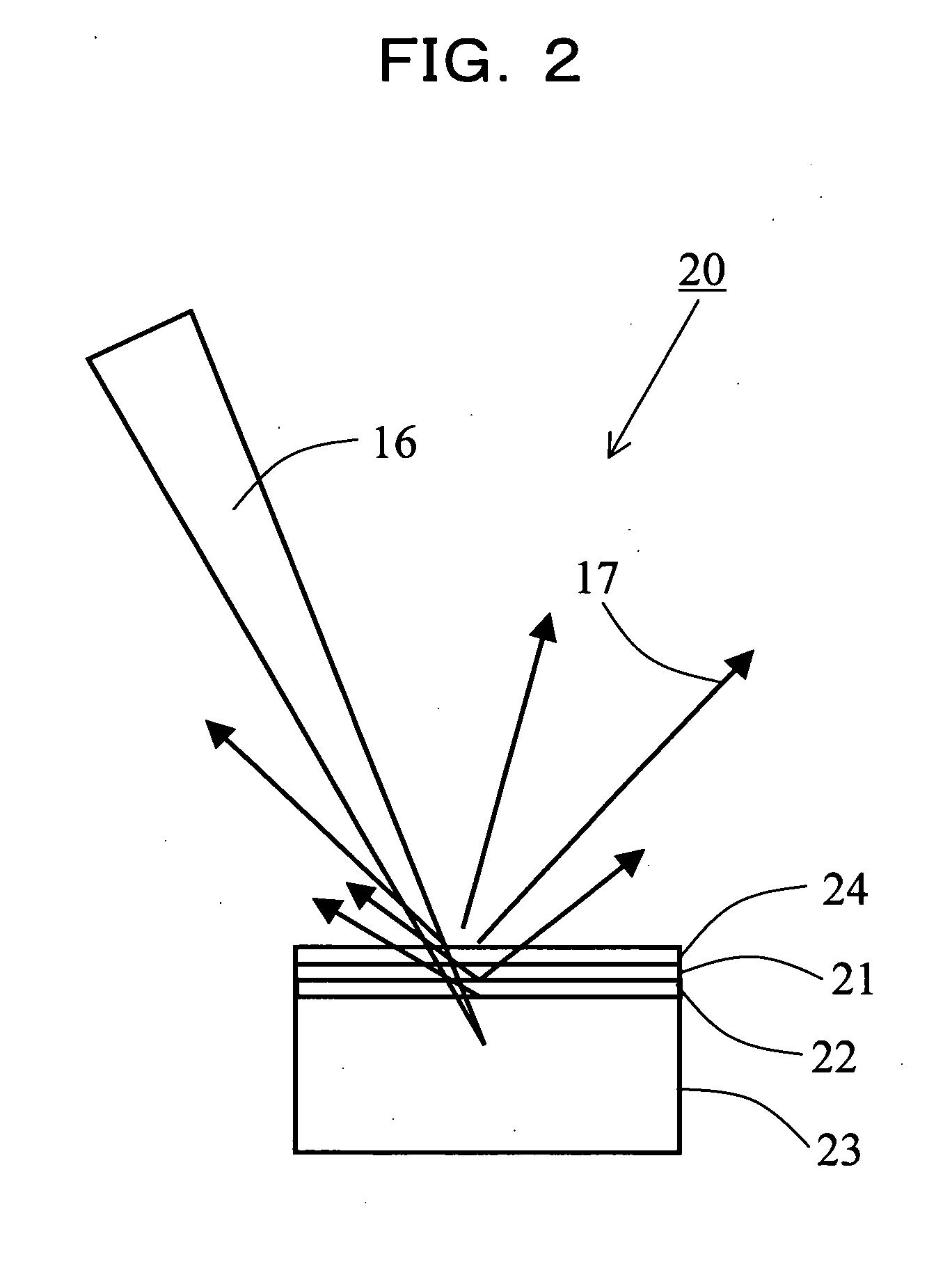

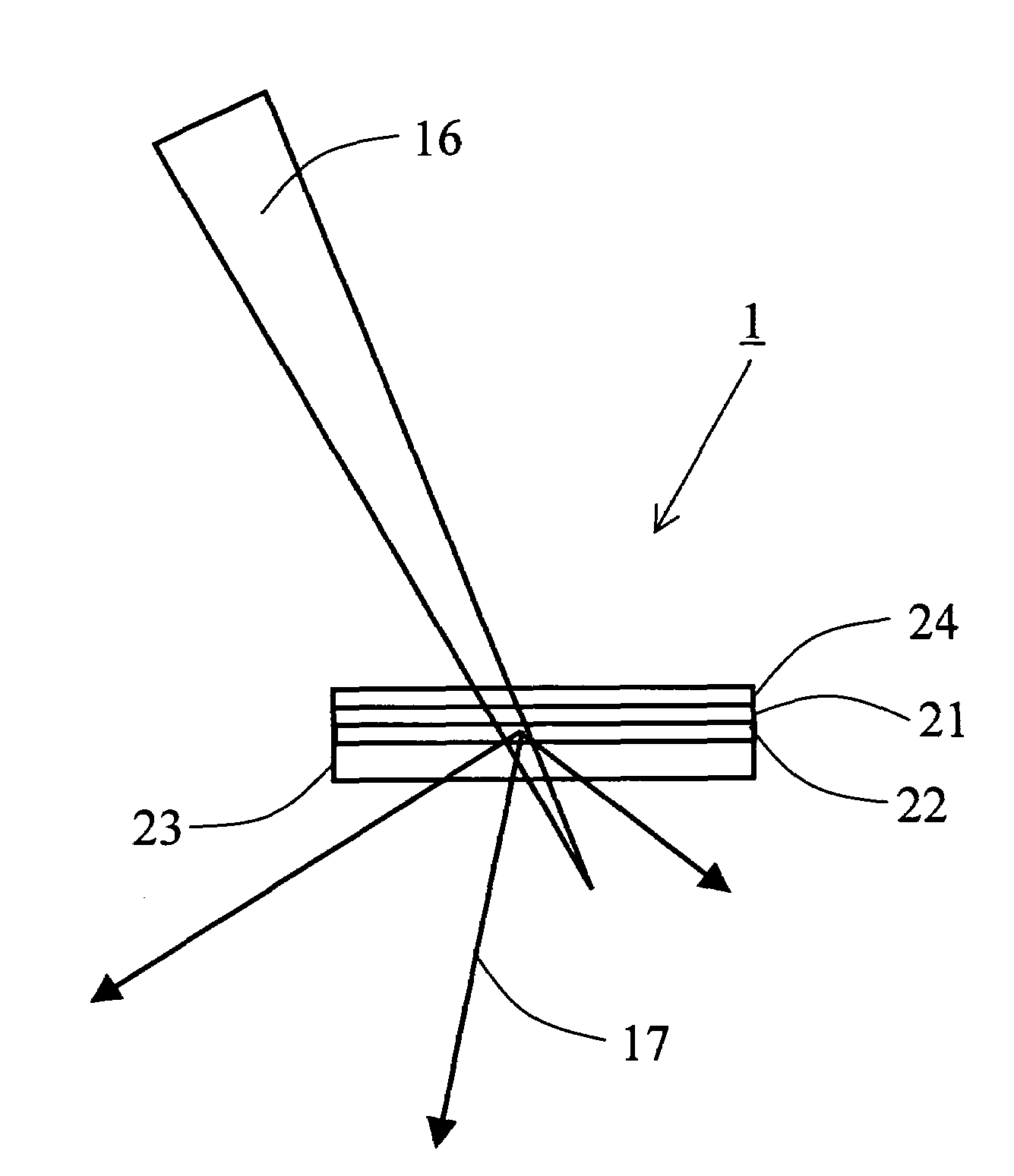

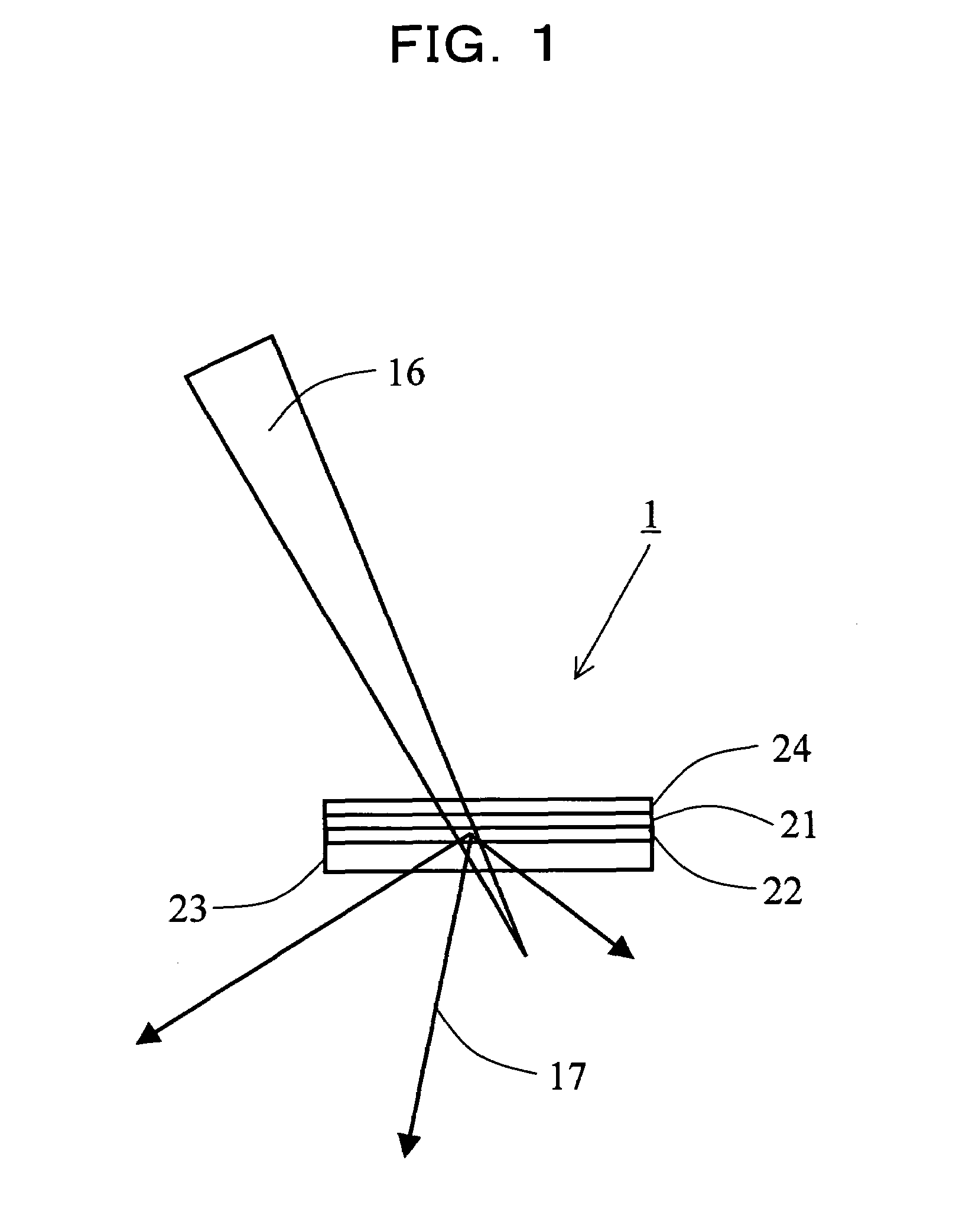

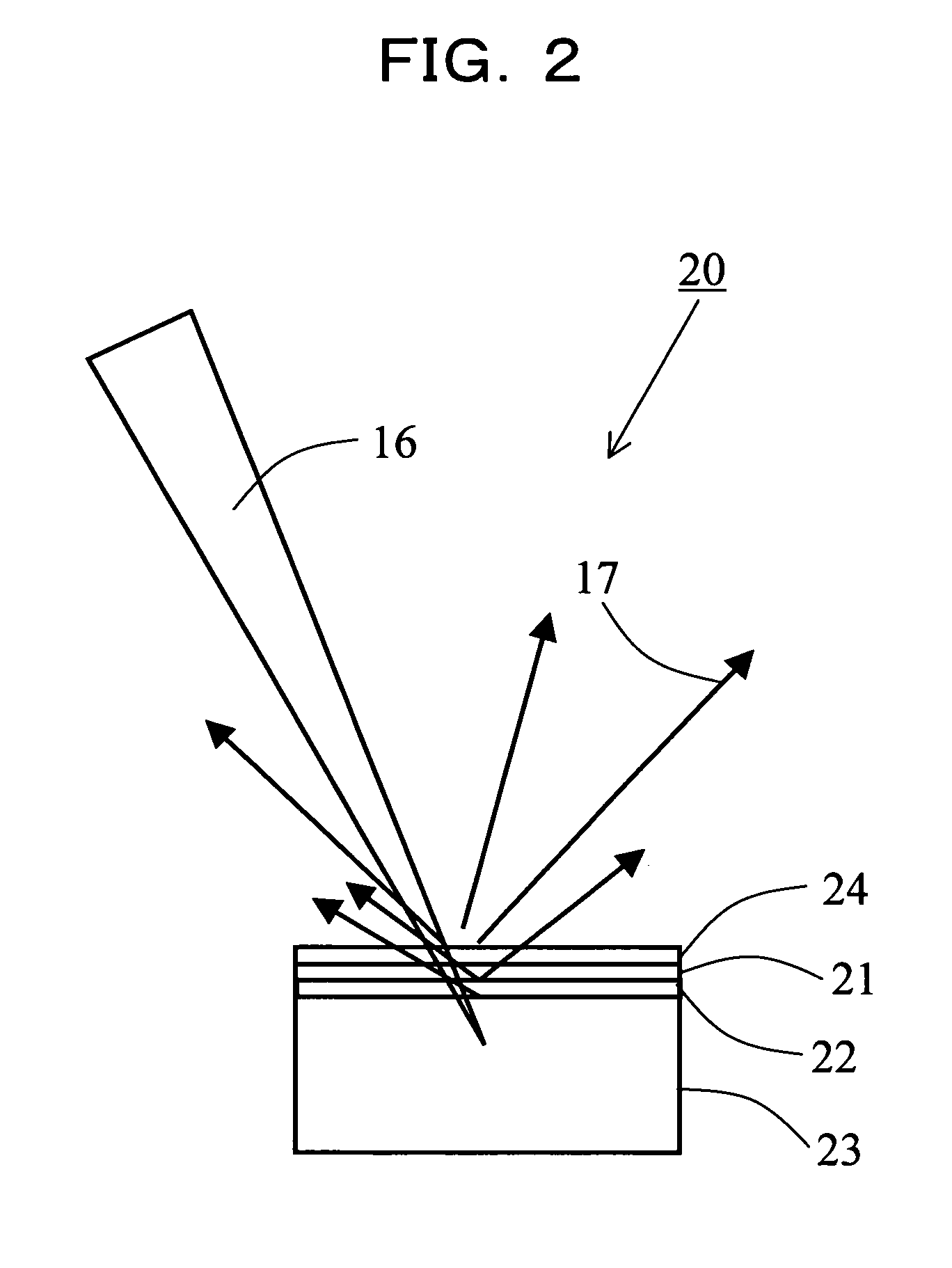

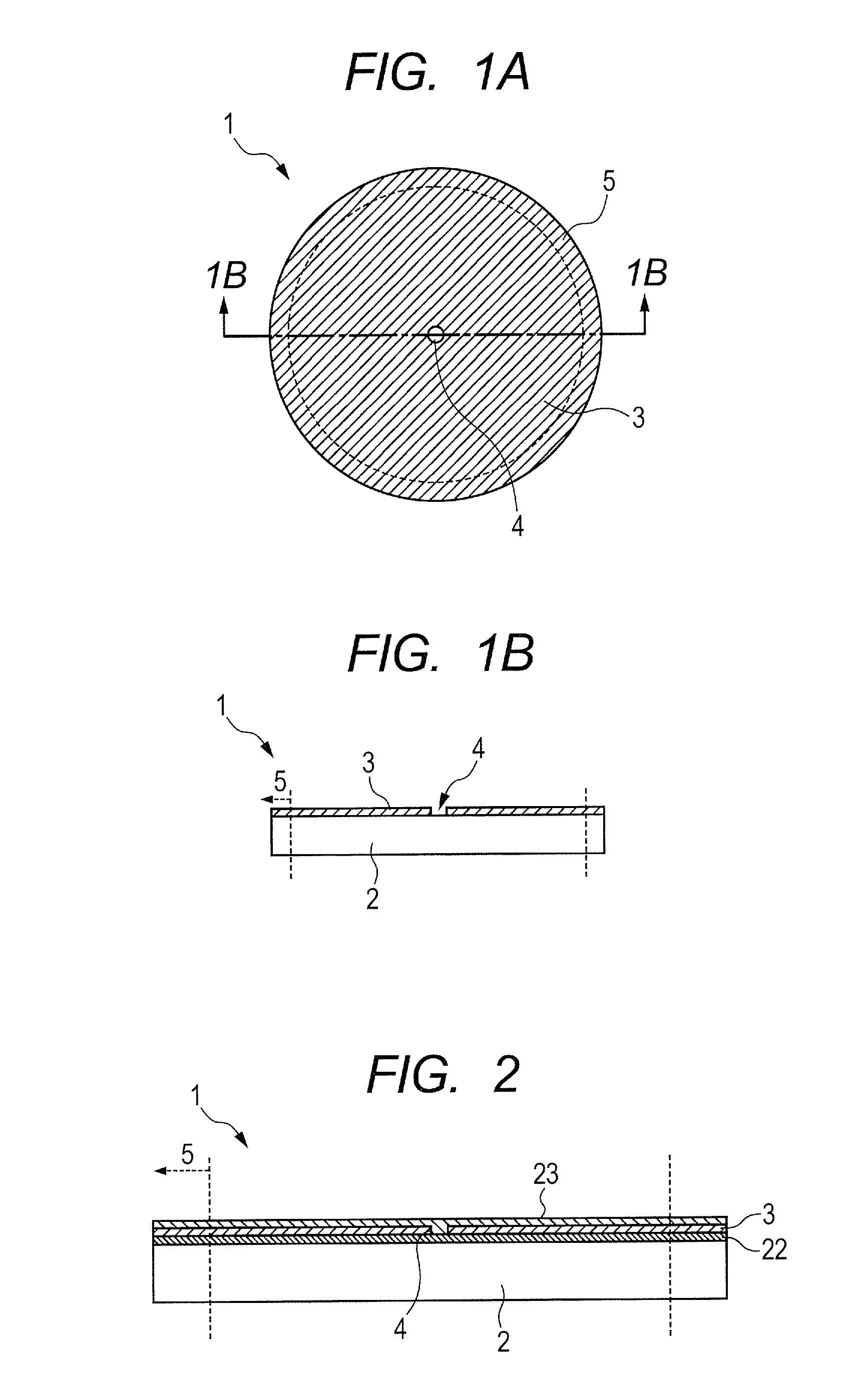

X-Ray Target and Apparatuses Using the Same

InactiveUS20070248215A1Highly convenientElectron beam absorptivityX-ray tube laminated targetsImaging devicesFluorescenceHigh intensity

Disclosed are an X-ray target having a micro focus size and capable of producing X-rays of high intensity, and apparatuses using such an X-ray target. The X-ray target (1) has a structure in which a first cap layer (21), a target layer (22), and a second cap layer (23) are successively laminated, wherein the first and second cap layers (21and 23) are each composed of a material which is lower in electron beam absorptivity than that of which the target layer (22) is composed. An X-ray generator using the X-ray target (1) can generate highly intense and nanofocus (several nm) X-rays (17). Using the X-ray generator, an X-ray microscope allows obtaining a high resolution transmission image, an X-ray diffraction apparatus allows obtaining an X-ray diffraction image of a very small area, and a fluorescent X-ray analysis apparatus allows making the fluorescent X-ray analysis of a minute area.

