Patents

Literature

95 results about "Field emission current" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

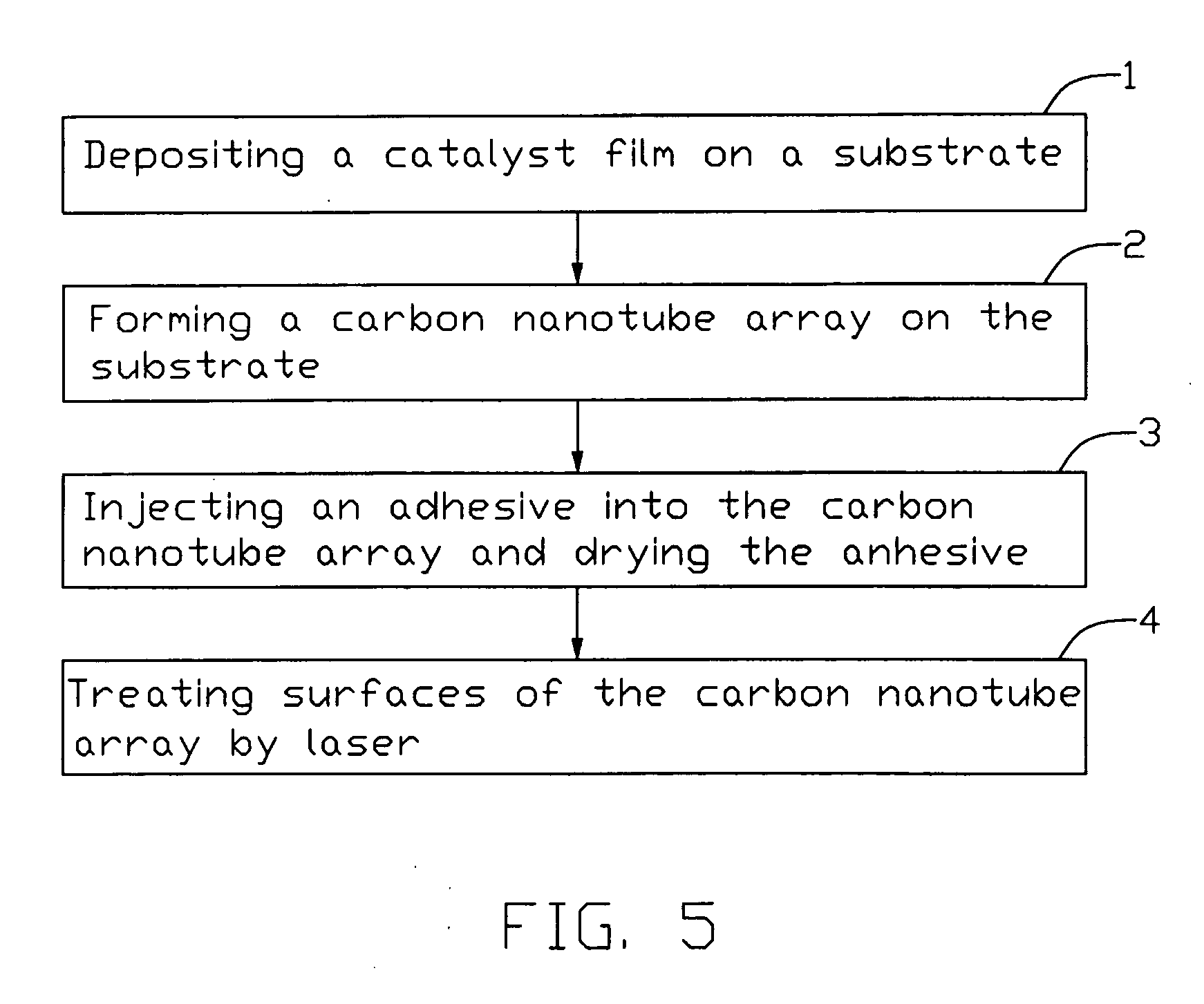

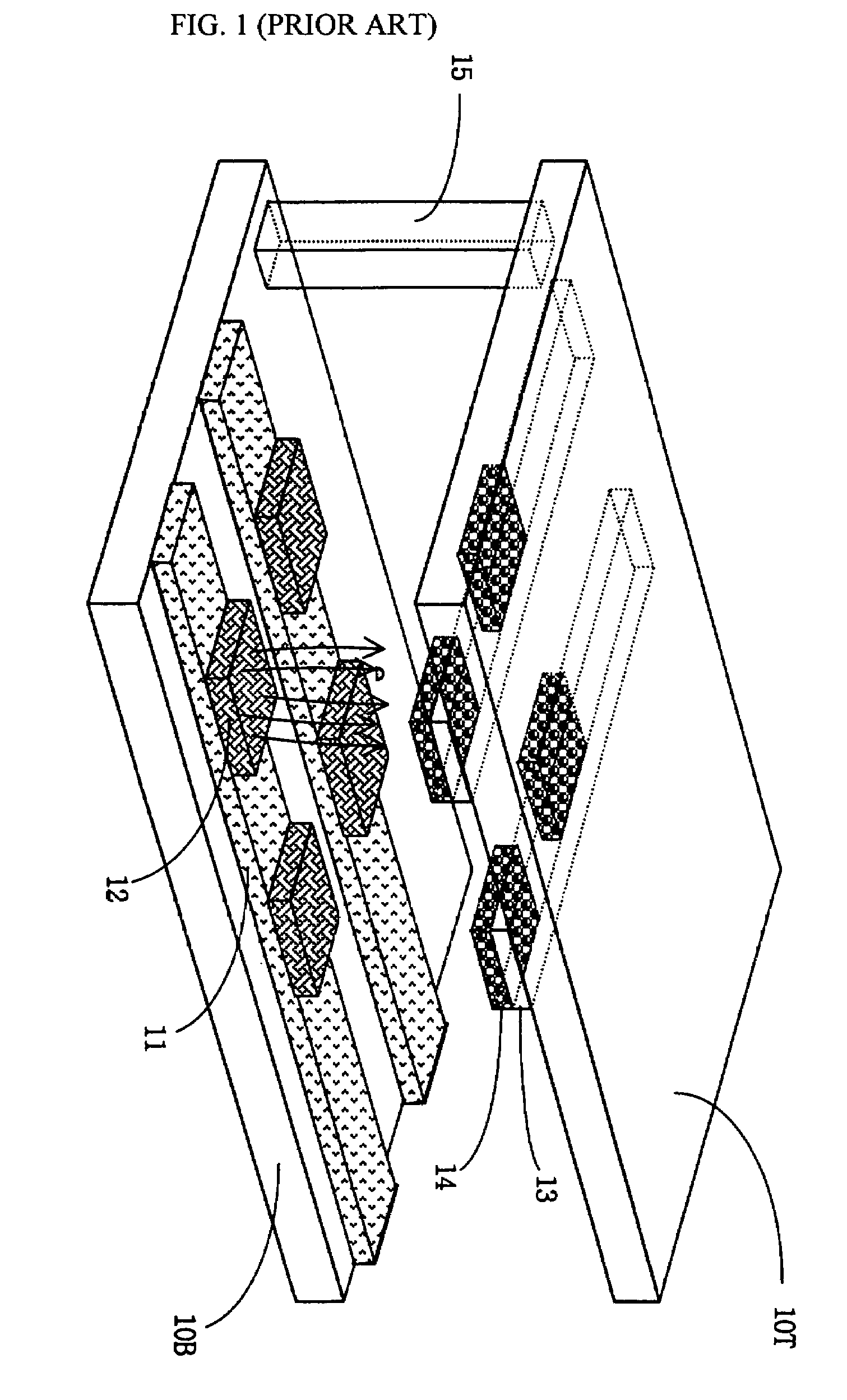

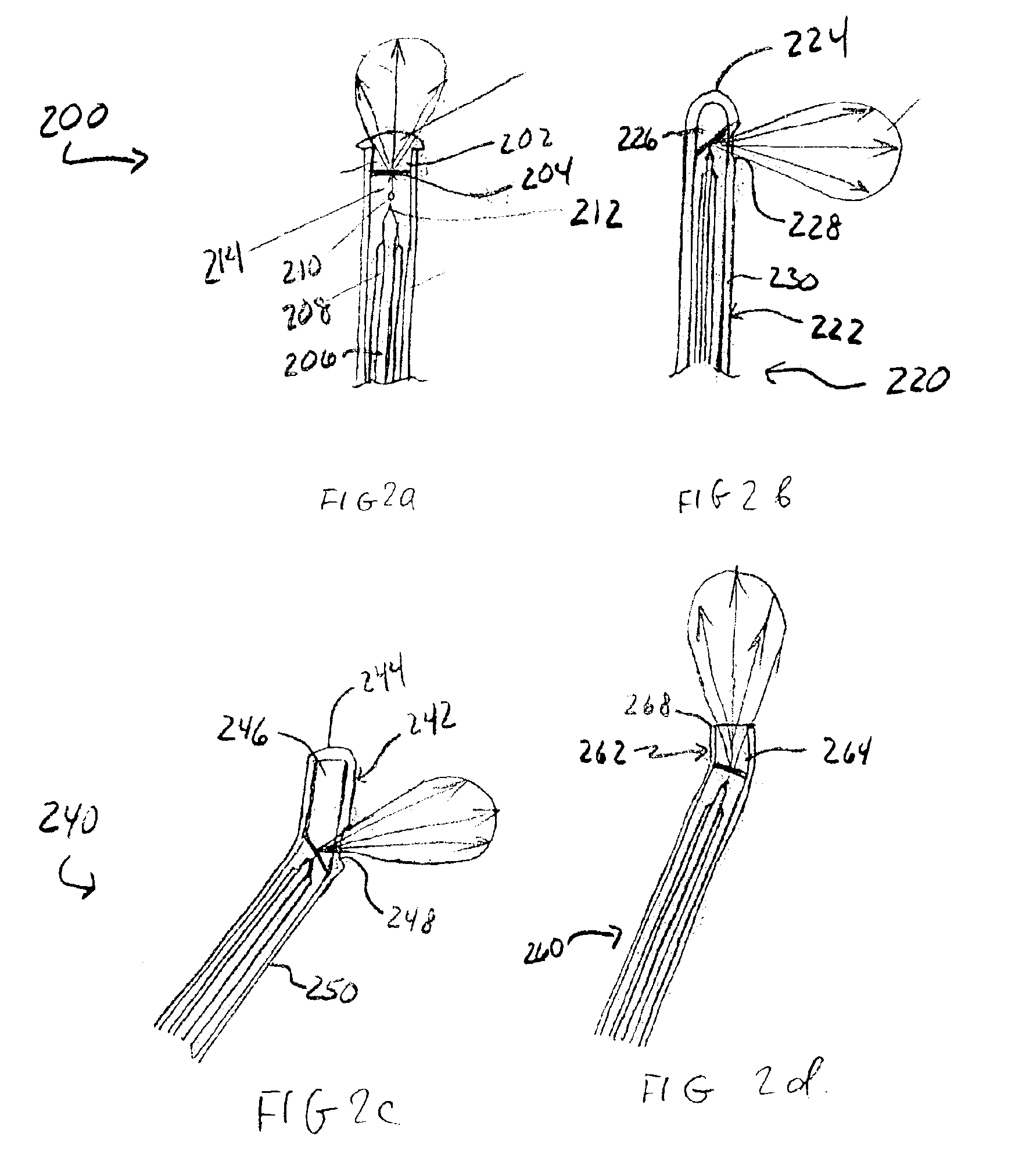

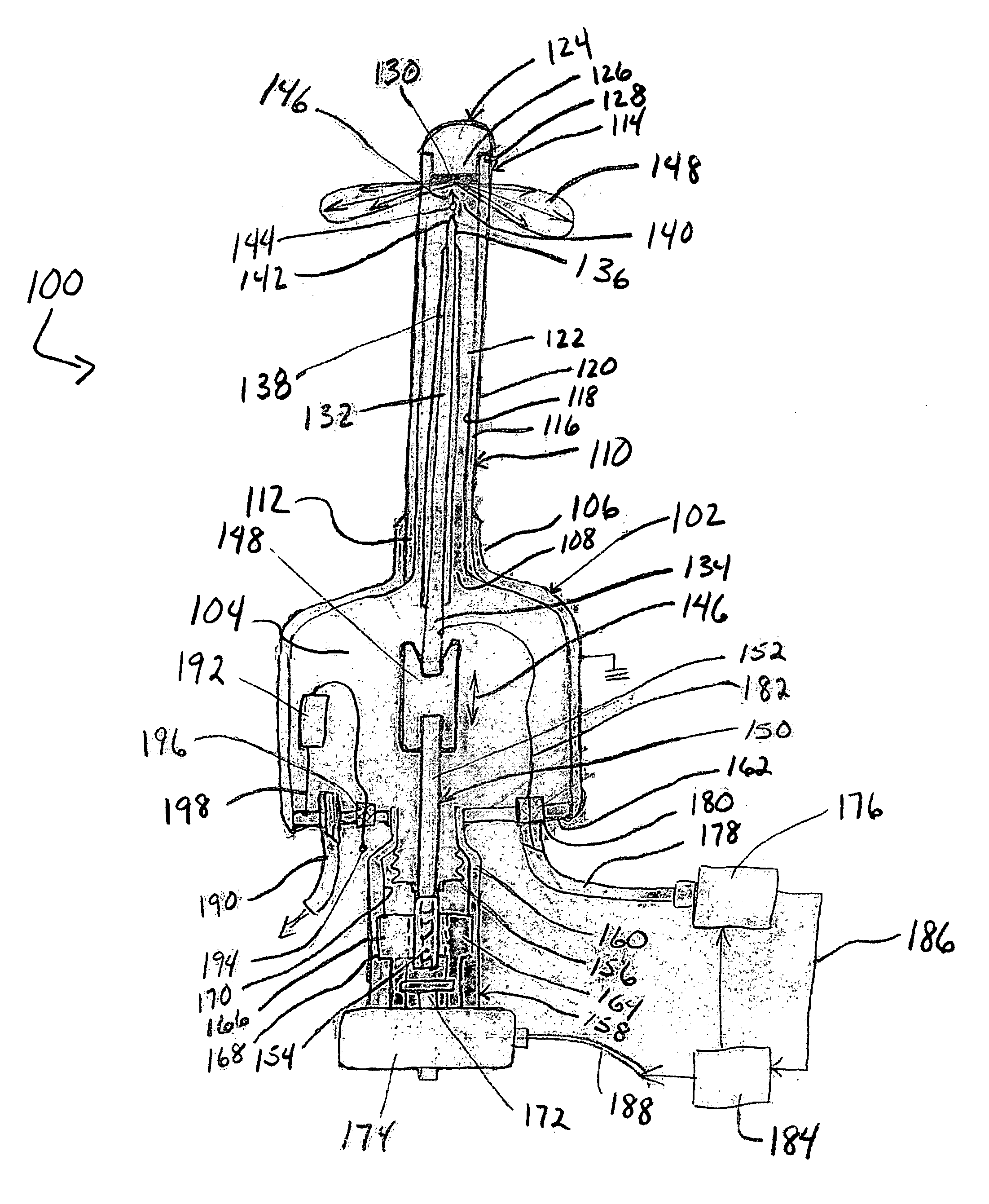

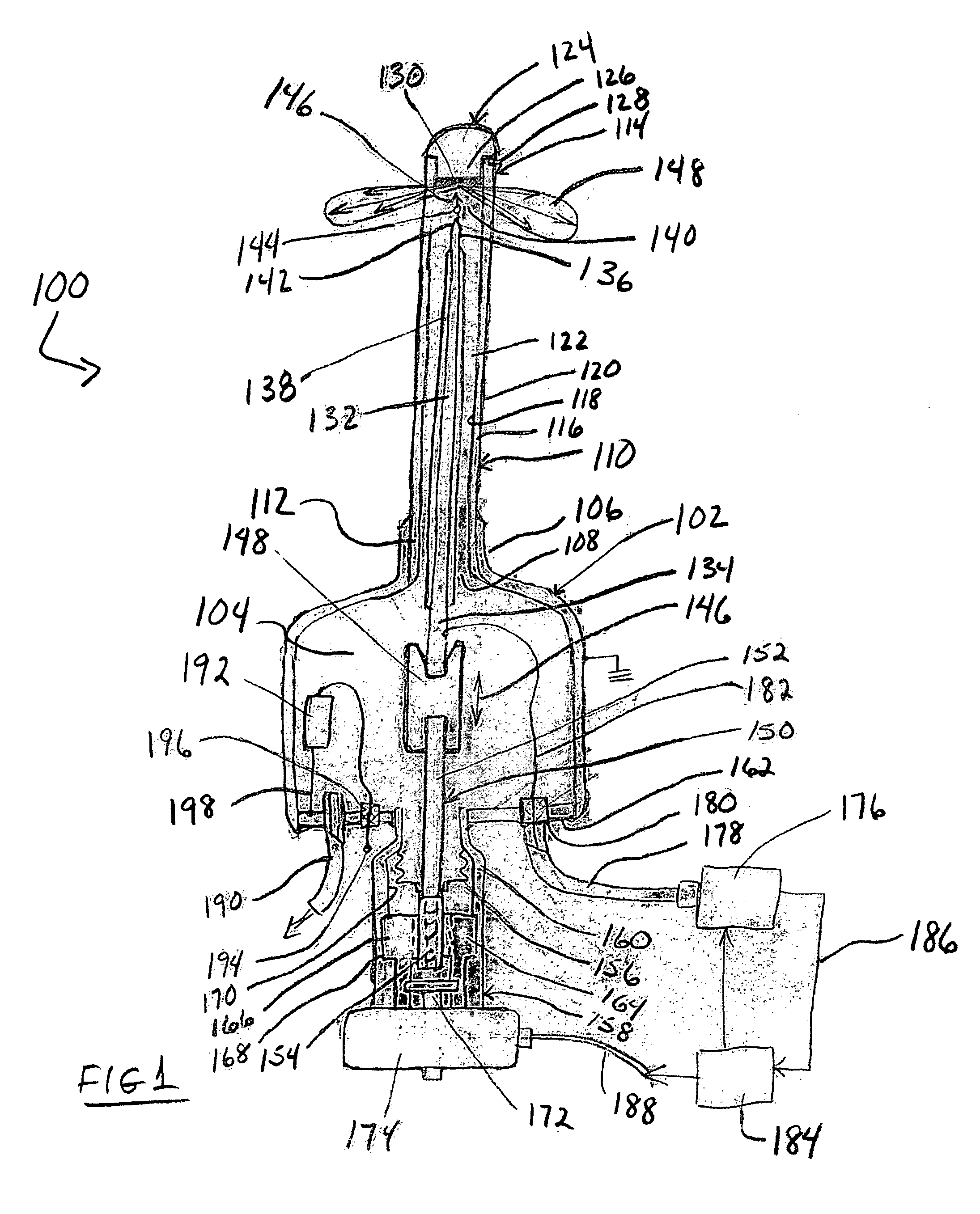

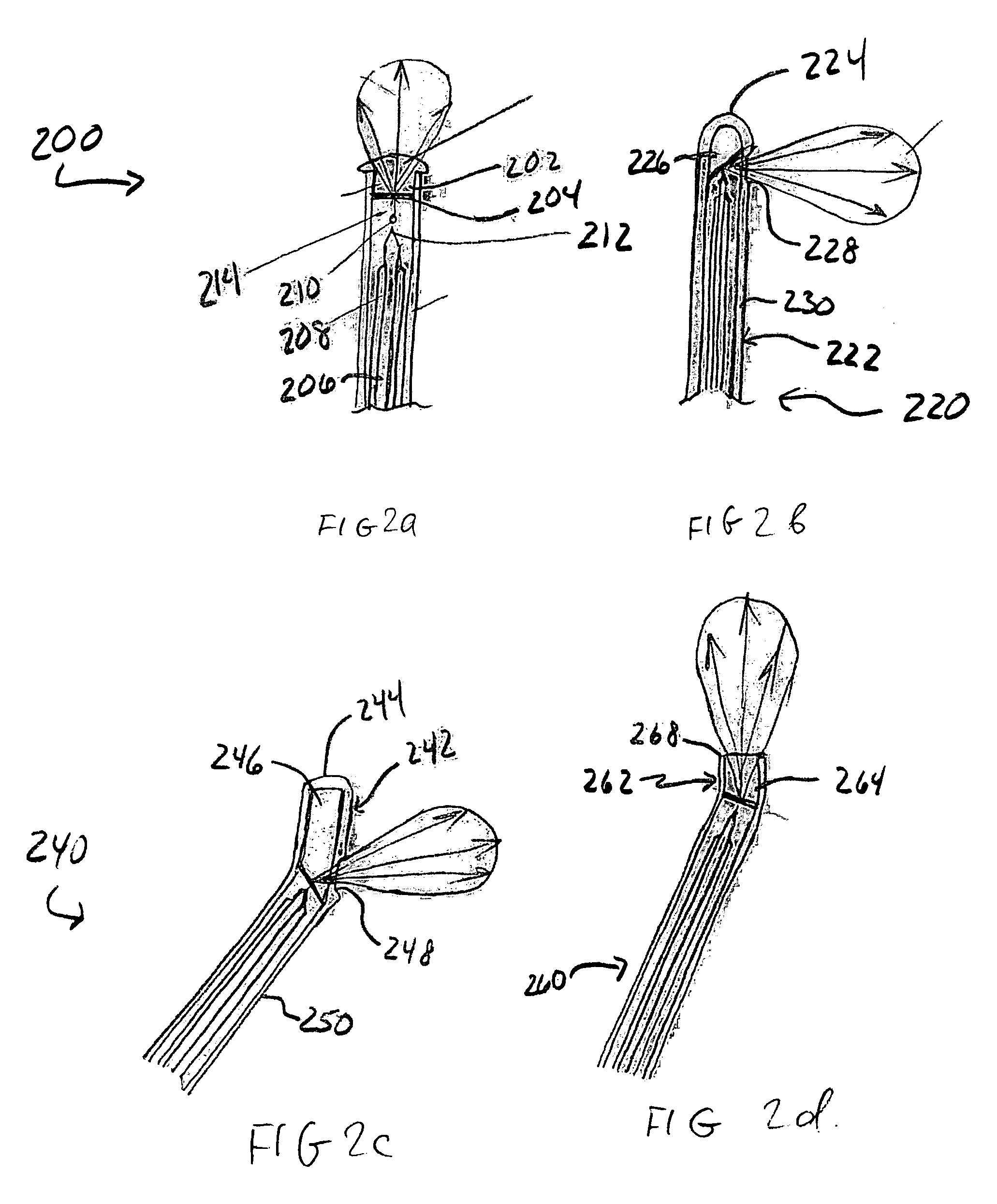

Method for manufacturing carbon nanotube field emission device

ActiveUS7448931B2Avoid separationReduced shieldingLiquid surface applicatorsDischarge tube luminescnet screensField emission deviceField emission current

