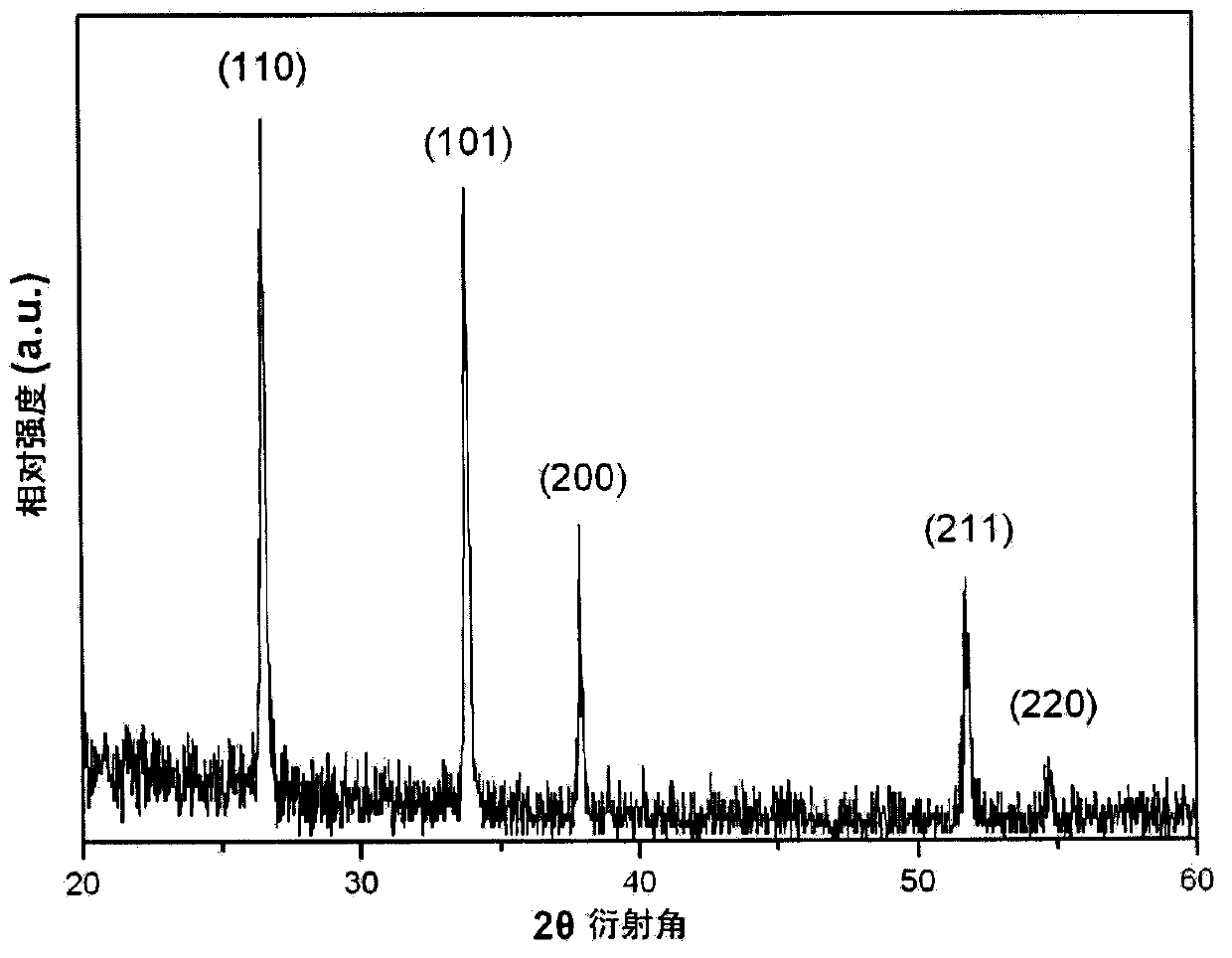

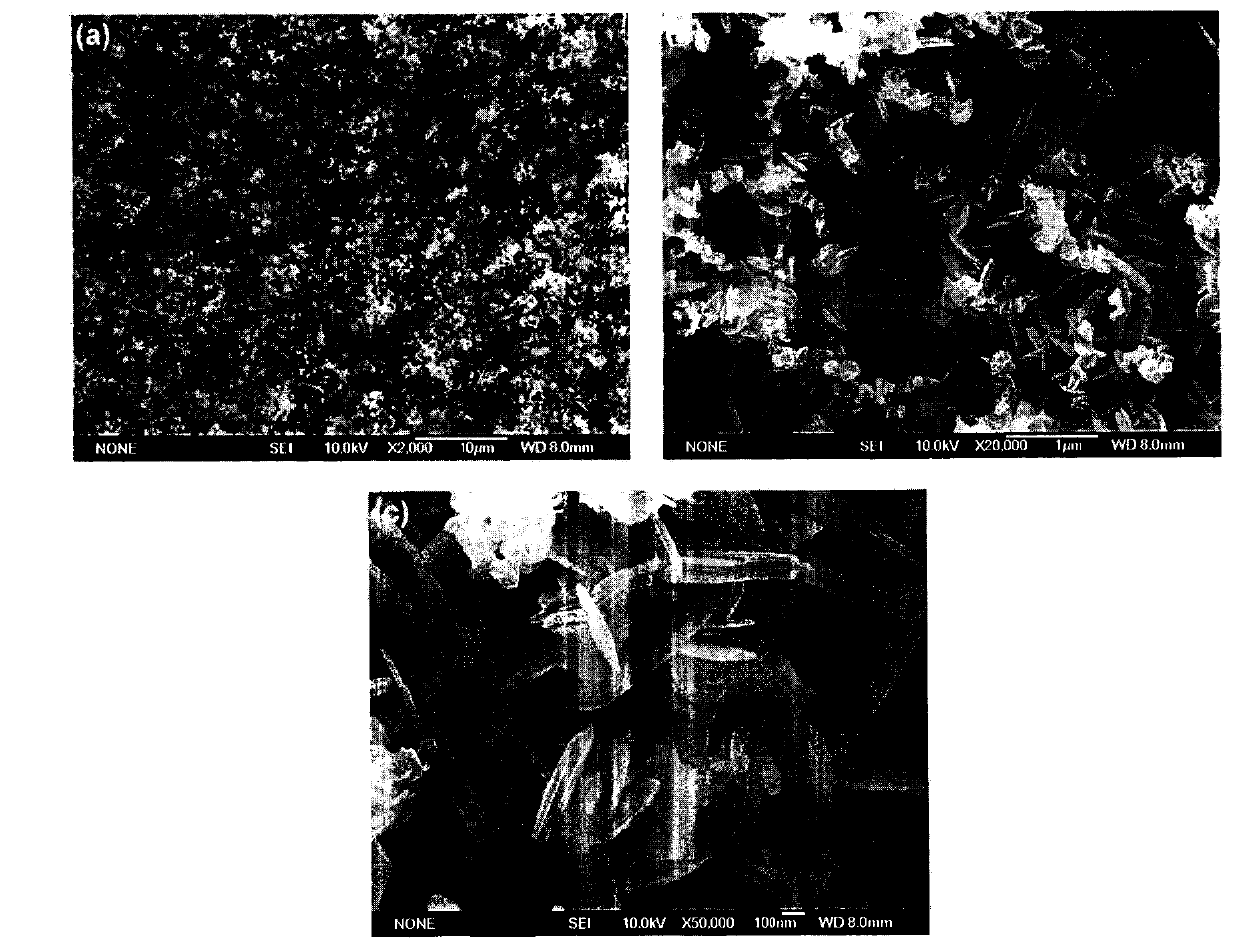

Nano wall structure composed of flaky tin oxide and preparation method thereof

A nano-wall and tin oxide technology, applied in chemical instruments and methods, gaseous chemical plating, from chemically reactive gases, etc., to achieve the effect of simple method, low reaction temperature, and reduced equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1. Proportion the stannous oxide powder and carbon powder according to the mass ratio of 2.5:1, add absolute ethanol, mix thoroughly by ultrasonic and dry as the source material;

[0018] 2. Heat the horizontal tubular growth furnace to 650°C at a rate of 15°C / min;

[0019] 3. Spread the source material in a quartz boat, put a silicon wafer as the substrate vertically at the outlet of the source material, the distance between the substrate and the source material is about 0.5cm, put the quartz boat carrying the source and substrate The boat is placed in the middle of the preheated horizontal tube furnace;

[0020] 4. Introduce high-purity argon gas with a flow rate of 0.5L / min as a protective gas, keep the gas outlet of the high-temperature furnace in a semi-closed state, and turn off the furnace after reacting at atmospheric pressure for 90 minutes, allowing it to cool naturally to room temperature. Keep the flow of argon gas constant;

[0021] 5. Take out the quartz...

Embodiment 2

[0023] 1. Proportion the stannous oxide powder and carbon powder according to the mass ratio of 1:1, add absolute ethanol, mix thoroughly by ultrasonic and dry as the source material;

[0024] 2. Heat the horizontal tubular growth furnace to 750°C at a rate of 15°C / min;