Owner:JAPAN SCI & TECH CORP

X-ray source and fluorescent X-ray analyzing apparatus

InactiveUS7809113B2Eliminates unwanted noise componentGenerate efficientlyX-ray tube laminated targetsMaterial analysis using wave/particle radiationSoft x rayX-ray

Owner:TOSHIBA ELECTRON TUBE & DEVICES

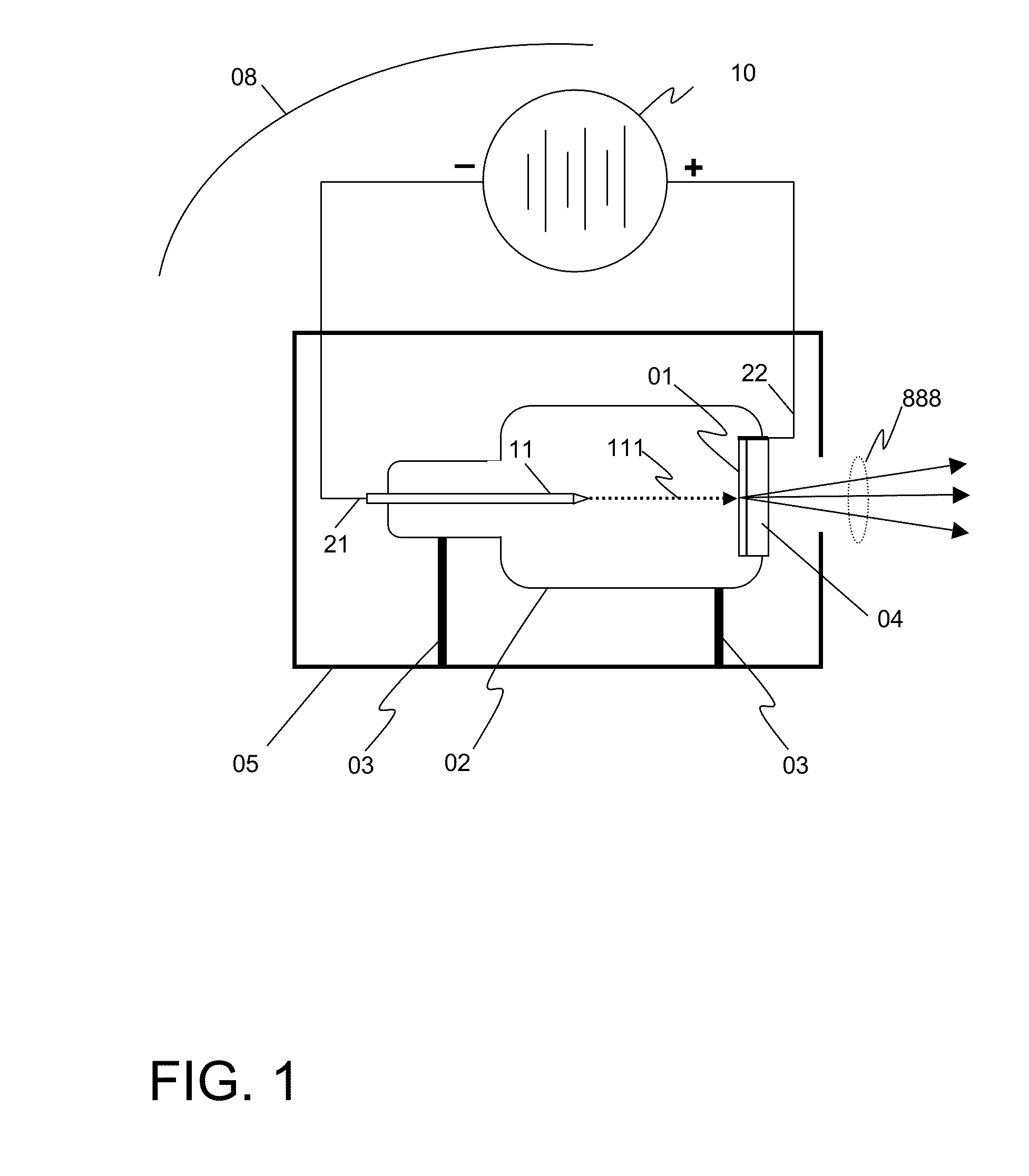

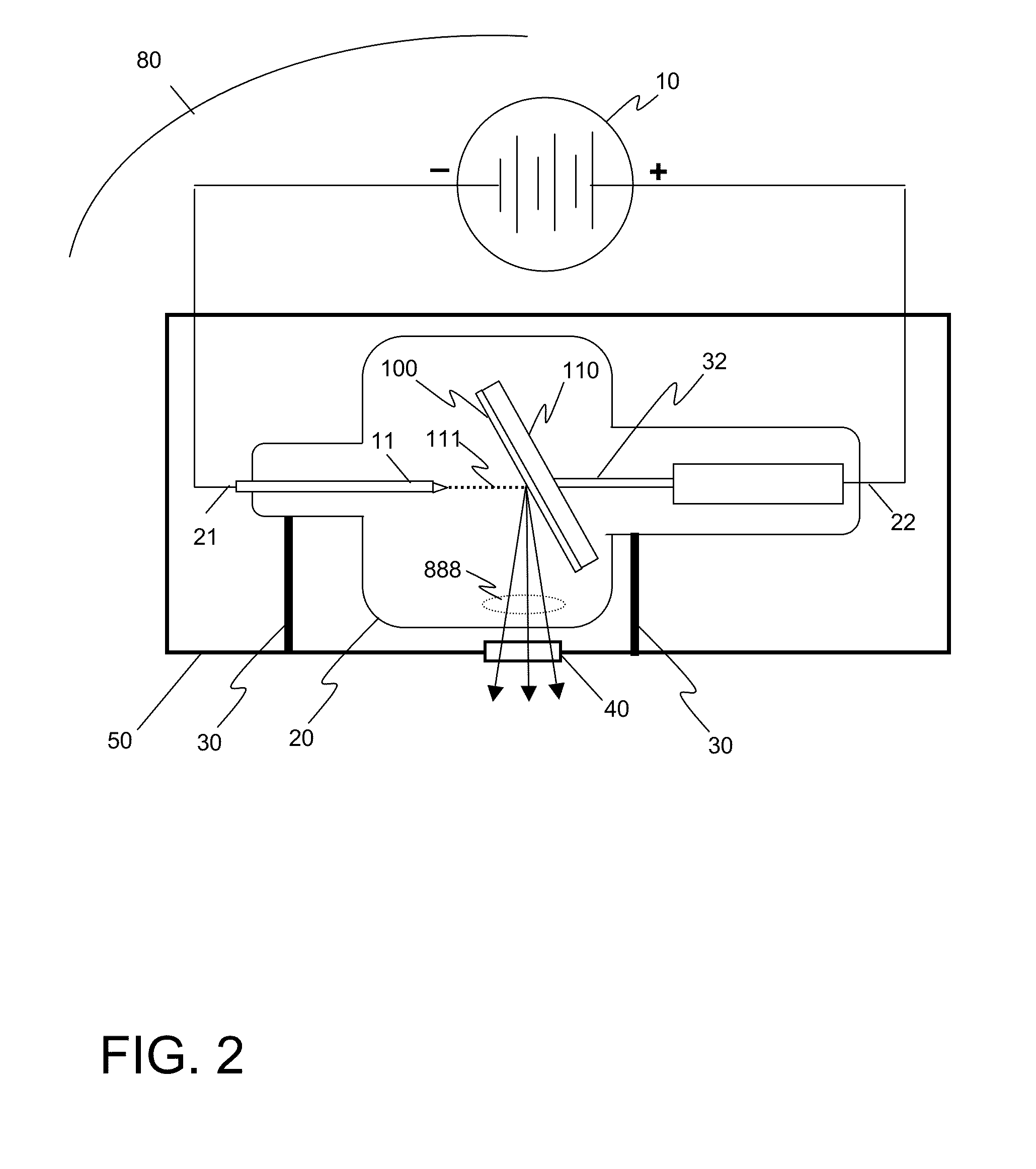

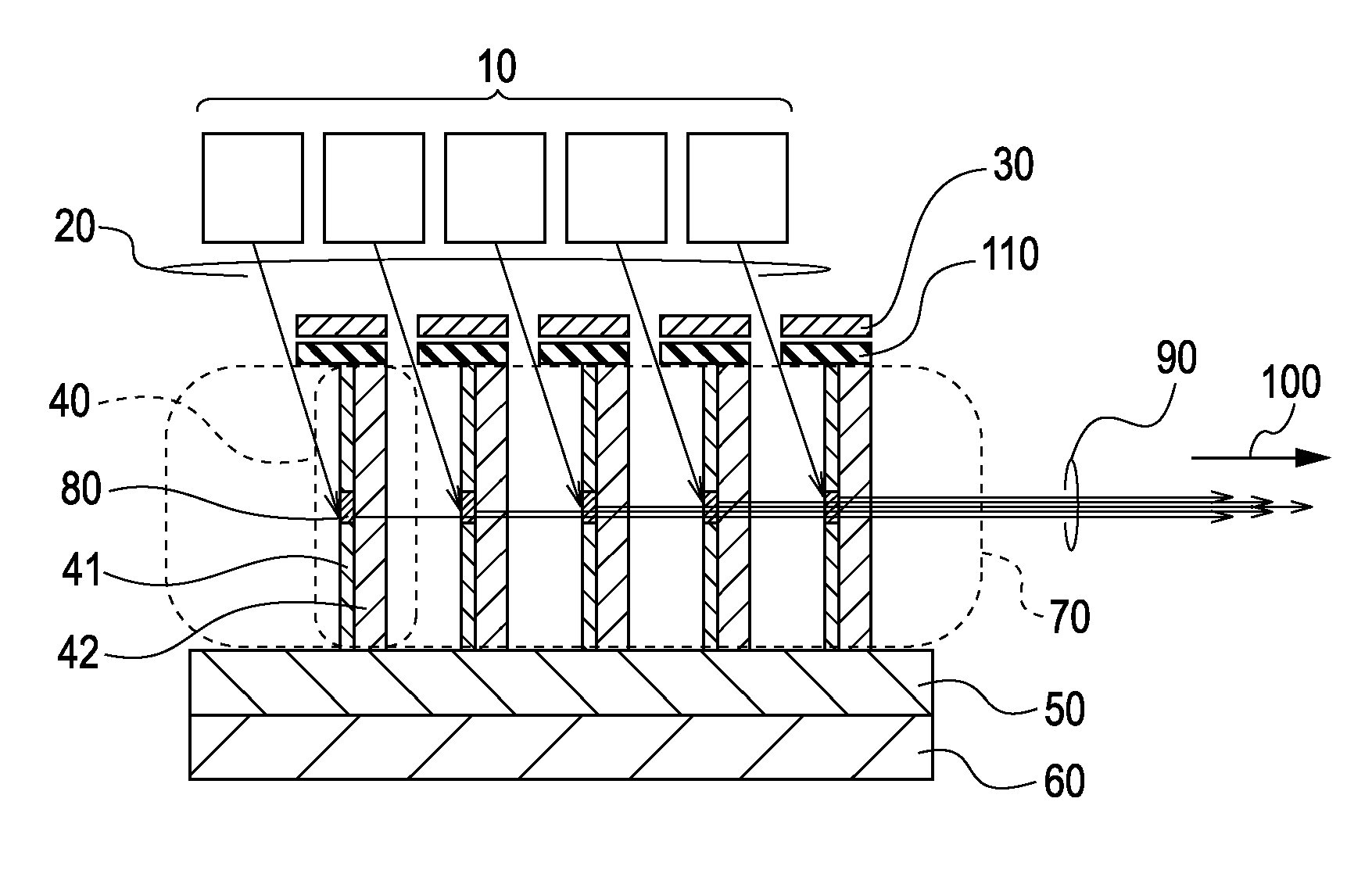

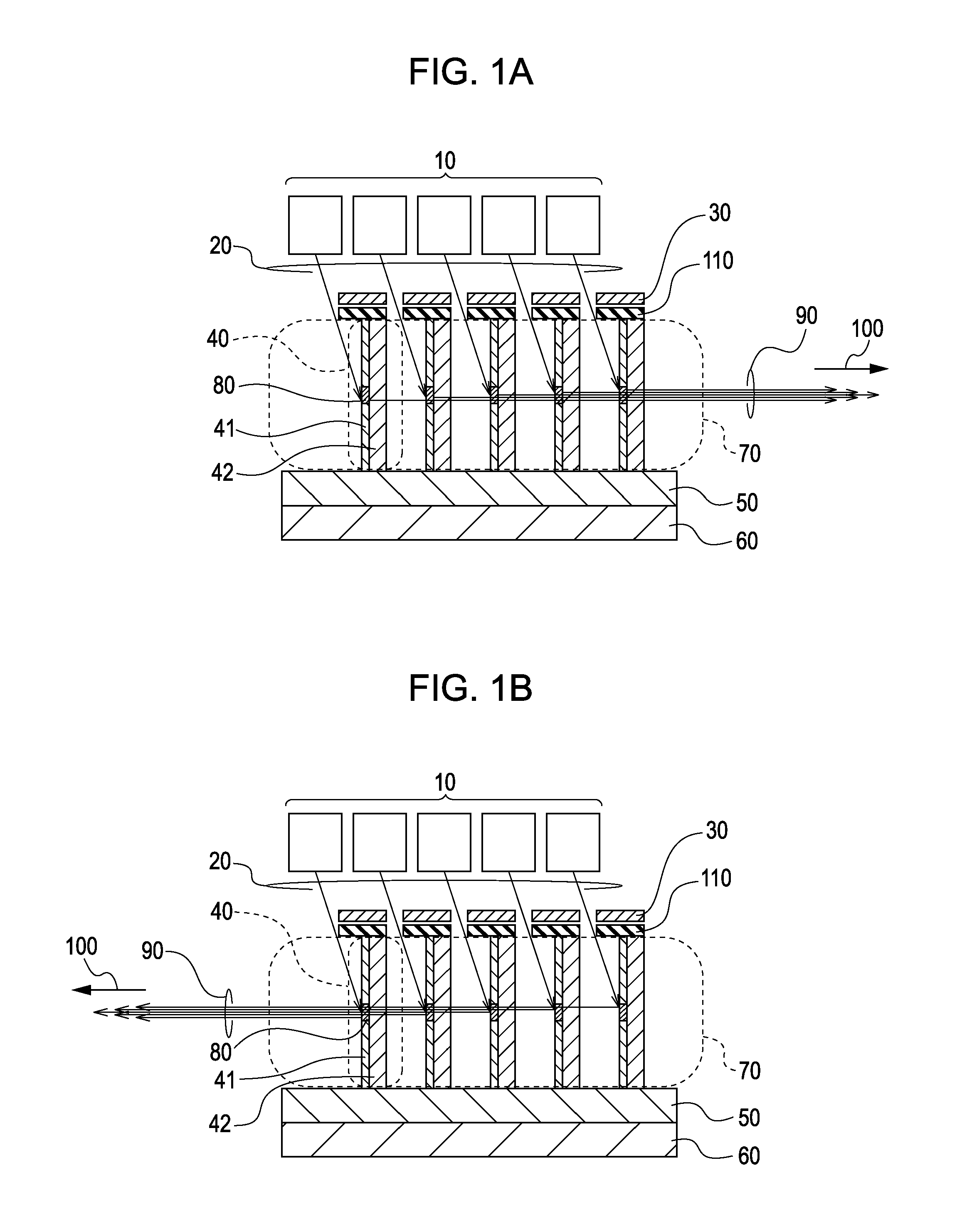

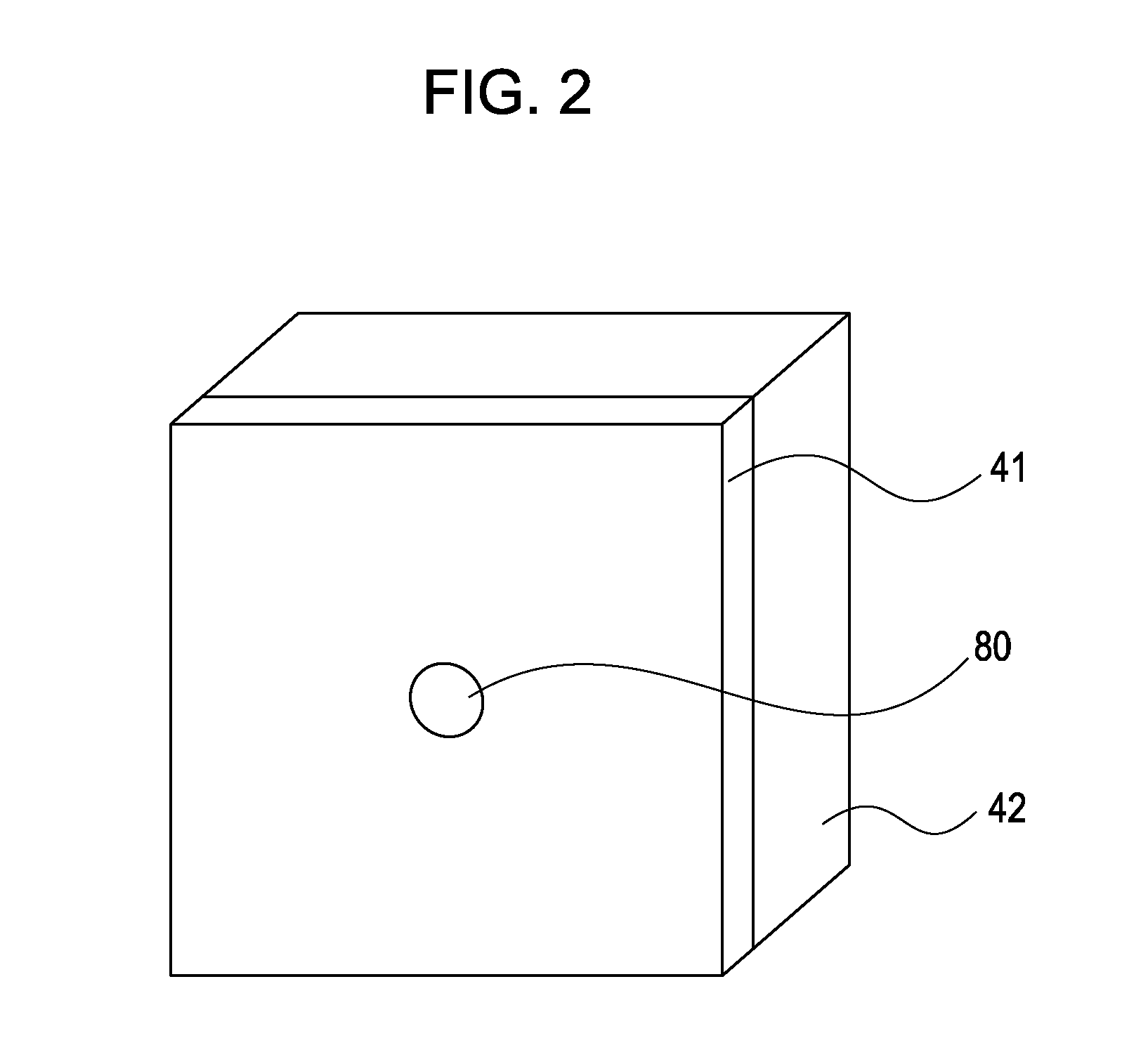

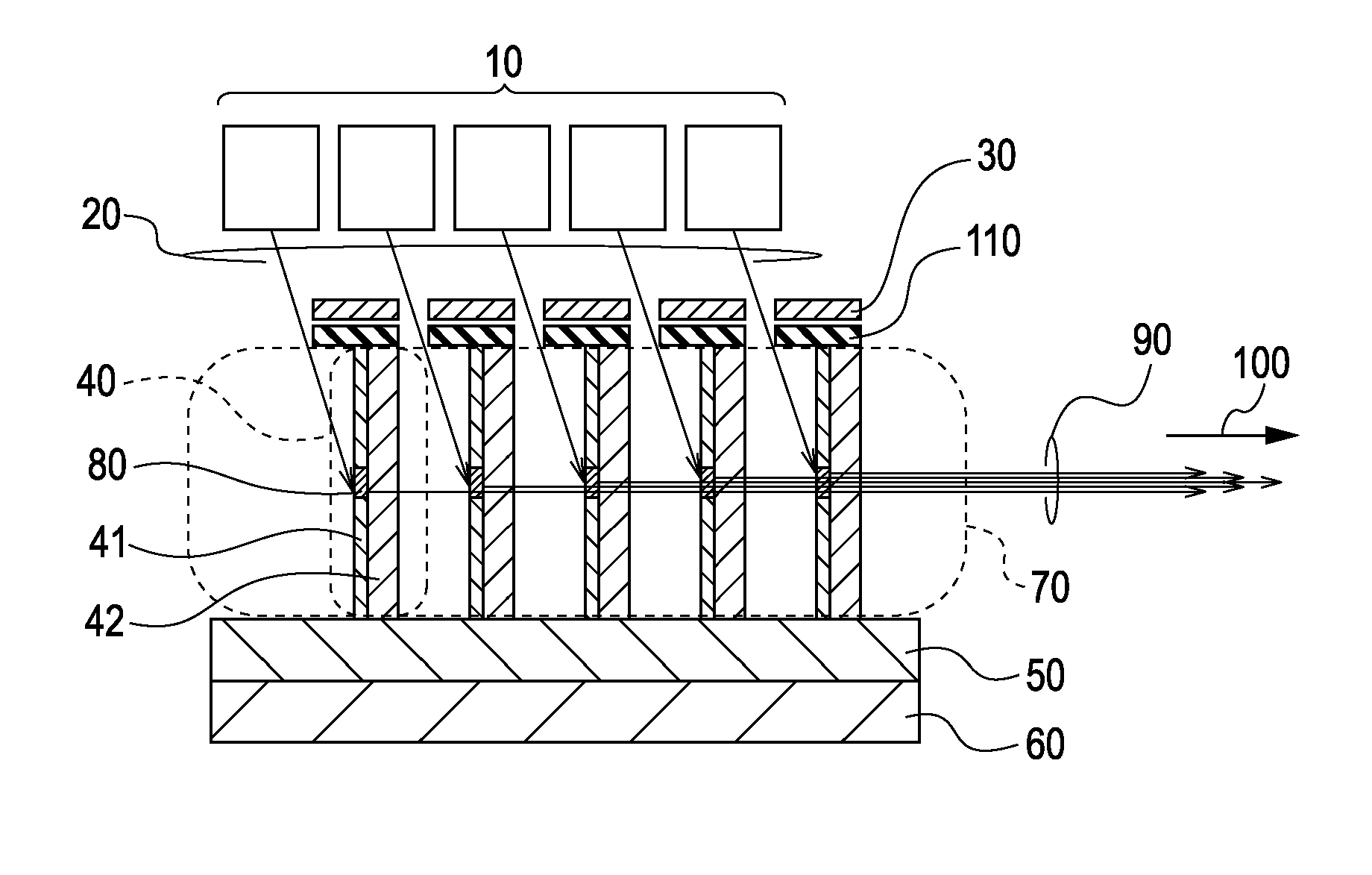

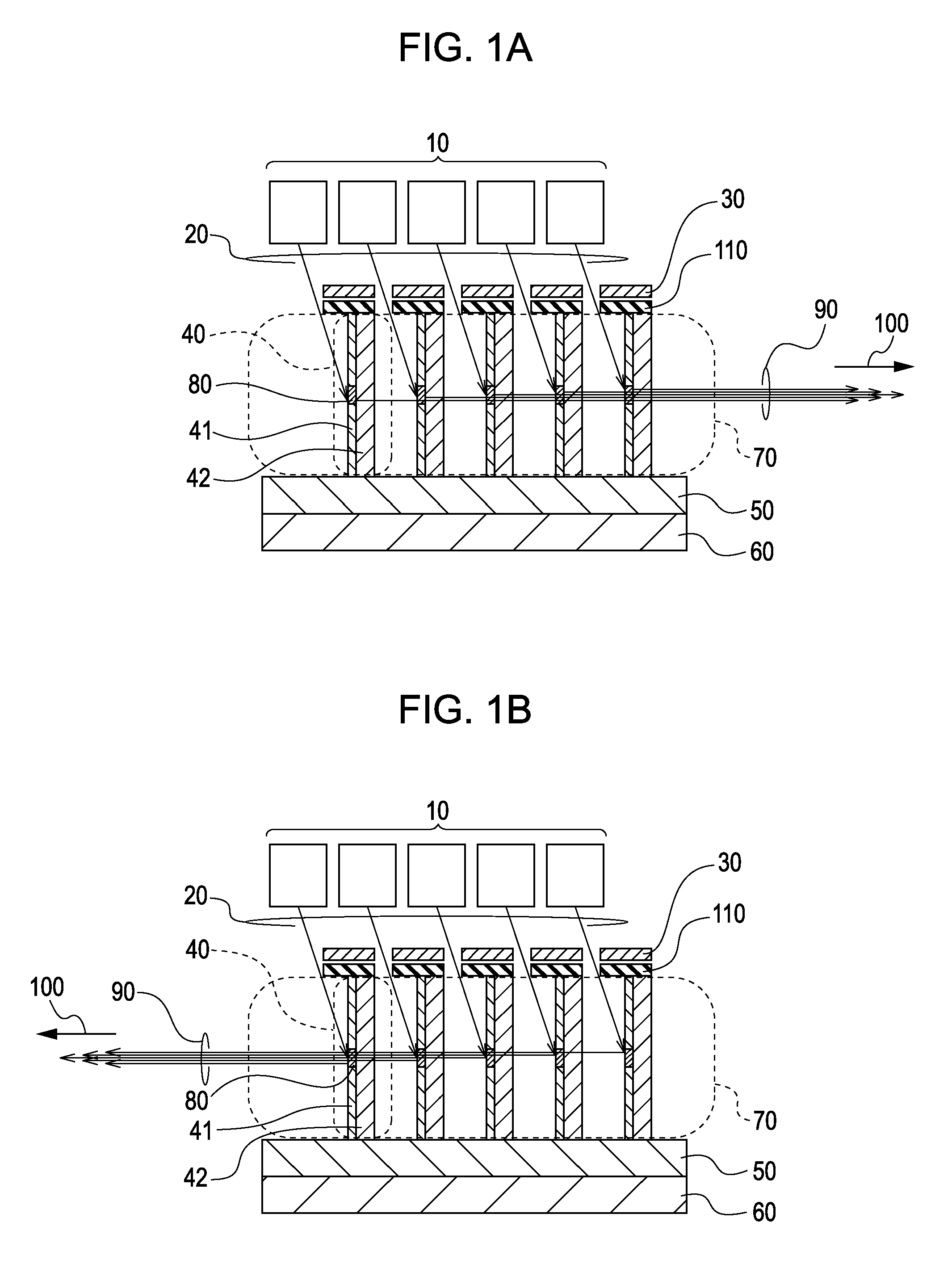

X-ray generating device

InactiveUS20110026680A1Increase volumeSmall sizeX-ray tube laminated targetsX-ray tube anode coolingSoft x rayX-ray

An X-ray generating device includes an electron-beam generator, a target assembly group, and an electron-beam focusing unit. The electron-beam generator generates electron beams. The target assembly group includes a plurality of target assemblies that are arranged along a straight line in a direction in which X-rays are output; each of the target assemblies includes a target and a supporting member; the target generates X-rays from one of the electron beams generated by the electron-beam generator; and the supporting member supports the target by being disposed adjacent thereto. The electron-beam focusing unit focuses the electron beams onto the targets included in the target assembly group so that X-rays are generated in each of the target assemblies and output along the straight line after passing through the target assemblies.