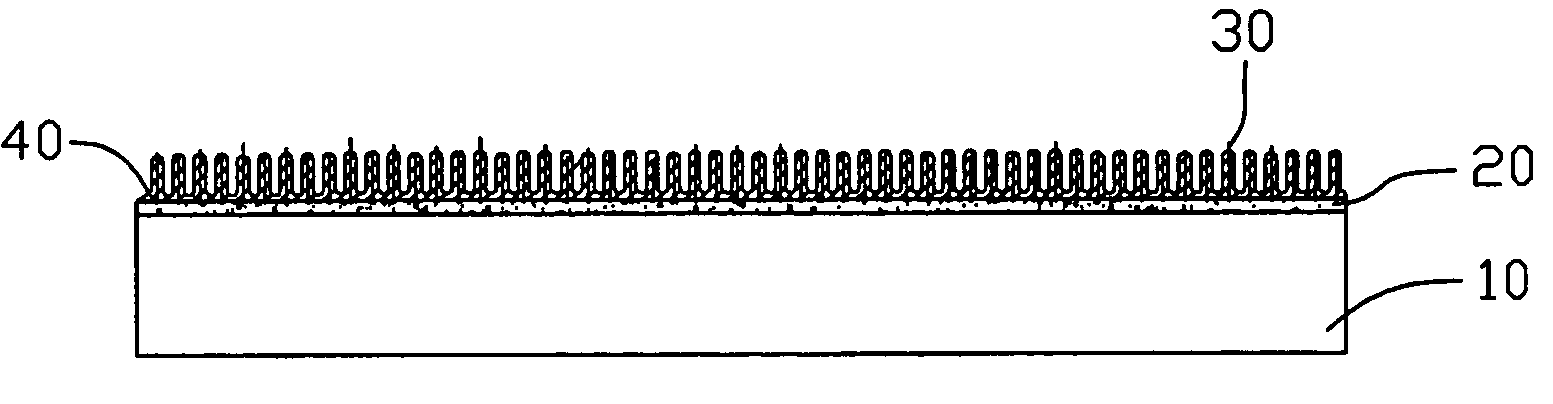

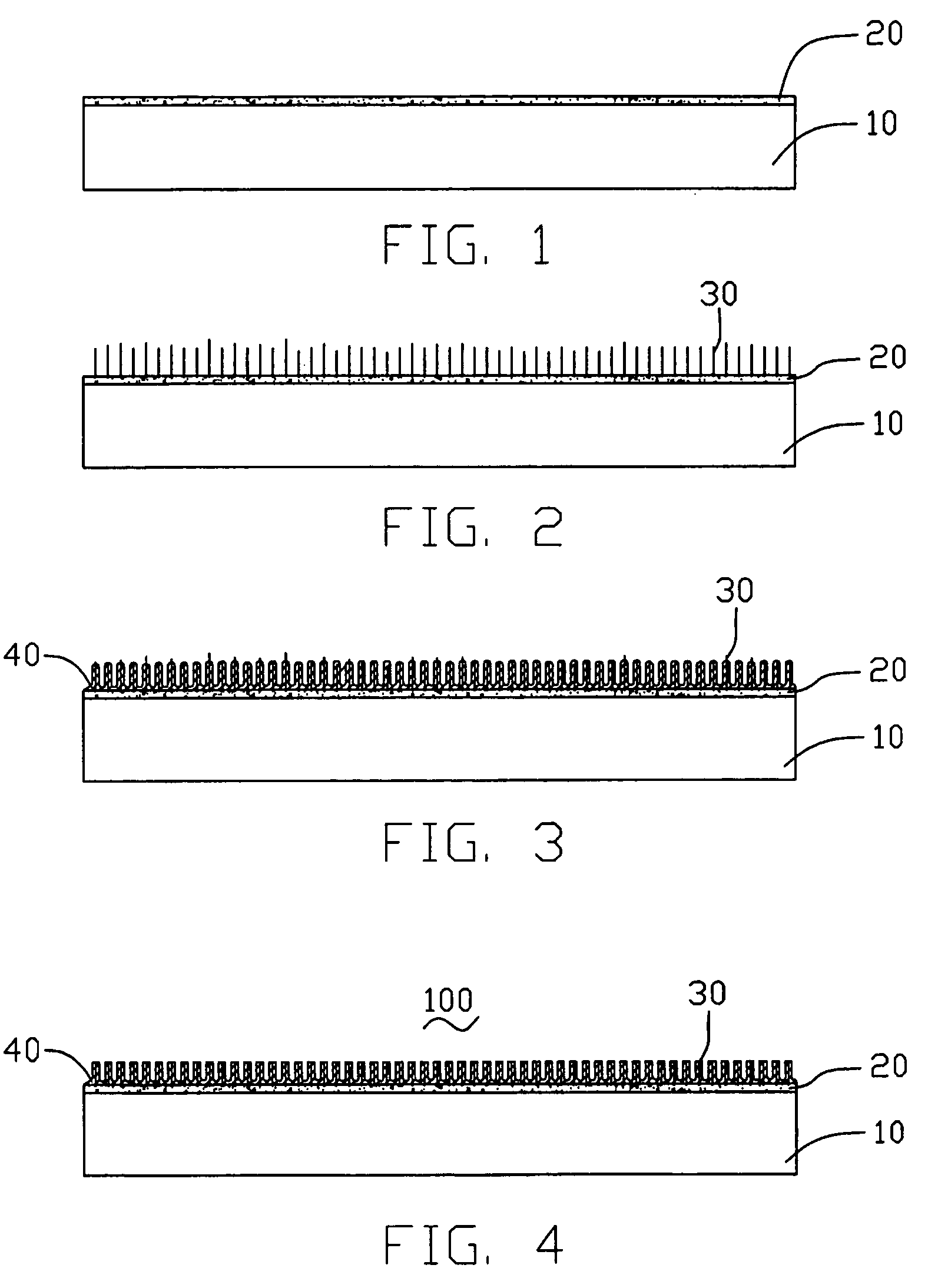

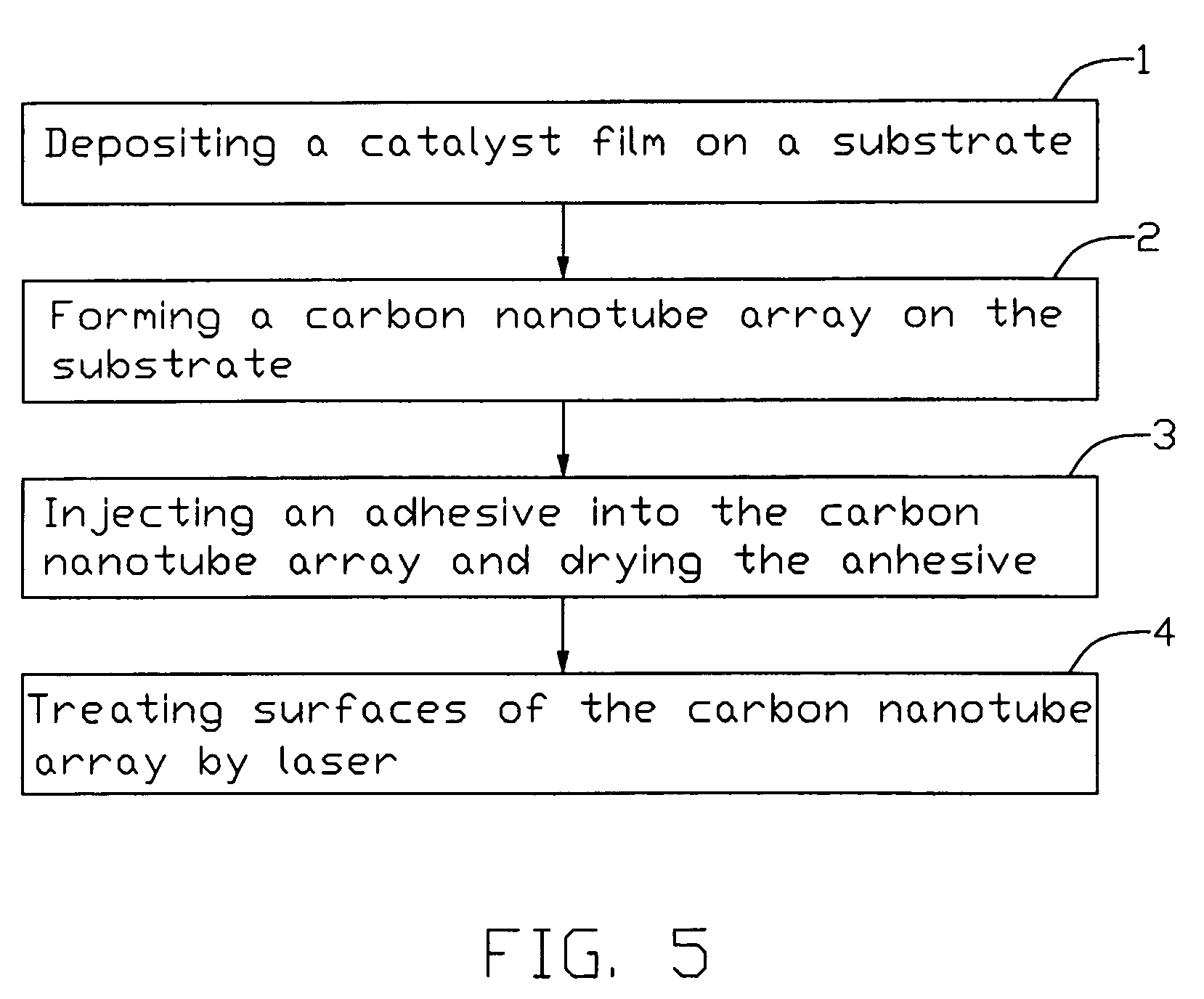

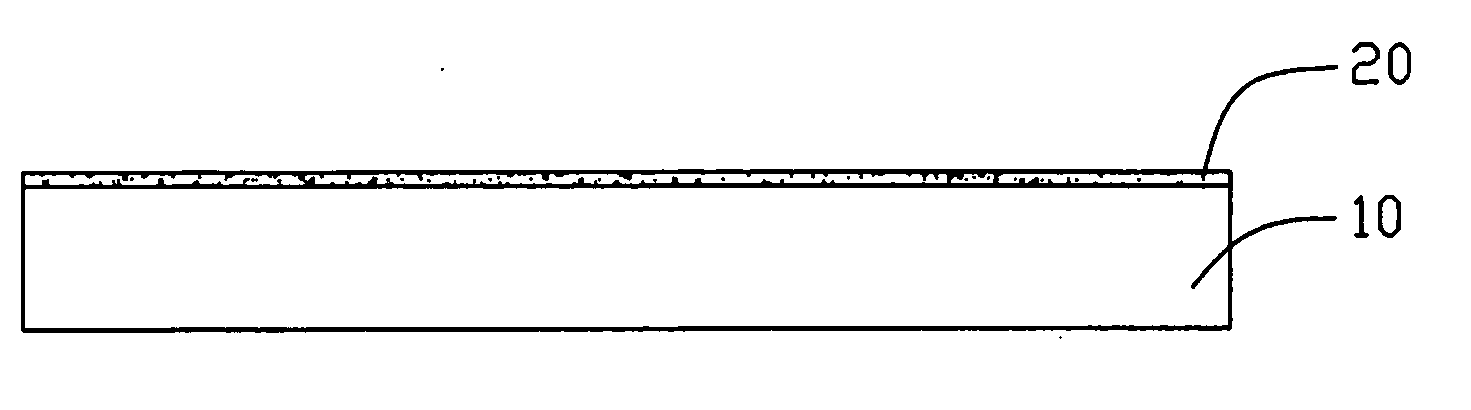

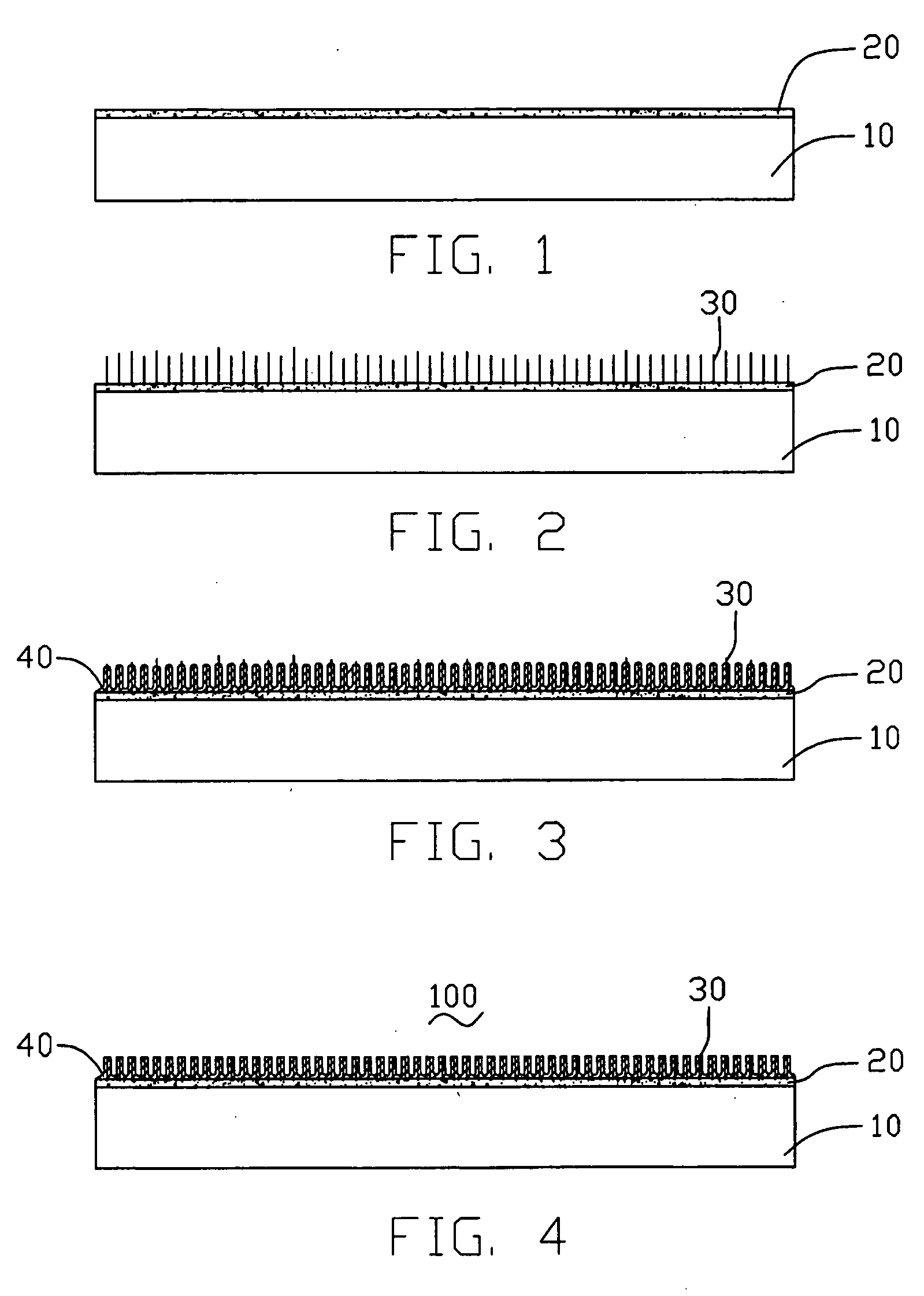

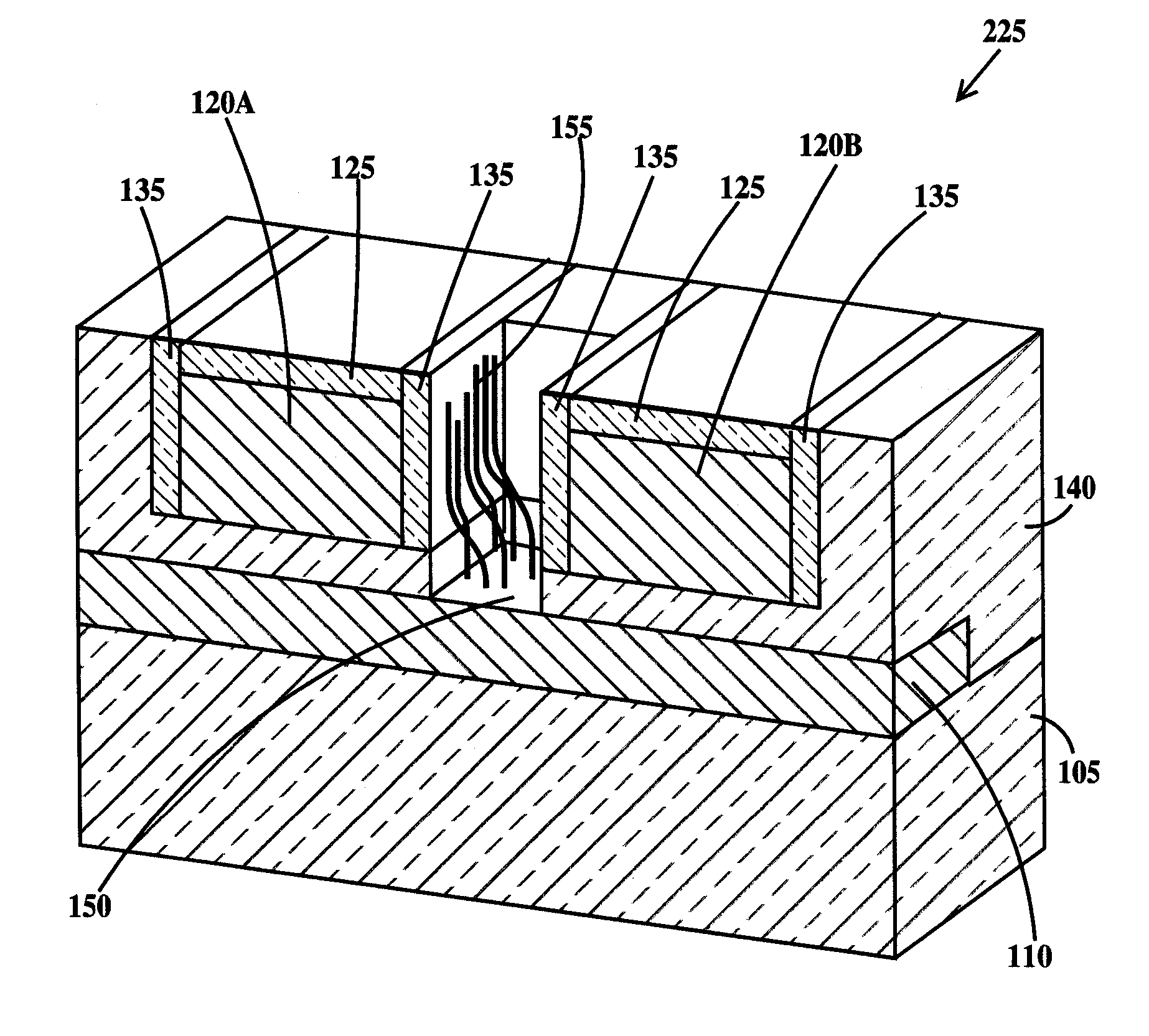

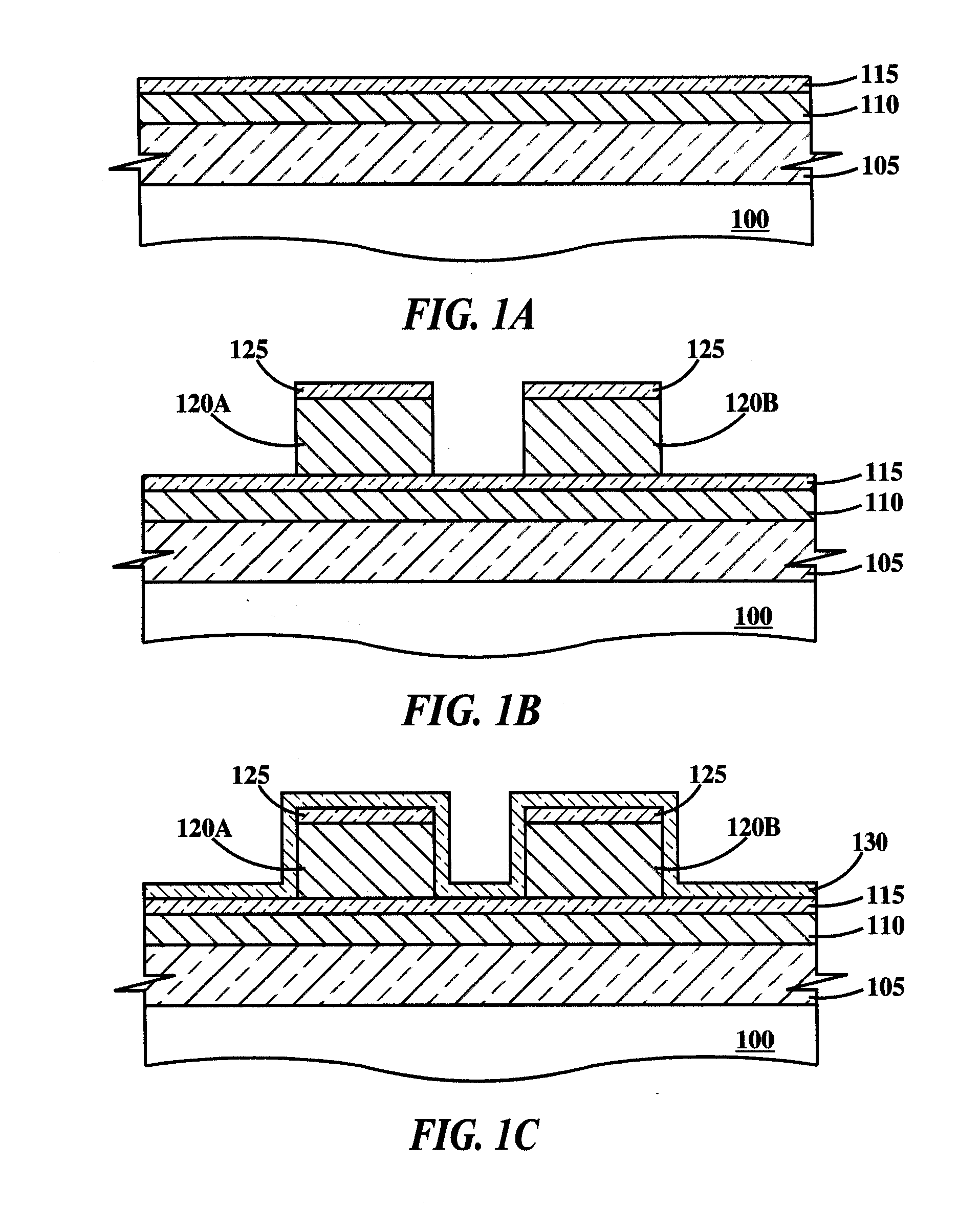

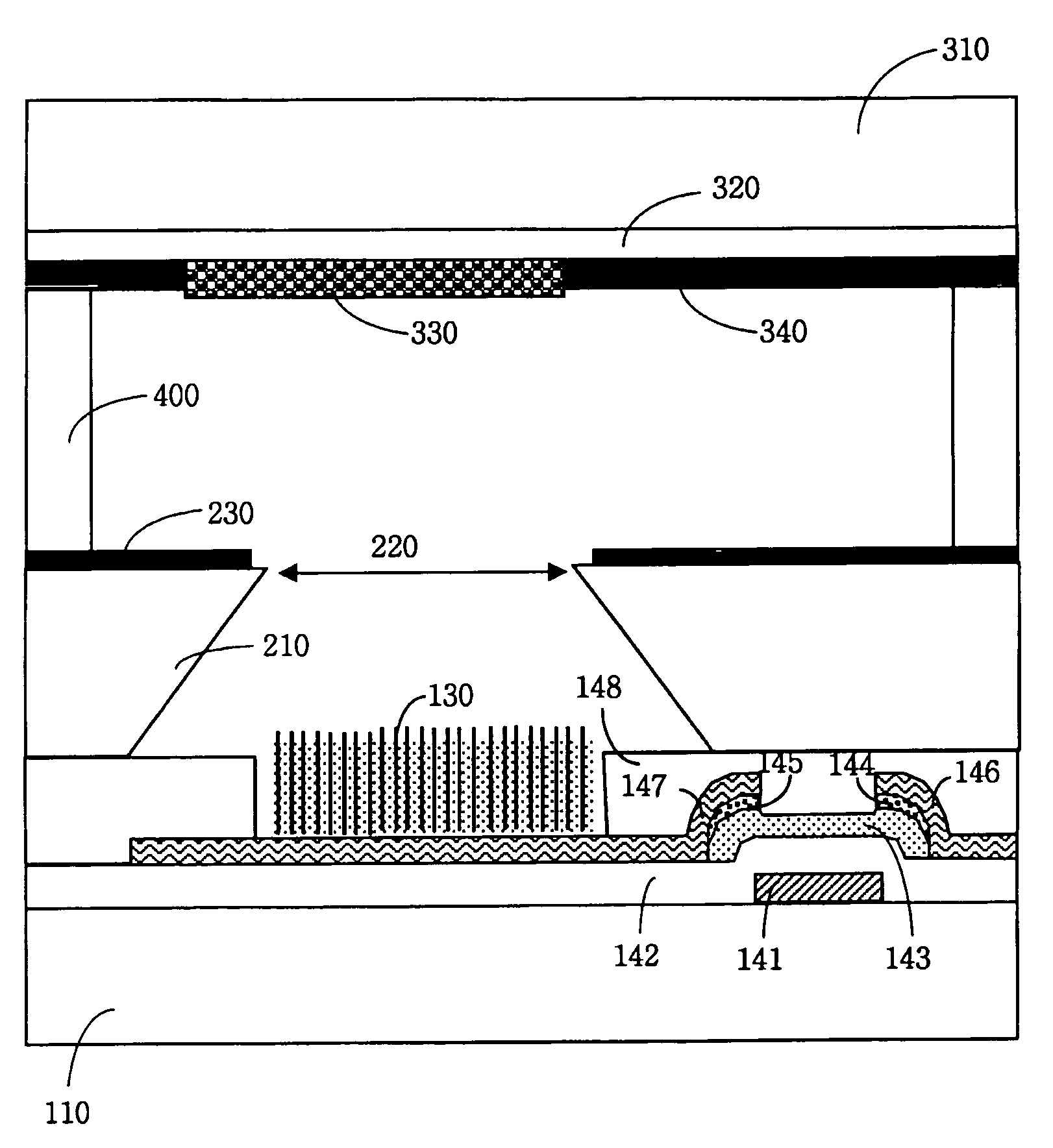

A carbon nanotube field emission device (100) includes a substrate (10), and a carbon nanotube array (30) formed on and secured to the substrate. This avoids separation of the carbon nanotubes from the substrate by electric field force in a strong electric field. Tips of the carbon nanotubes are exposed. A method for manufacturing the carbon nanotube field emission device includes the steps of: (a) depositing a catalyst film (20) on a substrate; (b) forming a carbon nanotube array on the substrate; (c) injecting an adhesive into the carbon nanotube array, and drying the adhesive; and (d) treating surfaces of the carbon nanotube array by laser. The carbon nanotube field emission device has reduced shielding between adjacent carbon nanotubes, reduced threshold voltage, and increased field emission current.

Owner:HON HAI PRECISION IND CO LTD +1

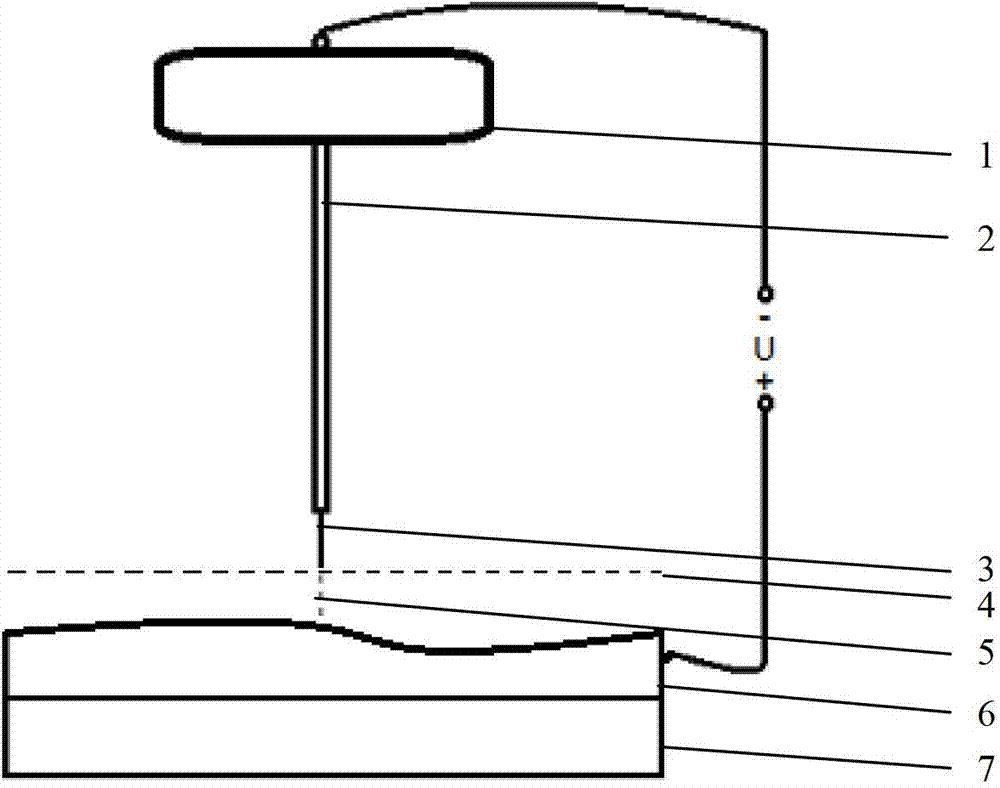

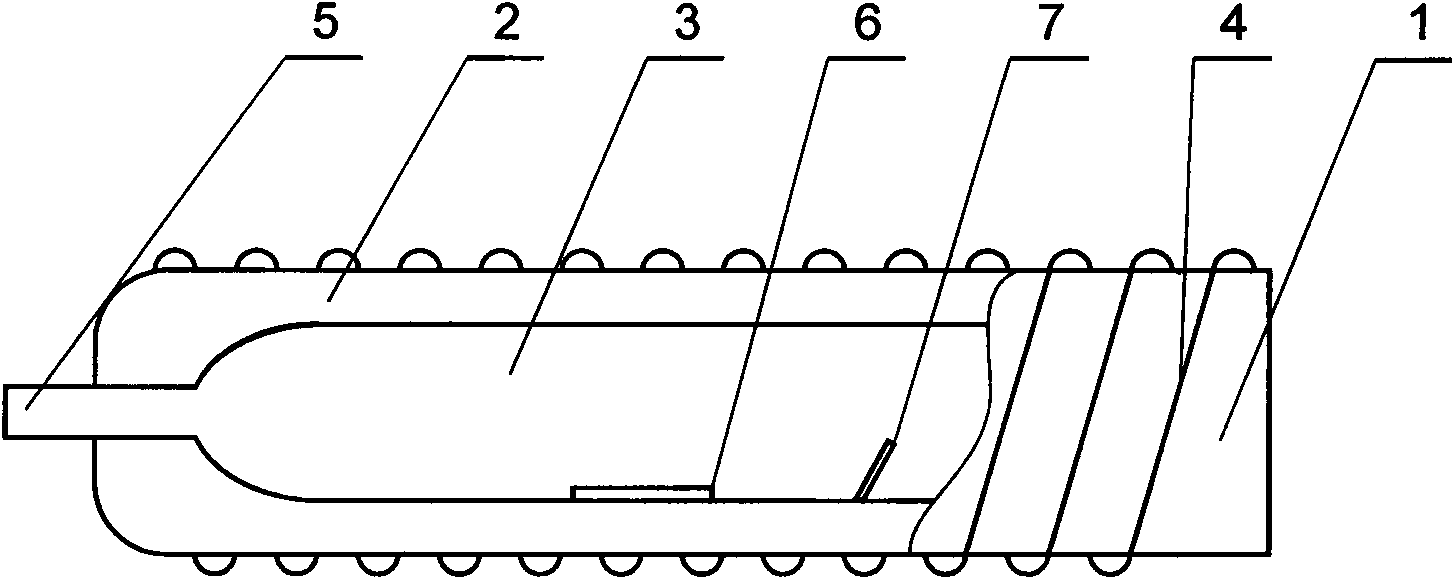

Field emission triode structure based on graphene

InactiveCN102339699AUneven solutionImprove effective utilizationControl electrodesDisplay deviceParticle physics

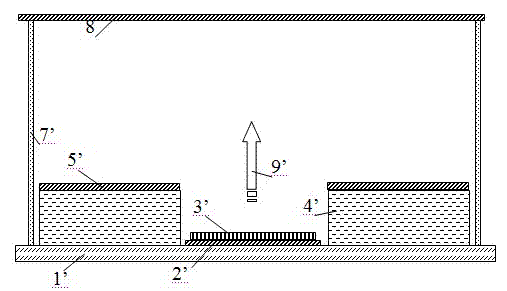

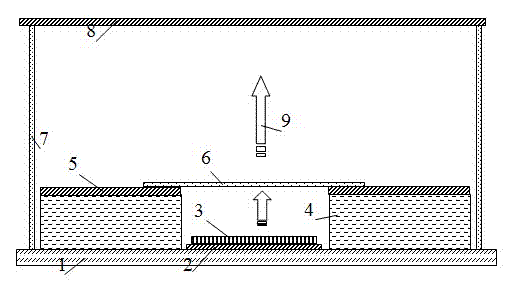

The invention relates to a field emission triode structure based on graphene. The field emission triode structure comprises a cathode substrate (1), a support body (7) and an anode (8), wherein the support body (7) is positioned on the cathode substrate (1), the anode (8) is positioned on the support body (7) and parallel to the cathode substrate (1), and the cathode substrate (1), the support body (7) and the anode (8) constitute a cavity; and the field emission triode structure also comprises a cathode electrode (2) positioned in the enclosed cavity, a field emission body (3) for emitting electron beams (9), an insulated dielectric layer (4), a grid electrode (5) and the graphene (6). The field emission triode structure based on the graphene, provided by the invention, can realize high-current uniform emission, has the capability of effectively separating emission of field emission current from acceleration and focusing of electronic beams and can be used for a cold cathode X-ray source, a microwave amplifier tube and a field emission display.