[0025] 3. Spread the source material in a quartz boat, put a silicon wafer as the substrate vertically at the outlet of the source material, the distance between the substrate and the source material is about 0.5cm, put the quartz boat carrying the source and substrate The boat is placed in the middle of the preheated horizontal tube furnace;

[0026] 4. Introduce high-purity argon gas with a flow rate of 0.4L / min as a protective gas, keep the gas outlet of the high-temperature furnace in a semi-closed state, and turn off the furnace after reacting at atmospheric pressure for 70 minutes, allowing it to cool naturally to room temperature. Keep the flow of argon gas constant;

[0027] 5. Take out the quartz b...

Embodiment 3

[0029] 1. Proportion the stannous oxide powder and carbon powder according to the mass ratio of 3:1, add absolute ethanol, mix thoroughly by ultrasonic and dry as the source material;

[0030] 2. Heat the horizontal tubular growth furnace to 850°C at a rate of 15°C / min;

[0031] 3. Spread the source material in a quartz boat, put a silicon wafer as the substrate vertically at the outlet of the source material, the distance between the substrate and the source material is about 0.5cm, put the quartz boat carrying the source and substrate The boat is placed in the middle of the preheated horizontal tube furnace;

[0032] 4. Introduce high-purity argon gas with a flow rate of 0.3L / min as a protective gas, keep the gas outlet of the high-temperature furnace in a semi-closed state, and turn off the furnace after reacting at atmospheric pressure for 60 minutes, allowing it to cool naturally to room temperature. Keep the flow of argon gas constant;

[0033] 5. Take out the quartz b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Lattice constant | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com