Owner:CANON KK

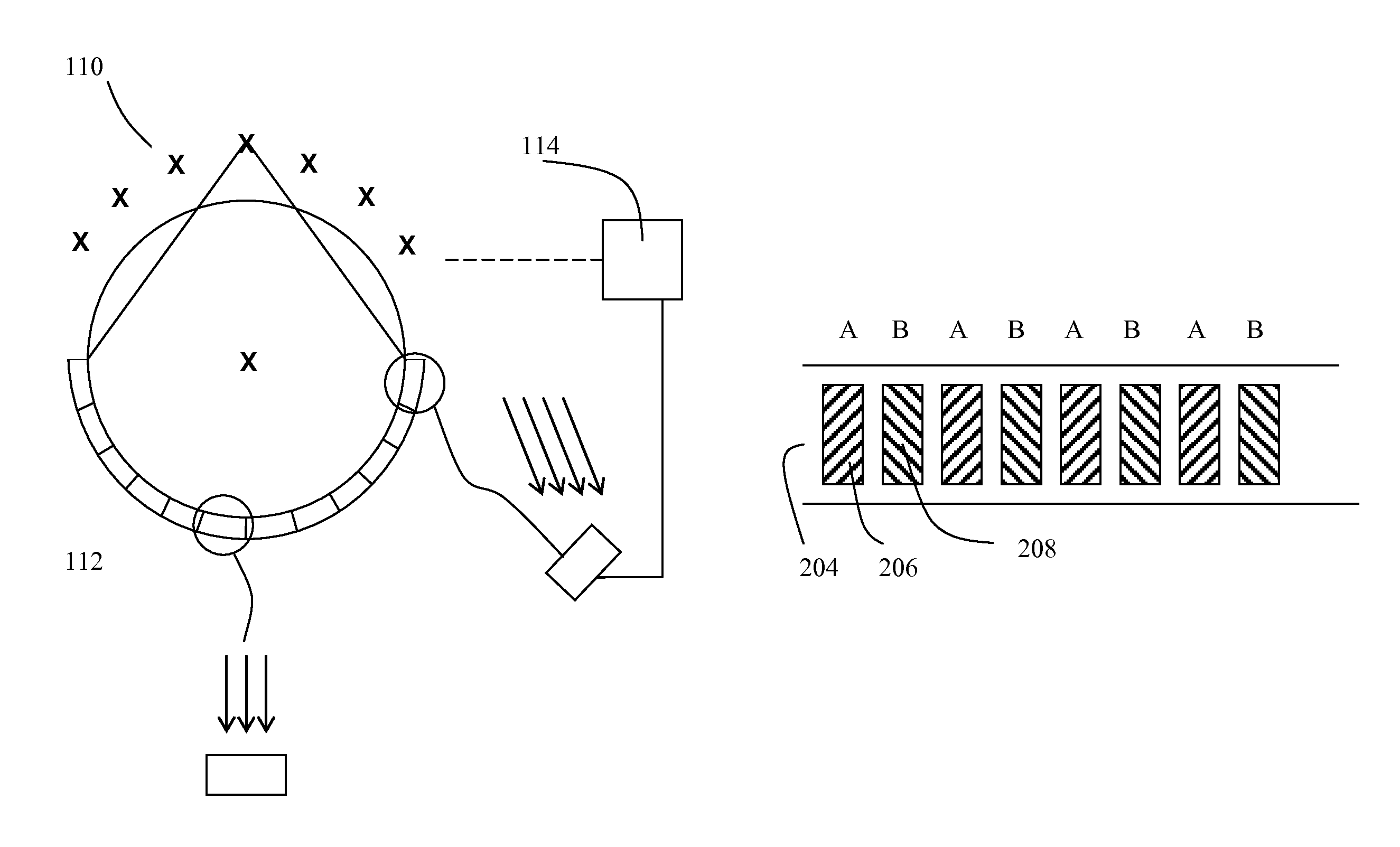

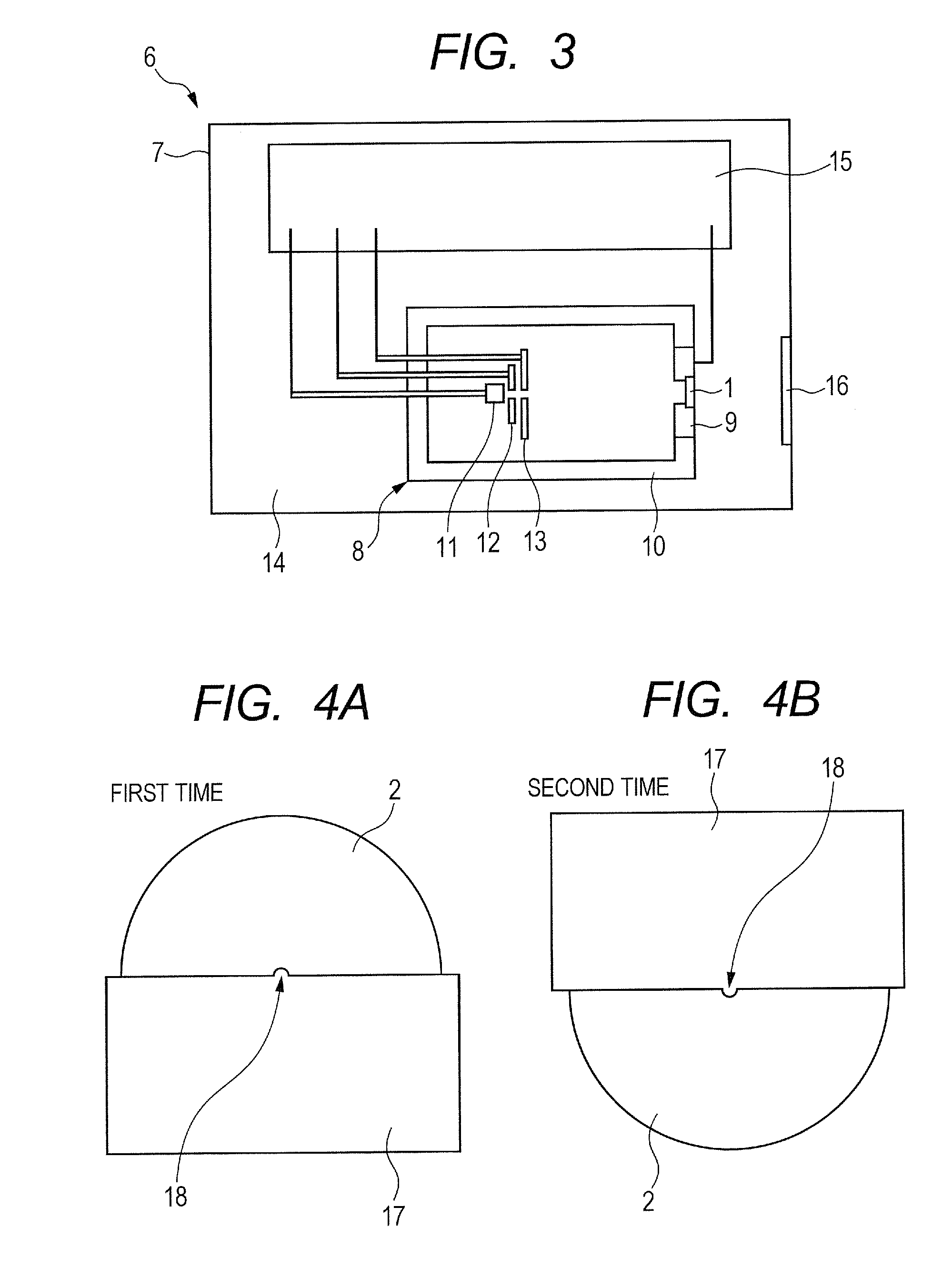

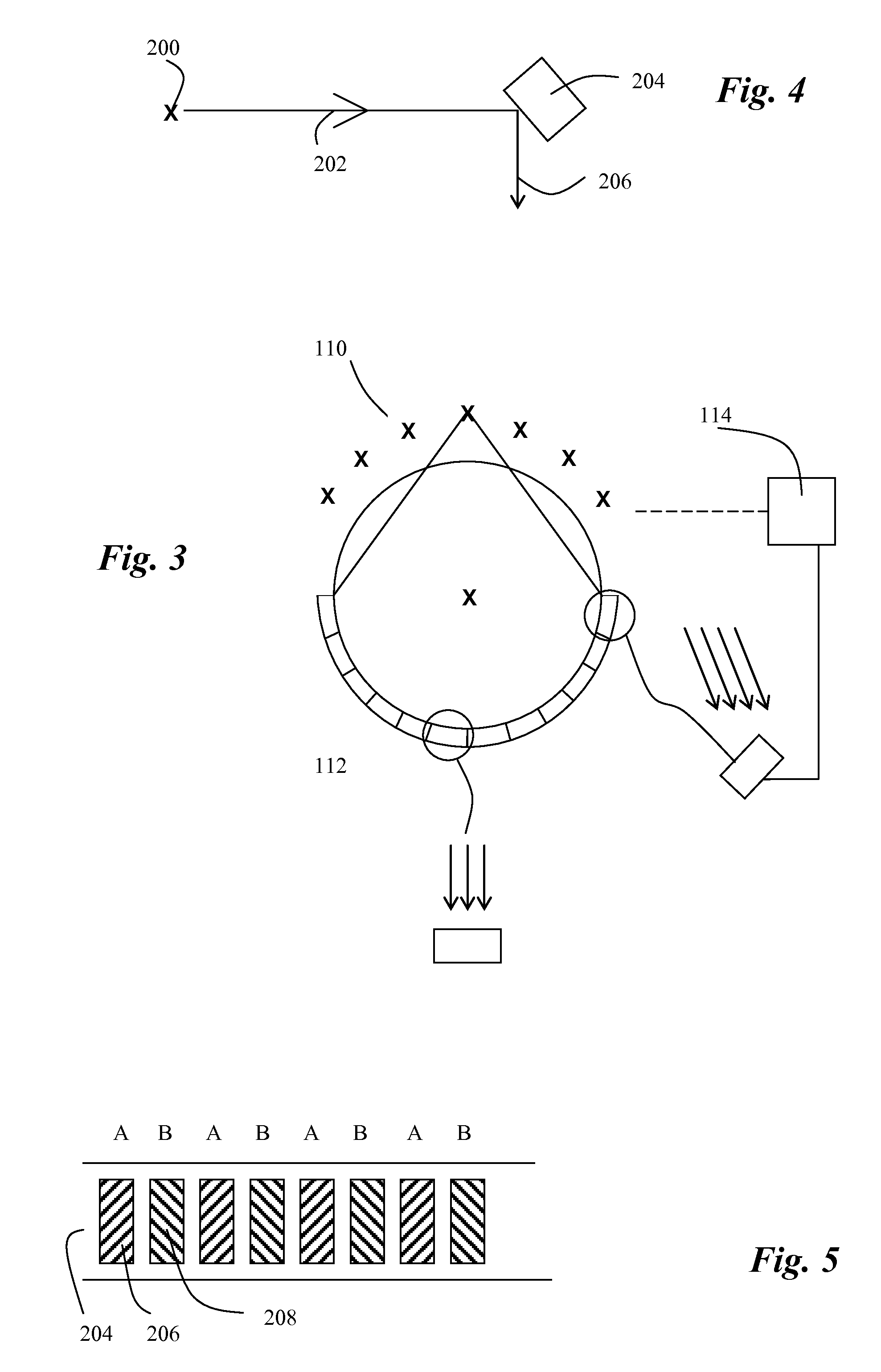

X-ray scanners and X-ray sources therefor

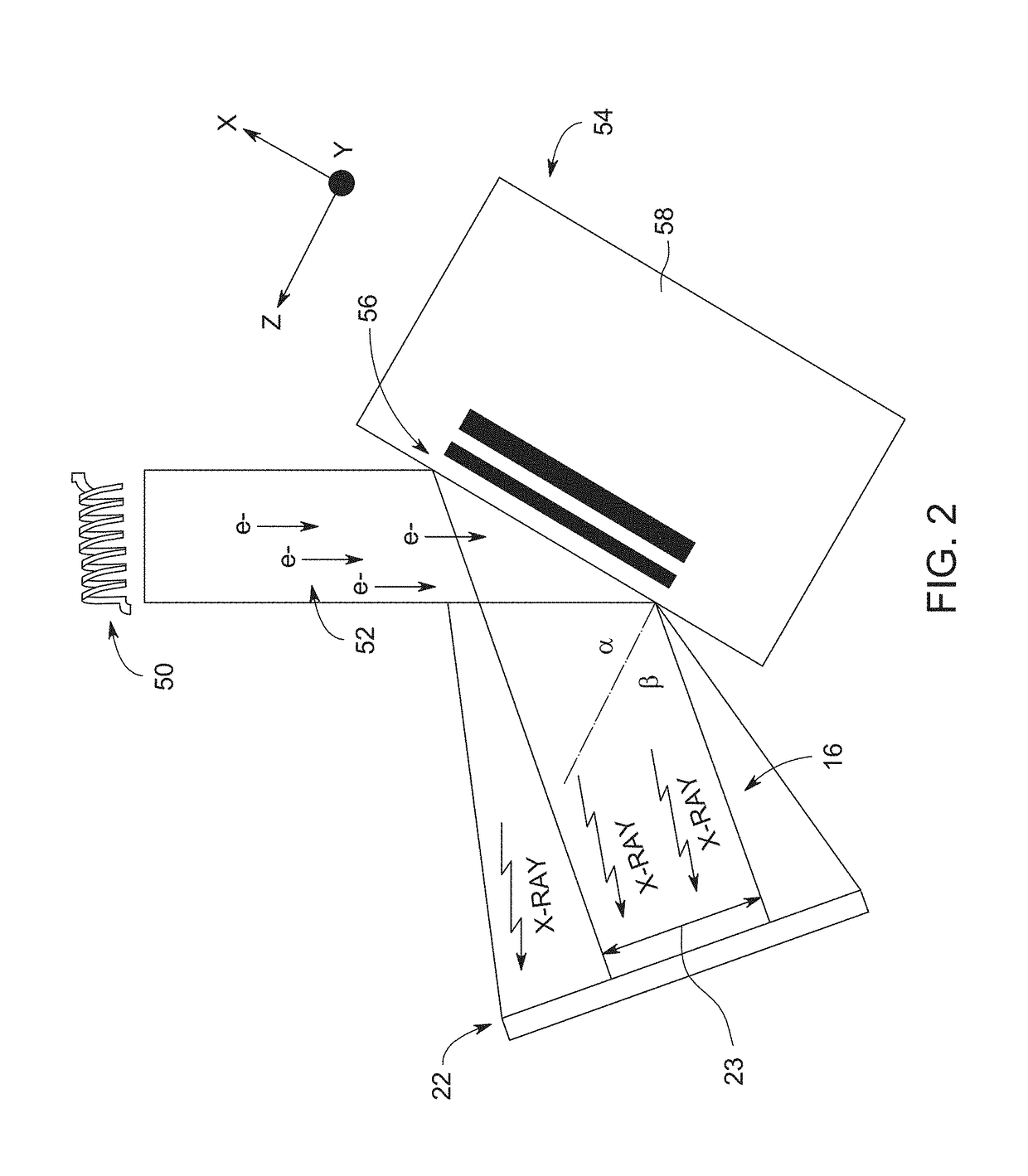

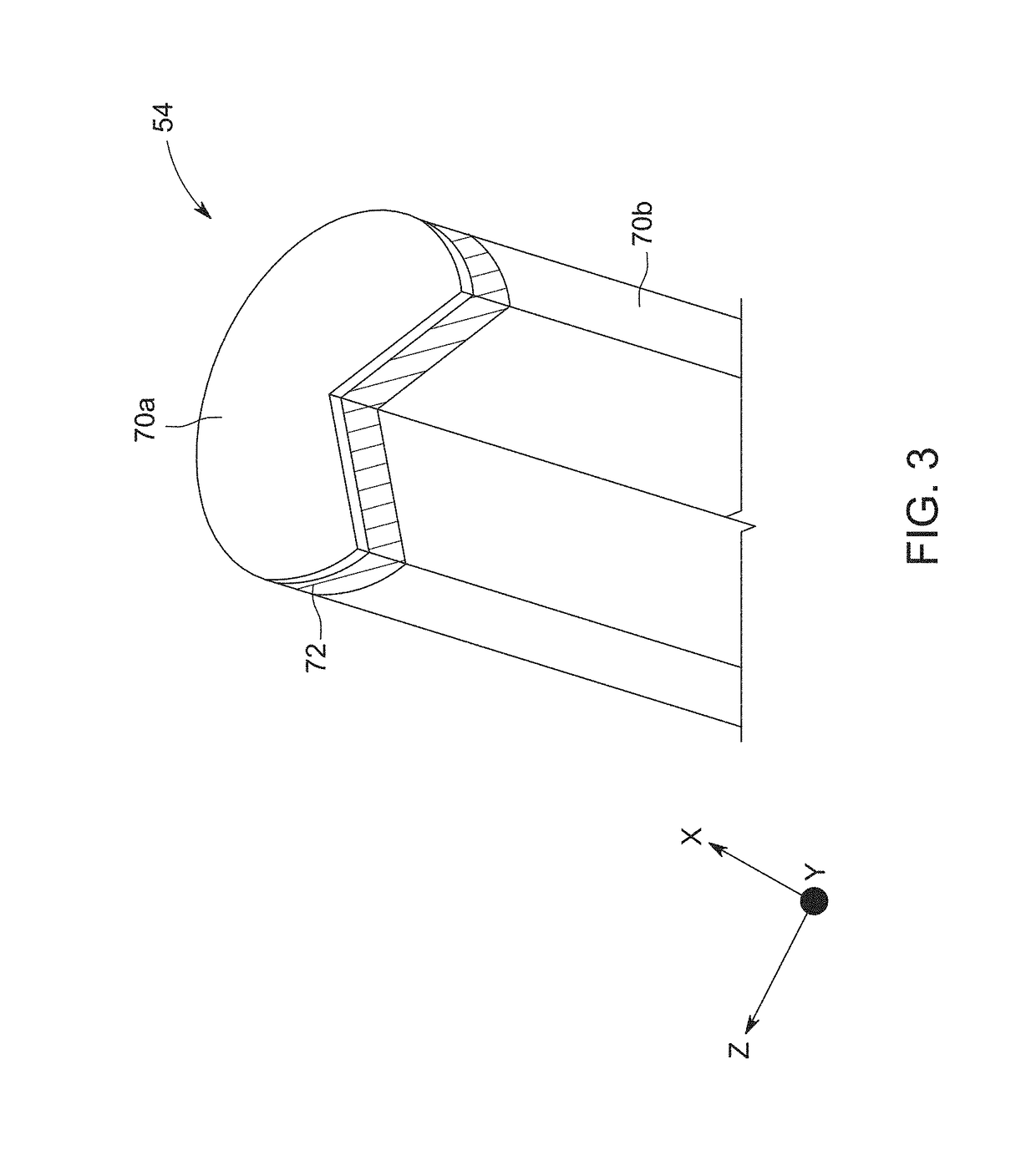

ActiveUS7949101B2X-ray tube laminated targetsRadiation/particle handlingTarget surfaceElectron source

The present invention is directed toward an X-ray scanner that has an electron source and an anode. The anode has a target surface with a series of material areas spaced along it in a scanning direction. The material areas are formed from different materials. The electron source is arranged to direct electrons at a series of target areas of the target surface, in a predetermined order, so as to generate X-ray beams having different energy spectra.

Owner:RAPISCAN SYST INC (US)

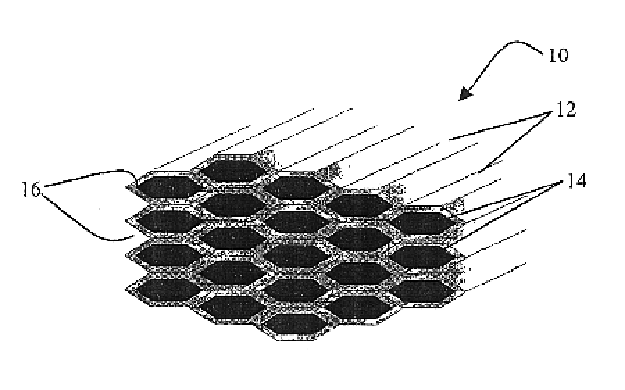

Composite components for use in high temperature applications

InactiveUS6847699B2Well formedImprove thermal shock resistanceX-ray tube laminated targetsAdditive manufacturing apparatusFiberThermal shock

Fibrous monolith composites suitable for use in high temperature environments and / or harsh chemical environments are provided, along with methods of preparation thereof. The fibrous monolith composites exhibit such beneficial properties as enhanced strength, corrosion resistance, thermal shock resistance and thermal cycling tolerance.