Owner:SOUTHEAST UNIV

Carbon nanotube field emission device and method for manufacturing same

ActiveUS20050264155A1Avoid separationReduced shieldingDischarge tube luminescnet screensElectric discharge tubesField emission deviceField emission current

Owner:HON HAI PRECISION IND CO LTD +1

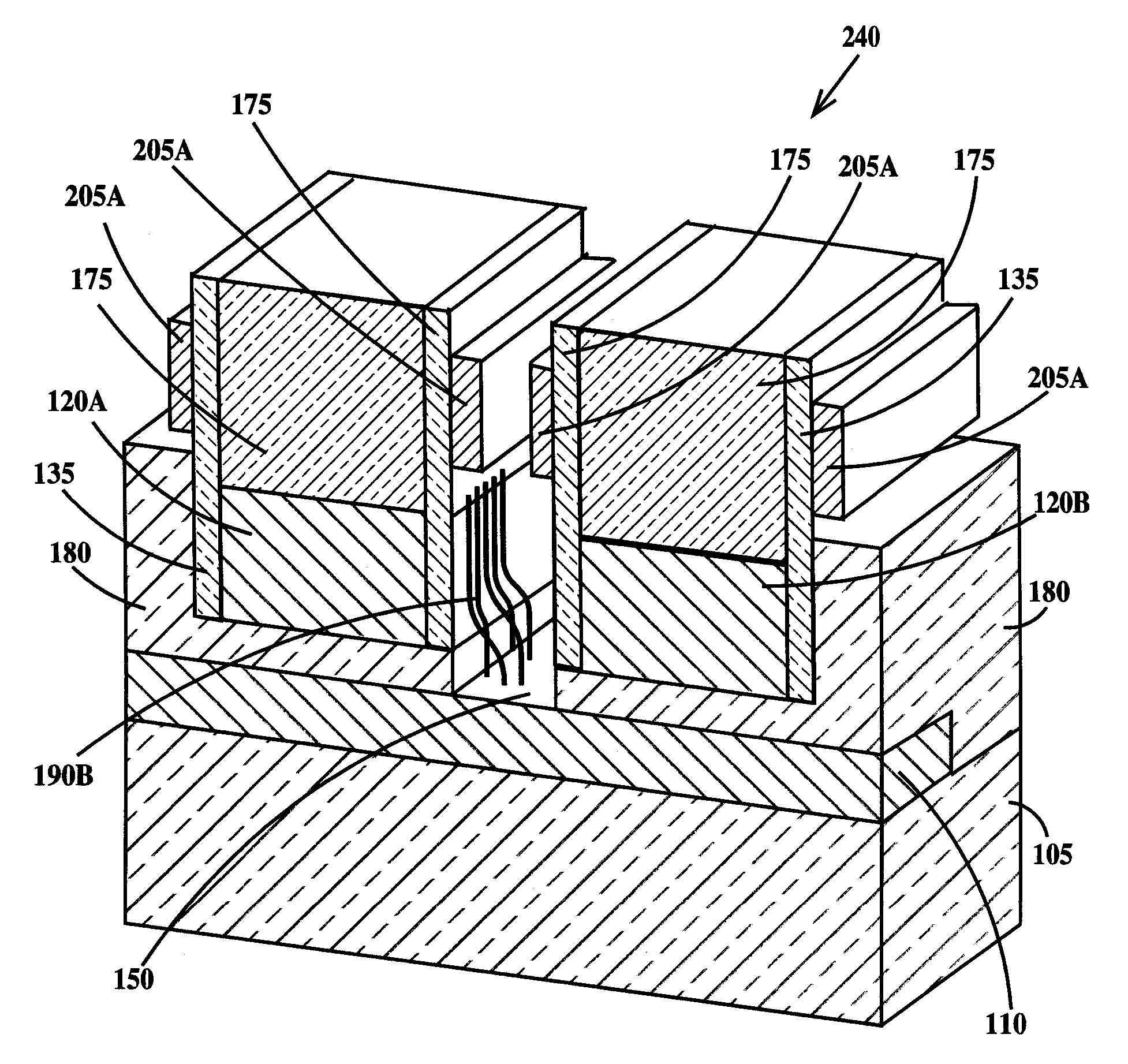

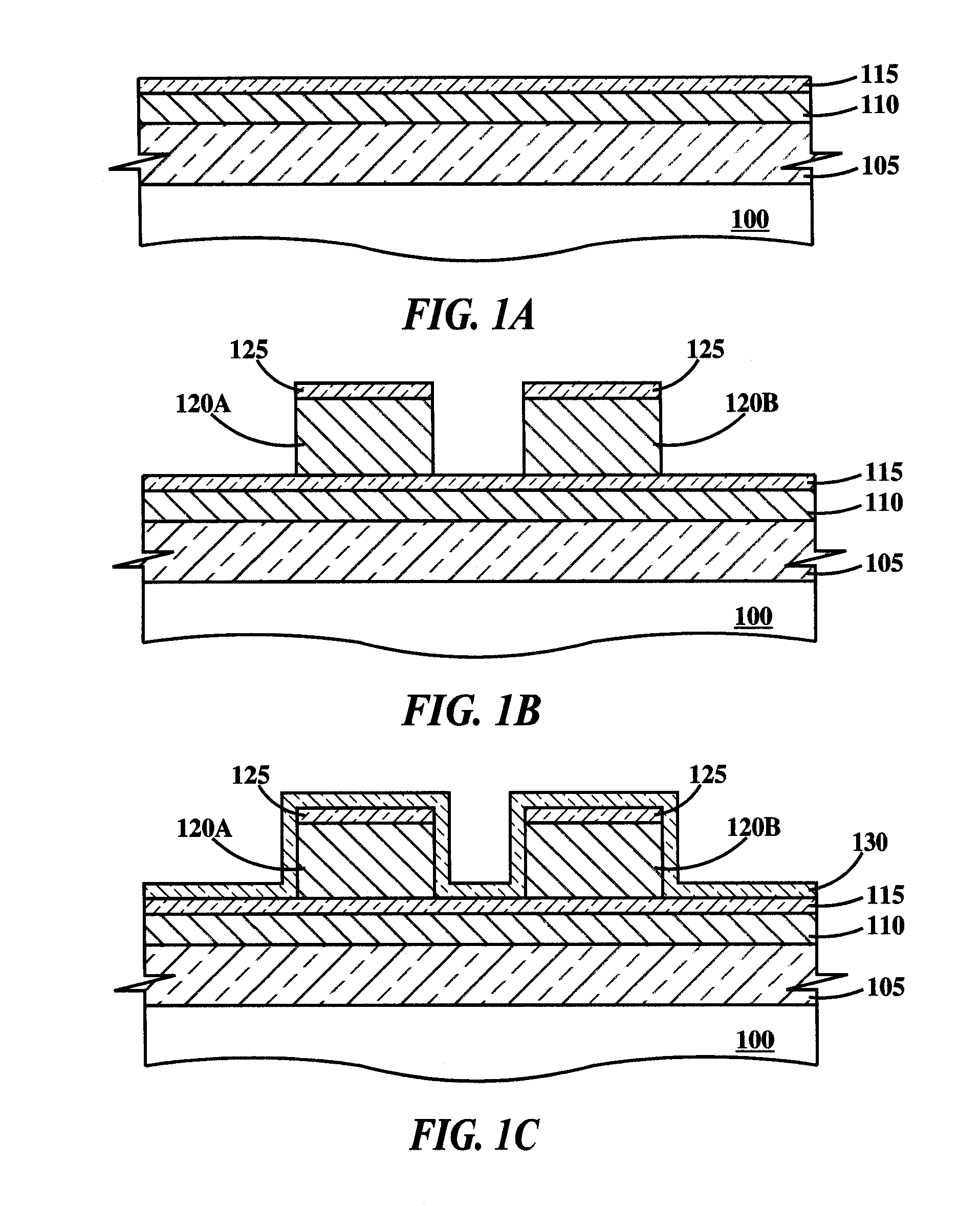

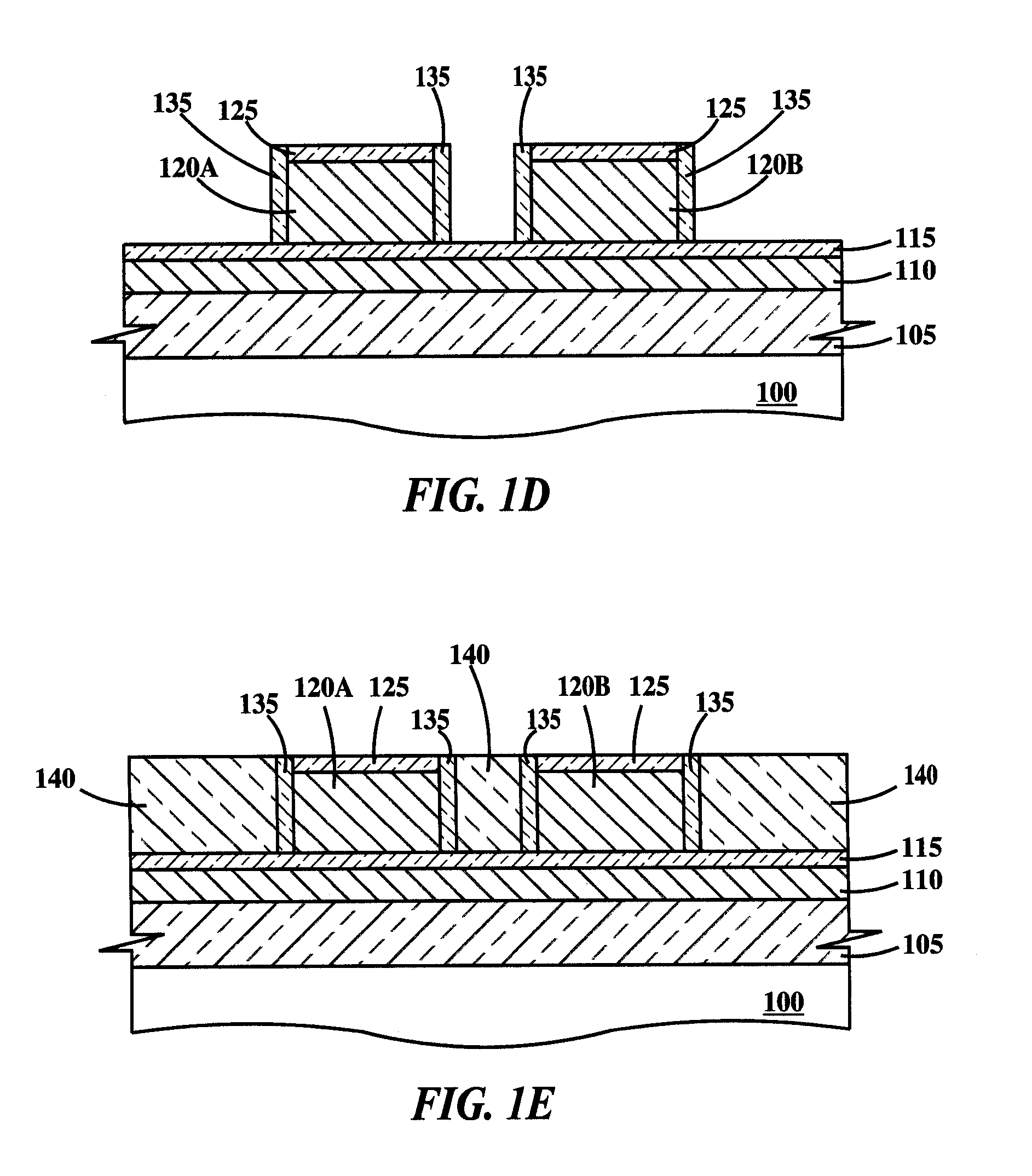

Non-volatile switching and memory devices using vertical nanotubes

Owner:GLOBALFOUNDRIES INC

Non-volatile switching and memory devices using vertical nanotubes

Non-volatile and radiation-hard switching and memory devices using vertical nano-tubes and reversibly held in state by van der Waals' forces and methods of fabricating the devices. Means for sensing the state of the devices include measuring capacitance, and tunneling and field emission currents.

Owner:GLOBALFOUNDRIES INC

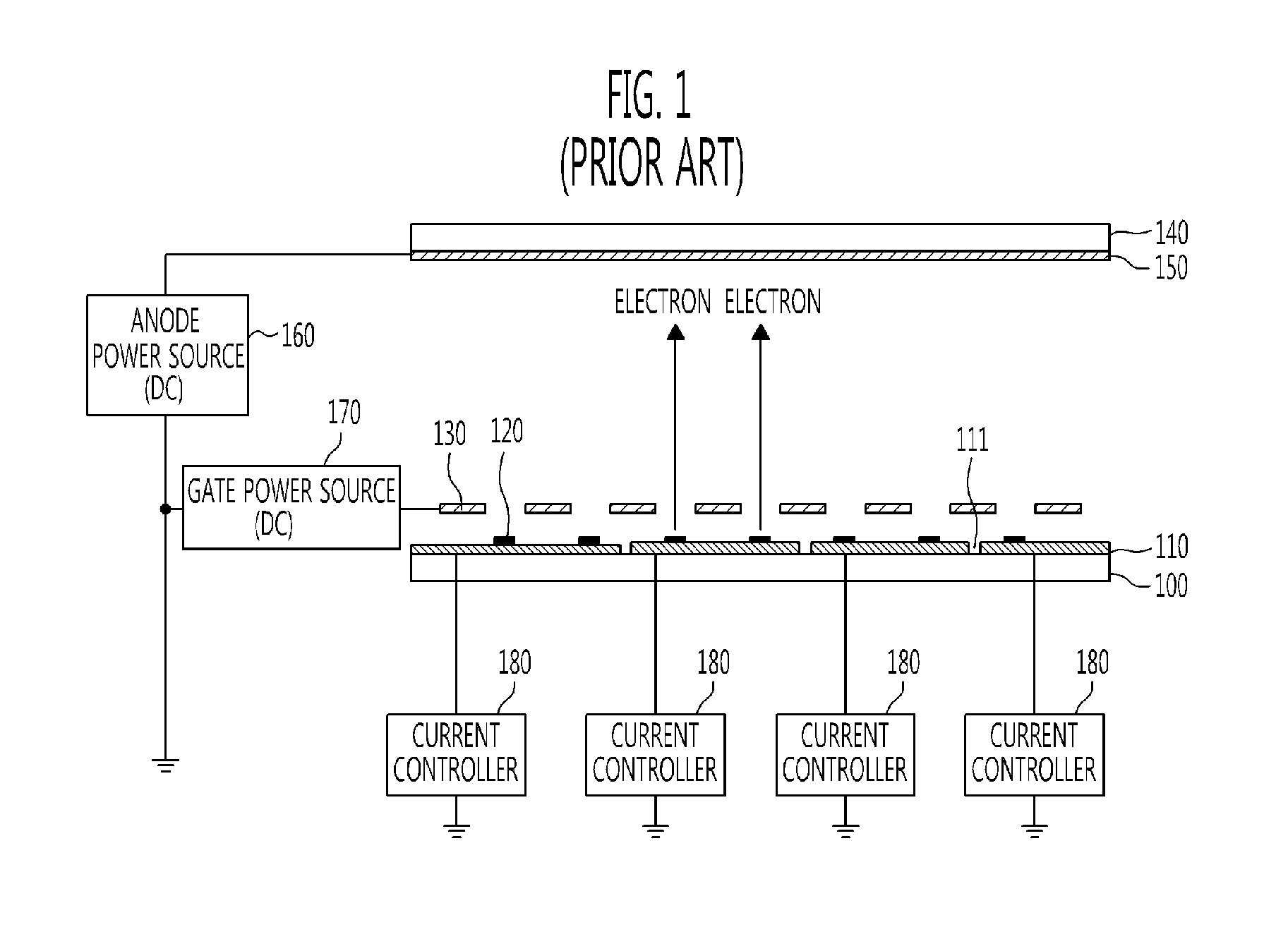

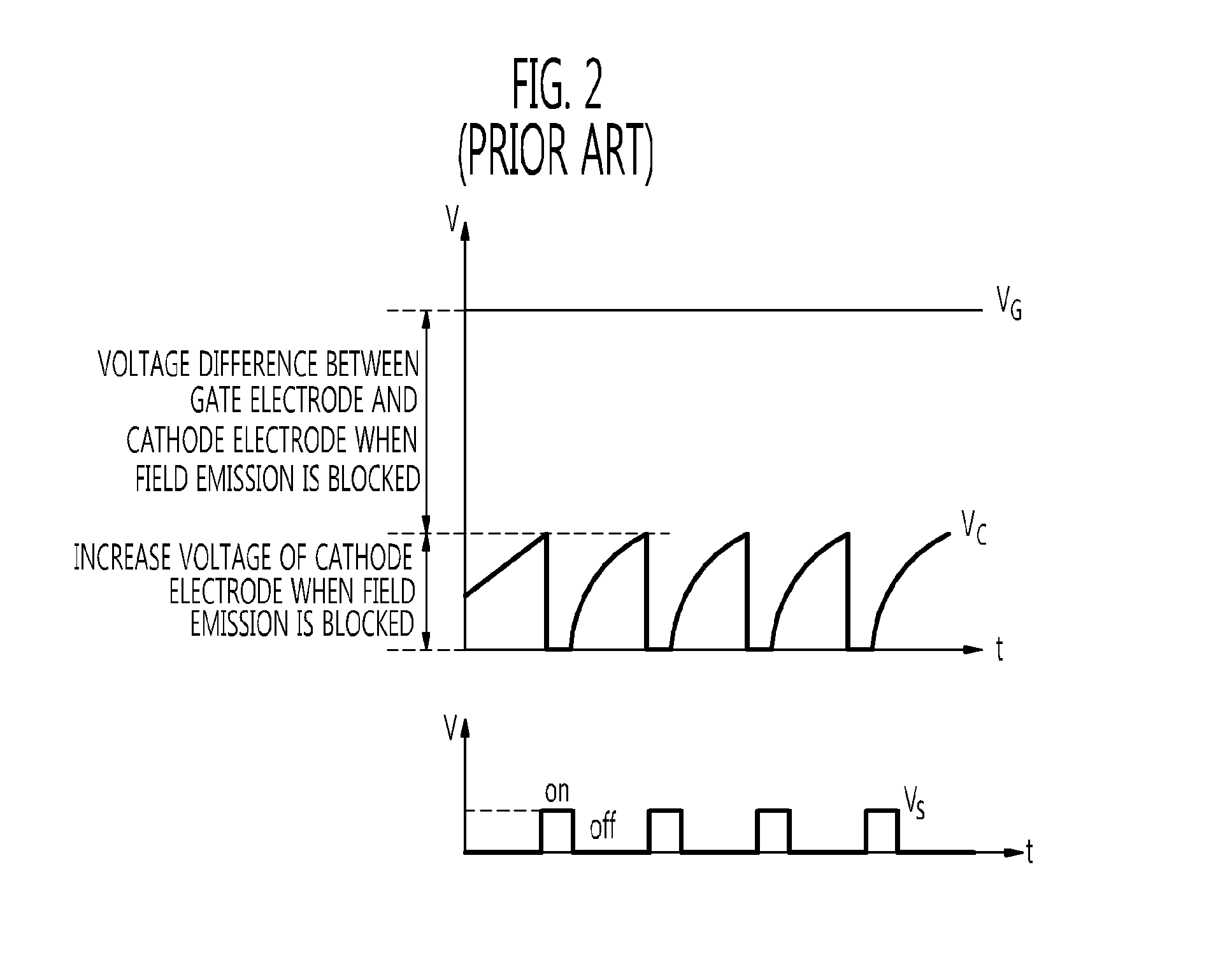

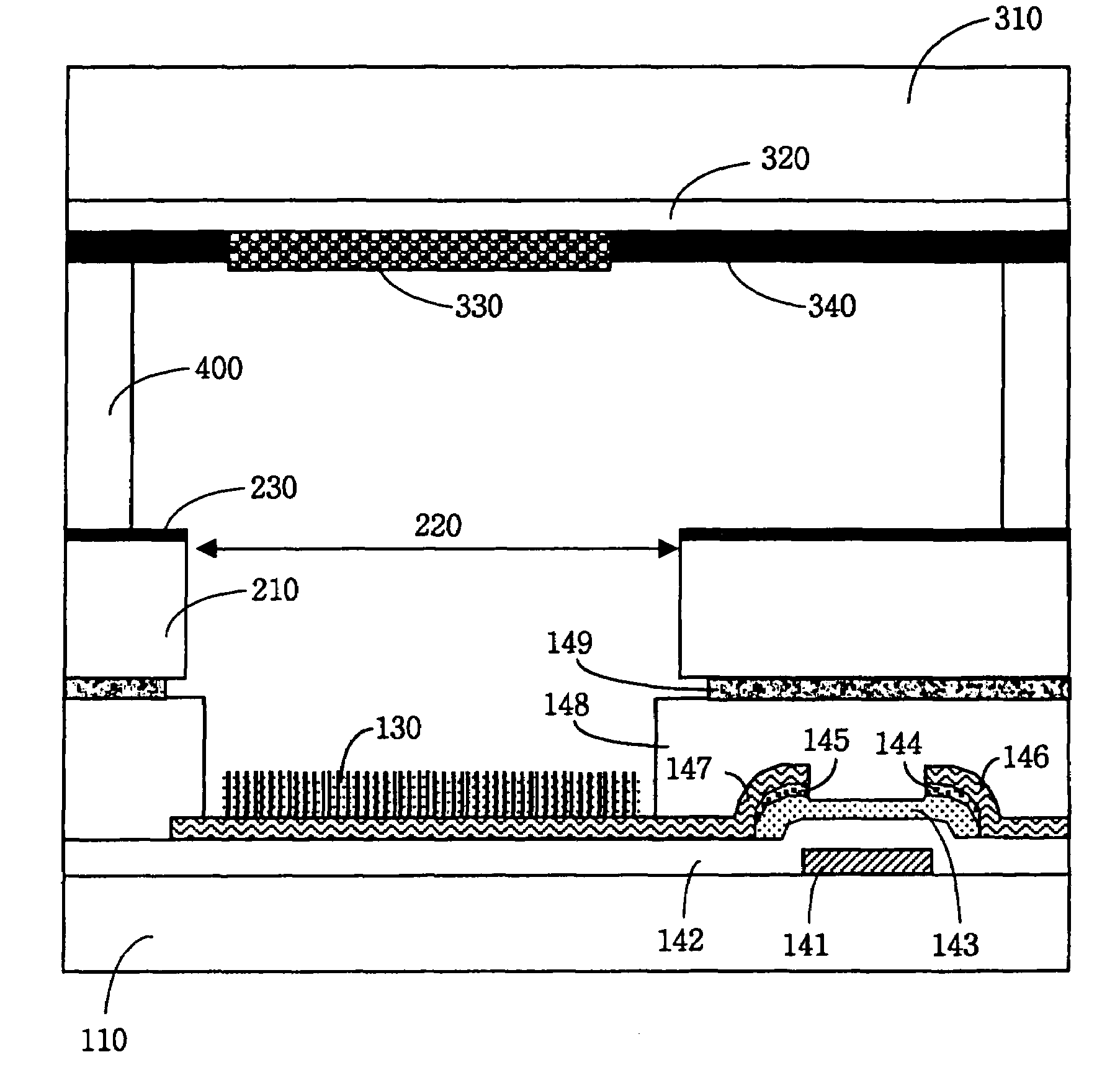

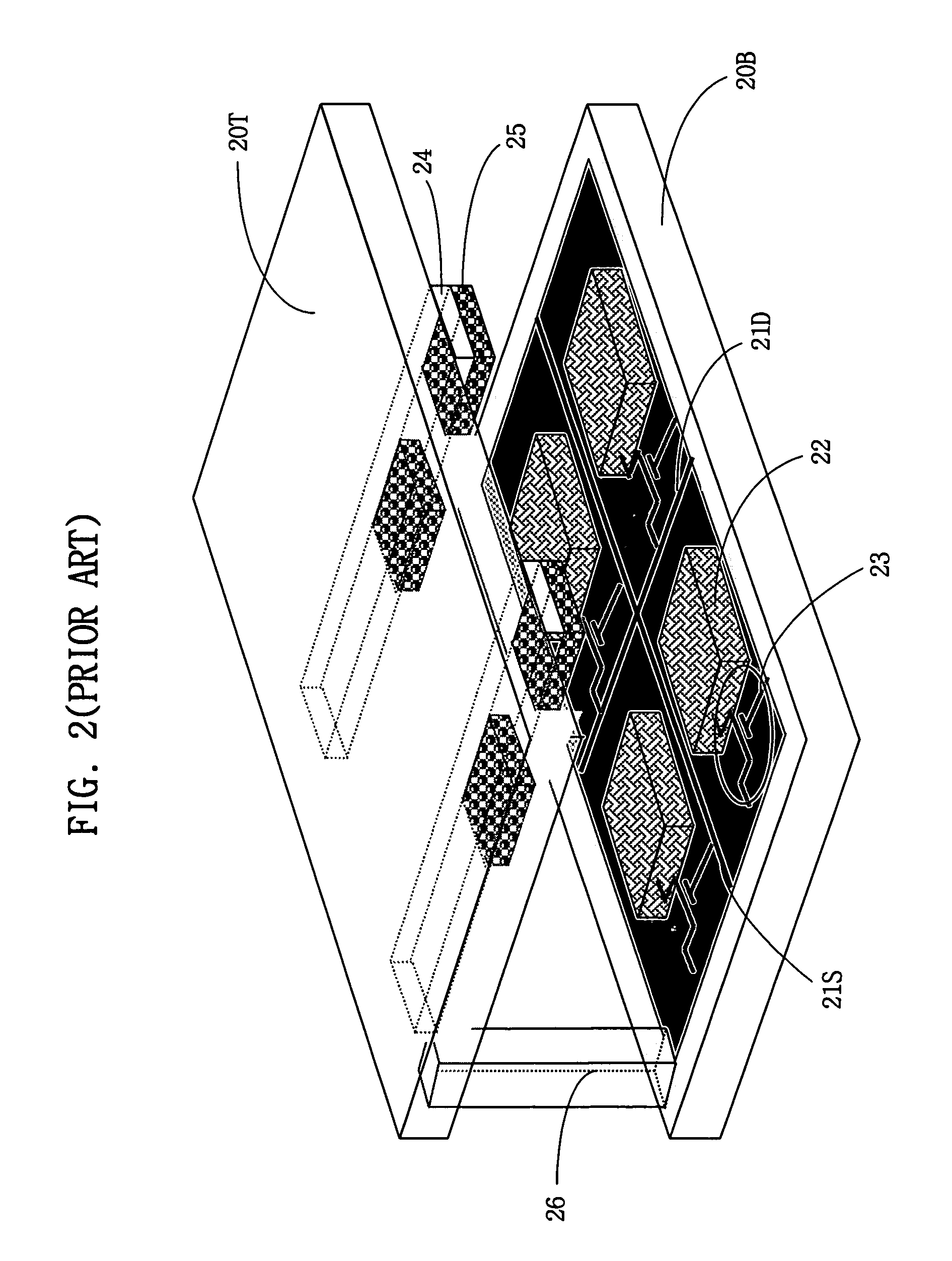

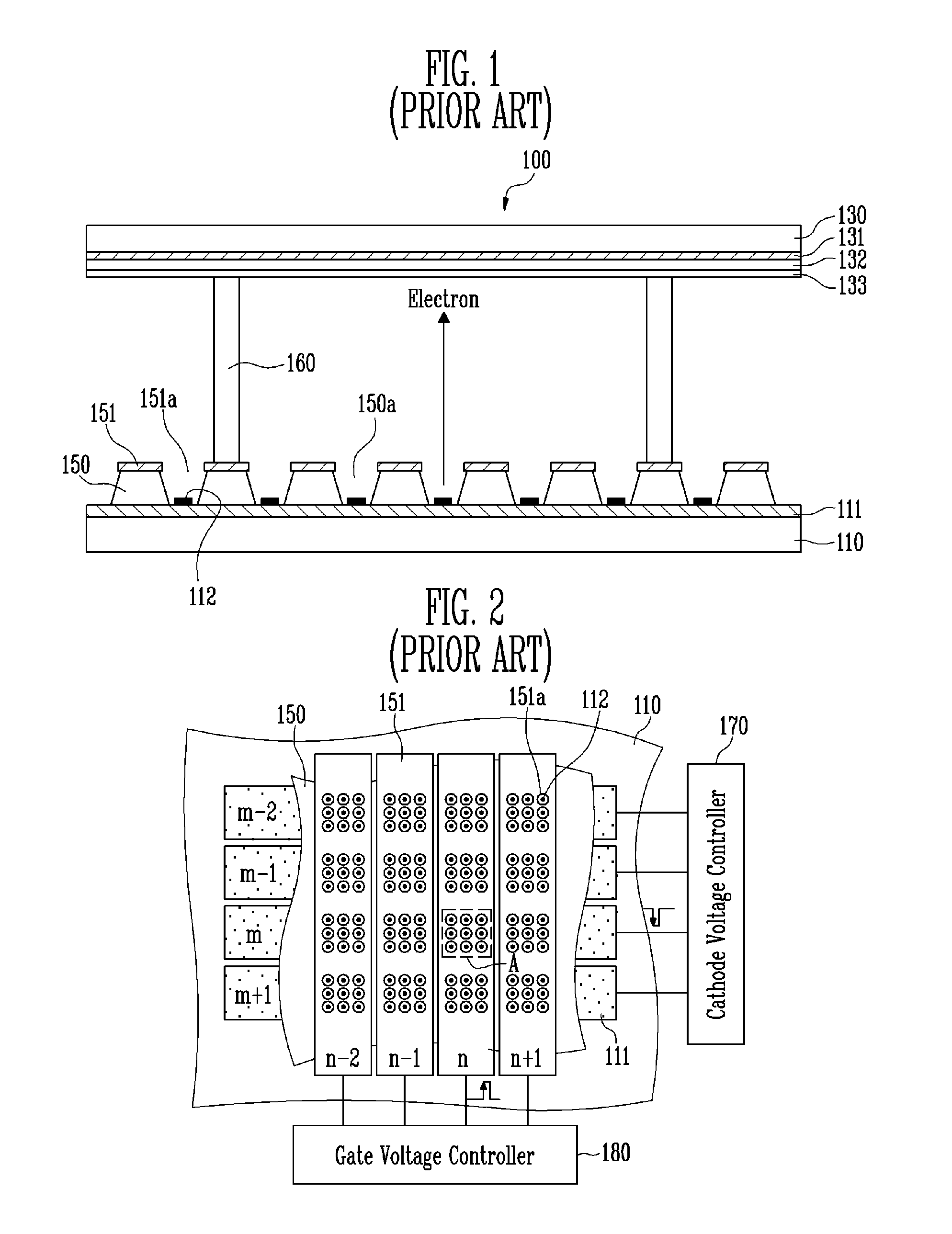

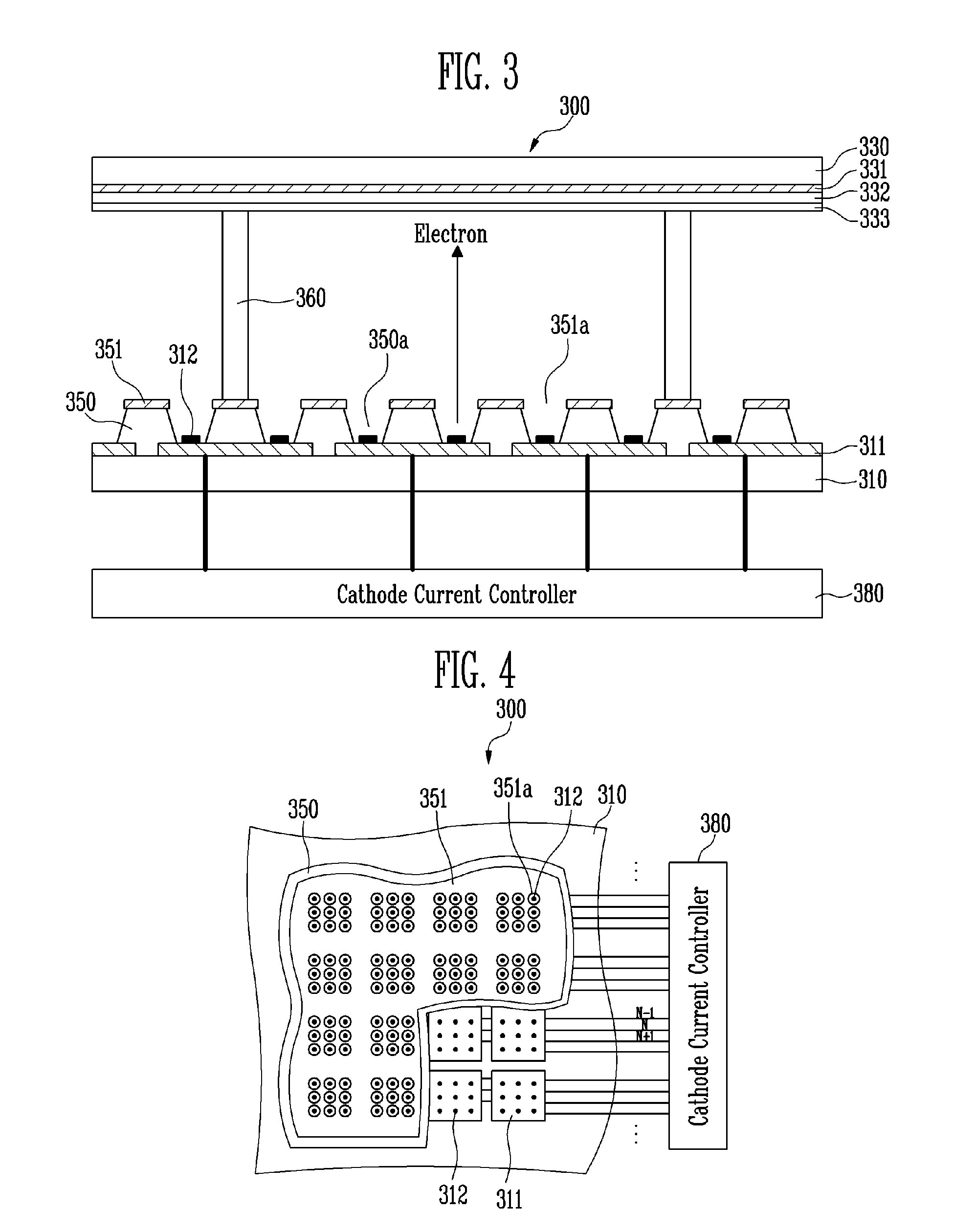

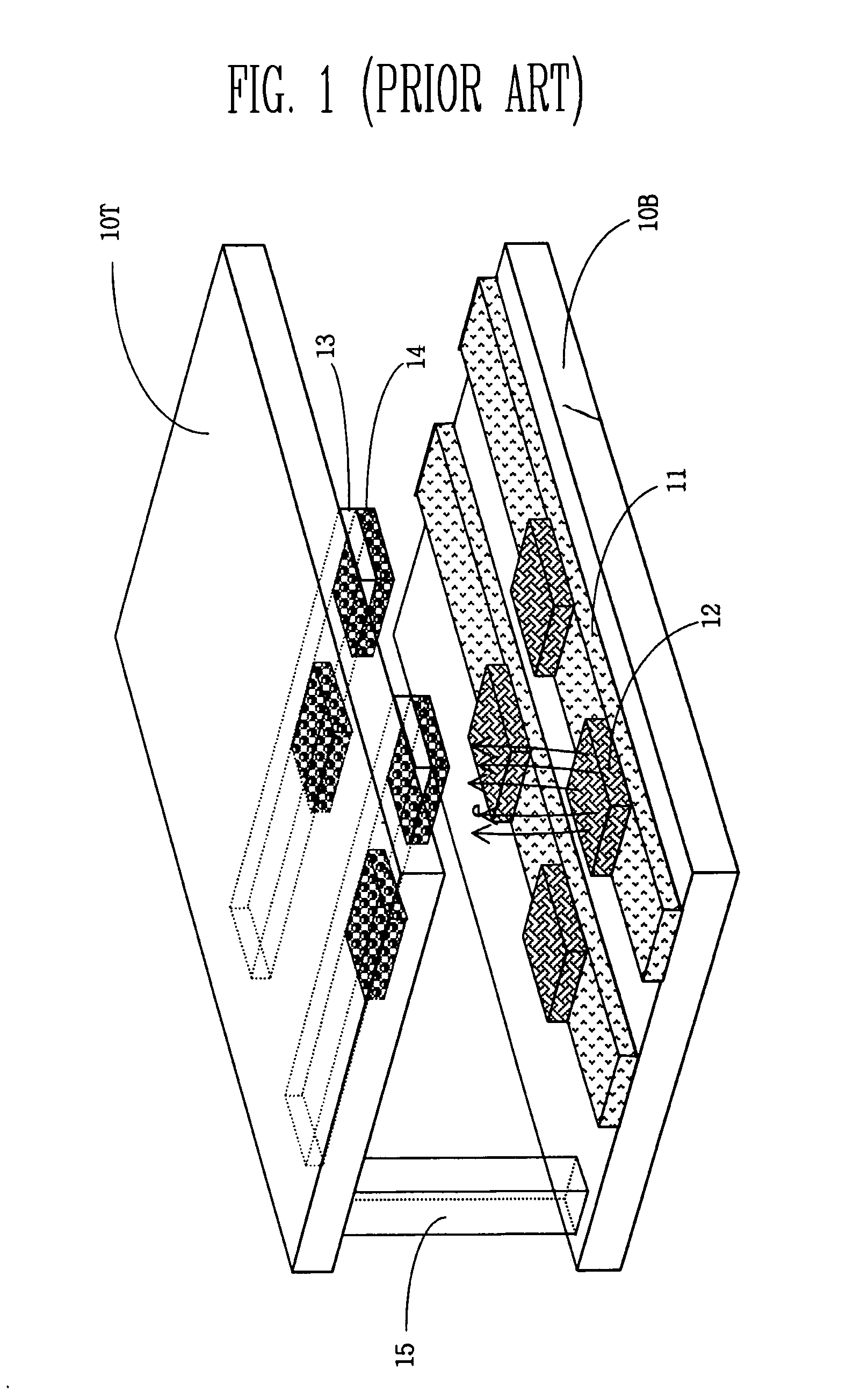

Field emission display

InactiveUS20050127821A1Reducing display row/column driving voltageReduce the driving voltageTransistorDischarge tube luminescnet screensDisplay deviceElectron

Provided is a field emission display in which a gate hole having an inclined inner wall and a gate electrode around the gate hole are formed between an anode plate having a phosphor and a cathode plate having a field emitter and a control device for controlling a field emission current, whereby the voltage applied to the gate electrode of the gate plate serves to prohibit an electron emission of the field emitter by the anode voltage, and prevent a local arching by forming a totally uniform potential, so that the life time of the field emission display can be improved, and the gate hole having the inclined inner wall enables a fabrication of a filed emission display panel having a high brightness without an additional focusing grid.

