Growing method for carbon nanotubes growing according to headchute type pattern structure and emitter thereof

A technology of carbon nanotubes and growth methods, applied in the field of electron sources, can solve the problems of difficult emission current, small total emission current, and limited application, and achieve the effect of increasing field emission current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

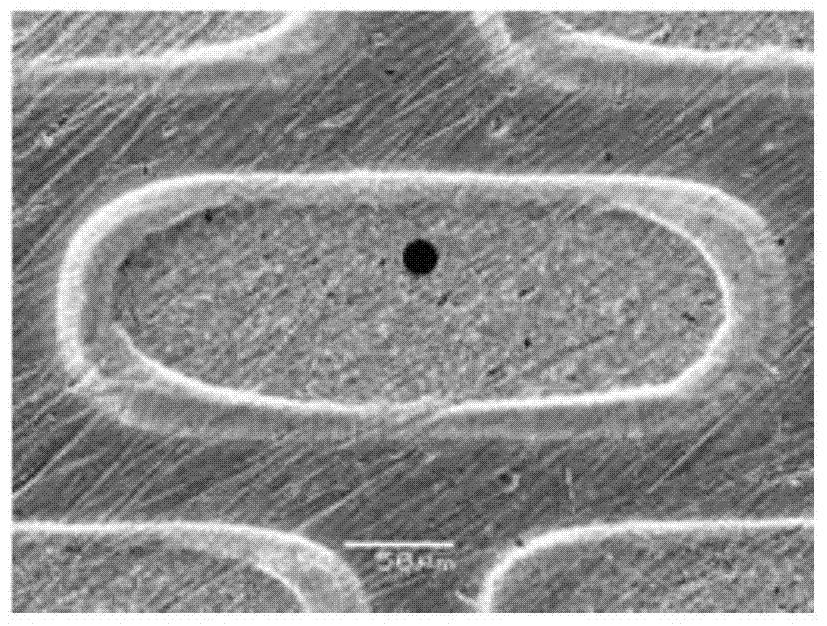

[0032] In an embodiment, the preparation process of carbon nanotubes grown with a new patterned structure in a boat trough is as follows:

[0033] (1) First select the substrate material. Here, molybdenum sheet is selected as the substrate. Silicon sheet, stainless steel, ITO conductive glass or quartz sheet can also be used. There is no significant difference in the obtained samples. The base sheet was ultrasonically cleaned with dilute acid, acetone, ethanol and secondary water for 30 minutes to remove organic matter and other impurities on the surface, and to remove surface moisture under a nitrogen atmosphere; the dilute acid was 1mol / L dilute hydrochloric acid, 1mol / L / L dilute nitric acid, 0.5mol / L dilute sulfuric acid or some 0.1mol / L weak acid (such as acetic acid, etc.).

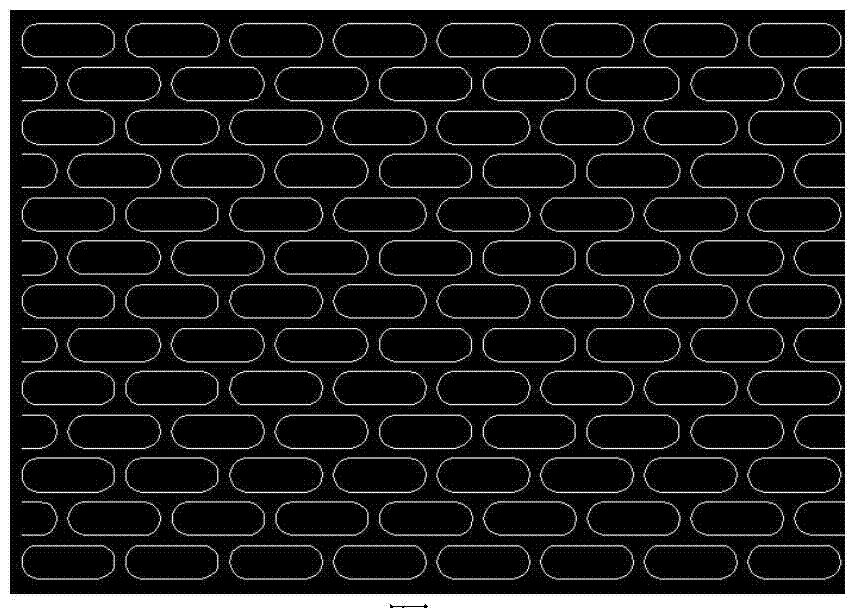

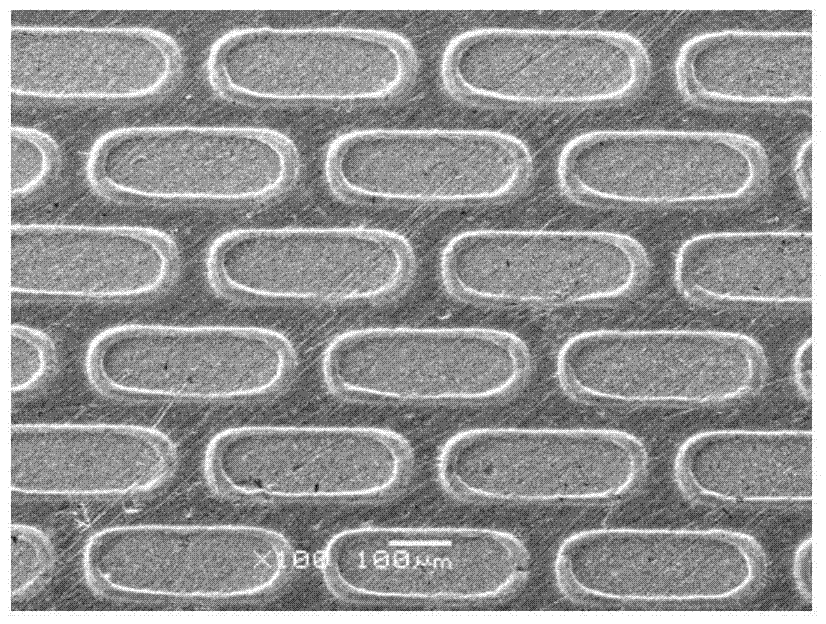

[0034] (2) Select a 0.1mm thick stainless steel material to prepare a pattern template with a boat groove pattern structure by laser cutting technology or electron beam technology, and the pattern c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com