Owner:BAE SYST UNMANNED AIRCRAFT PROGRAMS

X-ray tube of the end window type, and an X-ray fluorescence analyzer

ActiveUS7203283B1Good characteristic peakHigh strengthX-ray tube laminated targetsX-ray tube electrodesElectronX-ray fluorescence

In an x-ray tube comprising a housing, which define an enclosure, a cathode arrangement, which emits electrons within the enclosure, and a window, which seals an end of the enclosure, the window comprises a carrier layer and, on a side of the carrier layer that faces the enclosure, a layered anode arrangement having certain characteristics.

Owner:HITACHI HIGH TECH ANALYTICAL SCI FINLAND OY

X-ray generating device

InactiveUS8208603B2Increase volumeSmall sizeX-ray tube laminated targetsX-ray tube anode coolingX-rayElectron

An X-ray generating device includes an electron-beam generator, a target assembly group, and an electron-beam focusing unit. The electron-beam generator generates electron beams. The target assembly group includes a plurality of target assemblies that are arranged along a straight line in a direction in which X-rays are output; each of the target assemblies includes a target and a supporting member; the target generates X-rays from one of the electron beams generated by the electron-beam generator; and the supporting member supports the target by being disposed adjacent thereto. The electron-beam focusing unit focuses the electron beams onto the targets included in the target assembly group so that X-rays are generated in each of the target assemblies and output along the straight line after passing through the target assemblies.

Owner:CANON KK

X-ray target assembly

An x-ray transmission target assembly is disclosed. According to an aspect of the invention, an x-ray target assembly comprises an x-ray generating layer, a thermal buffer, and a support, wherein the thermal buffer is disposed between the x-ray generating layer and support. Another aspect of the invention is directed to a novel material for use as an x-ray generating layer in an x-ray target assembly.

Owner:AIRDRIE PARTNERS I LP +1

X-ray target and apparatuses using the same

InactiveUS7551722B2Electron beam absorptivitySmall in focus sizeX-ray tube laminated targetsImaging devicesHigh intensityX ray analysis