Owner:ELECTRONICS & TELECOMM RES INST

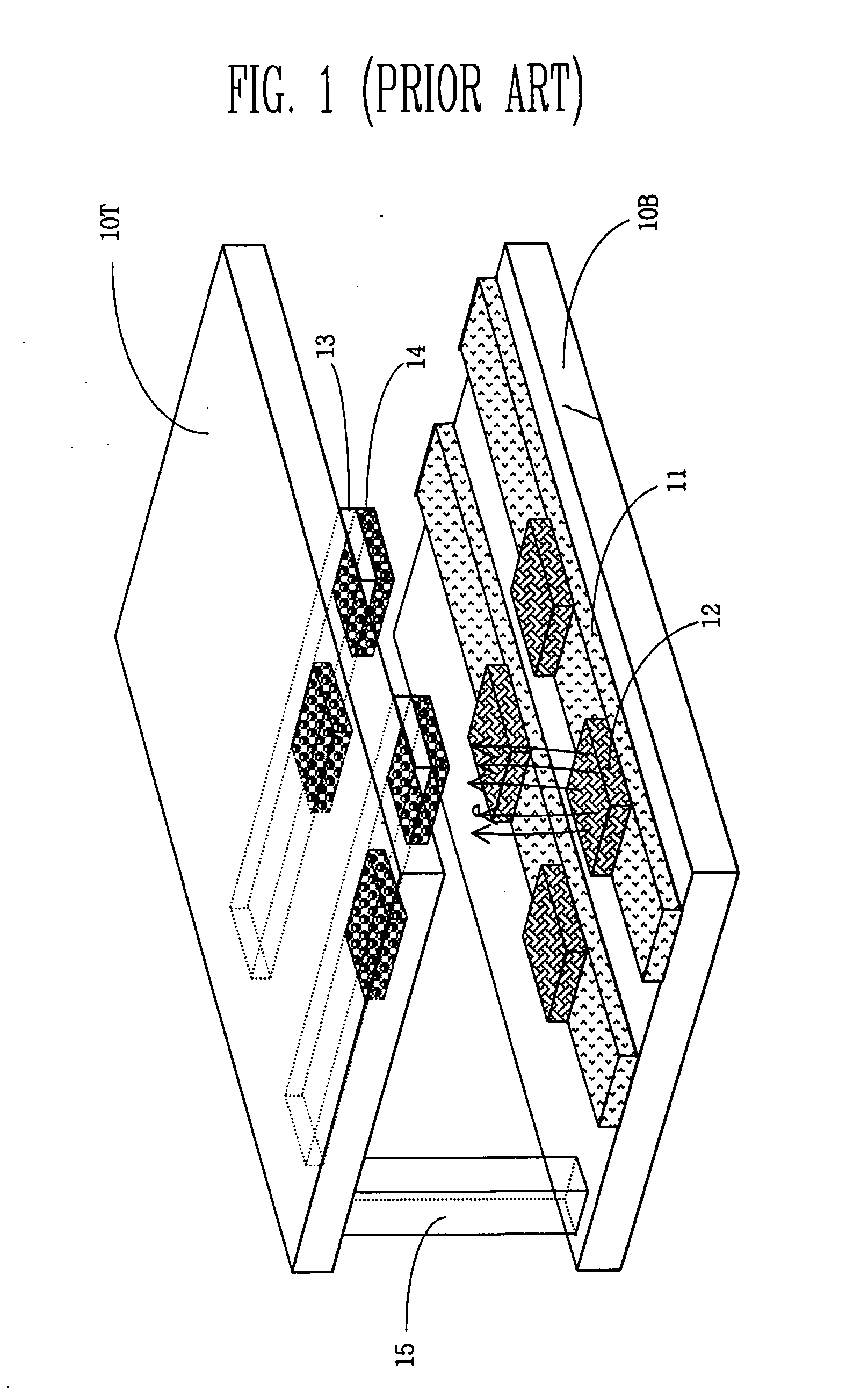

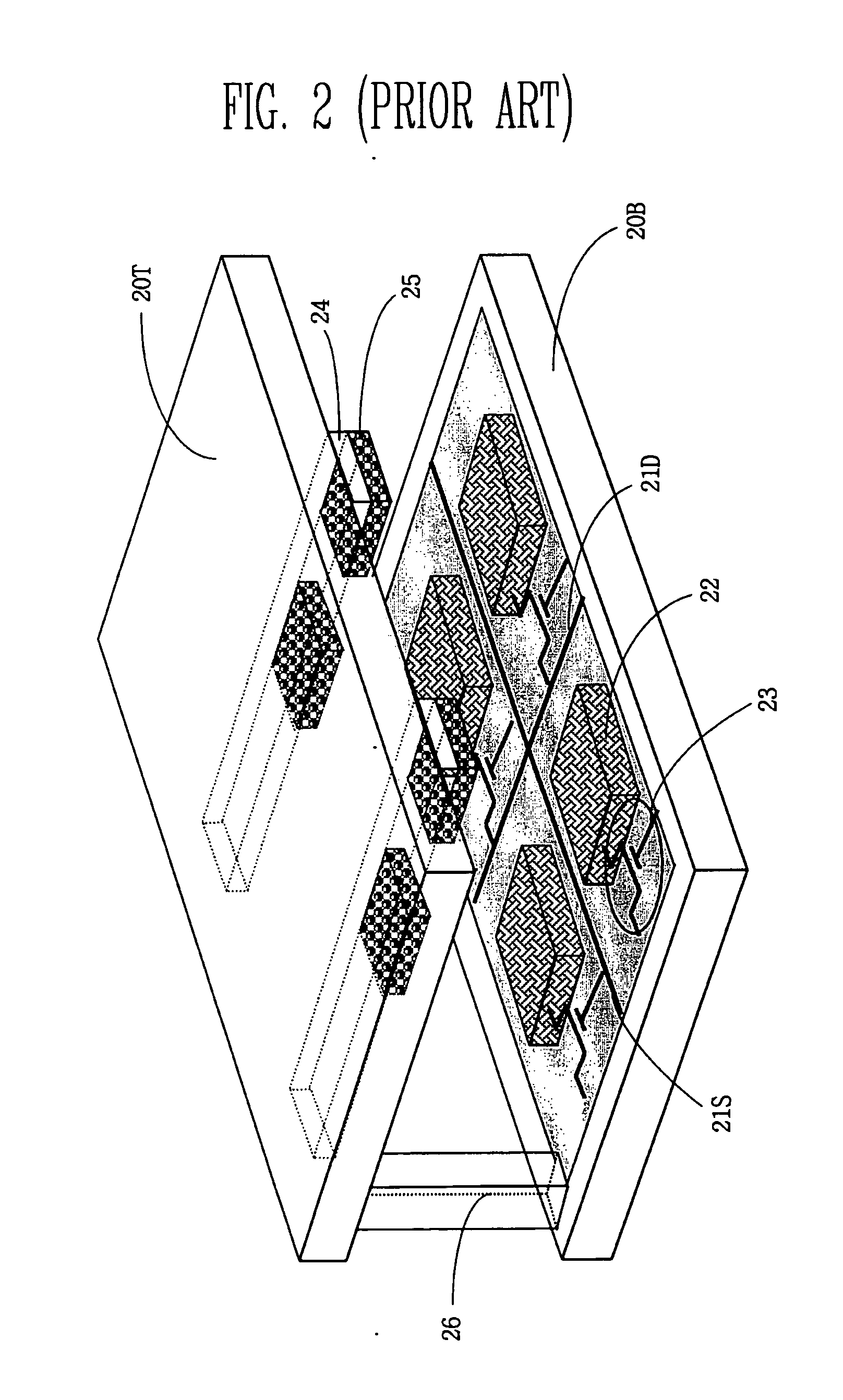

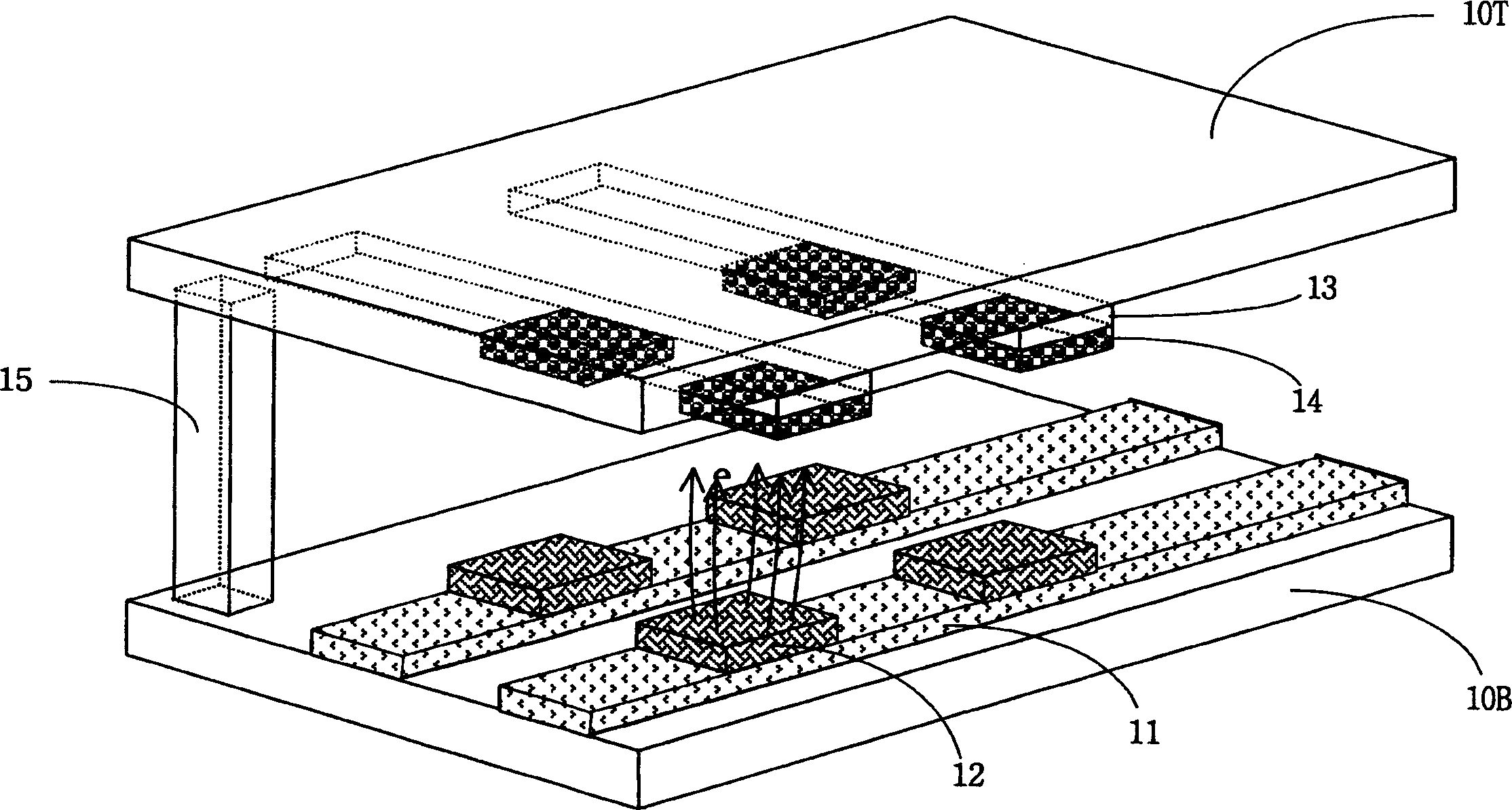

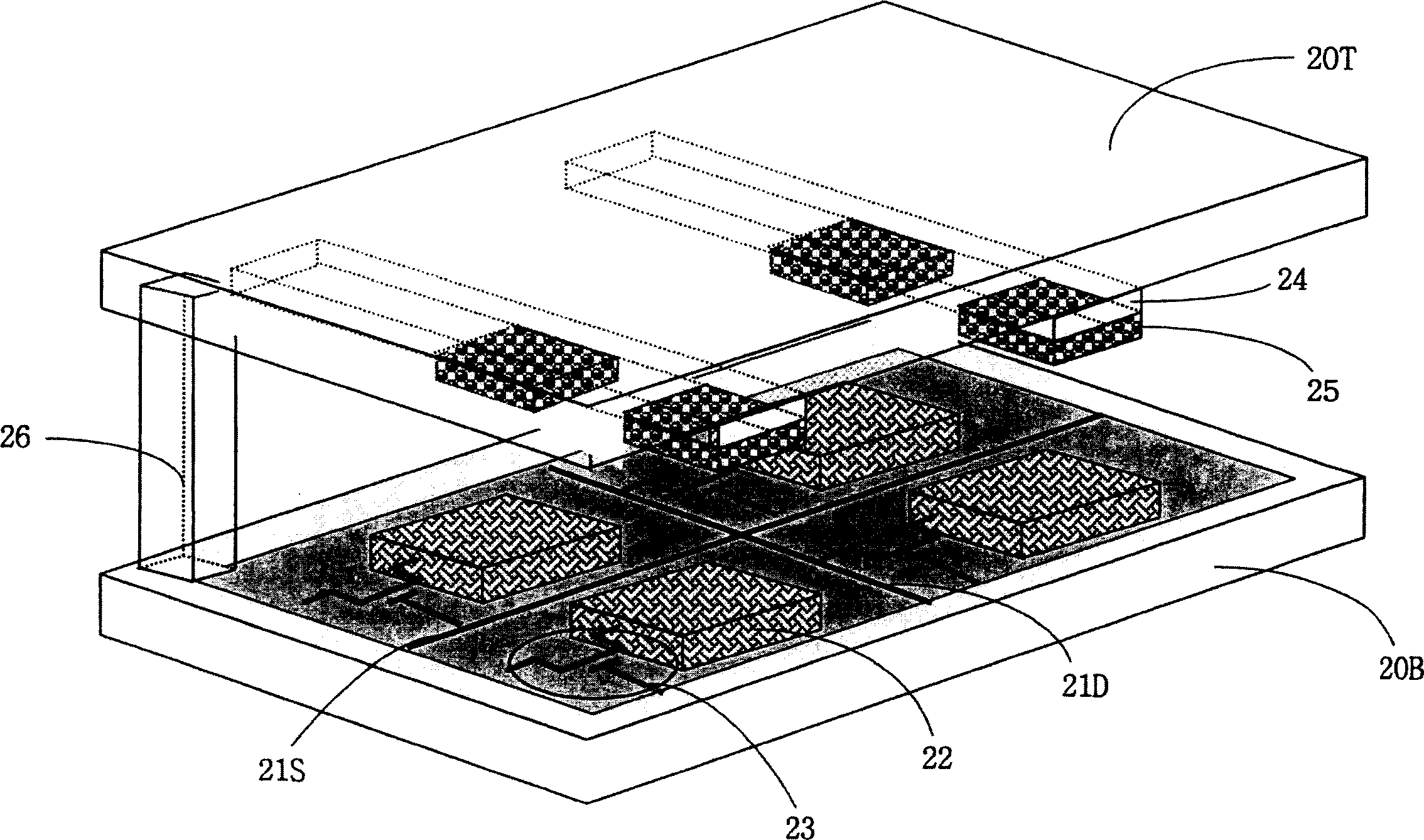

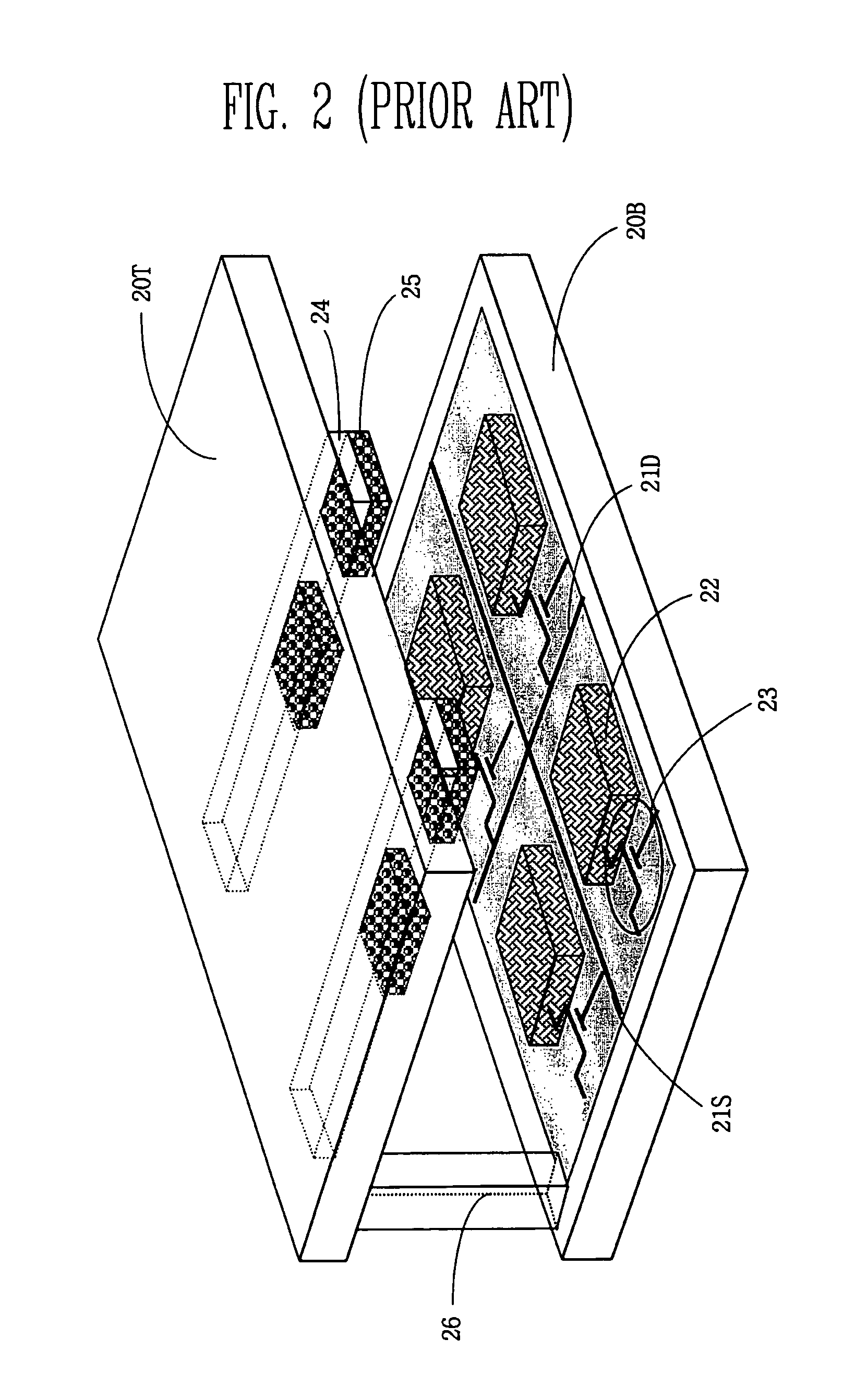

Field-emisson displaing device with grid board

InactiveCN1510713ADischarge tube luminescnet screensCathode-ray/electron-beam tube vessels/containersField emission currentPhosphor

The present invention relates to a field emission display in which a gate plate having a gate hole and a gate electrode around the gate hole is formed between an anode plate having phosphor and a cathode plate having a field emitter and a control device for controlling field emission current, wherein the field emitter of the cathode plate is constructed to be opposite to the phosphor of the anode plate through the gate hole. According to the present invention, it is possible to significantly reduce the display row / column driving voltage by applying scan and data signals of the field emission display to the control device of each pixel, And the present invention is directed to improve the brightness of the field emission display in such a manner that the electric field necessary for field emission is applied through the gate electrode of the gate plate to freely control the distance between the anode plate and the cathode plate, so that a high voltage can be applied to the anode.

Owner:ELECTRONICS & TELECOMM RES INST

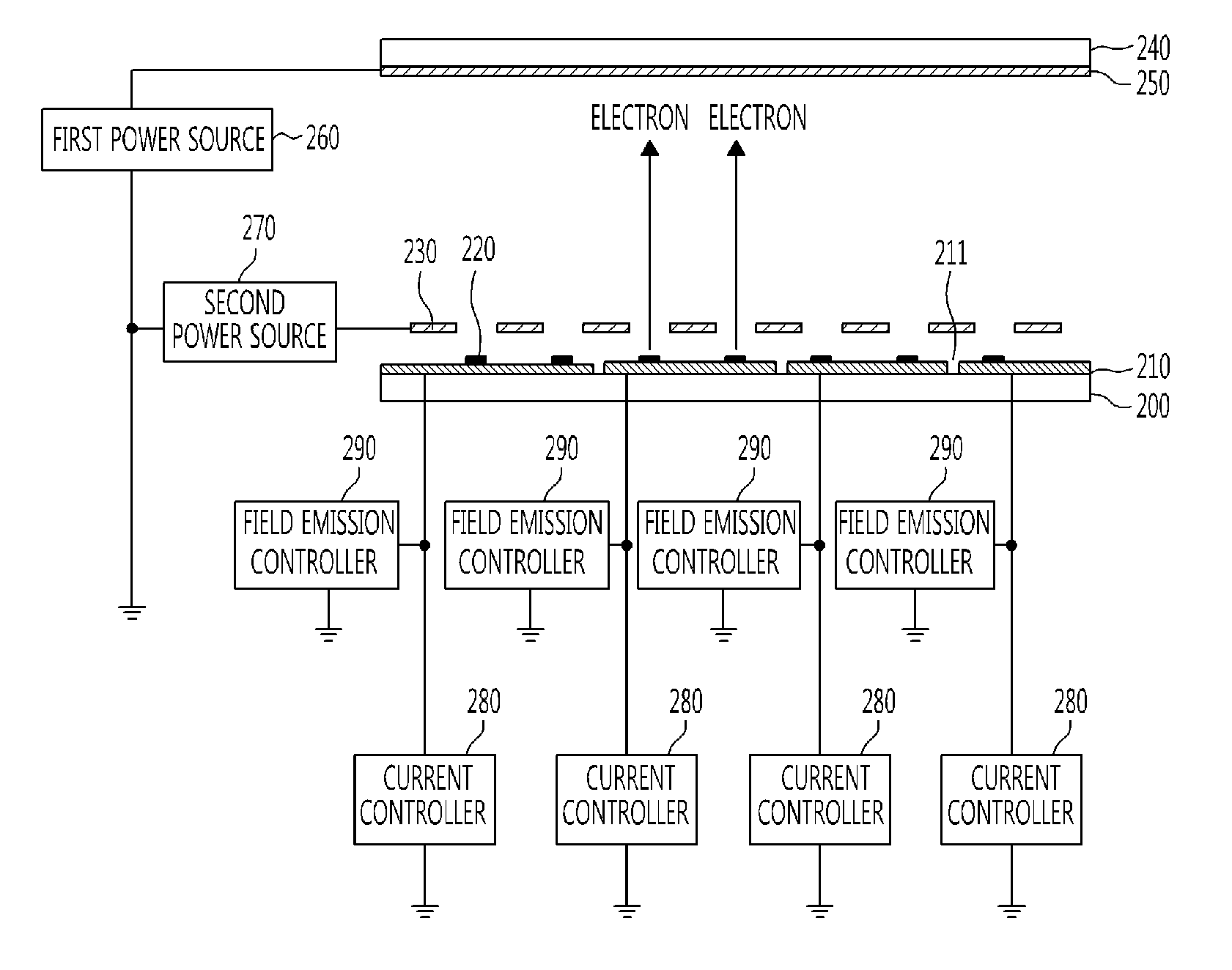

Field emission device and method of operating the same

ActiveUS20110074309A1Electrical apparatusStatic indicating devicesField emission deviceField emission current

Provided are a field emission device enabling rapid pulse operation and a method of operating the same. The field emission device includes a cathode electrode including a field emission source, an anode electrode disposed to face the cathode electrode and accelerating electrons emitted from the field emission source, a current controller controlling field emission current flowing through the cathode electrode, and a field emission controller applying a pull-up voltage to the cathode electrode when the current controller is turned off.