Owner:JAPAN SCI & TECH CORP

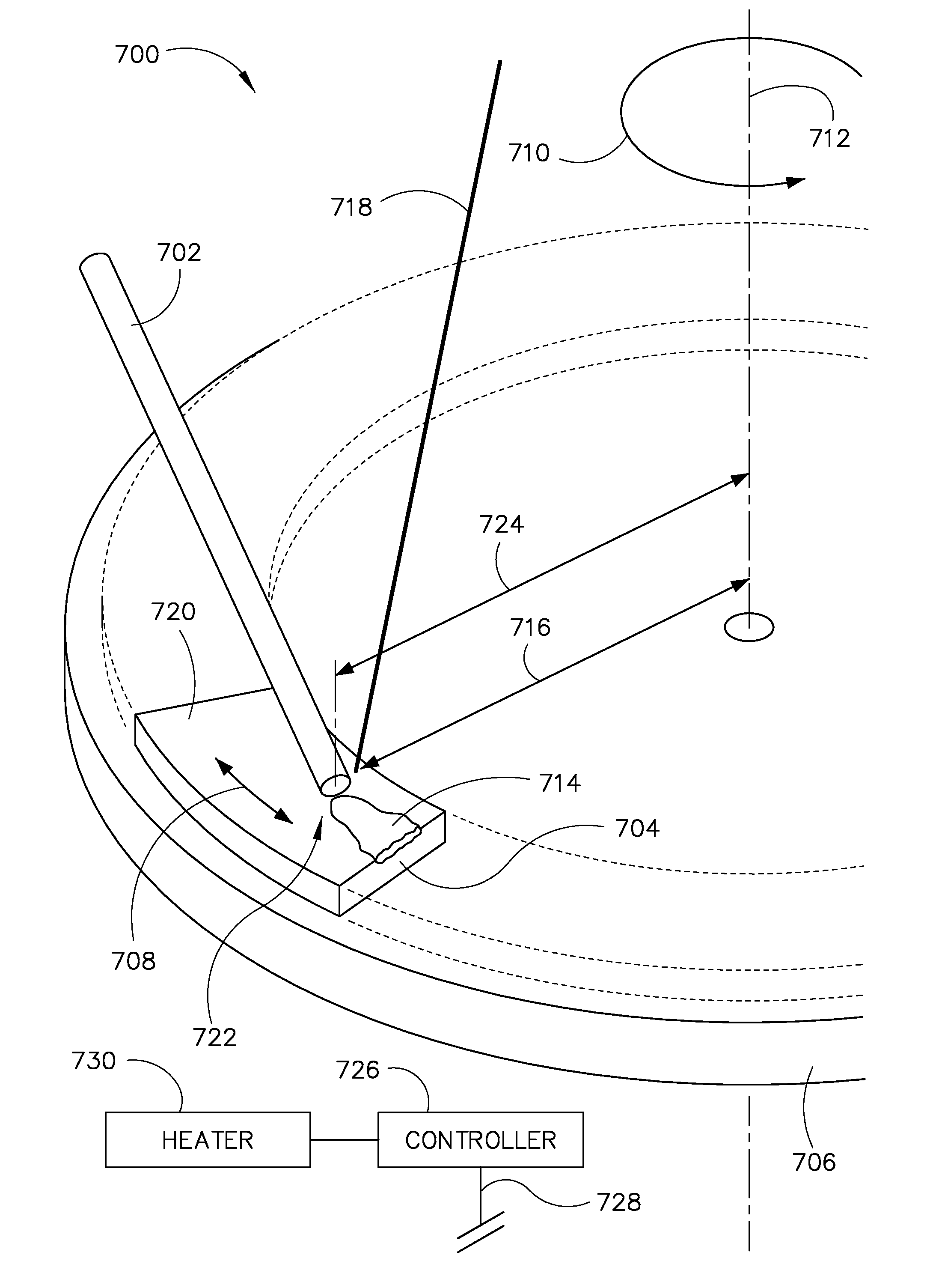

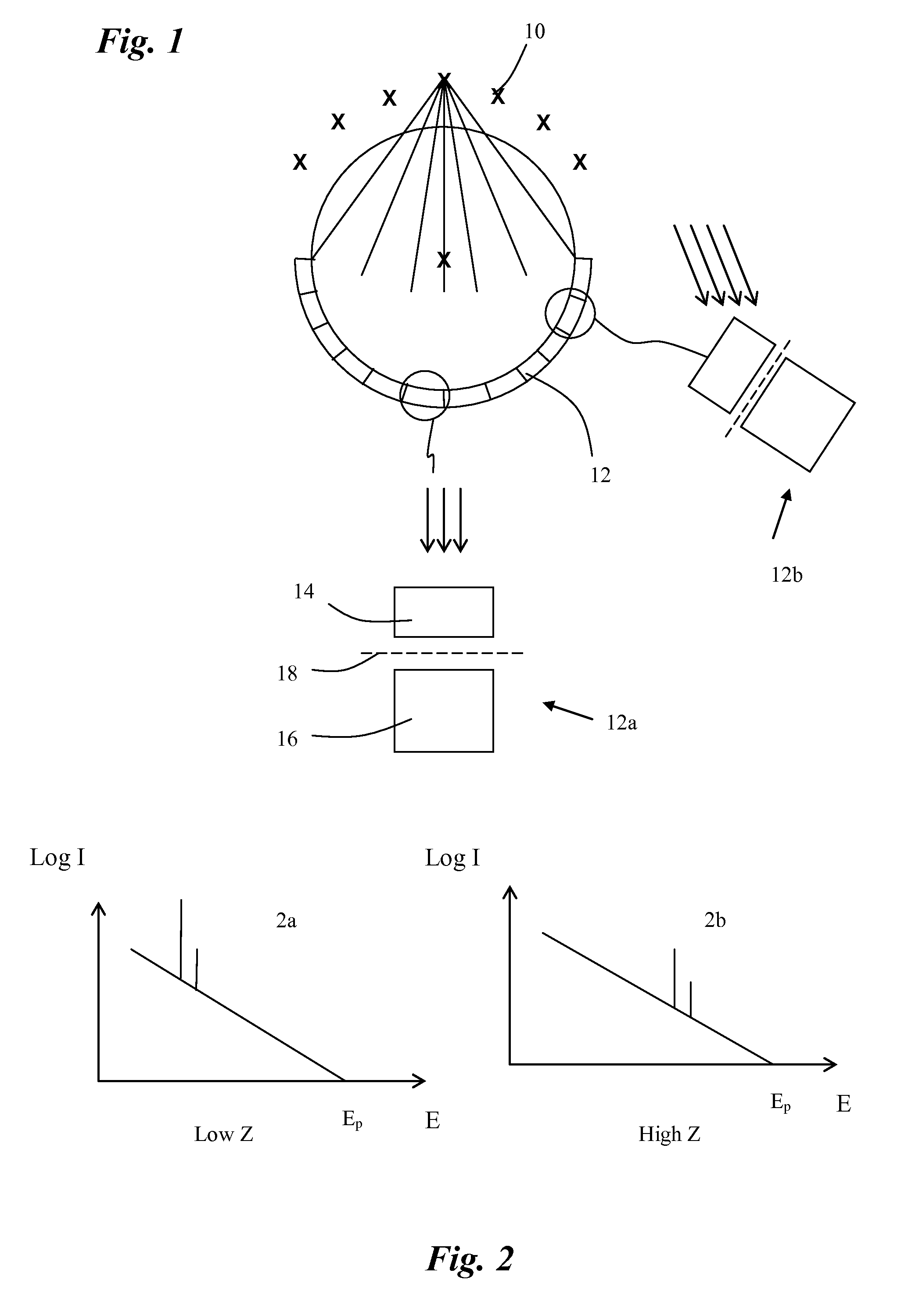

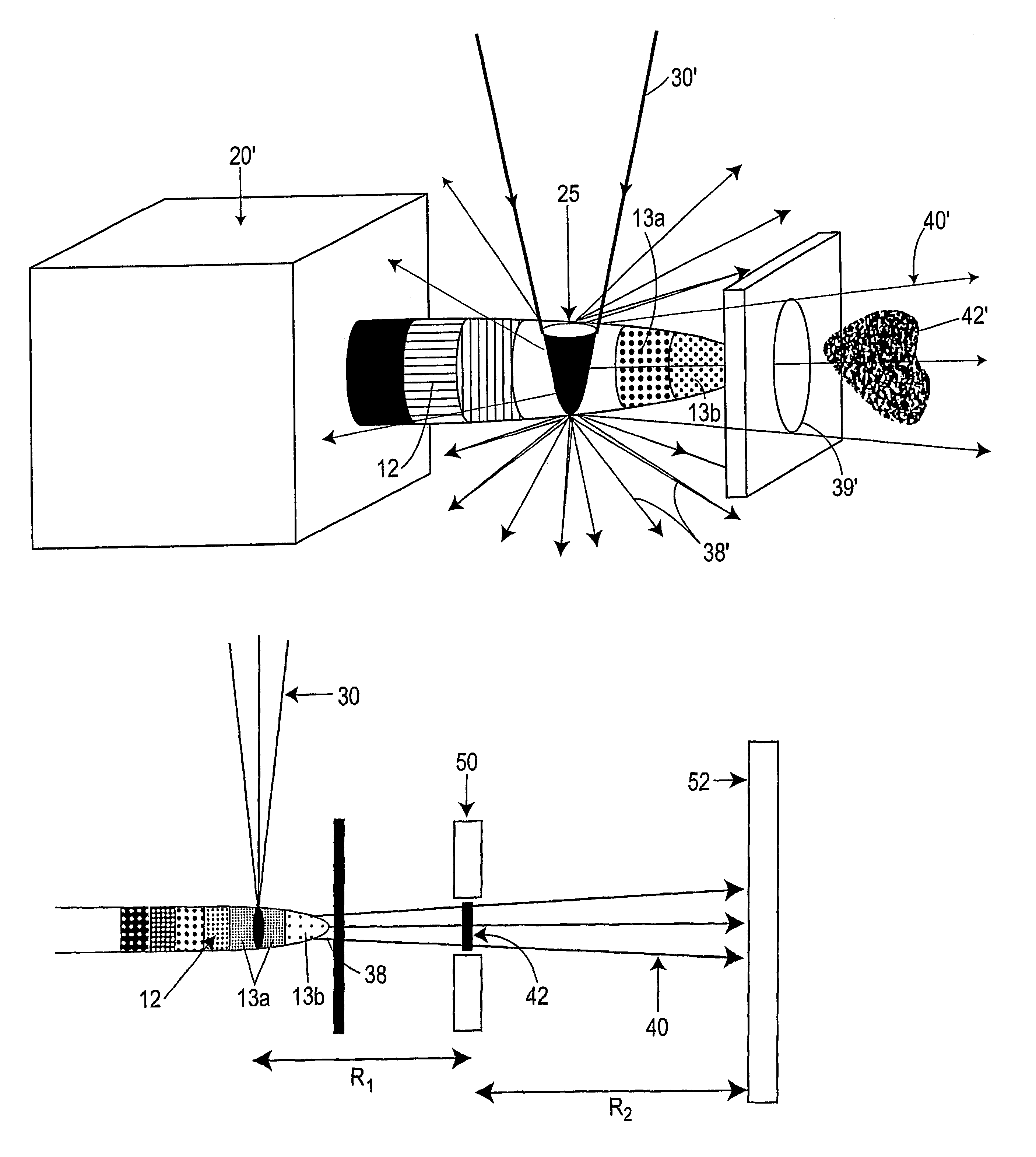

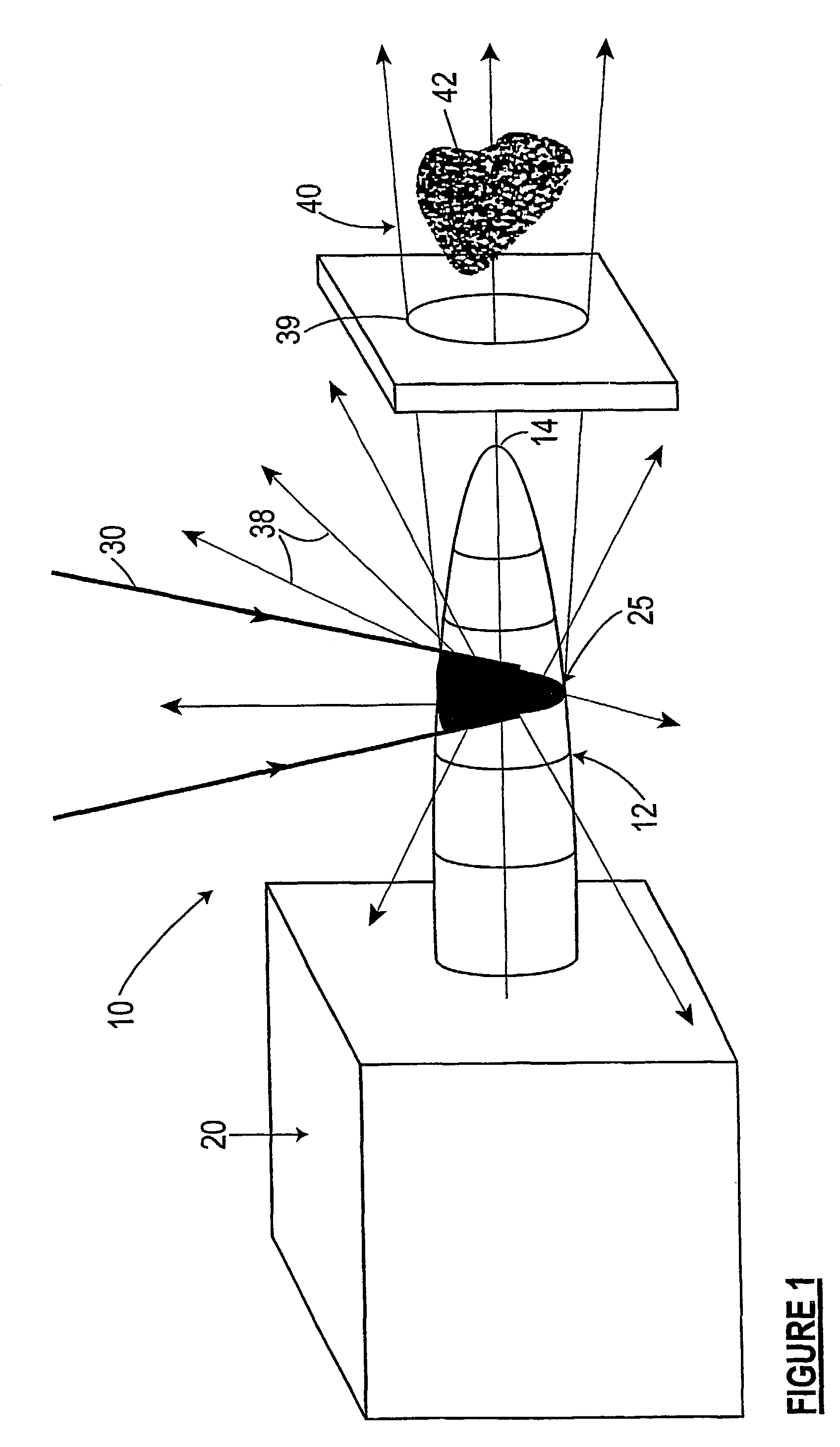

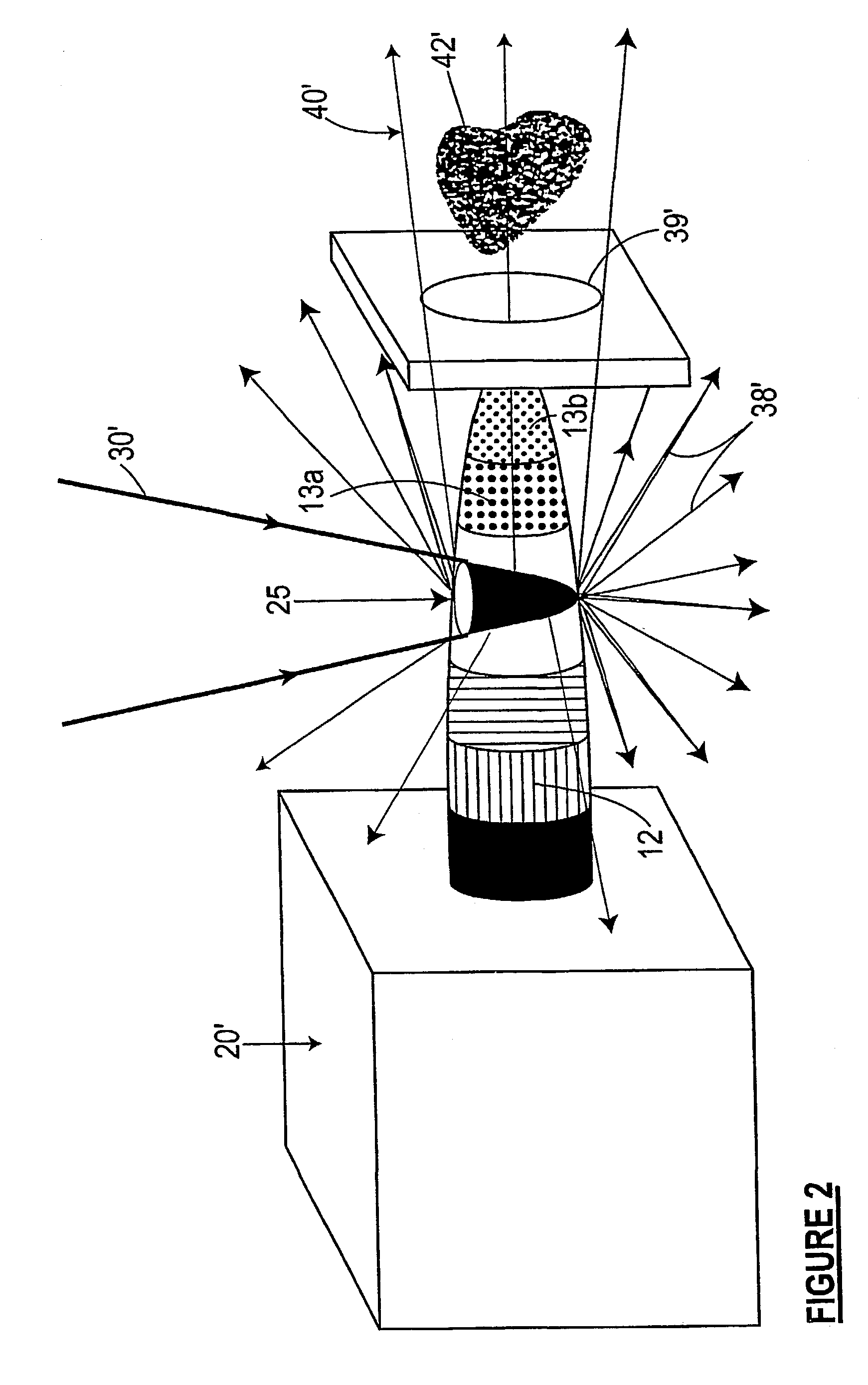

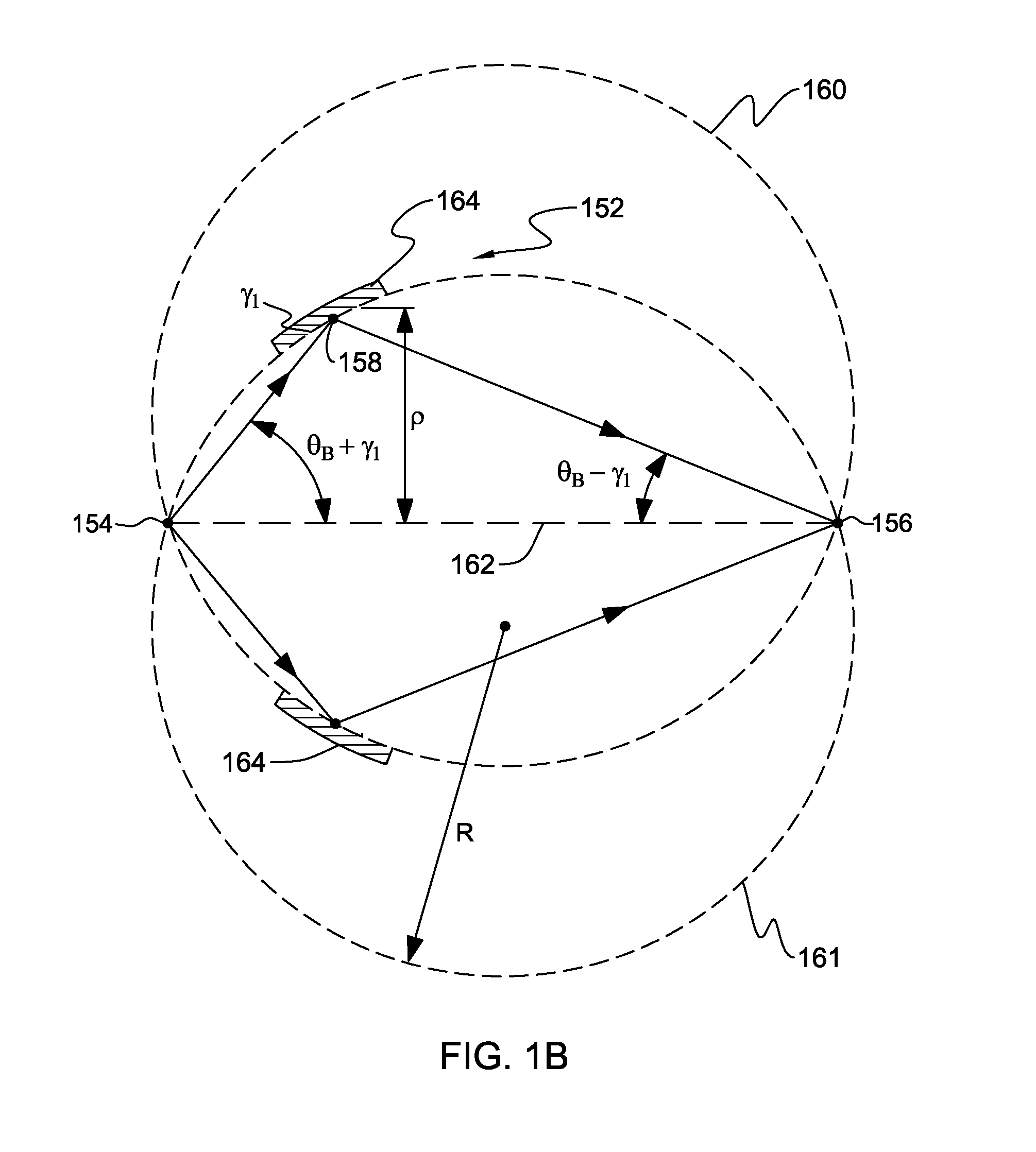

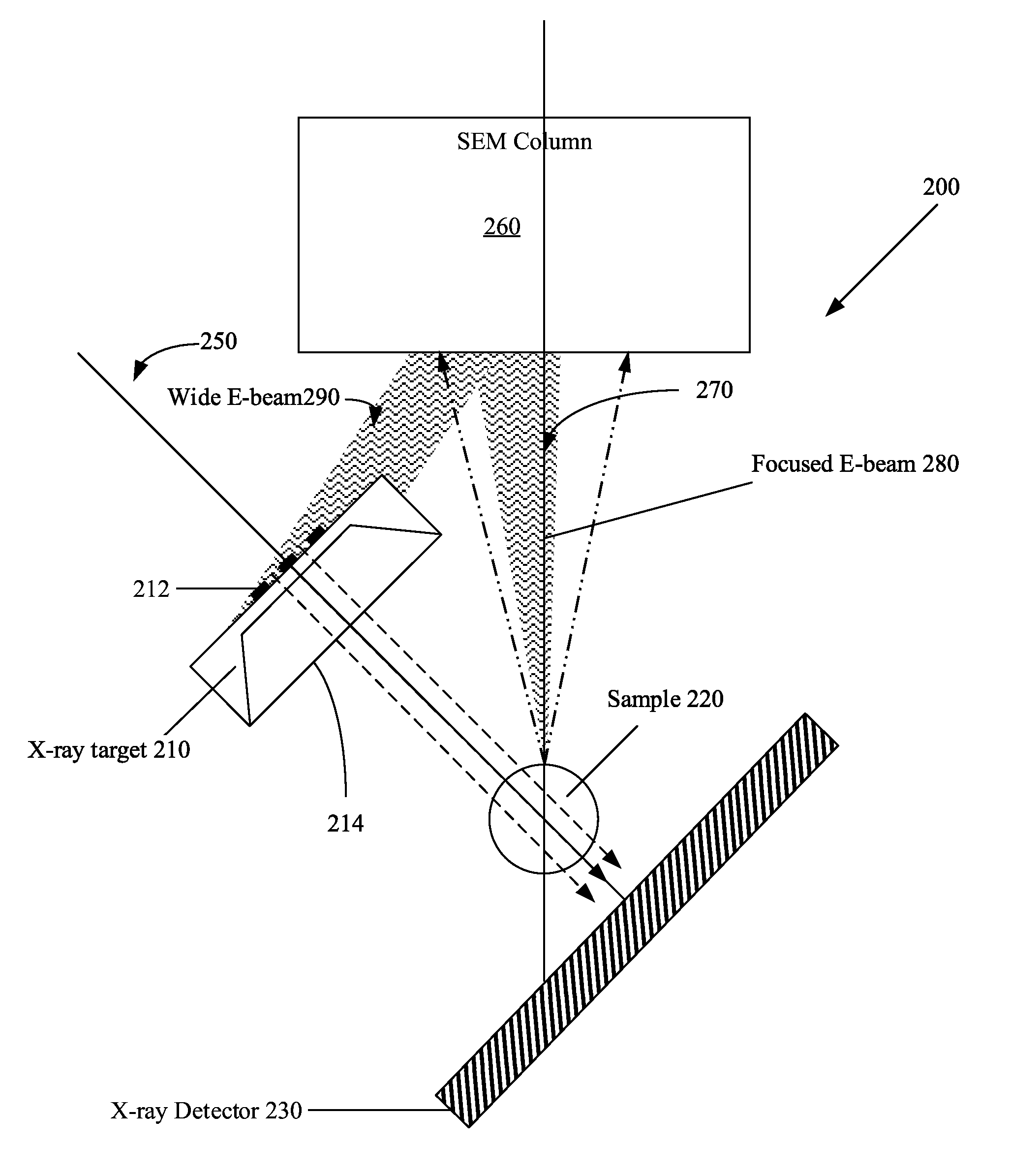

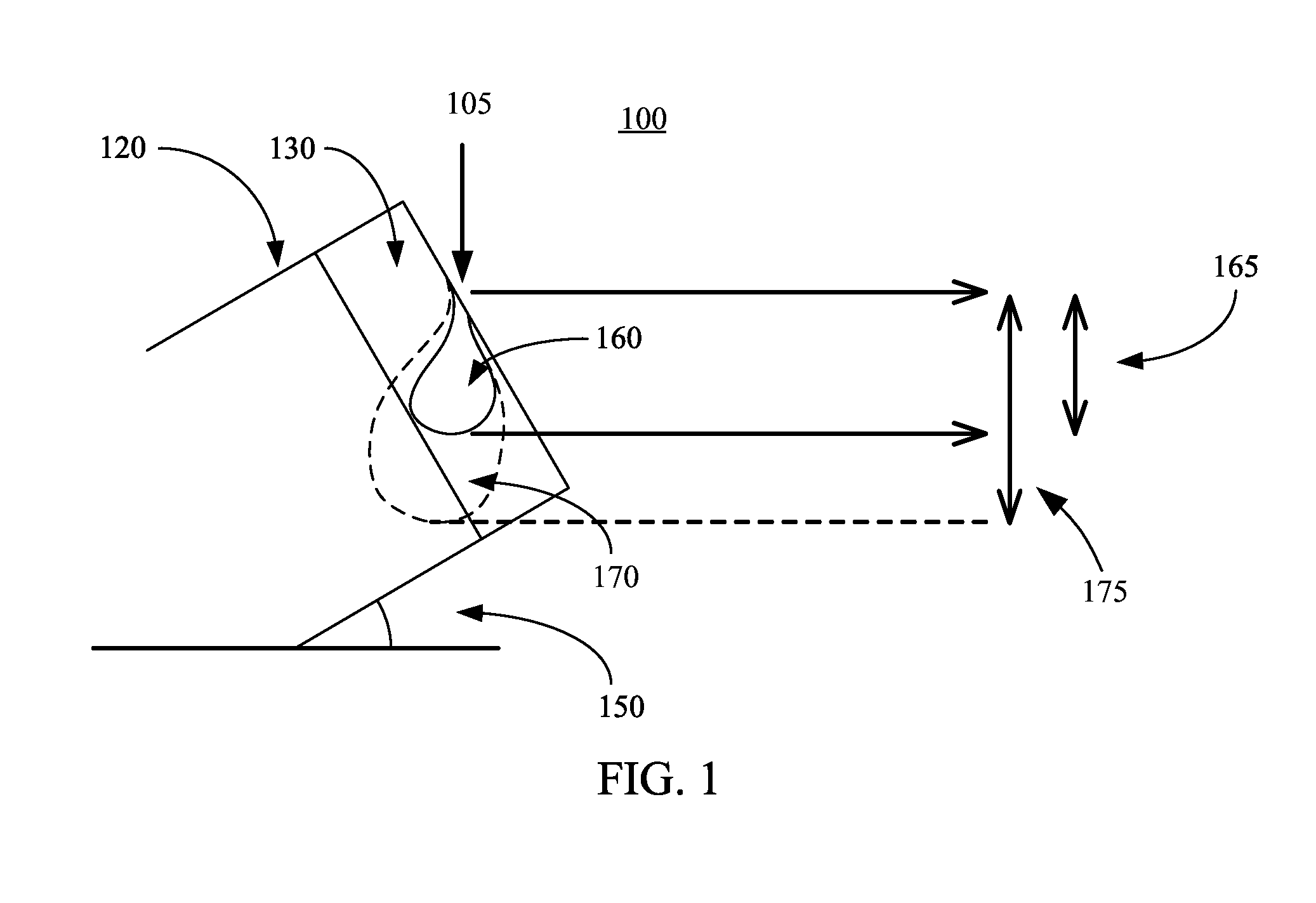

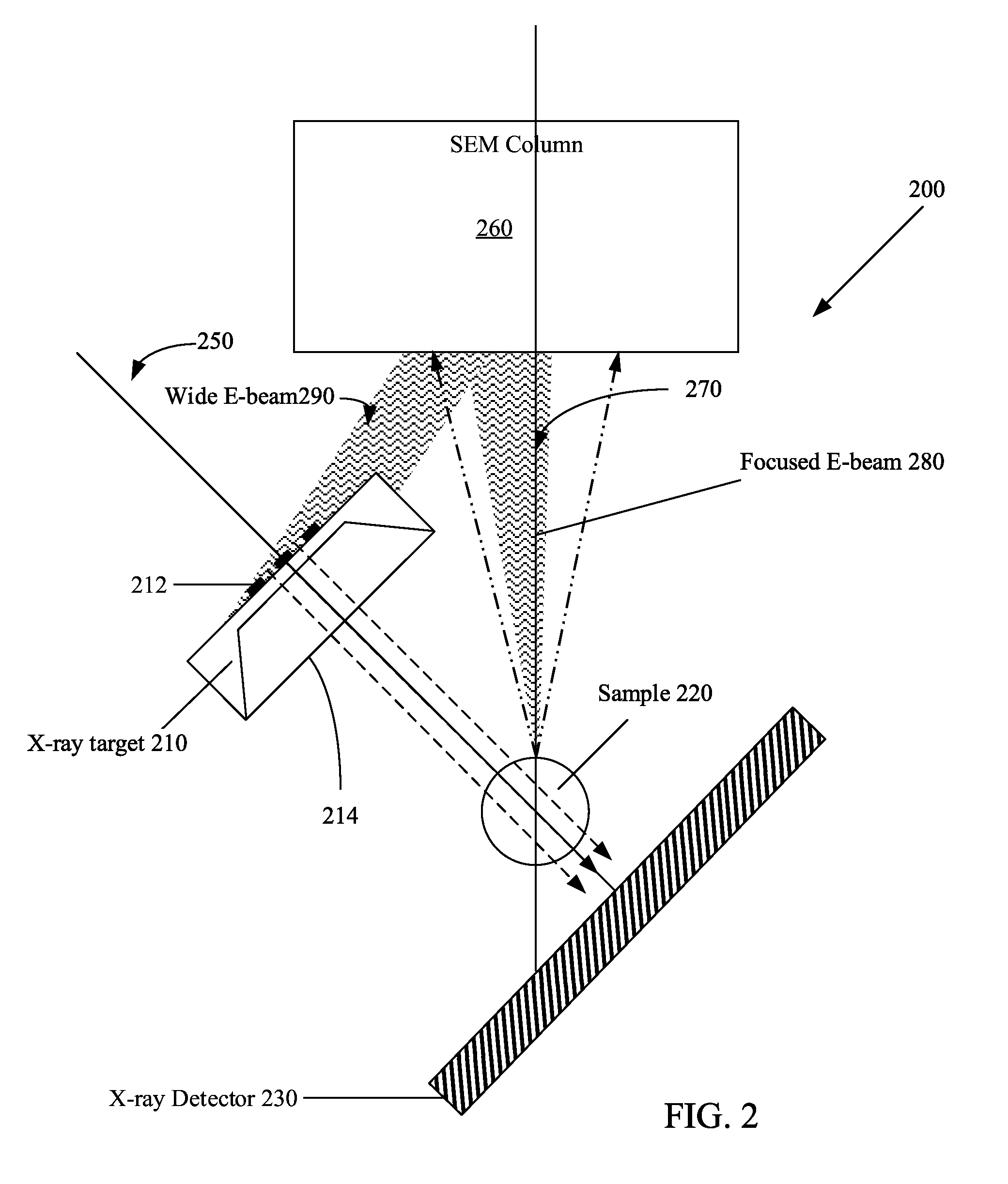

X-ray analyzer having multiple excitation energy bands produced using multi-material x-ray tube anodes and monochromating optics

ActiveUS20150043713A1Lower levelX-ray tube laminated targetsMaterial analysis using wave/particle radiationMulti materialFluorescence

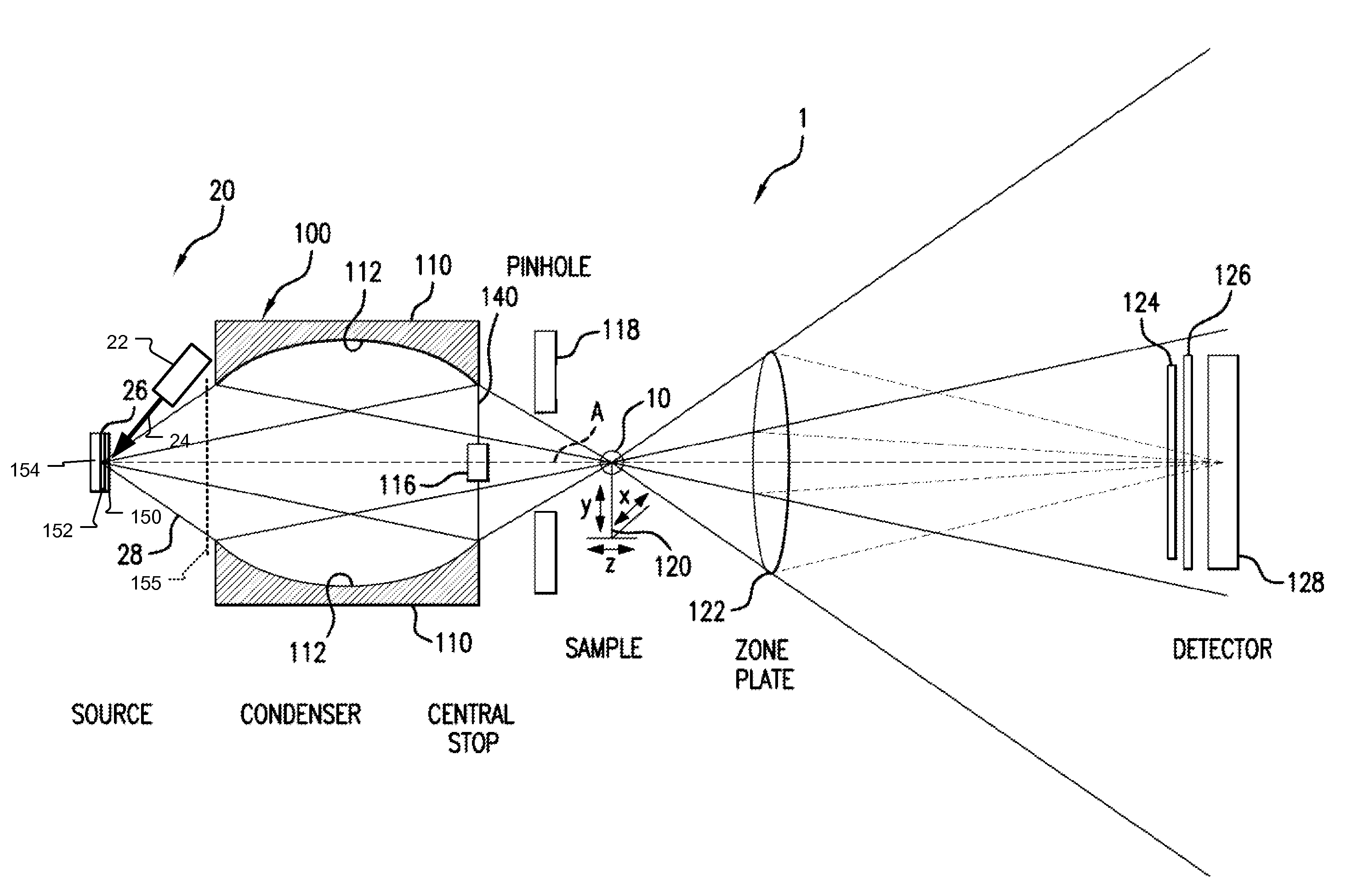

An x-ray tube includes a target on which electrons impinge to form a diverging x-ray beam. The target has a surface formed from first and second target materials, each tailored to emit a respective x-ray energy profile. A first x-ray optic may be provided for directing the beam toward the sample spot, the first x-ray optic monochromating the diverging x-ray beam to a first energy from the energy emitted by the first target material; and a second x-ray optic may be provided, for directing the beam toward the sample spot, the second x-ray optic monochromating the diverging x-ray beam to a second energy from the energy emitted by the second target material. Fluorescence from the sample spot induced by the first and second monochromated energies is used to measure the concentration of at least one element in the sample, or separately measure elements in a coating and underlying substrate.

Owner:X-RAY OPTICAL SYSTEM INC

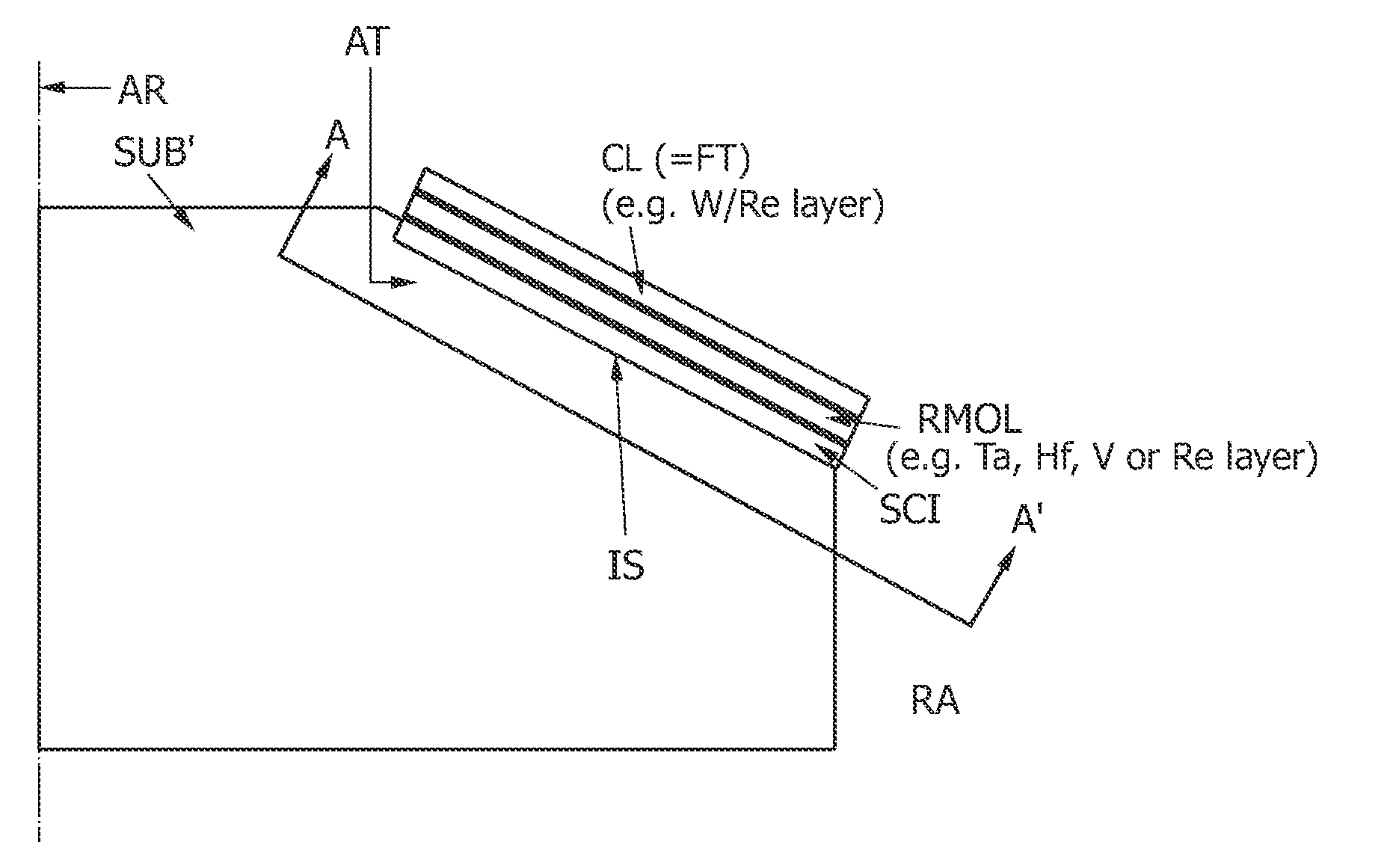

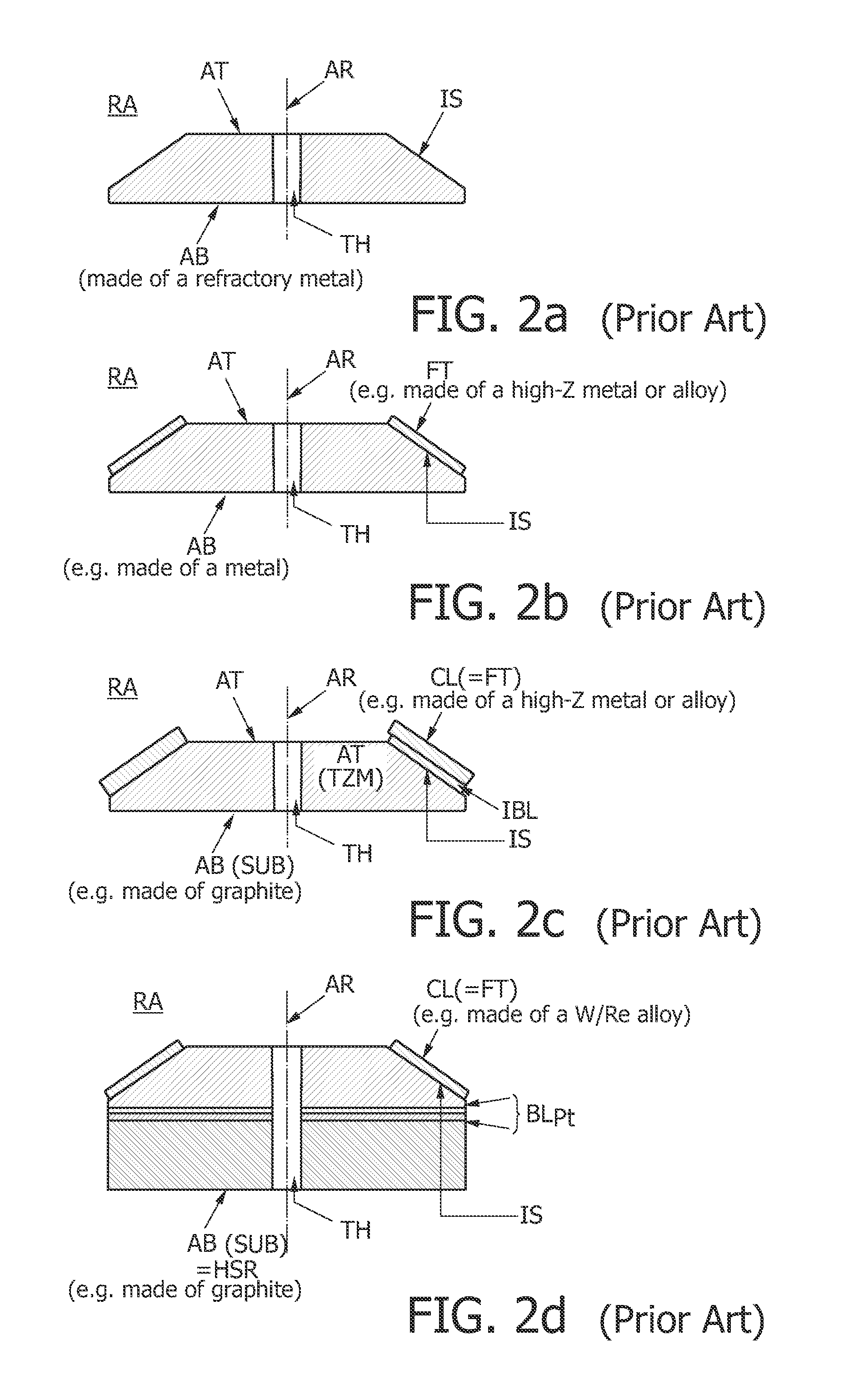

Attachment of a high-Z focal track layer to a carbon-carbon composite substrate serving as a rotary anode target

InactiveUS8553843B2Solve the slow scanning speedX-ray tube laminated targetsX-ray tube electrodesRheniumCarbon composites

The present invention refers to hybrid anode disk structures for use in X-ray tubes of the rotary anode type and is concerned more particularly with a novel light weight anode disk structure (RA) which comprises an adhesion promoting protective silicon carbide (SiC) interlayer (SCI) deposited onto a rotary X-ray tube's anode target (AT), wherein the latter may e.g. be made of a carbon-carbon composite substrate (SUB′). Moreover, a manufacturing method for robustly attaching a coating layer (CL) consisting of a high-Z material (e.g. a layer made of a tungsten-rhenium alloy) on the surface of said anode target is provided, whereupon according to said method it may be foreseen to apply a refractory metal overcoating layer (RML), such as given e.g. by a tantalum (Ta), hafnium (Hf), vanadium (V) or rhenium (Re) layer, to the silicon carbide interlayer (SCI) prior to the deposition of the tungsten-rhenium alloy. The invention thus leverages the tendency for cracking of the silicon carbide coated carbon composite substrate (SUB′) during thermal cycling and enhances adhesion of the silicon carbide / refractory metal interlayers to the carbon-carbon composite substrate (SUB′) and focal track coating layer (CL) by an interlocking mechanism. Key aspects of the proposed invention are: a) controlled formation of coating cracks (SC) in the silicon carbide layer (SCI) and b) conformal filling of SiC crack openings with a refractory metal.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Multilayer X-ray source target with high thermal conductivity

Owner:GENERAL ELECTRIC CO

Apparatus for x-ray generation and method of making same

Owner:GENERAL ELECTRIC CO

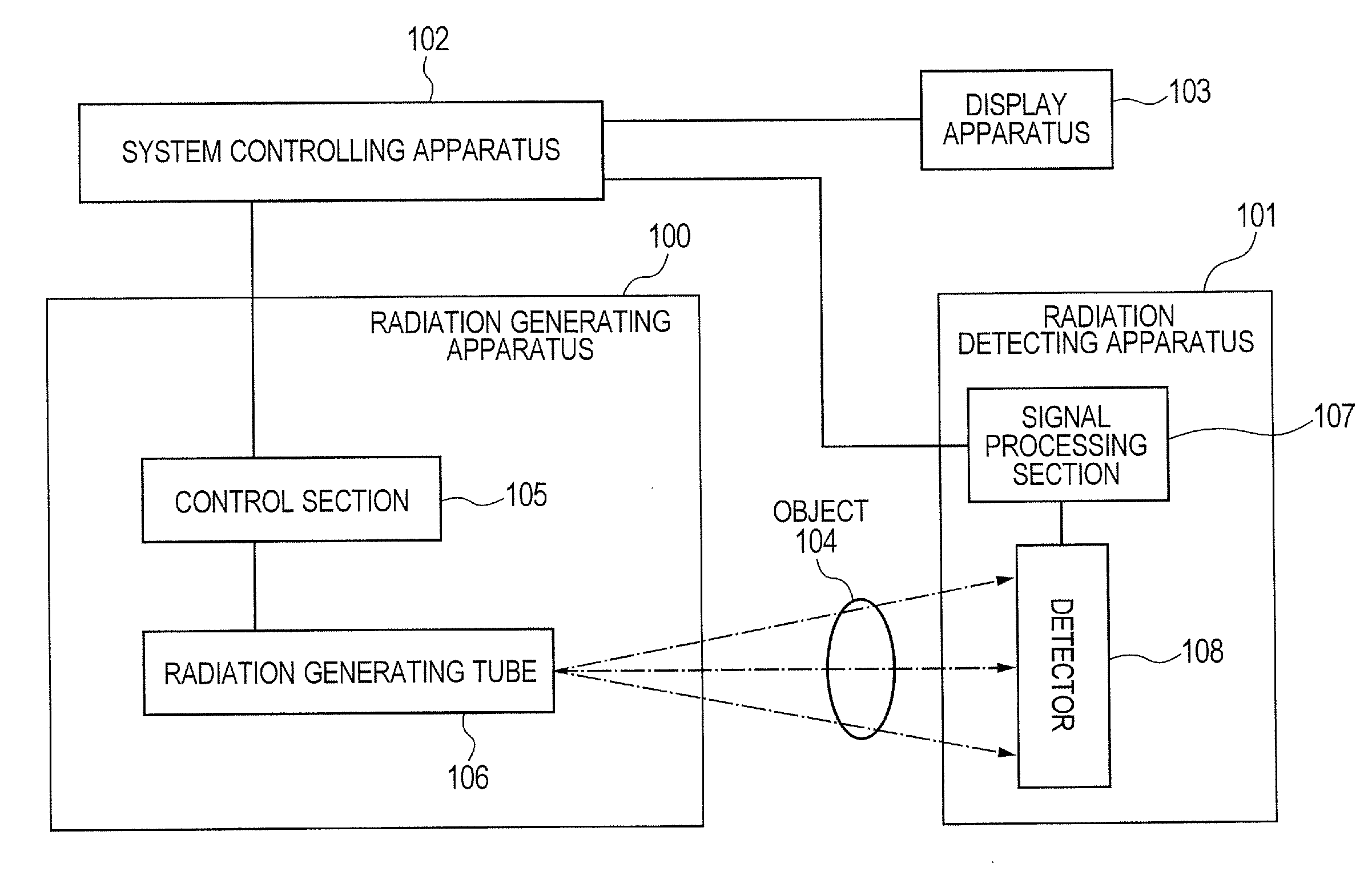

Radiation generating target, radiation generating tube, radiation generating apparatus, and radiation imaging system

The present invention provides a transmission type radiation generating target which can suppress the exfoliation or the crack of a target layer in an interface between a supporting substrate and the target layer, even when the density of incident electrons has been enhanced or the potential of the target has been enhanced. The transmission type radiation generating target includes a supporting substrate, and a target layer which is arranged on the supporting substrate and generates radiation in response to irradiation with an electron beam, wherein the target layer has an opening through which the supporting substrate is exposed, and the opening overlaps with a position at which the density of the irradiation with the electron beam is maximum.

Owner:CANON KK

X-Ray Scanners and X-Ray Sources Therefor

ActiveUS20100020934A1X-ray tube laminated targetsRadiation/particle handlingTarget surfaceElectron source

The present invention is directed toward an X-ray scanner that has an electron source and an anode. The anode has a target surface with a series of material areas spaced along it in a scanning direction. The material areas are formed from different materials. The electron source is arranged to direct electrons at a series of target areas of the target surface, in a predetermined order, so as to generate X-ray beams having different energy spectra.

Owner:RAPISCAN SYST INC (US)

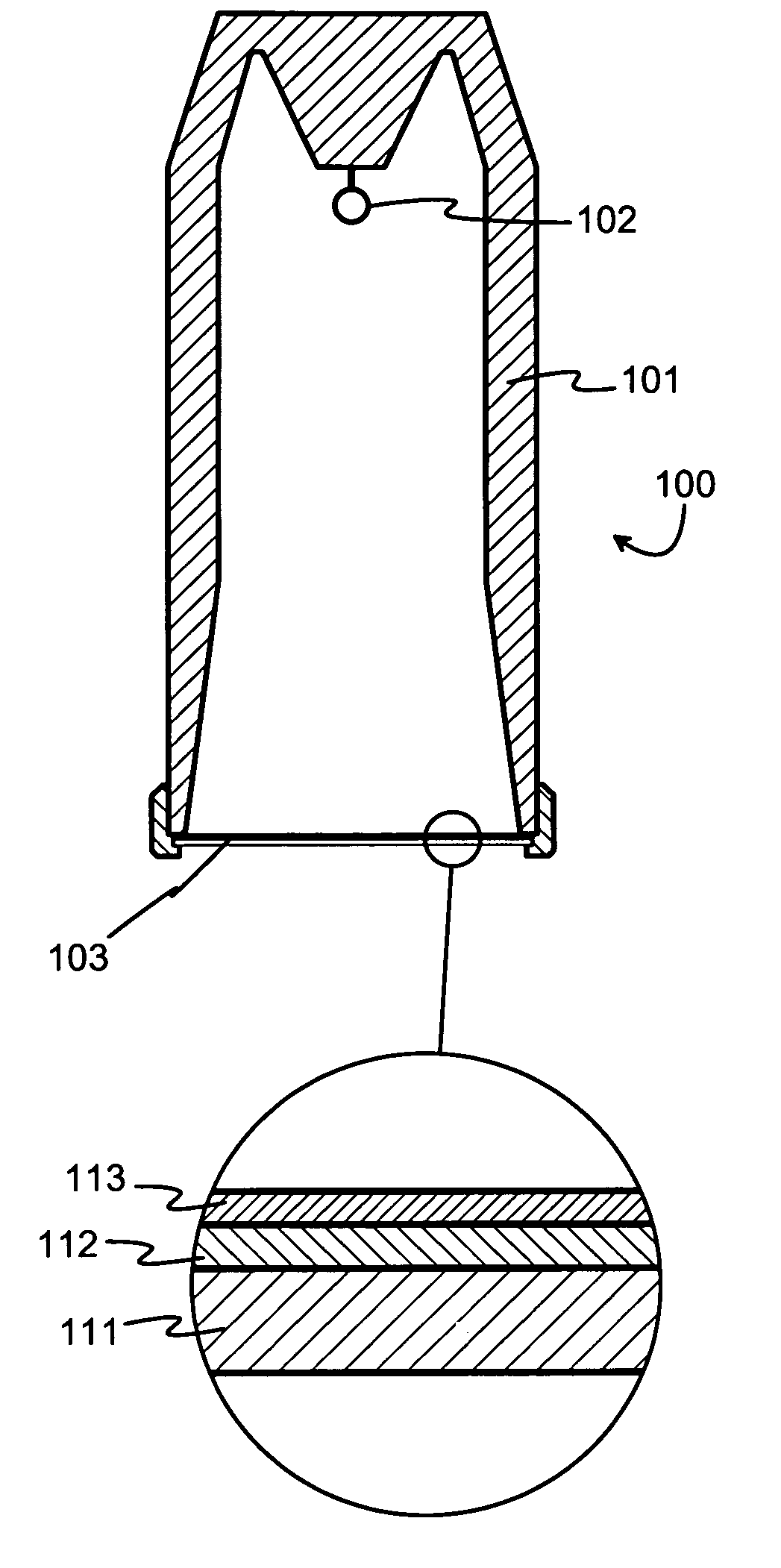

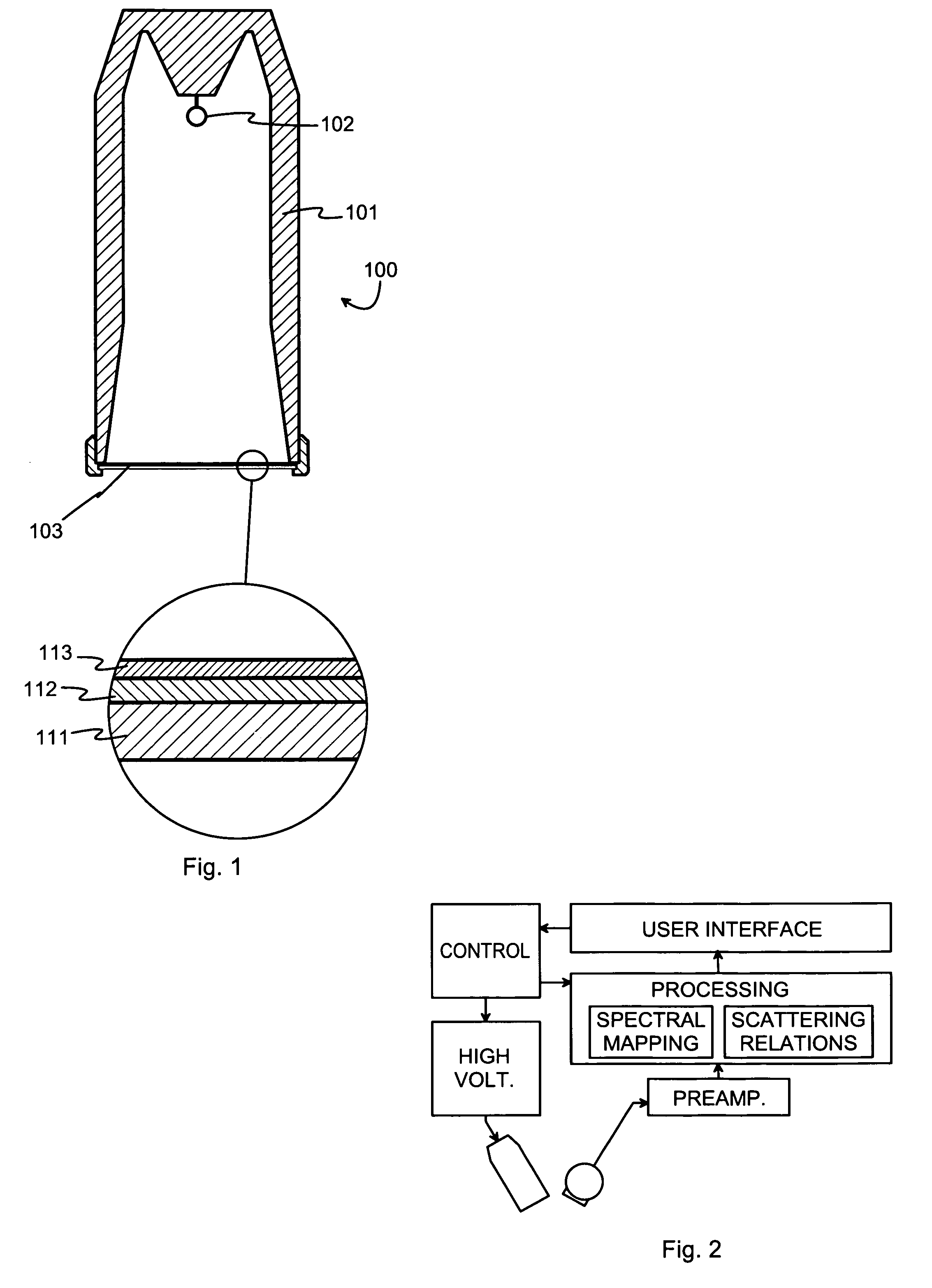

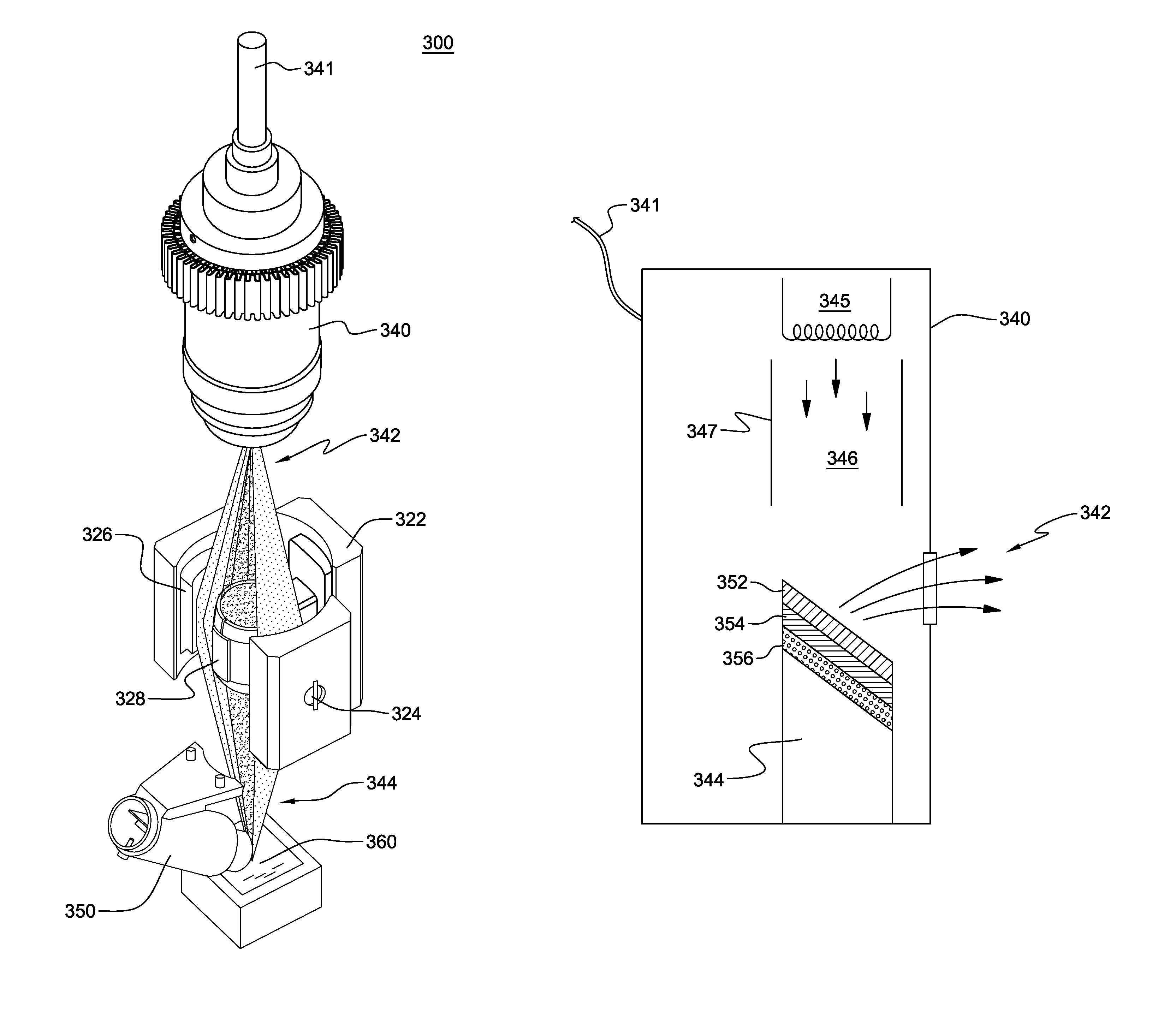

X-ray micro-target source

InactiveUS7050540B2Increase the amount of target material availableImprove efficiencyX-ray tube laminated targetsImaging devicesSoft x rayX-ray

X-ray generation apparatus including an elongated target body and a mount from which the body projects to a tip remote from the mount. The target body includes a substance that, on being irradiated by a beam of electrons of suitable energy directed onto the target body from laterally of the elongate target body, generates a source of x-ray radiation from a volume of interaction of the electron beam with the target body. The mount provides a heat sink for the target body.