Owner:ELECTRONICS & TELECOMM RES INST

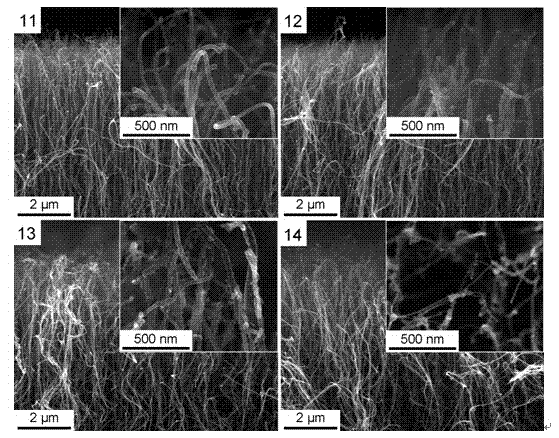

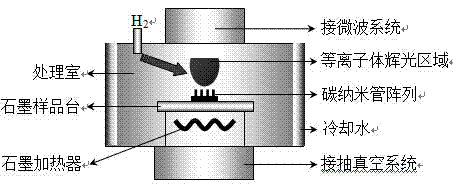

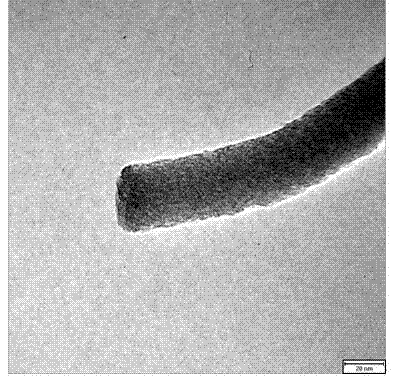

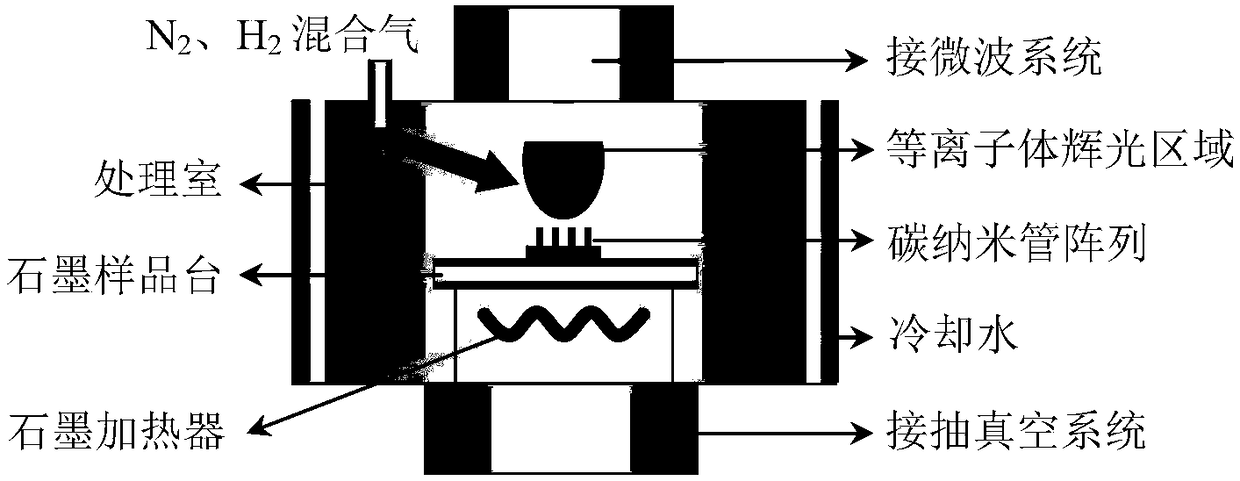

Method for improving field emission performance of carbon nano tube by microwave hydrogen plasma treatment

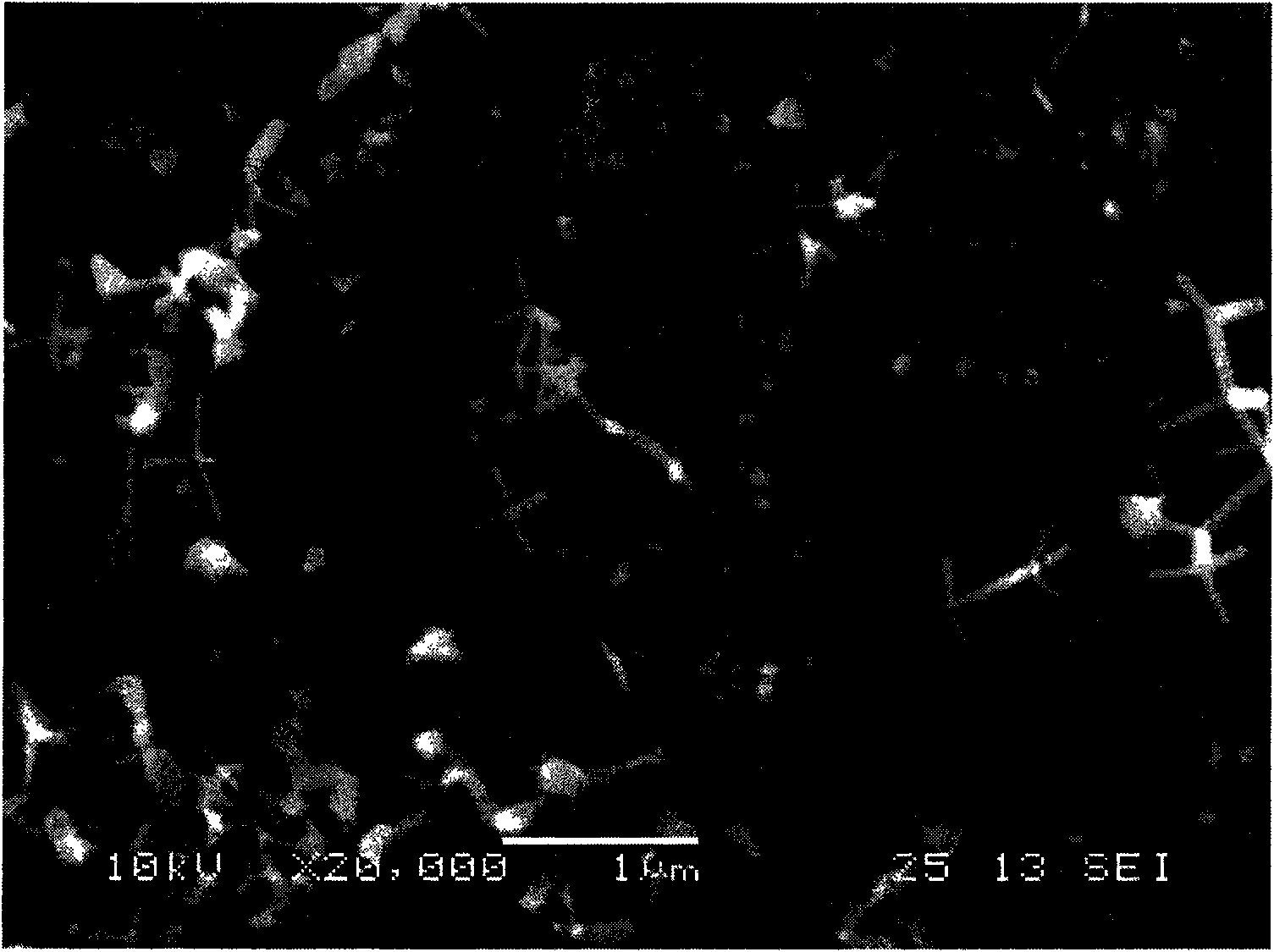

InactiveCN104851765AImprove launch performanceSmall diameterCold cathode manufactureField emission currentHydrogen

The invention discloses a method for improving field emission performance of a carbon nano tube by microwave hydrogen plasma treatment. The method mainly includes the preparation technologies of: performing bombarding pretreatment on a protreated clean silicon wafer with energy-carrying iron ions; using a conventional thermochemical vapor deposition method to prepare a carbon nano tube array on the silicon single crystal wafer; using low-power microwave hydrogen plasma to treat the carbon nano tube array; and performing heat treatment on the obtained carbon nano tube array for 3 hours at a temperature of 1273K, thereby obtaining a carbon nano tube array with improved field emission performance. Surfaces of the carbon nano tubes treated through the method enrich a large number of defects, part of the carbon nano tubes are open at the top and have smaller diameters, and when serving as field emission cathodes, the carbon nano tubes have very low opening fields and threshold fields. Heat treatment of the carbon nano tubes improves bonding of the carbon nano tubes to a substrate, thereby enabling maximum field emission current density to be substantially improved, and the method provided by the invention shows relatively high practical value in the aspect of application of large field emission current density.

Owner:TIANJIN NORMAL UNIVERSITY

Ultrahigh vacuum fast scanning microscopy method based on carbon nanotube probe

InactiveCN102768292AImprove reliabilityReliable scanningScanning probe microscopyIn planeScanning electron microscope

The invention belongs to the field of scanning probe microscopy and relates to an ultrahigh vacuum fast scanning microscopy method based on a carbon nanotube probe, comprising the following steps of: fixing a nanotube probe at the end of a probe of a scanning tunneling microscope; calibrating the field emission current sensitivity curve family of the carbon nanotube probe in the Z direction; fixing the carbon nanotube probe in a probe clamp and adjusting the carbon nanotube probe in a vacuum state required by scanning; enabling the carbon nanotube probe to enter a tunneling state under a constant current mode; keeping a piezoelectric ceramic scanner stationary in the Z direction; setting a scanning range, scanning velocity and sampling point parameters, recording the field emission current i of the carbon nanotube probe one point after another, and carrying out quick imaging scanning of a sample to be detected under a constant height mode. The ultrahigh vacuum fast scanning microscopy method based on the carbon nanotube probe is high in reliability and speed and capable of improving the in-plane resolution of scanning imaging.

Owner:TIANJIN UNIV

Field emission display having gate plate

ActiveUS7309954B2Reduce display row/column driving voltageReduce the driving voltageControl electrodesDischarge tube luminescnet screensField emission currentPhosphor

The present invention relates to a field emission display in which a gate plate having a gate hole and a gate electrode around the gate hole is formed between an anode plate having phosphor and a cathode plate having a field emitter and a control device for controlling field emission current, wherein the field emitter of the cathode plate is constructed to be opposite to the phosphor of the anode plate through the gate hole.According to the present invention, it is possible to significantly reduce the display row / column driving voltage by applying scan and data signals of the field emission display to the control device of each pixel, And the present invention is directed to improve the brightness of the field emission display in such a manner that the electric field necessary for field emission is applied through the gate electrode of the gate plate to freely control the distance between the anode plate and the cathode plate, so that a high voltage can be applied to the anode.

Owner:ELECTRONICS & TELECOMM RES INST

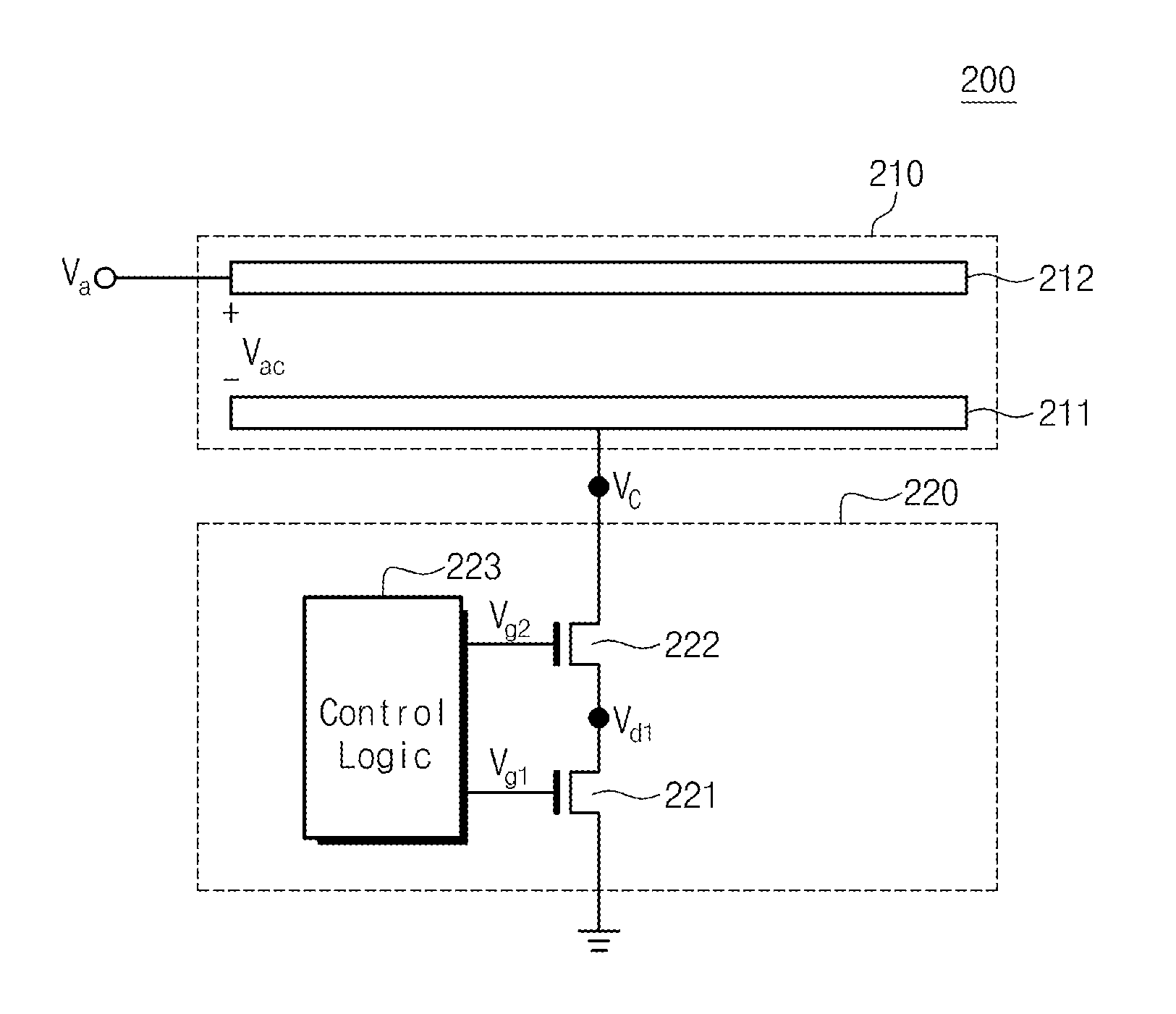

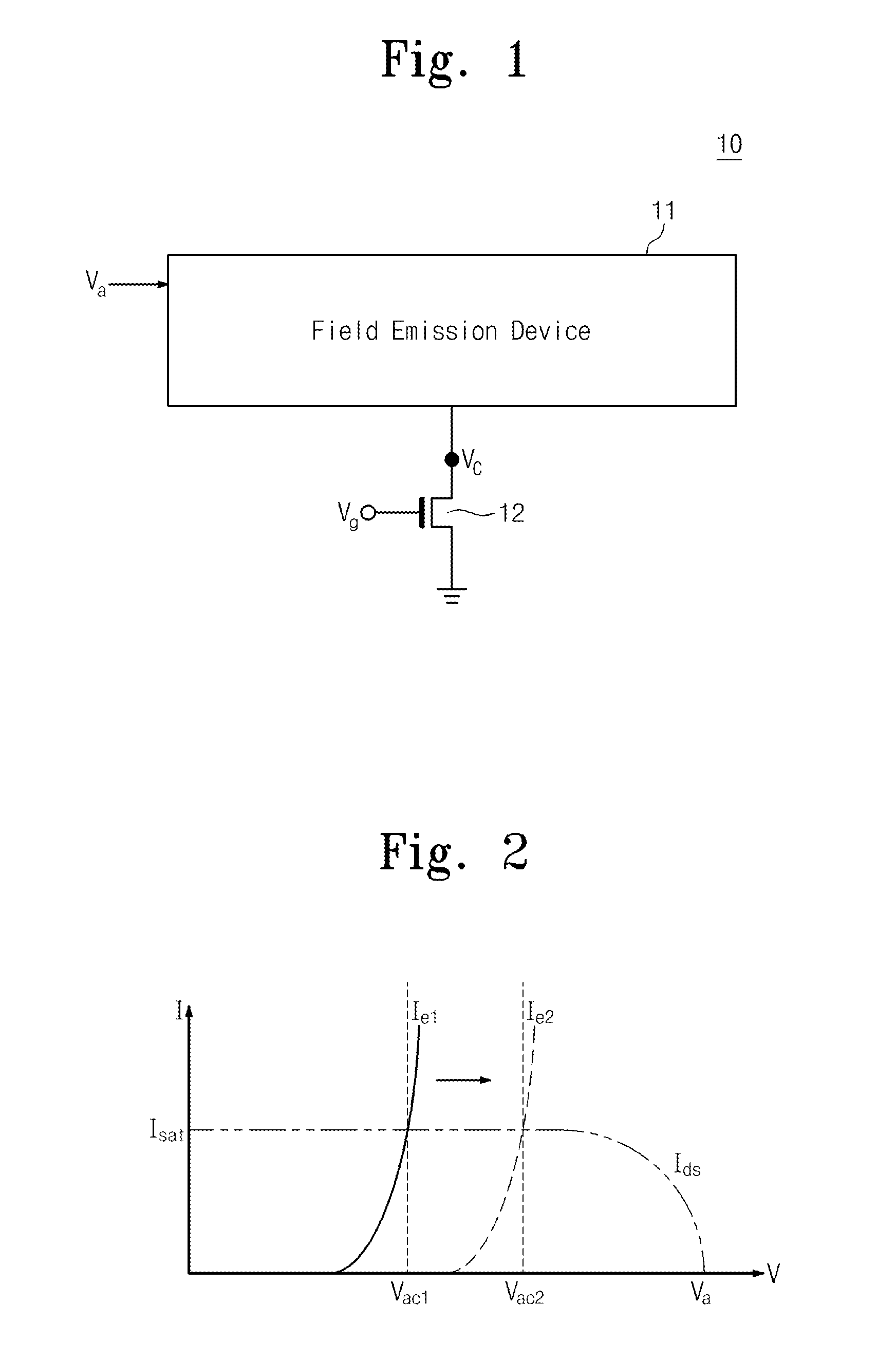

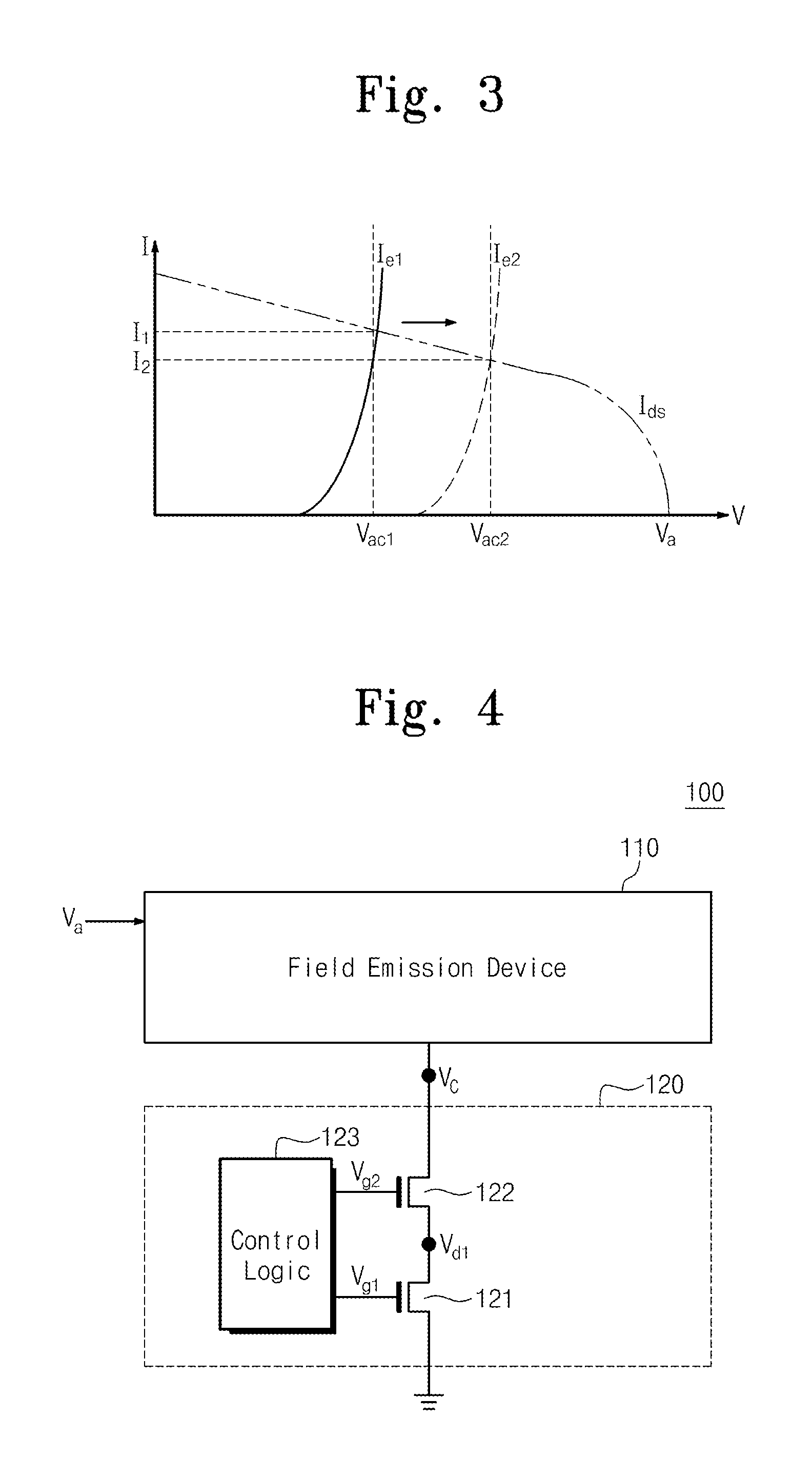

Current controlling device and electric field emission system including the same

ActiveUS20130271037A1Electrical apparatusElectric light circuit arrangementField emission deviceField emission current

Provided is a current controlling device for controlling an electric field emission current in connection with an electric field emission device which emits electrons in response to an applied voltage, the device including: a first current controlling transistor forming a current path in response to a first gate voltage; a second current controlling transistor connected between the field emission device and the first current controlling transistor and forming a current path in response to a second gate voltage; and a control logic controlling the first and second gate voltages, wherein the control logic controls a upper limit of the field emission current by using the first gate voltage.

Owner:ELECTRONICS & TELECOMM RES INST

X-ray apparatus with field emission current stabilization and method of providing x-ray radiation therapy

Owner:MINNESOTA MEDICAL PHYSICS LLC

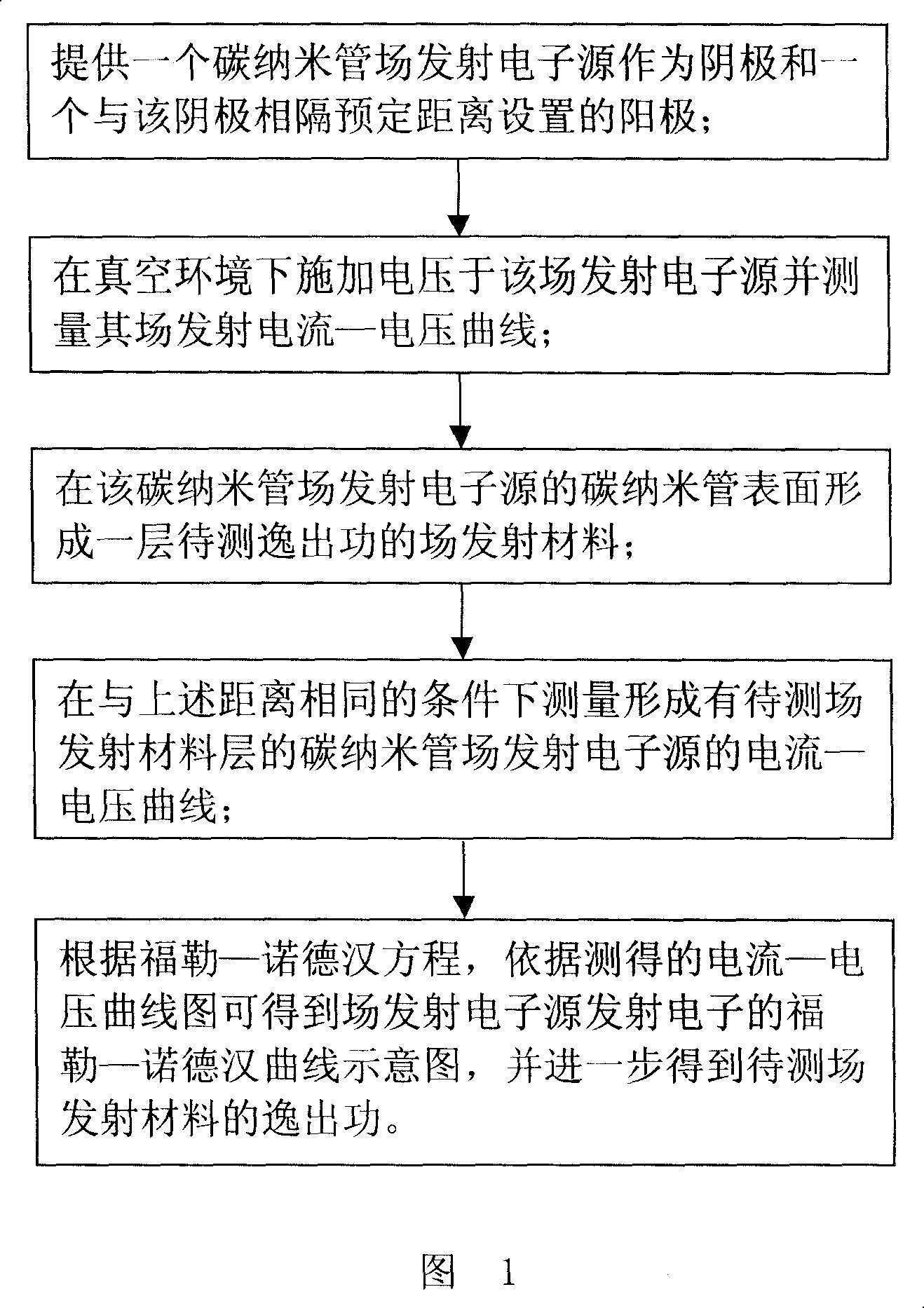

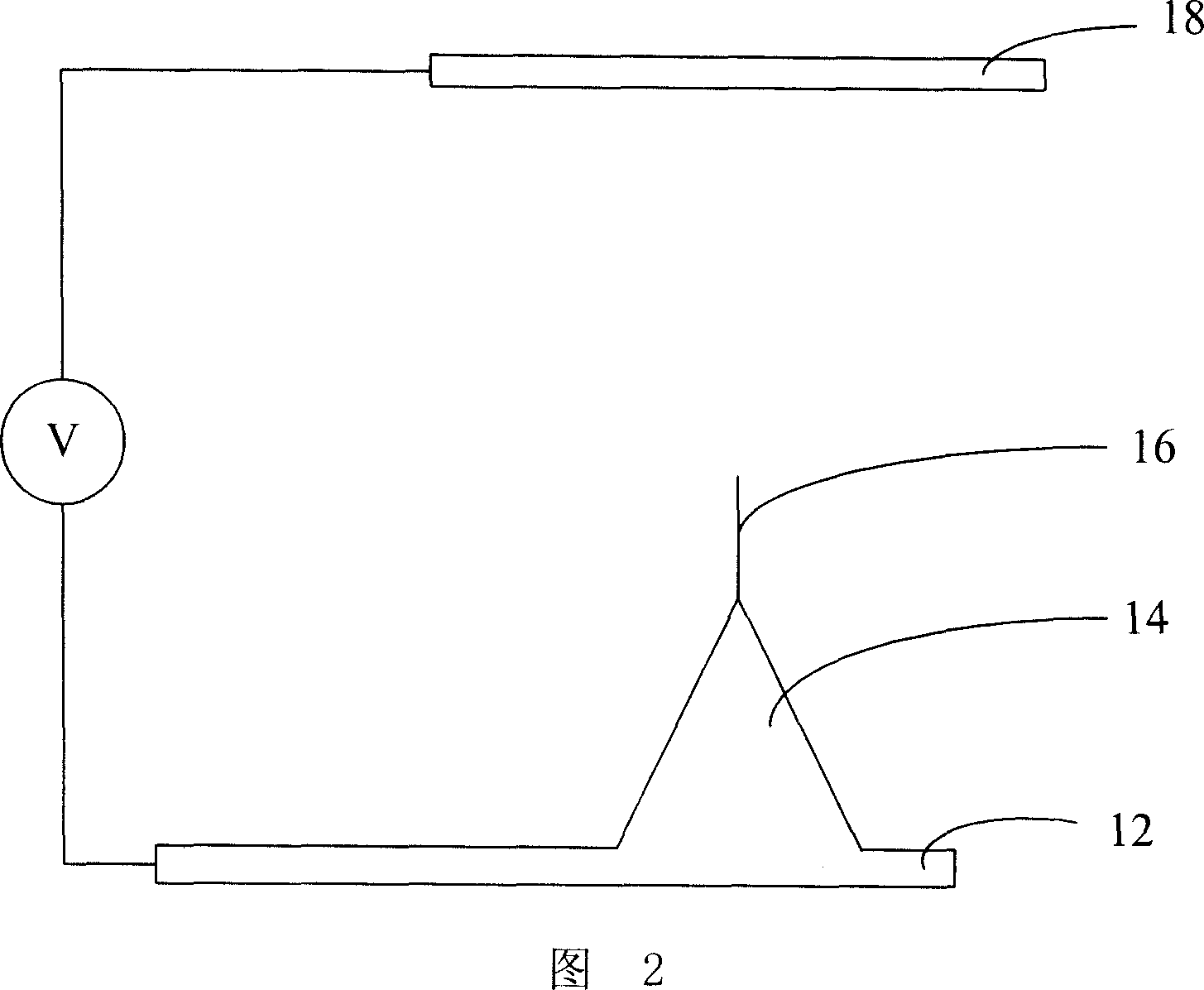

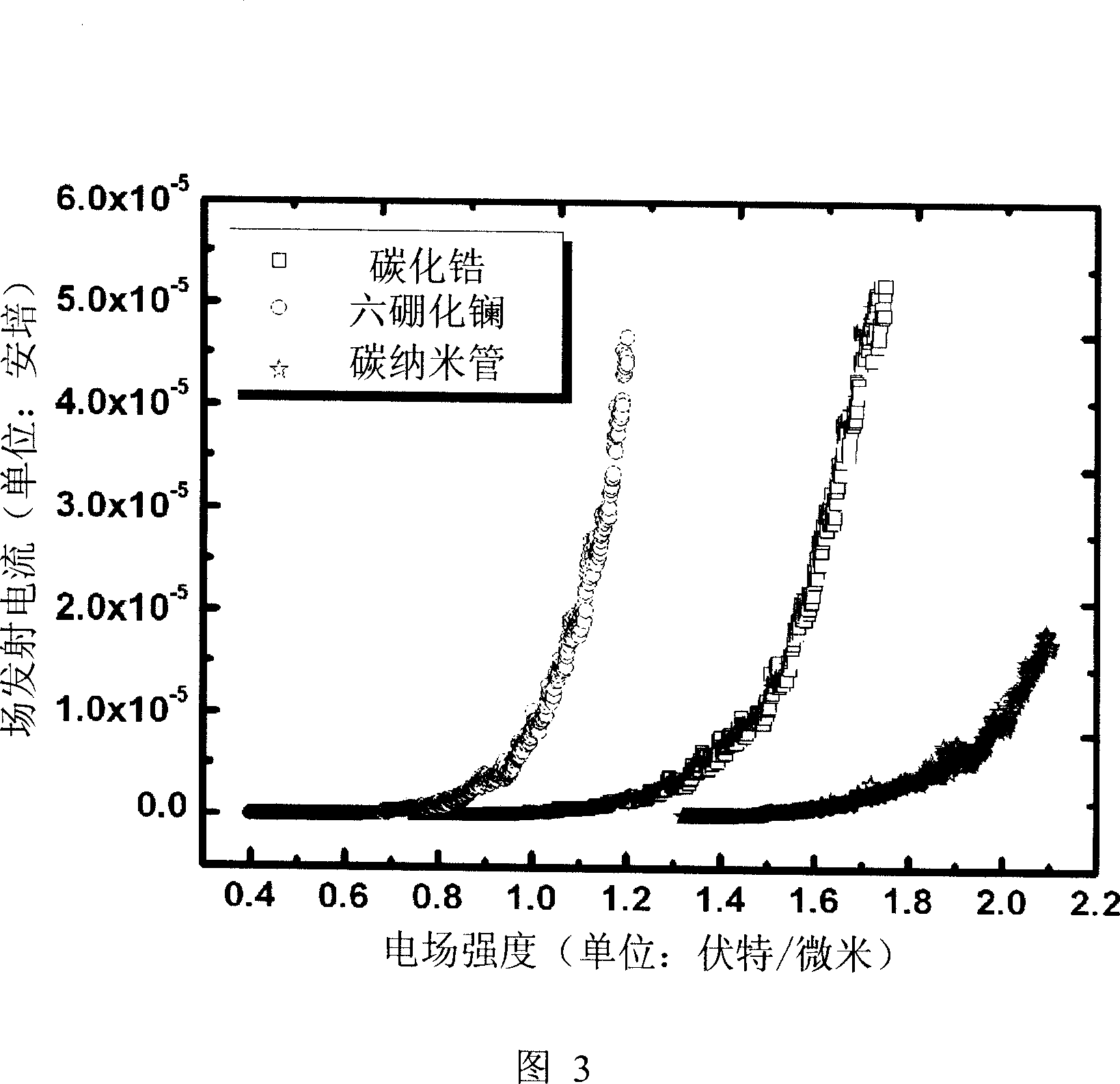

Work function measuring method

ActiveCN101105488AImprove conductivityAccurate measurementMaterial analysis using wave/particle radiationMaterial work function voltageElectron sourceField emission current

The invention relates to a measuring method of work function which comprises the following steps: a carbon nanometer tube field eradiation electron source is a cathode, and an anode is provided in the preset distance to the cathode; voltage is exerted in the field eradiation electron source in the vacuum environment, and the field eradiation current-voltage curve is measured; one layer of field eradiation material of measured working function is formed on the surface of the carbon nanometer tube of the carbon nanometer tube field eradiation electron source; under the same condition of the same distance, the current-voltage curve of the carbon nanometer tube field eradiation electron source of the measured field eradiation material is measured; according to the Fowler-Nordheim equation and the current-voltage curve diagram which is measured, the Fowler-Nordheim curve sketch diagram of electron eradiated from the field eradiation electron source can be measured; furthermore, the working function of the measured eradiation material can be measured.