Owner:XRT

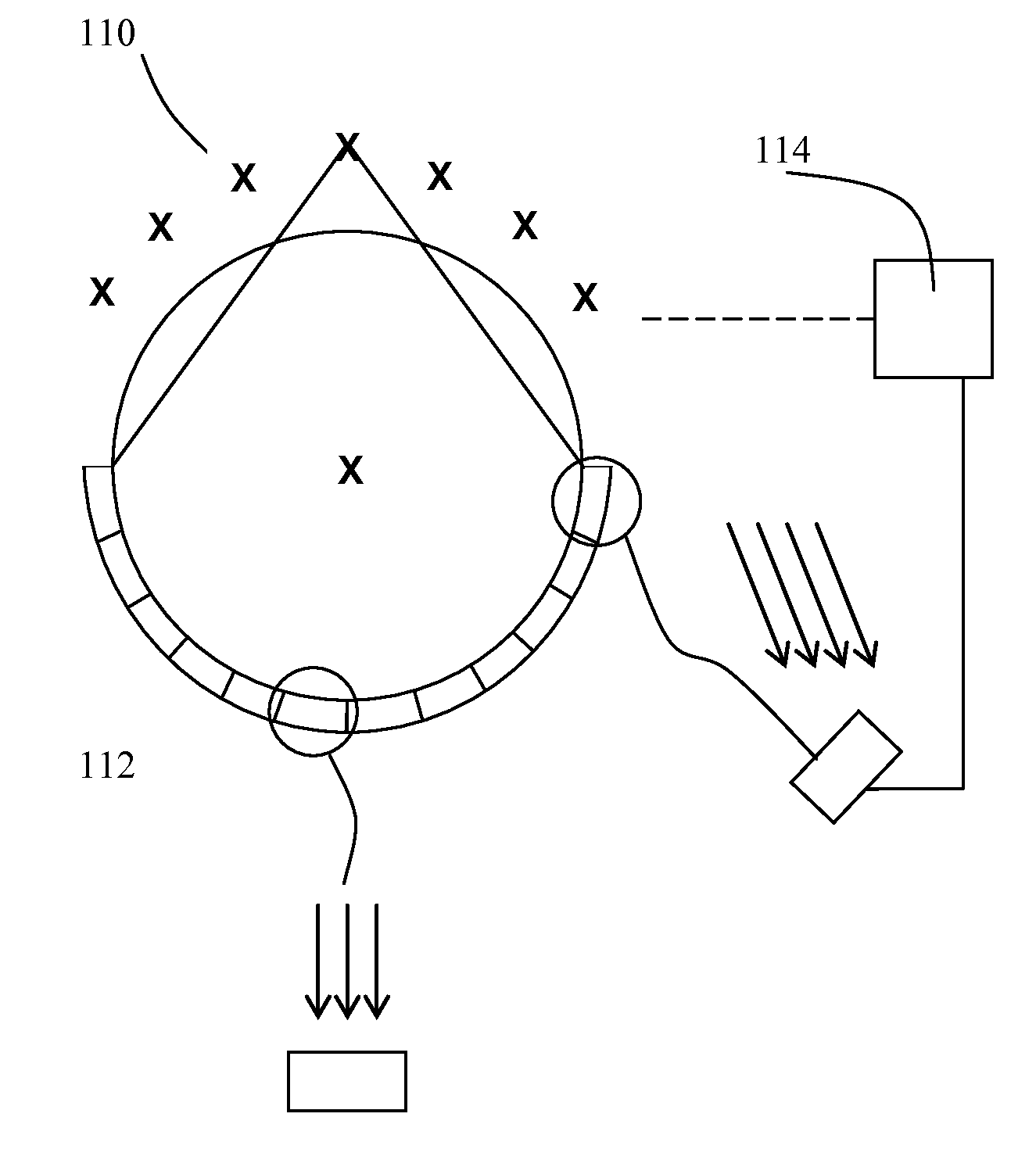

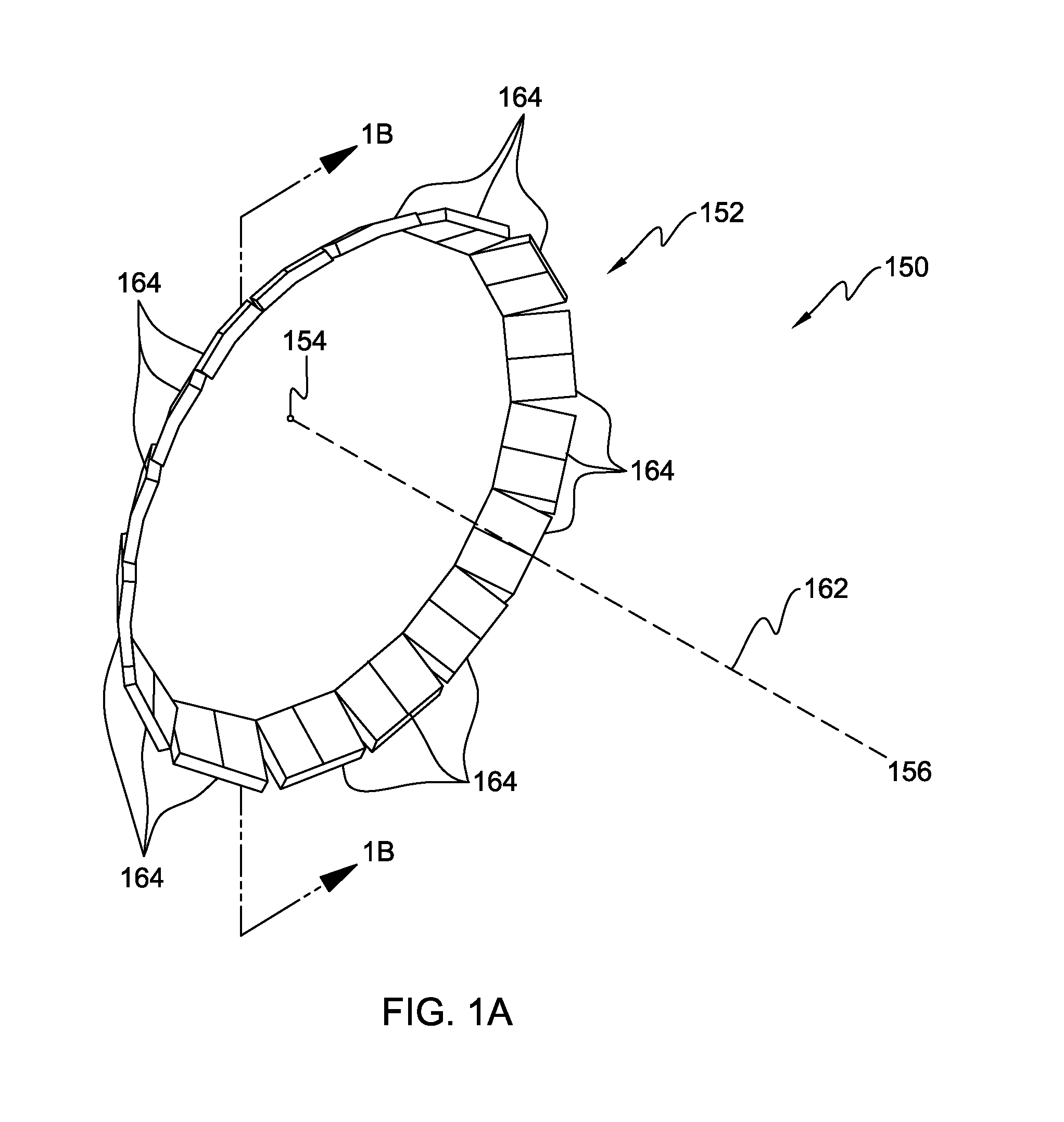

X-ray illumination system with multiple target microstructures

An x-ray illumination beam system includes an electron emitter and a target having one or more target microstructures. The one or more microstructures may be the same or different material, and may be embedded or placed atop a substrate formed of a heat-conducting material. The x-ray source may emit x-rays towards an optic system, which can include one or more optics that are matched to one or more target microstructures. The matching can be achieved by selecting optics with the geometric shape, size, and surface coating that collects as many x-rays as possible from the source and at an angle that satisfies the critical reflection angle of the x-ray energies of interest from the target. The x-ray illumination beam system allows for an x-ray source that generates x-rays having different spectra and can be used in a variety of applications.

Owner:SIGRAY INC

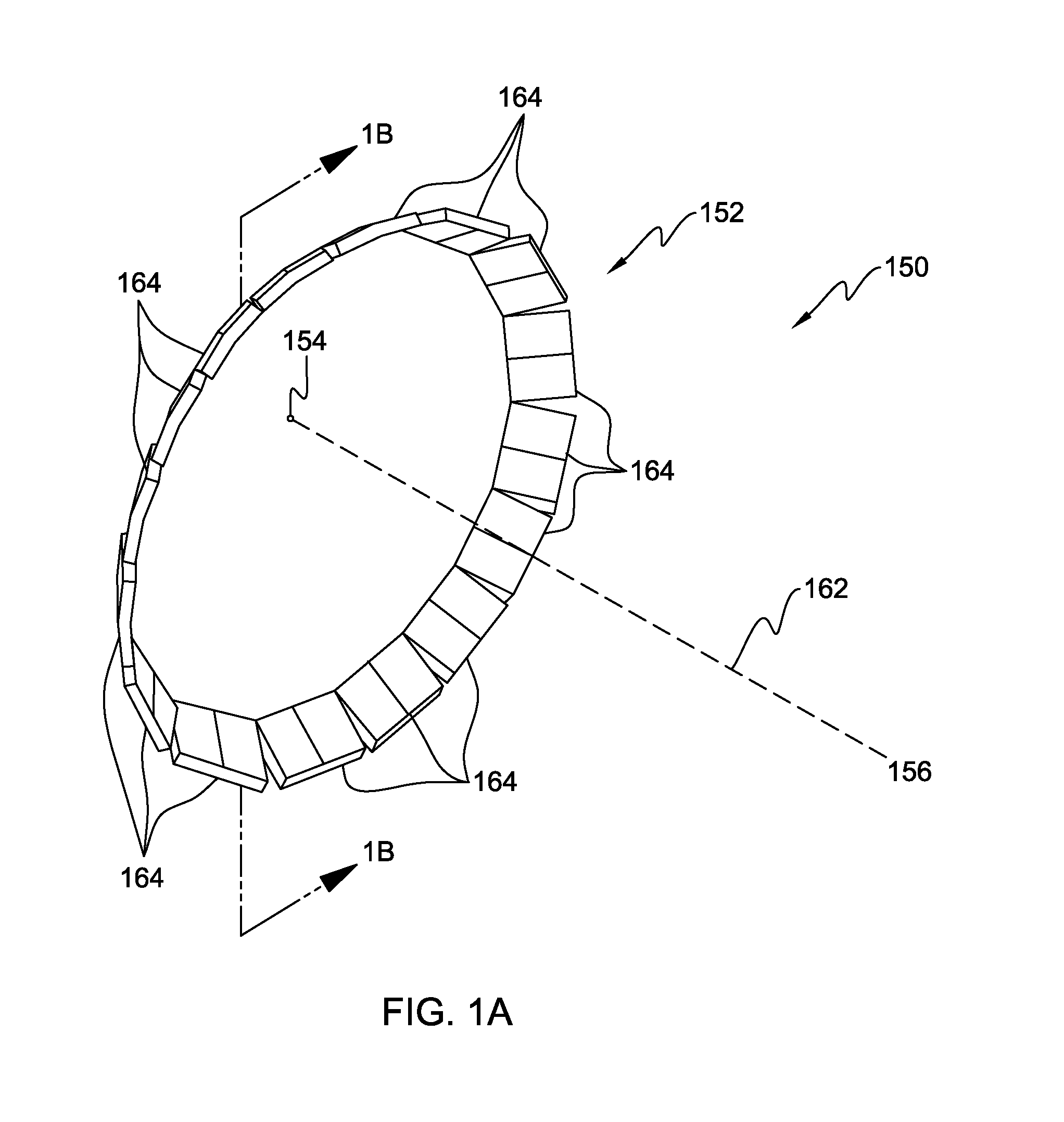

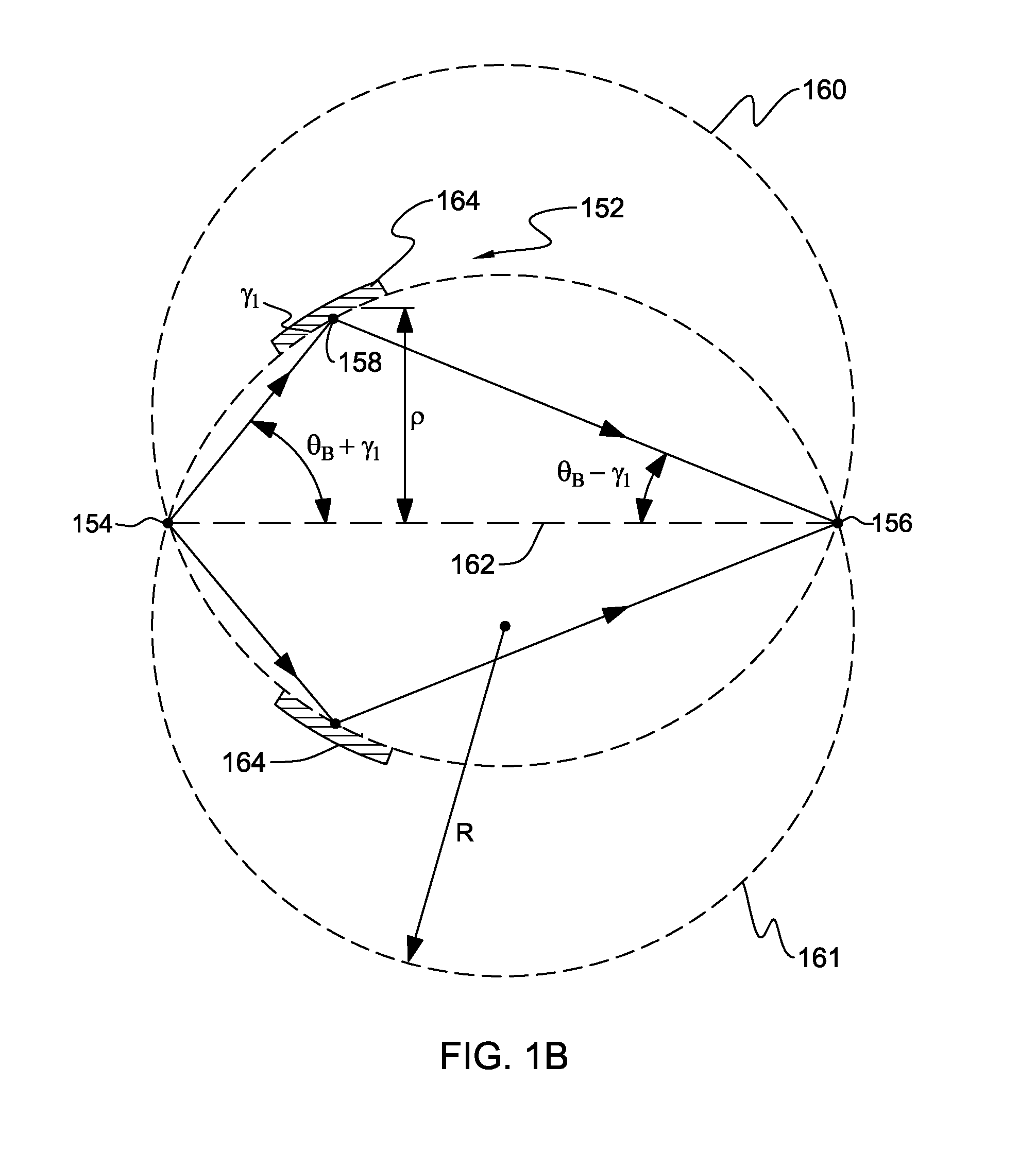

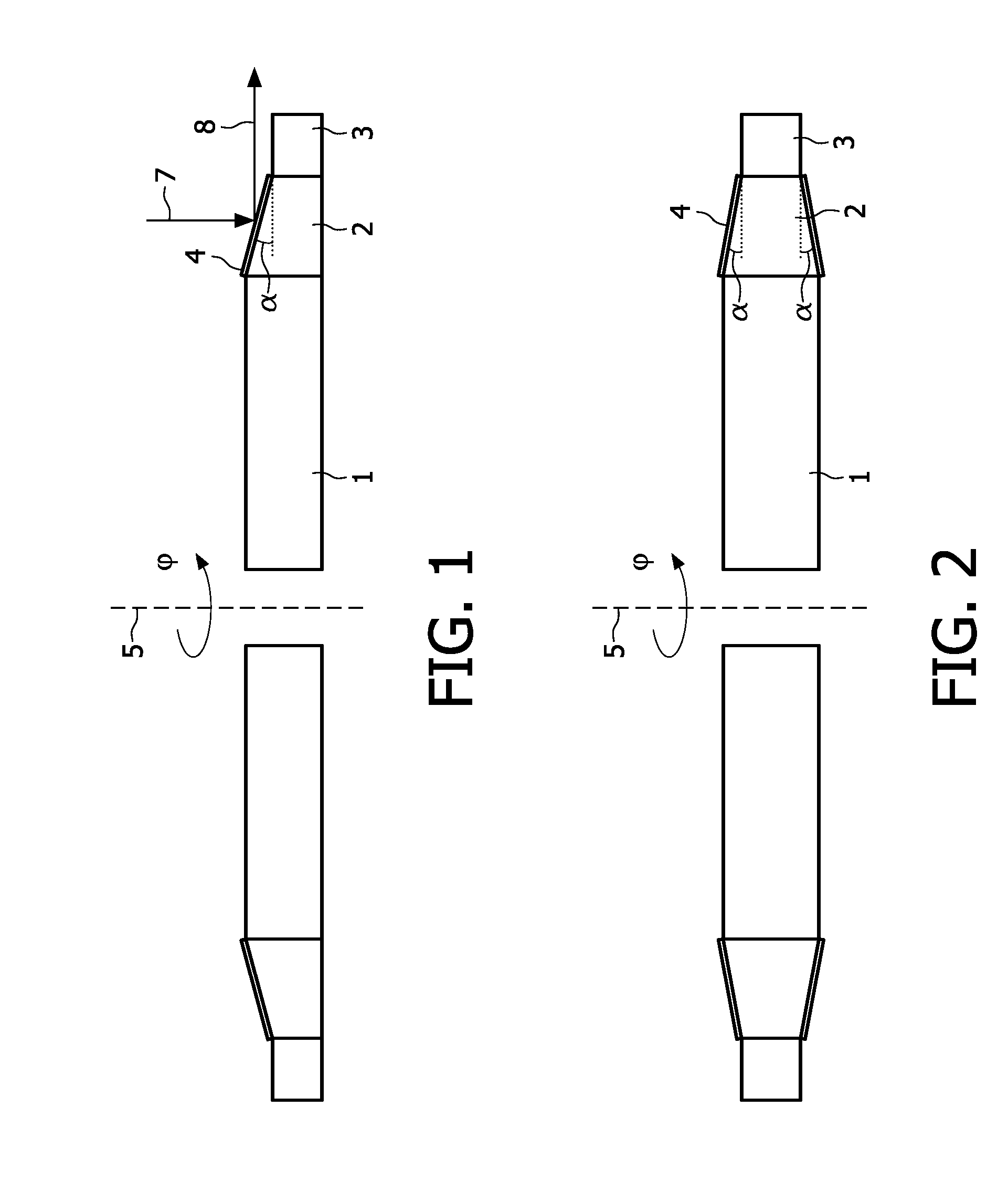

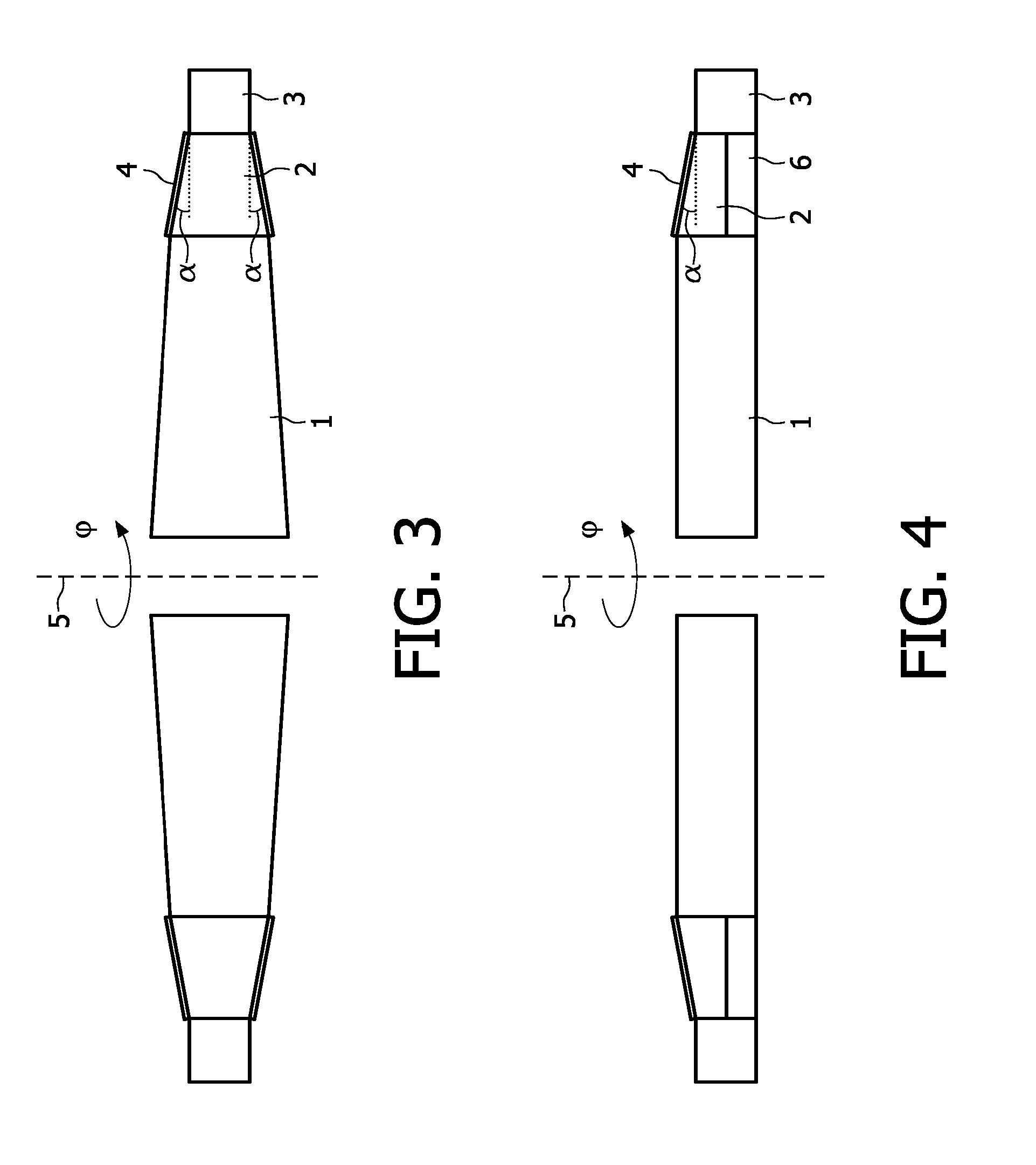

Hybrid design of an anode disk structure for high prower x-ray tube configurations of the rotary-anode type

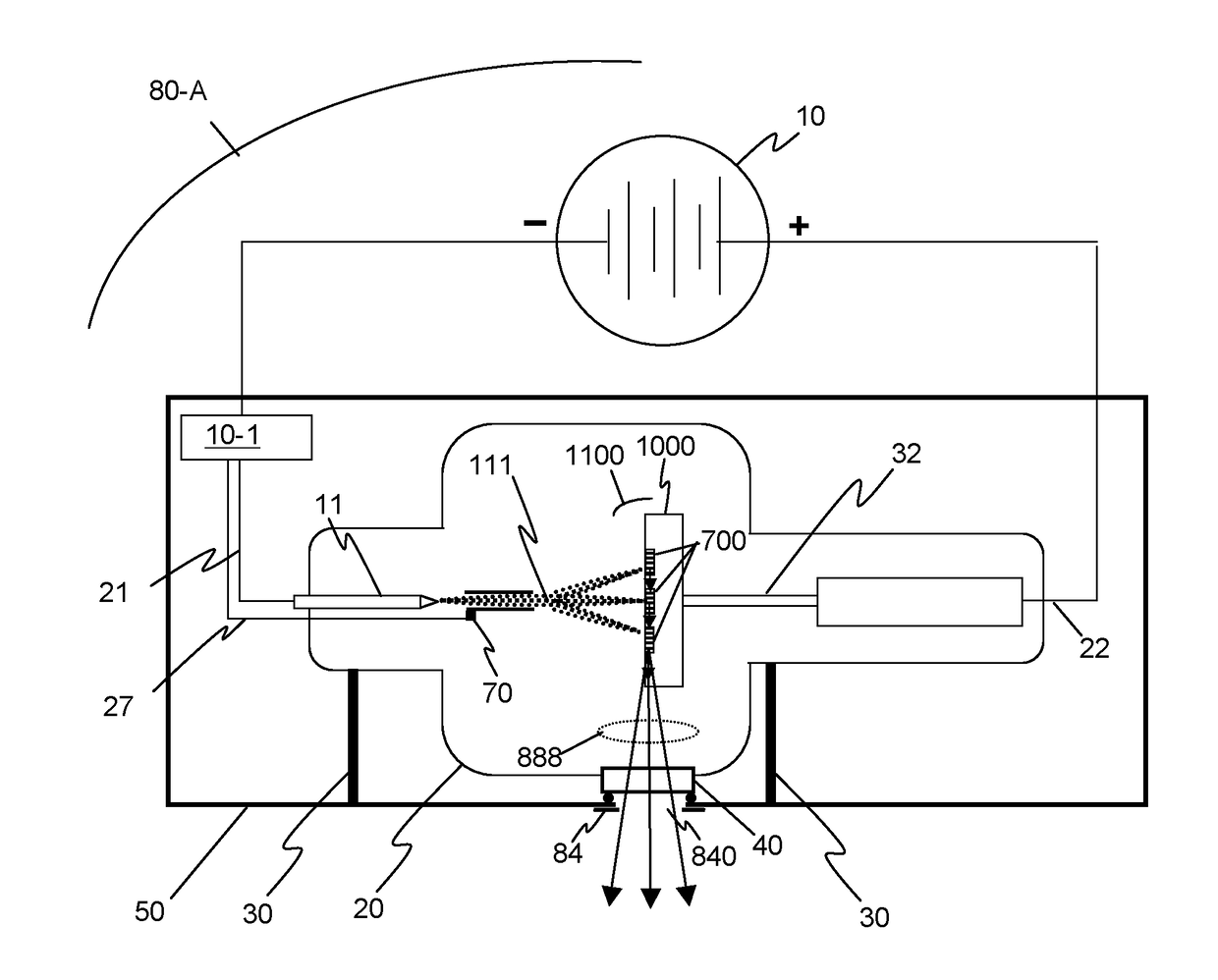

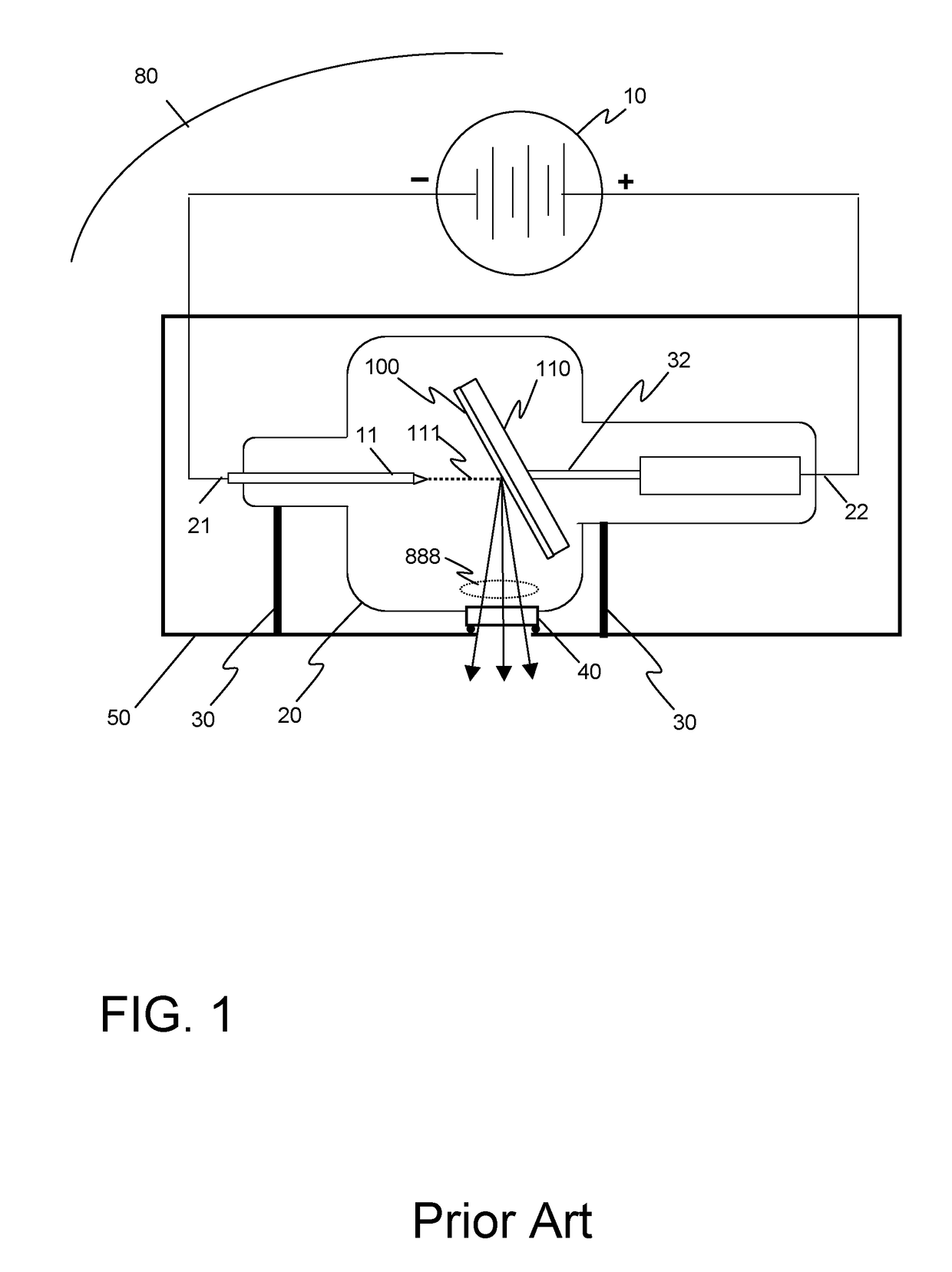

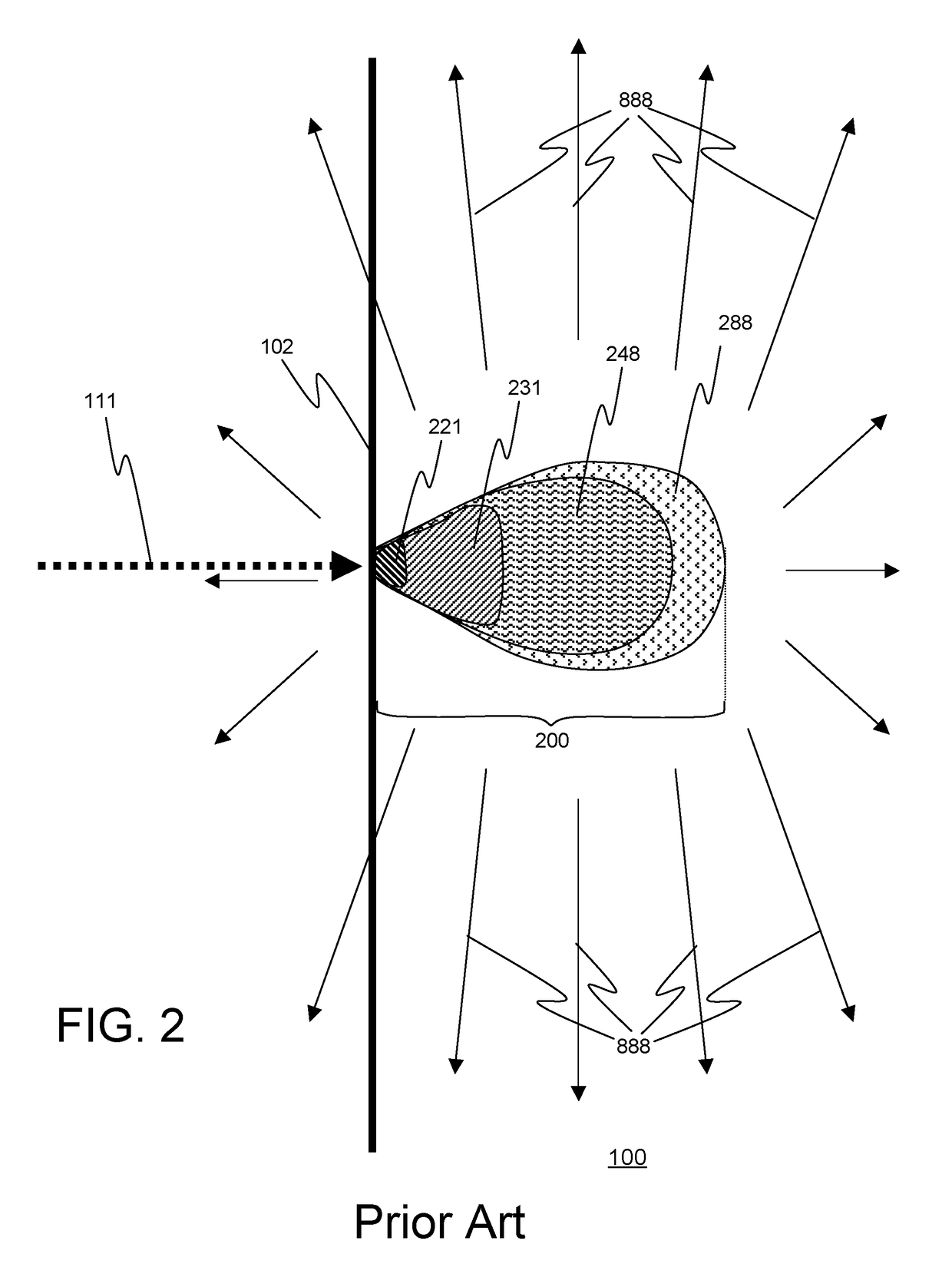

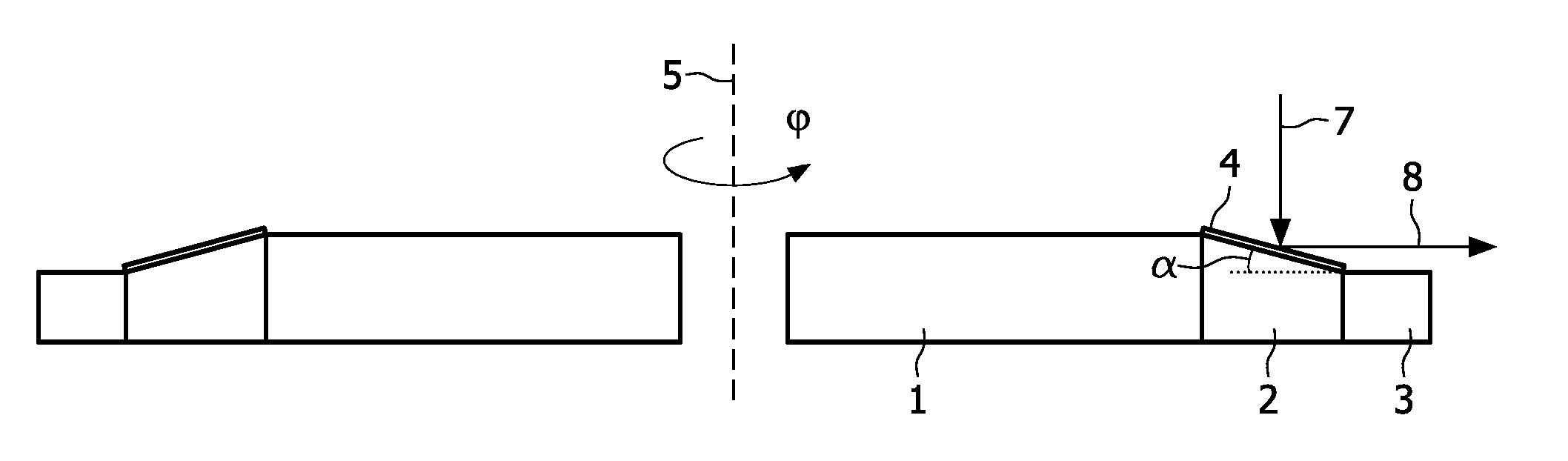

ActiveUS20110129068A1Fast spinHigh-speed imagingX-ray tube laminated targetsX-ray tube target materialsRotational axisFiber

The present invention is related to high power X-ray sources, in particular to those ones that are equipped with rotating X-ray anodes capable of delivering a much higher short time peak power than conventional rotating X-ray anodes according to the prior art. The herewith proposed design principle thereby aims at overcoming thermal limitation of peak power by allowing extremely fast rotation of the anode and by introducing a lightweight material with high thermal conductivity (2) in the region adjacent to the focal track material (4). The extremely fast rotation is enabled by providing sections of the rotary anode disk made of anisotropic high specific strength materials with high thermal stability (1, 3, 6) which will be specifically adapted to the high stresses building up when the anode is operated, as for example fiber-reinforced ceramic materials. An X-ray system equipped with a high peak power anode according to the present invention will be capable of high speed image acquisition with high resolution and high coverage. Such a high-speed rotary anode disk can advantageously be applied in X-ray tubes for material inspection or medical radiography, for X-ray imaging applications which are needed for acquiring image data of moving objects in real-time, such as e.g. in the scope of cardiac CT, or for any other X-ray imaging application that requires high-speed image data acquisition. According to a further exemplary embodiment, the invention is directed to a rotary anode disk divided into distinct anode segments (10a, 10b) with adjacent anode segments which may e.g. be limited to each other by straight radial (14a) or S-shaped slits (14b) ranging from the inner anode bulk (1) to the inner radial edge of the anode disk's outer frame section (3). Other exemplary embodiments of the present invention relate to a rotary anode disk structure design which comprises liquid metal conductors (16a) between the inner anode bulk (1) and a rotary shaft (12) needed for rotating the rotary anode disk about its rotational axis (5), said liquid metal conductors (16a) providing a liquid metal connection between the rotary anode and its rotary shaft (12), or to a rotary anode disk structure which comprises a sliding radial connection (17) and a flexible heat conductor (18) between the inner anode bulk (1) and the rotary shaft (12).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

X-ray analyzer having multiple excitation energy bands produced using multi-material x-ray tube anodes and monochromating optics

ActiveUS9449780B2Lower levelX-ray tube laminated targetsMaterial analysis using wave/particle radiationMulti materialFluorescence

An x-ray tube includes a target on which electrons impinge to form a diverging x-ray beam. The target has a surface formed from first and second target materials, each tailored to emit a respective x-ray energy profile. A first x-ray optic may be provided for directing the beam toward the sample spot, the first x-ray optic monochromating the diverging x-ray beam to a first energy from the energy emitted by the first target material; and a second x-ray optic may be provided, for directing the beam toward the sample spot, the second x-ray optic monochromating the diverging x-ray beam to a second energy from the energy emitted by the second target material. Fluorescence from the sample spot induced by the first and second monochromated energies is used to measure the concentration of at least one element in the sample, or separately measure elements in a coating and underlying substrate.

Owner:X-RAY OPTICAL SYSTEM INC

Device for outputting high and/or low energy X-rays

ActiveUS7645994B2Improve image qualityLarge adjustment rangeX-ray tube laminated targetsSolid-state devicesHigh energyX-ray

Owner:TSINGHUA UNIV +1

High aspect ratio x-ray targets and uses of same

ActiveUS20150303021A1Simple structureEasy to useX-ray tube laminated targetsRadiation/particle handlingSoft x rayHard X-rays

An x-ray target, a method of using the x-ray target, and a computer program product with instructions for carrying out a method of using the x-ray target. The x-ray target includes a substrate made from a soft x-ray producing material and a high aspect ratio structure made from a hard x-ray producing material. The hard x-ray producing material is embedded in the substrate, formed on the substrate, cantilevered out from the edge of the substrate, or any combination thereof. The high aspect ratio structure comprises a plurality of high aspect ratio structures arranged in one or more grids or arrays, and the high aspect ratio structures in one of the one or more grids or arrays are arranged to form a Hadamard matrix structure.

Owner:FEI CO

High temperature annealing in X-ray source fabrication

The present disclosure relates to multi-layer X-ray sources having decreased hydrogen within the layer stack and / or tungsten carbide inter-layers between the primary layers of X-ray generating and thermally-conductive materials. The resulting multi-layer target structures allow increased X-ray production, which may facilitate faster scan times for inspection or examination procedures.

Owner:MANTHEY DIANE MANT

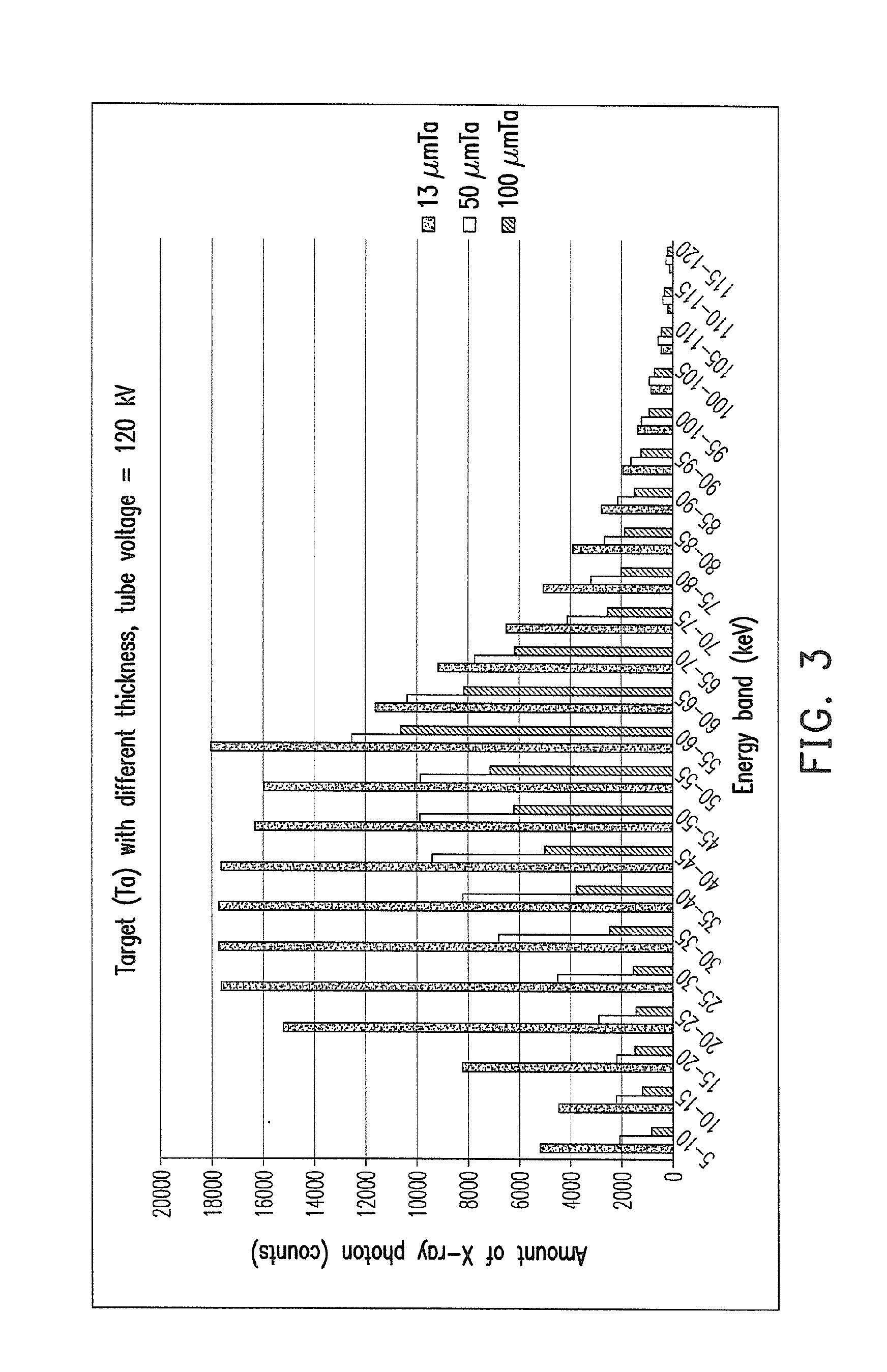

Composite target and x-ray tube with the composite target

ActiveUS20170018392A1Sufficient long service lifeWeaken energyX-ray tube laminated targetsRadiation/particle handlingHigh energyX-ray

A composite target is provided and is interacted with an electron to generate an X-ray, and an energy of the electron can be changed by controlling a tube voltage at least. The composite target includes a target body and an interposing layer which is connected with the target body. The interposing layer moves a highest peak of an energy spectrum of the X-ray toward a high energy direction. The interposing layer may be a single metal or a metal mixture. Not only a low energy photon of the X-ray can be filtered by the interposing layer, but also a distribution of the low energy photon of the X-ray can be increased by increasing a thickness of the interposing layer. As the tube voltage is enhanced, an amount of a high energy photon of the X-ray generated is dramatically increased. An X-ray tube containing the above composite target is also provided.

Owner:NANORAY BIOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com