Owner:TSINGHUA UNIV

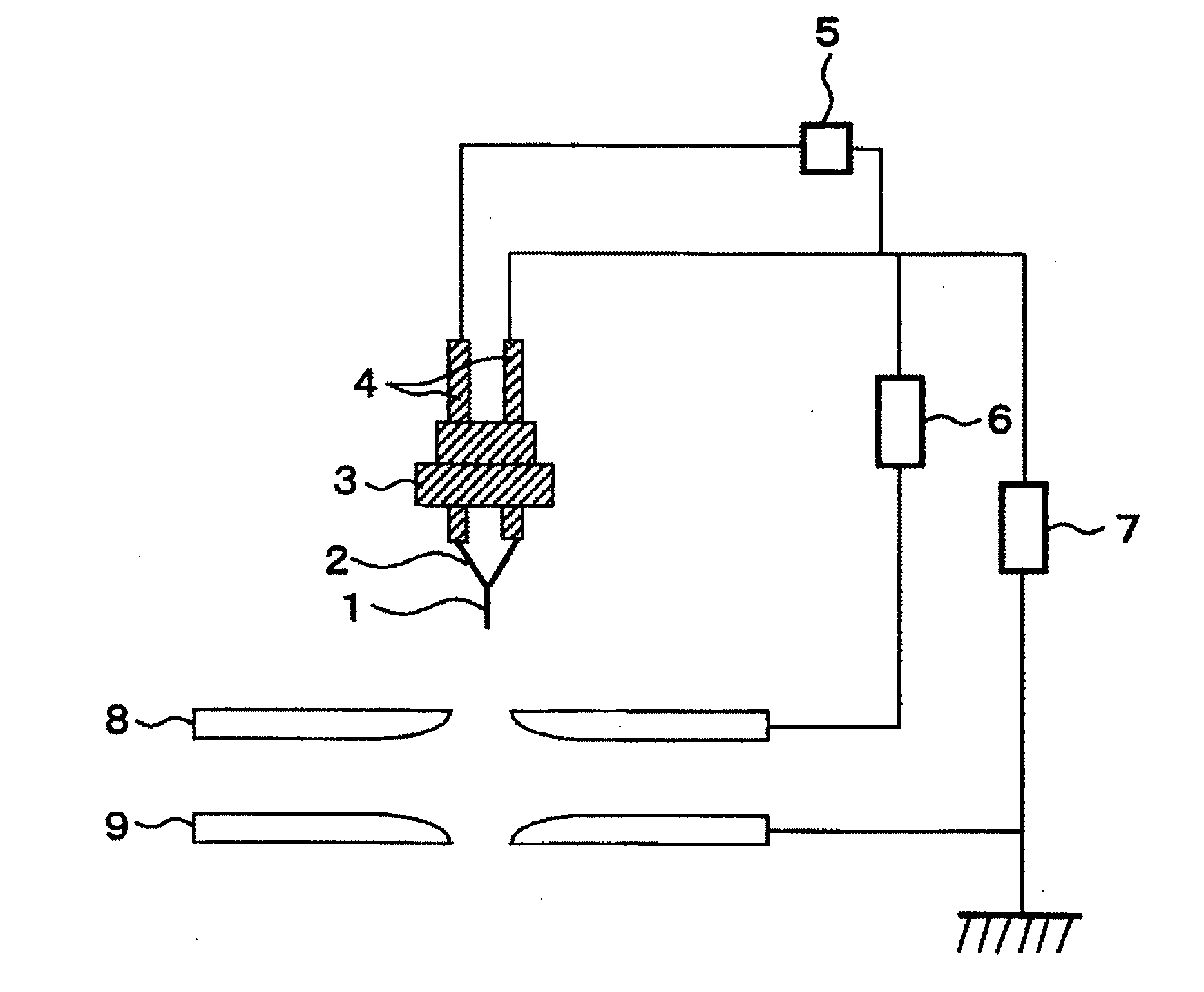

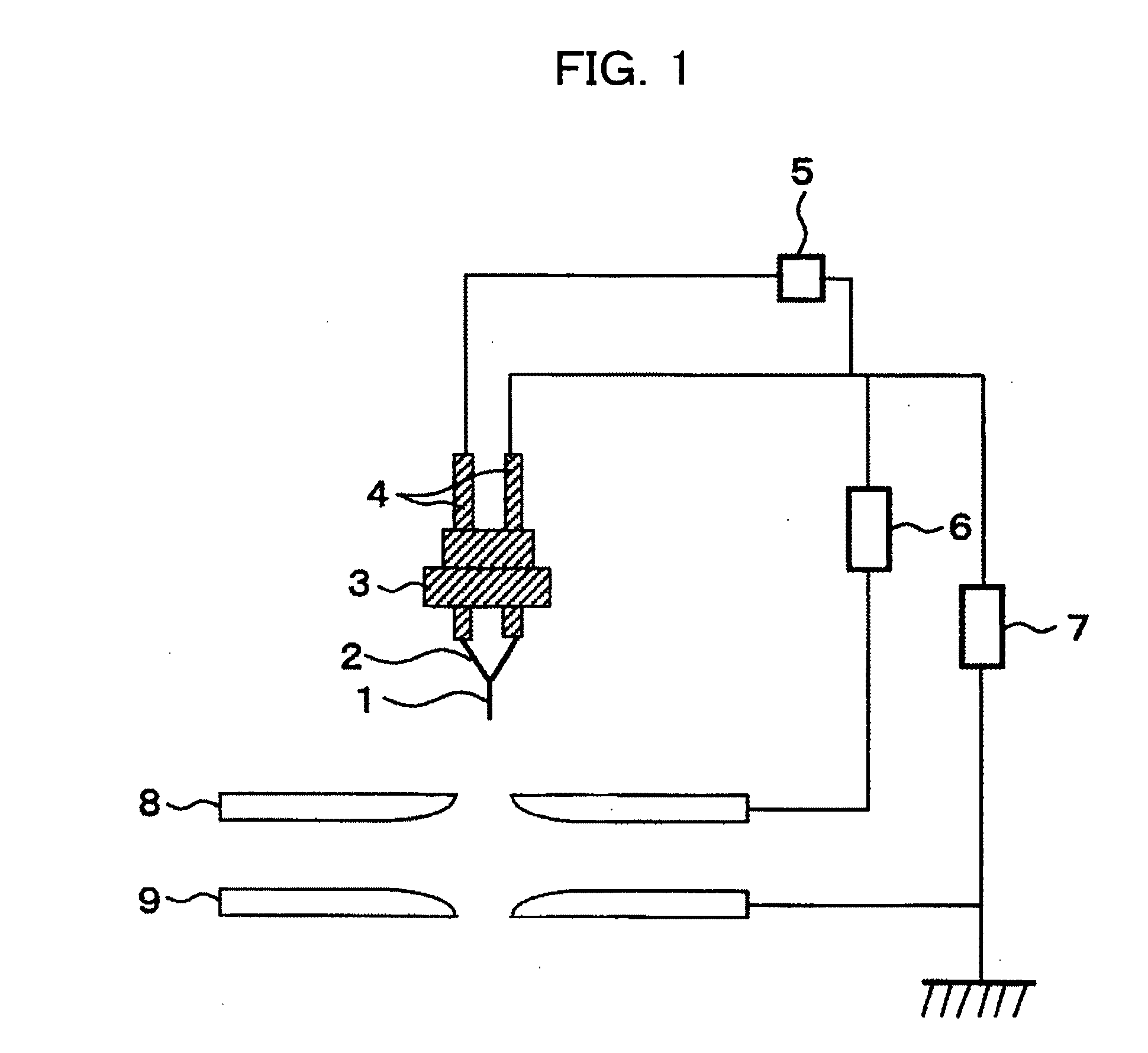

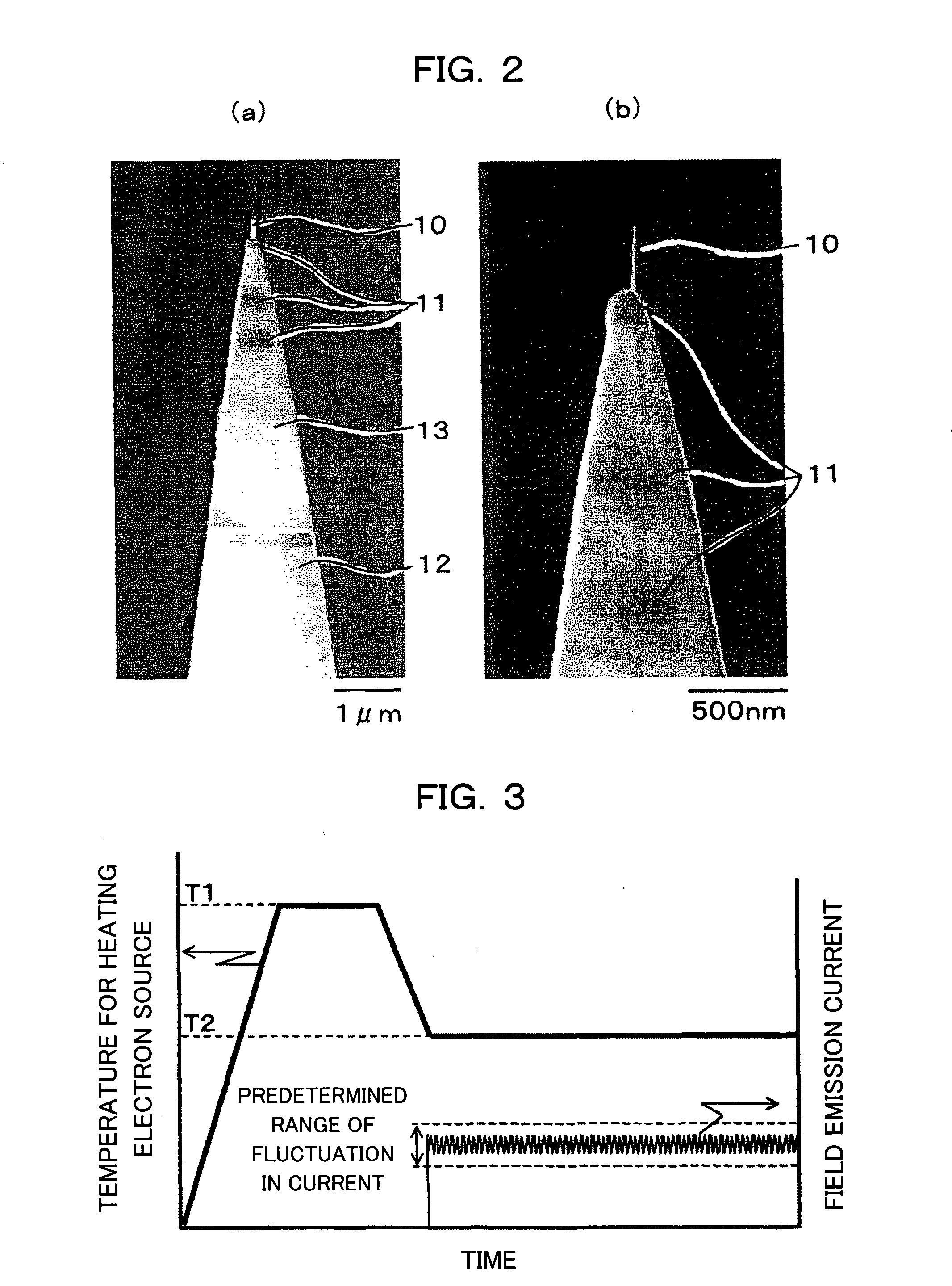

Field emission electron gun and method of operating the same

InactiveUS20080169743A1Stable field emission currentLong period of timeElectric discharge tubesDischarge tube main electrodesField emission currentElectron source

The present invention provides a field emission electron gun and its operating method. The field emission electron gun includes: an electron source including a fibrous carbon substance and a conductive base material for supporting the substance; a drawer device for causing electrons to be emitted by field emission; an accelerator for accelerating the electrons; and a means for heating the electron source. In the electron gun, the electron source is heated and held at the heating temperature before field emission, and thereafter the lowest heating temperature causing a range of fluctuation in the field emission current to fall within a predetermined value is adjusted when needed. By employing the electron gun and its operating method of the present invention, provided are various electron beam applied apparatuses each capable of continuously operating for a long time while being low in noise and high in resolution.

Owner:HITACHI HIGH-TECH CORP

Manufacturing method for nano rare earth tungsten electrode

InactiveCN106964783AIncrease current densityIncrease migration rateTransportation and packagingMetal-working apparatusHigh energyAmmonium paratungstate

The invention discloses a manufacturing method for a nano rare earth tungsten electrode. The manufacturing method comprises the following steps: step 1, weighing components in percentage by mass of 0.1%-0.37% of lanthanum nitrate, 2.33%-5.6% of yttrium nitrate, 0.35%-1.05% of cerous nitrate and 92.25%-96.5% of ammonium paratungstate; step 2, conducting reduction at high temperature under the protection of hydrogen to obtain rare earth composite tungsten dioxide powder; step 3, adding the rare earth composite tungsten dioxide powder into a high-energy ball mill, and performing grinding so as to obtain nano rare earth tungsten alloy powder with the powder grain size of 30nm-40nm; step 4, pressing the nano rare earth tungsten alloy powder into a nano rare earth tungsten alloy billet bar in an isostatic pressing machine; step 5, sintering the nano rare earth tungsten alloy billet bar in a medium-frequency induction furnace until a nano rare earth tungsten alloy bar with the density of more than 18.3kg / m<3> is obtained; and step 6, performing high-temperature rotary swaging cogging and stretching on the nano rare earth tungsten alloy bar so as to obtain a nano rare earth tungsten electrode. According to the manufacturing method for the nano rare earth tungsten electrode disclosed by the invention, the zero-field emission electric current density of a tungsten electrode is increased, the fare damage rate is reduced, and the service life of the tungsten electrode is prolonged.

Owner:HESHAN WODE TUNGSTEN & MOLYBDENUM

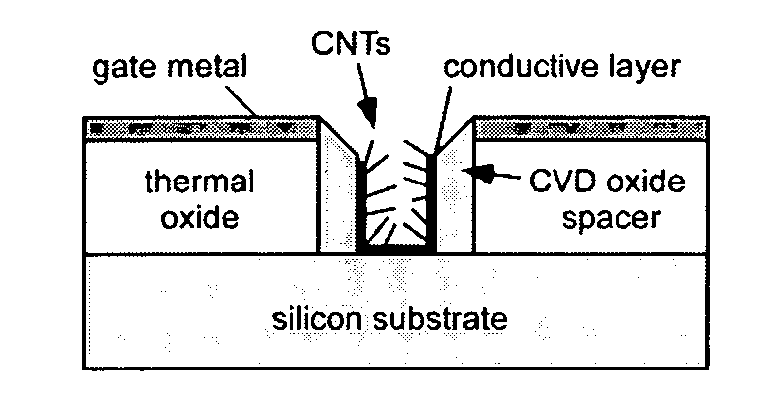

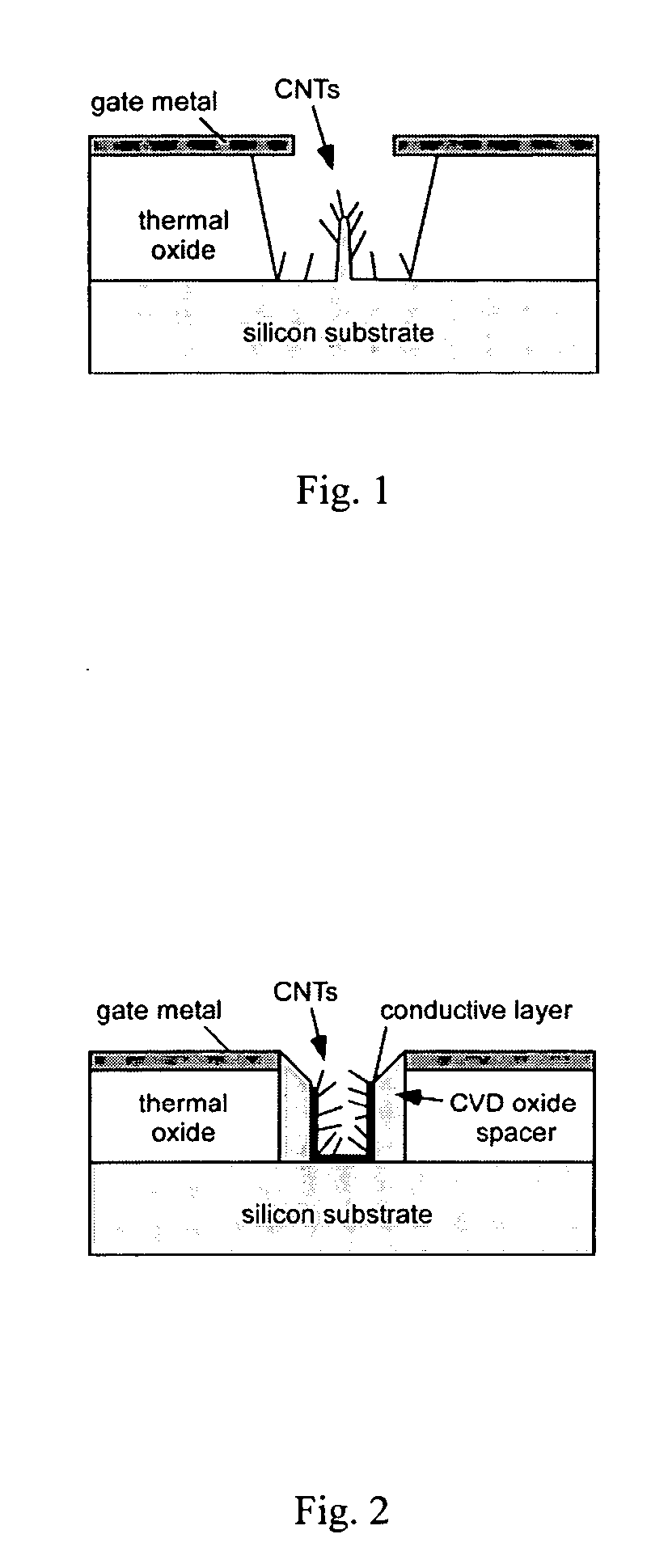

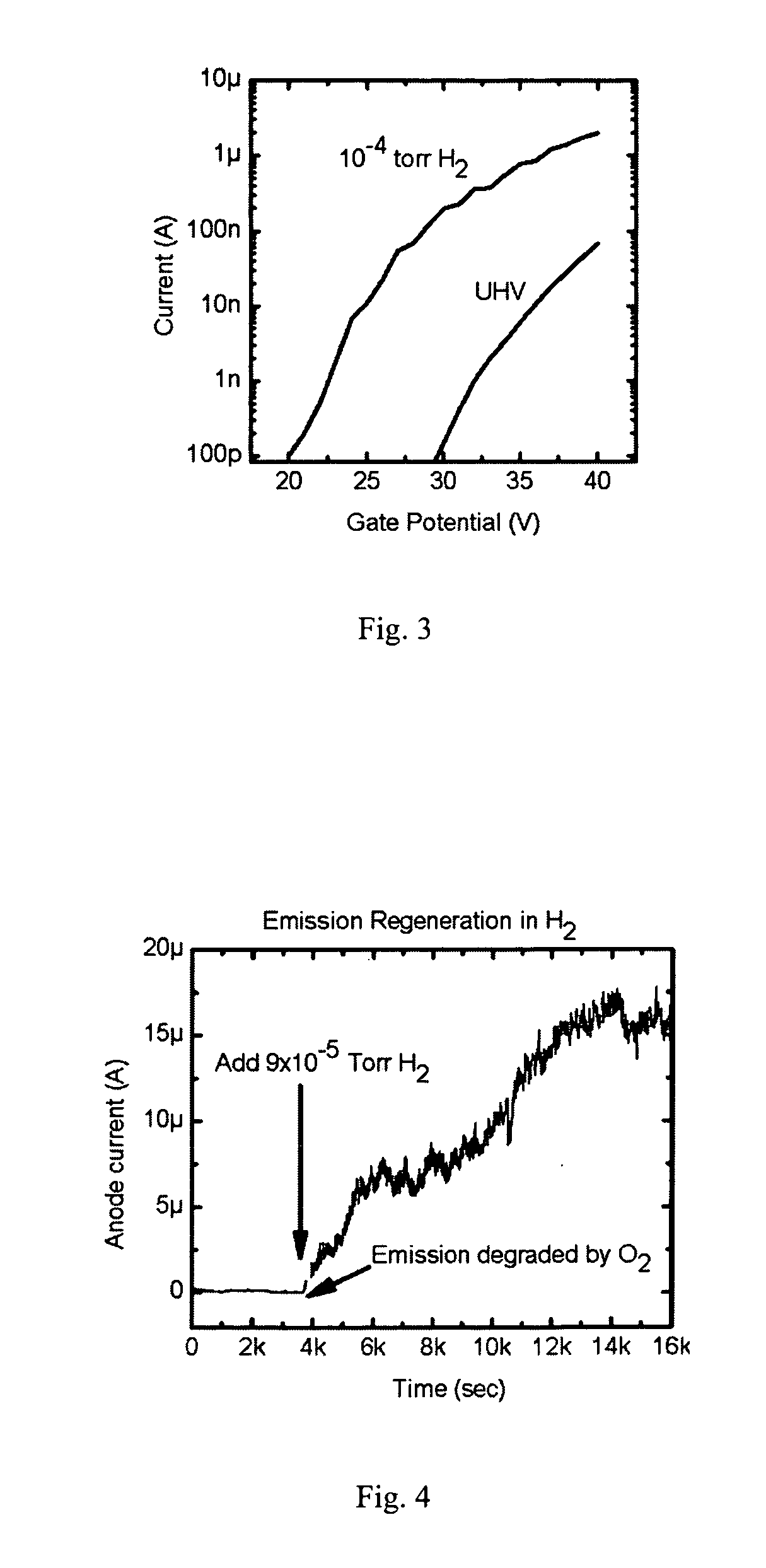

Regeneration of field emission from carbon nanotubes

InactiveUS20080048543A1Large enhancement factorIncrease emitter lifetimeElectric discharge tubesNanoinformaticsField emission currentHydrogen

Large increases in field emission current can be achieved when operating carbon nanotubes in substantial pressures of hydrogen, especially when the nanotubes were contaminated. Integrally gated carbon nanotube field emitter arrays were operated without special pre-cleaning in 10−6 Torr or greater of hydrogen to produce orders of magnitude enhancement in emission. For a cNTFEA intentionally degraded by oxygen, the operation in hydrogen resulted in a 340-fold recovery in emission.

Owner:NAVY USA AS REPRESENTED BY THE SEC OF THE THE

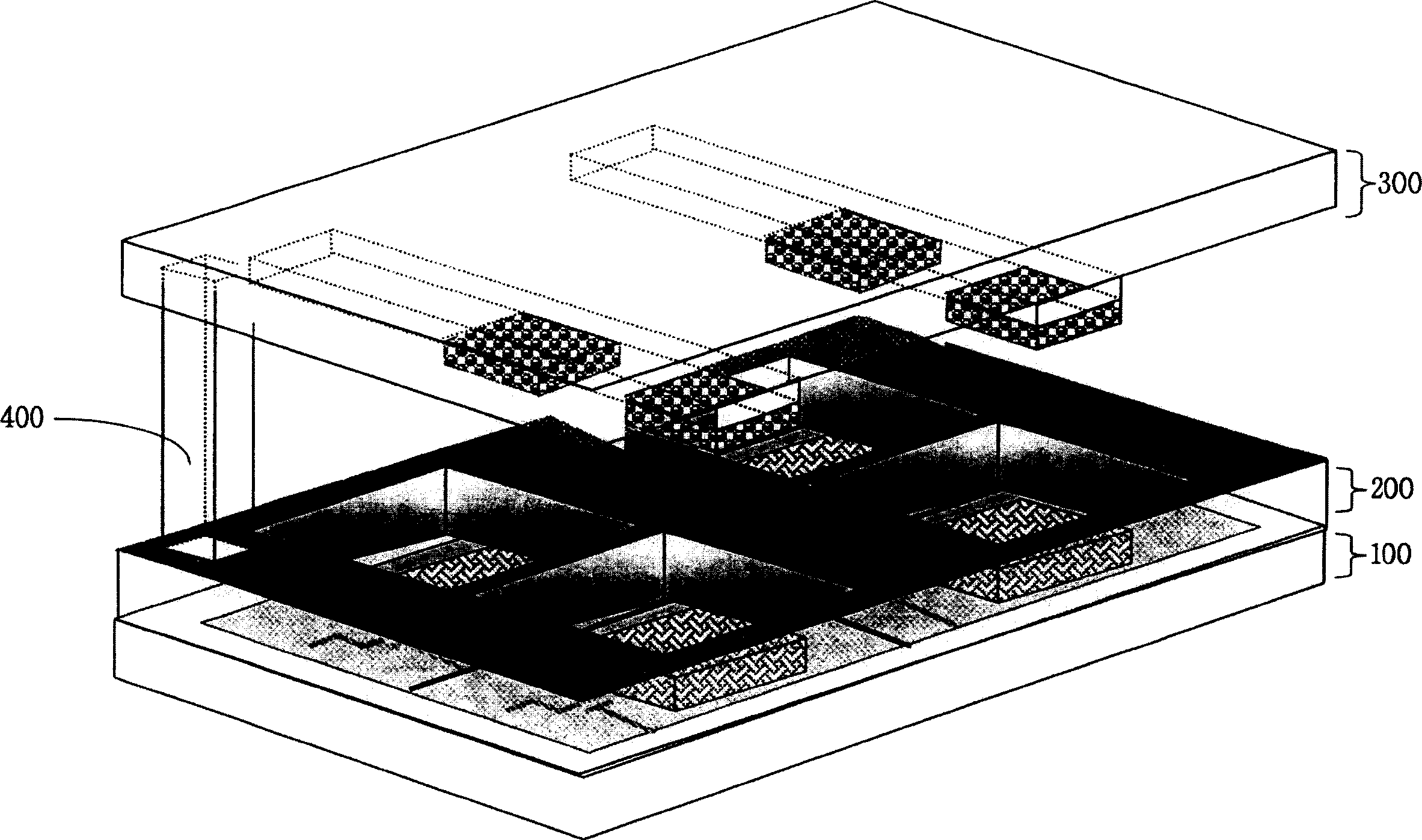

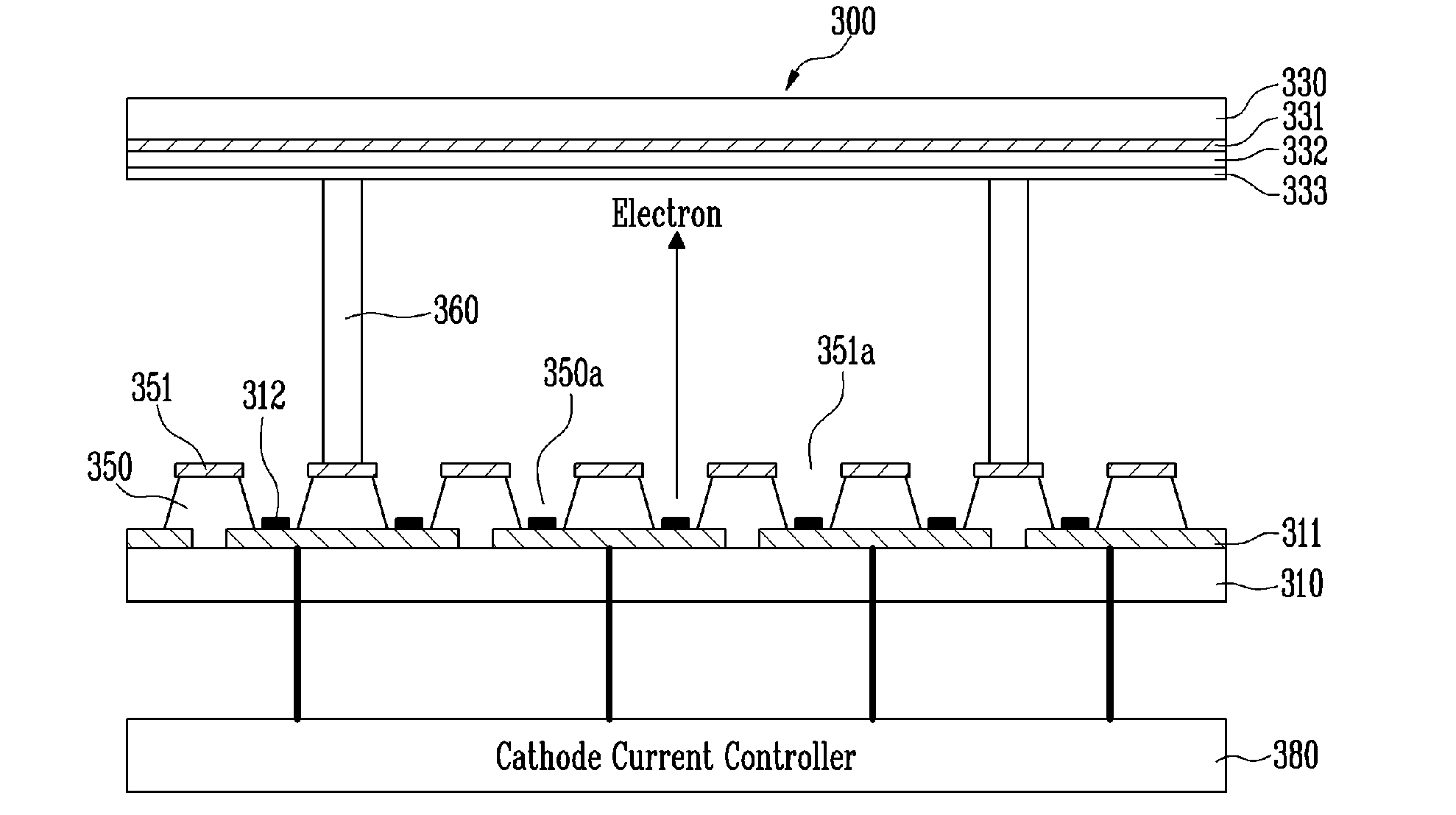

Field emission device

ActiveUS20100156305A1Simple structureDischarge tube luminescnet screensElectric discharge tubesField emission deviceField emission current

Provided is a field emission device having a simple structure and capable of pulse driving and local dimming. The field emission device turns a current flowing from each cathode electrode block on or off in response to a switching control signal having a very low voltage ranging from 0 to 5 V while a constant voltage is applied to an anode electrode and a gate electrode to control a field emission current. Compared with a conventional field emission device, the field emission device having a simple structure is capable of pulse driving and local dimming without using a separate pulse driving high voltage power source.

Owner:ELECTRONICS & TELECOMM RES INST

Method for electrophoretic anode deposition preparation of carbon nanotube field-emission film

InactiveCN1962960AImprove bindingLower turn-on voltageSemiconductor/solid-state device manufacturingElectrophoretic coatingsCarbon nanotubeNitrogen gas

The invention discloses a preparing method of launching film of carbon nanometer pipe field in the nanometer material preparing technical domain, which comprises the following steps: dispersing original carbon nanometer pipe in the sodium dodecyl sulfate solution through ultrasound; forming carbon nanometer suspension electrophoretic liquid; sedimenting dispersed carbon nanometer pipe on the surface of stainless steel or titanium anode; heating carbon nanometer pipe film slowly in the high-temperature furnace to 400 Deg C; insulating for 30 min; fetching; cooling protected by nitrogen.

Owner:TSINGHUA UNIV

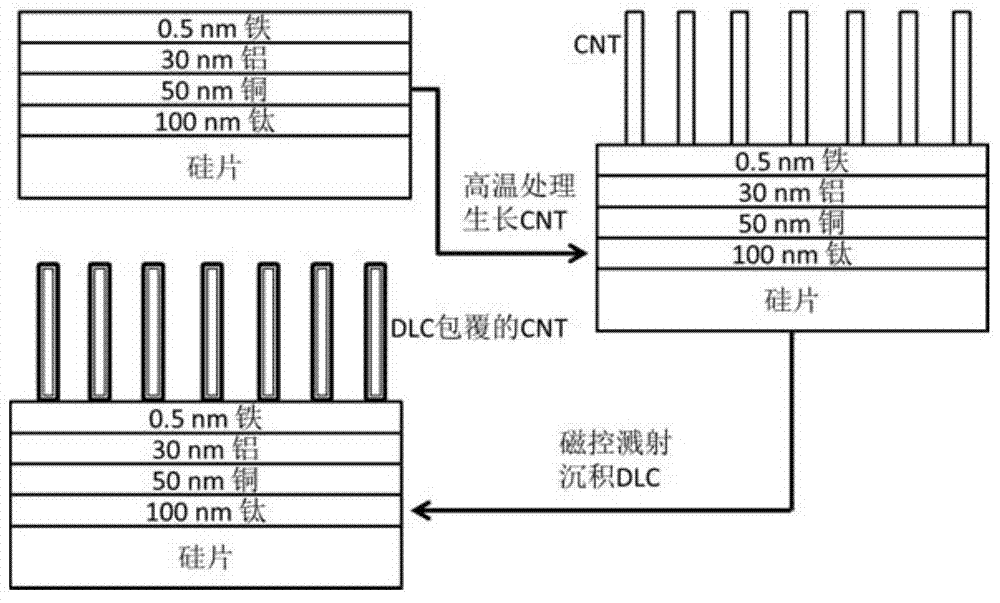

Method for improving carbon nanotube field emitting performance through diamond-like carbon film

ActiveCN104124122AChange surface propertiesIncreased Field Emission Current DensityCold cathode manufactureDiamond-like carbonField emission current

The invention relates to a method for improving carbon nanotube (CNT) field emitting performance through a piece of diamond-like carbon film (DLC). The method for improving the carbon nanotube (CNT) field emitting performance through the diamond-like carbon film (DLC) improves the field emitting performance of the CNT through using the DLC to coat the surface of the CNT. The DLC film has a negative surface affinity characteristic so that the DLC film is capable of changing the surface property of the CNT, lowering the opening field intensity of the CNT field emission and improving the field emitting current density of the CNT; the DLC film comprises a carbon atom sp3 hybrid structure ingredient so that the DLC film has good mechanical property and is capable of protecting the packaged CNT in a certain degree and improving the stability of the CNT field emitting performance; the method is capable of growing regularly arrayed array structures of upright CNT and DLC composite and obtaining the ideal CNT and DLC composite through regulating growth parameters; the method for improving the carbon nanotube field emitting performance through the diamond-like carbon film is convenient for the practical application.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Field emission display in which a field emission device is applied to a flat display

InactiveUS7141923B2Reduce the driving voltageIncrease brightnessTransistorDischarge tube luminescnet screensField emission deviceField emission current

Provided is a field emission display in which a gate hole having an inclined inner wall and a gate electrode around the gate hole are formed between an anode plate having a phosphor and a cathode plate having a field emitter and a control device for controlling a field emission current, whereby the voltage applied to the gate electrode of the gate plate serves to prohibit an electron emission of the field emitter by the anode voltage, and prevent a local arching by forming a totally uniform potential, so that the life time of the field emission display can be improved, and the gate hole having the inclined inner wall enables a fabrication of a filed emission display panel having a high brightness without an additional focusing grid.

Owner:ELECTRONICS & TELECOMM RES INST

Method for preparing zinc oxide nano-layer structure on supportless carbon nano-tube film

InactiveCN101560640AImprove field emission characteristicsImprove field emission performanceVacuum evaporation coatingSputtering coatingField emission currentNitrogen

The invention discloses a method for preparing a zinc oxide nano-layer structure on a supportless carbon nano-tube film, which is characterized in that zinc oxide is evenly attached to the supportless carbon nano-tube film to form the zinc oxide nano-layer structure through thermal evaporation by using nitrogen as carrier gas, wherein the zinc oxide nano-layer has a needle-like structure; the length thereof is 1mu m; and the particle size of zinc oxide particles is about 100 nanometers. The method improves the field emission characteristic of a carbon tube, improves the field emission performance and increases the field emission current density with lower turn-on electric field and good emission stability; and compared with the prior art, the method has the advantages of simple manufacturing process, low cost and good repeatability, is particularly suitable for large-area manufacture, and can perform kinking and clipping.

Owner:EAST CHINA NORMAL UNIV

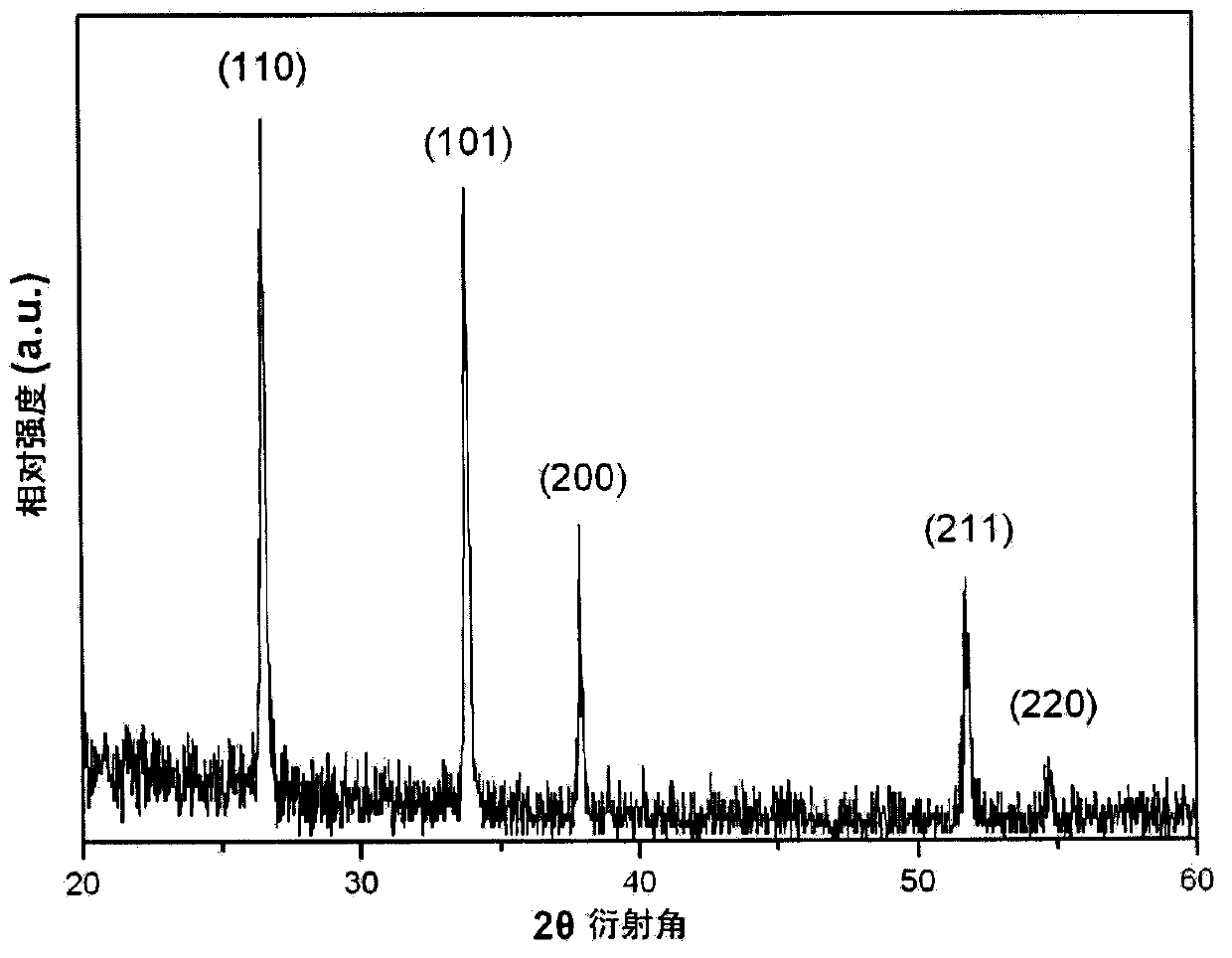

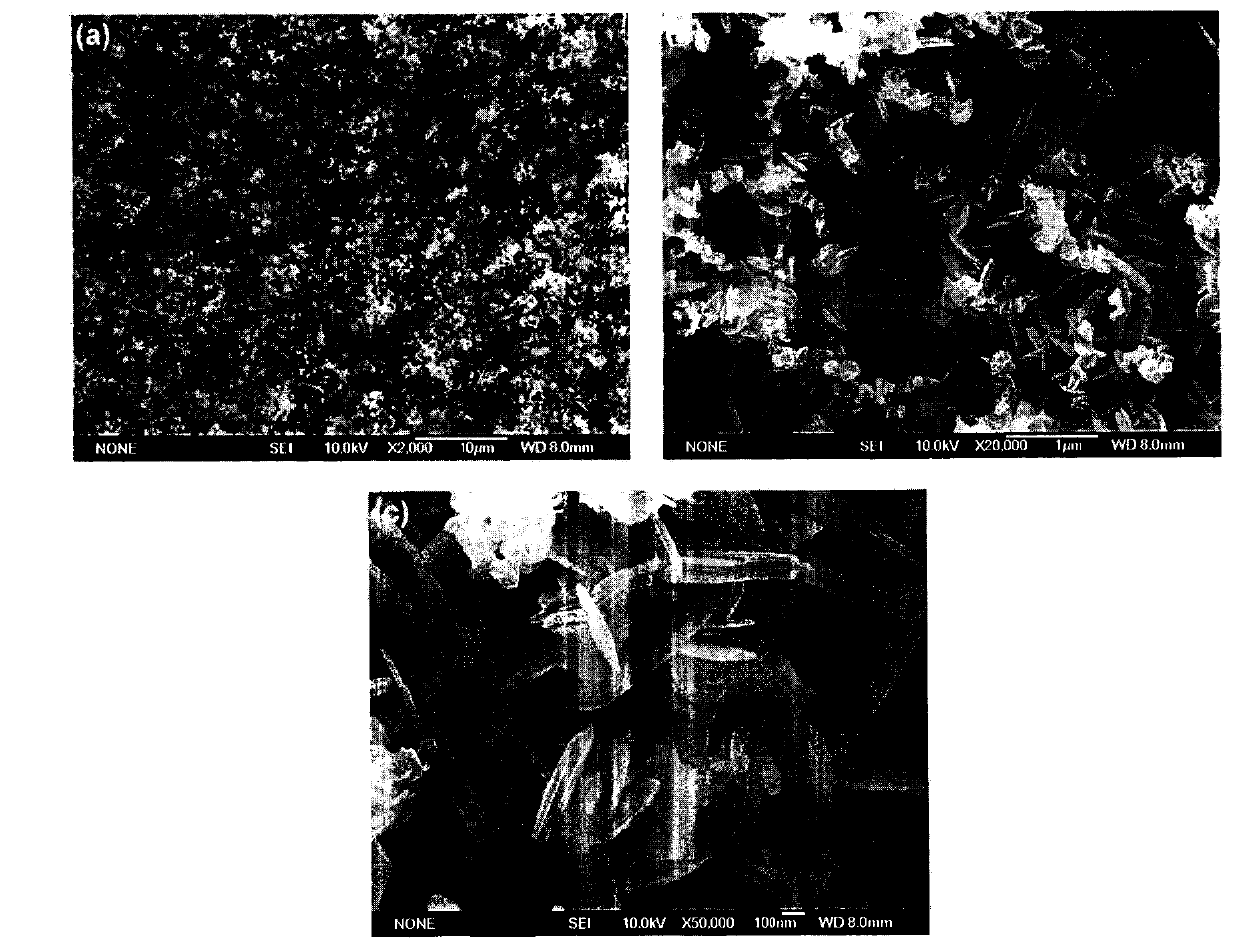

Nano wall structure composed of flaky tin oxide and preparation method thereof

InactiveCN104213098AReduce pollutionDiluted oxygen contentPolycrystalline material growthFrom chemically reactive gasesField emission devicePowder mixture

The invention particularly relates to a nano wall structure composed of flaky tin oxide and a preparation method thereof. The method takes a stannous oxide powder and carbon powder mixture as a source material, and utilizes a thermal evaporation method for growing. The edge of the prepared nano wall structure is irregular, the side face of each wall is not smooth, the diameter is about 100-1000 nm, and the thickness is about 30 nm. The nano wall structure can be grown on a silicon slice substrate in a large area; with the characteristics of unique structure, oxidation resistance, high-temperature resistance, high field emission current density, lower turn-on field, effective avoiding of a field shielding effect, good emission stability and the like, an application of the nano wall structure in a field emission device can be achieved; and the structure has large specific surface area, can obviously enhance sensitive properties of a tin oxide material on various chemical gases, can be used as a gas sensitized material applied in the micro / nano sensor field, thereby having great scientific research values and wide commercial application prospects.

Owner:XIAN UNIV OF POSTS & TELECOMM

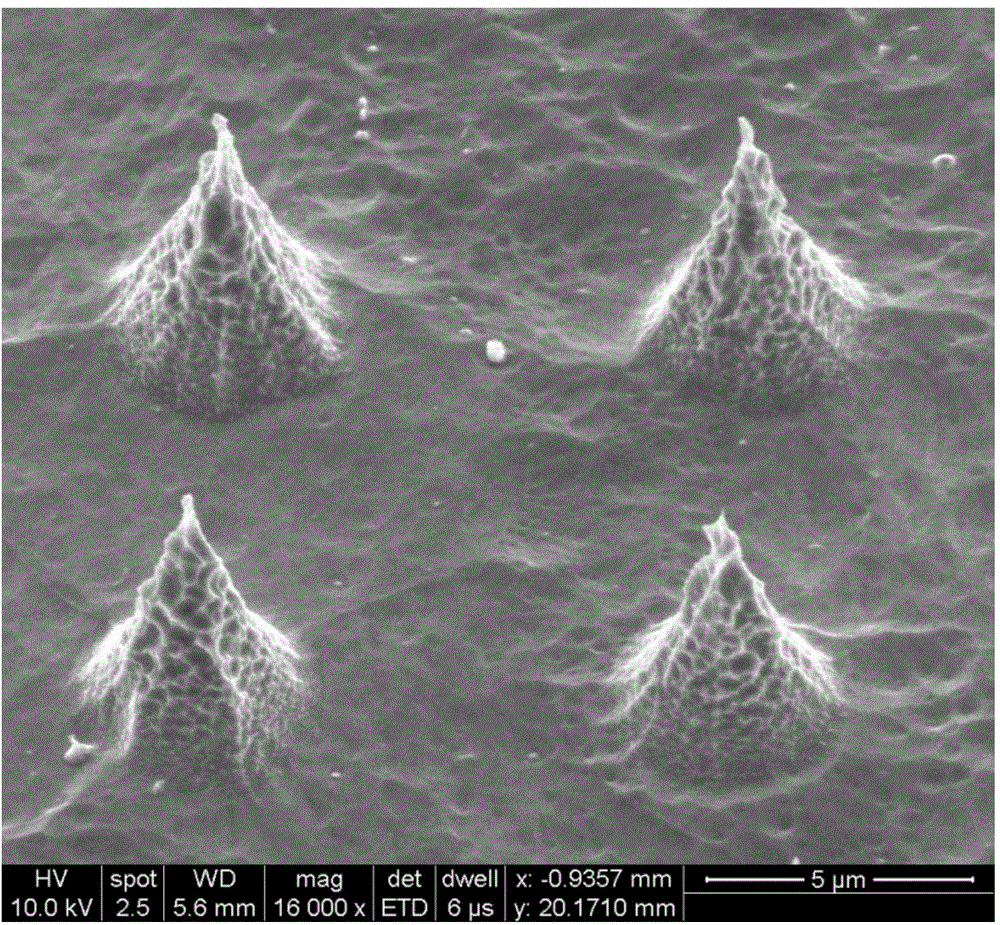

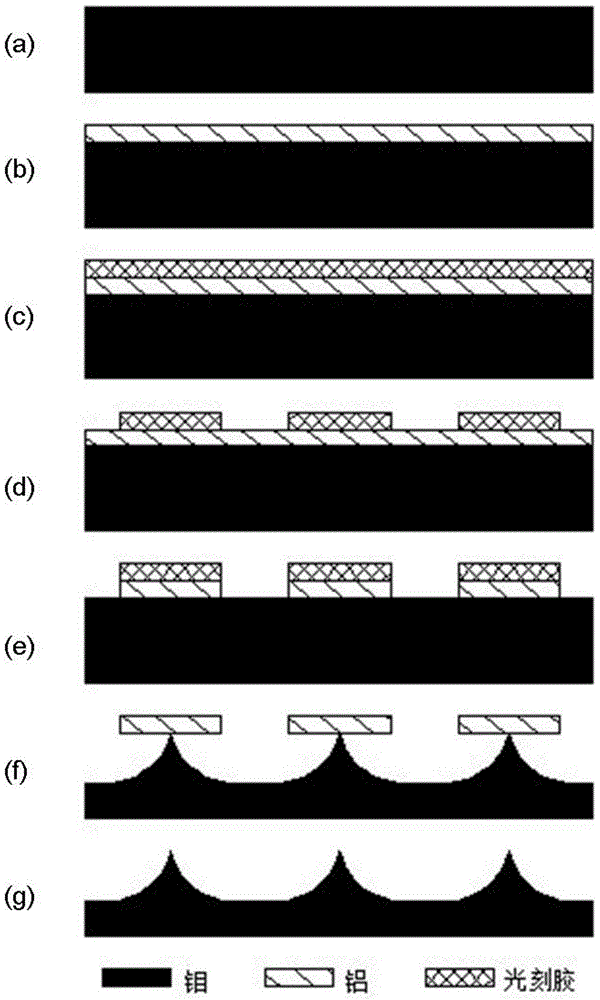

Metal molybdenum substrate-based field-induced electron-emitted cathode array and preparation method thereof

ActiveCN104934275AHigh densityImprove consistencyDischarge tube/lamp detailsCold cathode manufactureField emission currentManufacturing technology

The invention relates to a based on metal molybdenum of the substrate, field emission electron-emitting cathode array and a manufacturing method thereof. The field-induced electron-emitted cathode array comprises a plurality of metal molybdenum pointed cones consistent in morphology and regularly arranged. The metal molybdenum is subjected to plane manufacturing technology during the metal molybdenum substrate machining process, so that the array of pointed cones is high in morphology consistence. Through adjusting the machining parameters of the metal molybdenum substrate machining process, the morphology of the pointed cones can be conveniently changed. In this way, according to requirements of field emission currents, corresponding pointed cone arrays can be manufactured and machined for large-scale production. According to the technical scheme of the invention, through the metal molybdenum substrate machining process, pointed cone arrays are high in morphology consistence, and the number of simultaneously transmitted pointed cones is increased during operation. The density of the field emission current is further increased. Therefore, a large-area pointed cone array, which is good in shape consistency, can be obtained.

Owner:PEKING UNIV

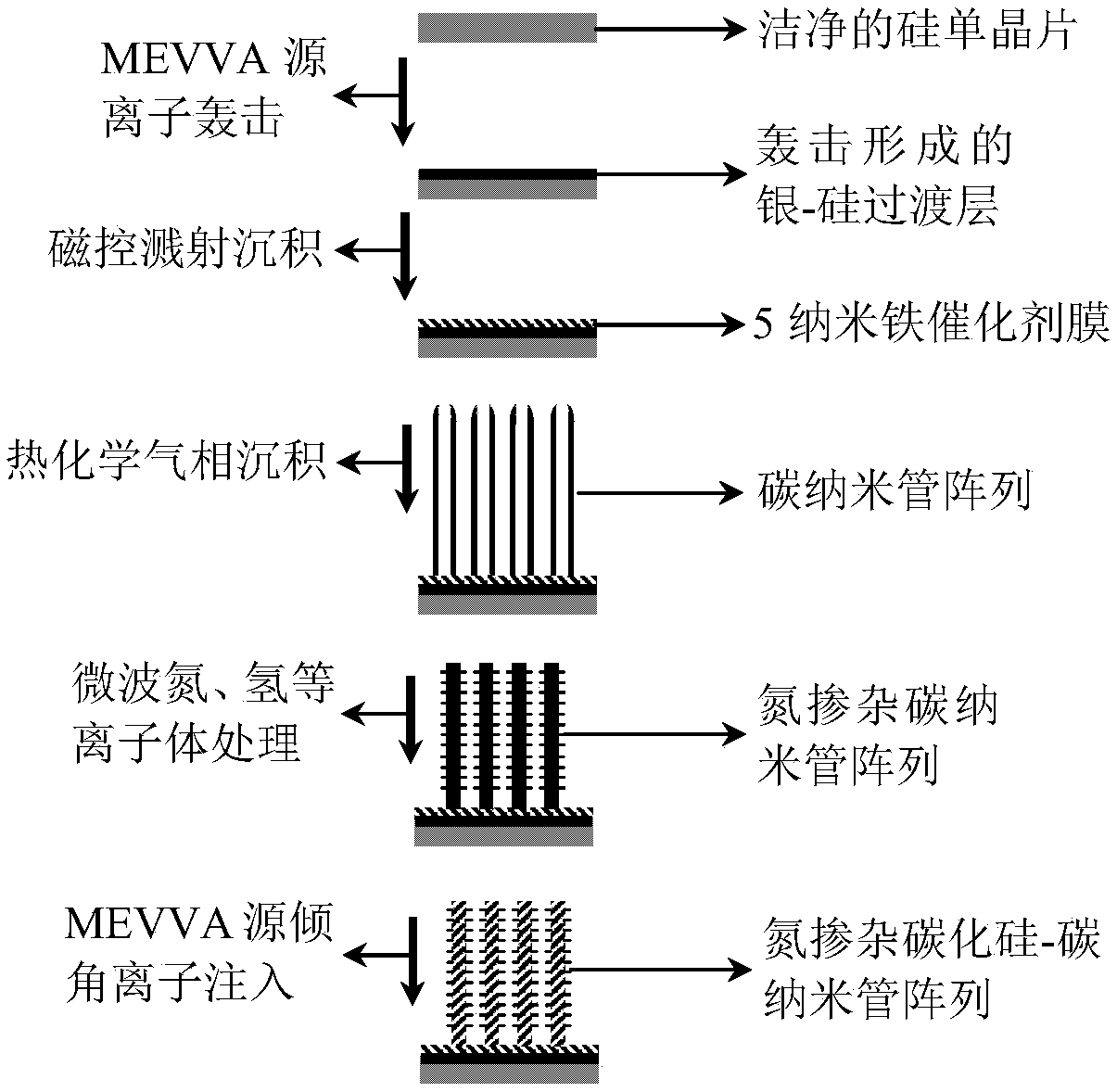

A method for improving field emission performance of carbon nanotube arrays

InactiveCN108987214AIncreased maximum field emission current densityDoes not affect shapeMaterial nanotechnologyElectric discharge tubesSilver ionHigh field

The invention discloses a method for improving field emission performance of a carbon nanotube array, belonging to the field of preparation and application of nano materials. Includes such steps 1, ascarrying out energetic silver ion bombardment pretreatment on monocrystalline silicon wafer; (2) preparing carbon nanotube arrays by conventional thermochemical vapor deposition and annealed at hightemperature; 3) treating the carbon nanotube arrays at room temperature with nitrogen and hydrogen plasma in a microwave plasma system; (4) Carrying out energetic silicon ion bombardment on carbon nanotubes by means of inclined angle implantation. Compared with pure carbon nanotube arrays and prior art, the nitrogen-doped silicon carbide prepared by the method has the advantages that: the Carbon nanotube arrays have very low working electric field and very high field emission current density, and excellent field emission stability at high field emission current density, so they have very highapplication value.

Owner:TIANJIN NORMAL UNIVERSITY

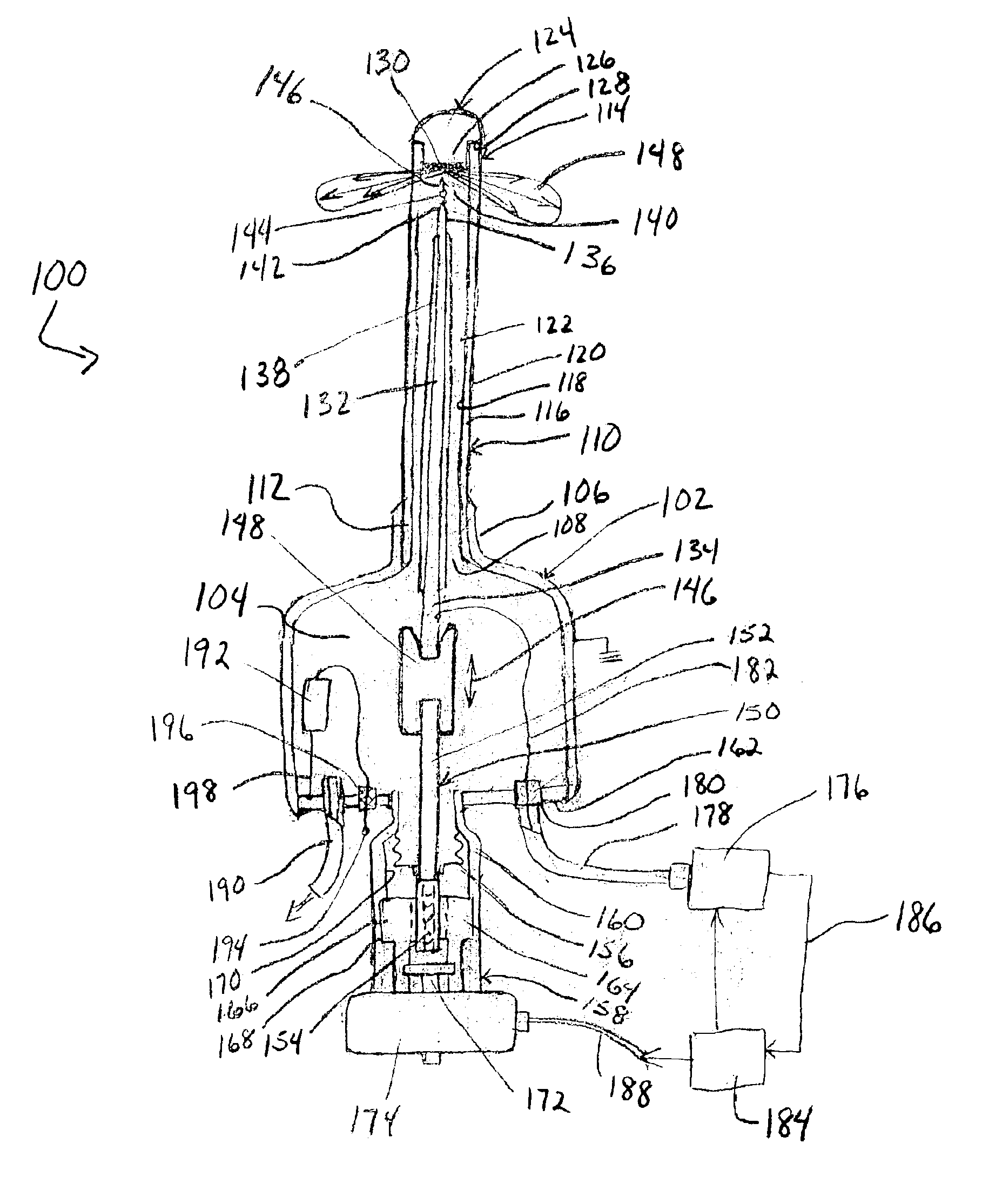

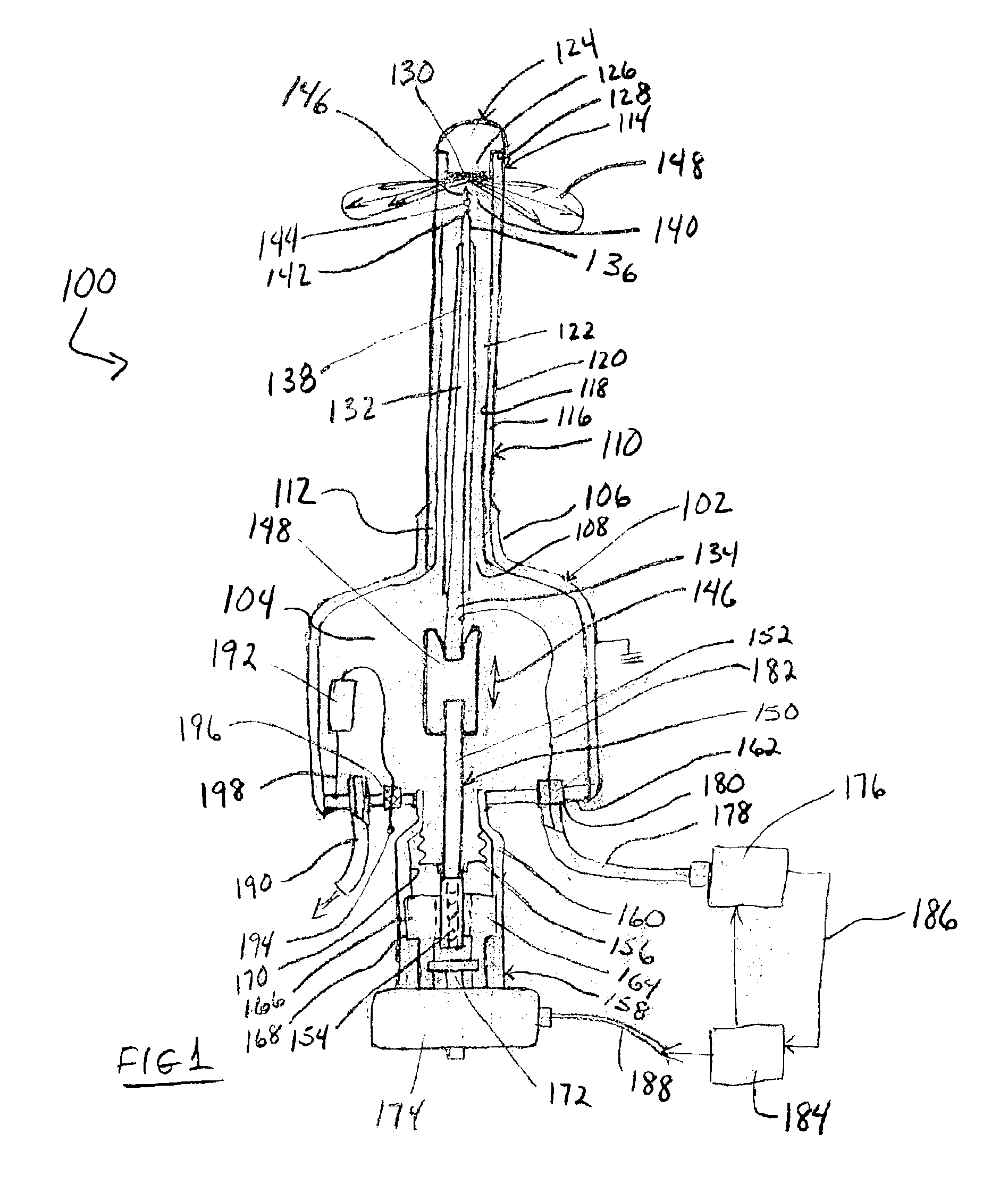

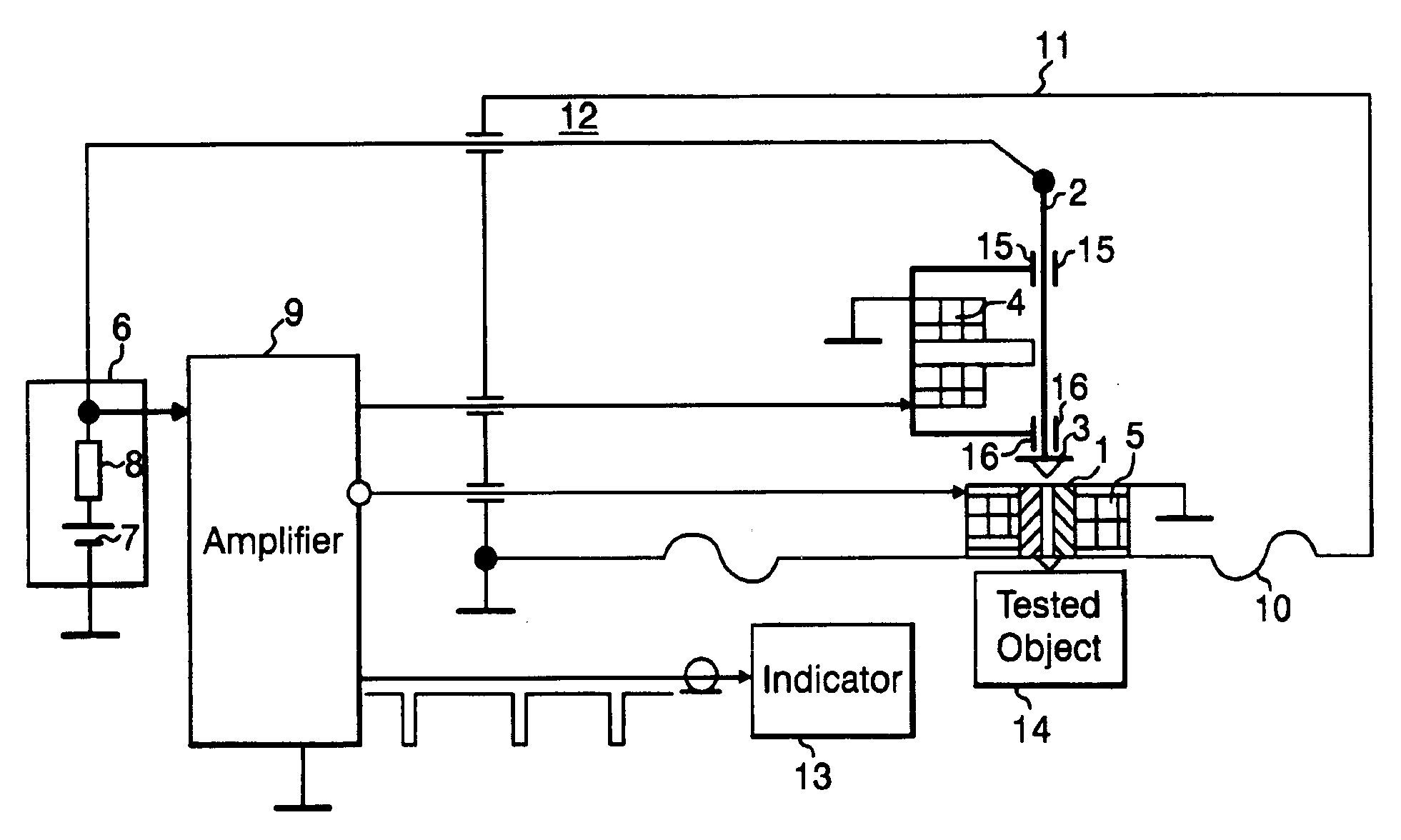

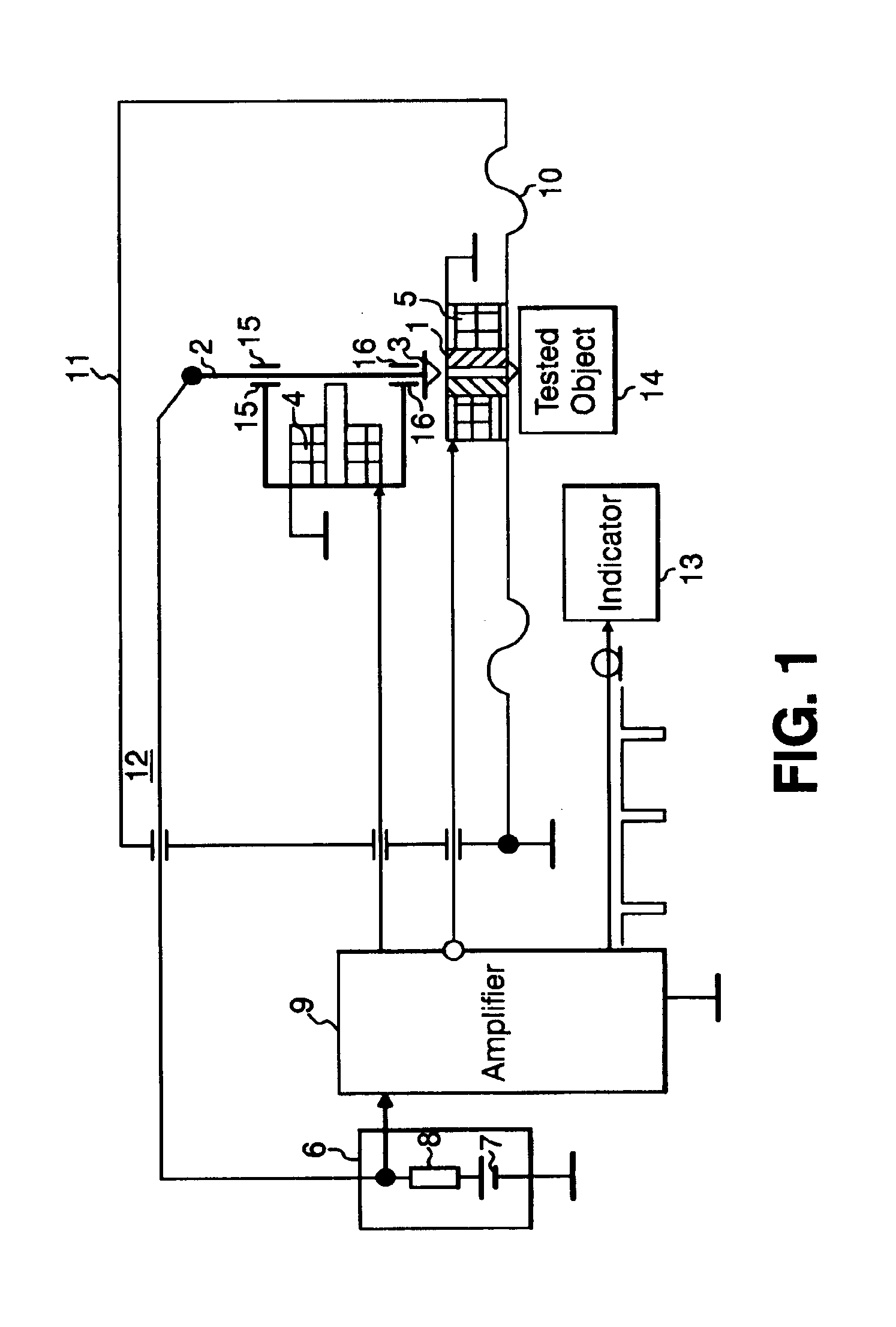

Micromovement measuring device and method of movement process conversion to an electric signal

InactiveUS6935200B2High sensitivityEliminate processingMagnetic measurementsMaterial analysis by electric/magnetic meansField emission currentElectric signal

A micromovement measuring device records creeping and dynamic infraprocesses both of natural and artificial origin, including seismic processes or infrasound and gravitational waves. The device has a sensitivity for measuring in a wide dynamic range. The device includes a measuring element, a sensitive element, a membrane, a signal conditioner, a fixing electromagnet, and a pulling electromagnet. The pulling electromagnet is located on the membrane which increases the range of the measurable movements. A hermetic housing prevents the formation of oxides or similar films at the working surfaces of the measuring and sensitive elements. A method of converting movement to electric signals is performed by the device, which takes an electronic field emission current to be a characteristic of quantization, and so movements in the range of Angstroms may be recorded.

Owner:A METRICS

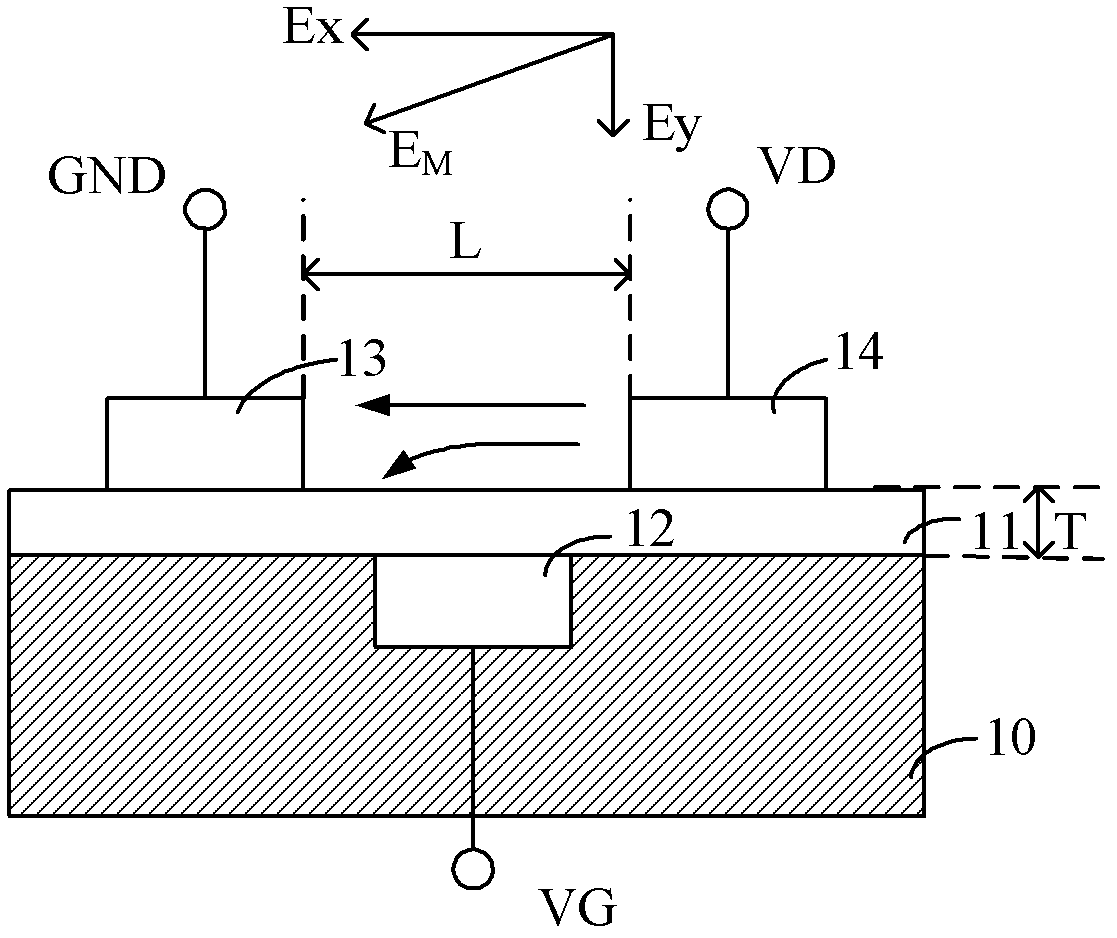

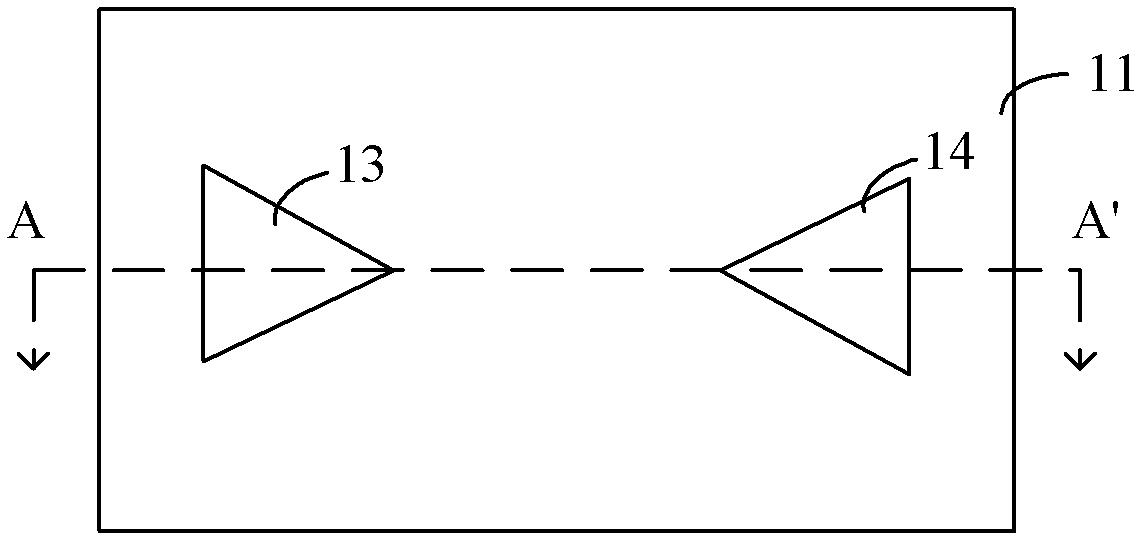

Isolated gate controlled transverse field emission transistor and driving method thereof

InactiveCN102856362AShipping restrictionsMeet the needs of process developmentSemiconductor/solid-state device manufacturingSemiconductor devicesField emission currentGate dielectric

The invention relates to an isolated gate controlled transverse field emission transistor and a driving method thereof. The transistor comprises a first gate dielectric layer, a first gate electrode, a collector electrode and an emitter electrode, wherein the first gate dielectric layer is provided with a first surface and a second surface which are opposite to each other; the first gate electrode is arranged on a first surface of the first gate dielectric layer; the collector electrode and the emitter electrode are arranged on a second surface of the first gate dielectric layer and at both sides of the first gate electrode; and the collector electrode and the emitter electrode are insulated from each other, and a gas is formed between the collector electrode and the emitter electrode. According to the invention, electric conduction is realized through a field emission current from the emitter electrode to the collector electrode in the field effect transistor, and a current switch of transverse field emission from the emitter electrode to the collector electrode is controlled by the first gate electrode at the same time, so that limitation in carrier transport by a lattice structure of a channel region in a conventional MOS ( field effect transistor) is eliminated, the need of process development can be met, and the transistor has a higher response speed.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

X-ray apparatus with field emission current stabilization and method of providing x-ray radiation therapy

Owner:MINNESOTA MEDICAL PHYSICS LLC

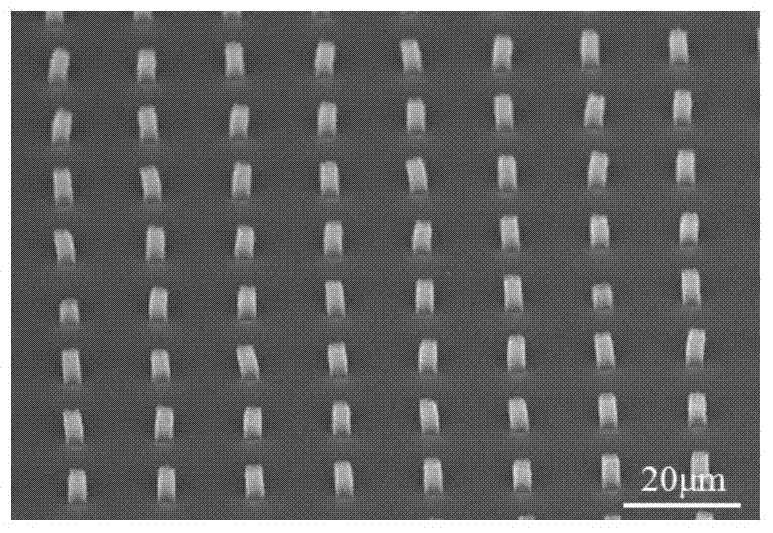

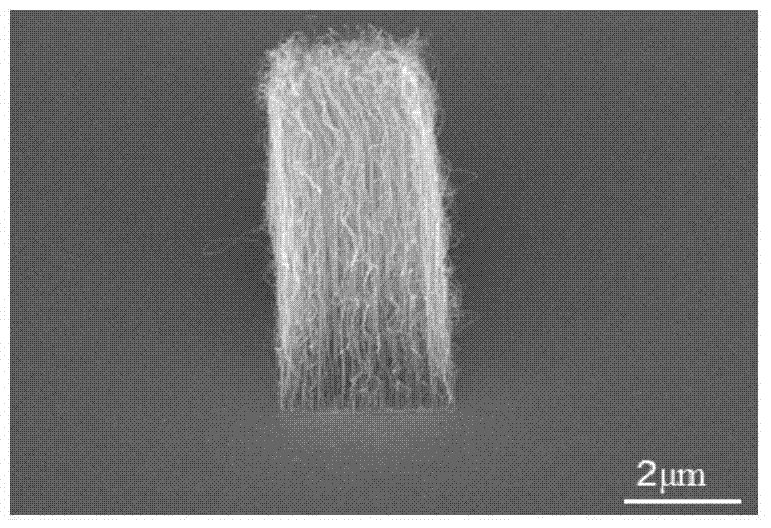

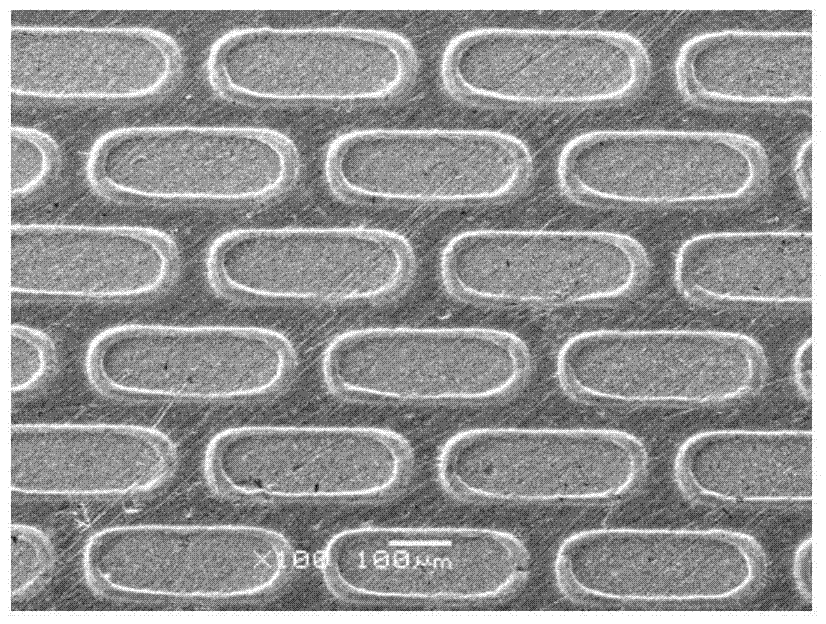

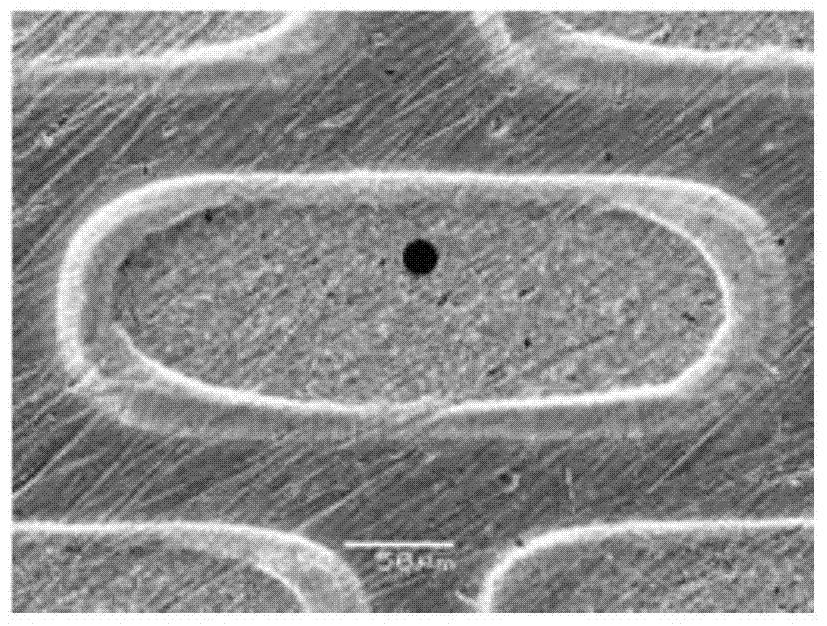

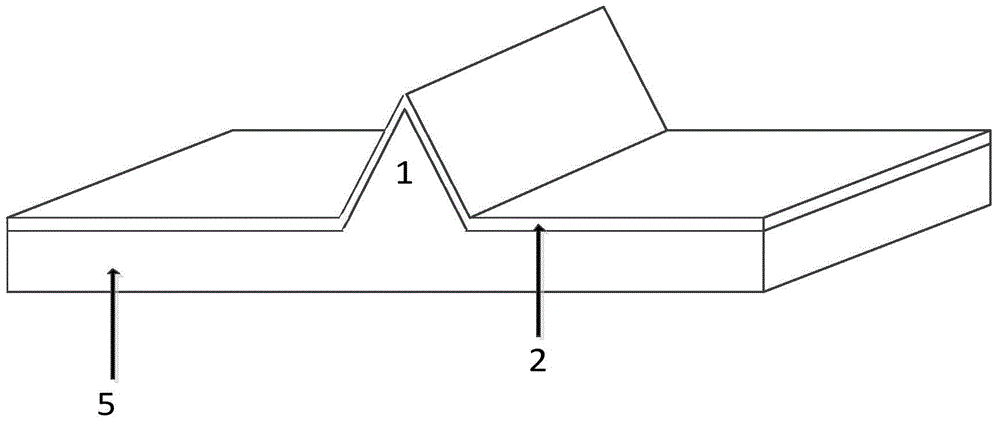

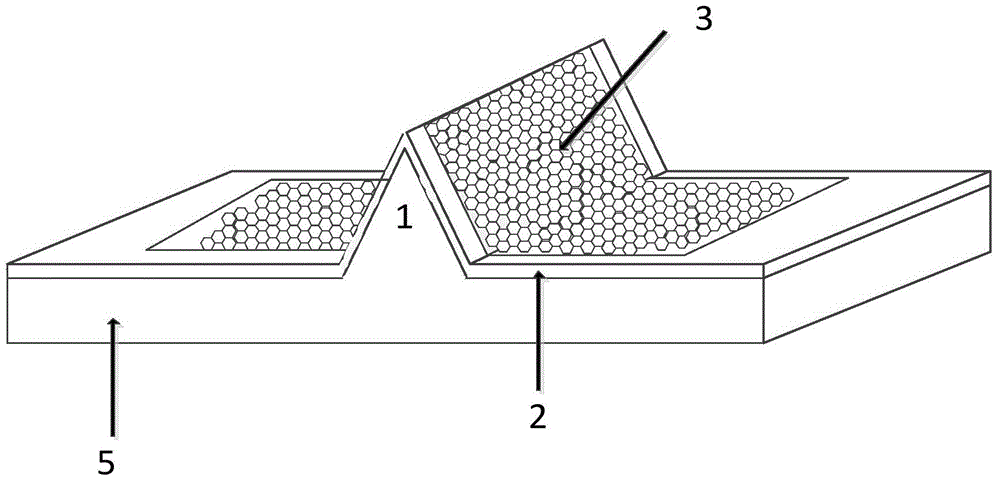

Growing method for carbon nanotubes growing according to headchute type pattern structure and emitter thereof

InactiveCN103833001AHigh field emission currentMaterial nanotechnologyCarbon compoundsField emission currentPower flow

The invention provides a growing method for carbon nanotubes growing according to a headchute type pattern structure. The method comprises the following steps: controlling of catalyst deposition and growth conditions and selection of a novel mask plate pattern structure and thickness thereof; and growth of a carbon nanotube emitter through hot chemical vapor deposition and plasma enhanced chemical vapor deposition. Thus, carbon nanotubes growing in the manners of array vertical growth and unordered vertical and horizontal growth are obtained; the carbon nanotubes growing in the manner of array vertical growth have height of 15 to 20 mu m and width of 4 to 6 mu m; unordered growth occurs in the pattern, the carbon nanotubes growing in the manner of unordered vertical and horizontal growth are surrounded by the carbon nanotubes growing in the manner of array vertical growth, and the thickness of the carbon nanotubes is equal to the diameter of a plurality of layers or tens of layers of nanotubes. Such a composite growth structure has uniformity of an array structure and considerable unordered carbon nanotube tips, which enables field emission current of the emitter of the carbon nanotubes to be effectively improved.

Owner:南京康众光电科技有限公司

Filed-effect tube channel type field emission cathode and preparation method thereof

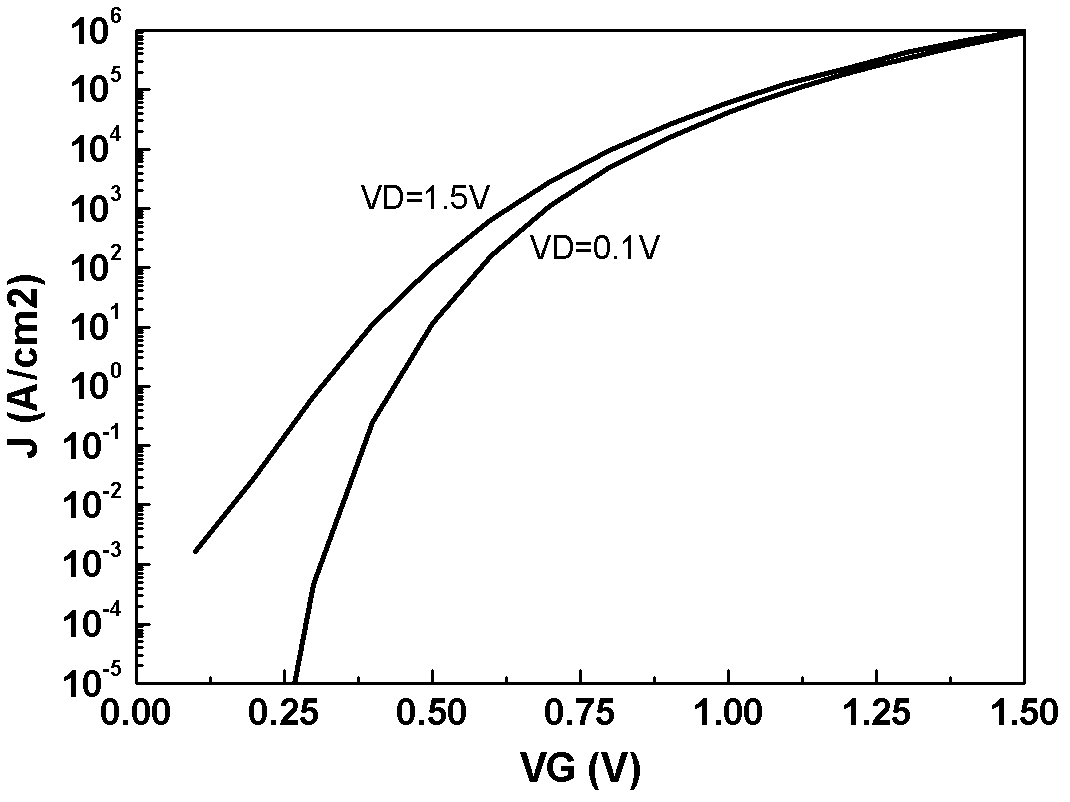

InactiveCN104992891AChange the supply functionRealize controllable operationDischarge tube/lamp detailsCold cathode manufactureEngineeringField-effect transistor

The invention discloses a field-effect tube channel type field emission cathode and a preparation method thereof. The cathode is modulated by a back gate and drain voltage. Additional bias voltage is used for changing electronic supply functions in two dimensional materials used as conductive channels, thereby adjusting field emission current density and achieving a field emission cold cathode modulated by the electric field. A new solution is provided for improving stability of field emission current of two-dimensional nano-materials, and a new path is provided for achievement of high-frequency regulated field emission cathode, thereby promoting actual application of two-dimensional nano cold cathodes with low emission threshold voltage in the vacuum microelectronic field.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com